Patents

Literature

47 results about "Epoxy polyamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal surface anti-corrosion layer structure and coating method thereof

ActiveCN101717942AImprove the protective effectRaise intrusionSynthetic resin layered productsPretreated surfacesEpoxy polyamideSizing

The invention provides a metal surface anti-corrosion layer structure and a coating method thereof. The anti-corrosion layer structure comprises a priming paint layer of 40-80 mu m, an intermediate paint layer of 50-100 mu m and a surface paint layer of 40-80 mu m, wherein, the priming paint layer is formed by coating object system paint on epoxy-polyamide, the intermediate paint layer is formed by coating object system paint on heavy-sizing epoxy-polyamide, and the surface paint layer formed by coating acrylic acid polyurethane system paint. The coating method comprises coating the priming paint layer on the metal surface; coating the intermediate paint layer on the priming paint layer; and coating the surface paint layer on the intermediate paint layer. The metal surface anti-corrosion layer structure in the embodiment of the invention has good anti-corrosion performance, ageing resistance and mechanical performance, simple technique, low cost which is lower than that of commonly used powdery paints at present, and no heavy metals, which is environment-friendly.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

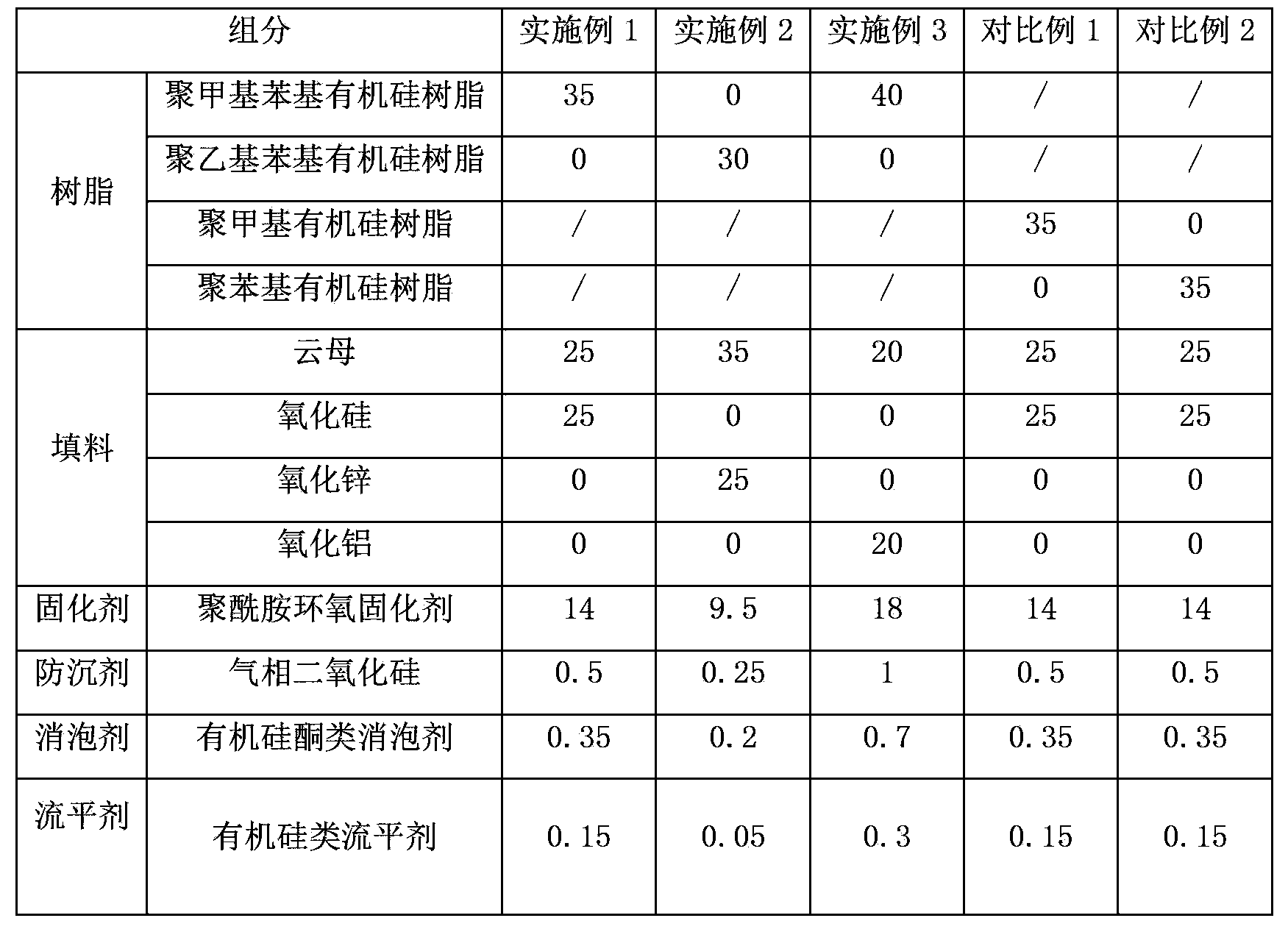

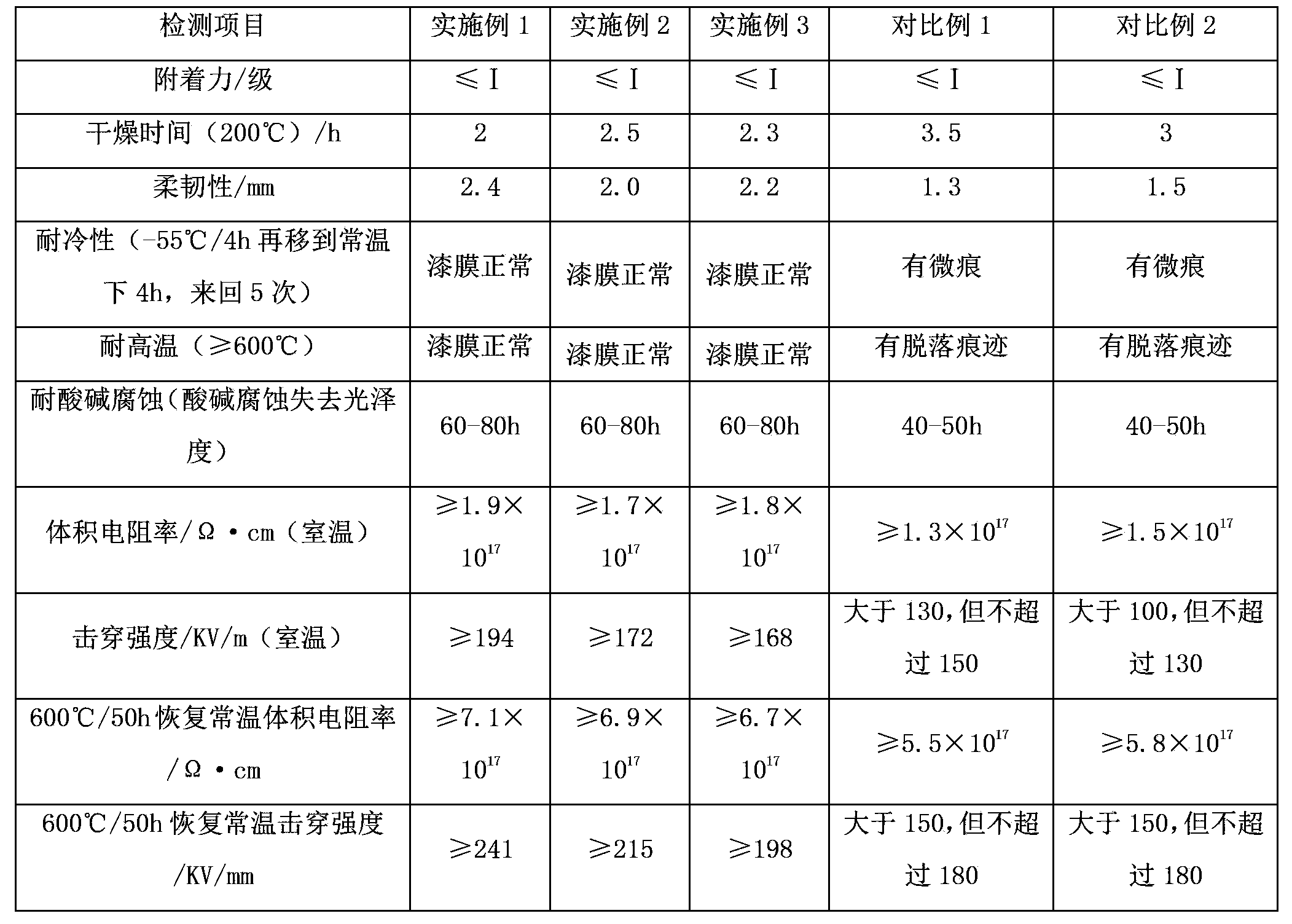

Novel high-temperature resistance insulation coating

The invention provides a novel high-temperature resistance insulation coating. The coating comprises following components in parts by weight: 30 to 40 parts of poly alkyl aryl organic silicon resin, 40 to 60 parts of stuffing material, 1 to 28 parts of curing agent, 0.01 to 0.1 part of anti-settling agent, 0.01 to 0.7 part of antifoaming agent, and 0.01 to 0.3 part of levelling agent. The poly alkyl aryl organic silicon resin is poly methyl phenyl organic silicon resin or poly ethyl phenyl organic silicon resin; the stuffing material is composed of one component or a plurality of components selected from following components: silicon oxide, zinc oxide, alumina, and mica; and the curing agent is an epoxy polyamide curing agent. The novel high-temperature resistance insulation coating has the advantages of high thermal resistance, capability of being used at the temperature of 600 DEG C while still having good mechanic performance and stability, good insulation performance, and long service life. Furthermore, the preparation method of the coating is simple, and meets the requirement of saving cost.

Owner:江苏达胜热缩防护用品有限公司

Method for preparing lithium iron cell protective film and solvent for cleaning said protective film

InactiveCN1588671ASolve corrosiveEasy to operateAnti-corrosive paintsCell component detailsEpoxy polyamideDiethyl ether

A prepn. method for protective film of lithium ion cell. At least one organic polymer among phenolic resin, epoxy resin, polyvinyl acetate, polyurethane, polytetrafluoroethylene, chloronorgutta, phenolic chloronorgutta, epoxy polyamide and phenolic polyvinyl acetal is added into particular solvent selected at least one from diionized water, carbinol, benzene, toluene, chloroform dichloroethylene, diethyl ether, acetone, ethyl acetate and normal ethane, they are mixed and stirred to organic solution which is coated on case of lithium ion cell, then the case is static placed to volatilize particular solvent in the organic solution in room temp. to form a layer of uniform and densify protective film on cell case. Said film can prevent corrding of electrolyte and perspiration in prodn process. The invent is also relates to a solvent used for cleaning said proctive film selected from deionized water, alcohol, acetone, oxolane and formyldimethylamine.

Owner:HENAN HUANYU GROUP

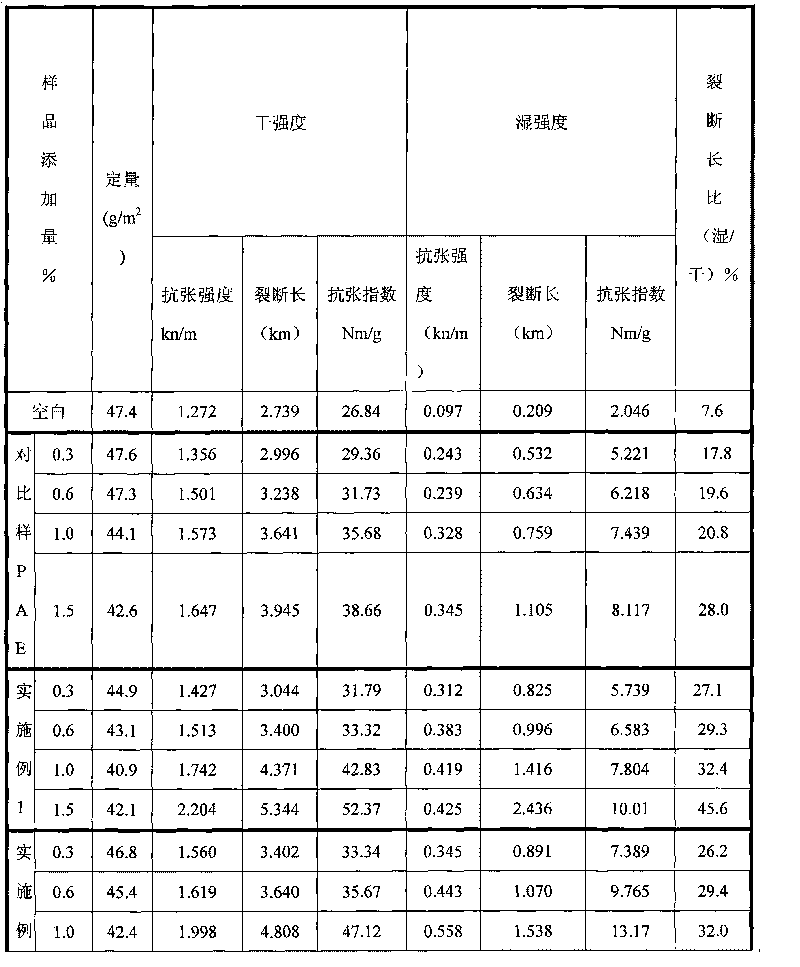

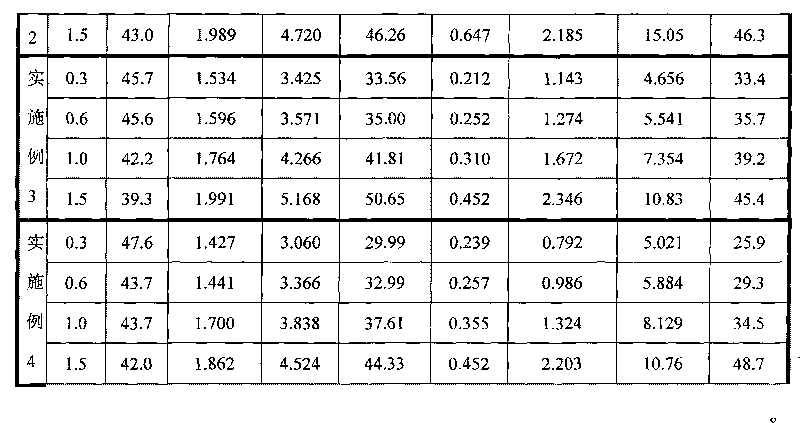

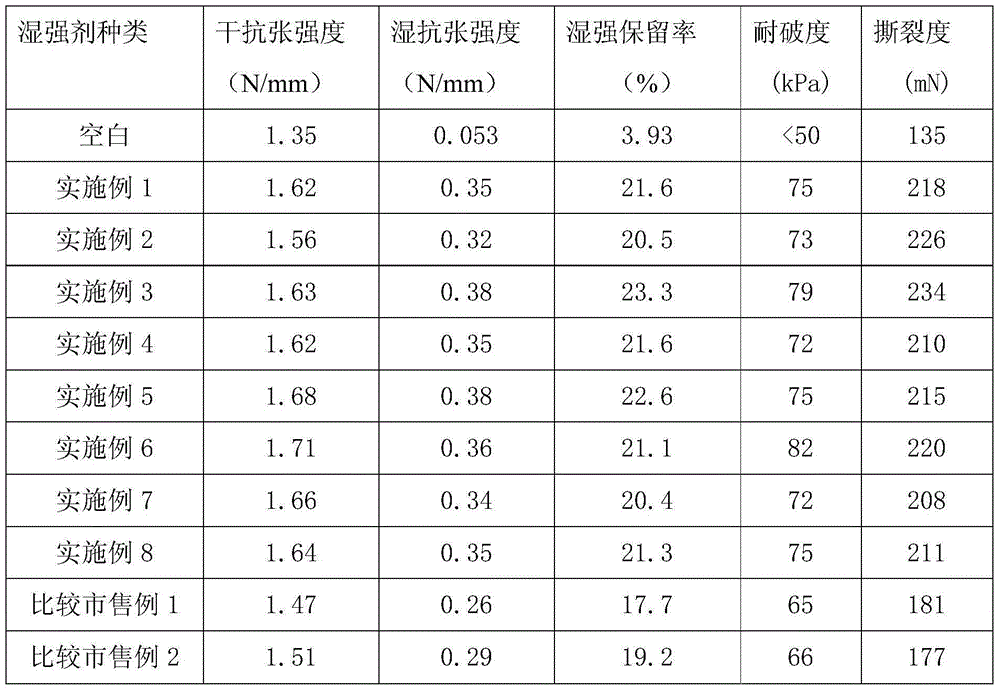

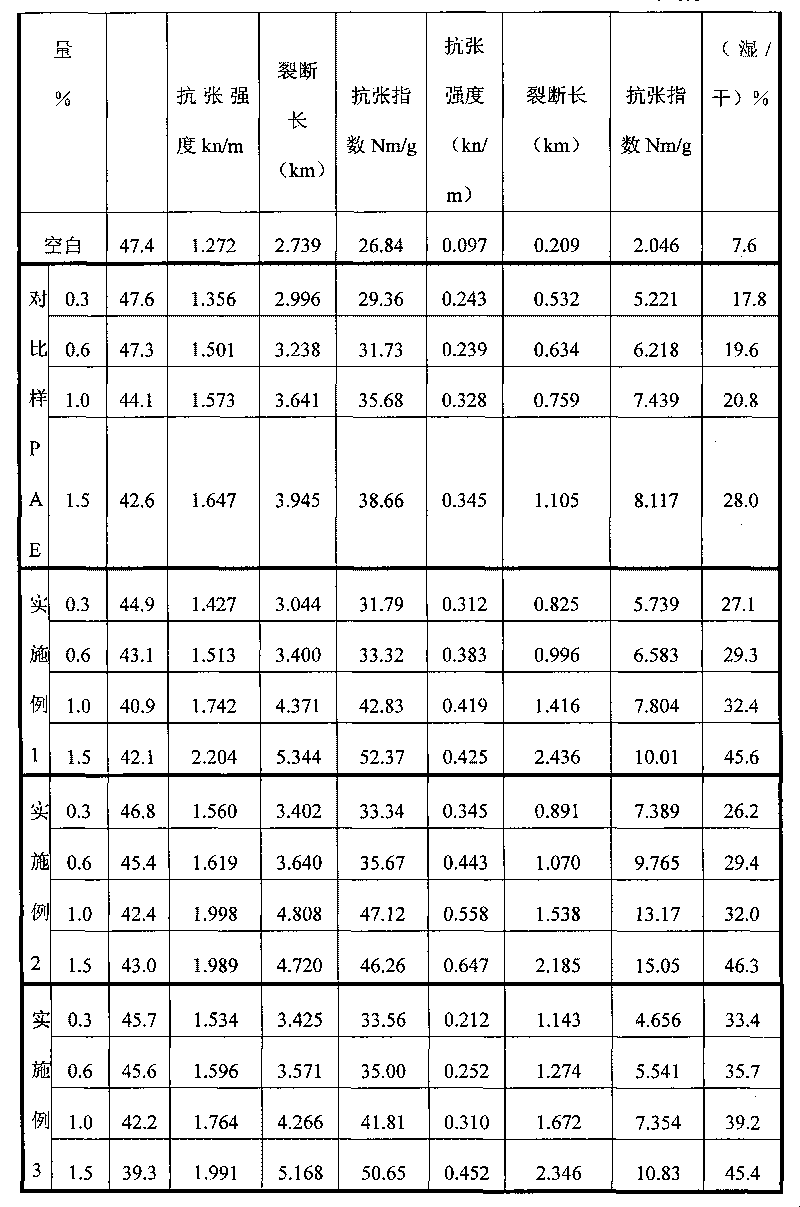

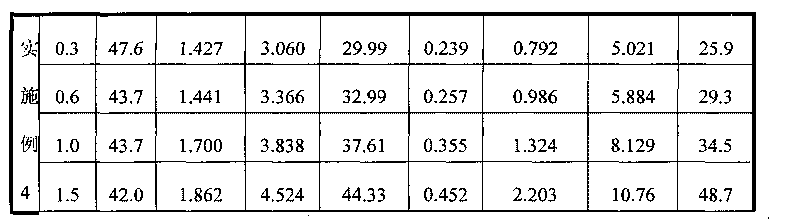

Epoxy polyamide resin wet strength agent and preparation method thereof

InactiveCN101705639AImprove wet strength performanceReduce sizeReinforcing agents additionPaper/cardboardEpoxy polyamideWet strength

The invention discloses an epoxy polyamide resin wet strength agent and a preparation method thereof. The preparation method comprises the following steps of: (1) reacting an aliphatic polyamine with an aromatic polyamine to obtain a condensation product of the aliphatic polyamine and the aromatic polyamine; (2) adding water in the condensation product obtained in the step (1), and adjusting the weight solid content of the condensation product to be 17%-35%; and then adding epoxy chloropropane for reaction to obtain the epoxy polyamide resin wet strength agent. The epoxy polyamide resin wet strength agent has higher wet strength effect in comparison with the traditional wet strength agent, and can evidently increase dry strength effect, and can enable paper to have high degree of sizing and good water resistance; and due to the action of an aromatic group, the epoxy polyamide resin wet strength agent has high stability and can be stored for half a year at normal temperature without influencing the use effect.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Heavy-duty art paint for nuclear power plant electric instrument cases and preparation method thereof

InactiveCN102898925AImprove the protective effectStable and reliable anti-rust and anti-corrosion performanceArtist's paintsAnti-corrosive paintsLacquerEpoxy polyamide

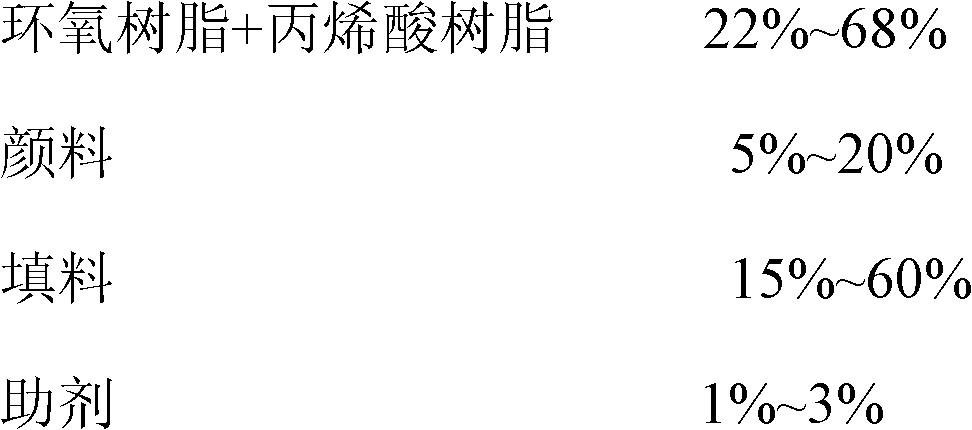

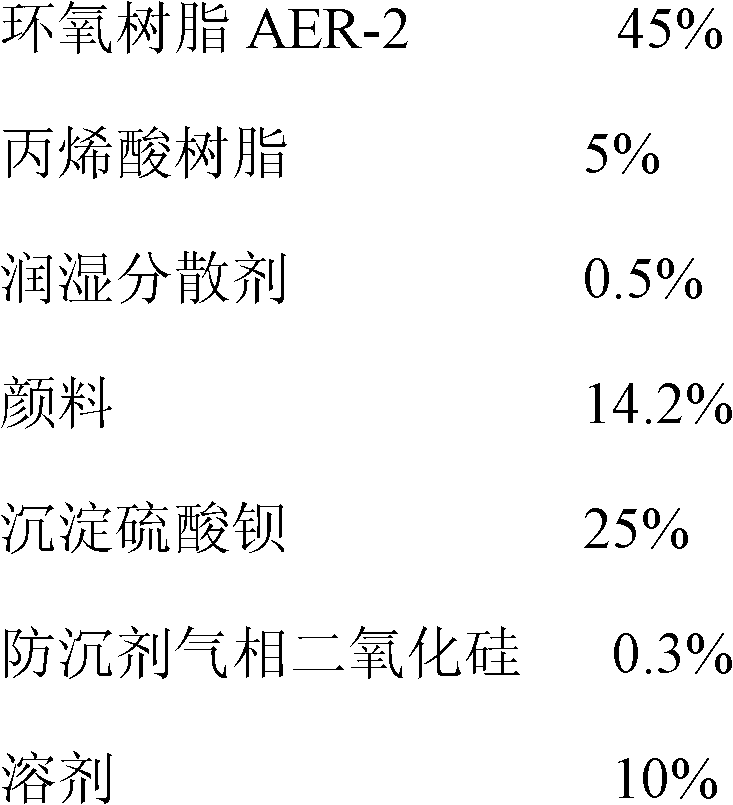

The invention provides a heavy-duty art paint for nuclear power plant electric instrument cases and a preparation method thereof. The art paint comprises a component A and a component B, wherein the component A comprises 22-68wt% of the total weight of epoxy resin and acrylic resin, 5-20wt% of pigment, 15-60wt% of filler, 1-3wt% of auxiliary agent, and 10-20wt% of solvent, and the weight ratio of epoxy resin to acrylic resin is 9-12:1; and the component B comprises 45-55wt% of epoxy polyamide curing agent and 45-55wt% of solvent. According to the invention, when the paint is used for coating, by cooperating with an anti-corrosive primer, good barrier property of the nuclear power plant electric instrument cases can be provided, and the application of the paint on the nuclear power plant electric instrument cases can provide stable and reliable rust protection and corrosion resistant performance.

Owner:上海华谊精细化工有限公司上海开林造漆厂

Coating, coated turbine component, and coating process

A coating, a coated turbine component, and a coating process are disclosed. The coating includes an epoxy-polyamide structure formed from a coating composition comprising a phenolic resin and a curing agent, the phenolic resin comprising a bisphenol F constituent and an epichlorohydrin constituent. The coating composition is solvent-free or substantially solvent-free. The cured coating is cross-linked from curing below 120° C., from curing using infrared-microwave radiation, or a combination thereof. The coated turbine component includes a surface and the coating. The coating process includes applying the coating and curing the coating.

Owner:GENERAL ELECTRIC CO

Epoxy polyamide adhesive and preparation method thereof

InactiveCN104403619AImprove adhesionHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

An epoxy polyamide adhesive and its preparation method belong to the field of adhesives. The epoxy polyamide adhesive is an adhesive prepared by using epoxy resin and polyamide as main materials, has good caking property with materials such as a steel plate, a rubber plate and the like, and can be applied in bonding between a steel plate and a steel plate as well as between a steel plate and a rubber plate. By interaction between an inorganic filling material and organic main materials, adhesive force, strength and toughness of the adhesive are enhanced. The epoxy adhesive prepared by using polyamide as a curing agent has advantages of high peel strength and high strength. By using melamine and polyamide as a composite curing agent, the defect that curing time is long when polyamide is separately used as a curing agent is solved. The epoxy polyamide adhesive has low curing temperature, can be cured at room temperature, and has advantages of simple technology and convenient operation.

Owner:山东华亚环保科技有限公司

Epoxy zinc alloy paint used for marine corrosion environment construction

ActiveCN104927564AImprove protectionImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsWaxOrganic solvent

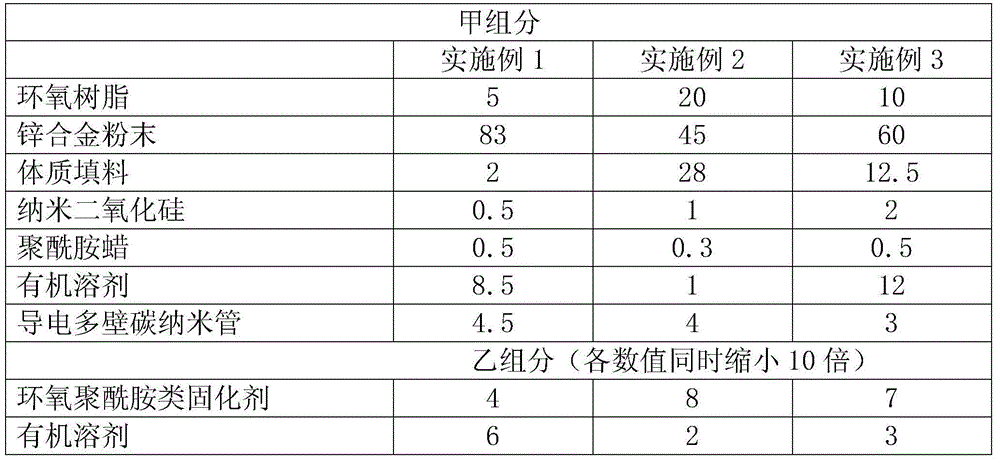

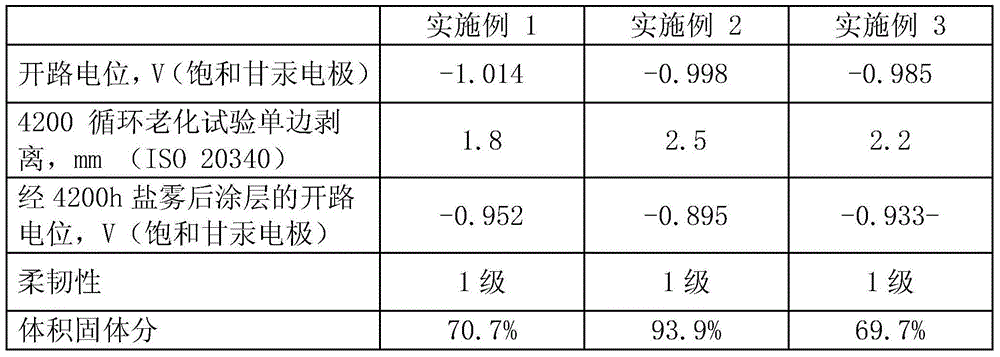

The invention discloses epoxy zinc alloy paint used for marine corrosion environment construction. The epoxy zinc alloy paint consists of a component A and a component B, wherein the component A comprises epoxy resin, zinc alloy powder, a body filler, nano silica, polyamide wax, an organic solvent and a conductive multi-wall carbon nano tube; the component B consists of an epoxy polyamide curing agent and an organic solvent; in use, the component A and the component B are mixed in a weight part ratio of 10 to 1 to prepare the epoxy zinc alloy paint; according to the IOS20340 standards, a coating has a single-side stripping value of less than 3.0 mm in a resistance to 4200h cycling ageing test, has excellent shielding performance, good wear resistance, outstanding cathode stripping resistance and cycling ageing resistance, relatively low VOCs (volatile organic chemicals) content performance and very outstanding corrosion resistance, and meets the authentication use requirements of the marine engineering paint.

Owner:XIAMEN SUNRUI SHIP COATING

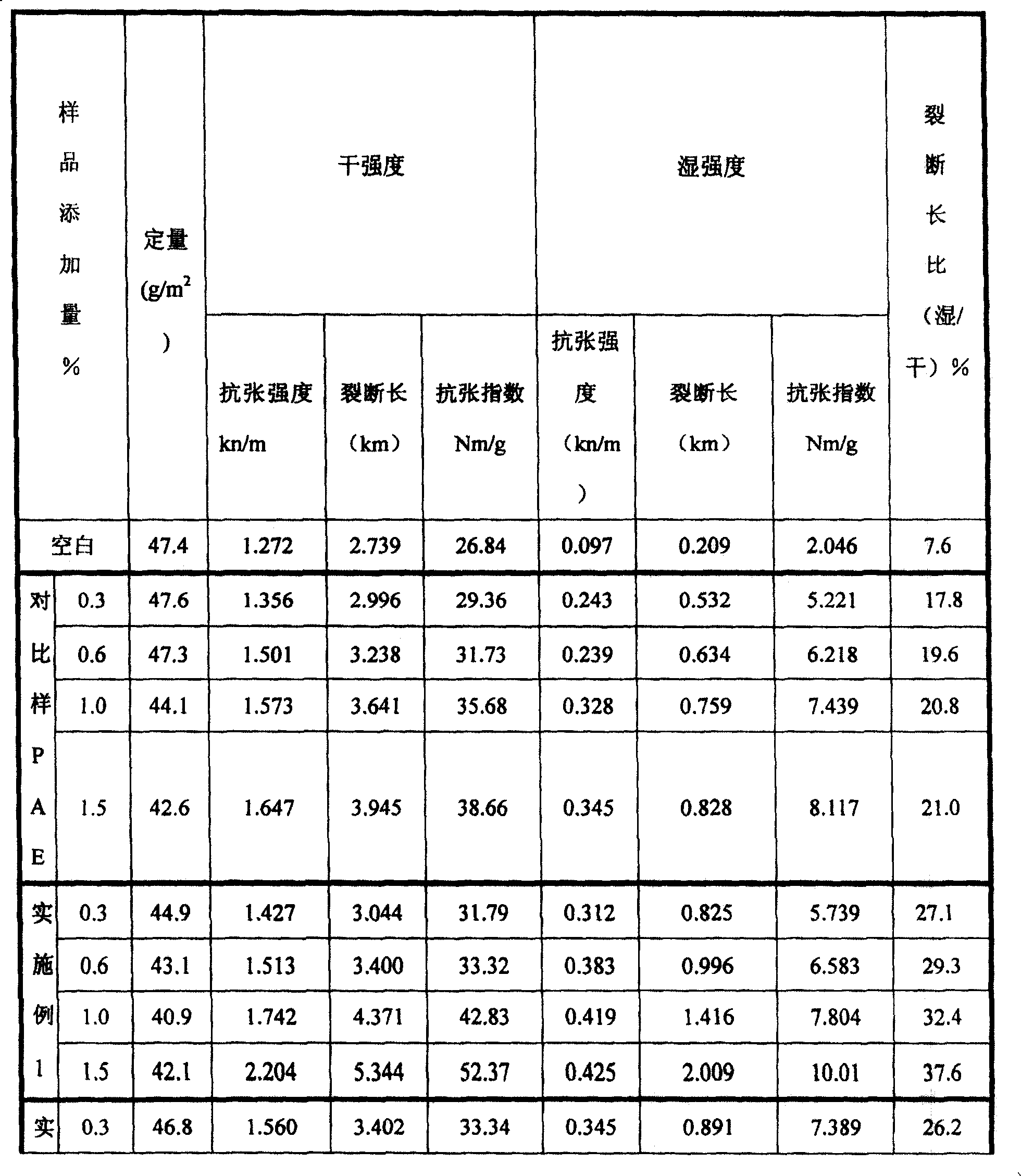

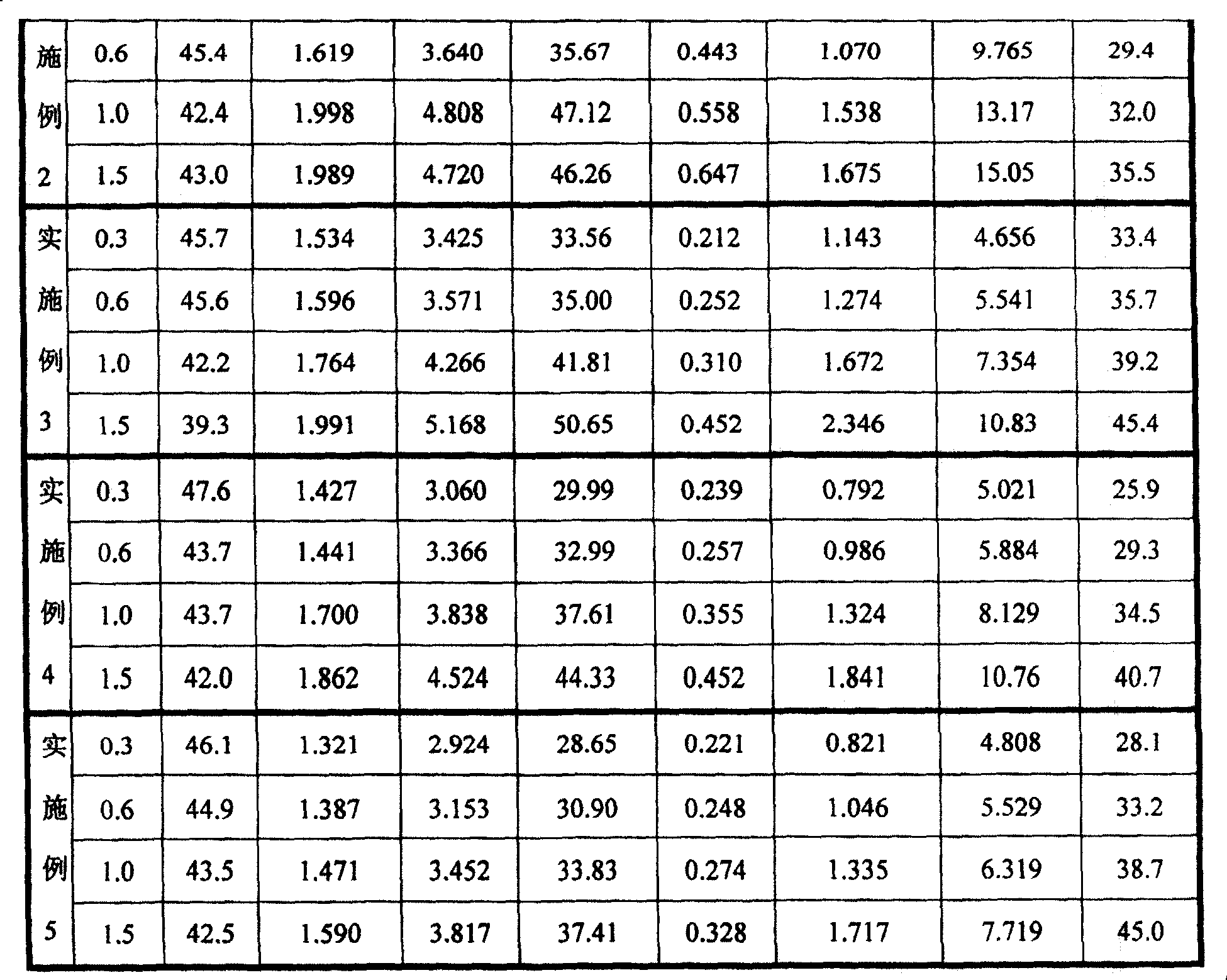

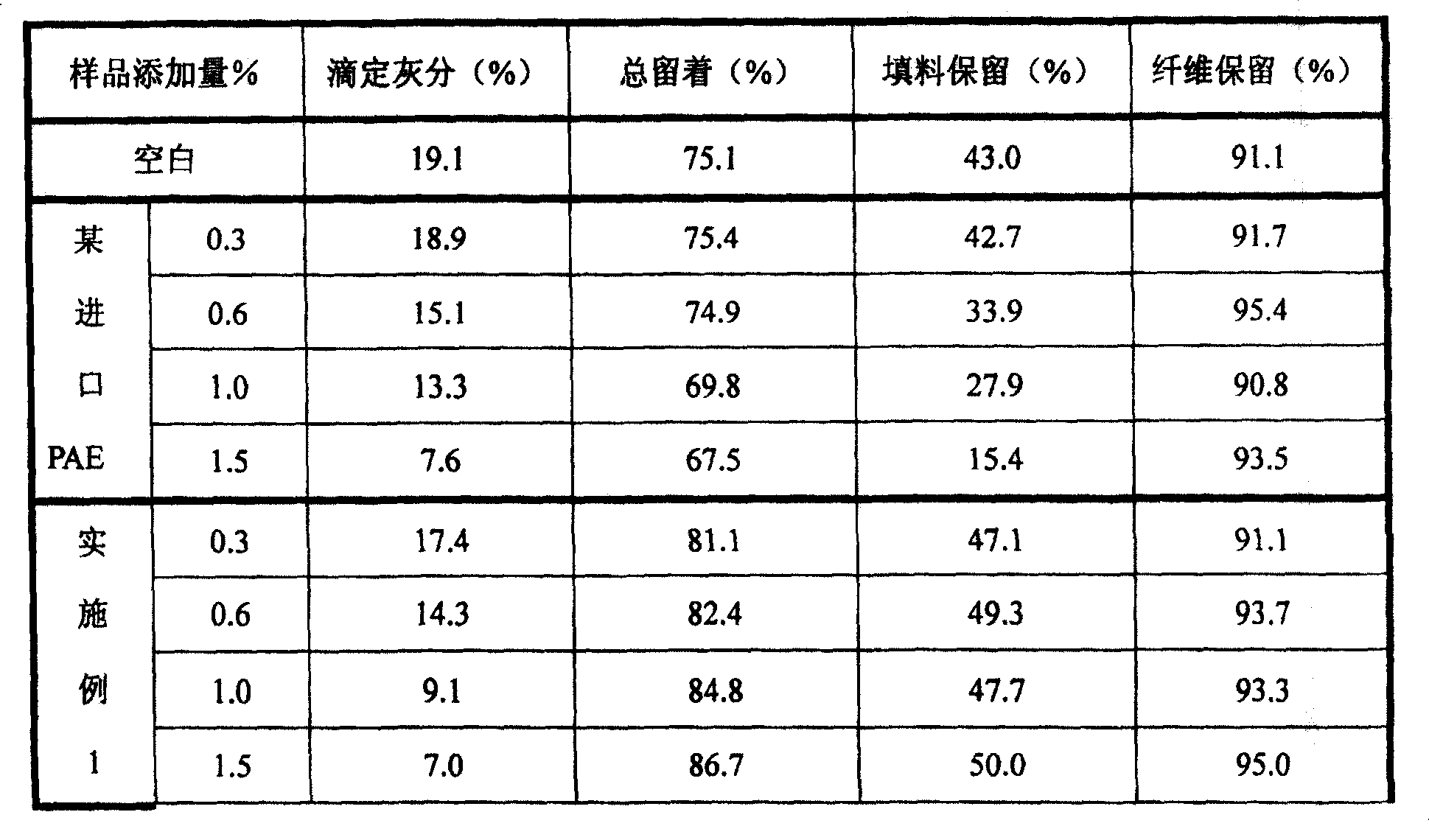

Preparation method of epoxy polyamide type paper making wet strength agent

ActiveCN103951812AReduce branching reactionImprove wet strengthReinforcing agents additionBreaking strengthEpoxy polyamide

The invention discloses a preparation method of an epoxy polyamide type paper making wet strength agent. A conventional preparation process has the problems of high energy consumption, low product quality controllability and the like. The preparation method disclosed by the invention comprises the following steps: (1) mixing polyamine with dicarboxylic ester to have high-temperature condensation polymerization; (2) adding water and epoxy chloropropane into the above-mentioned product, and performing a multi-temperature staged reaction to obtain the epoxy polyamide type paper making wet strength agent. Compared with similar products, the epoxy polyamide type paper making wet strength agent prepared by the method disclosed by the invention has a good wet strength effect, and also has relatively-great improvement in paper dry tensile strength, breaking strength and tearing strength. The preparation method disclosed by the invention needs no addition of a catalyst and has the advantages of simple operation, low energy consumption and the like.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Method for preparing lithium iron cell protective film and solvent for cleaning said protective film

A prepn. method for protective film of lithium ion cell. At least one organic polymer among phenolic resin, epoxy resin, polyvinyl acetate, polyurethane, polytetrafluoroethylene, chloronorgutta, phenolic chloronorgutta, epoxy polyamide and phenolic polyvinyl acetal is added into particular solvent selected at least one from diionized water, carbinol, benzene, toluene, chloroform dichloroethylene, diethyl ether, acetone, ethyl acetate and normal ethane, they are mixed and stirred to organic solution which is coated on case of lithium ion cell, then the case is static placed to volatilize particular solvent in the organic solution in room temp. to form a layer of uniform and densify protective film on cell case. Said film can prevent corrding of electrolyte and perspiration in prodn process. The invent is also relates to a solvent used for cleaning said proctive film selected from deionized water, alcohol, acetone, oxolane and formyldimethylamine.

Owner:HENAN HUANYU GROUP

An epoxy polyurethane resin wet-strengthening agent and a preparation method thereof

The epoxy polycyclamide resin wet strength agent featuring in the reaction of polyamine and polyunsaturated acid to make polyamide, which is cationised and then reacts with epichlorohydrin. The final product has a molecular weight range of 100, 000 -150, 000, viscosity range of 10-150 centipoise under normal temperature, with solid content 10-30%. It is applicable for paper making wet strength agent, retention filtration adjuvant, anion catching agent, making the paper having higher glue applicability and water resistance.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Epoxy polyamide resin wet strength agent and preparation method thereof

ActiveCN101747504AImprove wet strength performanceThere is no significant change in the application effectReinforcing agents additionEpoxy polyamideWet strength

The invention discloses an epoxy polyamide resin wet strength agent and a preparation method thereof. The preparation method comprises the following steps: (1) the pressure reaction of aliphatic polyamine and aromatic polyprotic acid is carried out; and (2) the water is added in a condensation compound in step (1), the epichlorohydrin is then added for normal pressure reaction, and the epoxy polyamide resin wet strength agent is obtained. The epoxy polyamide resin wet strength agent prepared by adopting the above method has the viscosity of 50-250 centipoises under 25 DEG C, the solid content of 10-30% by weight percent and the molecular weight range of 170, 000-180, 000. Compared with the conventional wet strength agent, the epoxy polyamide resin wet strength agent has higher wet strength effect as well as obvious dry-strengthening function, and also leads the paper to have better sizing degree and water resistance. The product has higher stability owing to the function of the aromatic group and can be stored for more than half a year under the normal temperature without influencing the using effect.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

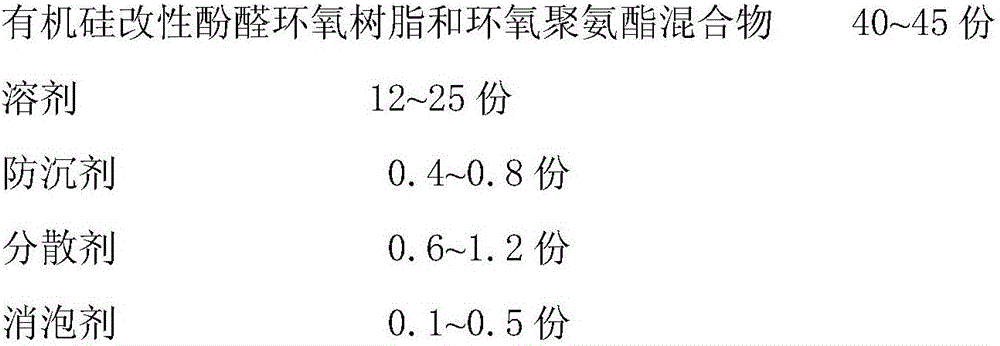

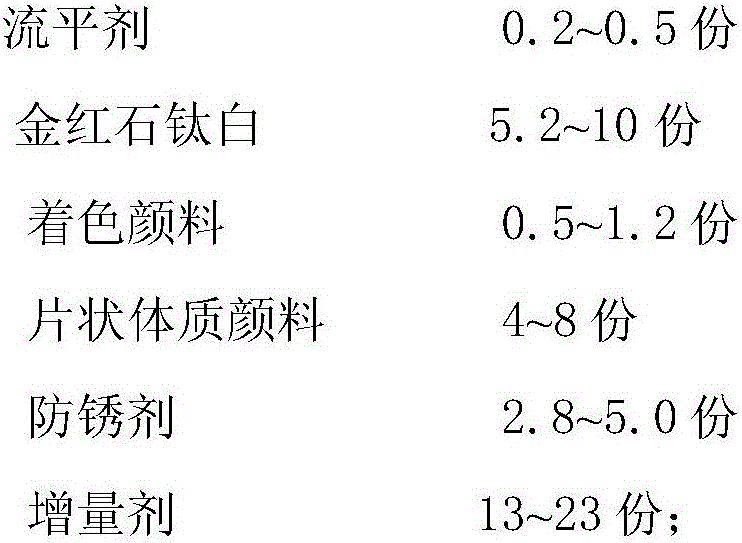

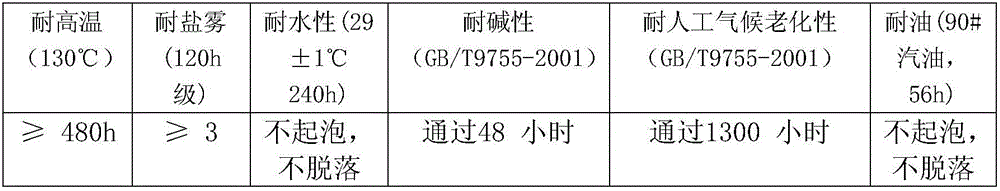

Gas cabinet anti-corrosion paint and preparation method thereof

InactiveCN106047088AGood compatibilityImproved rheological propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsCoating systemEpoxy polyamide

The invention discloses gas cabinet anti-corrosion paint and a preparation method thereof. The gas cabinet anti-corrosion paint is prepared from a component A and a component B at the mass ratio of 10 to 1, wherein the component A is composed of an organic silicon modified phenolic aldehyde epoxy resin and epoxy polyurethane mixture, a solvent, an anti-settling agent, a dispersant, a foaming agent, a leveling agent, rutile titanium white, a coloring pigment, a sheet-shaped extender pigment, an anti-rusting agent and an incremental agent; the component B is composed of an epoxy-polyamide curing agent and a solvent; and the mass ratio of organic silicon modified phenolic aldehyde epoxy resin to epoxy polyurethane is 1 to (0.8-1.5). By adopting the gas cabinet anti-corrosion paint, the adhesive force and the high-temperature-resisting and acid-alkali-resisting performances of a coating are improved; meanwhile, the water-resisting performance and the salt mist corrosion resisting performance of a coating system are improved and a coating color protection capability is also greatly enhanced; and the long-acting anti-corrosion effect is relatively remarkably improved.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

Ultraviolet resistant near space airship

ActiveCN103600833AUndamagedEnhanced self-cleaning effectSynthetic resin layered productsFuselage bulkheadsPolyesterEpoxy polyamide

An ultraviolet resistant near space airship comprises an airship skin, the skin sequentially comprises a weatherproof layer, a primer layer, a load carrying layer, a cohesive layer, a helium barrier layer and a heat sealing layer, the heat sealing layer is a polyurethane film, the helium barrier layer selects an aluminized polyester (Al-PET) film, the cohesive layer is polycarbonate, the load carrying layer selects a PBO plain fabric, the primer layer is two-component epoxy polyamide, and the weatherproof layer is a nanometer fluorocarbon coating. The adoption of the nanometer fluorocarbon coating in the invention enhances the automatic cleaning effect, the ultraviolet resistance and the environmental protection capability of the weatherproof layer, and substantially enhances the weatherproof property of the airship skin. The invention also relates to a making method of the airship skin.

Owner:LIYANG TECH DEV CENT

Preparation method of epoxy polyamide coating

InactiveCN107652837AImprove adhesionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsAdhesiveEpoxy polyamide

The invention discloses a preparation method of an epoxy polyamide coating. The preparation method comprises the following steps: introducing nitrogen into a reaction kettle, adding epoxy resin, acetone, methyl isobutyl ketone, a silane coupling agent and a dispersant, stirring above added substances for 0.5-1 h, sequentially adding ethylene glycol ethyl ether, amide modified hydrogenated castor oil and butanol, heating the obtained mixture to 50-60 DEG C, and stirring the heated mixture for 0.5 h; adding iron oxide red, talcum powder and an adhesive, continuously stirring the obtained mixturefor 1-1.5 h, standing the stirred mixture to cool the stirred mixture, filtering the cooled mixture to obtain a filtrate which is a coating primer, and dispersing the prepared coating primer until the fineness is less than 50 [mu]m; and adding polyamide, ether, a polyvinyl acetate emulsion, an antiseptic, an emulsifier and an antifoaming agent, and stirring the obtained mixture for 2-3 h to prepare the epoxy polyamide coating. The epoxy polyamide coating prepared in the invention solves a technical problem that the content of toxic and harmful substances in existing coatings exceeds a standard, and has the advantages of excellent adhesion, good chemical corrosion resistance and good alkali resistance.

Owner:ANQING HONGTAI NEW MATERIAL

Antistatic rubber sealing element material

The invention relates to the technical field of rubber seal processing, and discloses an antistatic rubber seal material, the antistatic agent used and polydimethylsiloxane, epoxidized polyamide resin, polyvinyl alcohol, polyethyleneimine Curing at the same time, compared with the antistatic agent directly coated on the surface of the product, the method of the present invention combines the antistatic component with the material, and under the directional action of the antistatic agent, lipophilic groups will be formed on the surface of the polymer. The dense monolayer of antistatic agent with the hydrophilic group facing outward can reduce the overall resistance and prevent charge accumulation, achieve structural antistatic effect, and have excellent durability.

Owner:宁国市润丰金属制品有限公司

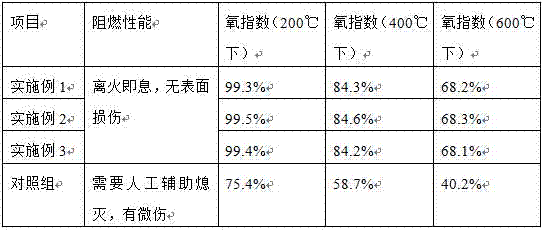

Flame-retardant flocking adhesive

InactiveCN109280497ARaw materials are easy to getEasy to manufactureNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseAcrylic resin

The invention relates to the technical field of adhesives, and discloses a flame-retardant flocking adhesive. The flame-retardant flocking adhesive has a formula which comprises the following components by weight: 150 to 180 parts of cellulose ester, 9 to 15 parts of a vinyl polymer, 260 to 300 parts of polyacrylate, 300 to 330 parts of alpha-cyanoacrylate, 4 to 6 parts of polyvinyl acetal, 200 to220 parts of ethylene-vinyl acetate, 190 to 230 parts of melamine-formaldehyde resin, 230 to 260 parts of organosilicone resin, 300 to 330 parts of acrylic resin, 15 to 20 parts of polyimide, 5 to 8parts of polybenzimidazole, 3 to 5 parts of phenolic aldehyde-polyvinyl acetal, 2 to 3 parts of phenolic aldehyde-polyamide, 150 to 180 parts of phenolic aldehyde-epoxy resin, 5 to 7 parts of epoxy-polyamide and 10 to 13 parts of decabromodiphenyl ether. The flame-retardant flocking adhesive provided by the invention has the advantages of easily-available and easily-manufactured raw materials, strong heat resistance, high flame retardancy, good oxidation resistance, good bonding effect, etc.

Owner:嘉善欣达胶业有限公司

Method for marine antifouling

InactiveCN106916477ASolve the adhesionSolve functionAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceEpoxy polyamide

The present invention provides a method for marine antifouling. The method comprises: coating an object requiring antifouling with an epoxy polyamide anticorrosion coating material; coating an adhesion layer on the anticorrosion coating material layer; and coating a low surface energy antifouling coating material topcoat on the adhesion layer. According to the present invention, the method uses the a low surface energy marine antifouling coating material and uses the three-component organic combination coating matching system, wherein the epoxy polyamide anticorrosion coating material is adopted as the primer, the middle coating is the styrene-butyl acrylate-polysiloxane interpenetrating network adhesion layer, and the upper layer is the low surface energy nanometer inorganic silicon antifouling coating material topcoat; and the excellent adhesion of the epoxy resin to the substrate and the excellent connection effect of the middle coating between the primer and the topcoat are used, and the problems of the adhesion among the steel iron substrate, the anticorrosion primer and the antifouling coating material, the antifouling function and the environmental protection are well solved.

Owner:HENAN RUNNAN PAINT IND

Stratospheric airship

A stratospheric airship comprises an airship skin. The skin comprises a weather-proof layer, a primer layer, a force-bearing layer, an adhesive layer, a helium resistant layer and a heat sealing layer sequentially from outside to inside. The heat sealing layer is a polyurethane film, the helium resistant layer is an aluminized polyester (Al-PET) film, the adhesive layer is made of polycarbonate, the force-bearing layer is made of PBO plain weave fabric, the primer layer is made of two-component epoxy polyamide, and the weather-proof layer is a nano-fluorocarbon coating. According to the stratospheric airship, the nano-fluorocarbon coating is adopted, capabilities of self-cleaning, ultraviolet proofing and environment protecting of the weather-proof layer are enhanced, and the weather proofing capability of the airship skin is improved greatly. The invention further relates to a production method of the airship skin.

Owner:LIYANG TECH DEV CENT

Sealing rubber ring for brake shoe automatic riveting device

InactiveCN106084337AImprove wear resistanceAnti-aging efficiency is obviousEpoxy polyamideBrake shoe

The invention relates to a sealing rubber ring for a brake shoe automatic riveting device. The sealing rubber ring is prepared from the following components in parts by weight: 15 to 20 parts of epoxy resin, 5 to 10 parts of dry oil alkyd resin, 6 to 12 parts of phenolic resin, 1 to 3 parts of polybenzimidazole, 20 to 30 parts of graphite powder, 4 to 8 parts of epoxy-polyamide, 6 to 18 parts of manganese dioxide, 20 to 40 parts of butadiene rubber, 3 to 5 parts of zinc stearate and 2 to 8 parts of silicon nitride. Being prepared from the epoxy resin, the dry oil alkyd resin, the phenolic resin, the polybenzimidazole, the graphite powder, the epoxy-polyamide, the manganese dioxide, the butadiene rubber, the zinc stearate and the silicon nitride according to the provided formula proportion, the sealing rubber ring for the brake shoe automatic riveting device not only has good wear resistance, but also is remarkable in anti-aging efficiency, can be used at high temperature for a long time, and has greatly prolonged service life.

Owner:HEFEI WANXIANG QIANCHAO AUTO PARTS

Method for improving flame retardance of fraxinus mandshurica wood

InactiveCN107199610AImprove flame retardant performanceImprove permeabilityRadiation/waves wood treatmentWood treatment detailsFraxinusEpoxy polyamide

The invention relates to the technical field of wooden product processing and manufacturing and discloses a method for improving flame retardance of fraxinus mandshurica wood. A used flame retardant is prepared from the following components of, by mass, 12.5-13.0% of tricresyl phosphate, 11.0-12.0% of tetrachlorophthalic anhydride, 7.5-8.0% of tripolycyanamide- formaldehyde resin, 7.0-7.5% of epoxy polyamide resin, 6.2-6.5% of ethidene diamine, 5.0-5.5% of dialkyl p-phenylenediamine, 4.5-5.0% of pentaerythritol, 2.8-3.0% of 2,6 ditert-butyl-4-cresol, 2.5-3.0% of bioctadecyl methylamino quaternary ammonium salt and the balance water. The flame retardant is applicable to the wood characteristic of fraxinus mandshurica, and meanwhile, a vacuum pressure treatment technology and microwave treatment are applied to wood flame retardance treatment, and the flame retardance effect is enhanced.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

Weather-proof near space airship

ActiveCN103587673AUndamagedEnhanced self-cleaning effectSynthetic resin layered productsRigid airshipsPolyesterEpoxy polyamide

A weather-proof near space airship comprises an airship skin. The skin comprises a weather-proof layer, a primer layer, a force-bearing layer, an adhesive layer, a helium resistant layer and a heat sealing layer sequentially from outside to inside. The heat sealing layer is a polyurethane film, the helium resistant layer is an aluminized polyester (Al-PET) film, the adhesive layer is made of polycarbonate, the force-bearing layer is made of PBO plain weave fabric, the primer layer is made of two-component epoxy polyamide, and the weather-proof layer is a nano-fluorocarbon coating. According to the weather-proof near space airship, the nano-fluorocarbon coating is adopted, capabilities of self-cleaning, ultraviolet proofing and environment protecting of the weather-proof layer are enhanced, and the weather proofing capability of the airship skin is improved greatly. The invention further relates to a production method of the airship skin.

Owner:LIYANG TECH DEV CENT

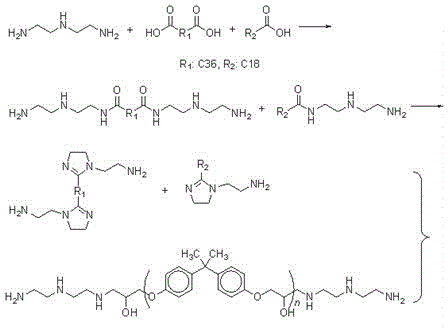

Diethylenetriamine amido low molecular weight 650 epoxy hardener used for epoxy polyamide coating and preparation method and application thereof

ActiveCN102977339BGood flexibilityIncrease elasticityEpoxy resin coatingsEpoxy polyamideDiethylenetriamine

The invention discloses a diethylenetriamine amido low molecular weight 650 epoxy hardener used for epoxy polyamide coating. The Diethylenetriamine amido low molecular weight 650 epoxy hardener used for the epoxy polyamide coating comprises, by weight, 6-10 parts of diethylenetriamine, 10-17 parts of dimer acid, 4-9 parts of fat single acid, 2-4 parts of epoxy resin, 1-4 parts of phenol, 1-4 parts of benzyl alcohol, and 1-4 parts of dimethylbenzene. According to the Diethylenetriamine amido low molecular weight 650 epoxy hardener used for the epoxy polyamide coating, the best raw material composition and ratio are preferably chosen by a large amount of tests. The Diethylenetriamine amido low molecular weight 650 epoxy hardener used for the epoxy polyamide coating has the advantages of being excellent in flexibility and antiseptic property, good in adhesion, good bisphenol A epoxy resin cure activity and compatibility, and wide in application range. According to a preparation method of the low molecular weight 650 epoxy hardener, reaction steps and reaction conditions are chosen through a large amount of technology, so the whole preparation technology is scientific and reasonable in design. Work efficiency is high and controllability is strong. Uniformity of epoxy hardener high-activity and high-phase is ensured, meanwhile, cost can be greatly reduced, industrialisieren mass production can be achieved, and convenience in popularization and application is achieved.

Owner:江苏三木化工股份有限公司

Environment-friendly decorative wall paper

InactiveCN101845773AImprove breathabilityImprove bindingSpecial paperWater-repelling agents additionEpoxy polyamidePulp and paper industry

The invention discloses an environment-friendly decorative wall paper. A base paper is mainly made of wood pulp, straw pulp and epoxy polyamide resin wet strength agent in percentage by weight: 85 to 95 percent of the wood pulp, 4 to 14 percent of the straw pulp and 0.5 to 1 percent of the epoxy polyamide resin wet strength agent; and the base paper is sequentially coated with a fire retardant coating layer and a resin adhesive layer from inside to outside. In the invention, the wall paper made of synthetic fibre in the prior art is abandoned. The base paper is made of the wood pulp, the straw pulp and the epoxy polyamide resin wet strength agent in proper proportion, so that delicate patterns can be printed on the base paper; and the base paper is coated with the resin adhesive layer to ensure that the base paper can be firmly combined with the wall while having good permeability.

Owner:福建希源纸业有限公司

A UV-resistant near-space airship

ActiveCN103600833BUndamagedEnhanced self-cleaning effectSynthetic resin layered productsFuselage bulkheadsPolyesterEpoxy polyamide

An ultraviolet resistant near space airship comprises an airship skin, the skin sequentially comprises a weatherproof layer, a primer layer, a load carrying layer, a cohesive layer, a helium barrier layer and a heat sealing layer, the heat sealing layer is a polyurethane film, the helium barrier layer selects an aluminized polyester (Al-PET) film, the cohesive layer is polycarbonate, the load carrying layer selects a PBO plain fabric, the primer layer is two-component epoxy polyamide, and the weatherproof layer is a nanometer fluorocarbon coating. The adoption of the nanometer fluorocarbon coating in the invention enhances the automatic cleaning effect, the ultraviolet resistance and the environmental protection capability of the weatherproof layer, and substantially enhances the weatherproof property of the airship skin. The invention also relates to a making method of the airship skin.

Owner:LIYANG TECH DEV CENT

A weather-resistant high-altitude airship

ActiveCN103612436BUndamagedEnhanced self-cleaning effectSynthetic resin layered productsNon-rigid airshipsPolyesterEpoxy polyamide

A weather resistant high altitude airship comprises an airship skin. The skin comprises from the outside to the inside a weather resistant layer, a primer layer, a bearing layer, a bonding layer, a helium resistant layer and a heat-sealing layer. The heat-sealing layer is a polyurethane film; the helium resistant layer employs an aluminized polyester (Al-PET) film; the bonding layer is made of polycarbonate; the bearing employs PBO plain weave fabric; the primer layer is prepared from two-component epoxy polyamide; and the weather resistant layer is a nanometer fluorocarbon coating. The invention adopts the nanometer fluorocarbon coating to enhance the self-cleaning effect, ultraviolet resistance and environmental protection capacity of the weather resistant layer, thereby greatly improving the weatherability of the airship skin. The invention also relates to a manufacturing method of the airship skin.

Owner:LIYANG TECH DEV CENT

A weather-resistant stratospheric airship

ActiveCN103600829BUndamagedEnhanced self-cleaning effectGas-bag arrangementsPolyesterEpoxy polyamide

A weather-proof stratospheric airship comprises an airship skin. The skin comprises a weather-proof layer, a primer layer, a force bearing layer, an adhesive layer, a helium blocking layer and a thermal sealing layer sequentially from outside to inside, wherein the thermal sealing layer is a polyurethane film; the helium blocking layer is an aluminized polyester (Al-PET) film; the adhesive layer is made of polycarbonate; the force bearing layer is made of PBO plain weave fabric; the primer layer is made of double-component epoxy polyamide; the weather-proof layer is made of nanometer fluorocarbon coating. As the nanometer fluorocarbon coating is adopted, the weather-proof stratospheric airship enhances self-cleaning effect, ultraviolet resistance and environment protection ability of the weather-proof layer and greatly enhances weather resistance of the airship skin. The invention also relates to a manufacturing method of the airship skin.

Owner:LIYANG TECH DEV CENT

A UV-resistant high-altitude airship

ActiveCN103600830BUndamagedEnhanced self-cleaning effectGas-bag arrangementsPolyesterEpoxy polyamide

An ultraviolet-resistant high-altitude airship comprises an airship skin. The skin comprises a weather-proof layer, a primer layer, a force bearing layer, an adhesive layer, a helium blocking layer and a thermal sealing layer sequentially from outside to inside, wherein the thermal sealing layer is a polyurethane film; the helium blocking layer is an aluminized polyester (Al-PET) film; the adhesive layer is made of polycarbonate; the force bearing layer is made of PBO plain weave fabric; the primer layer is made of double-component epoxy polyamide; the weather-proof layer is made of nanometer fluorocarbon coating. As the nanometer fluorocarbon coating is adopted, the ultraviolet-resistant high-altitude airship enhances self-cleaning effect, ultraviolet resistance and environment protection ability of the weather-proof layer and greatly enhances weather resistance of the airship skin. The invention also relates to a manufacturing method of the airship skin.

Owner:LIYANG TECH DEV CENT

A stratospheric airship

A stratospheric airship comprises an airship skin. The skin comprises a weather-proof layer, a primer layer, a force-bearing layer, an adhesive layer, a helium resistant layer and a heat sealing layer sequentially from outside to inside. The heat sealing layer is a polyurethane film, the helium resistant layer is an aluminized polyester (Al-PET) film, the adhesive layer is made of polycarbonate, the force-bearing layer is made of PBO plain weave fabric, the primer layer is made of two-component epoxy polyamide, and the weather-proof layer is a nano-fluorocarbon coating. According to the stratospheric airship, the nano-fluorocarbon coating is adopted, capabilities of self-cleaning, ultraviolet proofing and environment protecting of the weather-proof layer are enhanced, and the weather proofing capability of the airship skin is improved greatly. The invention further relates to a production method of the airship skin.

Owner:LIYANG TECH DEV CENT

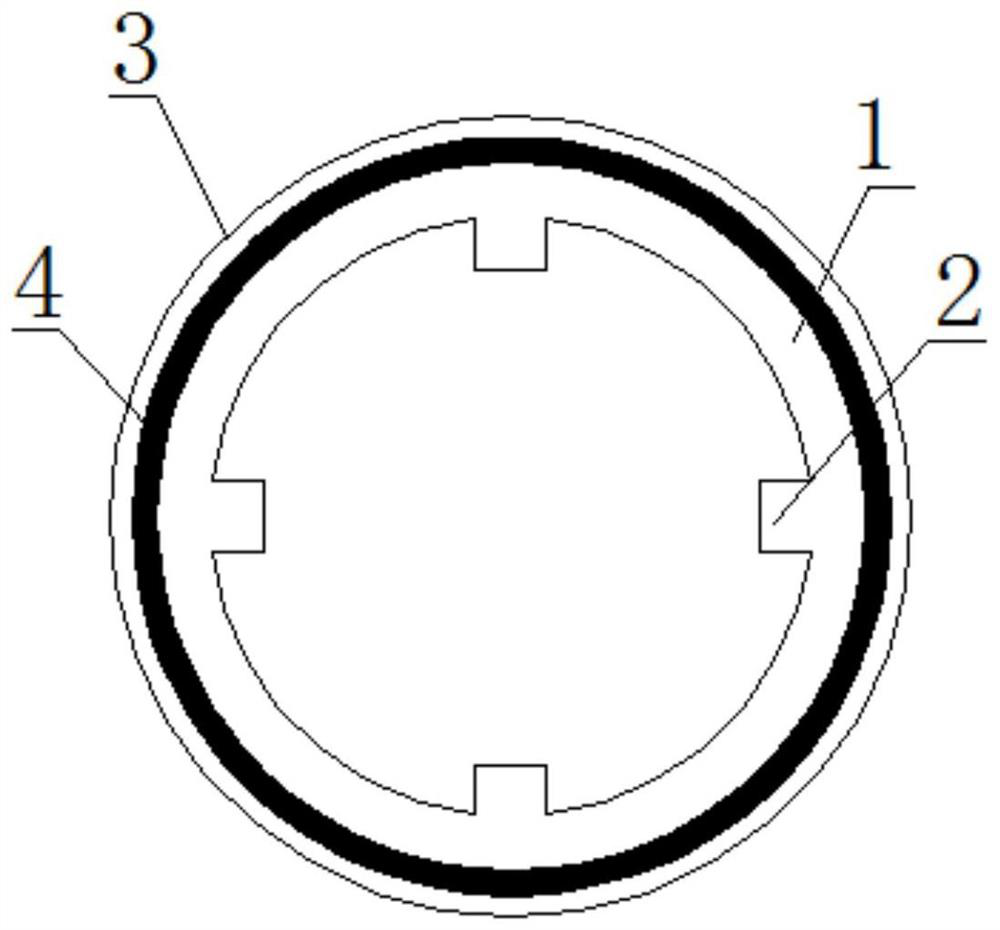

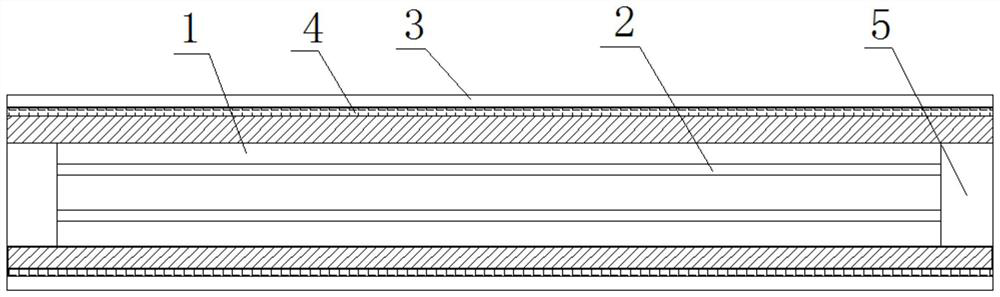

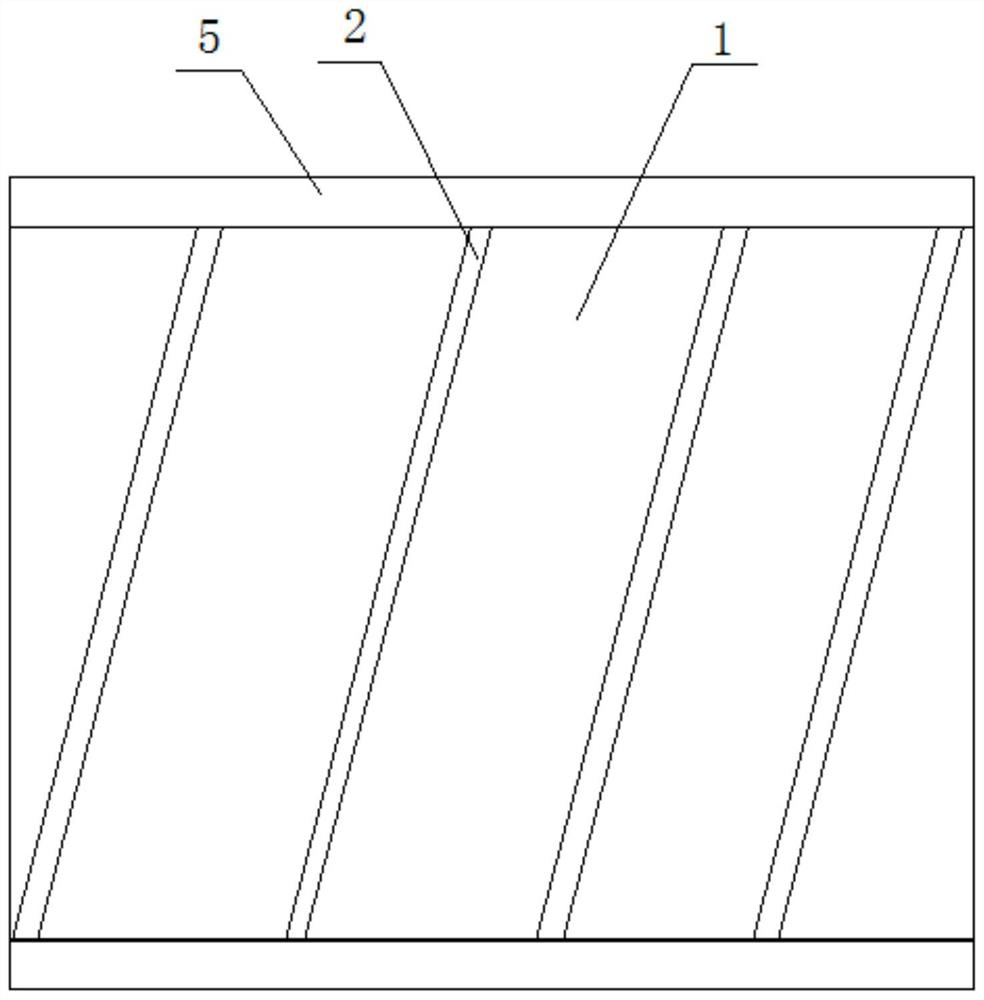

Fuzzing roller and preparation method thereof

PendingCN112831960AReduce weightGuaranteed StrengthPolyamide coatingsRougheningEpoxy polyamideEngineering

The invention discloses a fuzzing roller and a preparation method thereof, and belongs to the field of manufacturing of textile machinery. The fuzzing roller is of a cylindrical hollow structure, and the fuzzing roller structurally comprises a roller body and fixing parts at the two ends, wherein a plurality of reinforcing ribs are arranged on the inner wall of the roller body, the reinforcing ribs extend from one end of the inner wall of the roller body to the other end of the inner wall of the roller body, the bottoms of the reinforcing ribs are connected with the inner wall of the roller body, the tops of the reinforcing ribs protrude towards the axis of the roller body, and the inner wall of each fixing part is a smooth cylindrical surface. By arranging the reinforcing ribs, under the condition that the overall weight of the fuzzing roller is reduced, the strength of the fuzzing roller can be guaranteed; card clothing is bonded to the roller body through anti-skid coating, so that slipping of the card clothing is avoided; the anti-skid coating is prepared by adding jade powder into epoxy polyamide, is high in adhesive force and can resist the temperature of 120 DEG C, so that the whole fuzzing roller has the advantages of acid resistance, alkali resistance, corrosion resistance, and high hardness.

Owner:SHANDONG GUANGTAI ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com