Terolon coating hot-press shaping mould and production for ornament in vehicle

A technology for automotive interior parts and hot press forming, which is applied to coatings, household components, household appliances, etc., can solve problems such as poor stability and difficult to guarantee precision, and achieve the effects of easy assembly, improved quality, and reasonable mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

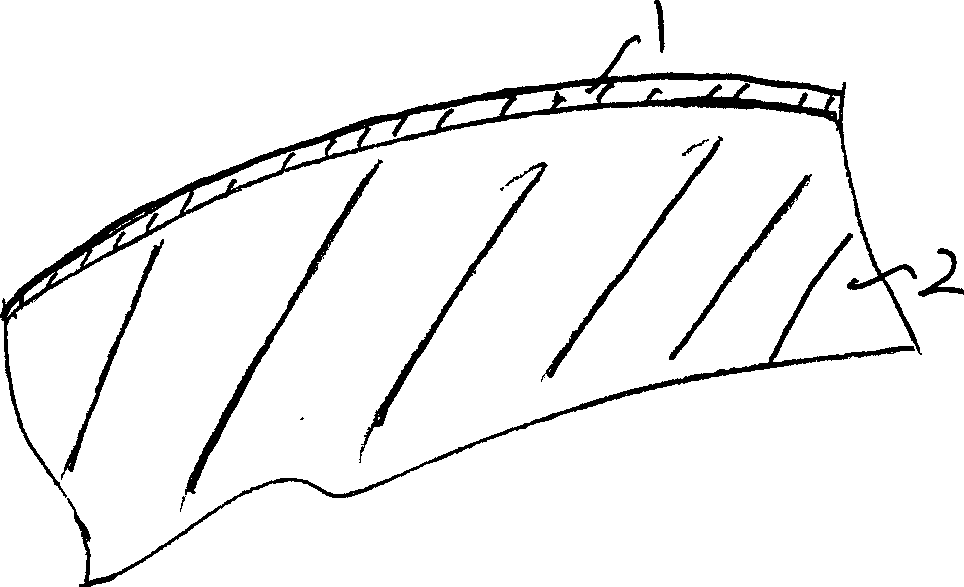

Image

Examples

Embodiment Construction

[0016] ①Cleaning treatment: Clean the surface of the mold with conventional detergents such as water, soap liquid or washing powder, and then degrease at a high temperature of 300-500°C (eg 300°C, 380°C, 420°C, 500°C) for 40 ~120 minutes (eg 40 minutes, 80 minutes, 120 minutes);

[0017] ②Sand blasting: Cool the mold treated in step ① to 80°C~100°C (for example, 80°C, 90°C, 100°C), perform surface sandblasting treatment, and use gas to remove dust from the mold surface;

[0018] ③Painting: Spray polytetrafluoroethylene paint evenly on the surface of the mold, and spray the paint in three times. After the first uniform spraying, dry it at 160°C-200°C, cool it to 30°C-50°C, and use air to spray the mold surface. Dust off, then spray a second coat evenly, followed by a third coat. The PTFE paint sprayed in the first pass is EK-1909BNK, the PTFE paint sprayed in the second pass is EK-3809M3, and the PTFE paint sprayed in the third pass is EK-3800C3. After spraying, heat and dry,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com