Epoxy zinc alloy paint used for marine corrosion environment construction

A corrosive environment, epoxy zinc technology, applied in the field of coatings, can solve the problems of reduced cathodic protection effect and large change in open circuit potential of coatings, and achieve excellent cathodic protection effect, high solid content, and reduced production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

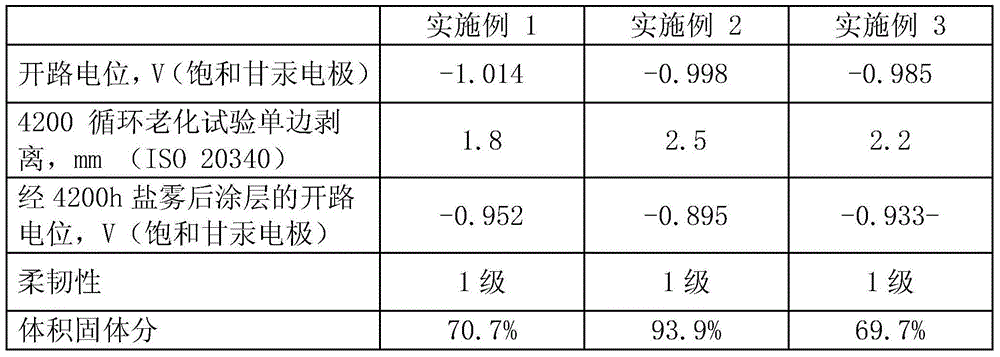

[0029] The present invention is an epoxy zinc alloy coating used for construction in a marine corrosive environment. The epoxy zinc alloy coating has excellent cathodic protection effect and anti-corrosion performance. After 4200h salt spray test, the open circuit potential of the coating has a small change and has a large Good anti-corrosion effect.

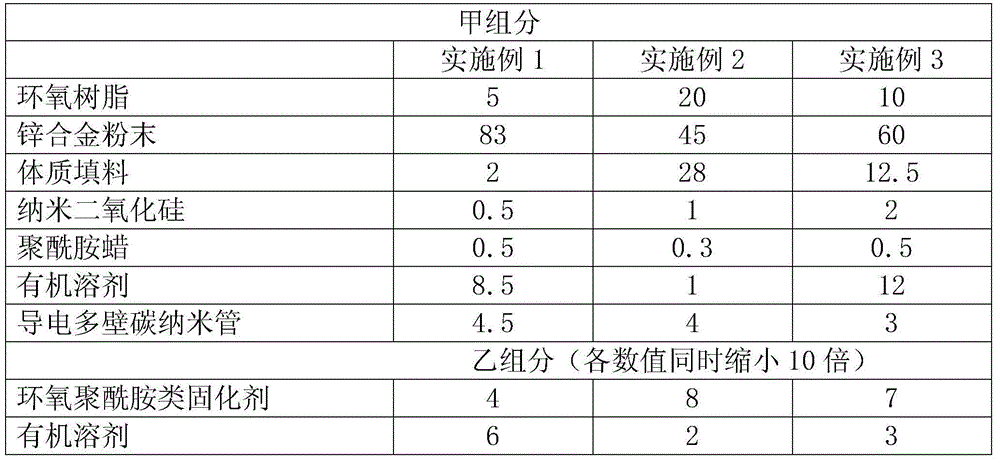

[0030] The epoxy zinc alloy coating of the present invention is composed of component A and component B, and component A contains epoxy resin, zinc alloy powder, body filler, nano silicon dioxide, polyamide wax, organic solvent and conductive multi-walled carbon Nanotubes, component B contains epoxy polyamide curing agent and organic solvent, wherein:

[0031] The epoxy resin is a bisphenol A type epoxy resin, and the molecular weight of the bisphenol A type epoxy resin is required to be between 200-1500 and its epoxy value is between 0.2-0.67.

[0032] The composition of the zinc alloy powder is Zn-Al-Mg-Si-Pb-Cd-Fe-Cu, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com