Equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag

A wet flue gas desulfurization and calcium carbide slag technology is applied in the fields of environmental protection and resource utilization, and can solve the problems of the wet flue gas desulfurization being unable to run continuously, reducing the service life of equipment, and failing to be effectively solved, and saving processing and processing. The effect of cost, reducing consumption and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

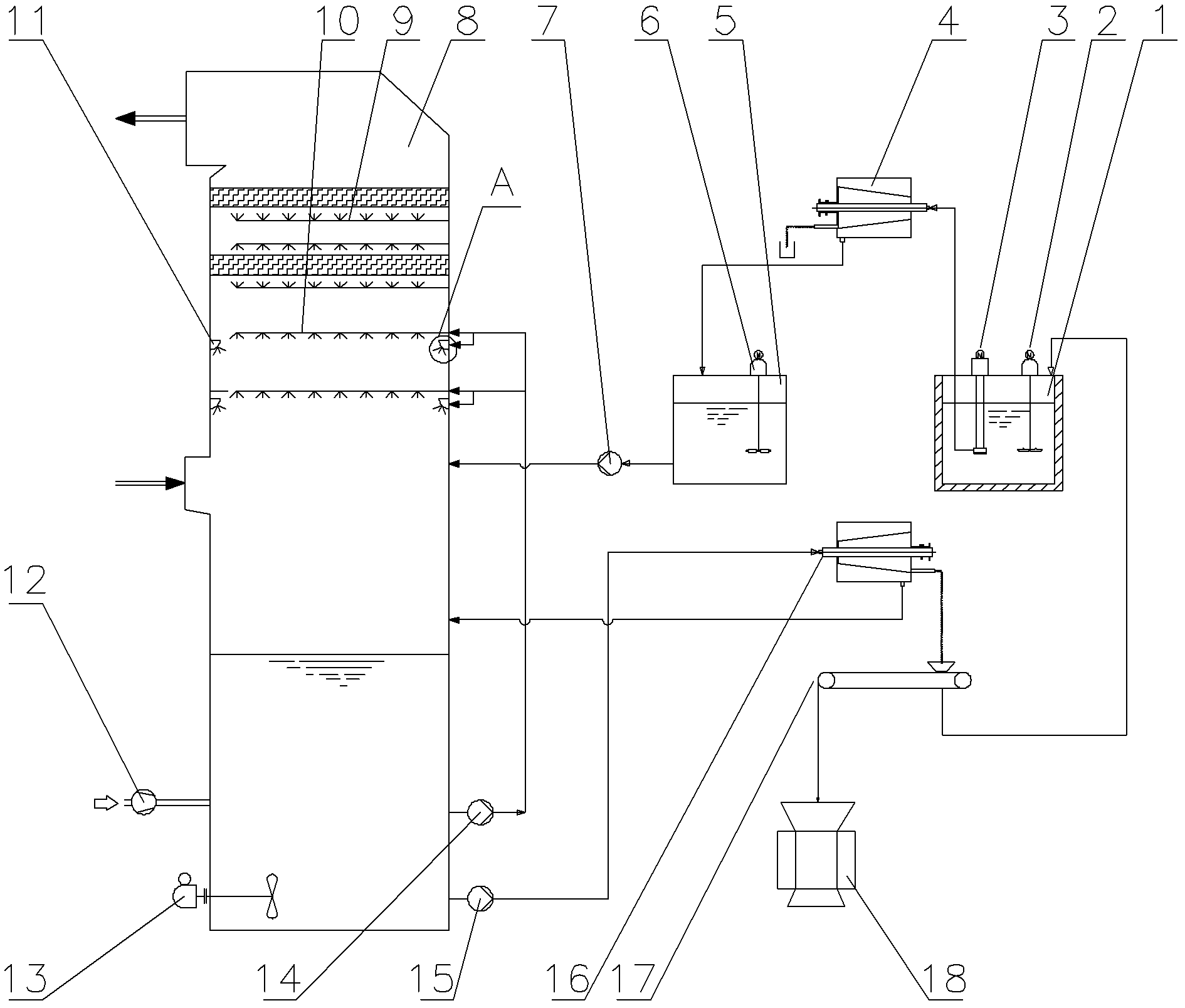

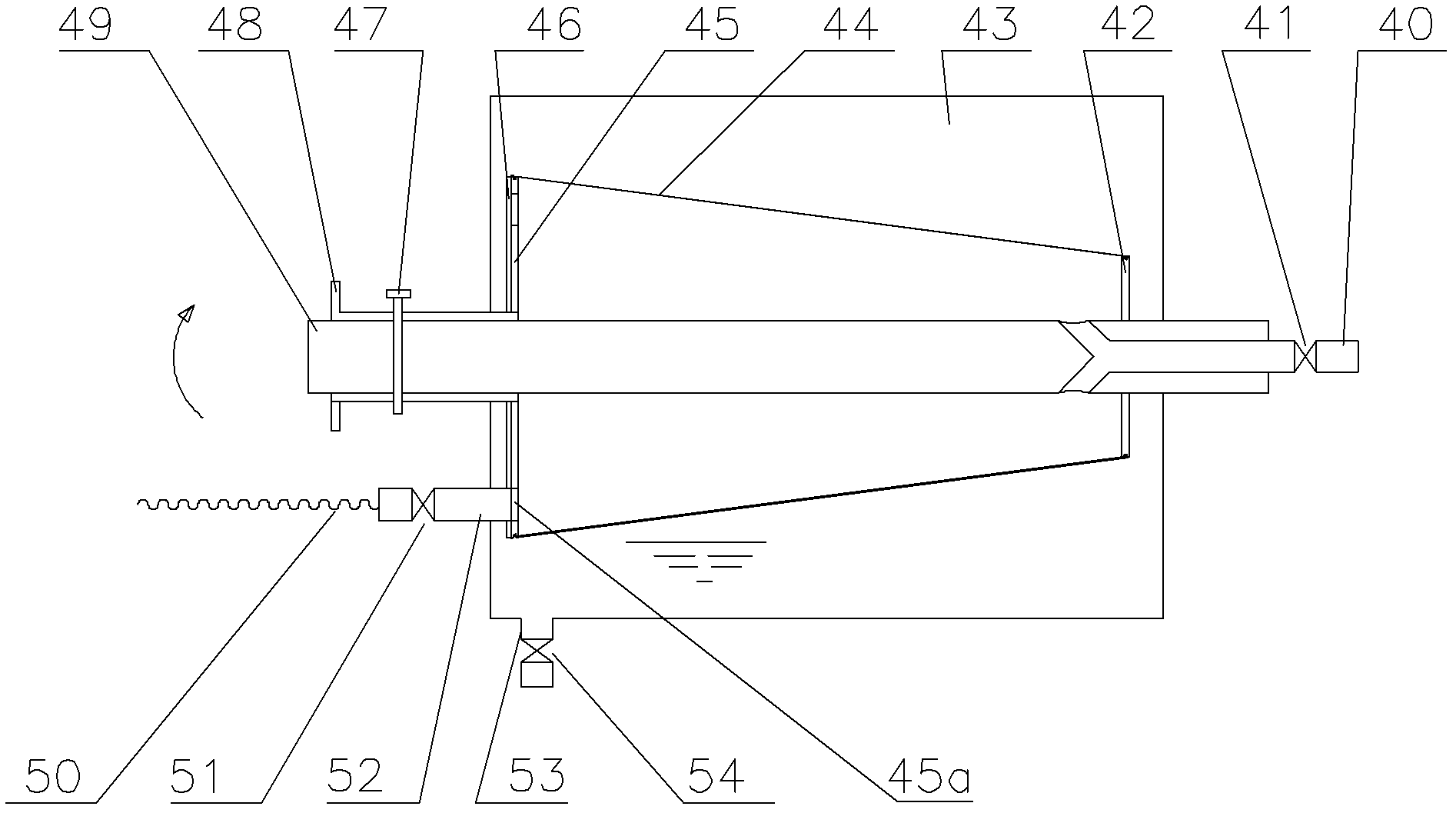

[0028] Such as Figure 1~4 The shown waste carbide slag wet flue gas desulfurization co-production equipment for gypsum is mainly composed of a wet flue gas desulfurization part, a carbide slag pretreatment part and a gypsum slurry reprocessing part. The specific structure of each part is as follows:

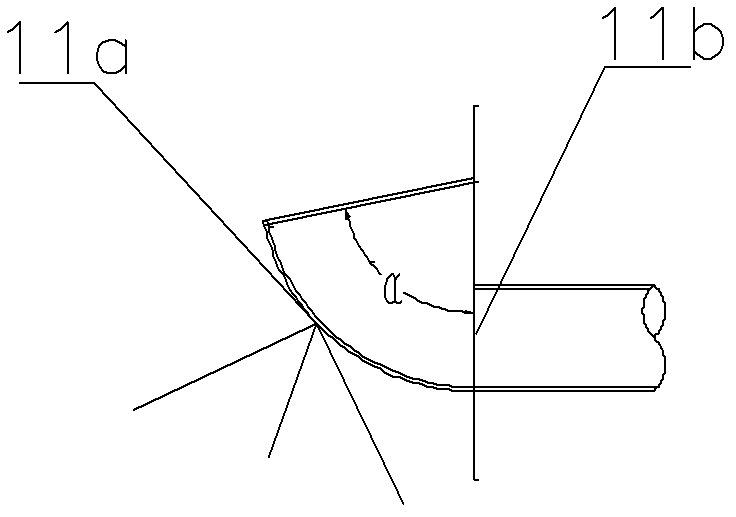

[0029] The wet flue gas desulfurization part has a spray tower cylinder body 8, a demister 9 is arranged below the top flue gas outlet of the spray tower cylinder body 8, and two Layer slurry spray layer 10, the slurry pool at the bottom of the spray tower cylinder body 8 is connected to the input end of the slurry circulation pump 14, the output end of the slurry circulation pump 14 is connected to the slurry spray layer 10, and the bottom of the spray tower cylinder body 8 An oxidation blower 12 and an absorption to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com