Patents

Literature

197results about How to "Solve the adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

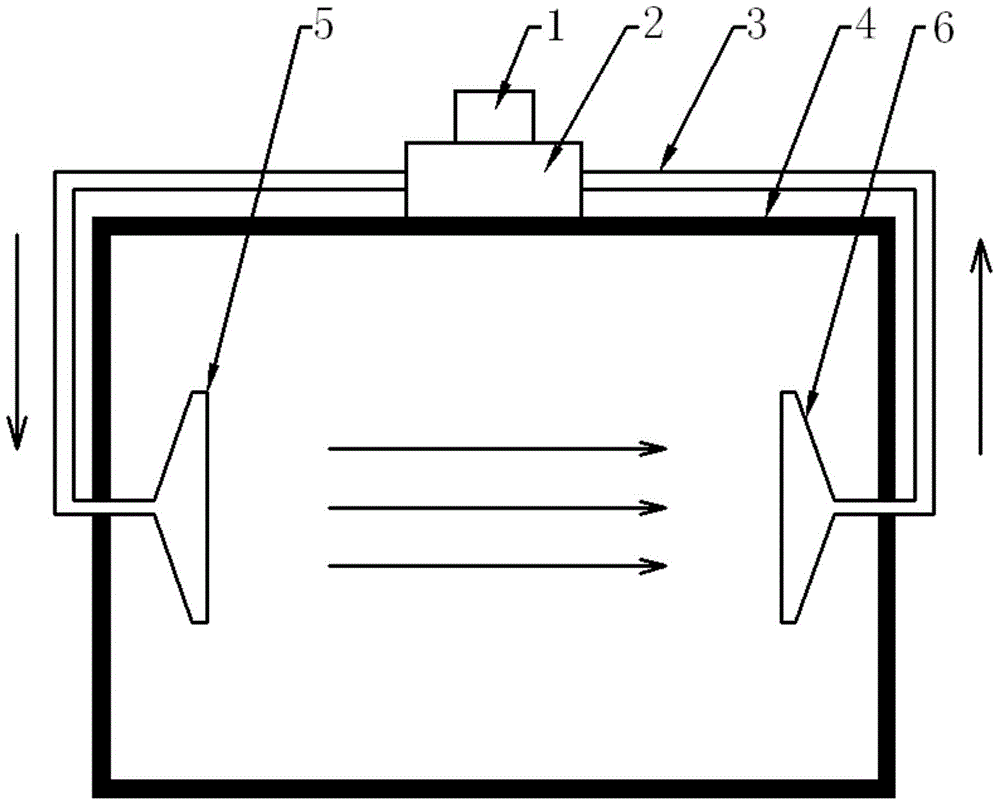

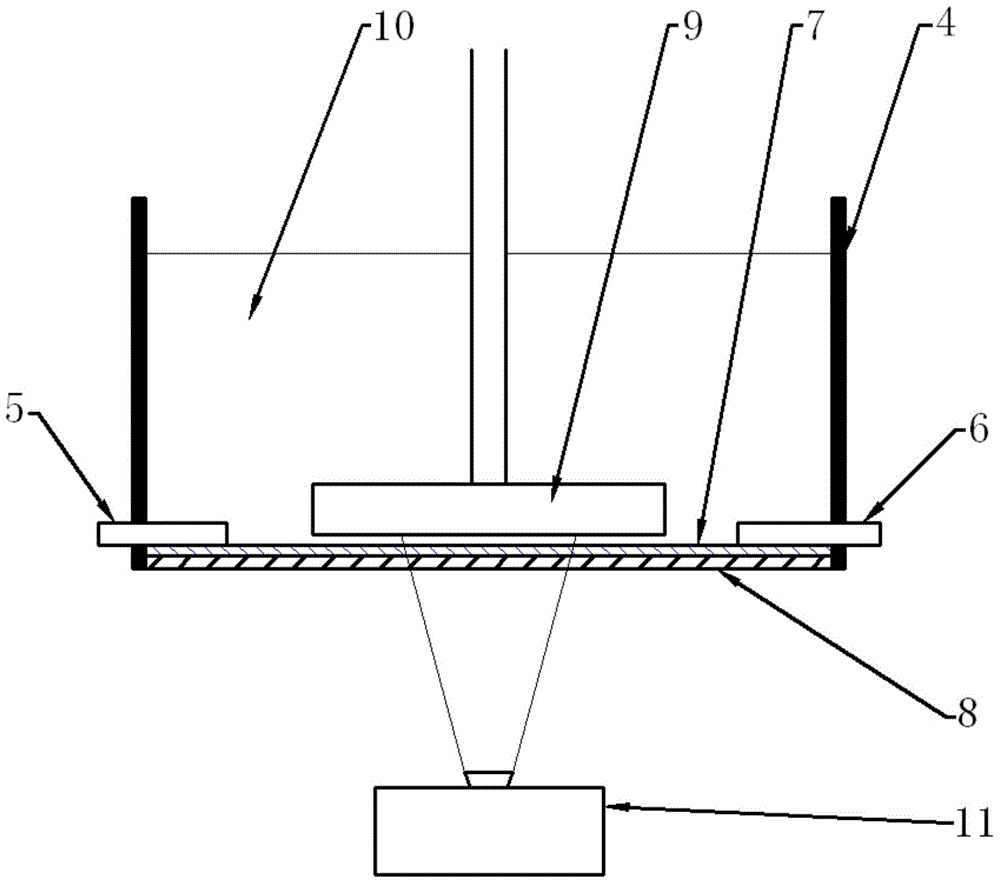

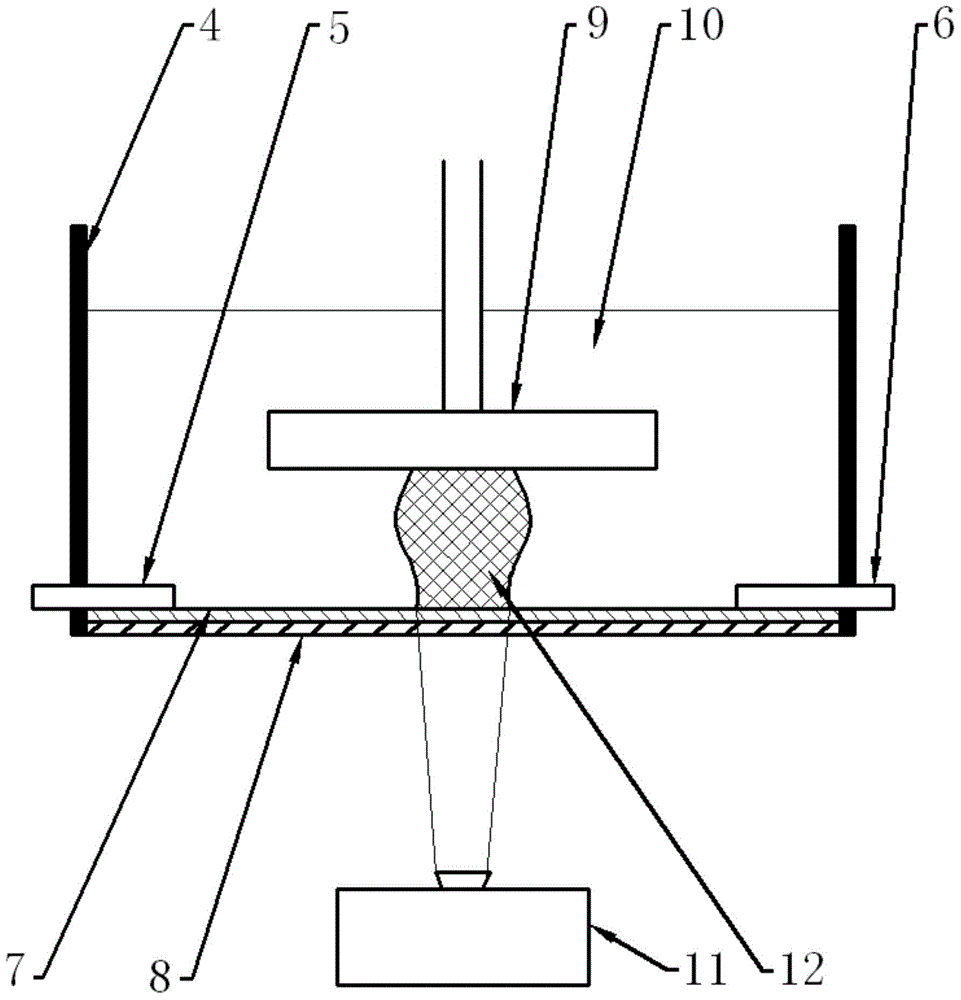

High-speed photocuring 3D printing device and printing method

ActiveCN105014974AInhibition of attachmentTroubleshoot disruptive technical issuesAdditive manufacturing apparatusEngineeringGlass sheet

The invention discloses a high-speed photocuring 3D printing device and method. The device comprises a liquid pool filled with liquid photosensitive resin, a printing platform and a radiation source. A transparent plate corresponding to the printing platform and the radiation source is arranged at the bottom of the liquid pool. The side, facing the printing platform, of the transparent plate is covered with a transparent anti-bonding coating. The device further comprises a liquid outlet and a liquid inlet which are formed in the side wall of the liquid pool, a pipeline connecting the liquid outlet and the liquid inlet, and a drive unit which is arranged on the pipeline and used for driving the liquid photosensitive resin to flow among the liquid outlet, the liquid inlet and the pipeline. A curing window is coated with the transparent anti-bonding coating, and therefore the problem that the curing photosensitive resin is bonded and attached to a glass plate due to excessively fast laser radiation is avoided. Pipelines promoting flowing of the liquid photosensitive resin are arranged on the two sides of a printing area, the mobility of the photosensitive resin near the printing area is improved, supplementing of the photosensitive resin is accelerated, and rapid printing of the SLA is achieved.

Owner:苏州智能制造研究院有限公司

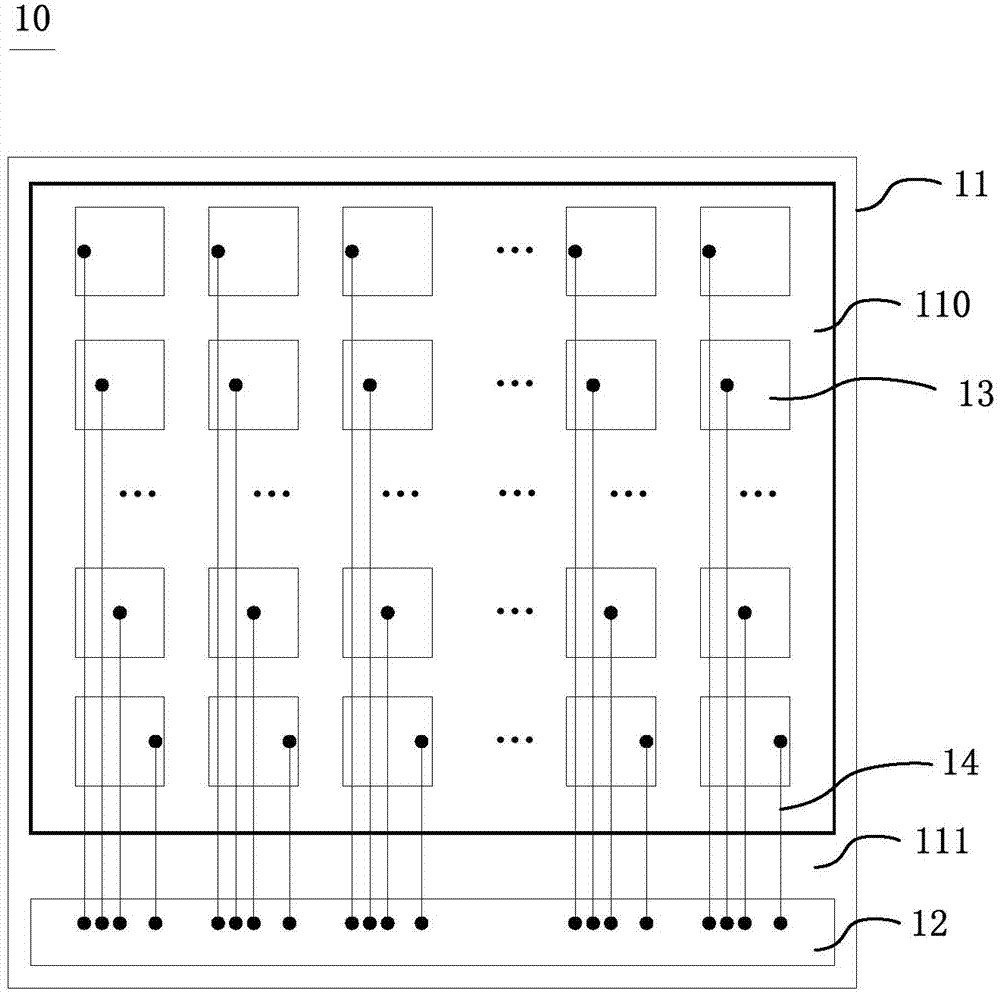

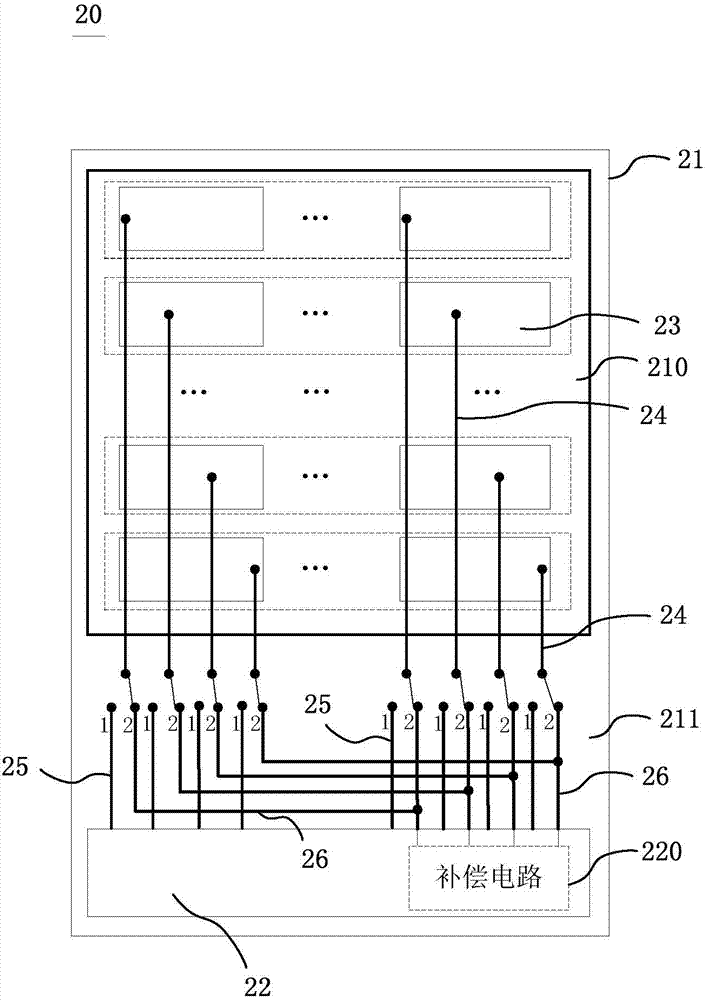

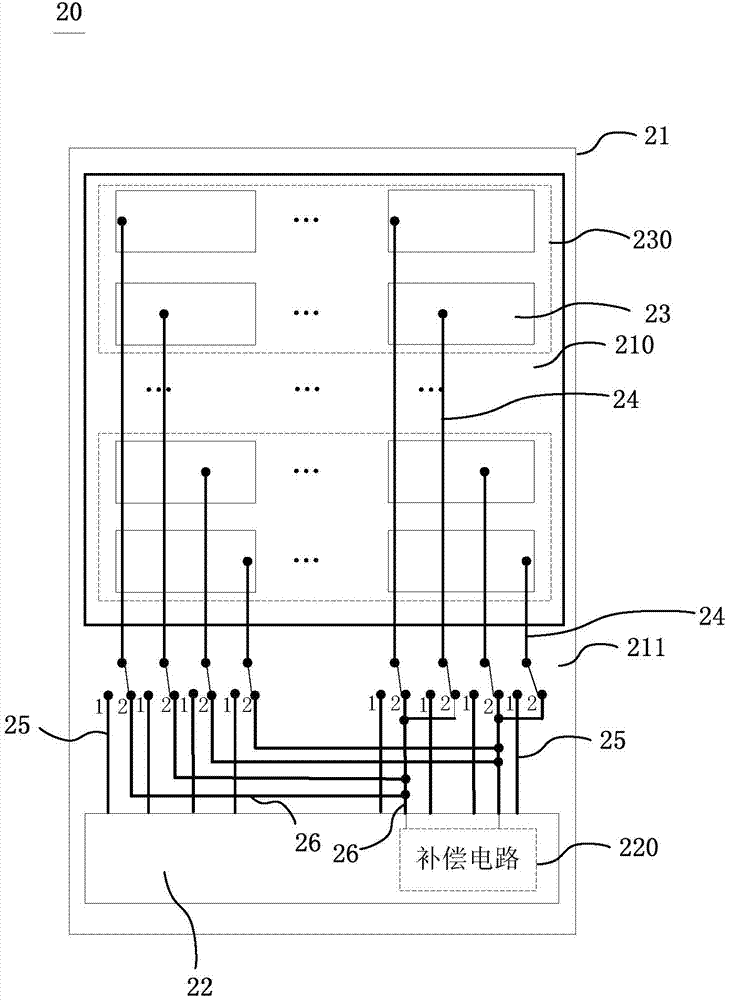

Touch control display panel, driving method and touch control display device

ActiveCN104777942ASolve flickeringSolve the adhesionNon-linear opticsInput/output processes for data processingElectricityDisplay device

The invention discloses a touch control display panel, a driving method and a touch control display device. The touch control display panel comprises a substrate, a control unit, a plurality of public electrode blocks, a plurality of first wires, a plurality of second wires and at least two third wires, wherein the substrate comprises a display area and a non-display area, the control unit is arranged in the non-display area; the public electrode blocks are arranged in the display area at intervals in an array mode, reused as touch control electrodes and are divided into at least two public electrode groups according to the distance from the control unit; the first wires are in electric connection with the first public electrode blocks respectively; the second wires are in electric connection with the control unit, each second wire is in electric connection with the corresponding first wire in the touch control stage and inputs a touch control signal to the first wire; at least two third wires are in electric connection with the control unit, and the third wires are in electric connection with the first wires corresponding to the public electrodes in the display stage. The touch control display panel, the driving method and the touch control display device can solve the technical problems of display screen flash and image adhesion and improve the display effect of a display screen.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

Production method of wool/Coolmax/mulberry silk/polyester fiber blended fabric

InactiveCN102560930ATo soften waterSolve the adhesionLiquid/gas/vapor removalLiquid/gas/vapor treatment of indefinite length materialsFiberPolyester

The invention relates to a production method of a wool / Coolmax / mulberry silk / polyester fiber blended fabric, which is characterized in that the blended fabric is made of 60% of Australasian wool, 20% of Coolmax fibers, 15% of polyester fibers, and 5% of mulberry silk by dyeing, recombing, spinning, weaving and dyeing and finishing. The fabric has good color fastness, is non-fading and is breathable.

Owner:江苏华西村纺织服装有限公司

Anti-sticking and wear resistant polyurea coating and its preparation method

ActiveCN102492357ASolve the adhesionSolve corrosivePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an anti-sticking and wear resistant polyurea coating and its preparation method. The coating is prepared by blending of component A and component B. Specifically, the component A is synthesized by the following raw materials by weight: 90-120 parts of isocyanate, 40-60 parts of polyether polyol and 20-30 parts of fluorocarbon diol; and the component B is prepared by the following raw materials by weight: 500-800 parts of polyether amine, 400-600 parts of organosilicon diamine, 300-400 parts of high activity polyether polyol, 400-500 parts of an amino chain extender, 80-100 parts of an amino cross-linking agent, 100-150 parts of a high boiling point diluent, 5-10 parts of a composite catalyst, 400-600 parts of composite nano-metal oxide surface active materials, 600-800 parts of a filling material, and 40-60 parts of a pigment. The invention also includes a preparation method of the anti-sticking and wear resistant polyurea coating. A coating layer obtained by spraying of the anti-sticking and wear resistant polyurea coating in the invention has strong adhesion, and has good adhesion resistance, wear resistance, corrosion resistance, as well as impact resistance. Therefore, the anti-sticking and wear resistant polyurea coating of the invention is especially suitable for spraying on the lining surface of a heavy transport dump truck.

Owner:湘江涂料科技有限公司

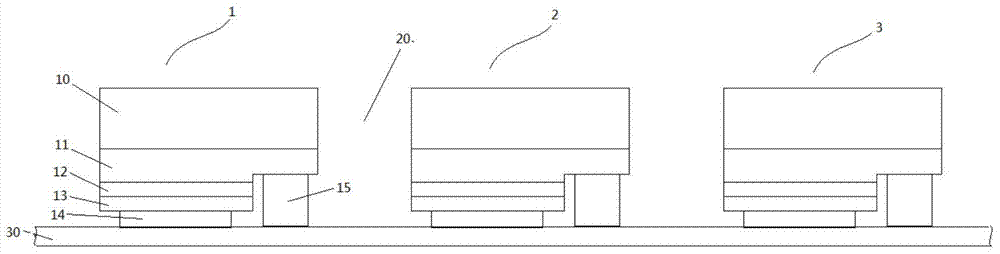

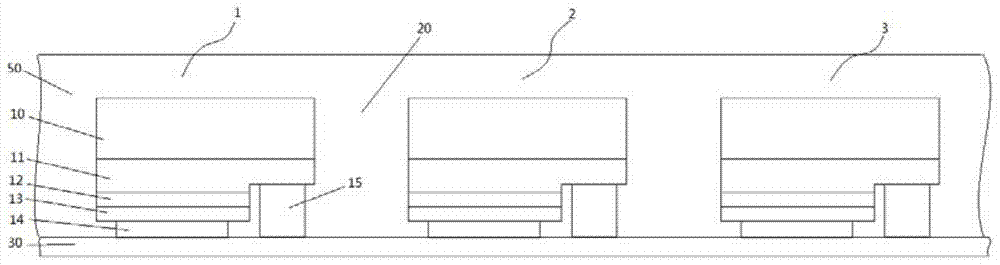

Chip scale packaging method and structure for light-emitting device

ActiveCN104851961ASimplify packaging process stepsReduce system thermal resistanceSolid-state devicesSemiconductor devicesEngineeringElectrical and Electronics engineering

The application discloses a chip scale packaging method for a light-emitting device. The scale packaging method includes steps: at least a flip light-emitting device is arranged on a conversion base film with equal intervals, a main light-outlet surface of the flip light-emitting device is opposite to the conversion base film, dams are formed between the flip light-emitting devices and / or around the flip light-emitting devices on the conversion base film, packaging glue is respectively coated on the flip light-emitting devices and the conversion film, the dams are removed when the packaging glue is cured to be non-liquid, the packaging glue is cut after the packaging glue is completely cured, the conversion base film is removed, and the chip scale packaging structure is obtained after molding. The invention also discloses a chip scale packaging structure for the light-emitting device. According to the chip scale packaging method and the structure for the light-emitting device, packaging process steps of the chip are greatly simplified, a submount of the chip is saved, the cost is lowered, and the work efficiency of users can be more conveniently improved.

Owner:湖南省日晶照明科技有限责任公司

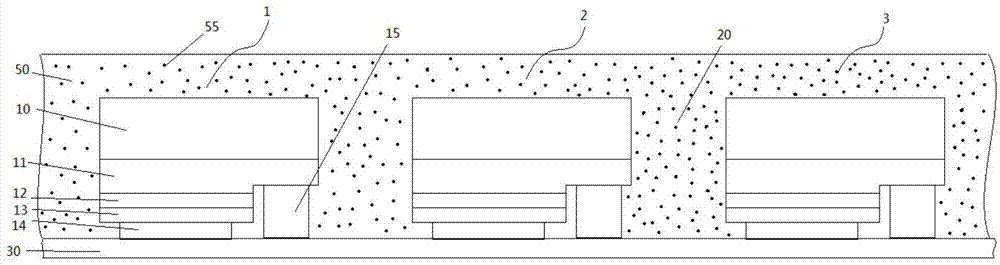

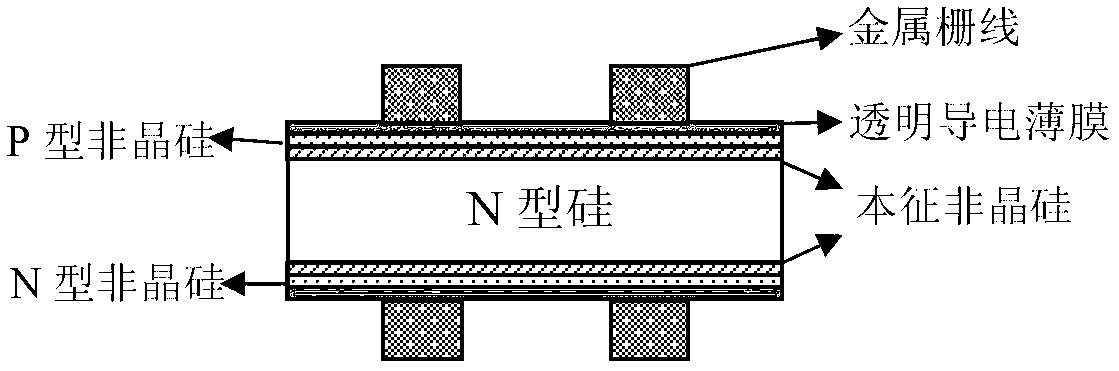

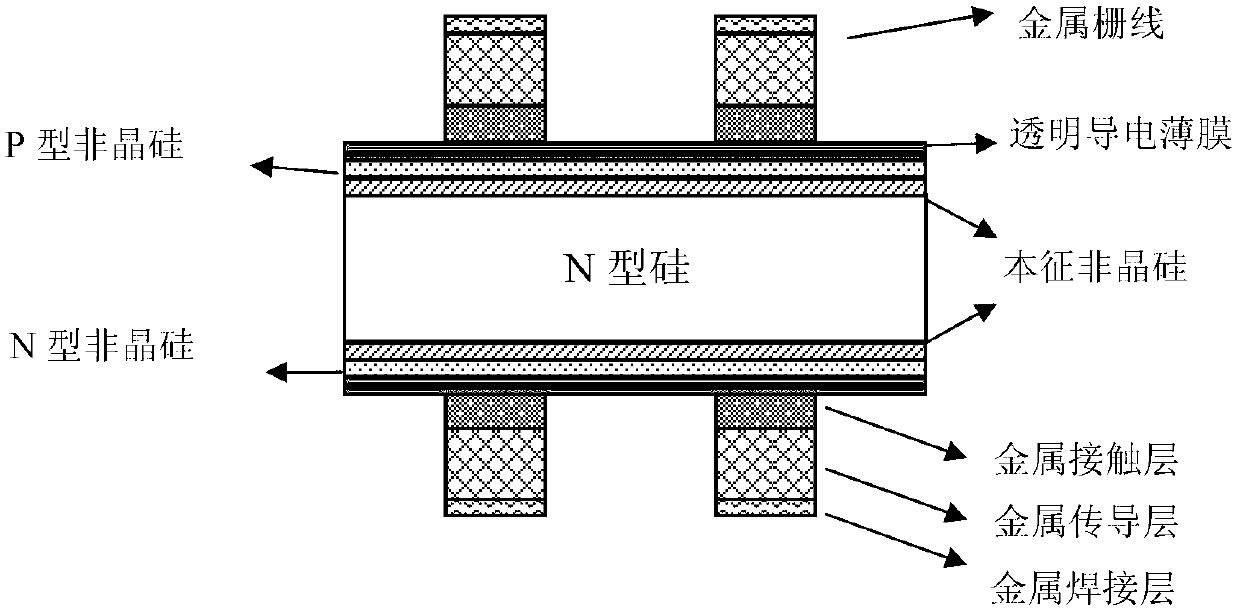

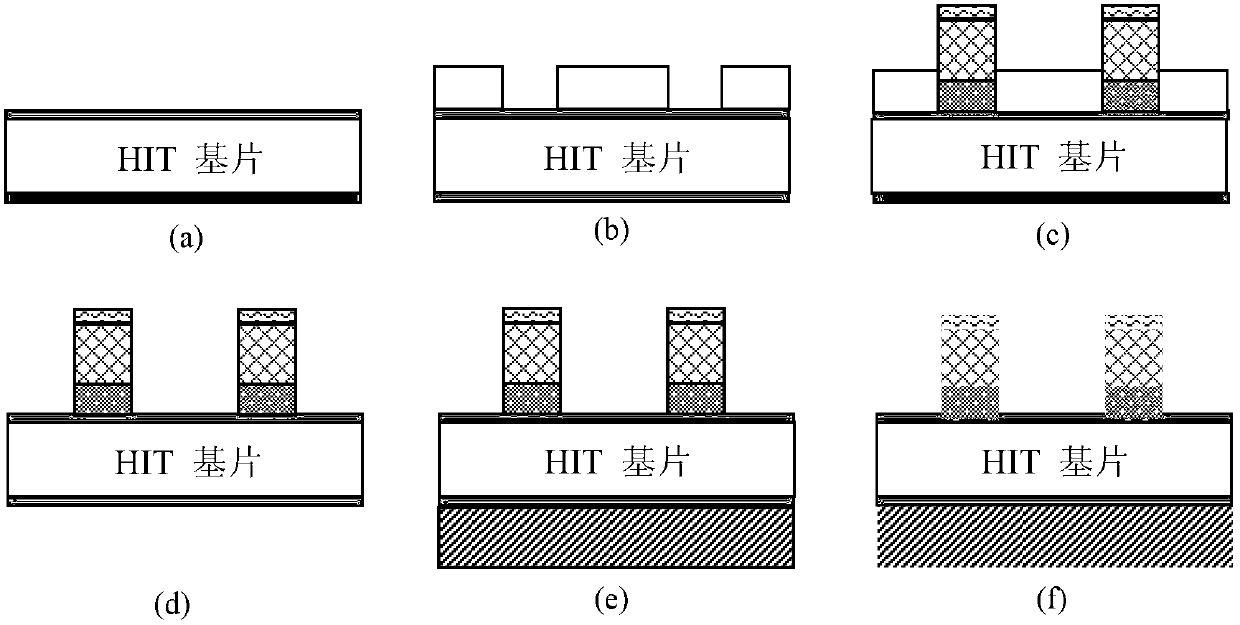

Preparing heterojunction solar cell method of combining wet process deposition with low temperature heat treatment

ActiveCN103137791ALow costSolve contact problemsRenewable energy productsSemiconductor devicesHeterojunctionContact layer

The invention relates to a preparing heterojunction solar cell method of combining wet process deposition with low temperature heat treatment. The preparing heterojunction solar cell method of combining the wet process deposition with the low temperature heat treatment is characterized in that metal grate lines are deposited on a single-face transparent conducting layers or a double-face transparent conducting layers, the low temperature heat treatment is conducted to alloying, wherein (1) the metal grate lines at least comprise metal contact layers, metal conducting layers and metal welding layers, the metal contact layers are located on the transparent conducting layers, and the metal conducting layers, and the metal welding layers are located on the metal contact layers in sequence; (2) the wet process deposition comprises electro-deposition, or light induction deposition, or chemical deposition, or the combination of the electro-deposition, and the light induction deposition and the chemical deposition ; (3) the low temperature heat treatment alloying can form good contact and adhesion property. The preparing heterojunction solar cell method of combining the wet process deposition with the low temperature heat treatment has the advantages that the metal grate lines which have no silvers or little silvers are achieved, cost is reduced, and the low temperature heat treatment is matched with existing heterojunction solar cell processing. In a word, preparing heterojunction solar cell method of combining the wet process deposition with the low temperature heat treatment has no seed layer electrofacing, the metal layers are metal or alloy which have specific temperature characteristic, the good contact and the adhesion property can be formed with transparent conducting films under the heat treatment temperature of 250 DEG C.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

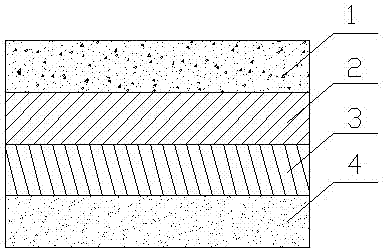

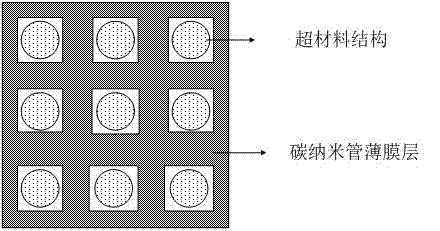

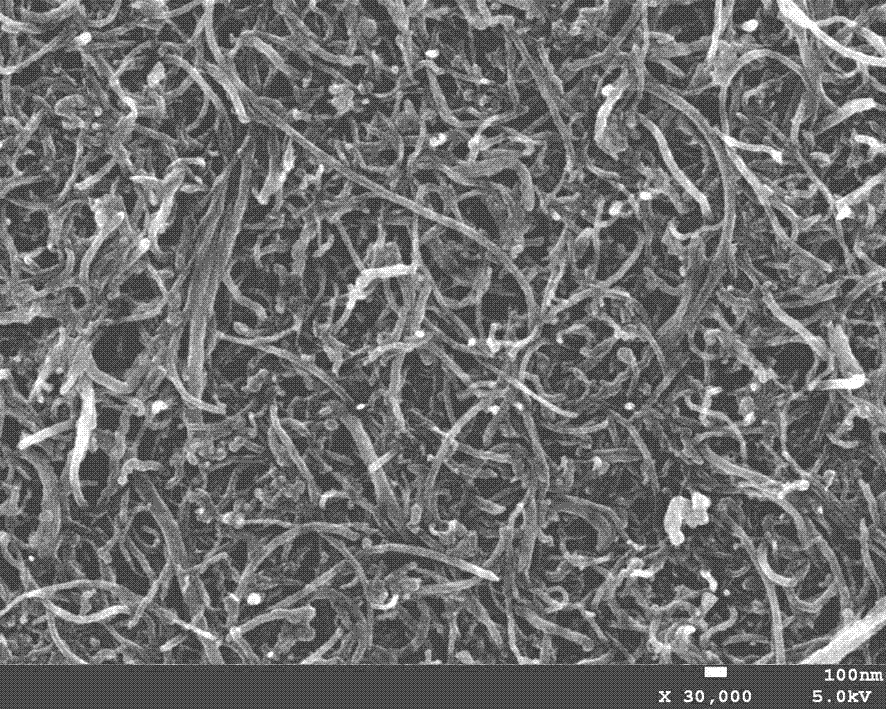

Terahertz absorption layer of carbon nano tube and metamaterial composite structure and preparation method of terahertz absorption layer

InactiveCN103489943ASolve the flatnessSolve the adhesionFinal product manufacturePhotometryTerahertz radiationCarbon nanotube

The invention discloses a terahertz absorption layer of a carbon nano tube and metamaterial composite structure and a preparation method of the terahertz absorption layer. The terahertz absorption layer sequentially comprises a top absorption layer, a dielectric layer, a metal reflection layer and a carbon nano tube film layer from top to bottom. According to special optical properties of the carbon nano tube film and the absorption rate close to 100 percent of the metamaterial composite structure on terahertz radiation, the absorption rate of a detection unit on terahertz waveband radiation is obviously enhanced, and the terahertz detection performance of a detector is improved. Meanwhile, because the carbon nano tube has high thermal conductivity, the absorbed heat energy can be rapidly transmitted to the detection unit, and the response speed of the detector is improved.

Owner:成都市金草阳科技有限公司 +1

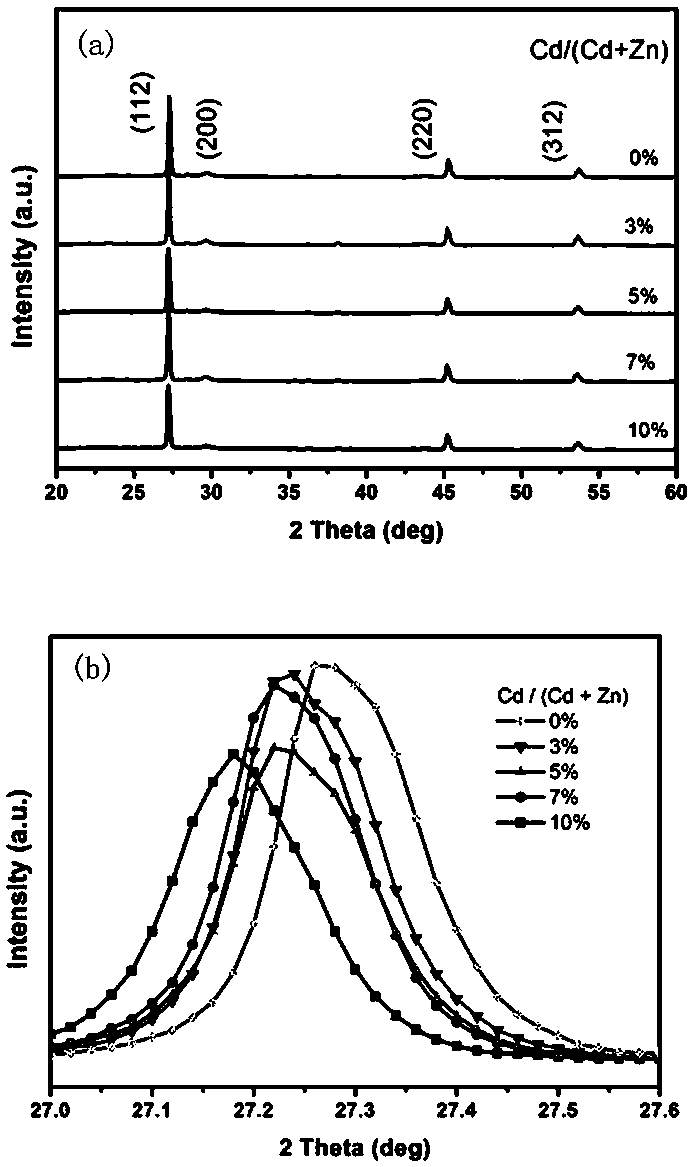

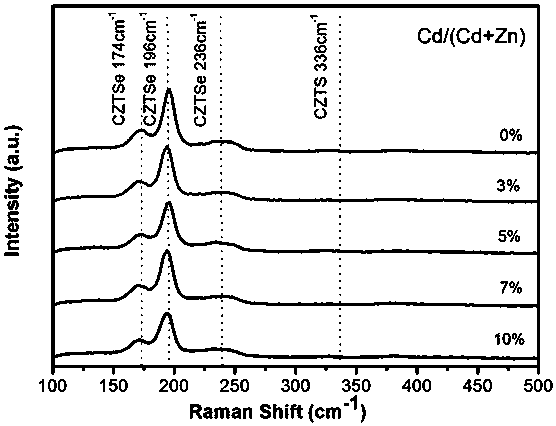

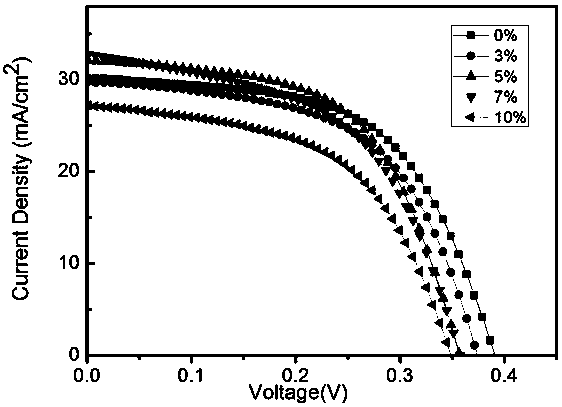

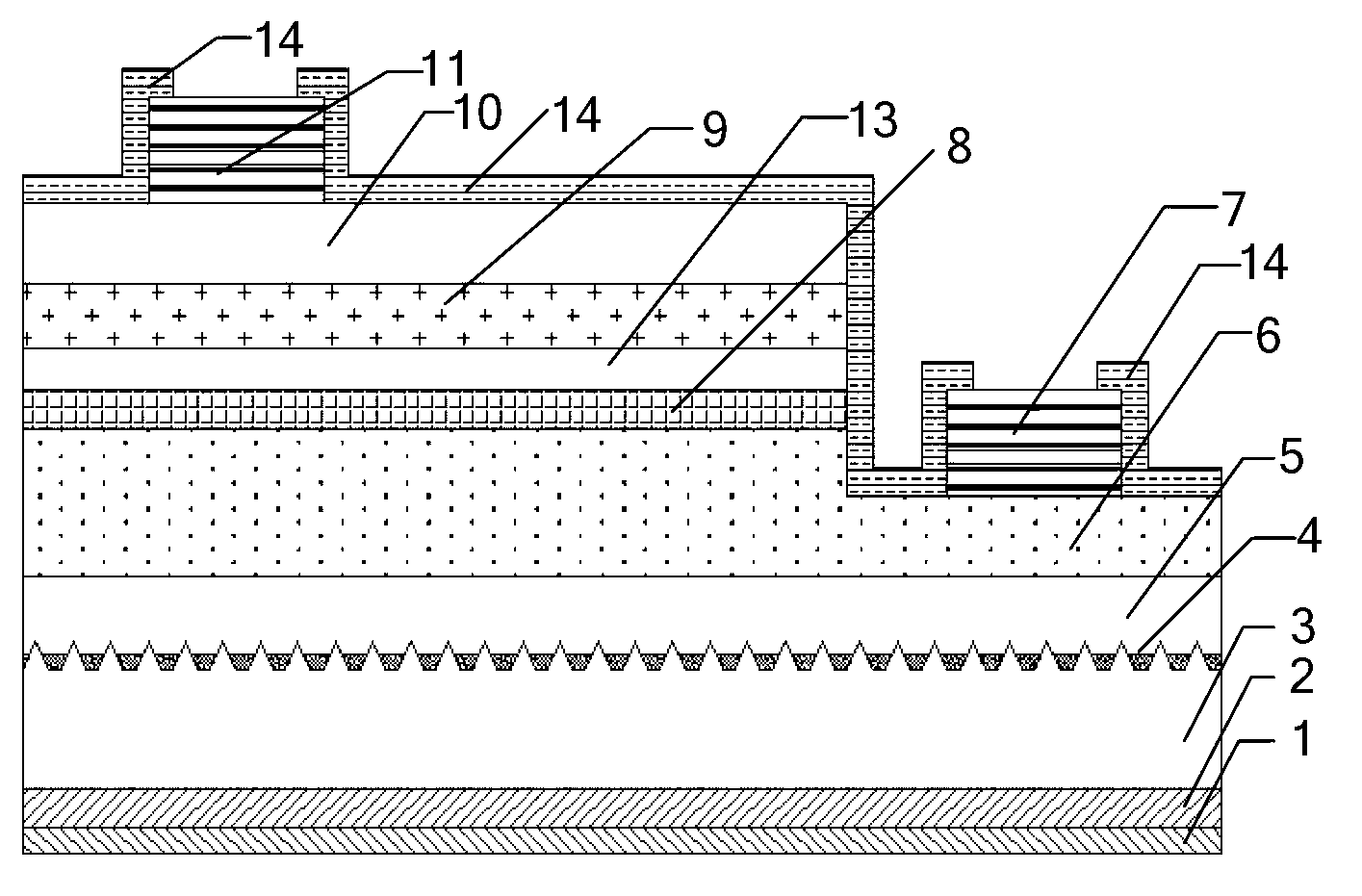

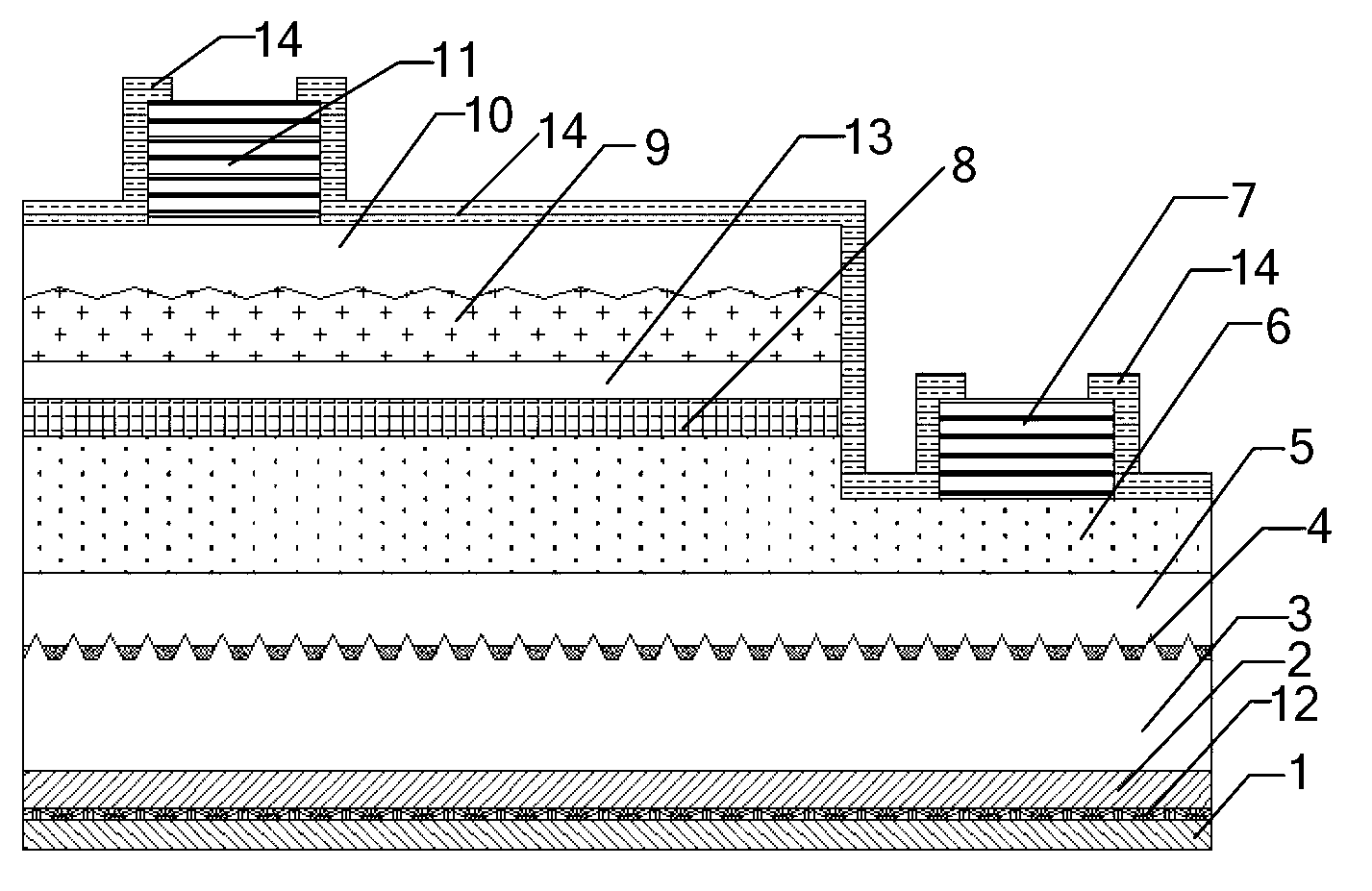

Regulation and control method of flexible molybdenum substrate-based cadmium-doped copper zinc tin sulfur selenium thin film with band gap gradient

ActiveCN107871795ASolve the adhesionReduce manufacturing costFinal product manufacturePhotovoltaic energy generationContact layerSolar battery

The invention relates to a regulation and control method of a flexible molybdenum substrate-based cadmium-doped copper zinc tin sulfur selenium thin film with a band gap gradient. The regulation and control method comprises the steps of performing cleaning on a flexible molybdenum foil sheet by an electrodeposition method firstly; and next, adopting a solution method for dissolving elementary substances and a post selenylation processing mode to realize changes of the CZCTSSe thin film with band gap gradient through a stacking layer, wherein the method can be used for preparing a thin film solar battery with CZCTSSe thin film with band gap gradient. By adopting the flexible molybdenum as the substrate and by virtue of high-purity molybdenum foil, the problem of adhesiveness between the thin film and the substrate can be solved; a sputtering metal conductive back contact layer in the battery structure is replaced, so that the manufacturing cost is lowered; by adopting the solution method to dissolve the elementary substances for preparing a precursor solution, the shortcoming of impurity ion introduction in metal salt dissolving is avoided; and in addition, the solution method is low in cost, simple in process, capable of realizing large-area production easily, green and environment friendly, capable of satisfying requirements of large-scale batch production and commercialization, and high in practicability.

Owner:FUZHOU UNIV

Light-emitting diode (LED) with reflector structure

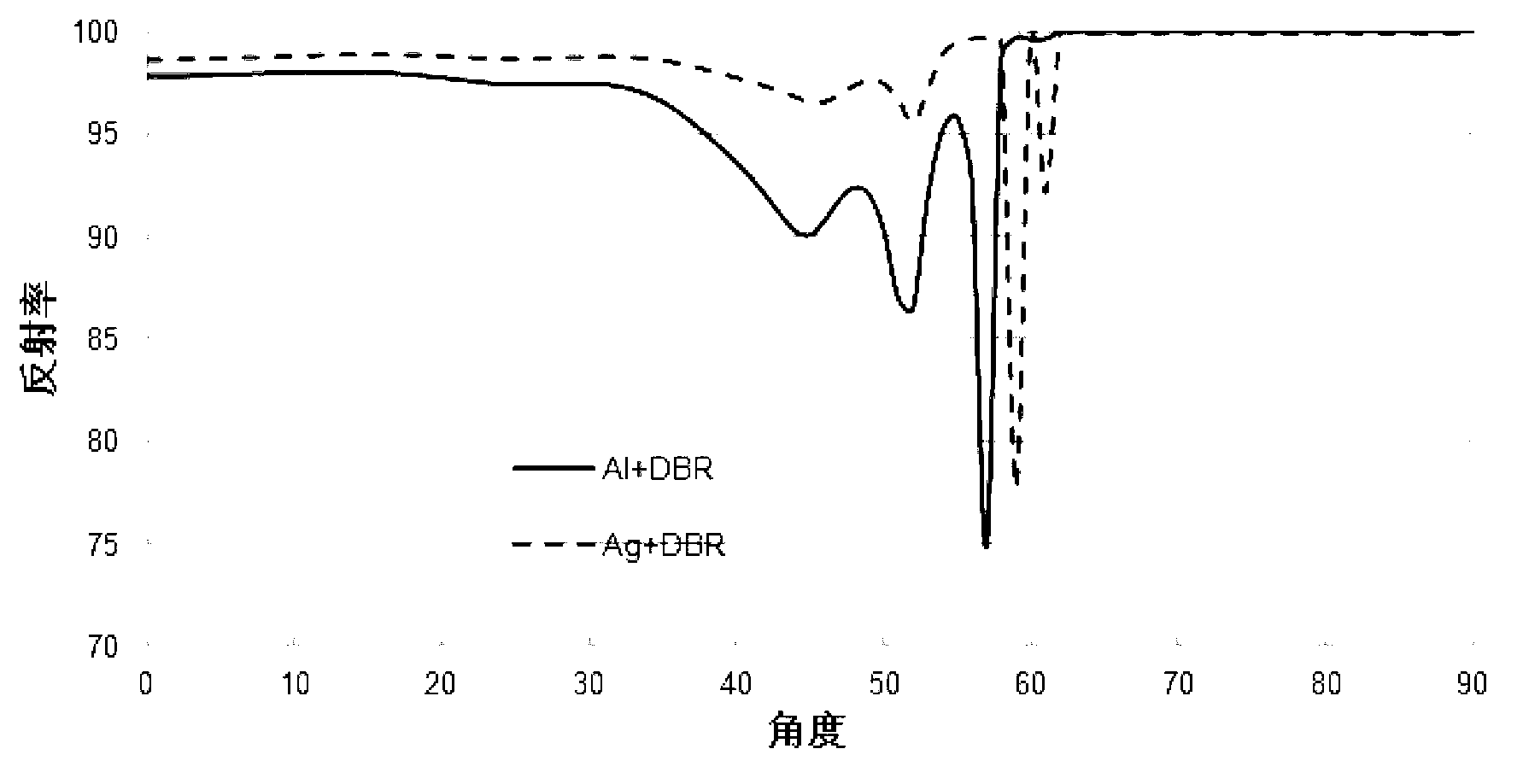

InactiveCN103078024AReduce dosageLow costSemiconductor devicesDistributed Bragg reflectorLight-emitting diode

The invention relates to a light-emitting diode with a reflector structure. The light-emitting diode with the reflector structure sequentially comprises a metal layer, a distributed Bragg reflector (DBR) layer, a substrate, a buffer layer, an undoped GaN layer, an n-type GaN layer, an n electrode formed on the n-type GaN layer, an active layer, a p-type GaN layer, a transparent conductive layer and a p electrode formed on the transparent conductive layer from bottom to top, and is characterized in that a transition layer for improving the adhesion of the DBR layer and the metal layer is inserted between the metal layer and the DBR layer; and the metal layer, the transition layer and the DBR layer form the reflector structure of the light-emitting diode. According to the light-emitting diode, an Ag metal reflection layer is adopted, and an Au barrier is not required, so that the using amount of Au is reduced; in addition, the reflectivity of Ag is higher than that of Al, so that the reflectivity is favorably improved; and moreover, the transition layer is inserted, so that the problems of low adhesion and high separation rate of Ag and the DBR layer are solved.

Owner:AQUALITE CO LTD

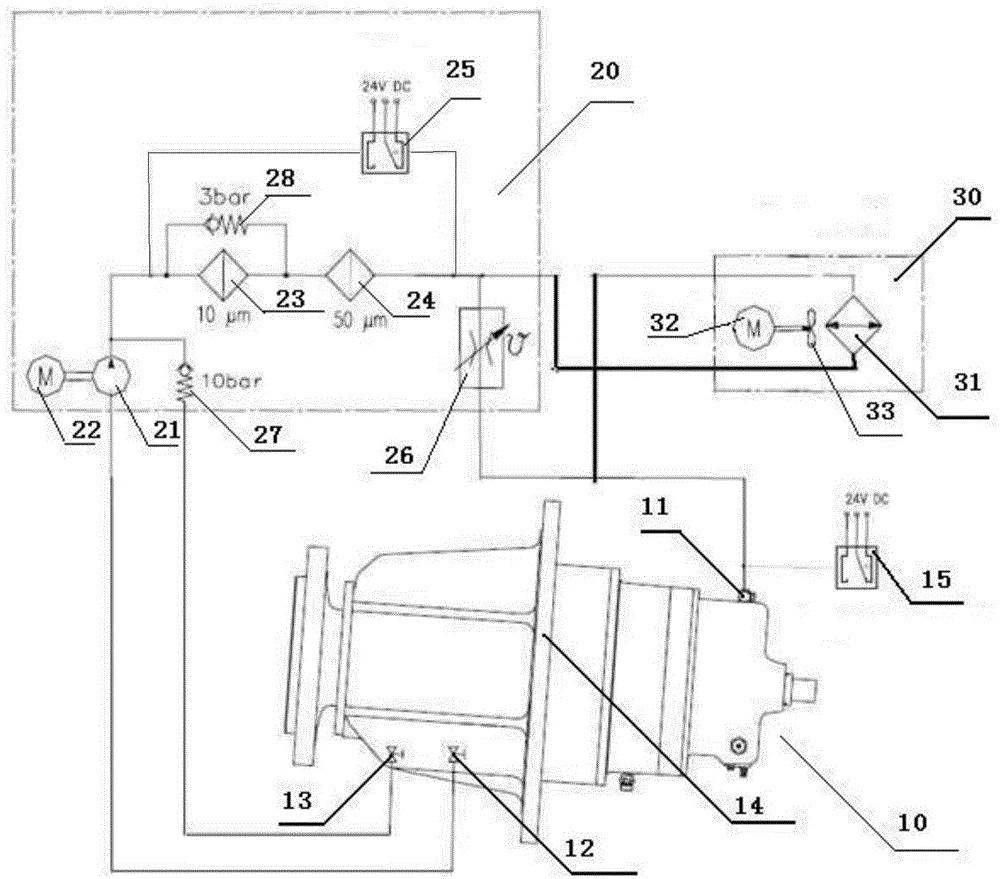

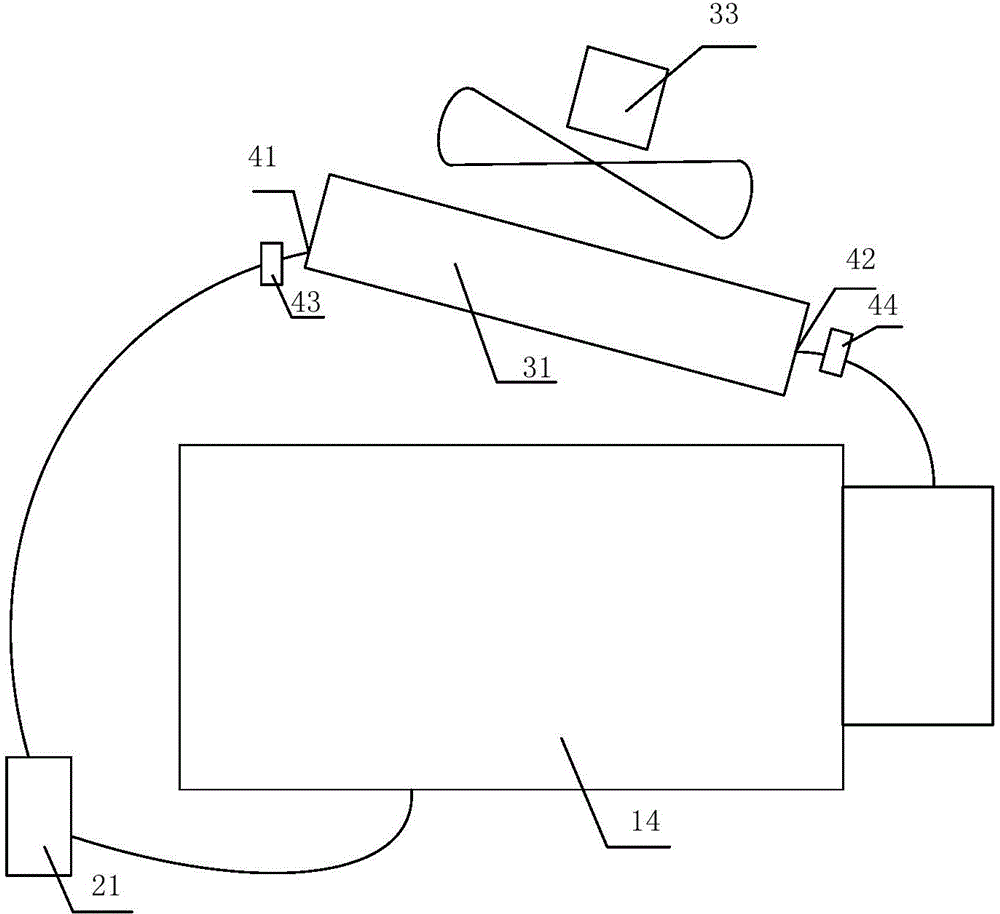

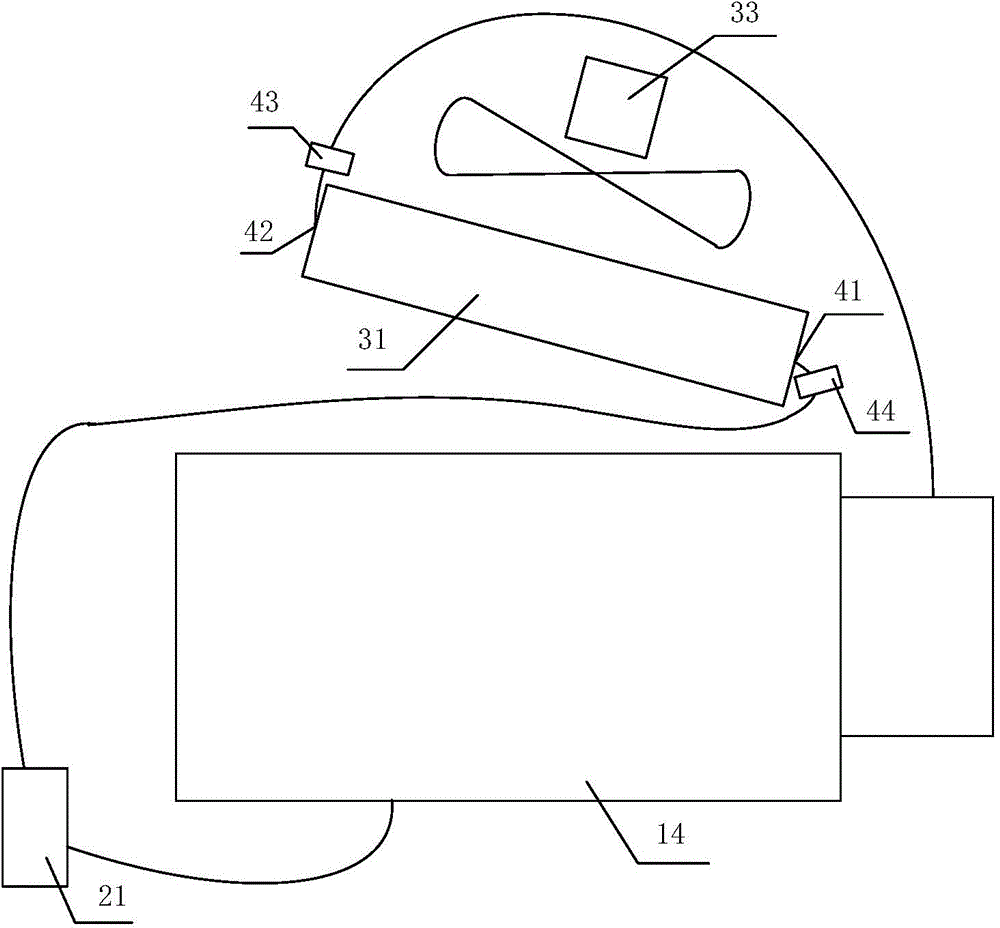

Cooling and dedusting method of gearbox lubricating and cooling system

ActiveCN104534072AEnergy savingSolve the insufficient utilization of cooling areaGear lubrication/coolingAutomatic controlChiller

A cooling and dedusting method of a gearbox lubricating and cooling system comprises the following steps that S1, the gearbox lubricating and cooling system is assembled; S2, the speed of an oil pump motor is regulated in the starting or running process; S3, dust and oil films bonded on a cooler and a cooler fan are removed. According to temperature information fed back by mounting in an oil tank of a gearbox, PID automatic control is carried out over the running frequency of the oil pump motor and a fan motor so that a frequency converter can control the running speed of the fan and the running torque of the oil pump motor. In the starting and running process of the oil pump motor, the oil pump motor is made to be started smoothly according to the temperature and viscosity condition of lubricating oil, and the aim of saving energy under the working condition of high temperature is achieved.

Owner:DALIAN SHINERGY SCI & TECH DEV

Gel polymer modified lithium ion battery diagraph and preparing method and application thereof

InactiveCN104377330AImprove ionic conductivityBoth mechanical propertiesCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityPolymer science

The invention relates to a gel polymer modified lithium ion battery diagraph and a preparing method and application thereof. The diagraph comprises a microporous polymer layer and at least one layer of gel polymer coating coated with which the microporous polymer layer is coated. The peel strength between the gel polymer coating and the microporous polymer layer in a 180-degree-condition is over 1.0N / cm. The surface and the interior of the gel polymer coating are in reticular porous connecting structures. The porosity of the gel polymer coating is over 40%. A gel polymer is a copolymer of vinylidene fluoride and hexafluoropropylene. According to the invention, the problems that the adhesion between the gel polymer coating and the microporous polymer layer is poor and the gel polymer coating is easy to strip from the polymer microporous layer are solved, and the problem that the gel polymer coating swells in electrolyte as to enable the coating porosity to be reduced, and further the battery internal resistance is increased is solved.

Owner:乐凯胶片股份有限公司 +1

Method for protecting converter with vanadium slag

ActiveCN103397133ASolve liquidity problemsSolve the adhesionManufacturing convertersNitrogenNitrogen gas

The invention provides a method for protecting a converter with vanadium slag, which comprises the following steps: adding vanadium-iron-containing water into a vanadium extraction converter, and adding quartz sand into the vanadium-iron-containing water to regulate the SiO2 content in the vanadium slag to 16-18%; after the converting starts, adding 10-25 kg / tFe magnesite, and adding 25-35 kg / tFe vanadium extraction cooling agent, wherein the converting time is controlled at 5-7 minutes, and the semisteel temperature is controlled at 1400-1450 DEG C; and after the converting finishes, tapping, blowing nitrogen with an oxygen lance to perform slag splashing on the vanadium slag. The invention can effectively solve the problems of poor flowability and difficulty in adhesion of the vanadium slag, and can improve the slag suspension effect, enhance the erosion resistance of the converter lining and effectively prolong the service life of the vanadium extraction converter lining when being used for slag splashing converter protection.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Thermal-resistance-processed silicon carbide back metal thickening method

ActiveCN104037075ASolve the adhesionImprove adhesionSemiconductor/solid-state device manufacturingSputteringWafering

The invention relates to a thermal-resistance-processed silicon carbide back metal thickening method. The method comprises the following steps of 1) forming a metal layer on the back surface of a SiC wafer through evaporation or sputtering, and forming an ohmic contact after an annealing process; forming a stopping metal layer on the back surface ohmic contact through evaporation or sputtering; 3) applying a layer of resin onto the front surface of the SiC wafer, heating the SiC wafer in a drying oven to solidify the resin; 4) performing coating protection, wet HF corrosion, cleaning and drying on the front surface of the SiC wafer; 5) forming thickening metal on the back surface of the SiC wafer through sedimentation; 6) performing photoresist removal and scribing, and after a chip is sintered onto a carrier, performing shear assessment. The thermal-resistance-processed silicon carbide back metal thickening method has the advantages of solving the problem of infirmness of the back surface metal of a high-temperature-processed SiC power device, and by means of the stopping metal layer sputtered onto the back surface ohmic contact, which can be diffused to combine with C on the surface of the ohmic contact after the high-temperature processing process, avoiding forming a dissociative C layer and guaranteeing the firmness and reliability of the back surface thickening metal.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Preparation method of copper-plated polyethylene monofilament for fisheries

ActiveCN103147283ASolve the adhesionSolve the situation of defacementFibre typesCopper platingMelt spinning

The invention discloses a preparation method of a copper-plated polyethylene monofilament for fisheries and relates to a preparation method of a polyethylene monofilament capable of preventing the adhesion of organisms. According to the technical scheme, the preparation method disclosed by the invention comprises the following three process steps of: (1) carrying out melt spinning on a high-density polyethylene slice to prepare a primary monofilament; (2) carrying out high-power hot drafting on the primary monofilament to prepare a drawn filament; and (3) carrying out vacuum copper plating surface treatment on the drafted filament. The preparation method is characterized in that in the step (1), the average molecular weight of the high-density polyethylene is 120-150 thousand dalton, the spinning temperature of the polyethylene monofilament is 260-320 DEG C and the spinning speed is 10-30m / min; in the step (2), the high-power hot drafting multiple of the primary monofilament is 8-12 and the drafting temperature is 100 DEG C; and in the step (3), the surface copper plating process of the drawn filament is that the vacuum degree is (1.3*10<-2>)-(1.3*10<-3>) Pa and the temperature of the heat source is 1200-1600 DEG C.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

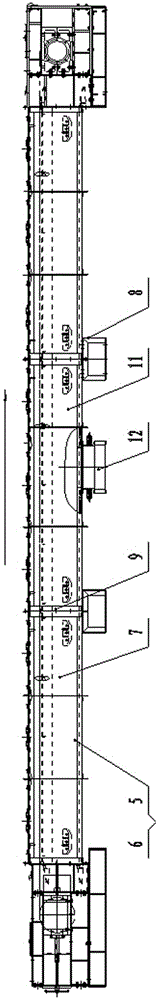

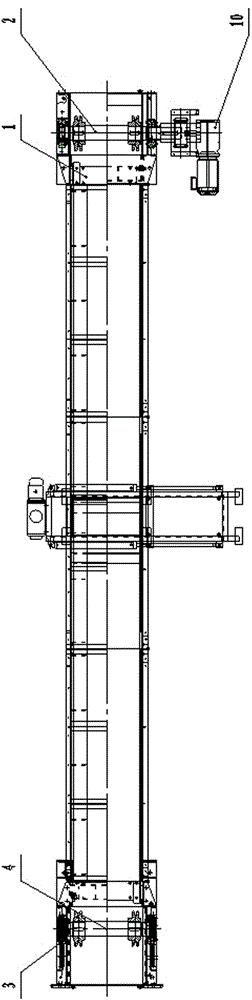

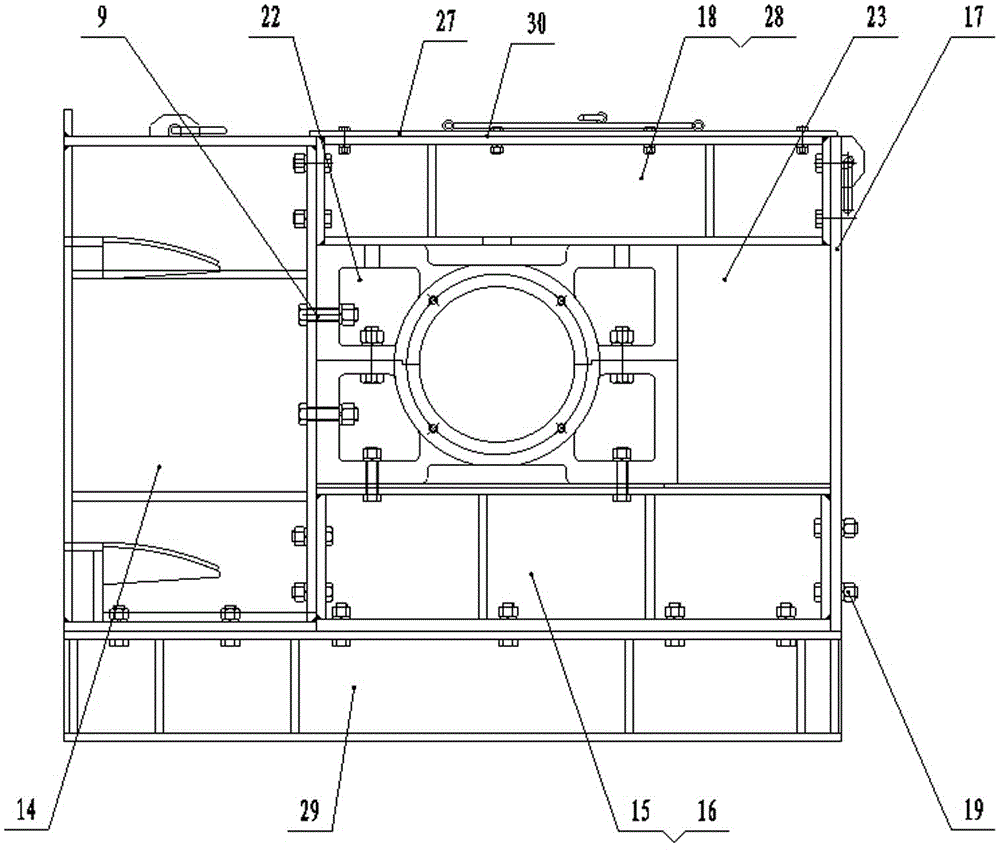

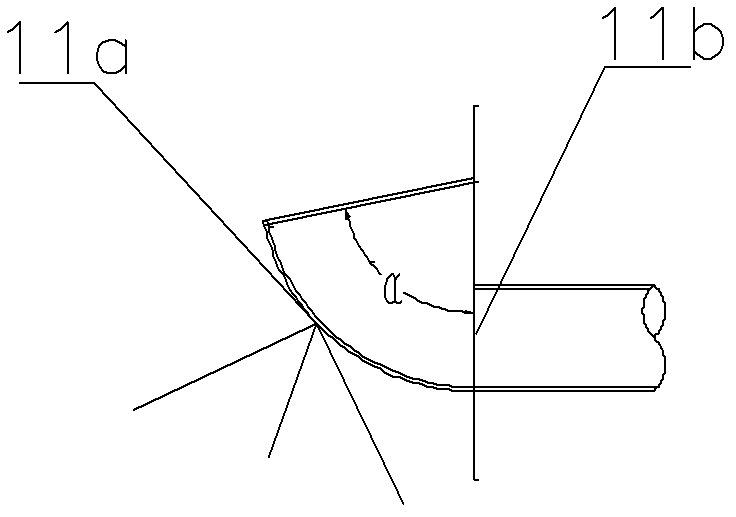

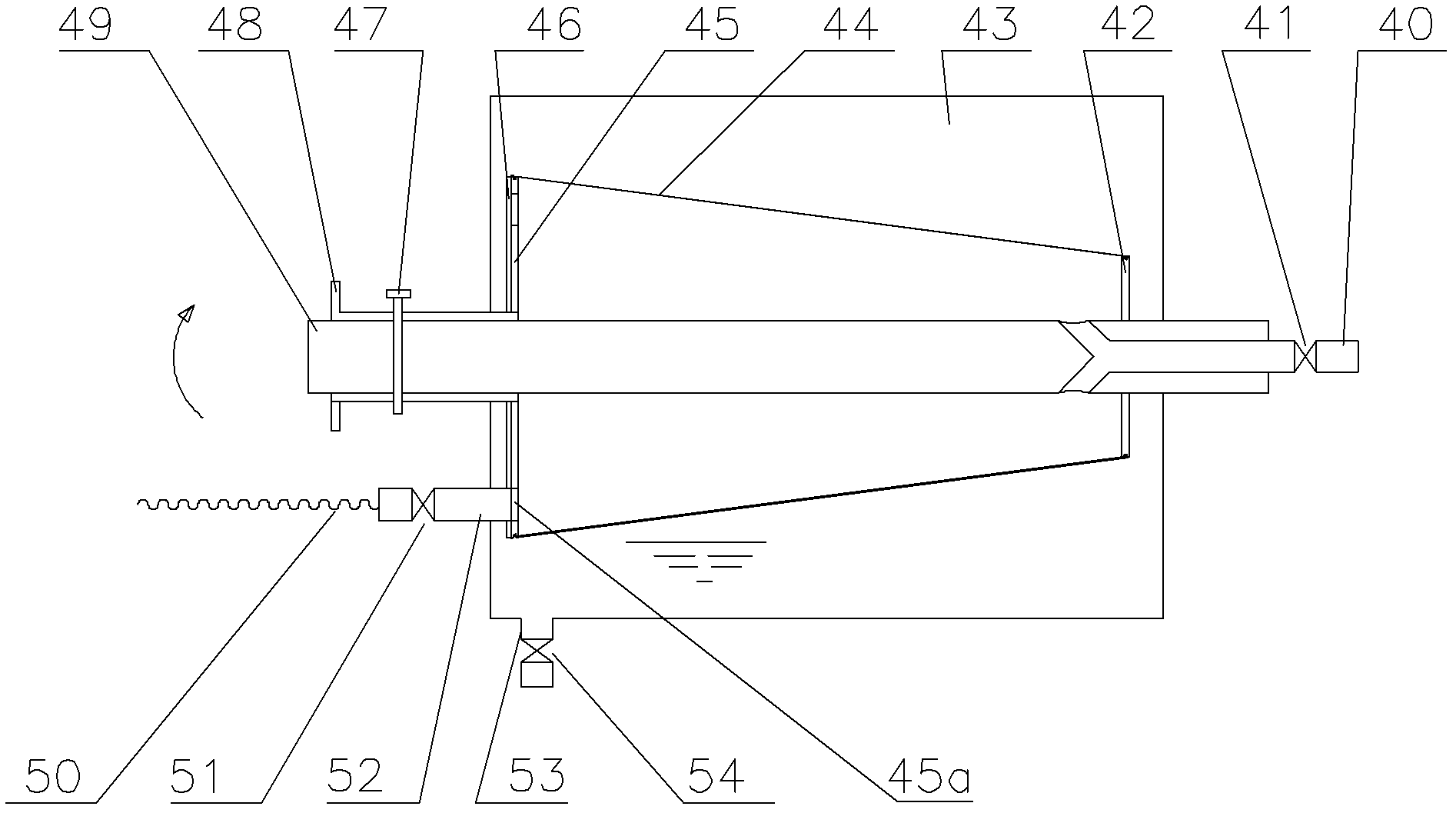

Novel seal box type scraper conveyor

ActiveCN103979265AImplement heavy-duty soft startRealize environmental protectionConveyorsEngineeringHeadstock

The invention discloses a novel seal box type scraper conveyor and belongs to the technical field of conveyors. By means of the novel seal box type scraper conveyor, the high-viscosity high-temperature powder-shaped material is avoided from hardening, bonding and dust in conveying. The novel seal box type scraper conveyor comprises a headstock, a head wheel component, a tail frame, a tail wheel component, a scraper chain, a regulating chain, a single-layer transportation intermediate tank, support legs, connecting bolts, a drive device, a single-layer transportation intermediate tank with a hole, and a flat plate gate; the head wheel component is connected with a left rack and a right rack through connecting bolts, after a closing plate A and a closing plate B are placed in side rack slots, each of a left press beam and a right press beam is fixed through connecting bolts; a left climb passage, a right climb passage and a transitional arc plate are fixed at the arc-shaped transition position of the inner side of a transition rack through countersunk bolts; a cover board and a rubber sealing strip are fixed with the side racks and the transition rack through connecting bolts. The novel seal box type scraper conveyor is mainly used for conveyors.

Owner:山西煤矿机械制造股份有限公司

Terolon coating hot-press shaping mould and production for ornament in vehicle

InactiveCN1746000AReasonable structureExtended service lifePretreated surfacesDomestic articlesIn vehicleHot press

A hot pressing die for preparing the coated teflon layer on the internal decoration of car features that the teflon paint is coated on the surface of die. Its preparing process includes such steps as cleaning, blasting sand and spraying paint. Its advantage is high stability and precision of product.

Owner:NANTONG CHAODA EQUIP CO LTD

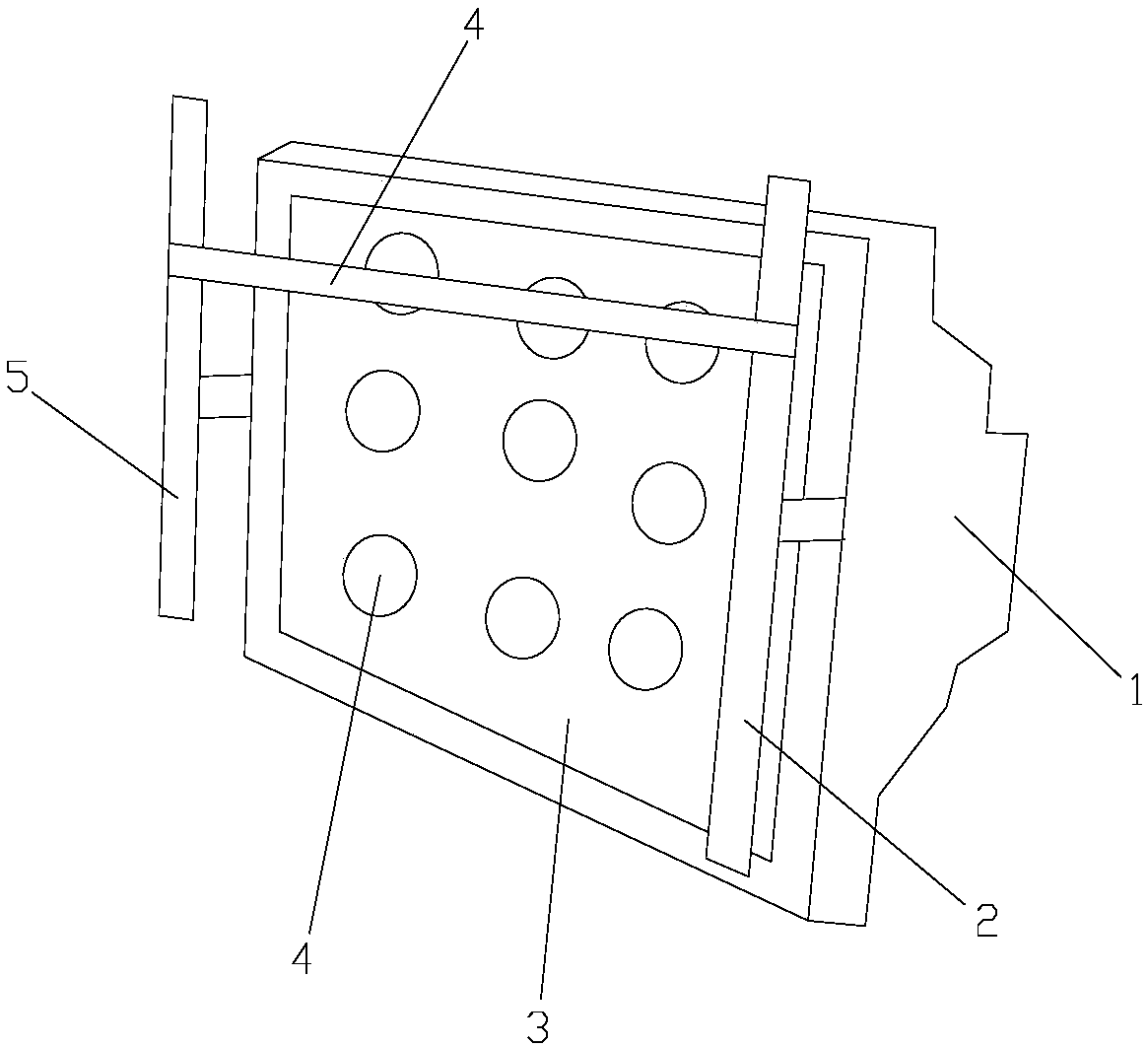

3D printing bearing table with sticking preventing function

InactiveCN106863804AWith anti-stick functionIngenious designManufacturing platforms/substratesElectric machineryEngineering

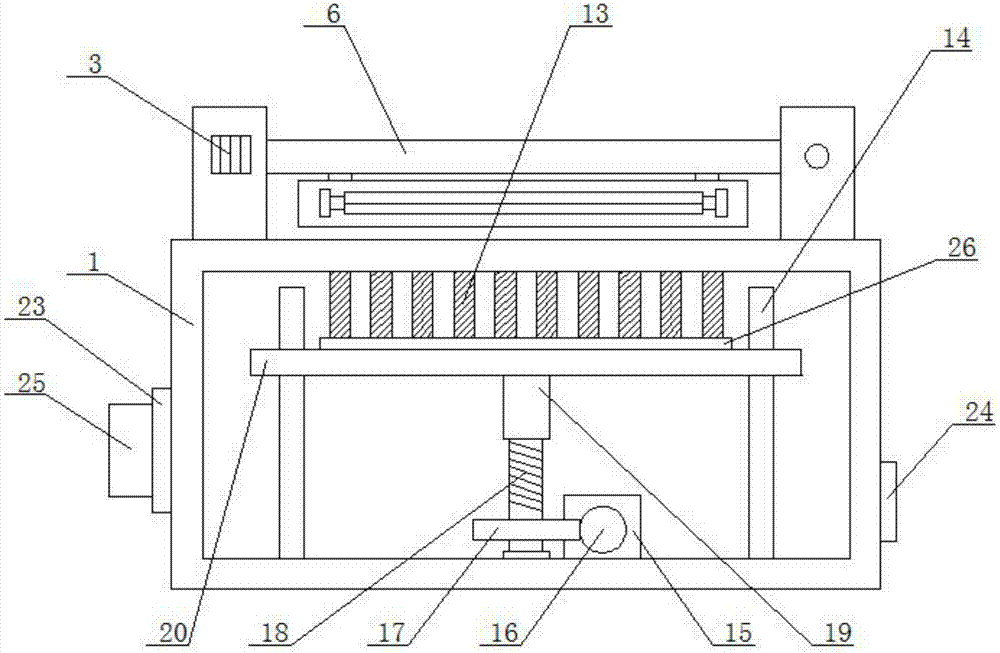

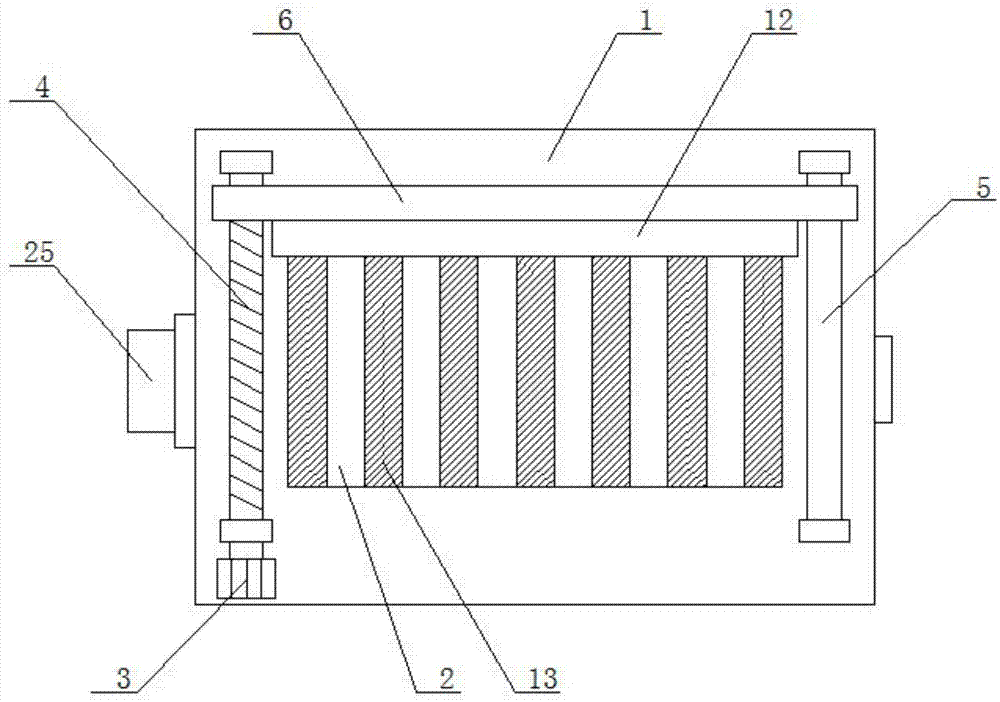

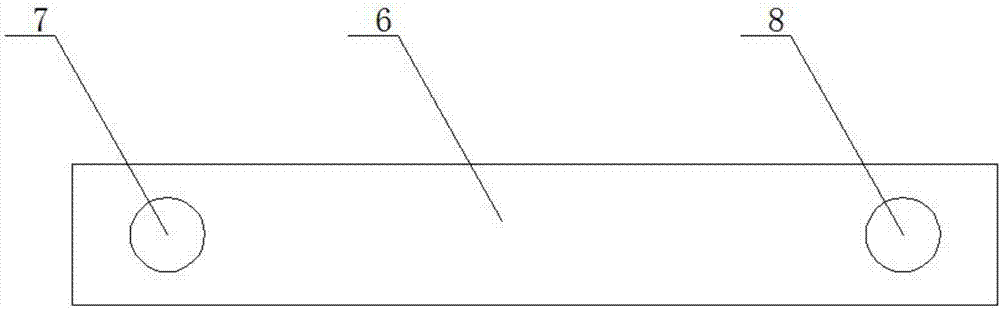

The invention relates to a 3D printing bearing table with a sticking preventing function. The 3D printing table comprises a box body, a first separation mechanism and a second separation mechanism. The first separation mechanism comprises a linear moving assembly and a separation assembly arranged on the linear moving assembly. The linear moving assembly comprises a first motor, a first screw rod, a first guide rod and a sliding block. The separation assembly comprises a fixing block and a blade unit arranged on the fixing block. The second separation mechanism comprises a lifting assembly, a separation plate arranged on the lifting assembly and a second guide rod. The lifting assembly comprises a third motor, a worm, a worm gear, a second screw rod, a sleeve and a supporting plate. According to the 3D printing bearing table with the sticking preventing function, separation between a printed finished product and a printing platform is achieved through two different manners through the special first separation mechanism and the special second separation mechanism, the problem that the printed finished product is firmly stuck to the printing platform and cannot be separated from the printing platform is solved, the printing platform cannot be damaged, and manpower and material resources are saved.

Owner:福建省速卖通电子商务有限公司

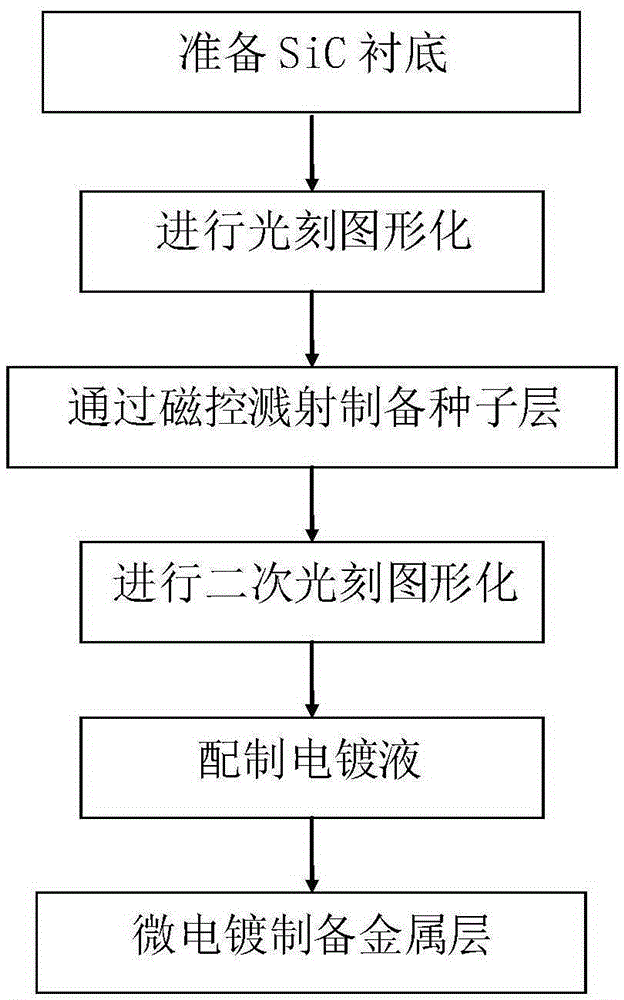

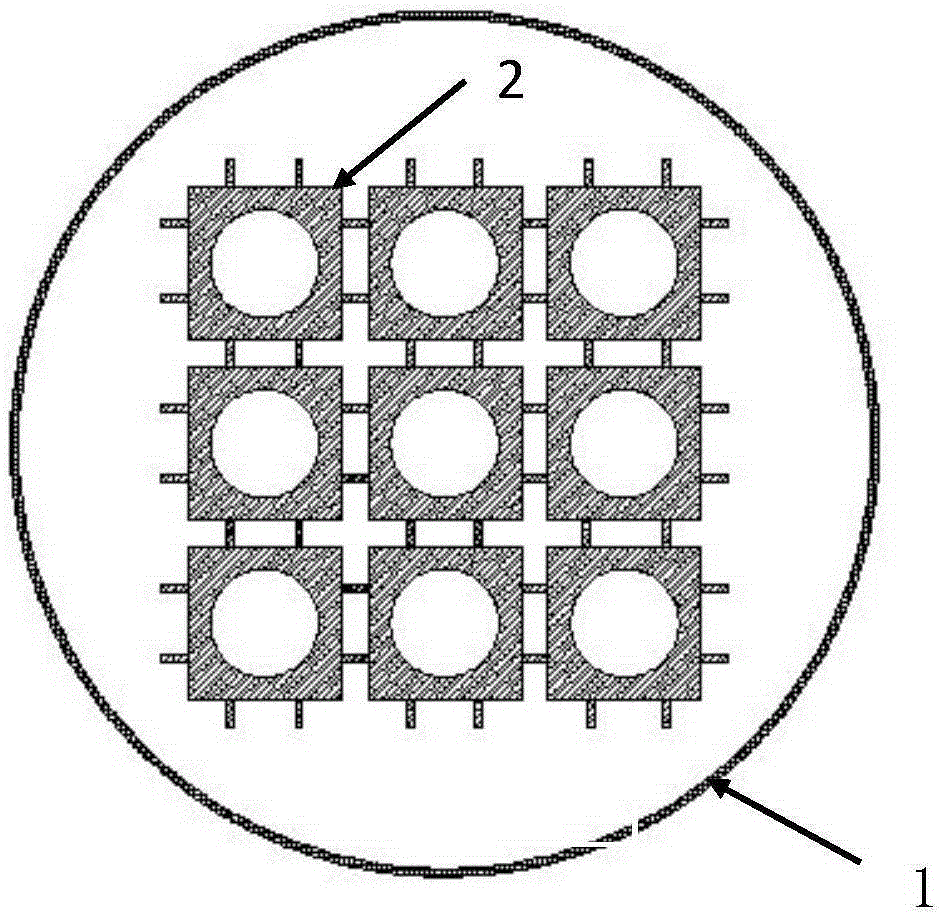

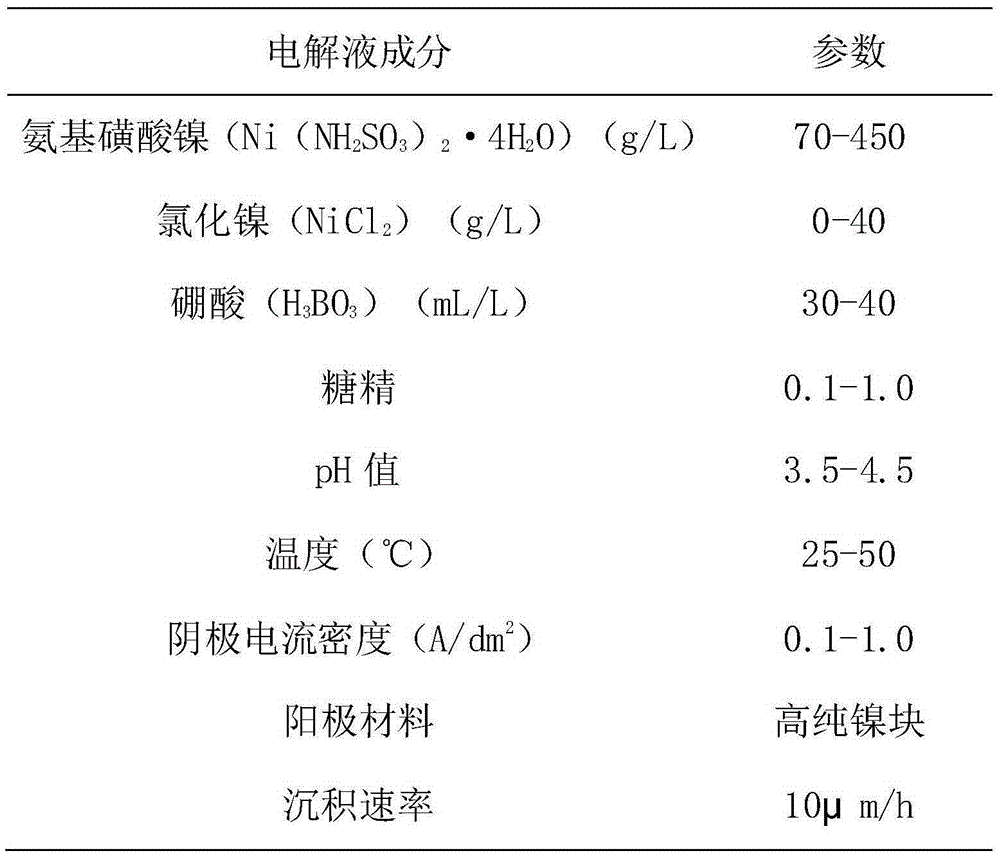

MEMS micro array structure processing method based on micro-electroplating

InactiveCN105329849AImprove adhesionAddressing inhomogeneityDecorative surface effectsVacuum evaporation coatingSemiconductor materialsHigh pressure

The invention discloses a MEMS micro array structure processing method based on micro-electroplating, and more specifically relates to a mask preparation method via semiconducting material deep etching processing, and belongs to the technical field of semiconducting material processing. A SiC material is taken as an example. The MEMS micro array structure processing method comprises following steps: SiC substrate preparation; photoetching pattern forming; seed layer preparation via magnetron sputtering; secondary photoetching pattern forming; preparation of an electroplate liquid; and preparation of metal layers via electroplating. A electroplate liquid component is optimized, micro electroplating conditions are modified, adhesive force of a coated metal with a substrate is increased, uniformity and thickness of the coated metal are increased, and a prepared metal coating is capable of satisfying requirements of SiC deep etching processing of a mask layer, and expanding applications of silicon carbide in related device preparation via a novel mask structure. The MEMS micro array structure processing method is capable of providing technical supports for applications of SiC pressure sensors at severe environments (high temperature, high pressure, strong corrosion, and strong radiation).

Owner:SHANGHAI NORMAL UNIVERSITY

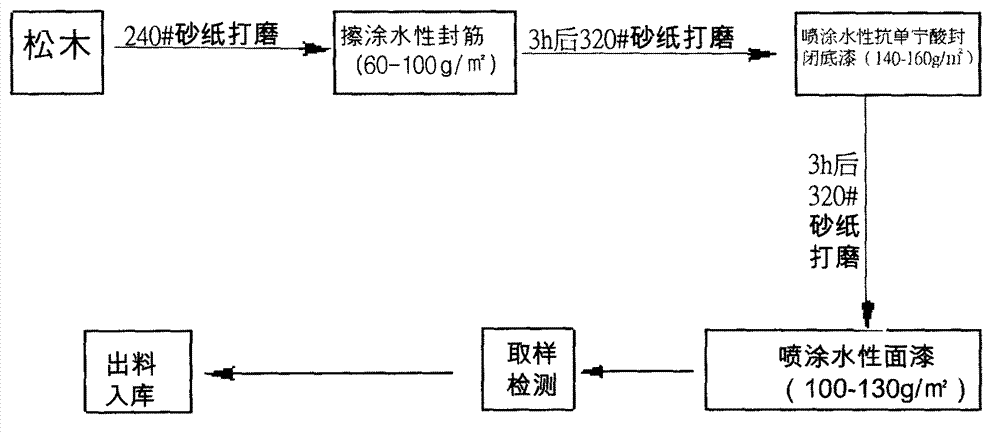

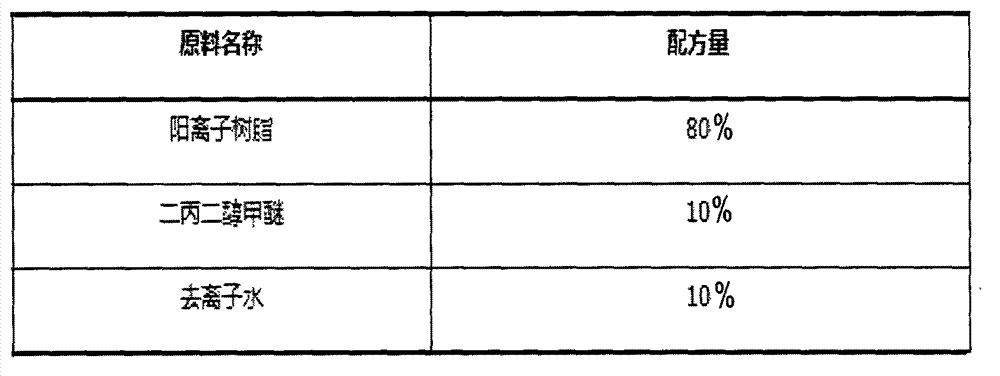

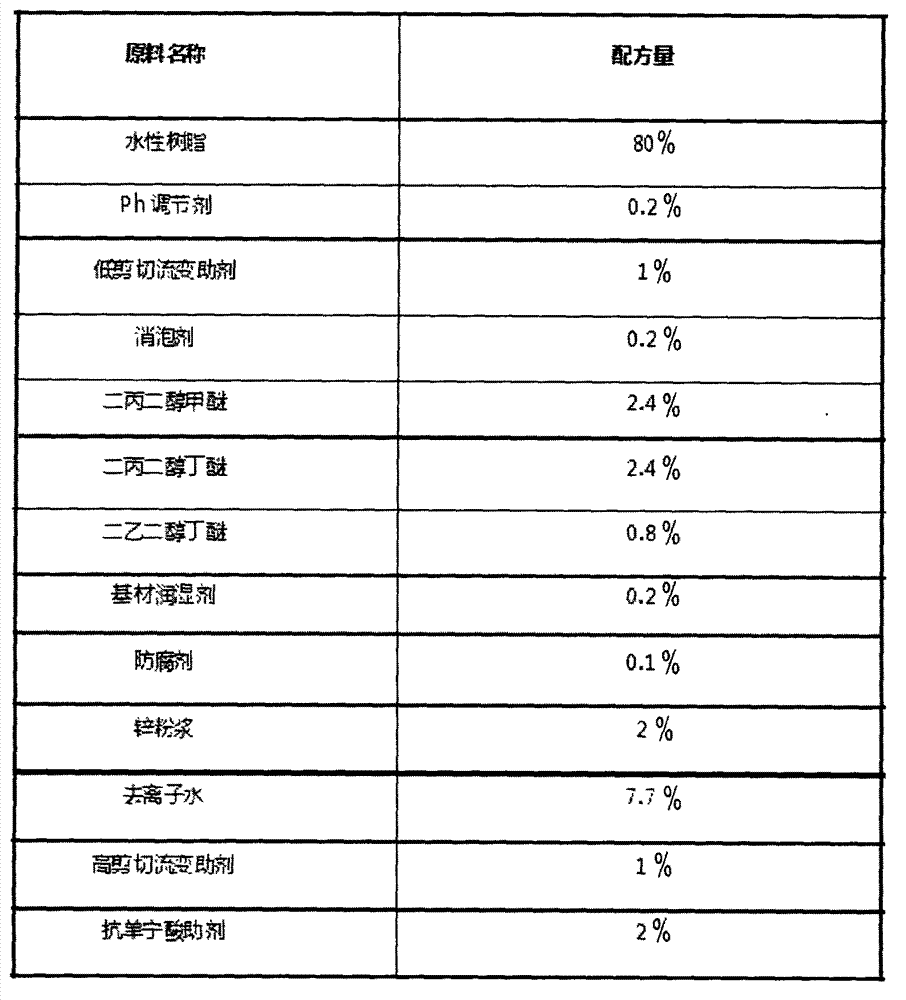

Water-based paint special for pinewood of furniture for children

ActiveCN103113828ANo pollution in the processEnvironmentally friendlyCoatingsWood impregnation detailsFiberWater based

The invention discloses a water-based paint special for pinewood of the furniture for children, and belongs to the technical field of chemical paint. The construction technology of the water-based paint comprises the steps of: firstly, sanding the pinewood by 240# sand paper, uniformly erasing water-based keel sealing agent, wherein the using amount of the water-based keel sealing agent is 60-100 g / sq.m., and the water-based keel sealing agent is rapidly combined with wood fiber so as to enable coarse fiber or wood keels to be swelled; sanding by 320# sand paper after three hours, and then uniformly spraying water-based tannin sealing primer for preventing the pinewood from yellowing and preventing oil from oozing at a high temperature, wherein the using amount of the water-based tannin sealing primer is 140-160 g / sq.m.; and sanding by 320# sand paper after three hours, at least uniformly spraying water-based finish paint, thus completing the construction, and then sampling, detecting, discharging and putting into storage, wherein the using amount of the water-based finish paint is 100-130 g / sq.m. The water-based paint special for pinewood of the furniture for children has the advantages of being environment-friendly, free of environmental pollution, simple and convenient in production technology, particularly suitable for the painting requirement of the furniture for children, good in mechanical property, greatly improved in scratch resistance and high-temperature after-tack resistance, and convenient for construction operation and the like.

Owner:SHANGHAI JINQIANG ADHESIVE

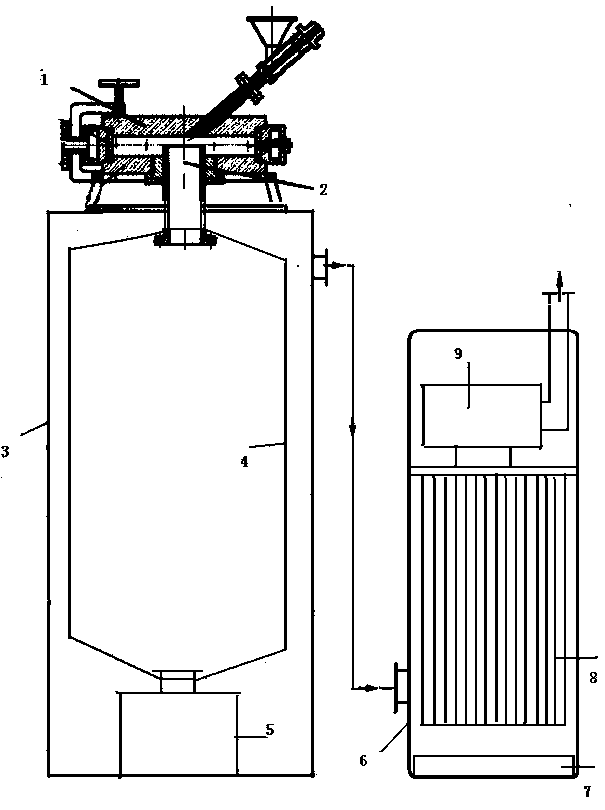

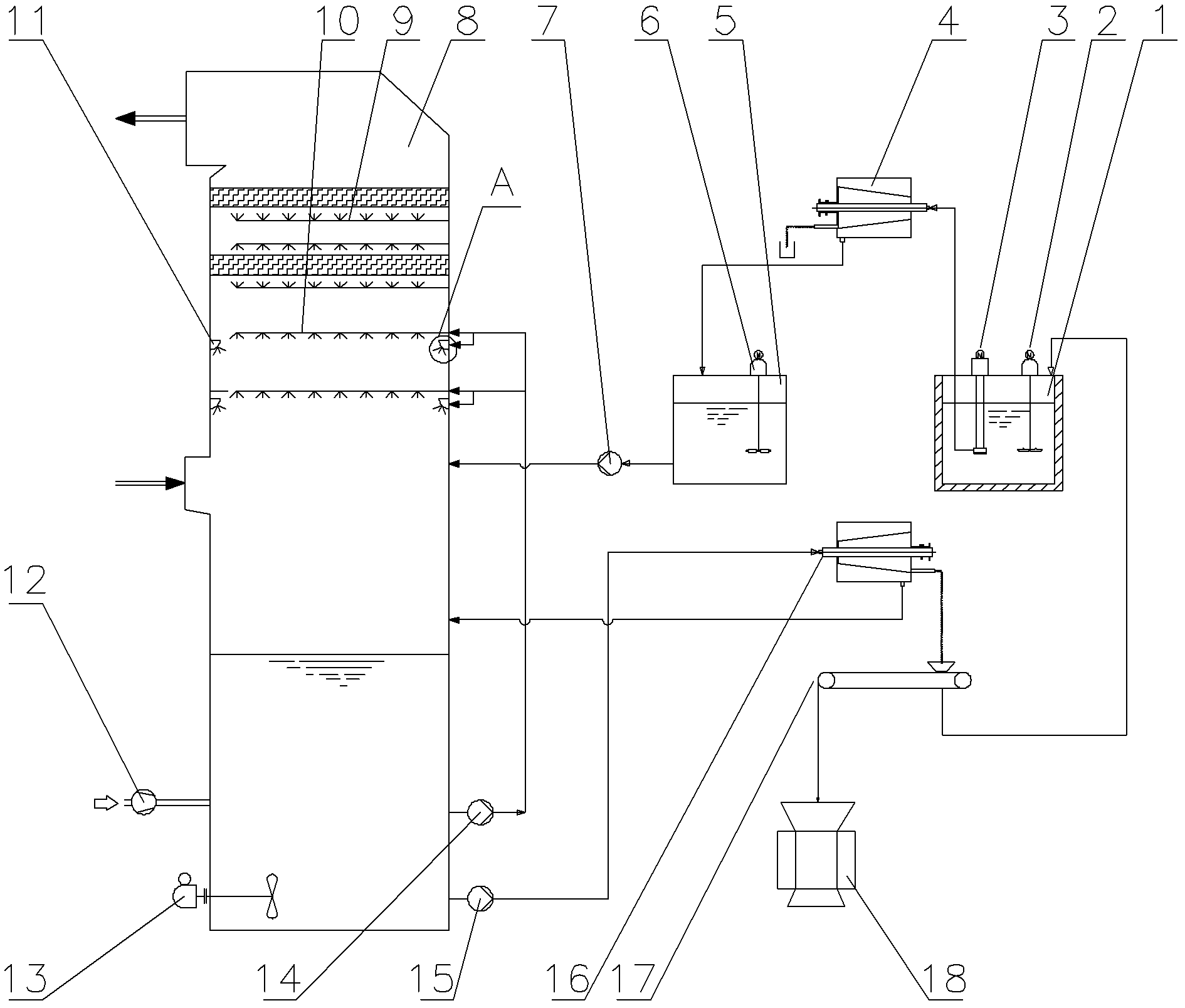

Device for jet milling of viscous material and gathering of dust

The invention relates to a device for jet milling of a viscous material and gathering of high-density powder and dust with certain viscosity. The device comprises a powder gathering apparatus, a deduster and a jet pulverizer. The powder gathering apparatus is connected to the deduster; the powder gathering apparatus comprises a discharging pipe, a powder gathering bag, a powder gathering case and a powder gathering barrel. The jet pulverizer is arranged outside on the top of the powder gathering case; the powder gathering bag is arranged in the powder gathering case; the discharging pipe passes through the top of the powder gathering case; the lower end of the discharging pipe is connected to the powder gathering bag, and the upper end of the discharging pipe is connected to the jet pulverizer; and the powder gathering barrel is arranged at the bottom of the powder gathering case and is connected to the lower end of the powder gathering bag. The device for ultrafine grinding and gathering provided by the invention does not contain a machinery rotary part, or employ a cyclone separator for gas-solid separation or a fixed pipeline for conveying a finished product and high speed dust-laden gas, so as to effectively solve the problems of adherence and obstruction of the viscous material under the effect of high speed jet; and an antistatic collection cloth bag timely eliminates statics, reduces obstruction of the dust on the apertures of the filter cloth of the powder gathering bag and facilitates material collection and gas-solid separation of the dust.

Owner:NANJING UNIV OF SCI & TECH

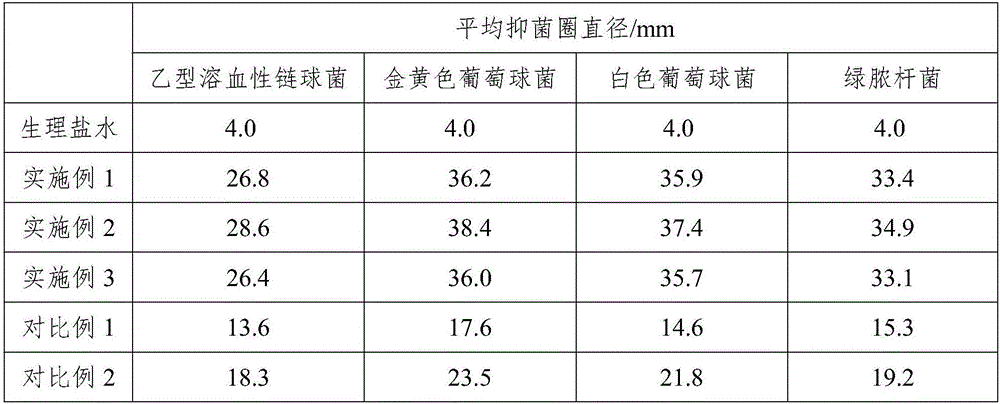

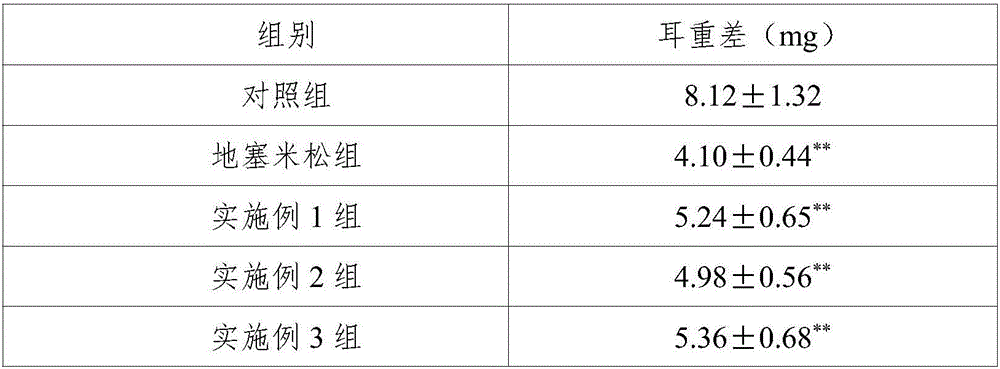

Oral ulcer treatment patch film and preparation method thereof

ActiveCN106063798AAddresses deficiencies that favor microbial growthImprove plasticityOrganic active ingredientsAntipyreticOral ulcersVitamin B6 synthesis

The invention belongs to the technical field of drugs and relates to an oral ulcer treatment patch film and a preparation method thereof. The oral ulcer treatment patch film mainly comprises oleanolic acid, polysaccharide sulfate, vitamin B6, chitosan, a film forming agent, glucoside, tributyl citrate and distilled water. The oral ulcer treatment patch film has a reasonable and scientific formula. Components of the oral ulcer treatment patch film interact with each other and have effects of inhibiting bacteria, diminishing inflammation and easing pain so that the oral ulcer treatment patch film can effectively relieve oral ulcer and shorten cure time. The oral ulcer treatment patch film has the advantages of good adhesion, fast dissolving speed and good uncovered film integrity, guarantees drug effects and is an ideal oral ulcer patch film.

Owner:宁波市诚德医疗科技有限公司

Magnetic block printing ink

Owner:CHINA BANKNOTE PRINTING & MINTING

Equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag

ActiveCN102500223ASolve the problem of "short circuit"Easy to combSolid waste disposalDispersed particle separationCycloneSlag

The invention discloses equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag. The equipment mainly comprises a wet-method flue gas desulfurization part, a carbide slag pretreatment part and a gypsum slurry retreatment part, wherein a hollow annular boss with a slurry spray nozzle is arranged below a slurry spray layer and on the inner wall of a spray tower cylinder body of the wet-method flue gas desulfurization part, so that the problem of flue gas 'short circuit' in the spray tower cylinder body is solved; according to the carbide slag pretreatment part, the problem of the stoppage of a filter layer in the process of separating the carbide slag slurry is solved by the design of a first rotation separator with a cleaning function; and according to the gypsum slurry retreatment part, an expensive cyclone separator in the conventional gypsum separation equipment is replaced effectively by the design of a second rotation separator with the cleaning function. According to the equipment, the flue gas desulfurization of fire coal, the comprehensive utilization of the discarded carbide slag and the processing of the gypsum serving as a desulfurization byproduct are integrated organically, and the equipment has a simple structure, is stable in running and high in desulfurization efficiency, treats wastes with the wastes and meets the requirement of current environment friendliness.

Owner:WUHAN YONGQING ENVIRONMENTAL PROTECTION TECH ENG

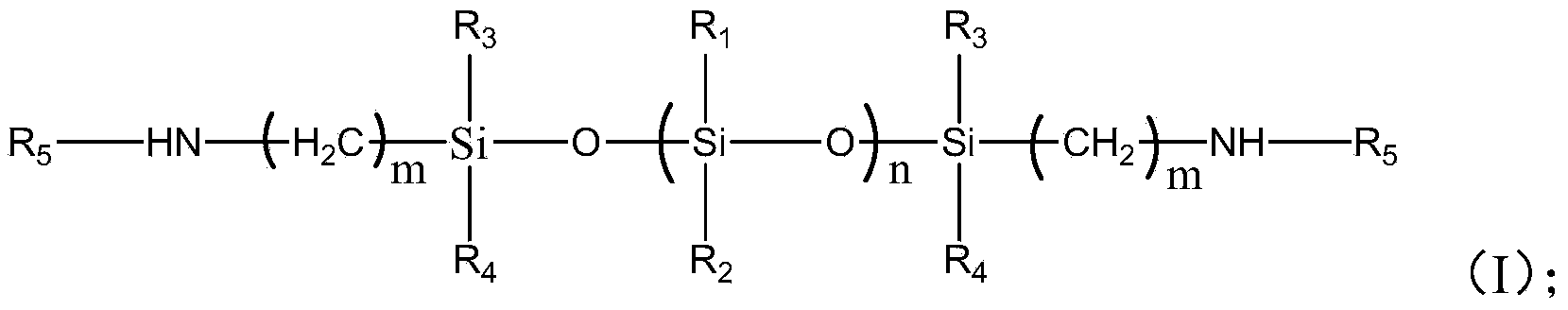

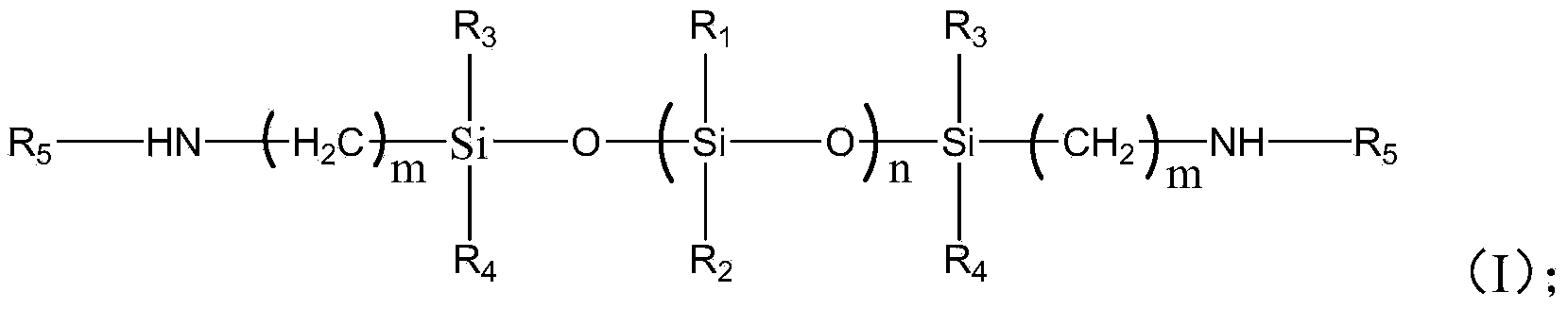

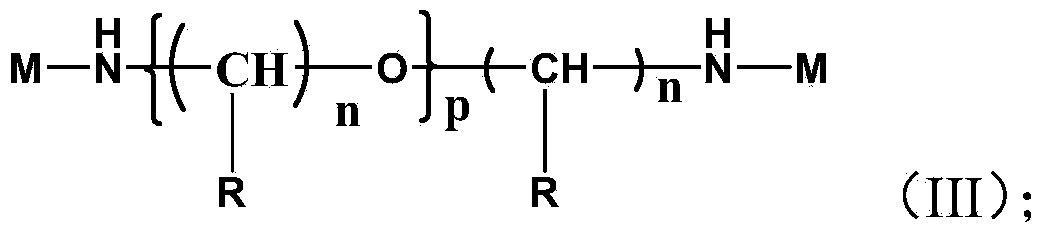

Polyureas copolymer with main chain containing siloxane composition unit and preparation method thereof

ActiveCN103834034AAvoid stickingExtended service lifePolyurea/polyurethane coatingsPolyesterEnd-group

The invention discloses a polyureas copolymer with a main chain containing siloxane composition units; the polyureas copolymer comprises the following constitution units: polysiloxanes constitutional units of aminoalkyl termination; polyether constitutional units of high-molecular amino termination; polyether alcohol or polyester alcohol constitutional units; single molecule chain extension double amine or low molecular amino termination polyether constitutional units; isocyanate constitutional units. Through the design of polysiloxanes molecular composition of aminoalkyl termination and adjustment of molecule mass; on one hand, a reaction amino group and an alkyloxy crosslinking group are introduced on a terminal group; on the other hand, a chain alkyl group or a perfluoro alkyl group are designed on a side chain; simultaneously three function hydroxy or amino groups are embedded in the composition, thereby obtaining excellent anti adhesiveness, abrasion resistance, corrosion resisting, impact resistance and anti contamination functions, effectively preventing contamination objects from pasting on special equipment, improving anti pollution function, solving adherence of adherence fluid, anti pollution and wearing corrosion problems, satisfying demands of different application fields, and prolonging service life of the special equipment.

Owner:HUBEI UNIV +1

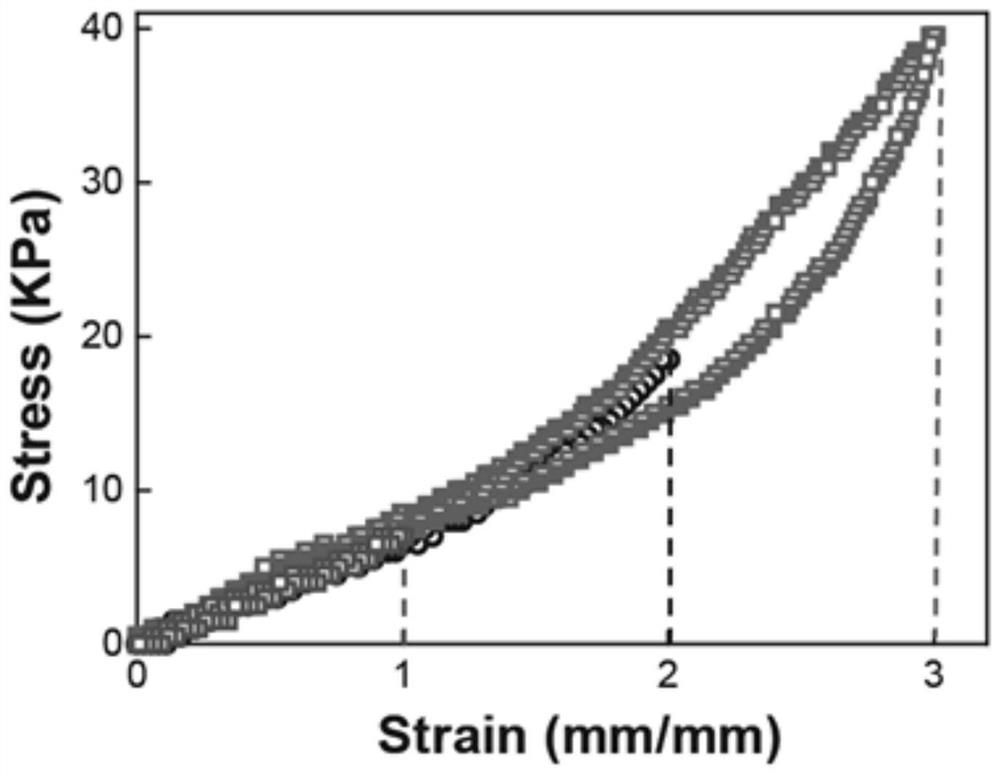

High-transparency polyvinyl alcohol hydrogel as well as preparation method and application thereof

ActiveCN112646206ATransparent highImprove adhesionAerosol deliveryOintment deliveryInorganic saltsPolymer science

The invention provides high-transparency polyvinyl alcohol hydrogel as well as a preparation method and application thereof. According to the high-transparency polyvinyl alcohol hydrogel, polyvinyl alcohol and inorganic salt are used as raw materials, water is used as a solvent, the concentration of the polyvinyl alcohol is 3-30 wt%, and the concentration of the inorganic salt is 0.5-29.9 wt%. The method disclosed by the invention is green and environment-friendly, and the prepared polyvinyl alcohol hydrogel has high transparency, adhesion and ultralow-temperature freezing resistance, and has elasticity, ductility, ionic conductivity and moisture retention, so that the problems of non-transparency, no adhesion, no freezing resistance and the like of the polyvinyl alcohol hydrogel during application are solved, and the prepared polyvinyl alcohol hydrogel can be applied to the fields of medicines, materials and sensors.

Owner:QINGDAO UNIV

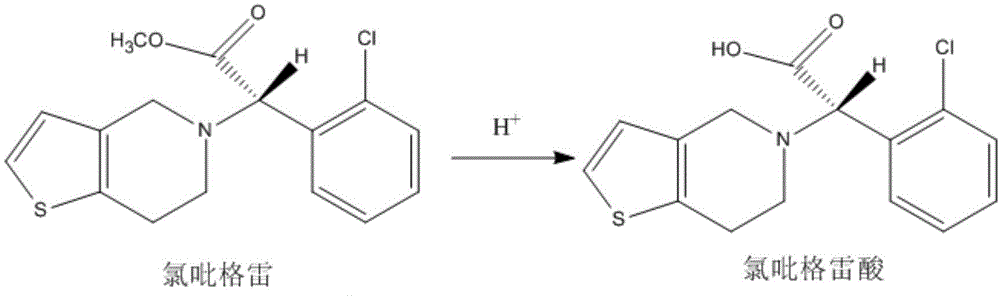

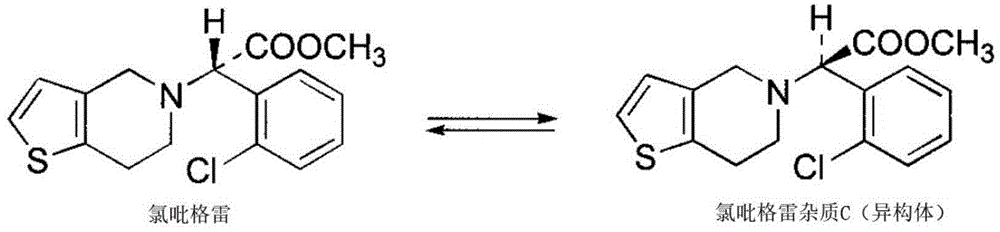

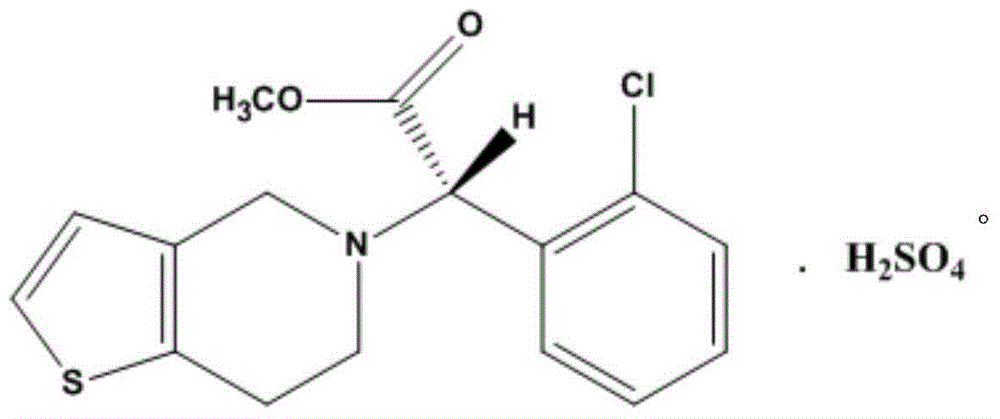

Solid pharmaceutical composition with clopidogrel

ActiveCN104644595AInhibit productionQuality improvementOrganic active ingredientsPharmaceutical non-active ingredientsMedicineMutarotation

In order to overcome shortcomings of material sticking of a clopidogrel crude drug and hydrolysis of the crude drug in a preparation thereof in storage, the invention designs a solid pharmaceutical composition with clopidogrel and provides a prescription and a process for further preparing the solid pharmaceutical composition into a tablet. The tablet has good forming property and is capable of inhibiting hydrolysis of the crude drug in the process of existence; and unexpectedly, the tablet also inhibits mutarotation of the crude drug. The tablet of the invention is simple in preparation method and can be manufactured by conventional preparation methods without special devices, so that the tablet has the advantages of easy industrialization, high production efficiency, good stability and controllable quality. Thus the solid pharmaceutical composition has outstanding substantive features and obvious inventive steps.

Owner:吕霄芳

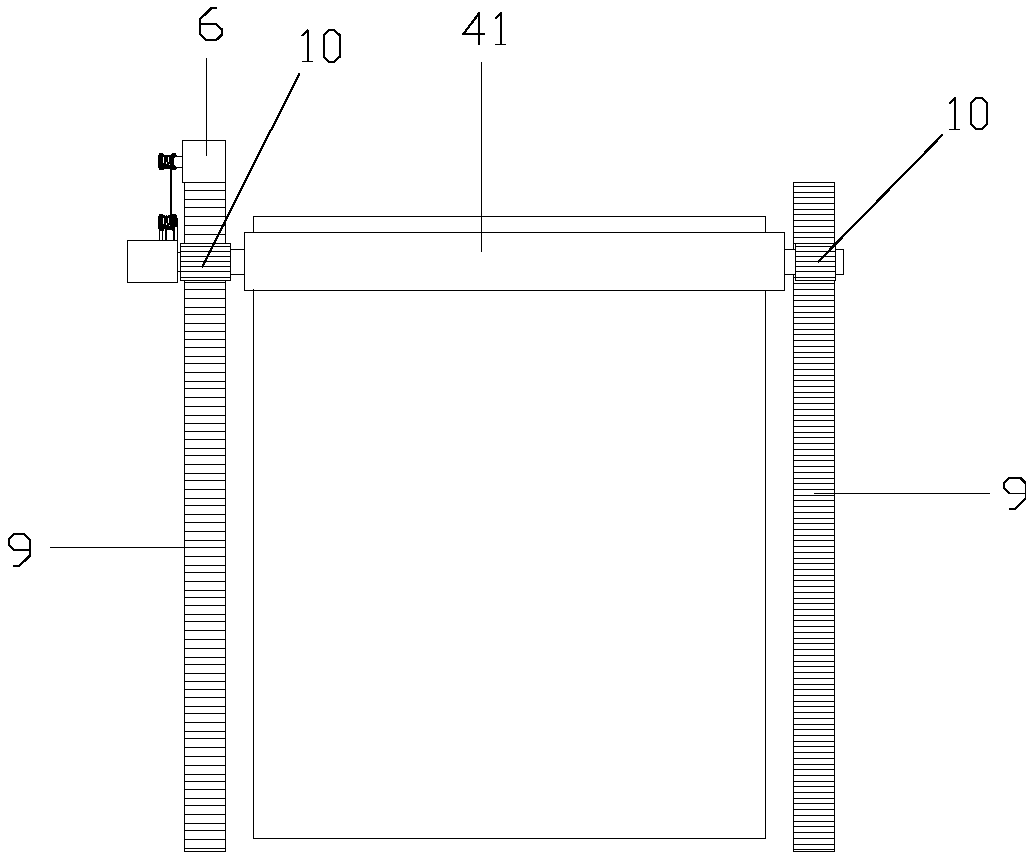

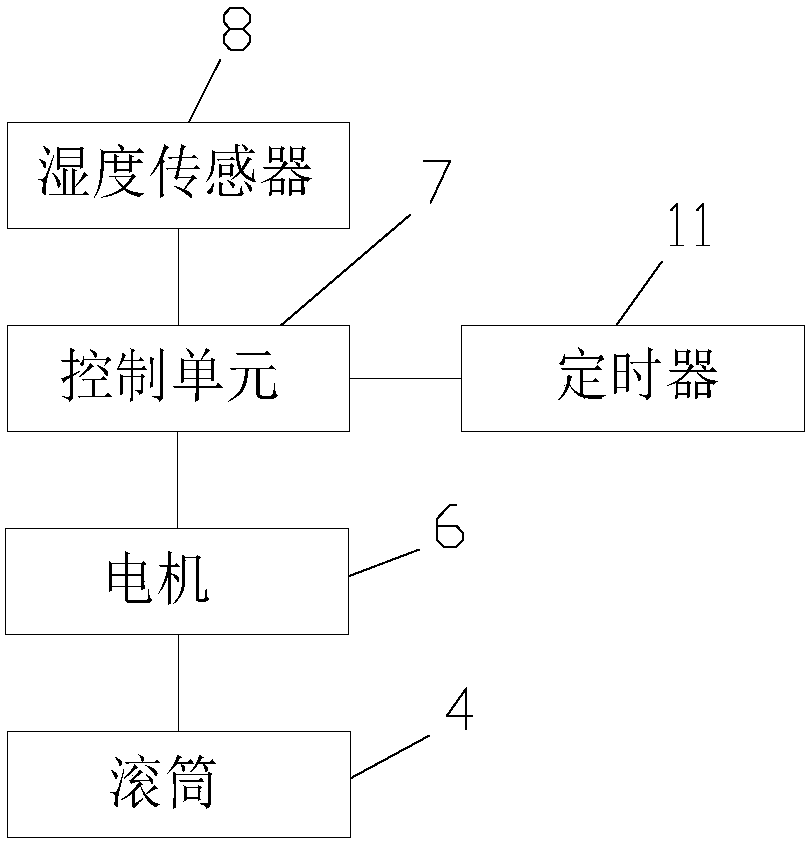

Self-cleaning type outdoor illuminating lamp

InactiveCN107726131ASolve the adhesionSolve technical problems that affect the glow effectLighting elementsCleaning using toolsElectrical connectionLight fixture

The invention relates to the technical field of illuminating lamps, in particular to a self-cleaning type outdoor illuminating lamp. The self-cleaning type outdoor illuminating lamp comprises a housing, a lampshade and a lamp bead, and further comprises a cleaning device, wherein the lamp bead is mounted in the housing; the lampshade is mounted on the housing and is used for sealing the lamp bead;the cleaning device comprises a roller, guide rails, a motor, a control unit and a humidity sensor; the two guide rails are separately arranged at the two sides of the housing in a mutually parallelmode; the two ends of the roller are separately arranged on the two guide rails perpendicularly; a cleaning layer is covered on the roller; a rolling shaft of the roller is arranged on the guide railsin a sliding mode; the control unit is electrically connected with the motor; and the temperature sensor is used for detecting humidity information. With the adoption of the technical scheme, the roller which is covered with the cleaning layer and is used for cleaning operation is arranged on the outer surface of the lampshade, and the roller rolls back and forth on the lampshade under driving ofthe motor to complete cleaning work, so that the illuminating effect is improved.

Owner:刘闯

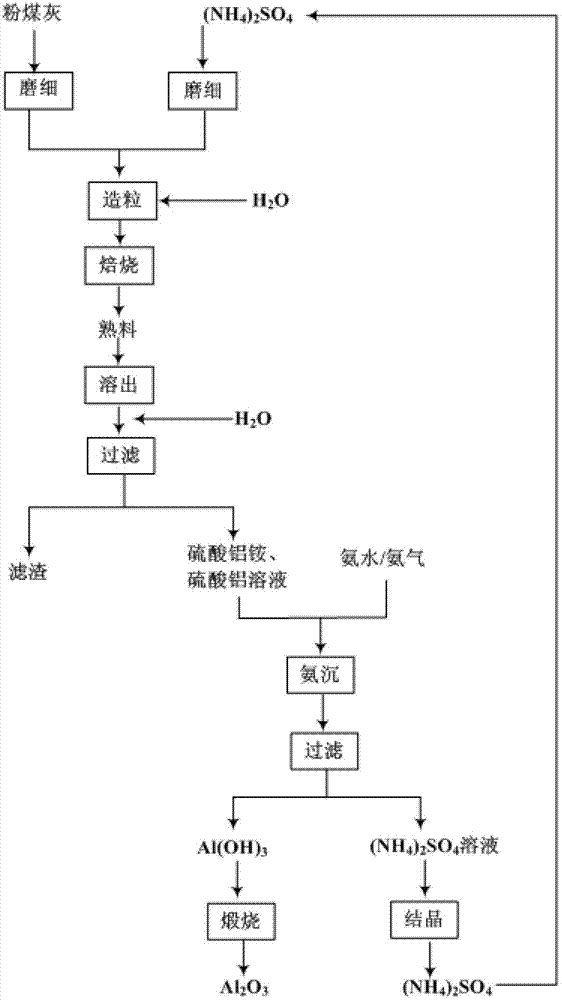

Method for extracting alumina through coal ash

InactiveCN103086412AImprove close contactHigh yieldAluminium hydroxide preparationAluminium oxides/hydroxidesTemperature controlAmmonia

The invention particularly discloses a method for extracting alumina through coal ash. The method comprises the following steps of: (1) respectively finely grinding and activating the coal ash and finely grinding ammonium sulfate in order to increase the superficial area; (2) carrying out solid-to-solid mixing on the finely ground coal ash and the ammonium sulfate (on the basis of Al2O3: (NH4)2SO4=1: 3 to 6 (molar ratio) in the coal ash) until reaching the consistency; (3) adding a certain rate of water to the mixed and consistent raw materials in the step (2), which is a mixture of the coal ash and the ammonium sulfate, and granulating; (4) placing the particles in the step (3) into roasting equipment to roast, wherein a two-section temperature control method is carried out in the roasting process; (5) adding the roasted clinker to the water to dissolve into solution; (6) filtering the solution prepared in the step (5), and respectively collecting the filter residue and the filtrate; (7) adding ammonia water to the filtrate in the step (6) to obtain Al(OH3) sediment; and (8) roasting Al(OH3)3 to obtain the Al2O3 product.

Owner:NORTH UNITED POWER CO LTD +1

Method for preparing substrate for high formyl group functional group density biological chip

The invention discloses a substrate for a high formyl group functional group density biological chip and a preparation method of the substrate. The method comprises the following steps: performing a polishing process by adopting ultra-white glass of low fluorescence background, so that the surface smoothness is improved; and realizing surface formylation by adopting a chemical grafting method, so that the adhesion is improved. The experiment proves that the substrate for the biological chip is small in fluorescence background and uniform in surface property, and the shape of sample points is always consistent in the long-term sample application process. The substrate is suitable for DNA, proteins and other types of probes and is suitable for point preparation of high-throughput chips, and the problem that a common substrate is non-uniform in sample application and low in adhesion is solved.

Owner:江苏贝思安特生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com