Patents

Literature

167results about How to "Solve the problem of short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pb-free sn-based material, wiring conductor, terminal connecting assembly, and pb-free solder alloy

InactiveCN101096730AImprove connection reliabilityReduce stressPrinted circuit aspectsPrinted circuit manufactureElectrical conductorBase metal

A Pb-free Sn-based material part of a wiring conductor is provided at least at a part of a surface the wiring conductor, and the Sn-based material part includes a base metal doped with a transformation retardant element and an oxidation control element. The transformation retardant element is at least one element selected from a group consisted of Sb, Bi, Cd, In, Ag, Au, Ni, Ti, Zr, and Hf. The oxidation control element is at least one element selected from a group consisted of Ge, P, Zn, Kr, Cr, Mn, Na, V, Si, Al, Li, Mg and Ca. The wiring conductor is reflow processed, such that at least one of the Sn, the transformation retardant element and the oxidation control element is diffused to form an alloy.

Owner:HITACHI CABLE

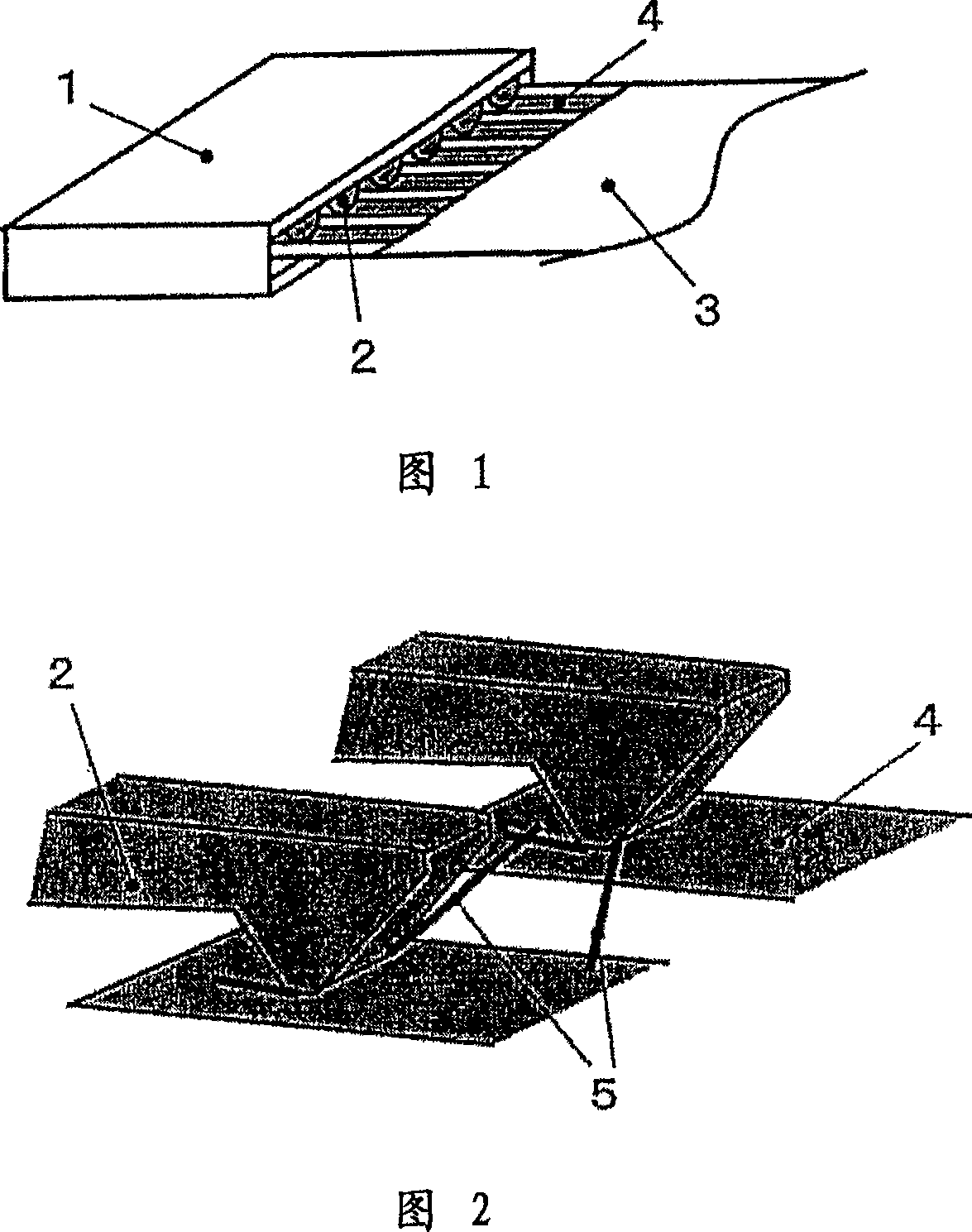

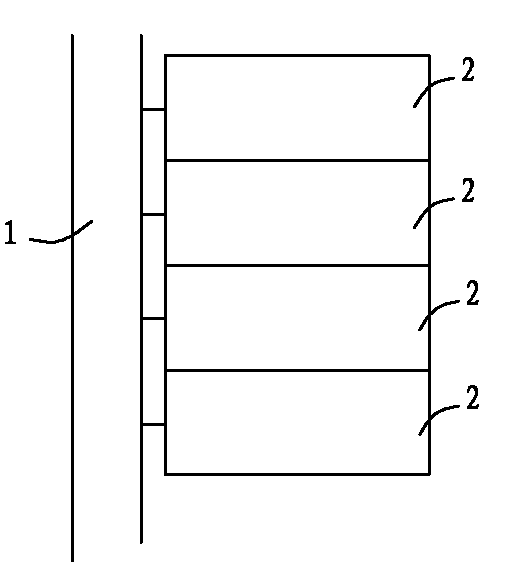

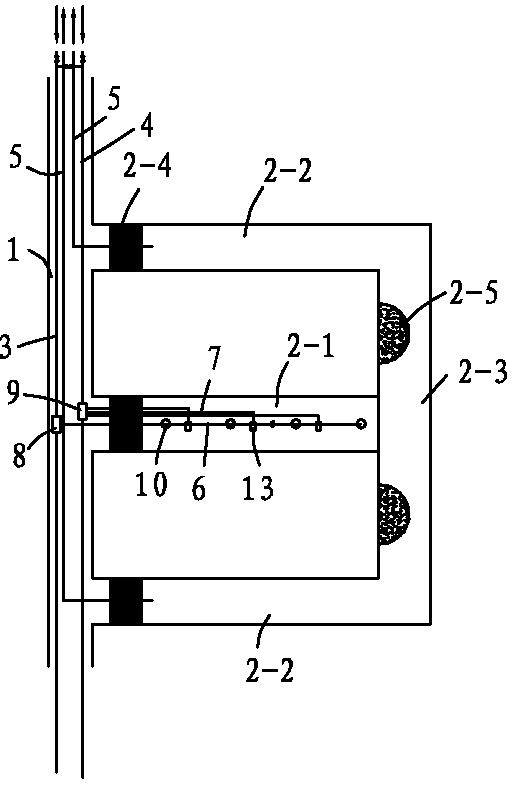

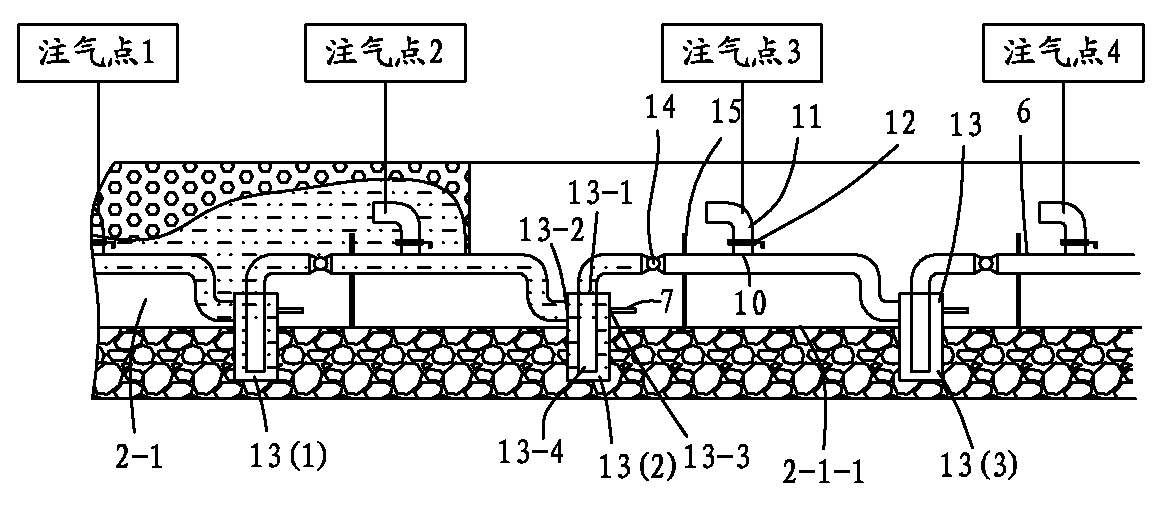

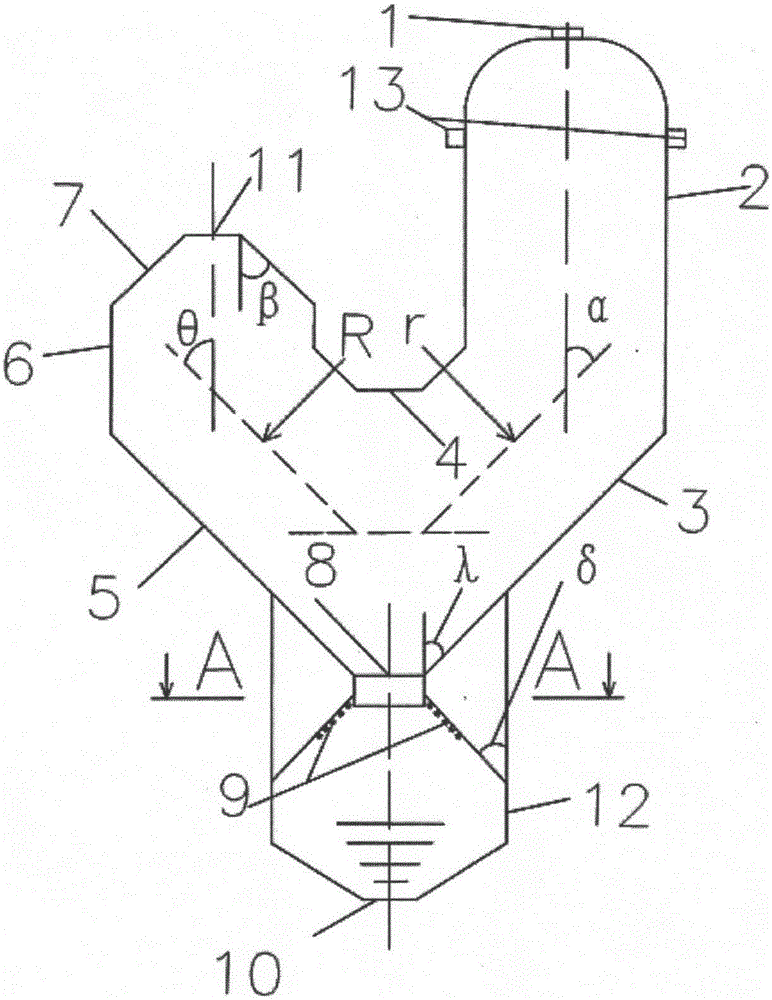

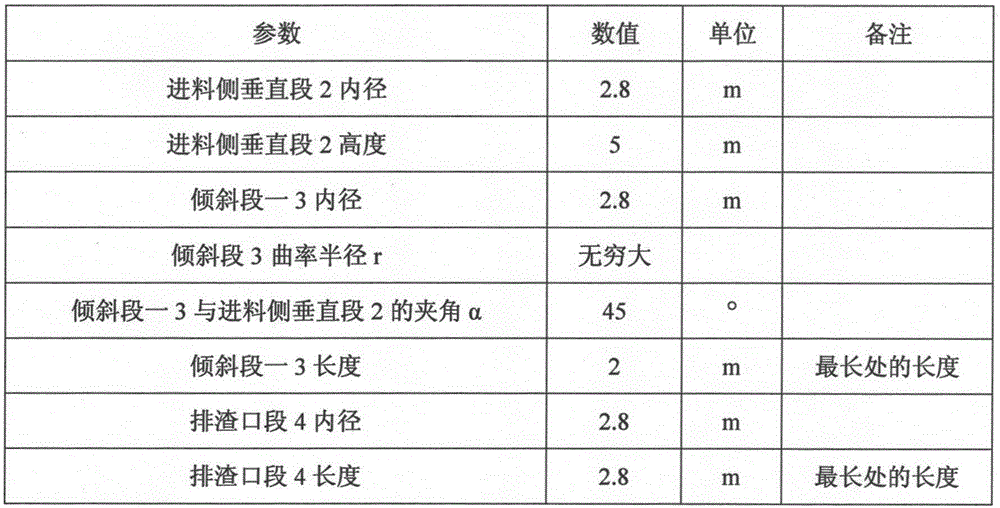

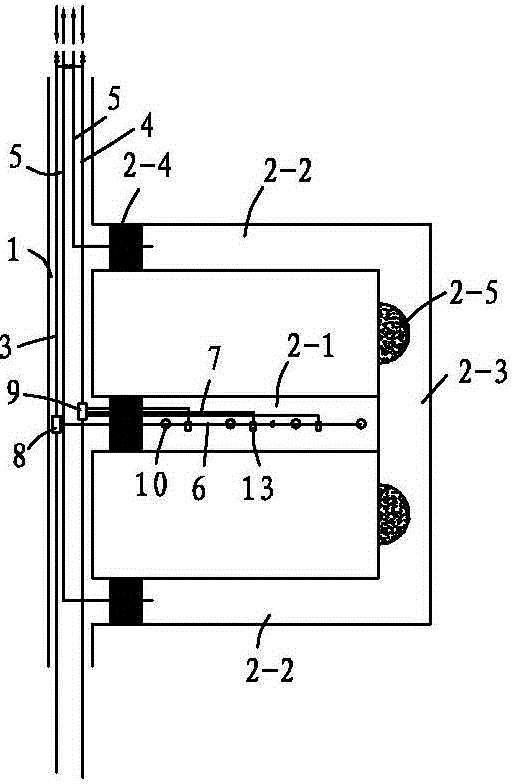

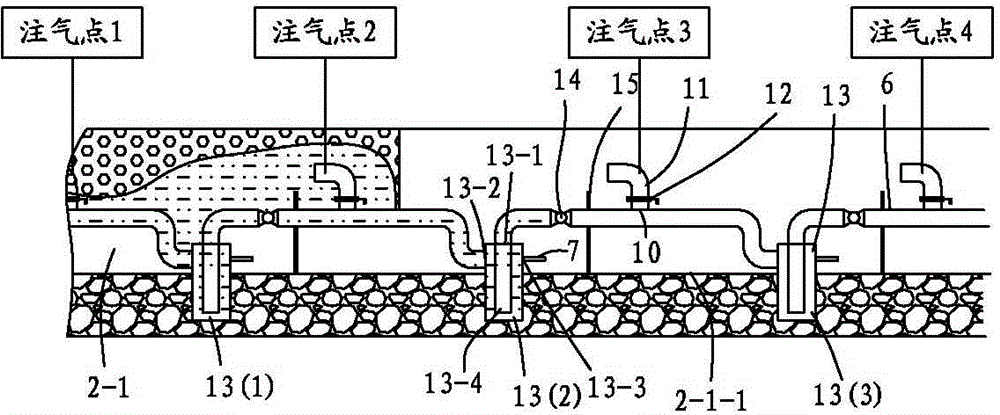

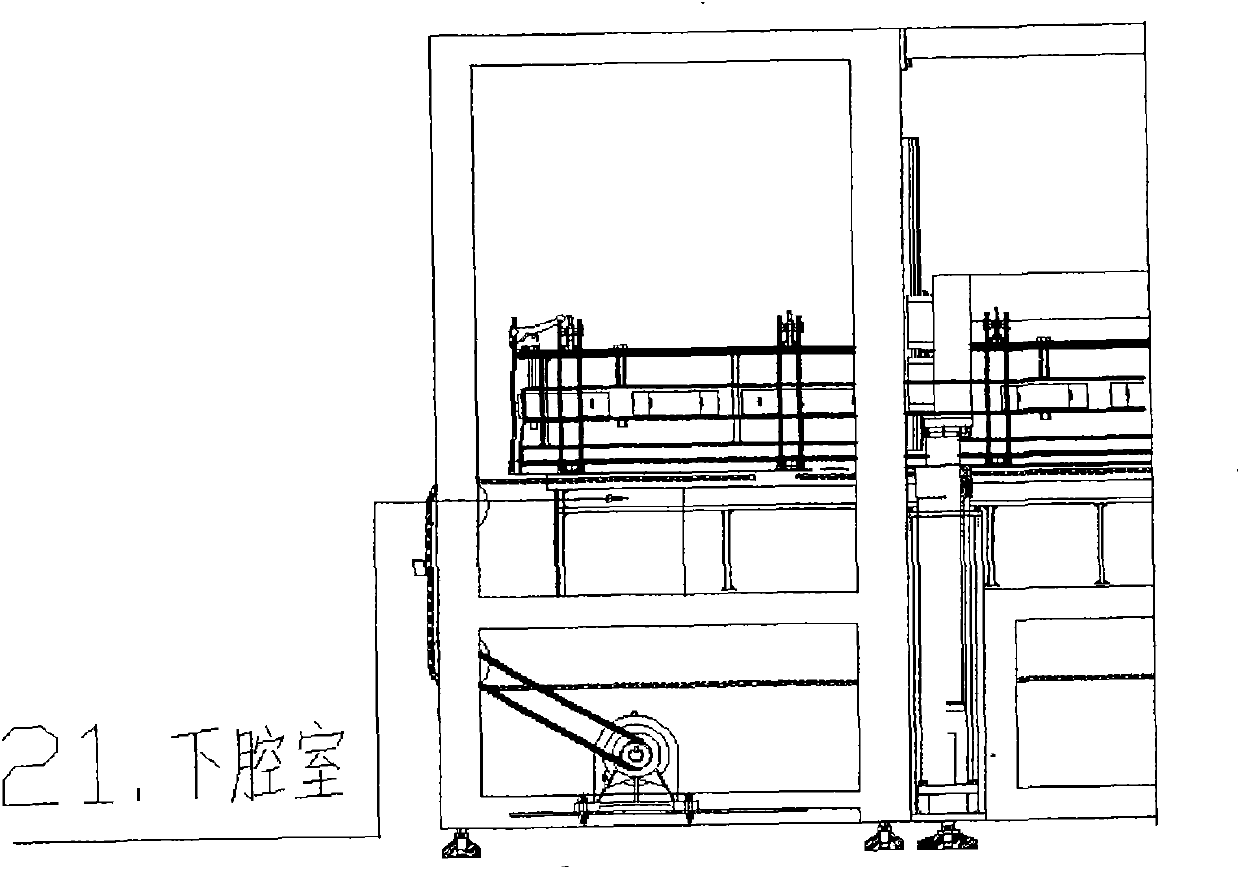

Gas injection point retreating type coal underground gasification system and process

InactiveCN103277082AAvoid cloggingPrevent backflowConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

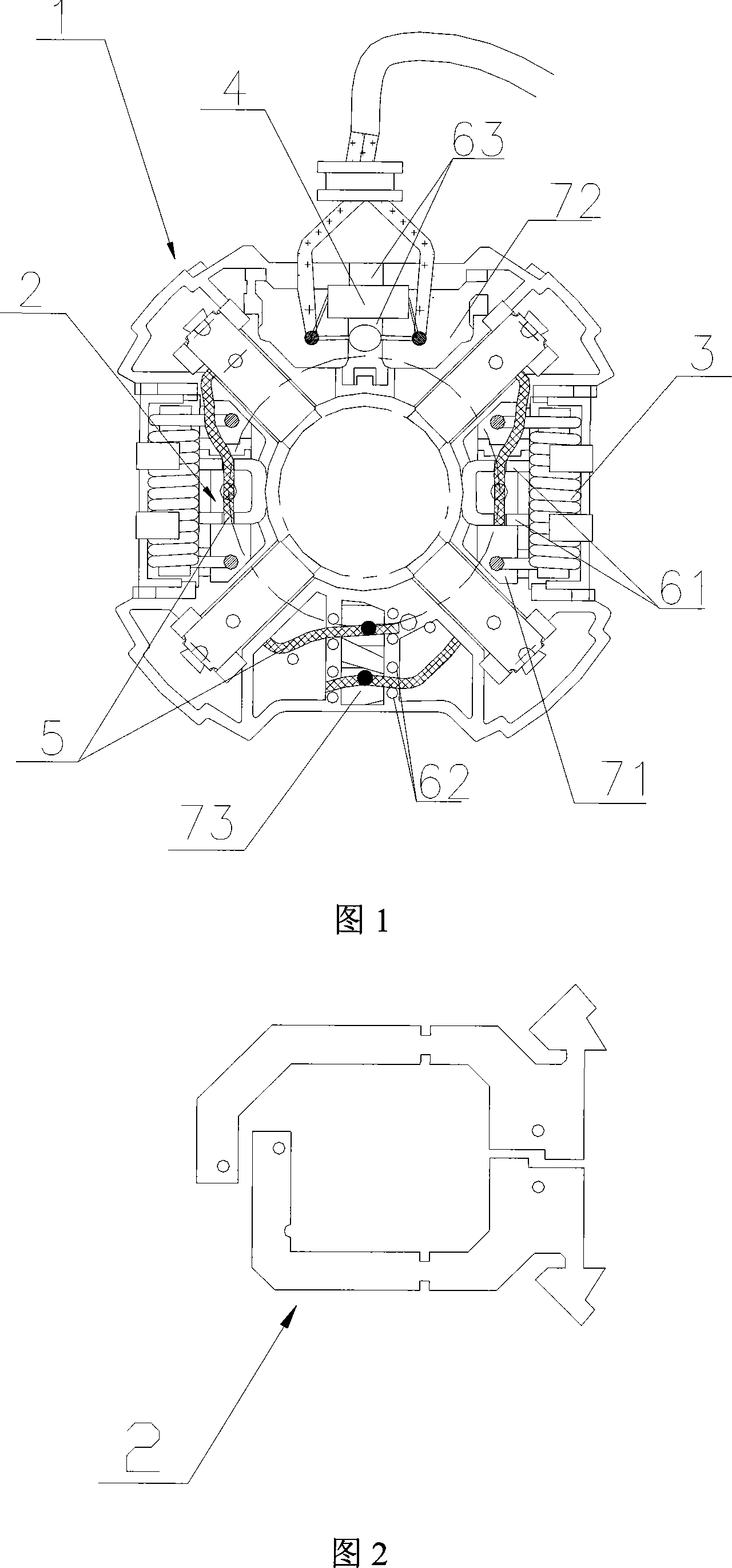

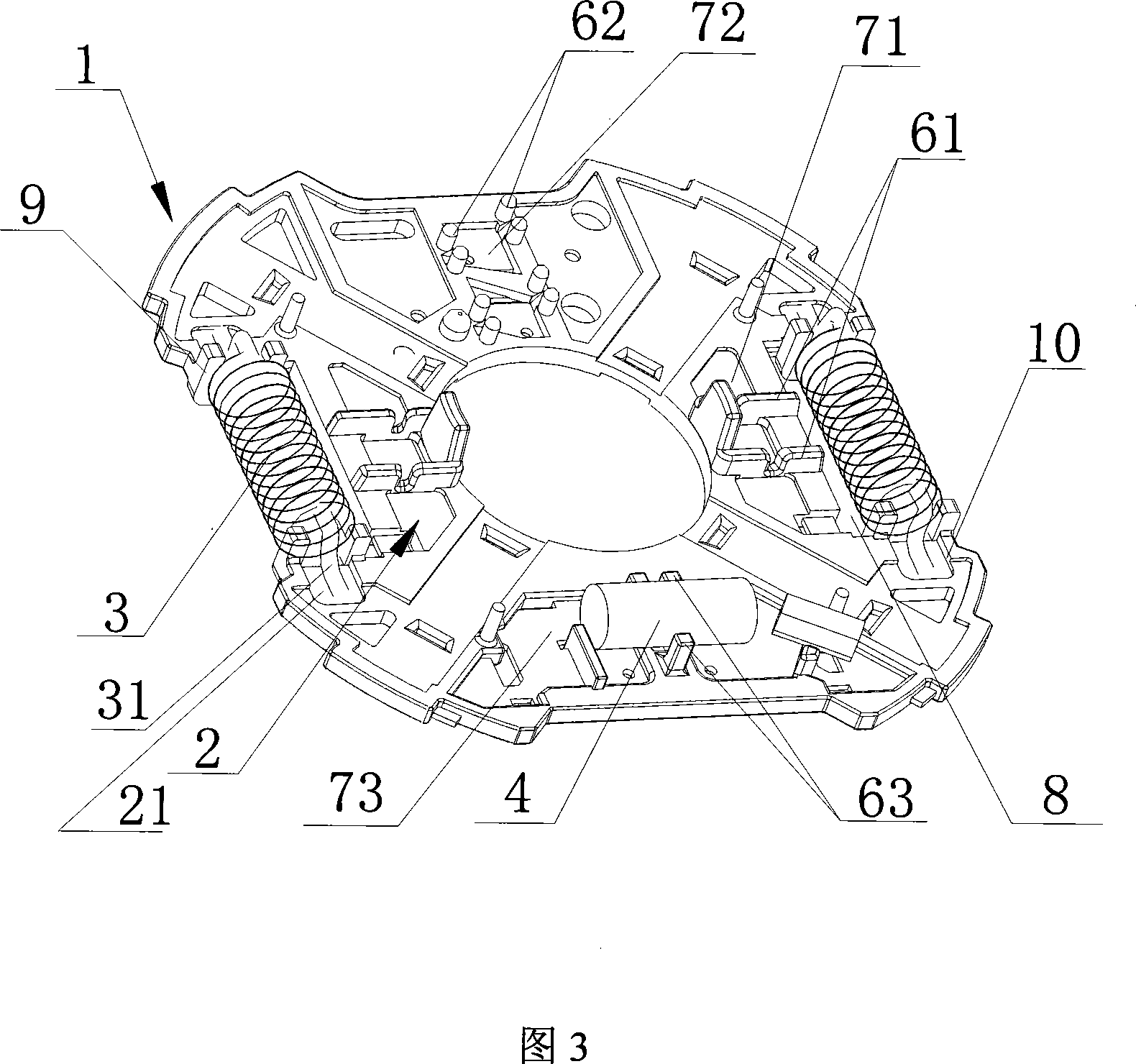

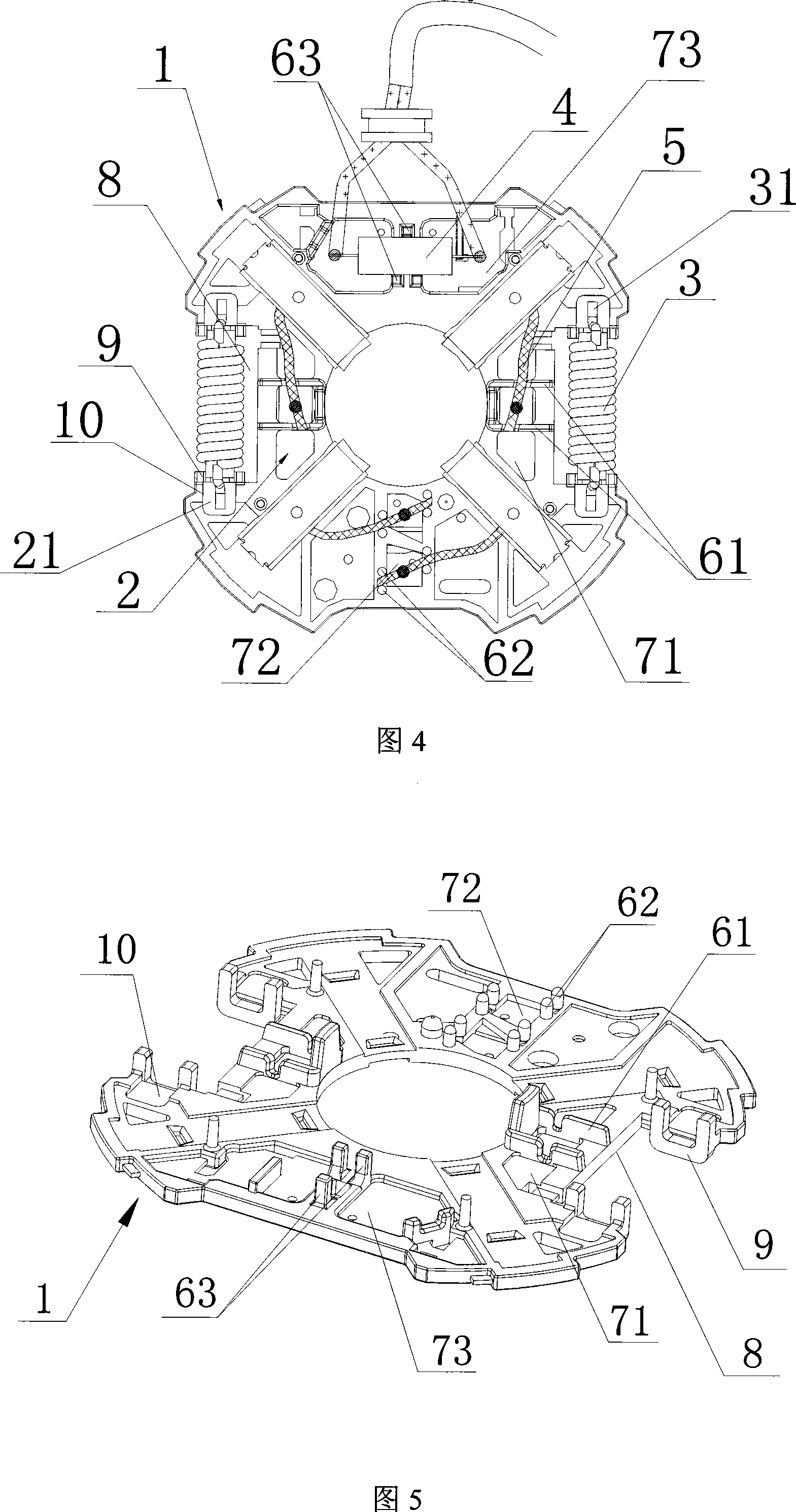

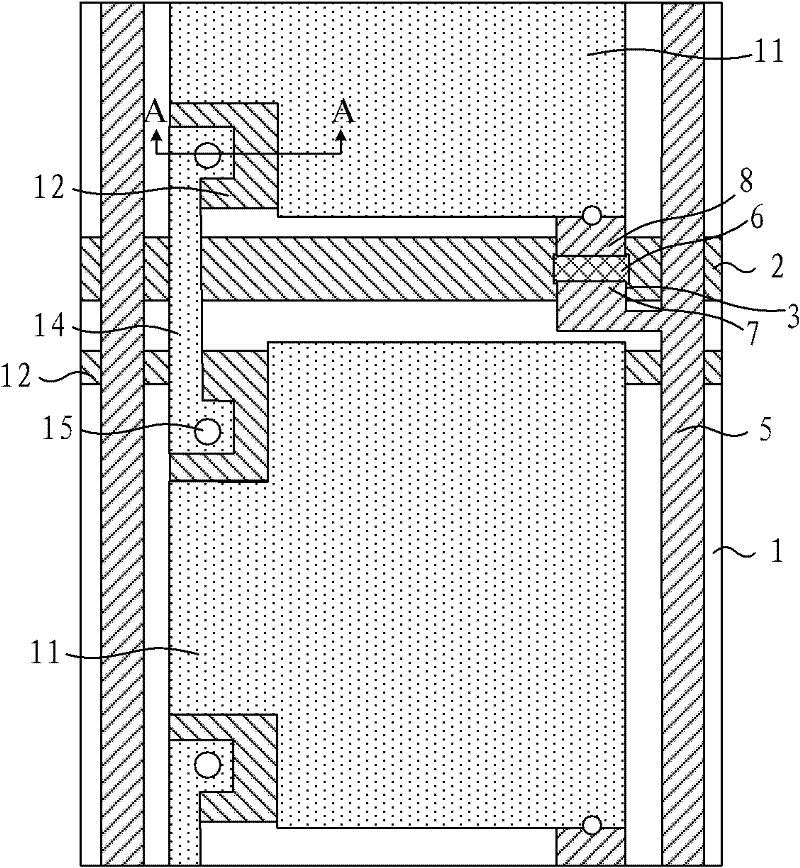

Fan, generator and brush yoke component of car radiator

ActiveCN101110531AEasy to fixSolve the problem of short circuitRotary current collectorStructural associationCapacitanceEngineering

The present invention relates to an electric brush carrier assembly for vehicle-mounted radiator fan motors, which comprises an electric brush carrier base plate 1, a metal bonding pad 2, a brush handle, a compression spring, an electric brush, an inductance 4 and an electric brush outgoing wire 5. Wherein, two edges of the electric brush carrier base plate are symmetrically arranged with two openings 8. Two internal walls of these two openings 8 wholly arranged with a U-shaped inductance bracket 9 to support two ends of the inductance. Both sides of the electric brush carrier base plate 1 are positioned with a base plate opening II 10 along the opening 8. The metal bonding pad is additionally composed of an extending pad 21 extended towards the base plate opening II 10. The inductance 3 is fixed on the inductance bracket 9 with its pins welded with the extending pad 21 at the base plate opening II 10, Compared with prior arts, the present invention eliminates short circuit, emits an inductance bracket, saves production cost and improves product reliability.

Owner:SHANGHAI RIYONG JEA GATE ELECTRIC +1

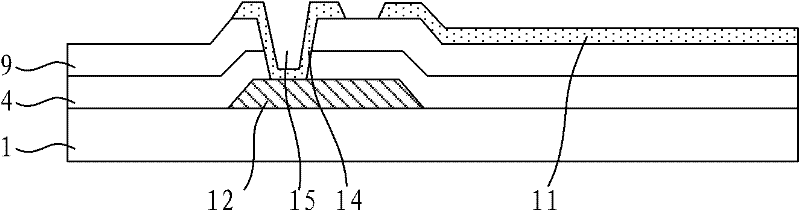

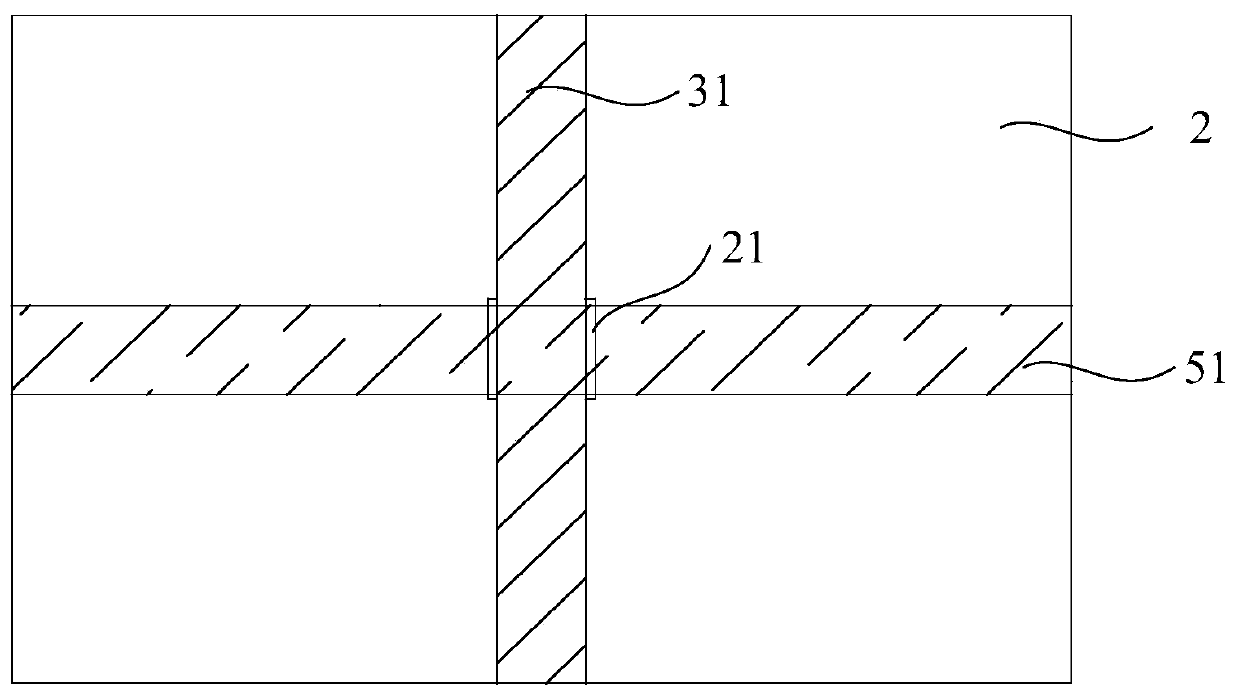

Array substrate and method for manufacturing same and liquid crystal display

InactiveCN102468308ASolve the problem of short circuitWill not short circuitSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention discloses an array substrate and a method for manufacturing the same and a liquid crystal display. The method for manufacturing the array substrate comprises the steps of forming conductive patterns and an insulating layer on a substrate base plate, wherein the conductive patterns at least comprise a grid line, a grid electrode, an active layer, a source electrode, a drain electrode, a data line, a pixel electrode and public electrodes, the public electrodes on the array substrate are communicated through a public electrode connecting line, and a blocking block and a blocking groove are arranged between the public electrode connecting line and the pixel electrode. The blocking block and the blocking groove are formed according to the following steps of: forming patterns containing the blocking block on the substrate base plate formed with the grid line, the public electrodes, the grid electrode and the insulating layer by a patterning process; and forming patterns containing the blocking groove on the substrate base plate formed with the patterns by the patterning process. With the adoption of the array substrate and the method for manufacturing the same, the problem of short circuit of the pixel electrode and the public electrodes caused by material residue of the pixel electrode can be solved, and the qualified rate is improved.

Owner:BOE TECH GRP CO LTD

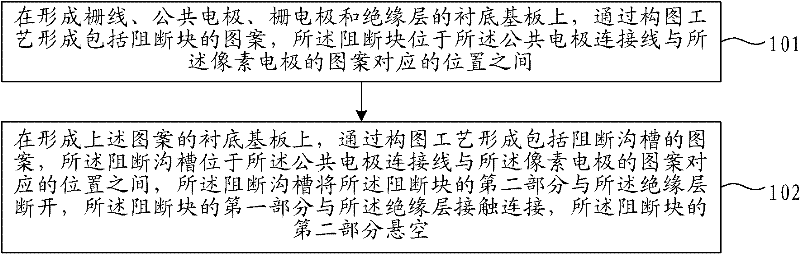

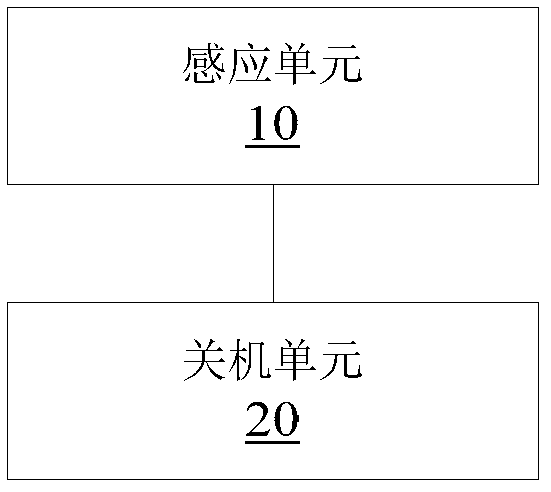

Waterproofing device

InactiveCN102724335ASolve the problem of short circuitAvoid lostFault responsePower supply for data processingEngineeringCut-off

The invention discloses a waterproofing device used in electronic equipment. The waterproofing device comprises a sensing unit and a powering off unit, wherein the sensing unit is arranged in an electronic equipment shell and is used for outputting corresponding sensing signals when sensing water permeates into the electronic equipment, and the powering off unit is used for generating a powering off signal according to the sensing signals to power off the electronic equipment. According to the invention, power supply of an electronic equipment circuit board is immediately and automatically cut off when the sensing unit senses water permeates into the electronic equipment, so that the problem that the circuit board is easily to be shorted out when water comes into the electronic equipment is solved, and an effect of avoiding losses is achieved in turn to a large extent.

Owner:ZTE CORP

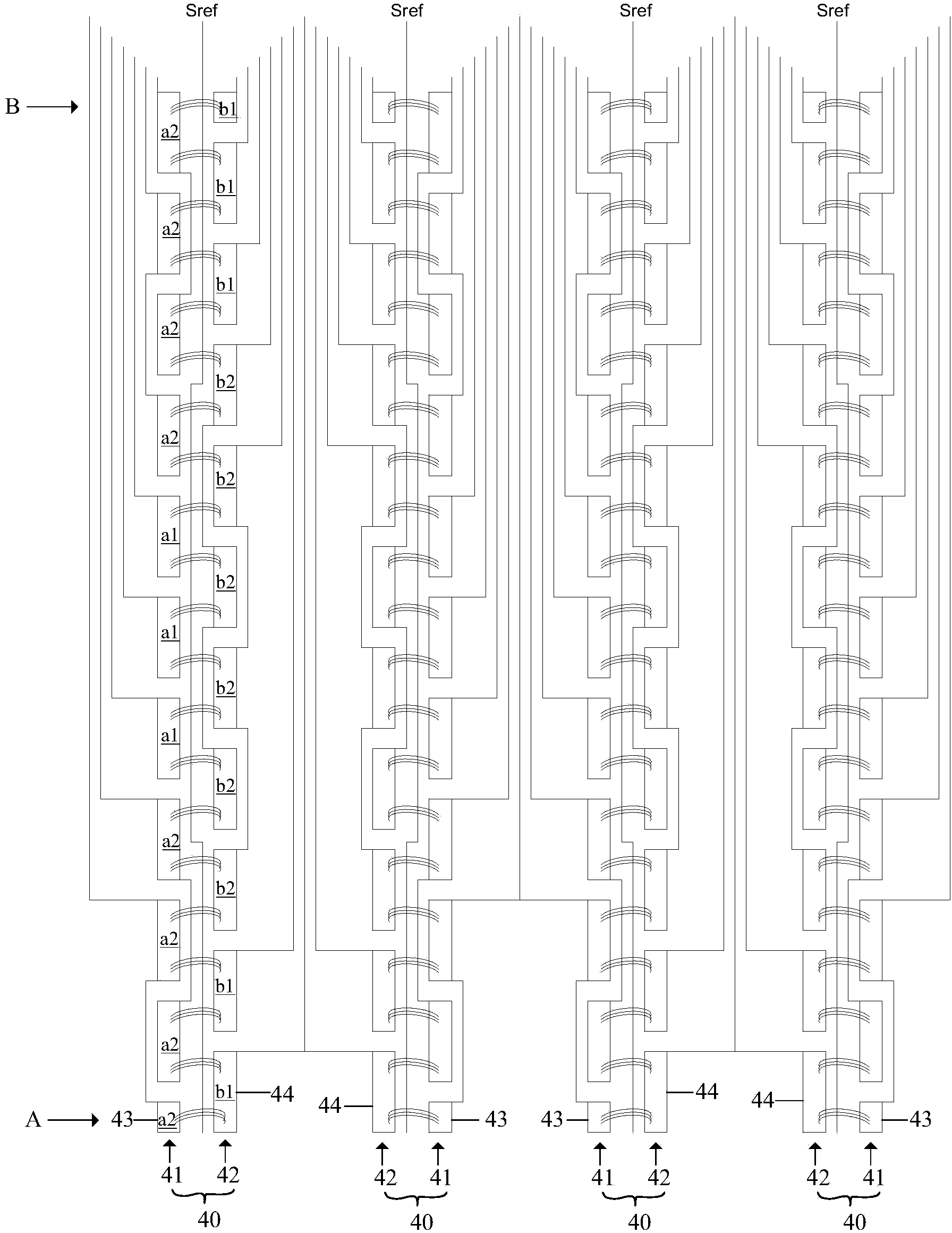

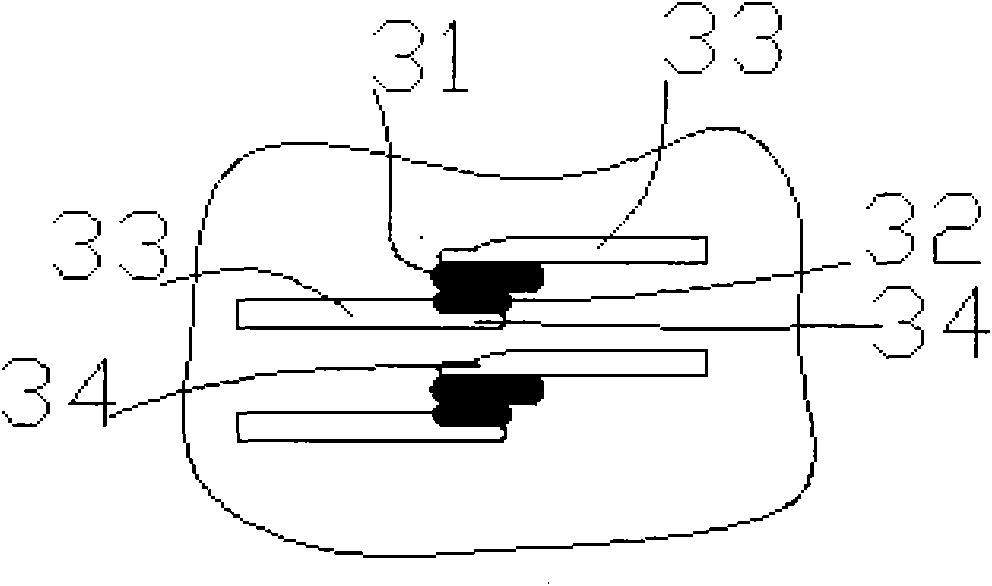

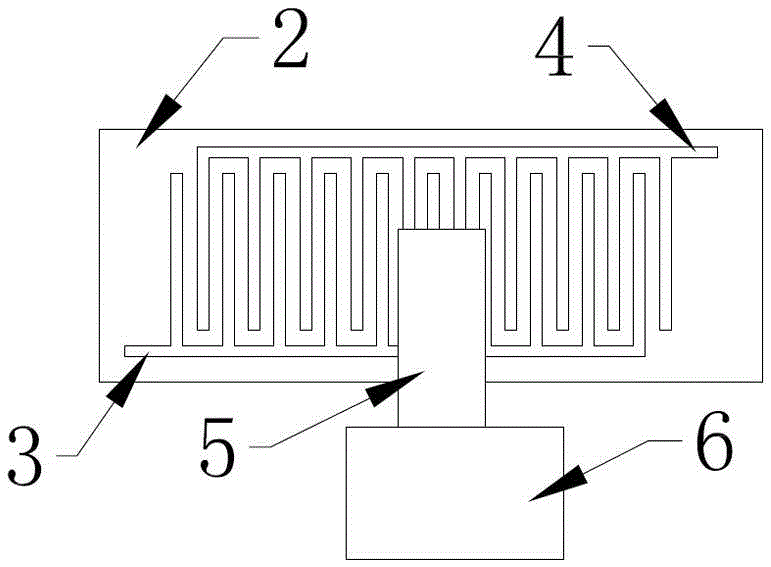

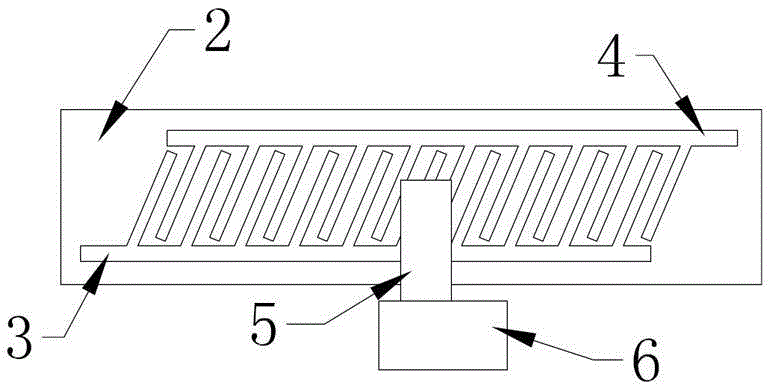

Thin-film transistor, gate driver on array (GOA) gate drive circuit, array substrate and display device

ActiveCN105140293AShort circuit will not happenAvoid short circuit problemsTransistorSolid-state devicesEtchingDisplay device

The invention discloses a thin-film transistor, a gate driver on array (GOA) gate drive circuit, an array substrate and a display device, and relates to the technical field of display. The problem of a short circuit, caused by uneven etching, between a source electrode and a drain electrode can be solved. The thin-film transistor comprises a source electrode and the drain electrode, which are arranged at the same layer and are in a comb form respectively; the source electrode is connected with a source electrode lead; the source electrode comprises a plurality of first source electrode comb tooth parts, a source electrode comb handle part and a second source electrode comb tooth part; the source electrode comb handle part is connected with the plurality of first source electrode comb tooth parts; the drain electrode comprises at least one first drain electrode comb tooth part, a drain electrode comb handle part and a second drain electrode comb tooth part; the drain electrode comb handle part is connected with the first drain electrode comb tooth part; the second source electrode comb tooth part is connected with the source electrode comb handle part and is connected with the source electrode lead; the second drain electrode comb tooth part is located between the second source electrode comb tooth part and the first source electrode comb tooth part close to the second source electrode comb tooth part; and the second drain electrode comb tooth part is not connected with the drain electrode comb handle part. The thin-film transistor disclosed by the invention can be applied to the array substrate.

Owner:BOE TECH GRP CO LTD +1

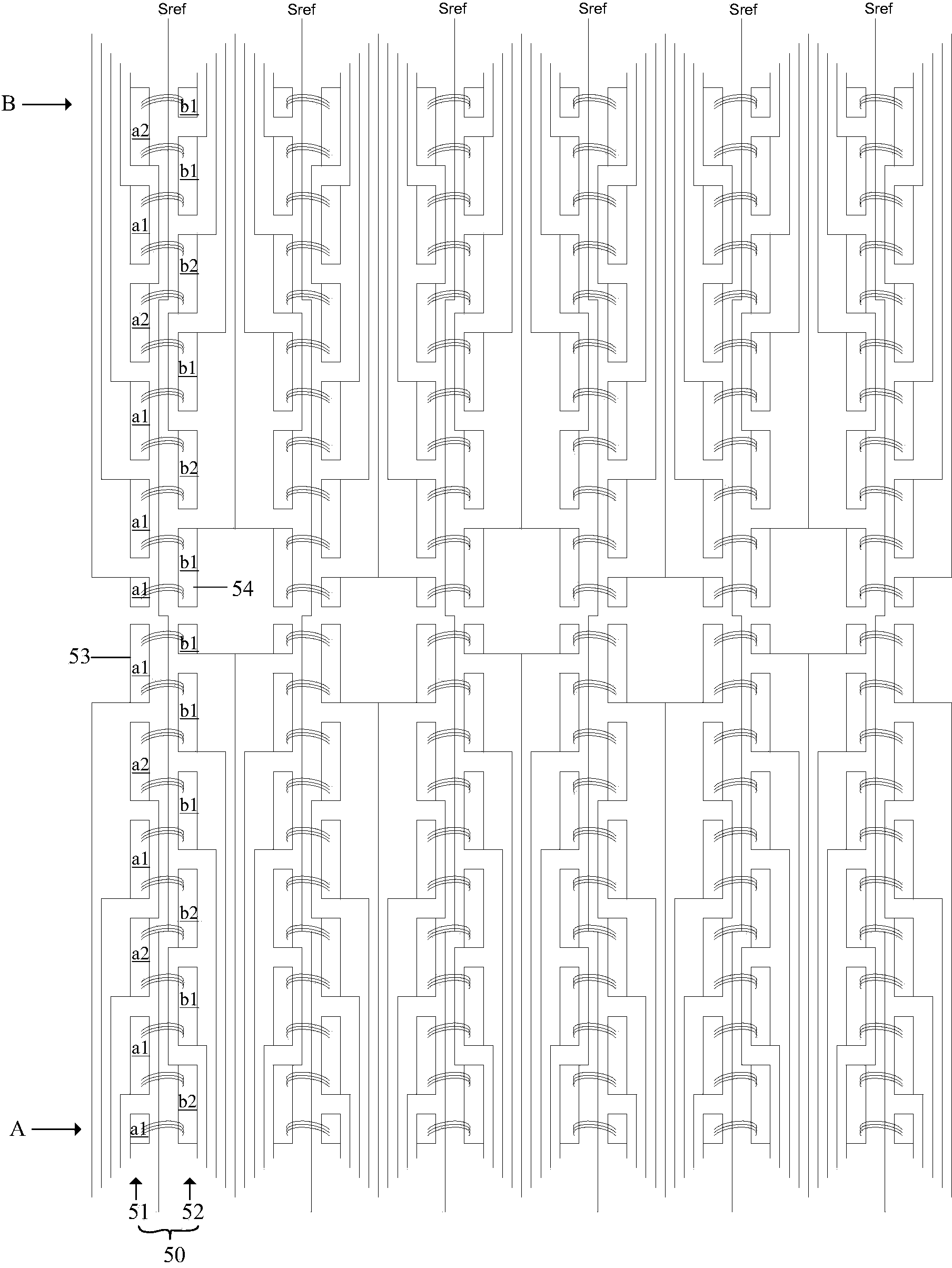

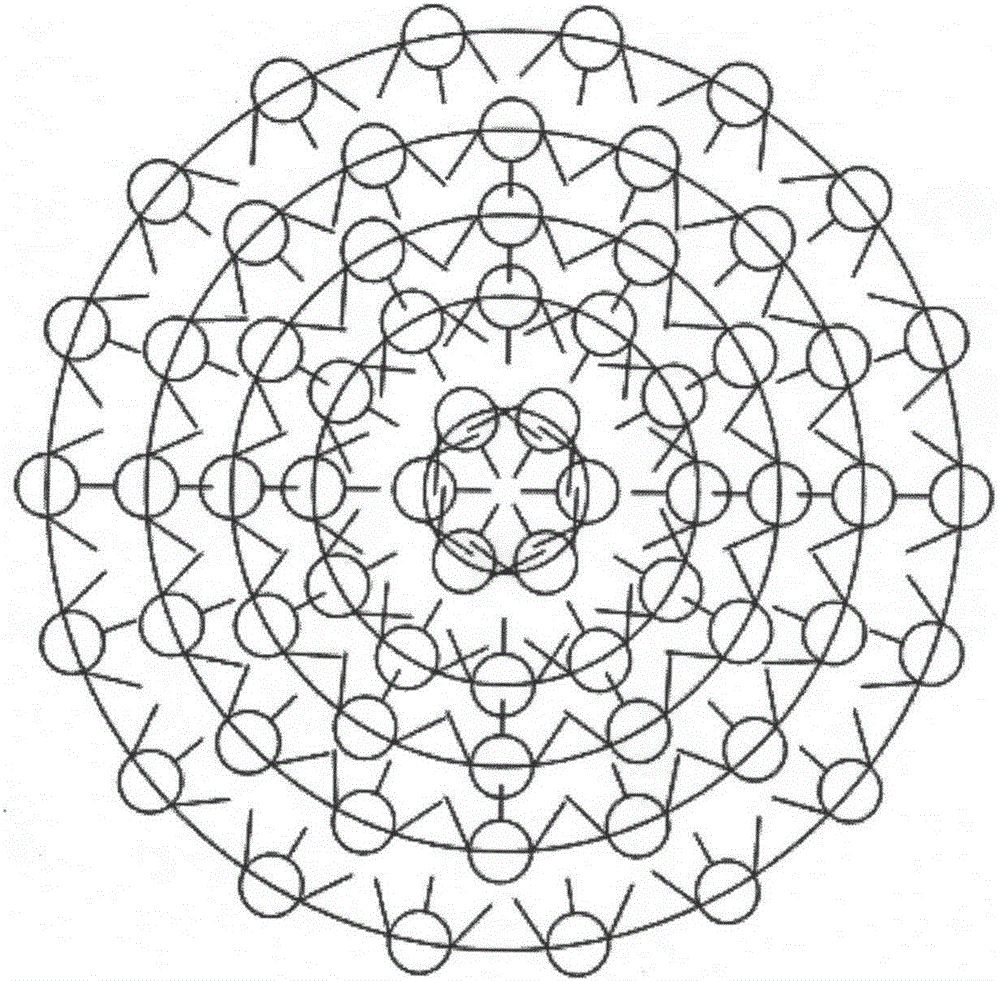

Single-layer multi-point capacitive touch screen

ActiveCN103793121AImprove production yieldSolve the short circuit of adjacent lead wiresInput/output processes for data processingPhysicsCapacitance

A single-layer multi-point capacitive touch screen comprises multiple electrode units, wherein each electrode unit comprises multiple first electrodes and multiple second electrodes. In at least one electrode unit, each first electrode of at least one part of first electrodes corresponds to at least two second electrodes. The first electrodes and the second electrodes comprise two types of electrodes. The first-type first electrodes and the first-type second electrodes are independent and are not connected. The second-type first electrodes and the second-type second electrodes are respectively connected at least one of the other second-type first electrodes and the other second-type second electrodes, and the second-type first electrodes and the second-type second electrodes which are connected are not adjacent. The connected second-type first electrodes do not correspond to the same-type first electrodes, and the connected second-type second electrodes do not correspond to the same-type first electrodes. In addition, the connected second-type first electrodes and the connected second-type second electrodes are not provided with corresponding portions, or only one of the connected second-type first electrodes is in one-to-one correspondence with one of the connected second-type second electrodes. The touch screen production yield is improved.

Owner:ORISE TECHNOLOGY CO LTD

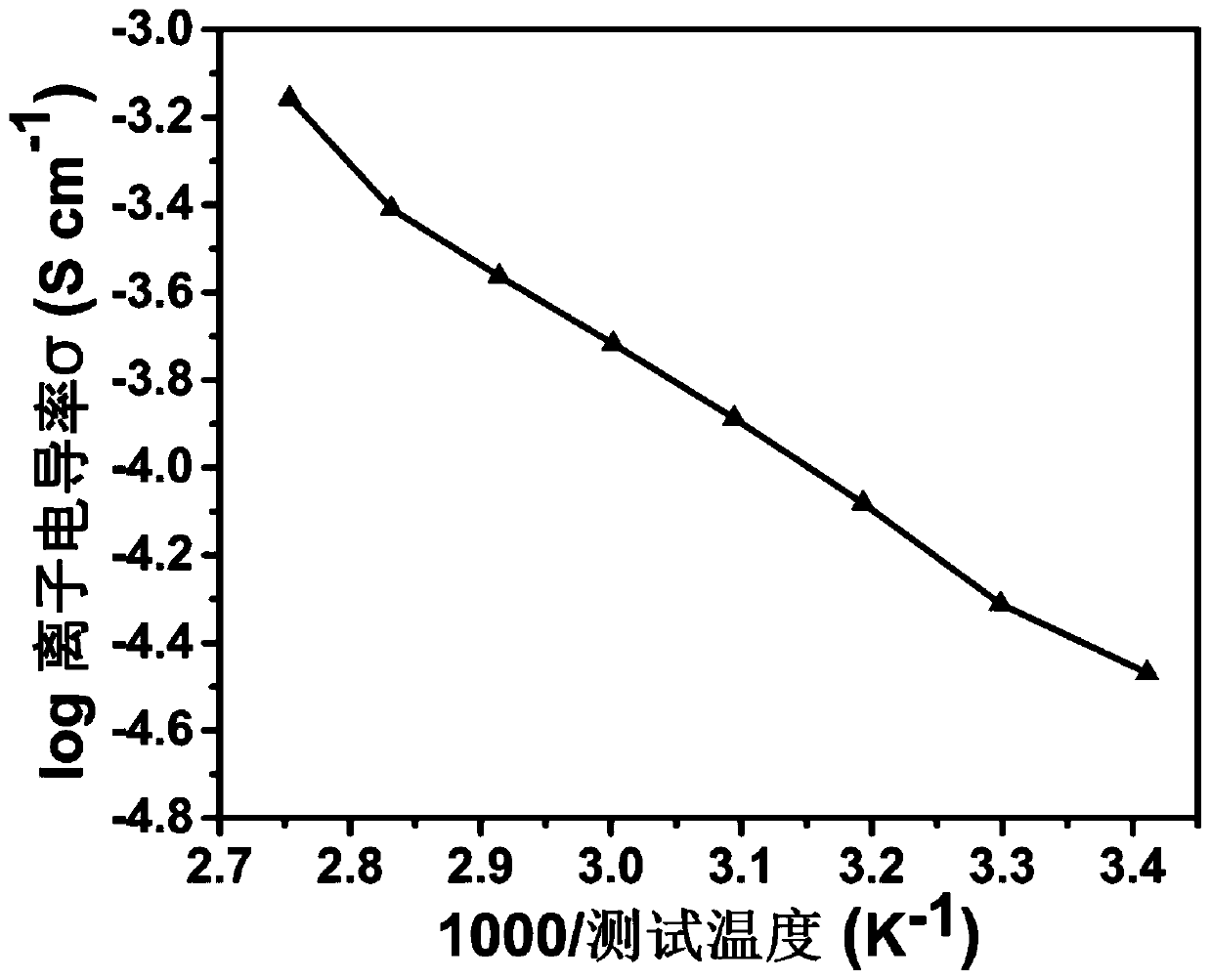

Self-healing composite polymer electrolyte and preparation thereof, and application thereof

InactiveCN110148780AImprove electrochemical performanceGrowth inhibitionSecondary cellsSilica nanoparticlesSelf-healing

The invention belongs to the technical field of polymer electrolytes and discloses a self-healing composite polymer electrolyte, preparation thereof, and application thereof. The polymer electrolyte is mainly formed by the composition of surface-functionalized nanoparticles and a self-healing polymer matrix with the mass ratio of 1 / 49 to 2 / 5. According to the invention, by improving the composition of key composite components in a composite polymer electrolyte, an overall corresponding microstructure of the composite and the design of the overall process flow of the preparation method, the self-healing composite polymer electrolyte with excellent performance can be obtained by using a supramolecular network constructed by UPy functionalized silica nanoparticles and the self-healing polymermatrix, compared with the prior art, the dispersion of the nanoparticles in the matrix is better, and the electrochemical performance, mechanical performance, self-healing efficiency of the composite polymer electrolyte can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

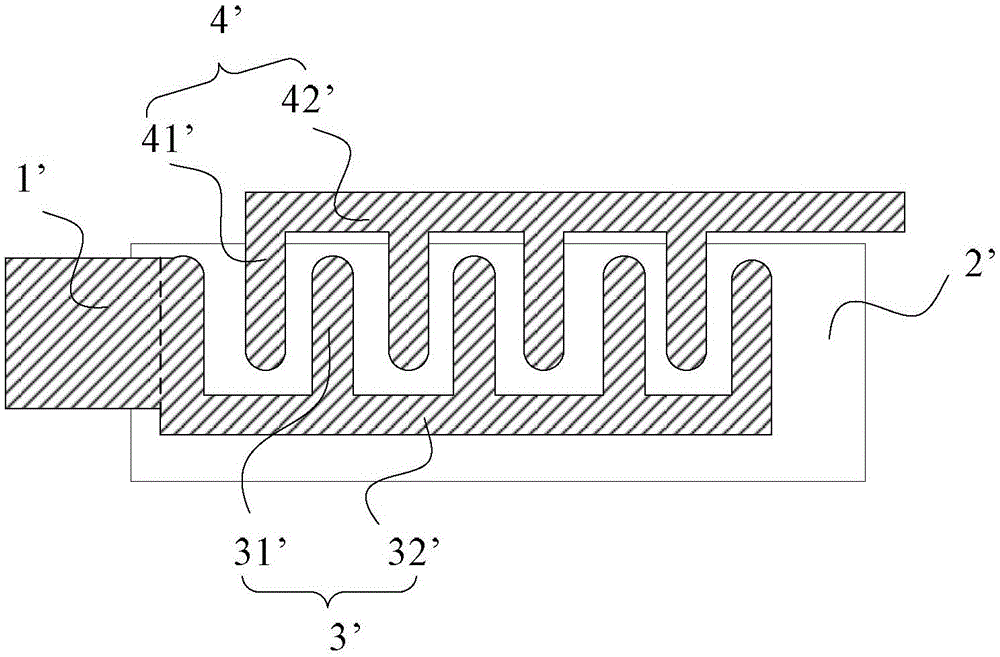

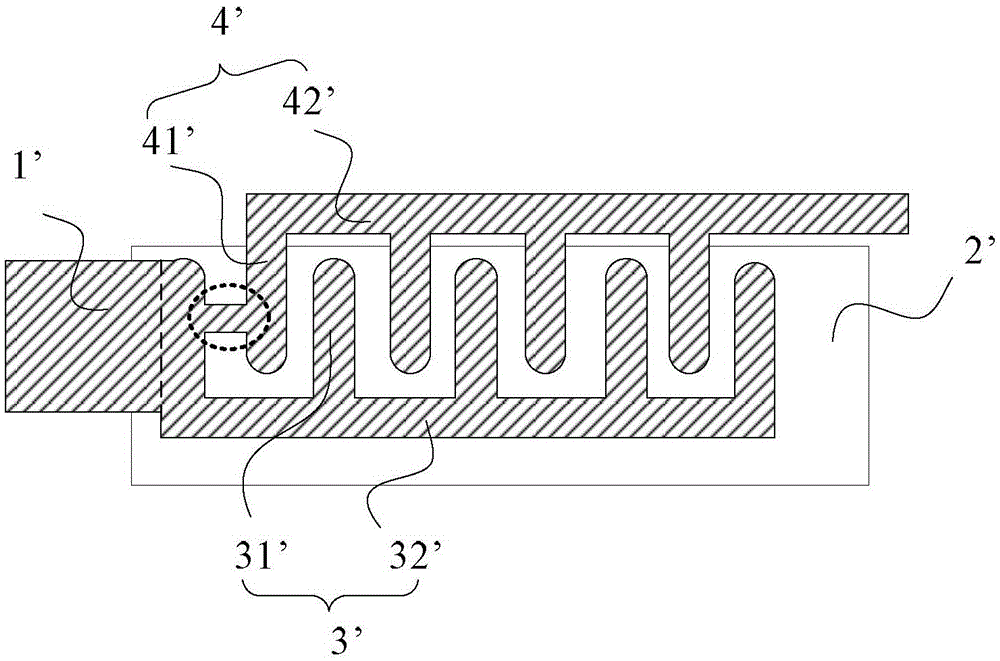

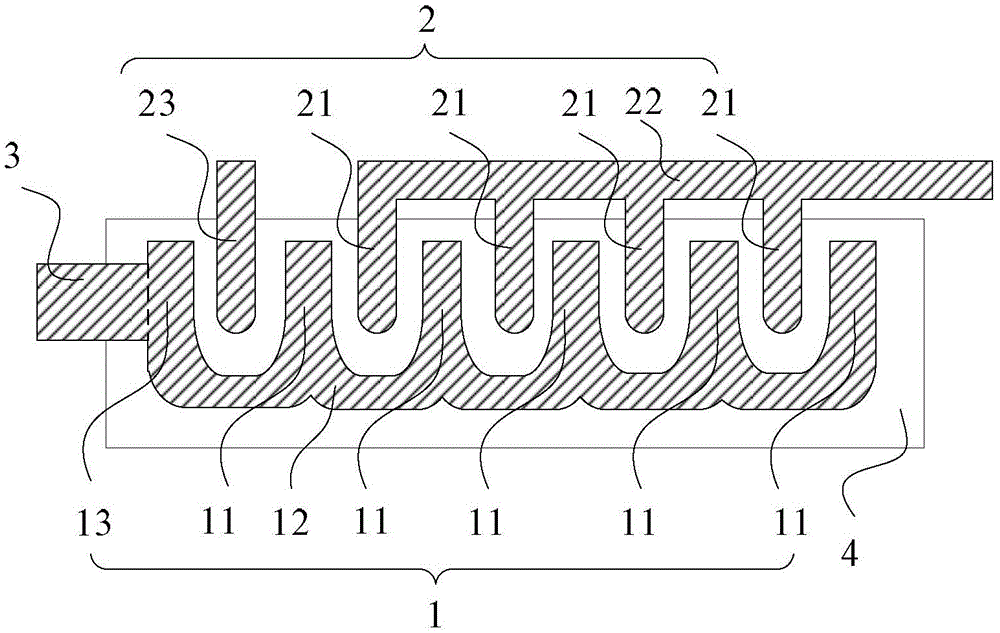

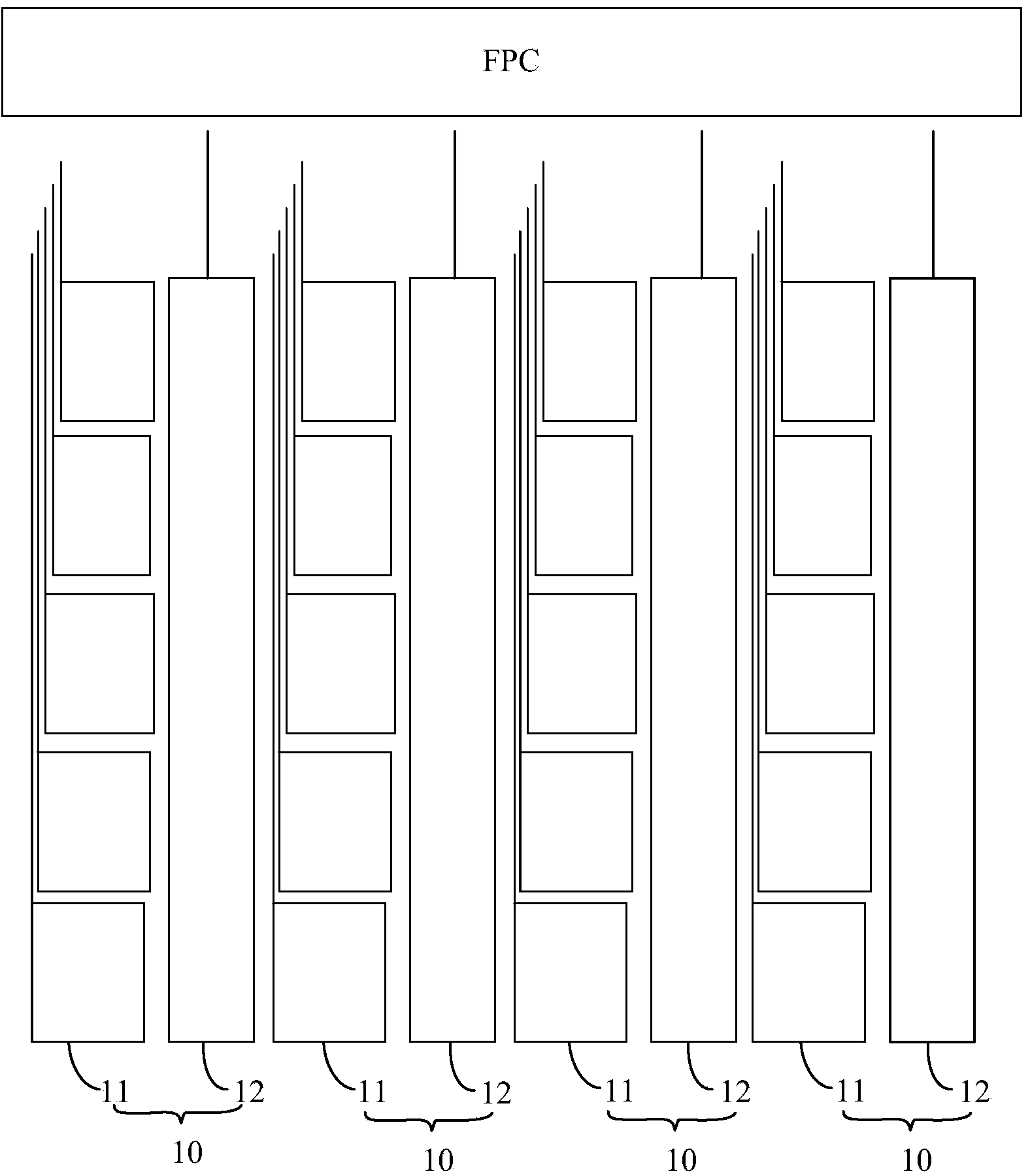

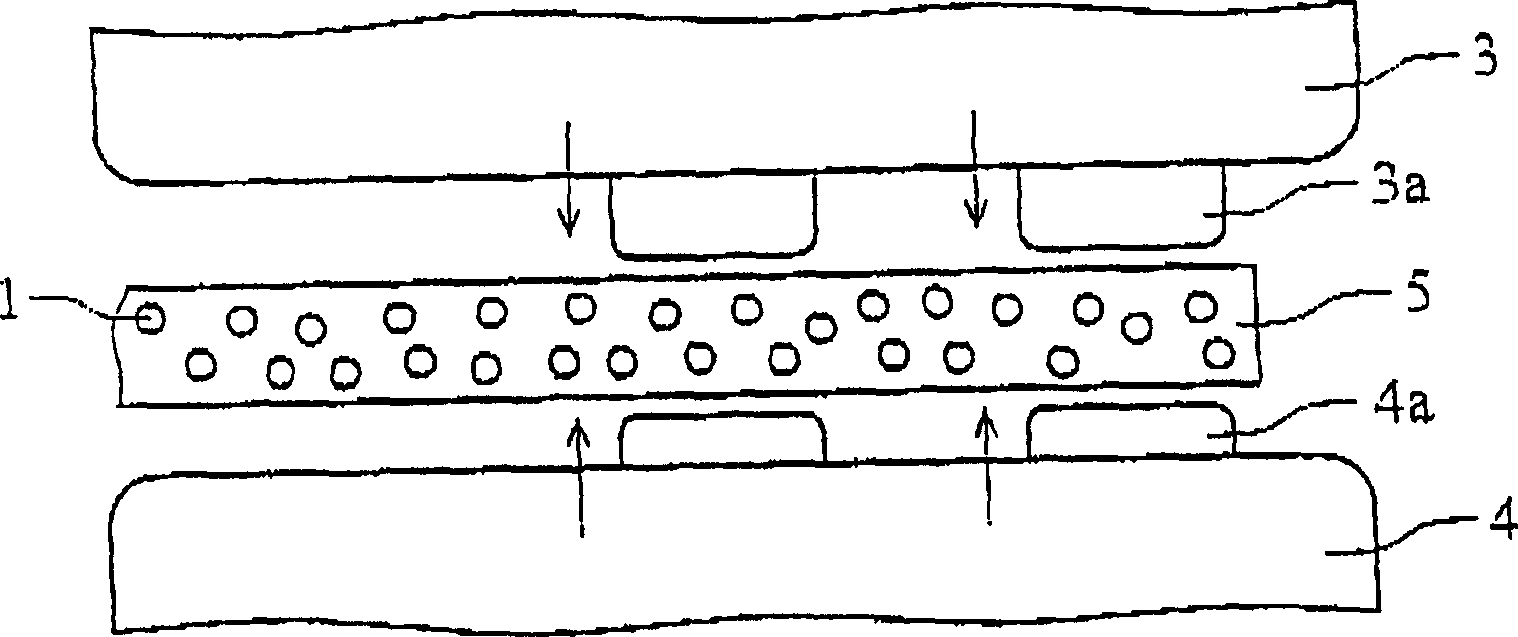

Coil electric conductor device and manufacture method thereof

ActiveCN101834050AReduces the possibility of short circuitsIncrease connection areaPrinted electric component incorporationCoils manufactureTip positionElectrical conductor

The invention provides a coil electric conductor device and a manufacture method thereof. The method comprises the following steps of: a lower leading-out end step, a coil conductor step, a casting step and an upper leading-out end step, wherein the coil conductor step comprises a connection point step: printing a coil conductor, wherein cavities can be generated at the tip position of a lower leading-out end and the middle position of the tip position of the coil conductor if the thickness of the tip position of the coil conductor is less than that of the middle part of the coil conductor; drying again; printing first connection points at the positions of the cavities; then casting a layer of ferrite pulp film; and printing second connection points the area of which is larger than that of the first connection points on the first connection points after the ferrite pulp film is dried; in the casting step, casting a layer of ferrite pulp film, and exposing the second connection points out of the ferrite pulp film; drying, and then repeating the coil conductor step, the connection point step and the casting step on the ferrite pulp film for several times so as to form the coil conductor.

Owner:SHENZHEN SUNLORD ELECTRONICS

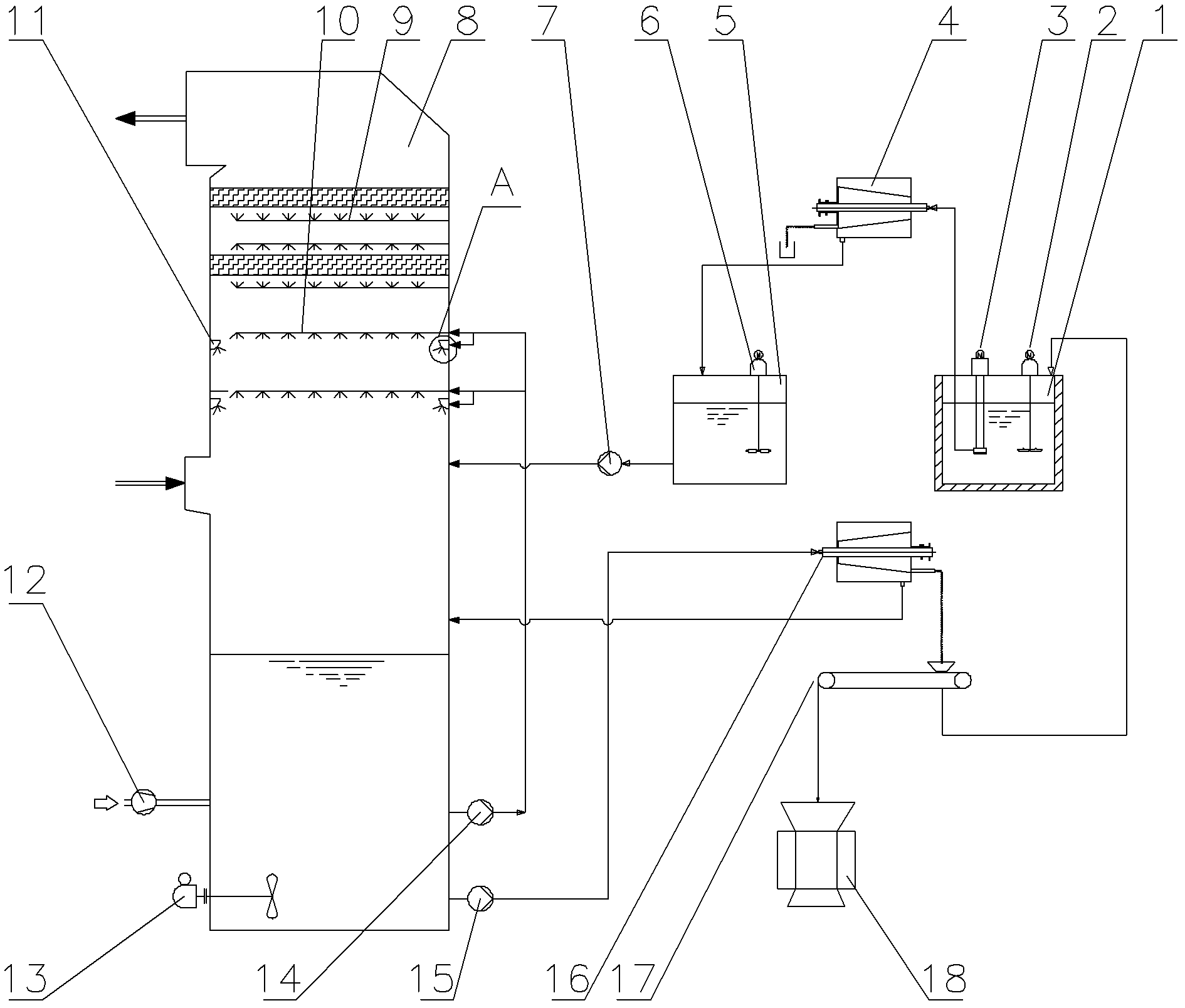

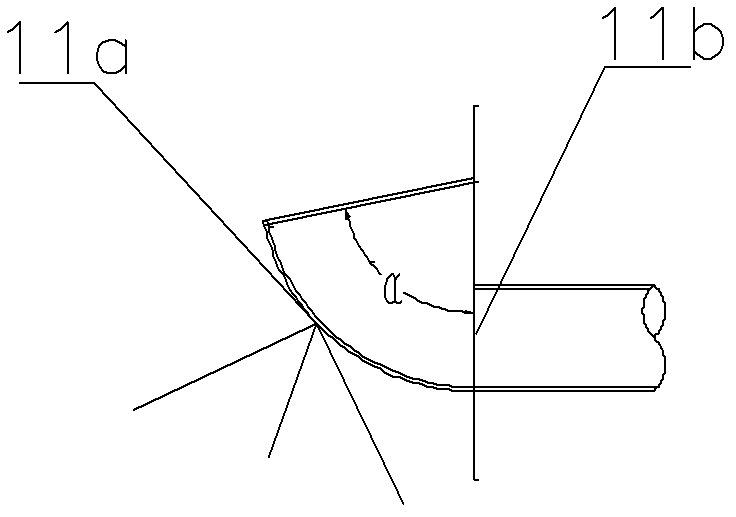

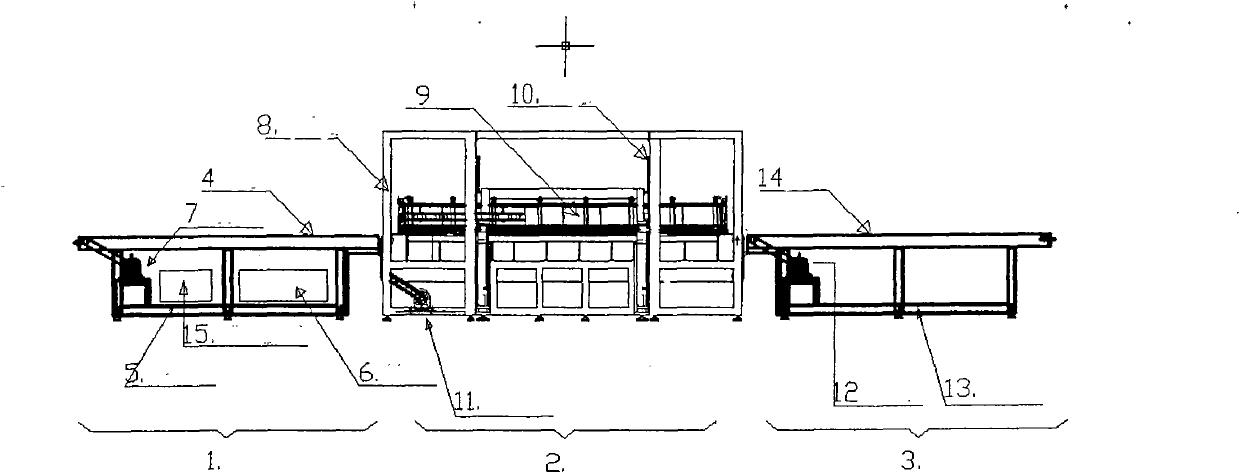

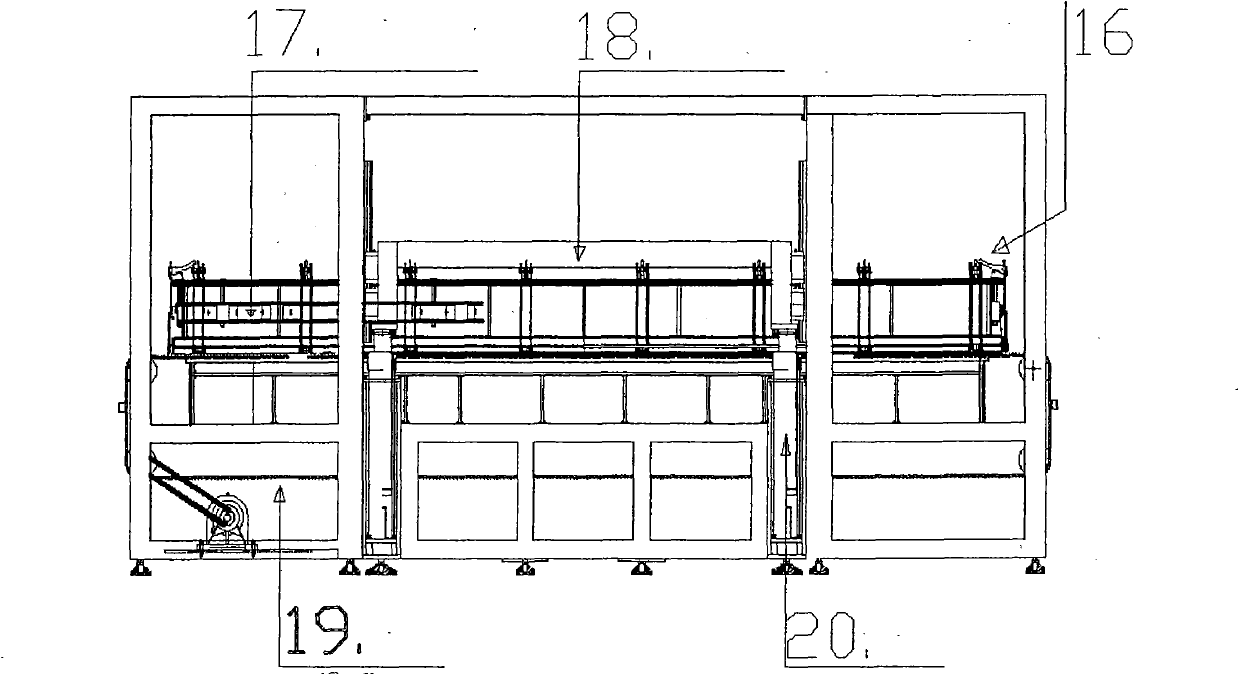

Equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag

ActiveCN102500223ASolve the problem of "short circuit"Easy to combSolid waste disposalDispersed particle separationCycloneSlag

The invention discloses equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag. The equipment mainly comprises a wet-method flue gas desulfurization part, a carbide slag pretreatment part and a gypsum slurry retreatment part, wherein a hollow annular boss with a slurry spray nozzle is arranged below a slurry spray layer and on the inner wall of a spray tower cylinder body of the wet-method flue gas desulfurization part, so that the problem of flue gas 'short circuit' in the spray tower cylinder body is solved; according to the carbide slag pretreatment part, the problem of the stoppage of a filter layer in the process of separating the carbide slag slurry is solved by the design of a first rotation separator with a cleaning function; and according to the gypsum slurry retreatment part, an expensive cyclone separator in the conventional gypsum separation equipment is replaced effectively by the design of a second rotation separator with the cleaning function. According to the equipment, the flue gas desulfurization of fire coal, the comprehensive utilization of the discarded carbide slag and the processing of the gypsum serving as a desulfurization byproduct are integrated organically, and the equipment has a simple structure, is stable in running and high in desulfurization efficiency, treats wastes with the wastes and meets the requirement of current environment friendliness.

Owner:WUHAN YONGQING ENVIRONMENTAL PROTECTION TECH ENG

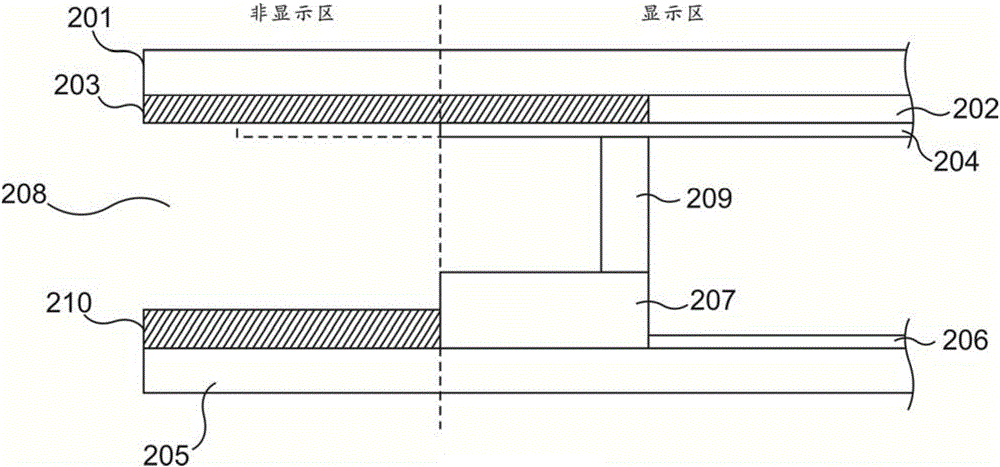

Liquid crystal display panel and liquid crystal display

ActiveCN106647054ASolve the problem of short circuitSolve the problem of light leakageNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display panel. A common electrode is arranged in the manner of being kept away from a projection area formed by projecting metal wires onto a color film substrate, and the intersection area of the common electrode and a projection formed by projecting the metal wires in a non-display area of the array substrate onto the color film substrate is removed through laser cutting. The liquid crystal display panel has the advantages that compared with an existing liquid crystal display panel, the problem that due to conducting particles generated between a common electrode of a liquid crystal display panel and metal wires in a non-display area because of the manufacturing process, short-circuiting occurs can be solved, meanwhile, the technical problem that due to the arrangement of spacing pillars in a non-display area of an array substrate, light leakage or color cast occurs at the boundary of a display area can be solved, and thus better display quality is obtained.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

J-shaped entrained-flow gasifier

ActiveCN105779014ASolve the problem of short circuitImprove conversion rateGasifier mechanical detailsGranular/pulverulent flues gasificationSyngasThermal energy

The invention discloses a J-shaped entrained-flow gasifier. The J-shaped entrained-flow gasifier is characterized in that the gasifier has a J-shaped design, a slag-drip opening is formed in the lowest point at the bent position of the J-shaped gasifier, and a slag collection chamber is formed in the lower part of the slag-drip opening; a gasifying raw material inlet is formed in the higher side of the J-shaped gasifier, and a synthesized gas outlet is formed in the lower side of the J-shaped gasifier. According to the entrained-flow gasifier, the gasifier is designed into J shape, flying gas carried in synthesized gas is collected by the wall surface of the bent position, so that the carbon conversion rate can be effectively improved, and the ash carrying capacity at the synthesized gas outlet can be reduced; and slag bonding and ash accumulation can be prevented when heat of a synthesized gas is reclaimed by a radiant syngas cooler and a convective syngas cooler. The slag-drip opening is close to the high-temperature region of the gasifier, so that the temperature of the slag-drip opening is higher, and smooth slag drip can be ensured.

Owner:SHANGHAI BOILER WORKS

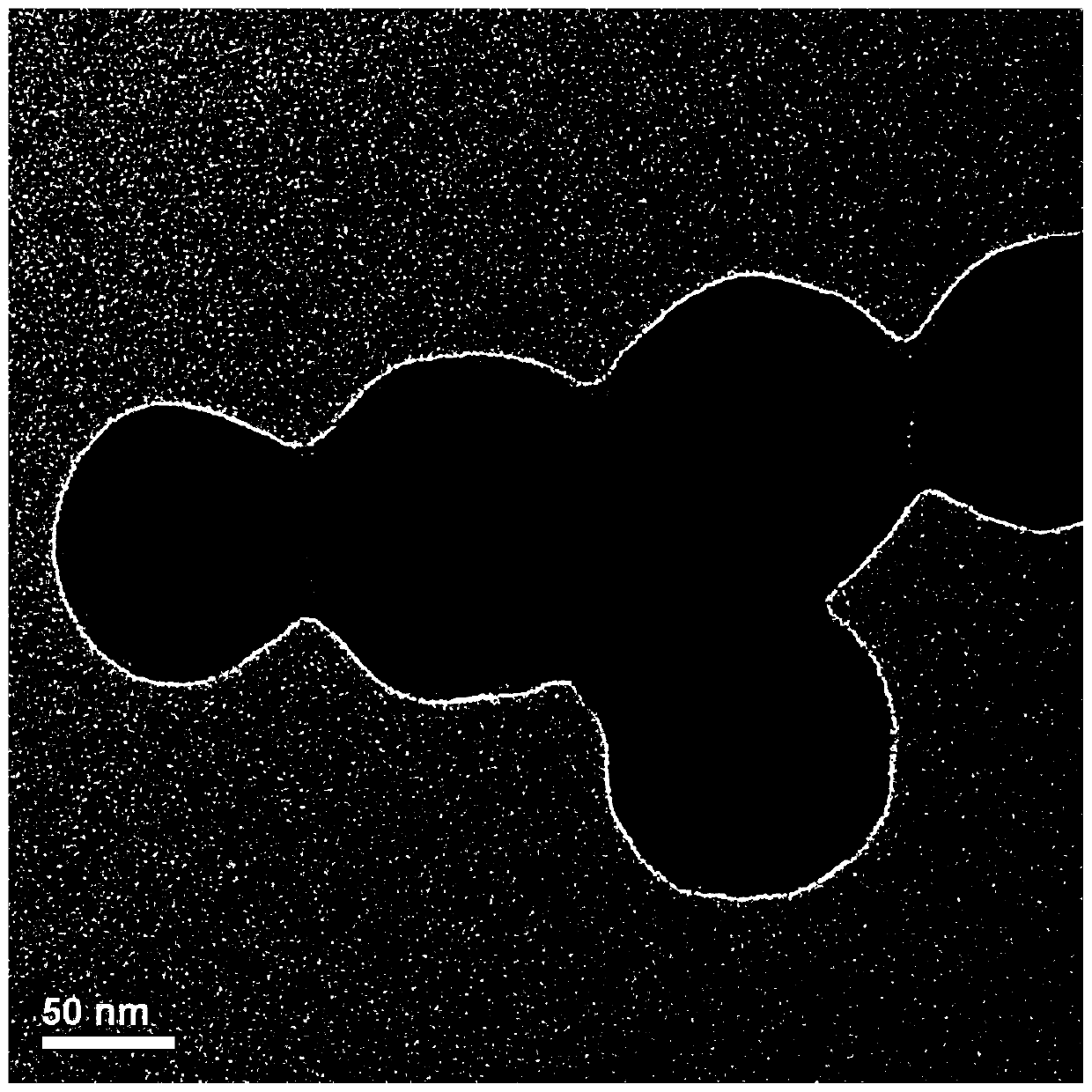

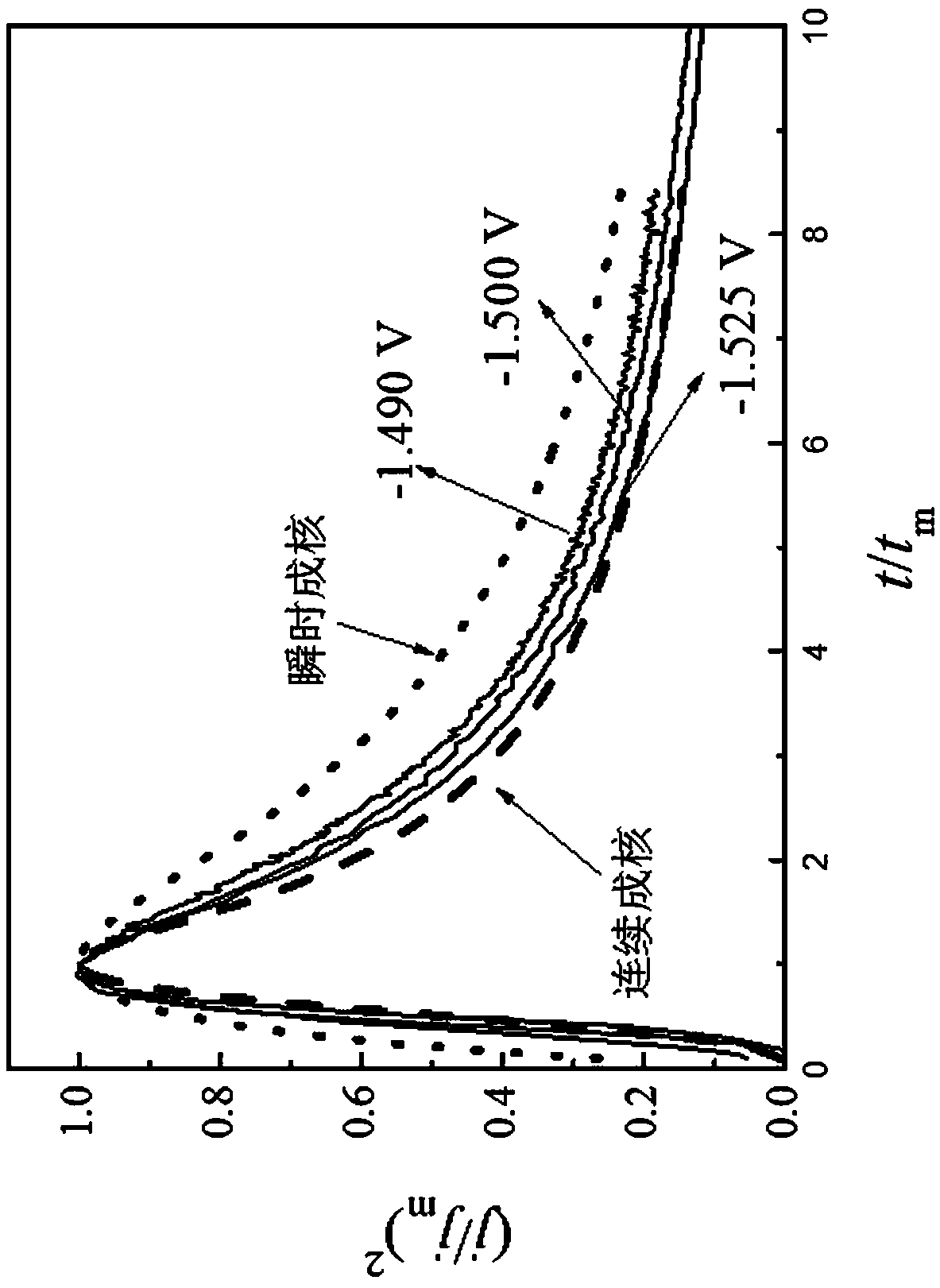

Uranium-bearing low-temperature molten salt system, preparation method thereof and application of system

ActiveCN107779615AReduce water contentLow oxygenNuclear energy generationReactor fuel susbtancesMolten saltEngineering

The invention discloses a uranium-bearing low-temperature molten salt system, a preparation method thereof and an application of the system to the field of electrolytic preparation of metallic uranium, and aims to solve the problems that in current spent fuel dry reprocessing, an LiCl-KCl-UCl3 molten salt system within the temperature range of 400-500 DEG C is usually adopted, uranium is refined by molten salt electrolysis to generate structurally loose dendritic metallic uranium, short circuit of an electrolytic tank is easily caused, and large-scale continuous production cannot be realized.The metallic uranium electrolytically prepared by the uranium-bearing low-temperature molten salt system is high in purity and compact in structure and in the shape of a nodule (but the metallic uranium prepared by the LiCl-KCl-UCl3 molten salt system is structurally loose and dendritic and has essential difference from the metallic uranium electrolytically prepared by the uranium-bearing low-temperature molten salt system), and the electrolytic refining process is safe and controllable, can be applied to development of industrial spent fuel dry reprocessing technology to meet the requirementsof Chinese industrial continuous production of high-purity metallic uranium, and has a good application prospect. Further, the uranium-bearing low-temperature molten salt system is simple in production process, low in equipment and experimental condition requirement, low in energy consumption and pollution, has a good application prospect and is worthy of large-scale popularization and application.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

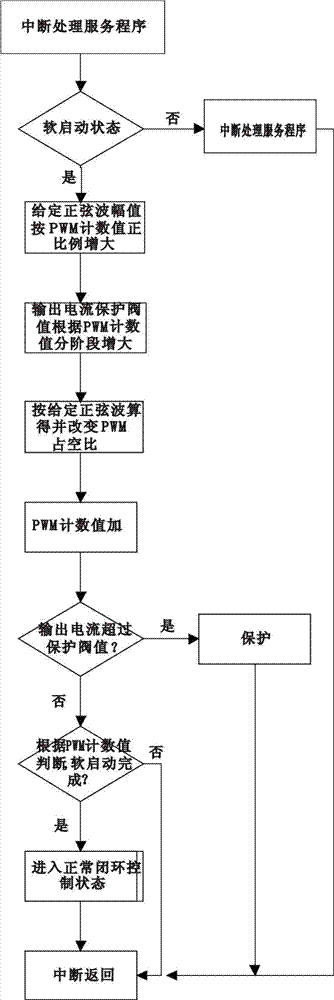

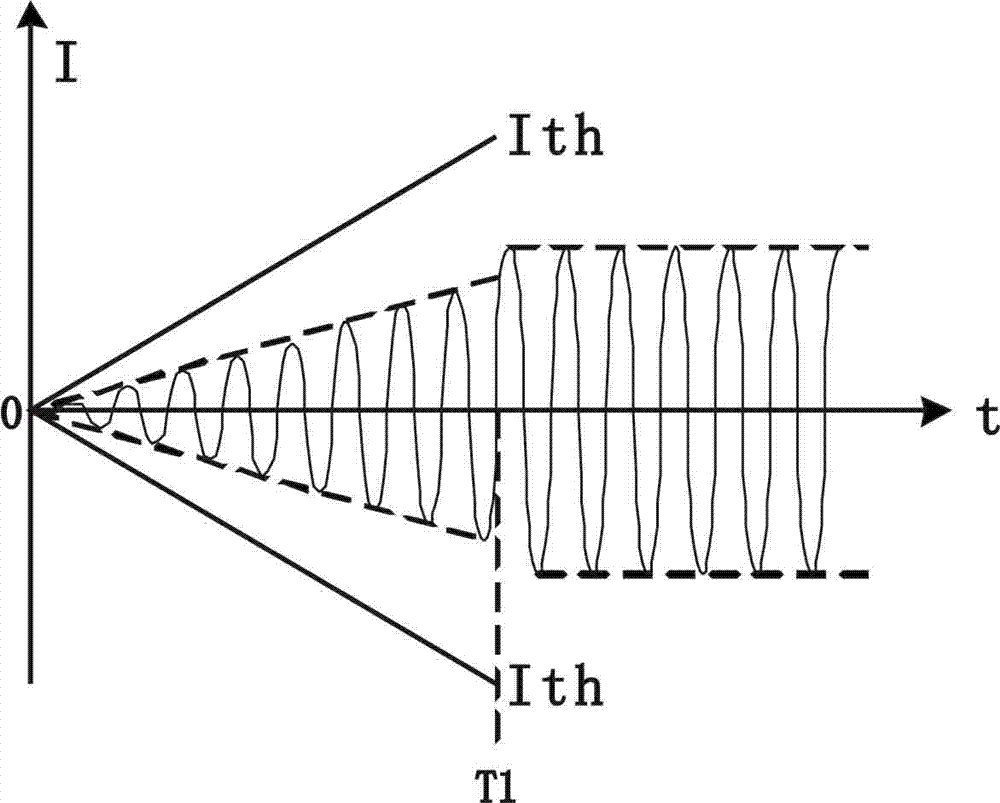

Software protecting method for start short circuit of off-line inverter

ActiveCN103683893AAvoid damageSolve the problem of short circuitEmergency protective circuit arrangementsPower conversion systemsPower inverterLoop control

The invention discloses a software protecting method for start short circuit of an off-line inverter. When the inverter is started, a PMW (Pulse-Width Modulation) duty ratio is set to be zero, PWM output is enabled, a PWM counting value is set to be zero, and a given sine wave amplitude value is set to be zero by software in an open-loop control way; in a start process, the change of the given sine wave amplitude value is controlled by the software to gradually increase the given sine wave amplitude value; the software judges whether the start process is in the last period of open-loop adjustment control or not according to the PWM counting value, when the open-loop adjustment control is at a zero-over point of the last period, the software switches the inversion output from the open-loop control way to a close-loop control way, and voltage is quickly adjusted to be stable at a rated value. By the software protecting method for start short circuit of the off-line inverter, at the start or in the start process, current can be prevented from being increased suddenly in case of short circuit, so that a power pipe is prevented from being damaged by over current, and the aim of protecting a power apparatus is fulfilled.

Owner:HUIZHOU TEN SOURCES SOLAR ELECTRICITY

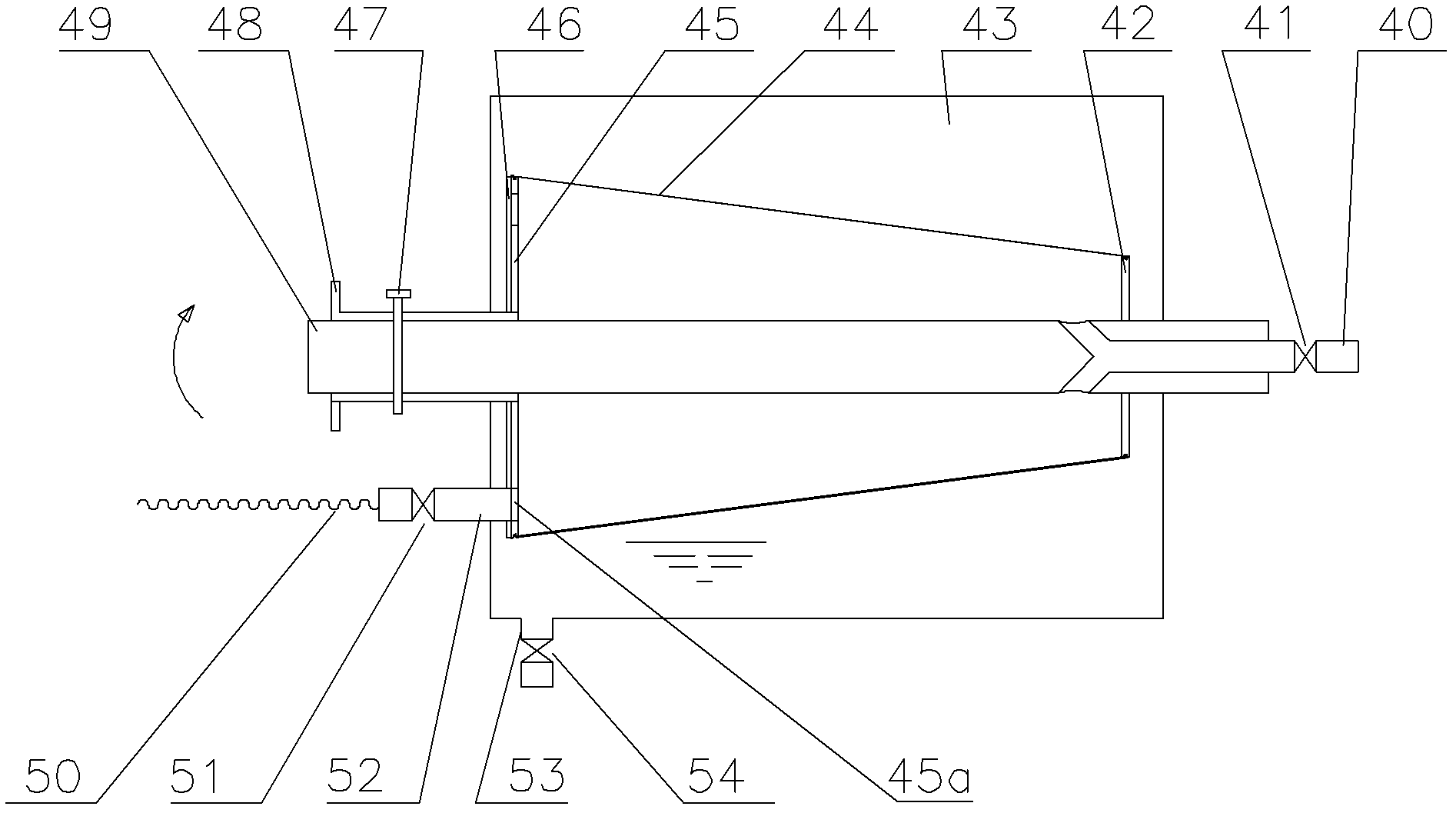

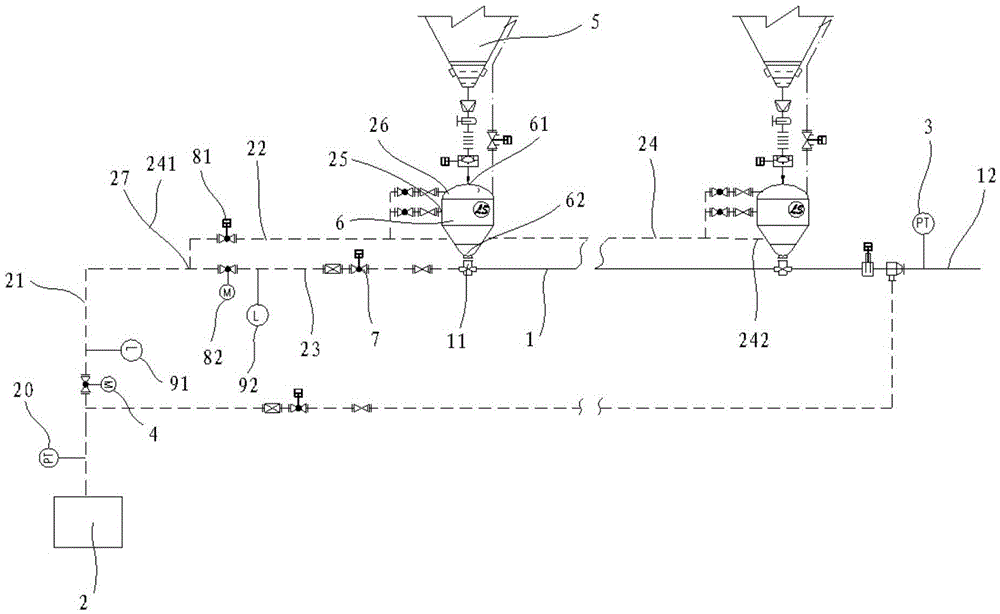

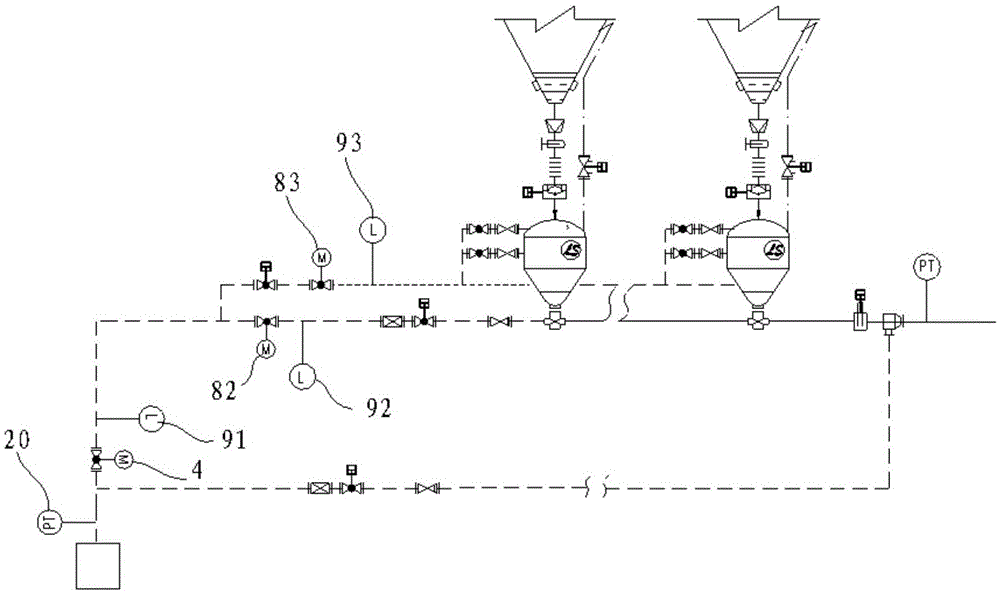

Pneumatic conveying device and auxiliary pipeline control system of pneumatic conveying device

The invention discloses a pneumatic conveying device which comprises a conveying pipeline, an air feeding device, a material way pressure detecting device, a main flow adjusting device and an intelligent control system, wherein the conveying pipeline is provided with a material falling inlet, the air feeding device is used for introducing compressed air into the conveying pipeline so that materials can fall into the conveying pipeline, the material way pressure detecting device is arranged on the portion, close to the downstream portion of a material falling inlet of the air feeding device, of the conveying pipeline, and the intelligent control system is used for controlling adjustment of the main flow adjusting device according to the material way pressure detected by the material way pressure detecting device. An auxiliary pipeline control system of the pneumatic conveying device comprises a flow detecting device, a flow adjusting device and a controller, wherein the flow detecting device is used for detecting real-time air flow of the auxiliary pipeline, the flow adjusting device is used for adjusting the air flow of the auxiliary pipeline, and the controller comprises a receiving unit, a comparing unit and a processing unit. By the adoption of the pneumatic conveying device and the auxiliary pipeline control system of the pneumatic conveying device, the pressure of a material way mixed with the materials can be directly detected, measuring results and flow adjustment are more accurate, and the utilization rate of a fluidization nozzle and a pressurization nozzle is increased.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

A kind of underground coal gasification system and process with retreating gas injection point

InactiveCN103277082BImplement fixed-point injectionImprove stabilityConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

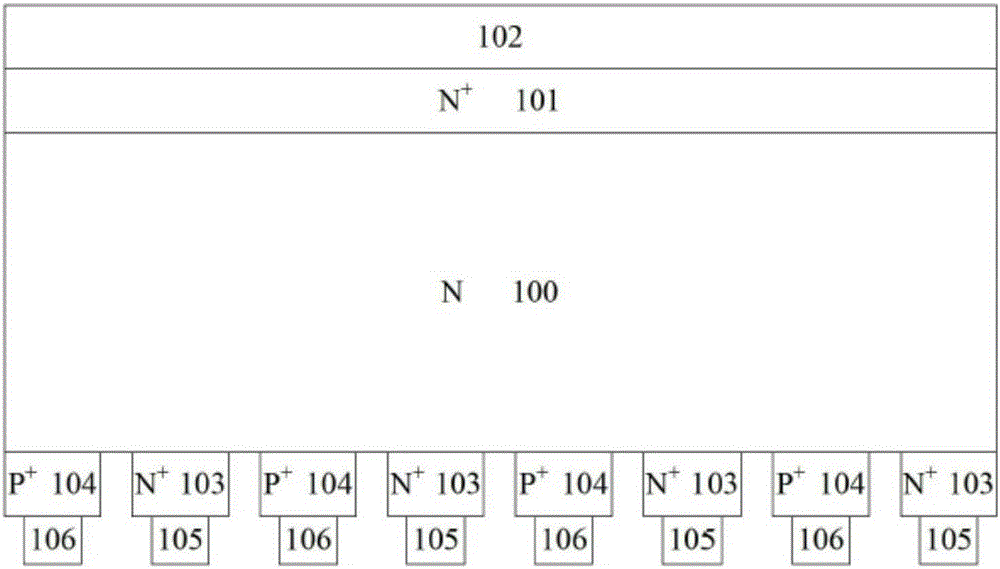

Back-contact solar cell and preparation method

ActiveCN105185849AImprove stabilitySolve the problem of printing biasFinal product manufacturePhotovoltaic energy generationSlurrySolar cell

The invention provides a back-contact solar cell and a preparation method. The back-contact solar cell comprises a silicon wafer substrate. The back side of the silicon wafer substrate is provided with an N+ first conductive area and a P+ second conductive area with an interval. The N+ first conductive area is provided with a first electrode, and the P+ second conductive area is provided with a second electrode. An isolation area is arranged between the N+ first conductive area and the P+ second conductive area. The top surfaces of the first electrode and the second electrode are on the same horizontal plane, and the top surface of the isolation area is higher than that of the first electrode and the second electrode. According to the back-contact solar cell, through arranging the isolation area between the N+ first conductive area and the P+ second conductive area, the electrodes are lower than the isolation area, the problem of electrode offset printing is solved well, the problem of positive electrode and negative electrode short circuit caused by metal slurry offset is solved, and the stability of the cell is improved greatly.

Owner:CSI CELLS CO LTD +1

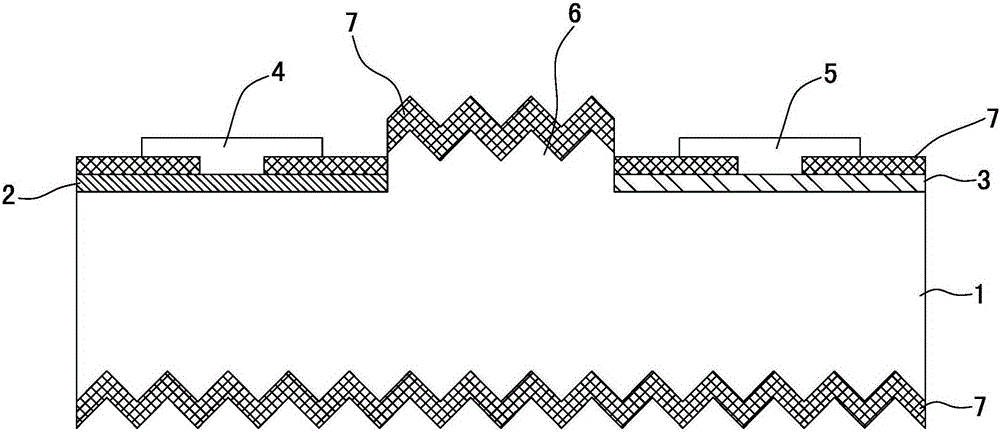

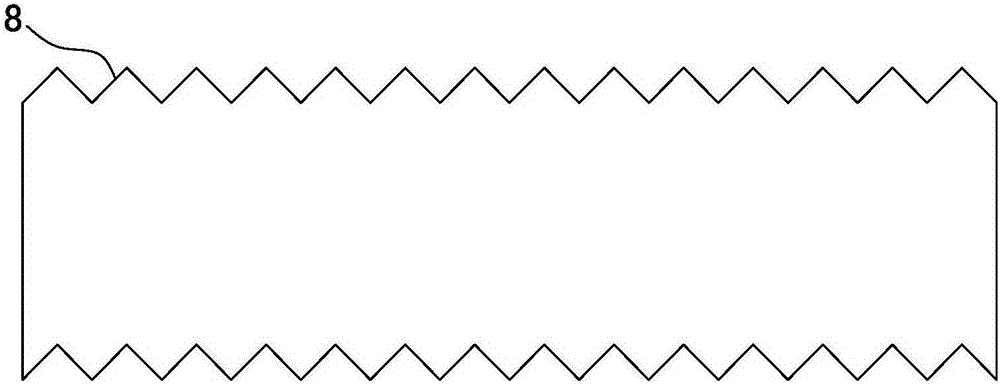

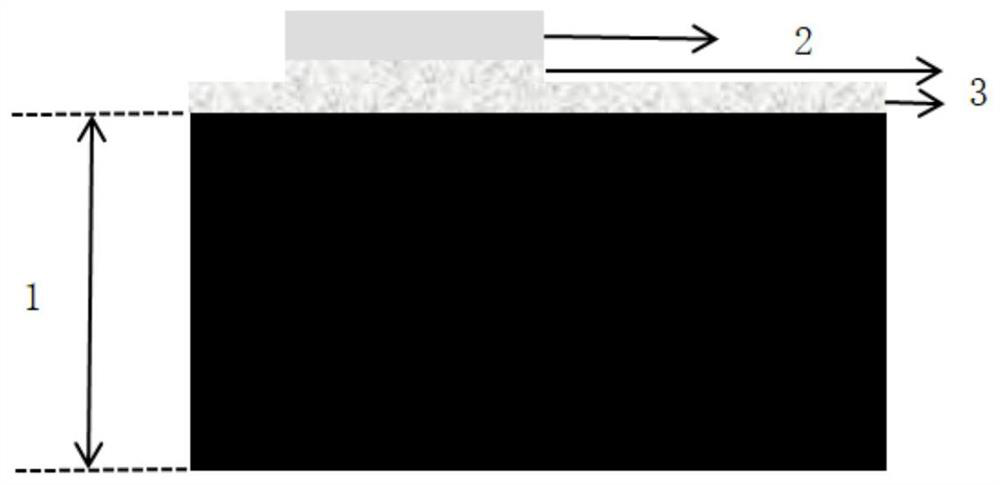

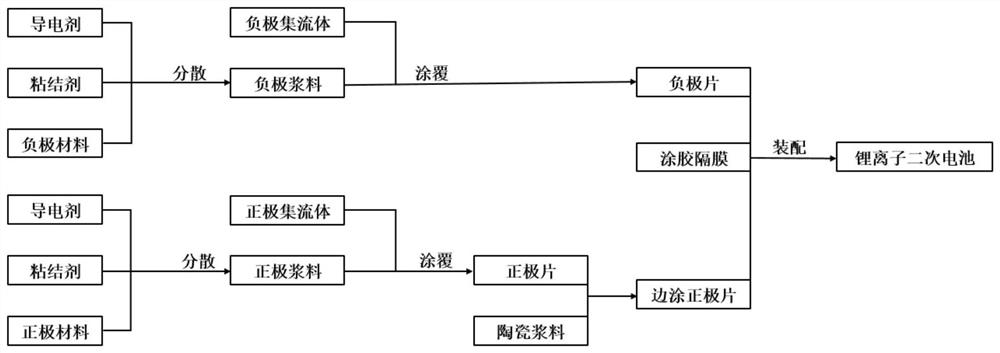

Oily ceramic slurry, preparation method thereof, positive plate coated with slurry and lithium ion battery

InactiveCN112397716ASolve the problem of short circuitIncrease energy densityPositive electrodesSecondary cells servicing/maintenancePolyolefinCeramic coating

The invention discloses oily ceramic slurry, a preparation method of the oily ceramic slurry, a positive plate coated with the slurry and a lithium ion battery. The oily ceramic slurry comprises the following raw material components: a first binder, a second binder, ceramic powder and an organic solvent; wherein the first binder comprises a mixture of at least two of polyacrylic acid, polyacrylate, polyacrylamide, polyacrylonitrile, polyamide or polyamideimide, the molecular weight of the first binder is 300,000-600,000, and the glass transition temperature of the first binder is 60-80 DEG C;and the second binder comprises fluorine-containing polyolefin, and the molecular weight of the second binder is 800,000-1300,000. The oily ceramic slurry provided by the invention solves the problemsthat a water-based ceramic coating is large in swelling and easy to fall off, and the oily ceramic coating is easy to split phases, easy to fall off, hard and the like.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

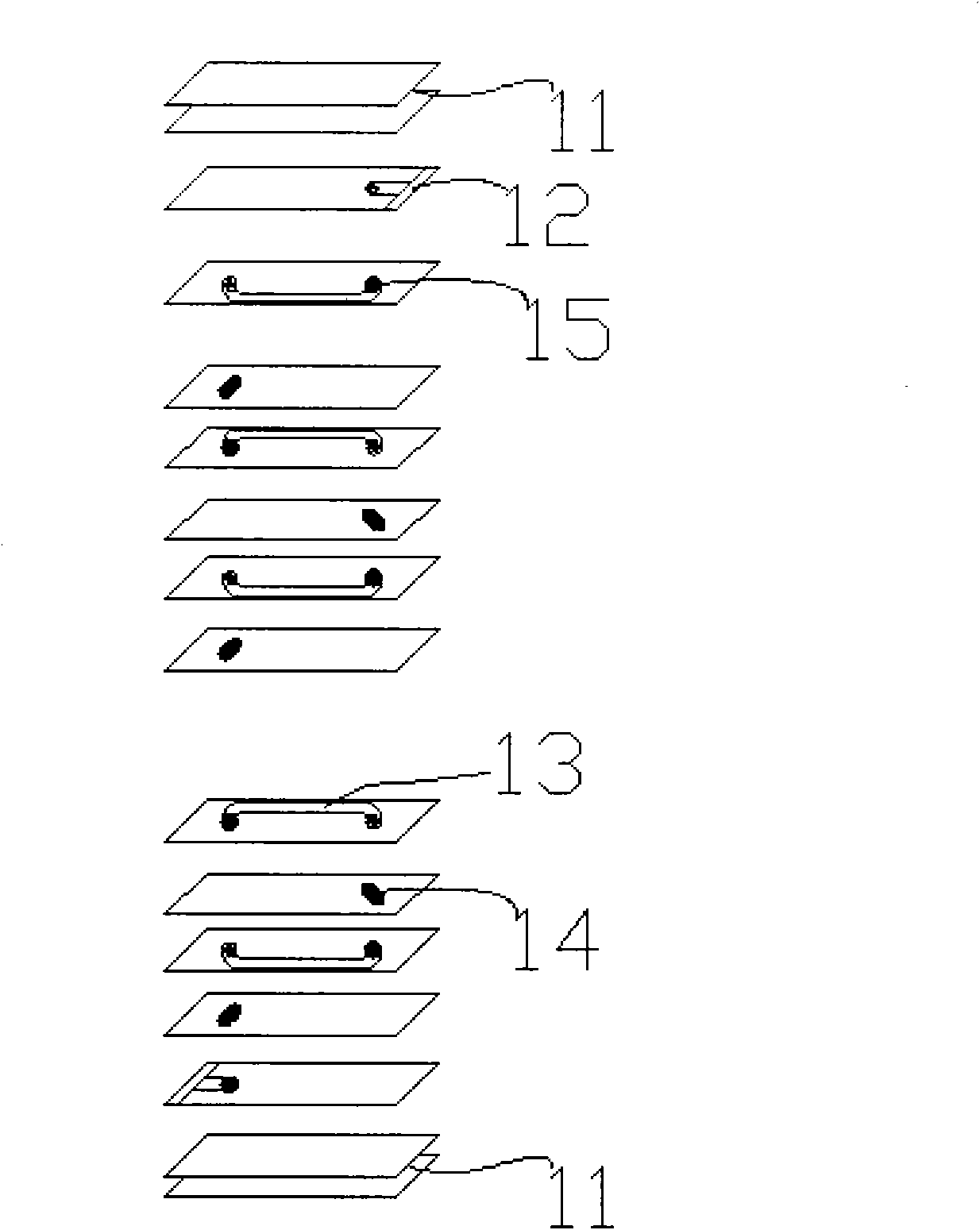

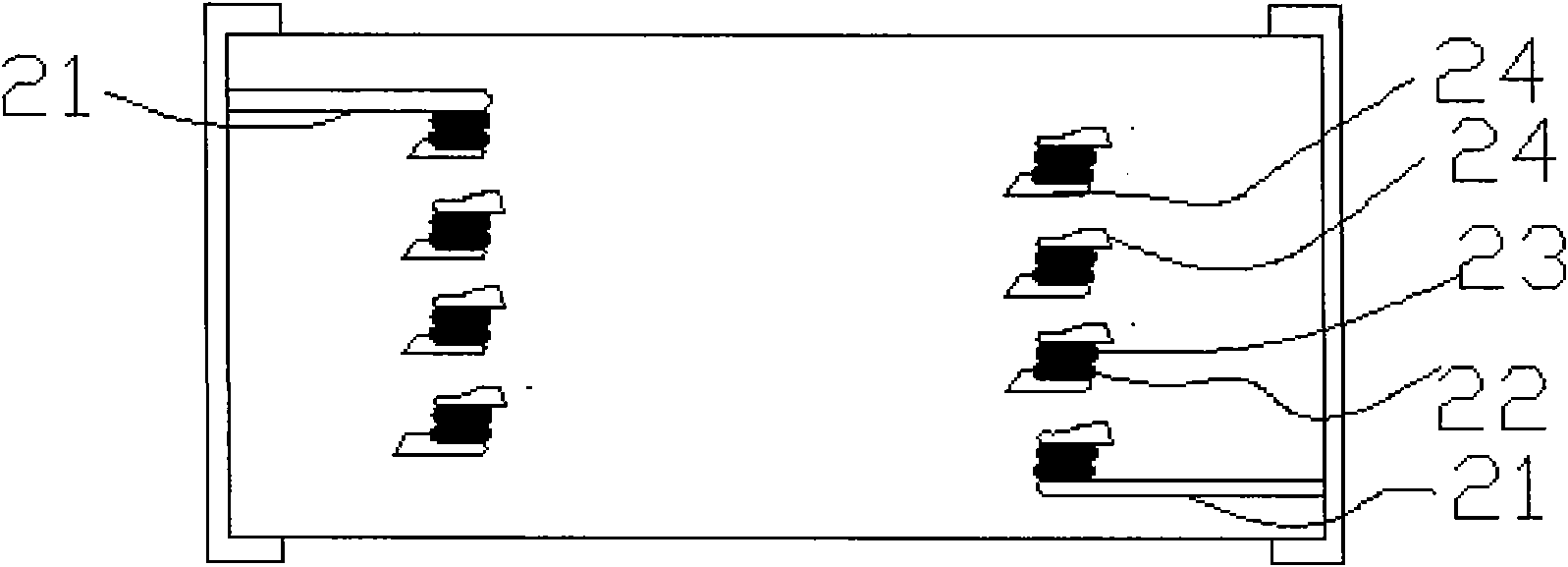

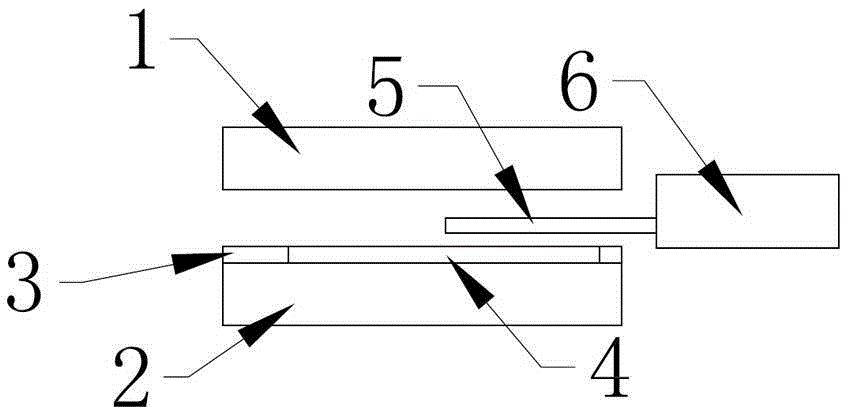

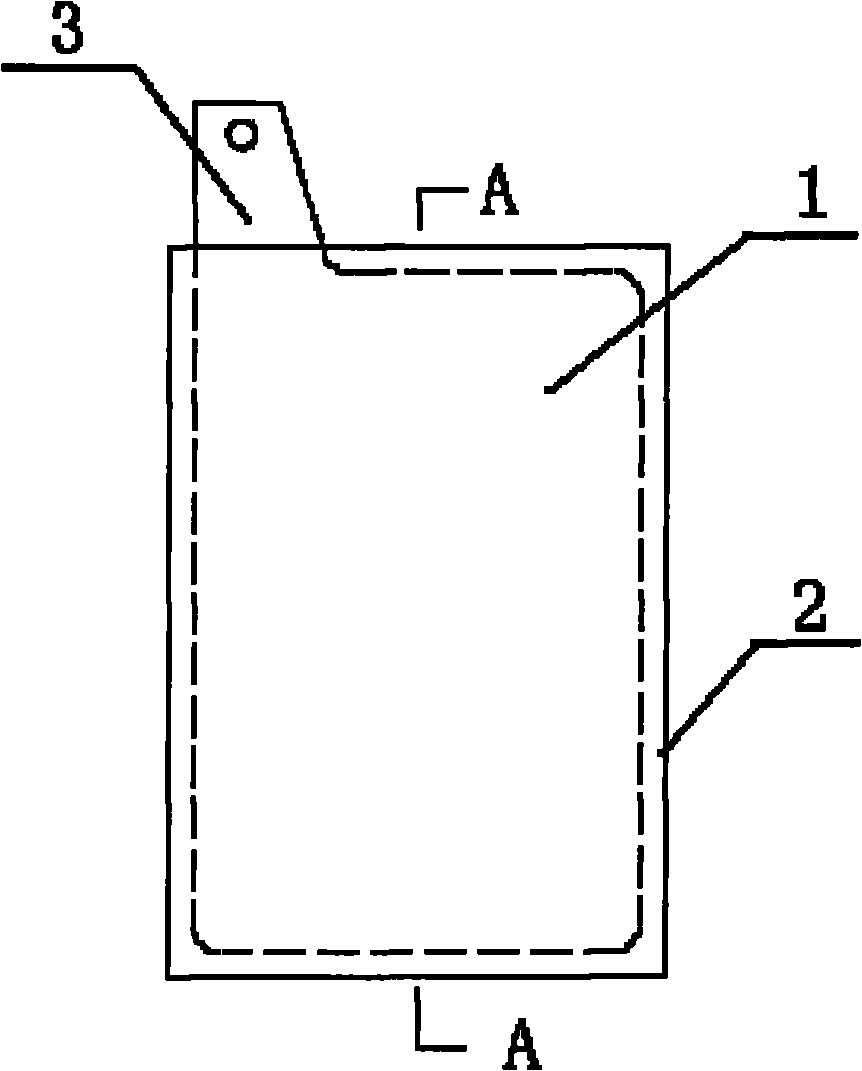

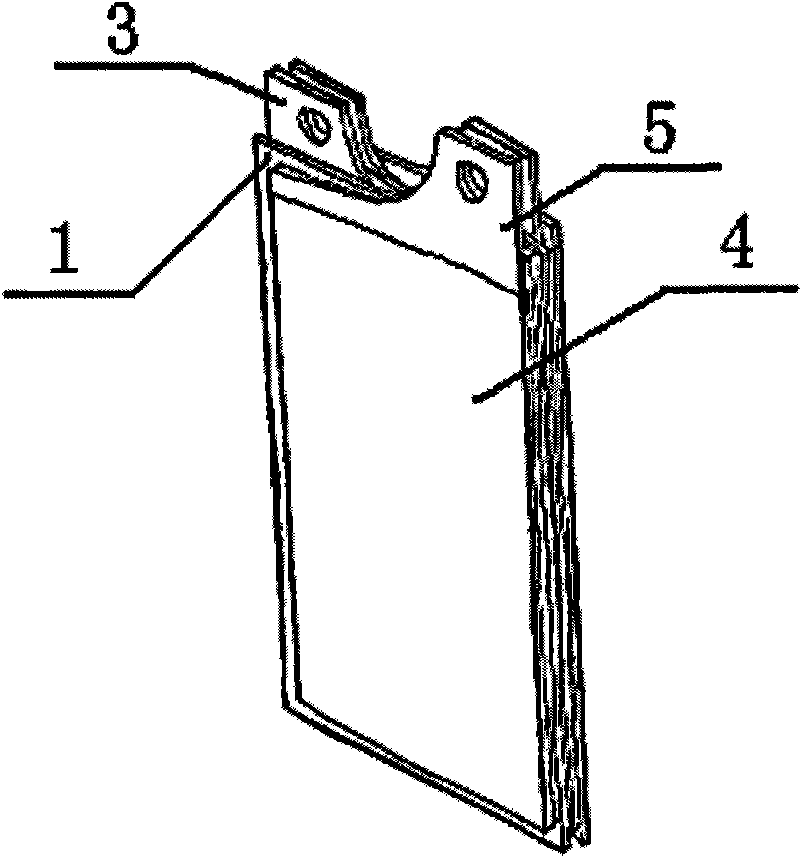

Electrode tab clamping device for battery formation

ActiveCN105336988AReasonable structureEasy to manufactureFinal product manufactureCell component detailsCharge and dischargeEngineering

The invention relates to an electrode tab clamping device for battery formation and charging and discharging of lithium battery formation. According to the electrode tab clamping device, a voltage conducting layer and a current conducting layer are each formed through the steps that no less than one divided conducting strip are arranged at even intervals to form a conducting area, and then the conducting area is communicated through a corresponding conducting bus to form the conducting layer; the conducting area of the voltage conducting layer is in gap meshing with the conducting area of the current conducting layer through the corresponding conducting strips to form an electrode tab clamping area. The electrode tab clamping device for battery formation has the advantages that the structure is reasonable, manufacturing is convenient, and the electrode tab clamping device can adapt to formation of various types of lithium batteries; meanwhile, the phenomena that short circuit of a voltage line and a current line occurs, and the electrode tab voltage sampling precision is influenced by charging and discharging currents cannot occur during work; in addition, the phenomenon that the electrode tab clamping device is in bad contact due to the fact that an upper pressing plate and a lower pressing plate are unsmooth cannot occur, the service life is long, and the safety and reliability are achieved.

Owner:深圳市华创众成智能装备有限公司

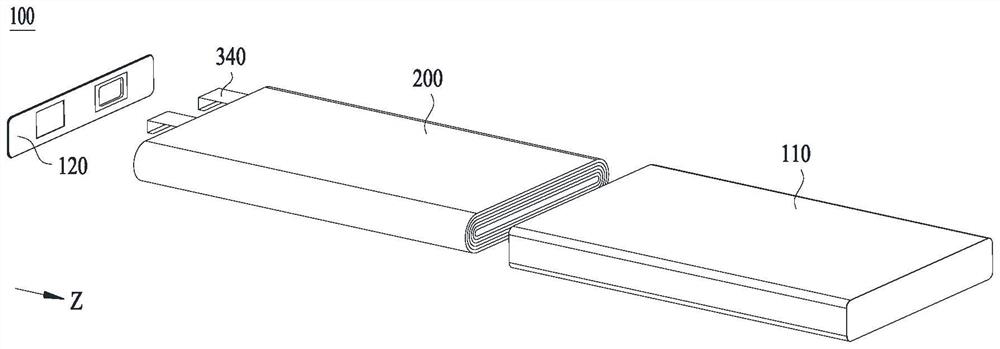

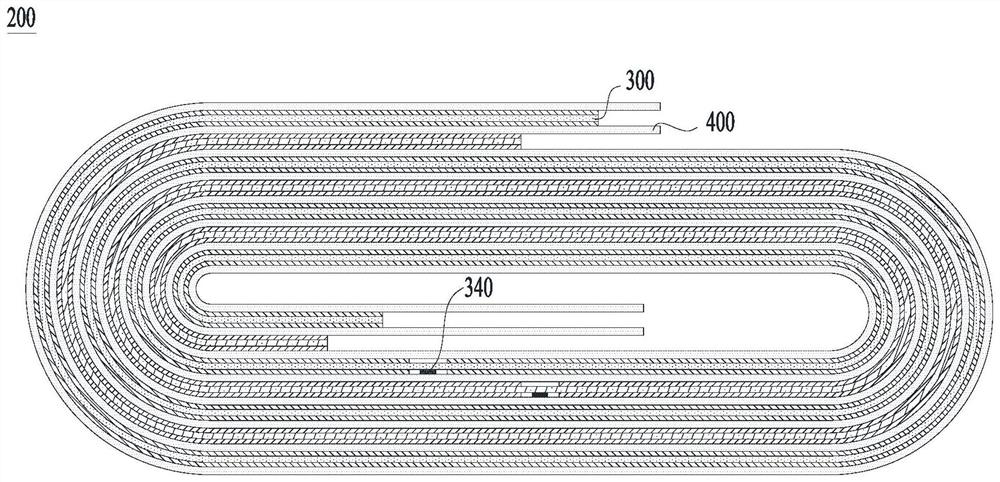

Pole piece, winding battery cell and battery

PendingCN114583097ASolve the problem of short circuitFinal product manufactureSecondary cellsEngineeringPole piece

The invention provides a pole piece, a winding battery cell and a battery. The pole piece comprises a current collector, an active material layer and an insulating layer. The current collector comprises two opposite surfaces. At least one of the two surfaces of the current collector is provided with an active material layer. Along the length direction of the current collector, the current collector comprises an empty foil region exceeding the active material layer. The active material layer and the insulating layer are provided in the longitudinal direction. And one part of the insulating layer is lapped with the empty foil region, and the other part is lapped with the active material layer. The insulating layer covers an edge of the active material layer. The pole piece can solve the problem that burrs on the current collector penetrate through the diaphragm to cause short circuit in the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Short circuit-proof electric heating laminating machine

InactiveCN102085740AAvoid safety hazardsSolve the problem of short circuitLaminationLamination apparatusBrickCopper wire

The invention relates to a short circuit-proof electric heating laminating machine, which comprises a heating workbench and an upper cover, wherein the upper cover is formed by combining an upper box chamber, a silica gel plate and an upper chamber sealing ring in turn, wherein a laid battery component is arranged on the workbench top of the laminating machine, the upper cover is pressed down to be tightly combined with the edge of the heating workbench and a vacuum chamber is formed between the upper cover and the heating workbench. A lower chamber sealing ring is arranged on the periphery of the heating workbench to seal the vacuum chamber. A heater and a temperature controller are also arranged in the heating workbench, a disc which is made of a steel plate and has a spring is laid below the heater, and an aluminum silicate light brick, which is as large as the heating plate and some 5 centimeters thick and is covered by tetrafluoride cloth, is arranged below the disc. The heater is positioned between the heating plate and the aluminum silicate light brick, a lead of the heater is welded with a small section of copper wire and connected with a screw of a bakelite plate, and the screw is communicated with the outside. In the invention, the control mode of the electric heater is primarily described, a primary coil of a transformer is controlled by a silicon-controlled solid-state relay, and the heater is connected with the secondary coil of the transformer, so short circuit of the heater under vacuum is voided effectively, the repair rate of device is greatly reduced, the service life of the device is prolonged, and the heater is suitable to be applied to the electric heating laminating machine for use in a solar battery assembly process.

Owner:SHANGHAI SHENKE TECH

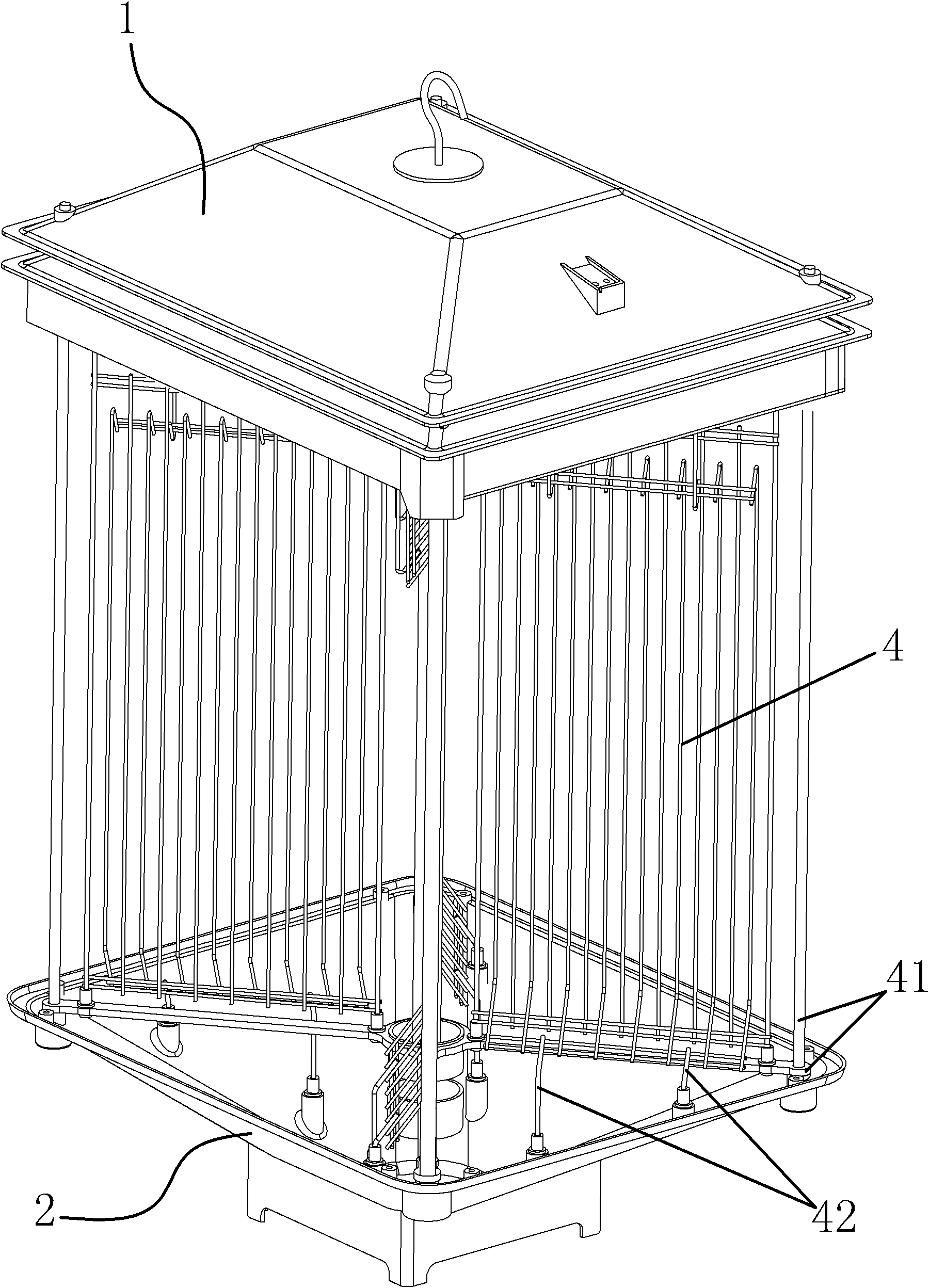

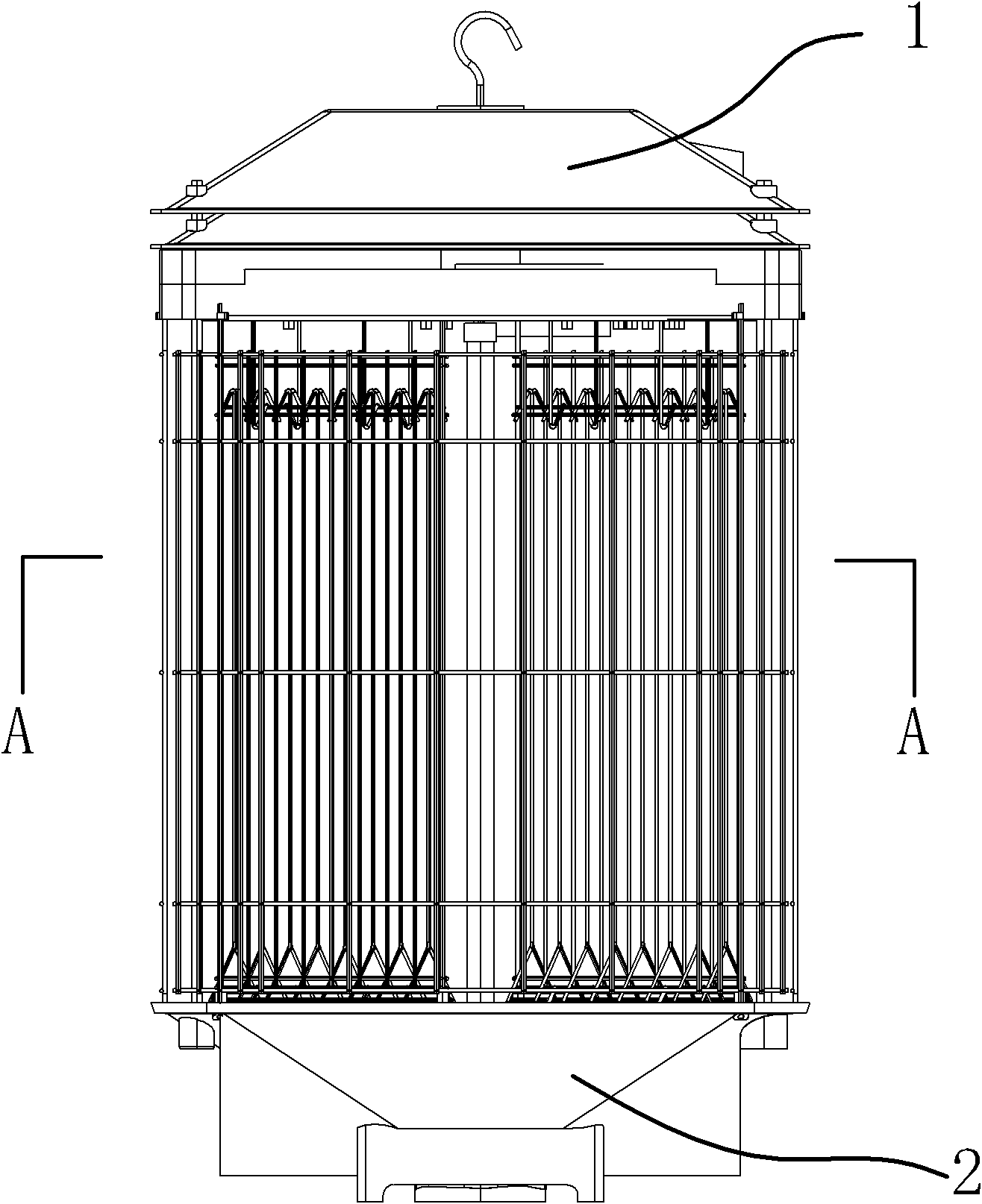

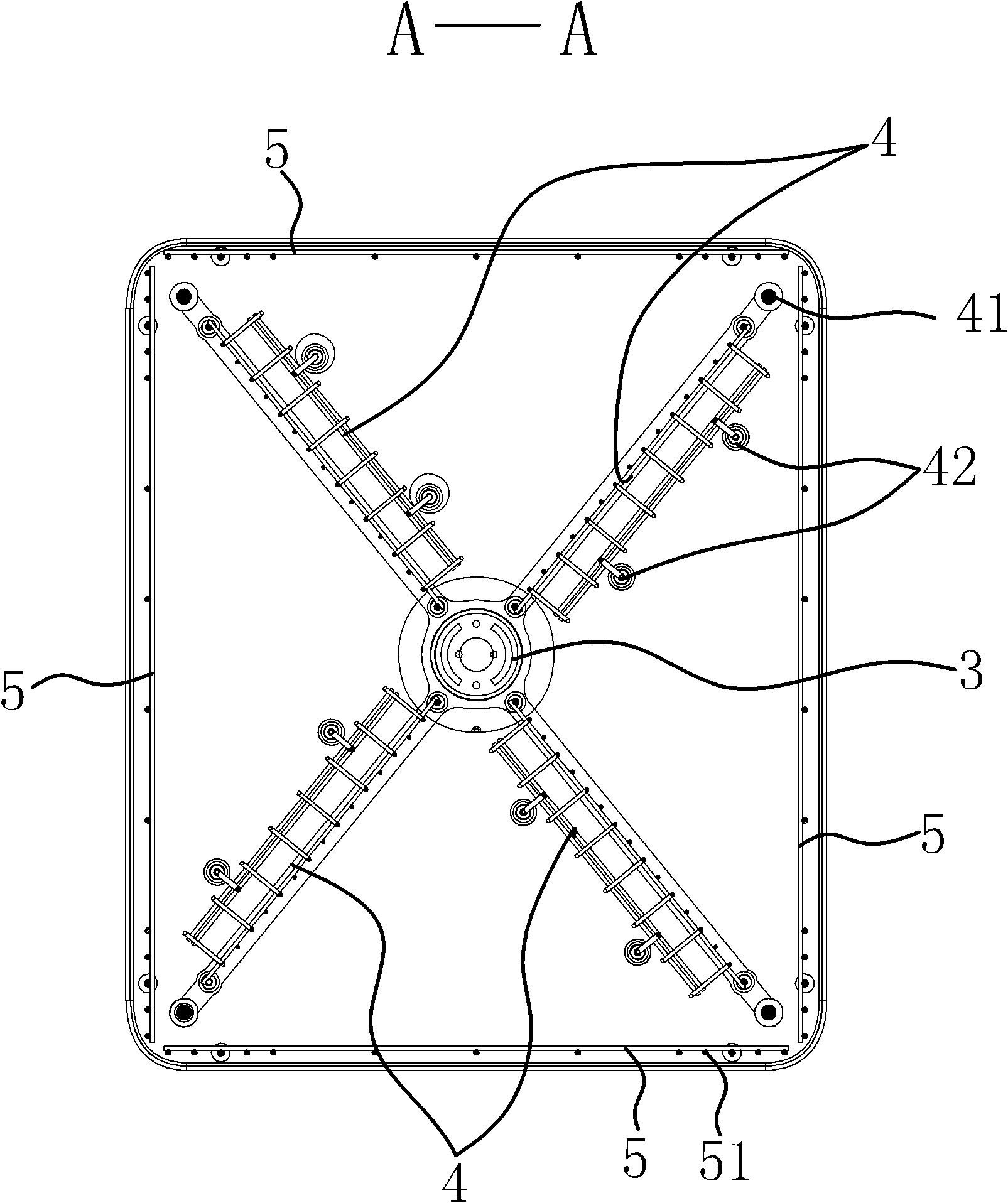

High-voltage net-boom radiation-type insecticidal lamp of improved structure

InactiveCN101861854ASolve the problem of short circuitSolve the problem of blocking the high-voltage grid and affecting the effect of attracting insectsElectric shock equipmentsInsect catchers and killersPower flowHigh pressure

The invention provides a high-voltage net-boom radiation-type insecticidal lamp of an improved structure, which belongs to the technical field of the electric appliance, and solves the technical problems of the present insecticidal lamp that the insecticidal effect is poor, the killed insects cannot be automatically cleared and the application is unsafe, and comprises a lamp cap and an insect collecting disc, wherein an insect attractive lamp is arranged between the lamp cap and the insect collecting disc, a plurality of flaky high-voltage net booms are arranged at the outer side of the insect attractive lamp, the high-voltage net book is connected with a power source which can provide the high-voltage current, and the high-voltage net booms are vertically arranged in a radiation shape with the insect attractive lamp as the center. The high-voltage net-boom radiation-type insecticidal lamp has the advantages of simple structure, good insecticidal effect, automatic clearing of insects, safer application and the like.

Owner:徐昌春

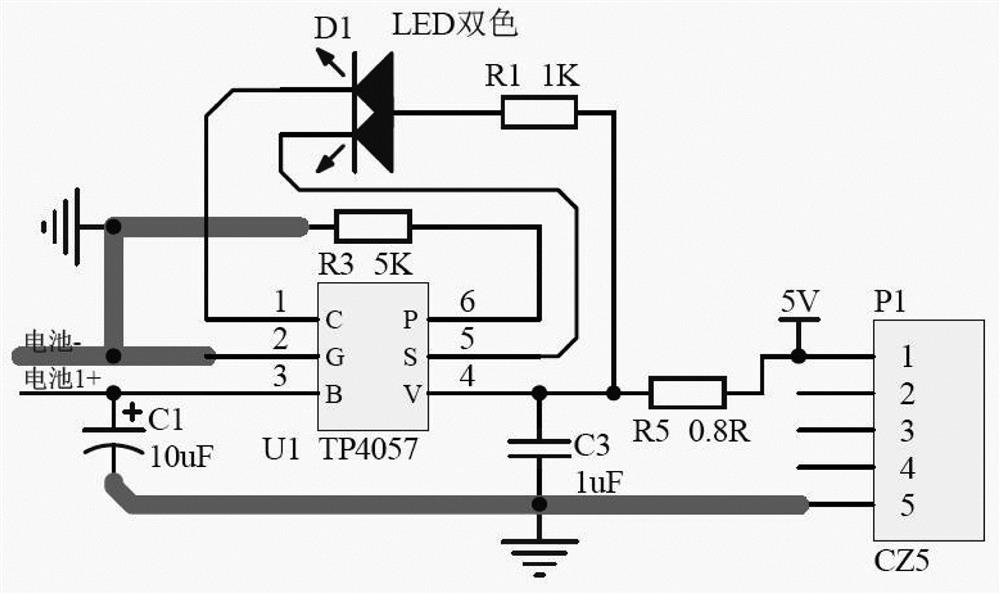

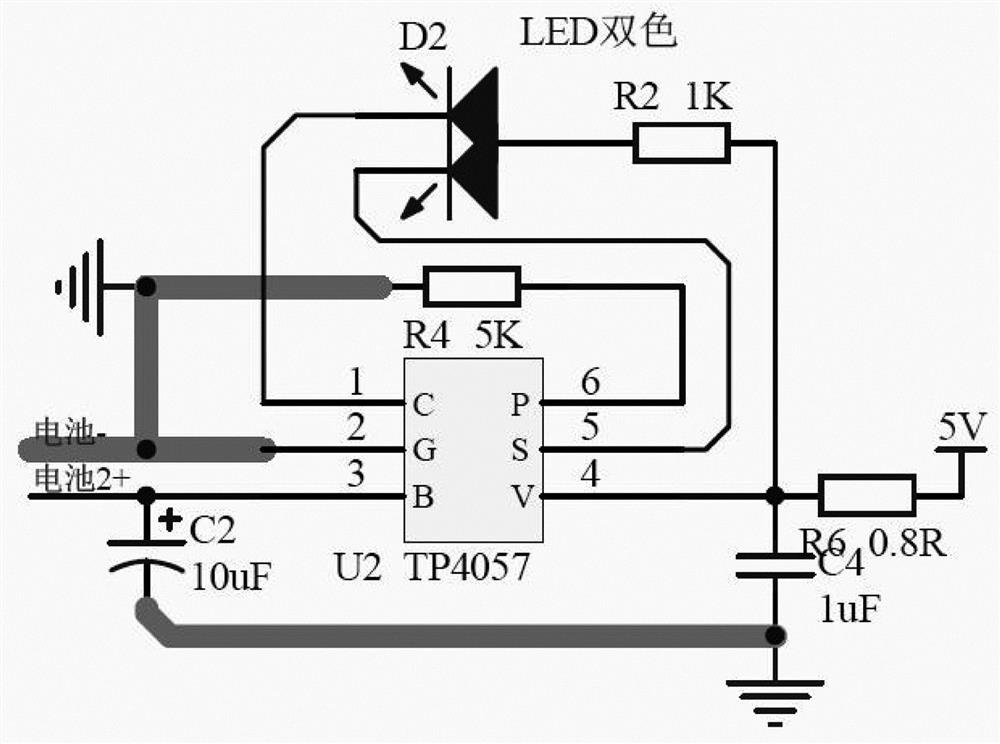

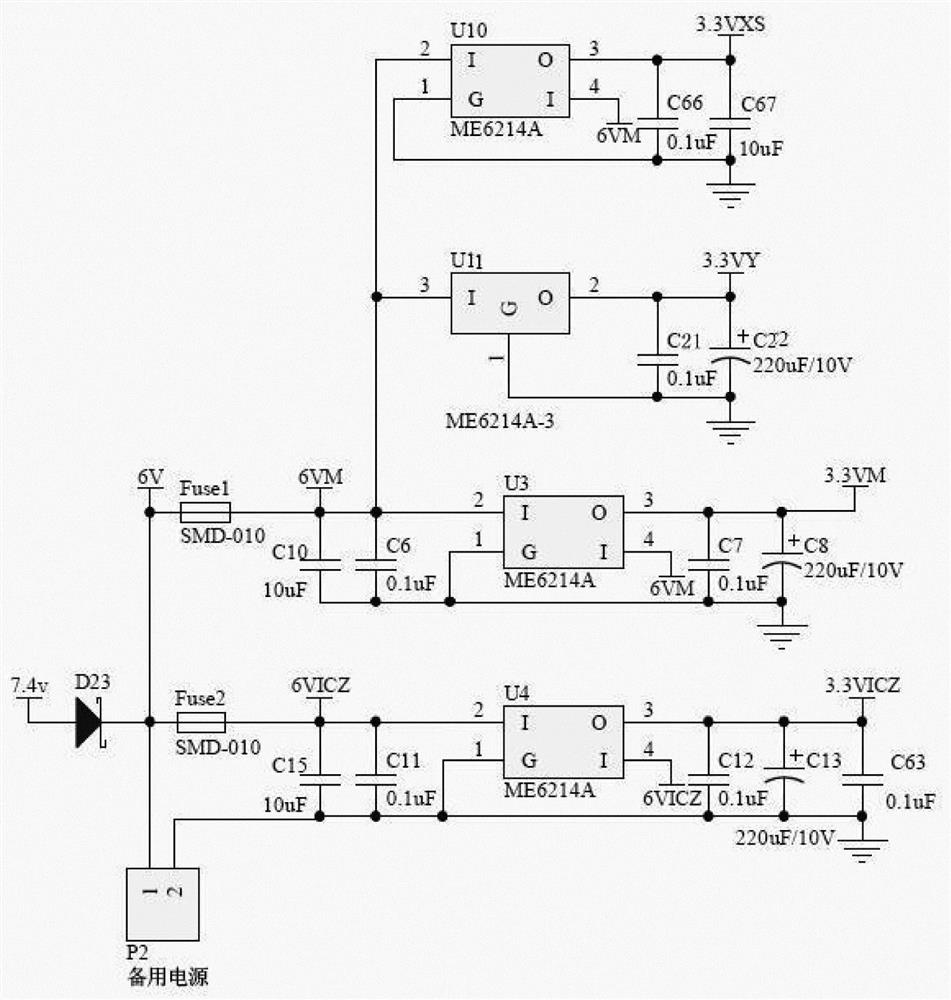

Control system of power supply for intelligent lock

ActiveCN112184969ALower requirementLow costIndividual entry/exit registersBattery chargeControl system

The invention discloses a control system of a power supply for an intelligent lock. The control system comprises a battery charging module, the battery charging module comprises a chip U1 and a chip U2, and the model of the chip U1 and the model of the chip U2 are TP4057. The system has the advantages that the quiescent current is extremely low, the actually measured quiescent current is smaller than 1 microampere, the problems that the temperature of the battery rises rapidly due to large current and a short circuit is caused to an internal diaphragm of the lithium battery due to overheatingare solved, the requirement for the battery is greatly reduced, and therefore the battery cost is reduced; a dual power system is adopted, and if the battery is out of power, an external standby powersupply can be used for unlocking.

Owner:山东艾琳智能科技有限公司

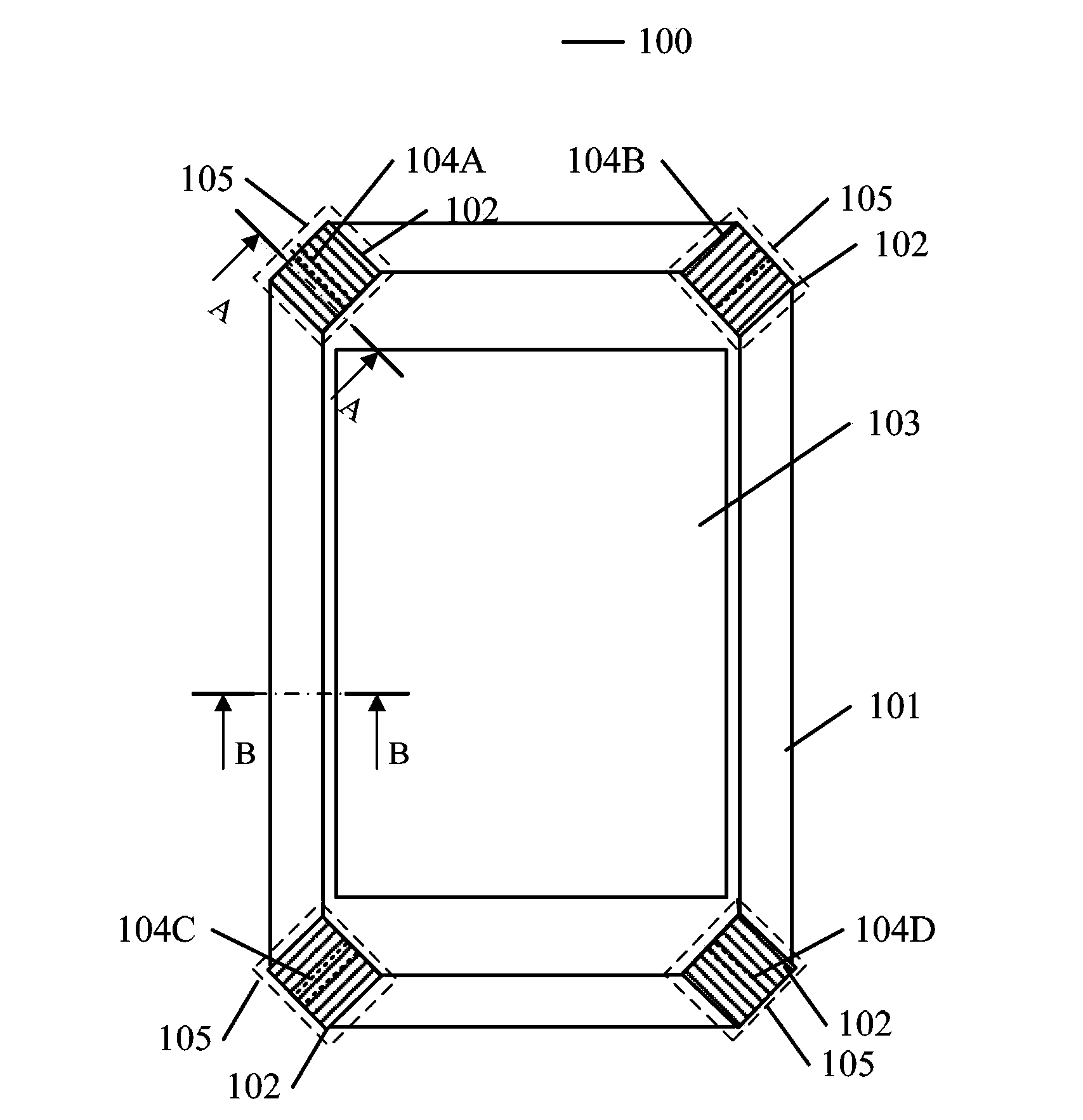

Portable terminal

ActiveCN103840256ASolve the problem of short circuitImprove experienceAntenna supports/mountingsAntenna equipments with additional functionsComputer terminalComputer science

Owner:LENOVO (BEIJING) CO LTD

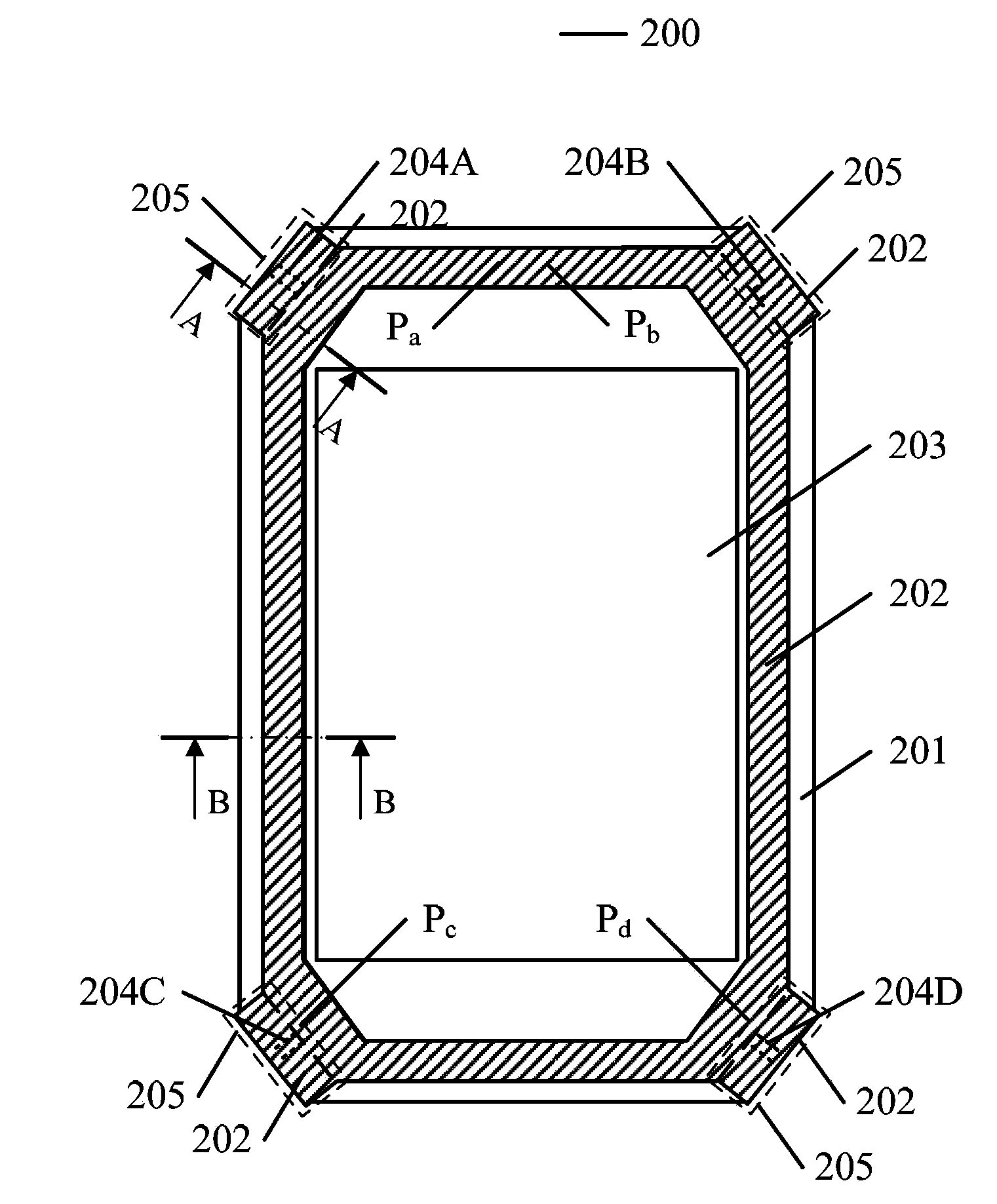

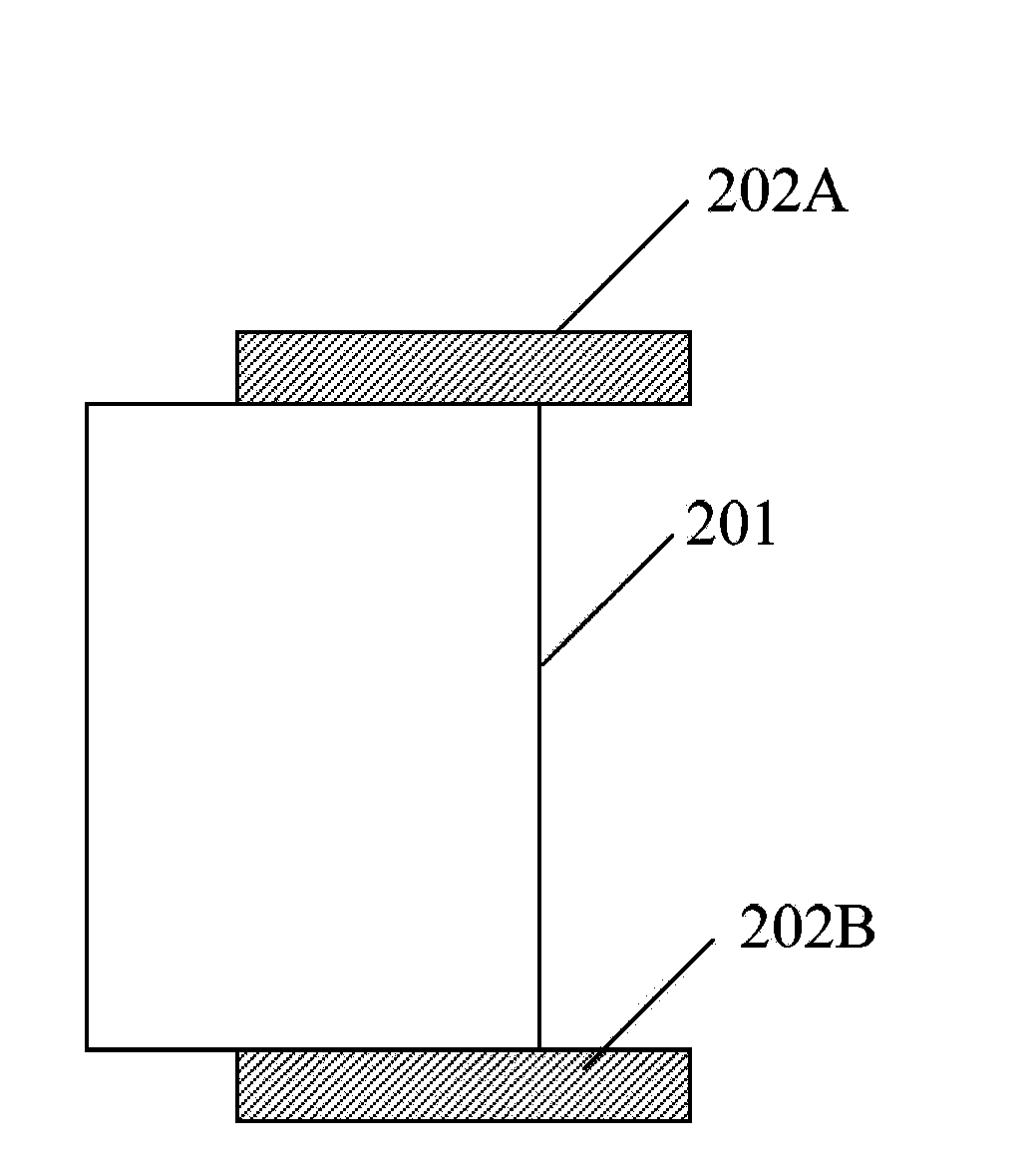

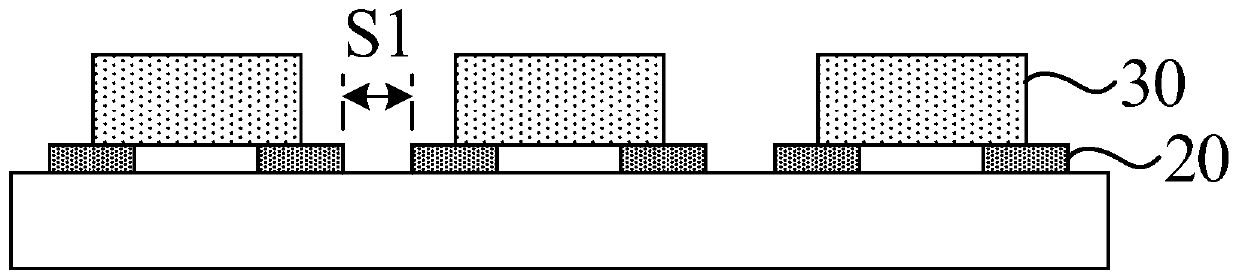

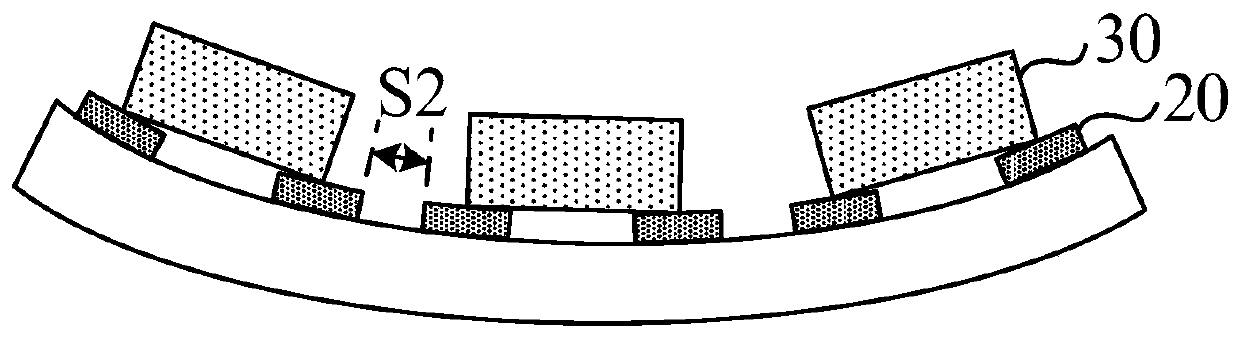

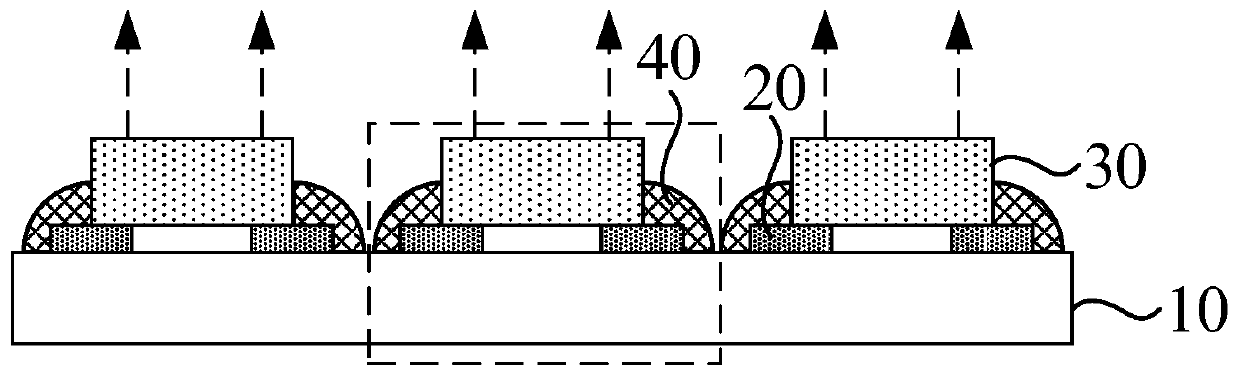

Light board, backlight module and curved display device

InactiveCN110297356AEasy accessSolve the problem of short circuitNon-linear opticsElectricityDisplay device

The embodiment of the invention discloses a light board, a backlight module and a curved display device. The light board comprises a substrate basal plate, multiple light sources and an insulation structure; multiple bonding pads are arranged on the substrate basal plate; each the bonding pad comprises a first part and a second part; the light sources are electrically connected with the substratebasal plate through the bonding pads; orthographic projection of the first part in the plane, where the substrate basal plate is, is positioned in corresponding orthographic projection of the light source in the plane, where the substrate basal plate is; and orthographic projection of the second part in the plane, where the substrate basal plate is, is positioned in orthographic projection of theinsulation structure in the plane, where the substrate basal plate is. According to the light board in the embodiment of the invention, the short-circuiting problem due to the fact that bonding pads of adjacent light sources are easily contacted when the light board is curved can be solved; mutual insulation among the bonding pads is ensured; simultaneously, the insulation structure can be used for relieving bending stress of the bonding pads; and breakage of the bonding pads when the light board is curved is prevented.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

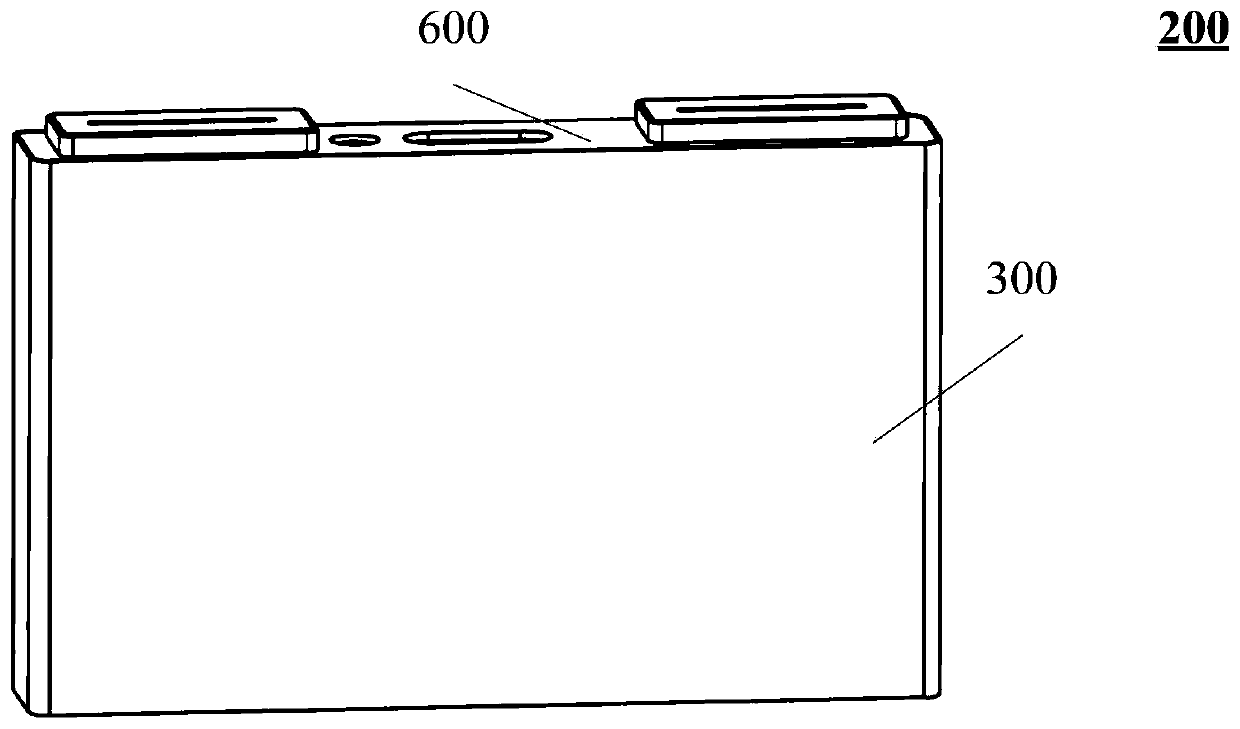

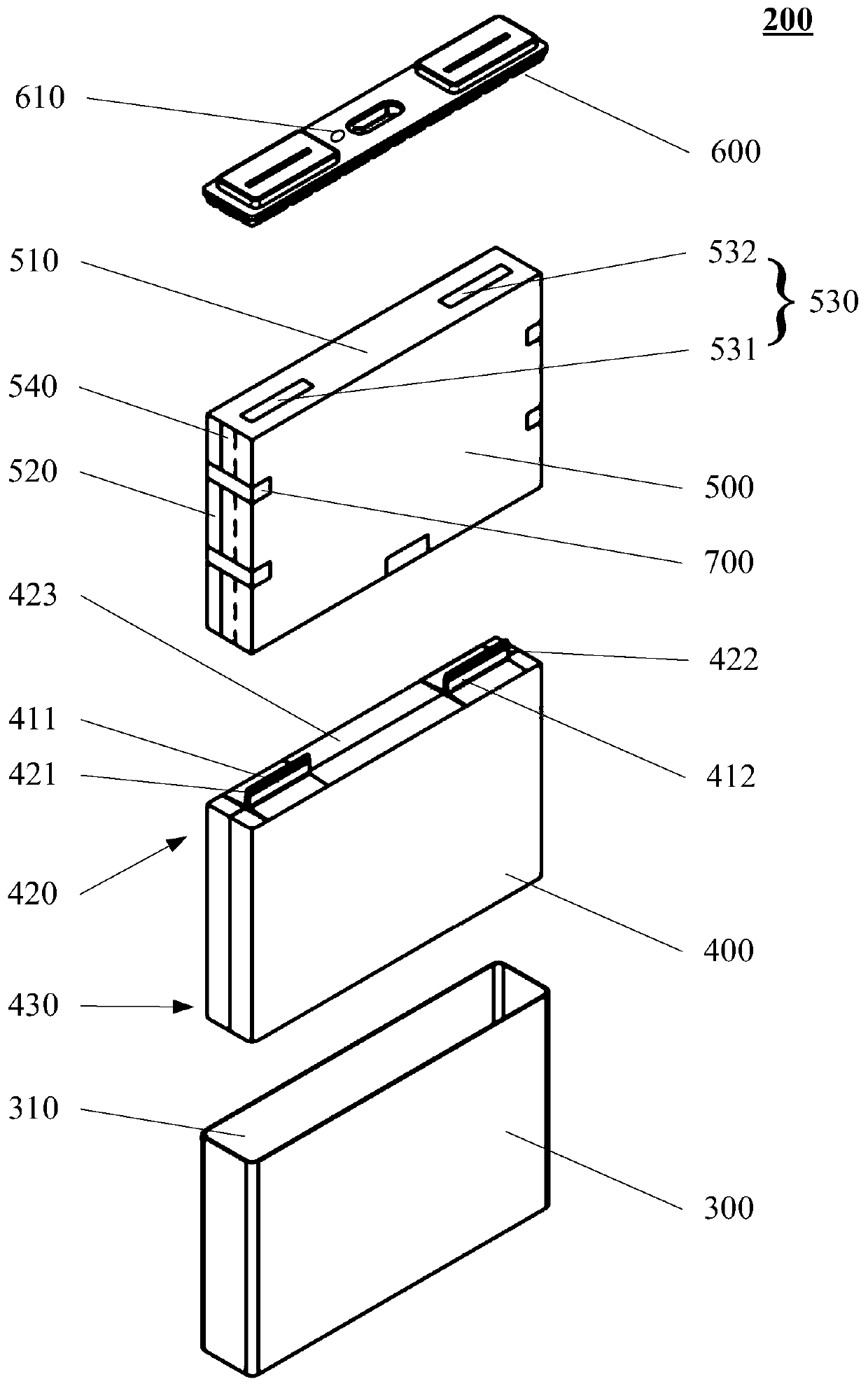

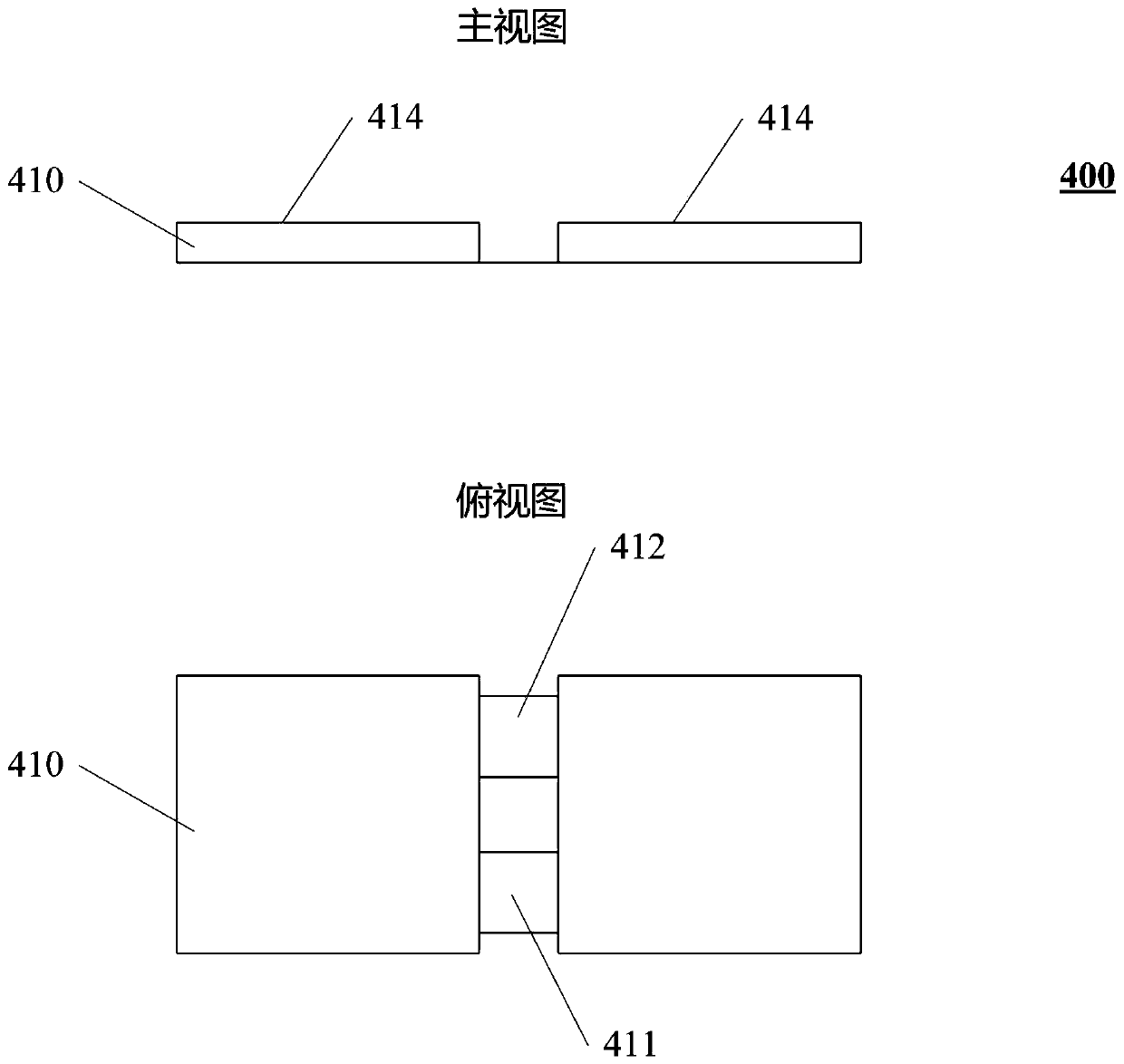

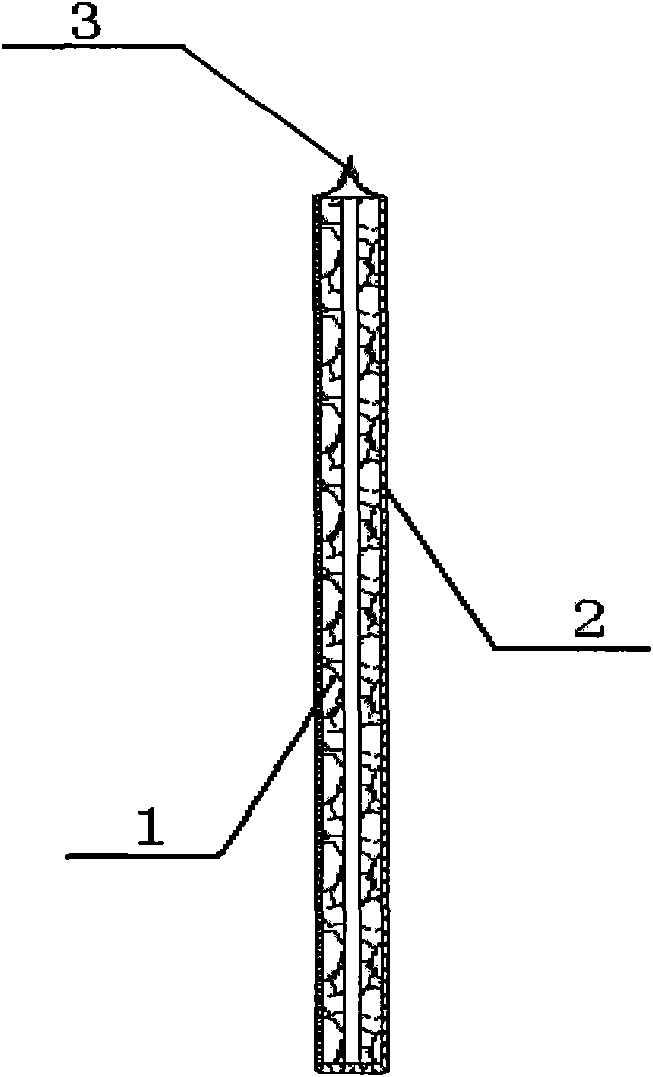

Battery and battery preparation method

PendingCN111477946ASolve the problem of short circuitIncrease energy densityFinal product manufactureSmall-sized cells cases/jacketsStructural engineeringPlastic film

The invention provides a battery. The battery comprises a shell, a battery cell, an insulating film and a cover plate, the insulating film includes an interlayer region. And the interlayer area is positioned between the cover plate and the top surface of the battery cell. And the cover plate is attached to the top surface of the battery cell to fix the interlayer area. And the insulating film is folded from the interlayer area to the free end of the battery cell to wrap the battery cell. According to the battery, the battery cell is wrapped by the insulating film from top to bottom, so that the problem of short circuit of the battery caused by damage of the plastic film on the outermost layer of the battery cell is solved. Meanwhile, according to the battery disclosed by the invention, theinsulating film can be fixed between the battery cell and the cover plate without adopting a retainer, so that the equipment investment cost is reduced, the production space is reduced, the operationenergy consumption is reduced, and the energy density of the battery is improved.

Owner:湖南领湃达志科技股份有限公司 +4

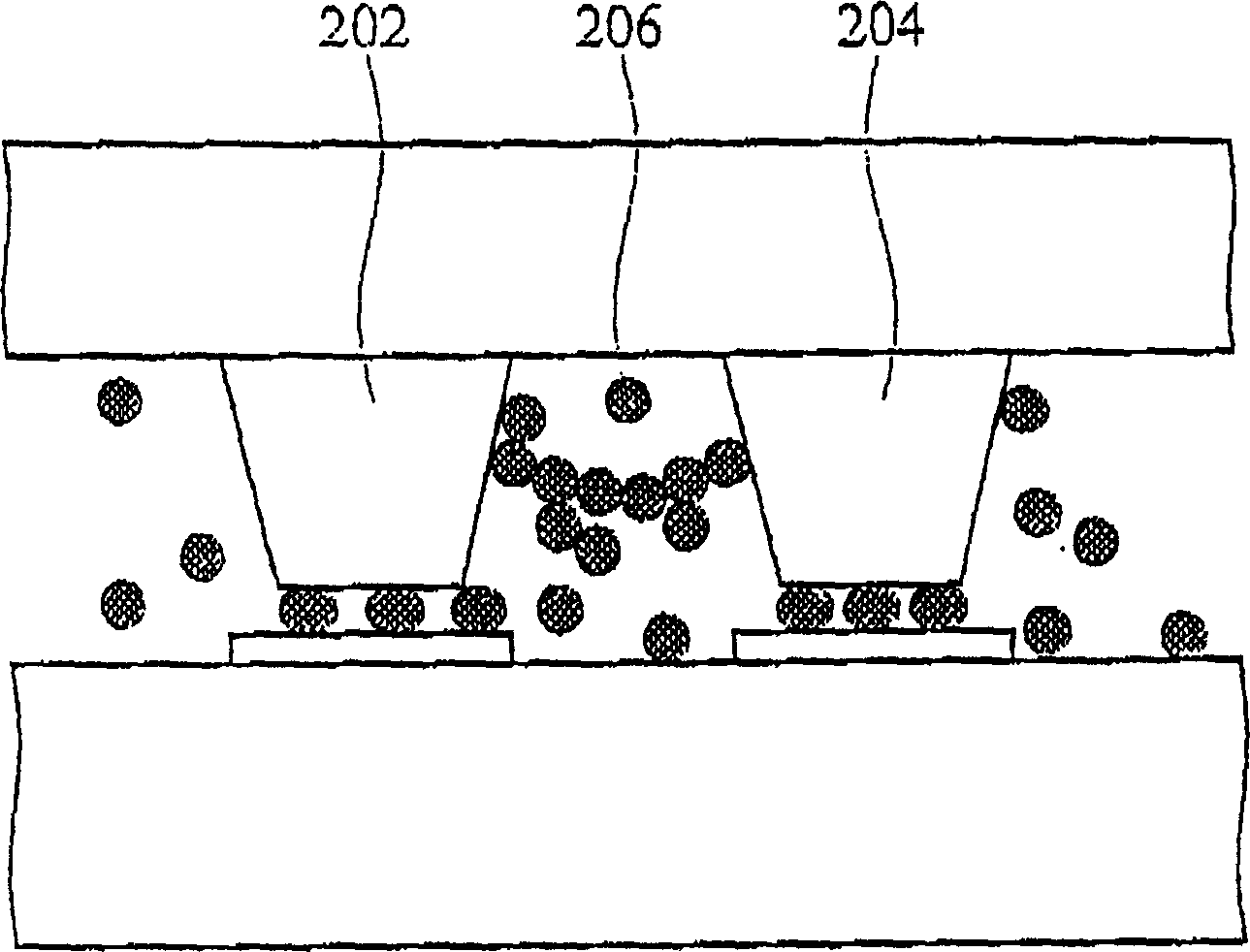

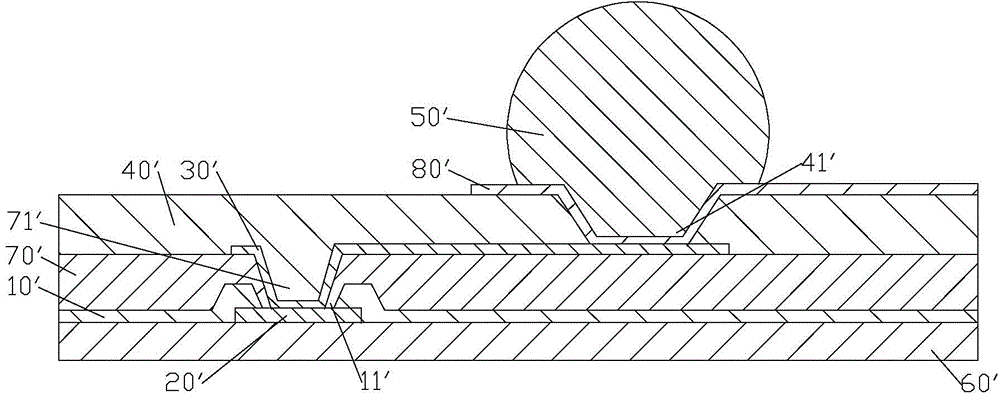

Composite scab structure and producing method thereof

InactiveCN1585122ASolve the problem of short circuitSolve the deformationSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

The compound cam structure is composed of a base plate, a contacting pad located on the base plate, a main body comprised of the polymer on the contacting pad, a conducting socket in the main body, which interpenetrates the main body. The conducting layer connects with the conducting pad via the conducting socket and the protecting layer on the base plate covers part of the contacting pad.

Owner:AU OPTRONICS CORP

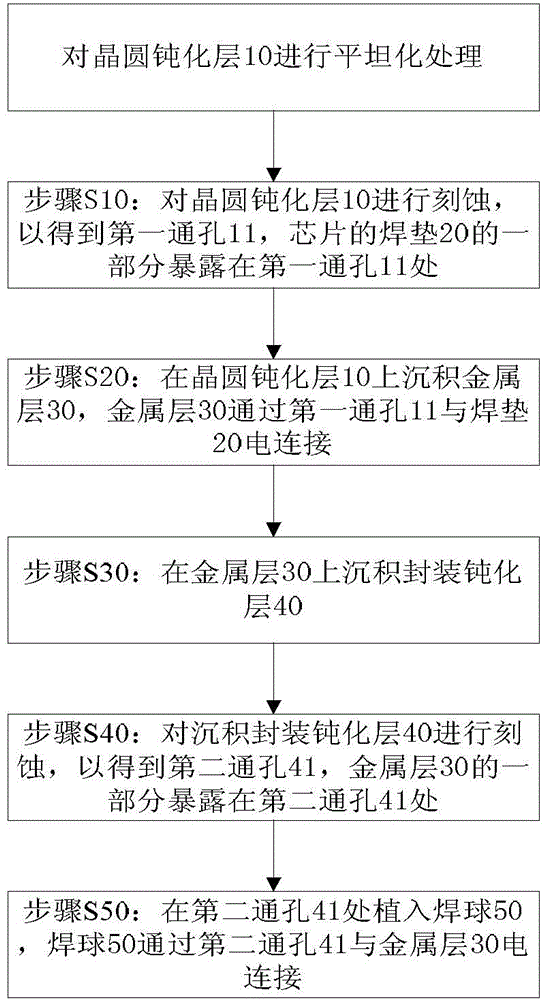

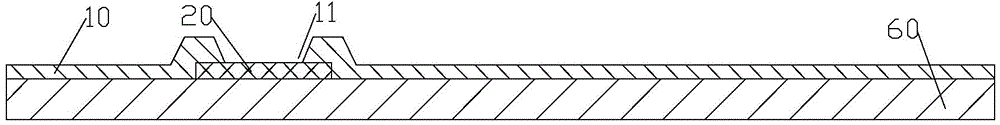

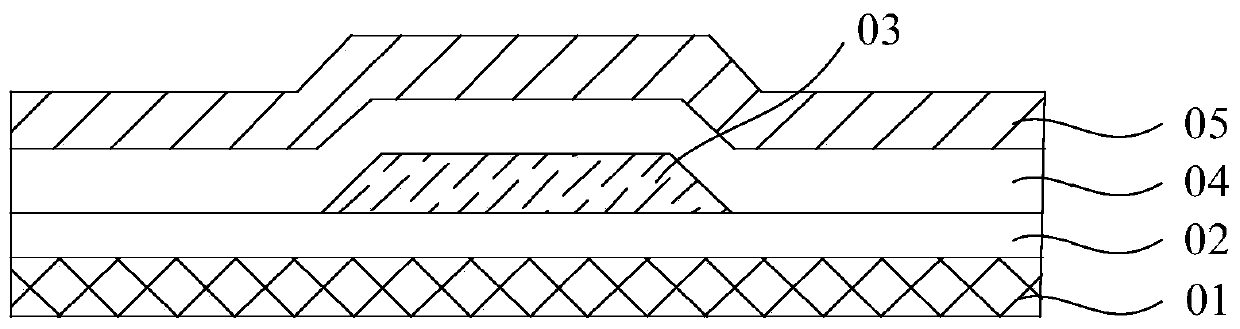

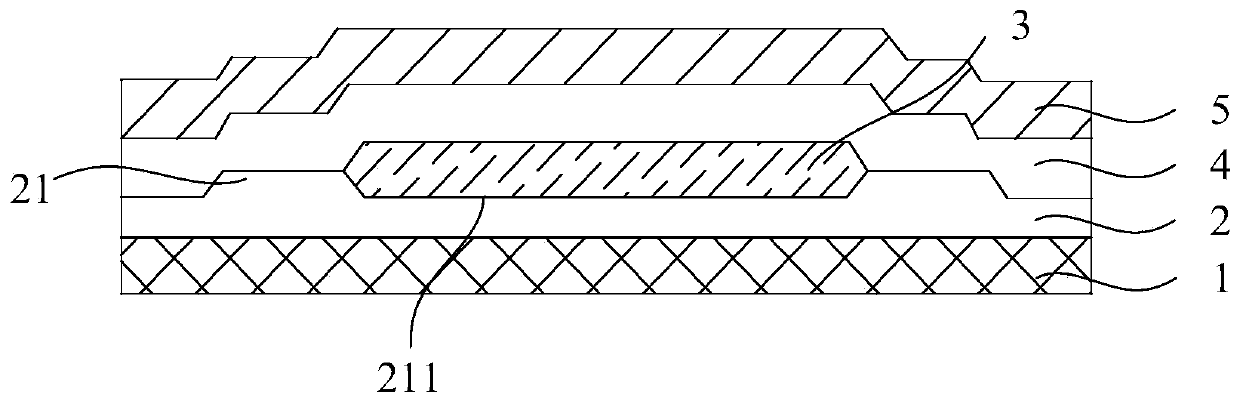

Chip manufacture process and chip

InactiveCN105097492ASimple preparation processSimple processSemiconductor/solid-state device manufacturingEngineeringMetal

The application provides a chip manufacture process and a chip. The chip manufacturing process comprises performing planarization treatment on a wafer passivation layer. After the wafer passivation layer is flattened, the surface is flatter, unevenness is reduced, and tiny grooves are eliminated, accordingly allowing more stable and uniform connection between the metal layer deposited on the wafer passivation layer and the wafer passivation layer, thereby avoiding the loosening of the metal layer, solving the problem of chip short circuit caused when the metal layer extends outwards along the groove of the wafer passivation layer to conduct with the peripheral metal layer, and furthermore guaranteeing chip finished product quality and serviceability; meanwhile the chip manufacture process of the application possesses the characteristics of simple preparation and high manufacture reliability.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Array substrate, display panel and display device

ActiveCN110518024ASolve the problem of short circuitReduce adverse effectsSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention relates to the technical field of display equipment, and discloses an array substrate, a display panel and a display device. The array substrate comprises an underlayer substrate, a functional film layer formed on one side of the underlayer substrate, a grid line formed on the side, which is away from the underlayer substrate, of the functional film layer, an interlayer insulating layer formed on the side, which is away from the functional film layer, of the grid line, and a data line formed on the side, which is away from the grid line, of the interlayer insulating layer, wherein the data line and the grid line are mutually crossed; fluctuation structures are formed on the two sides of the portion, which is opposite to the grid line, of the functional film layer, and the data line and the fluctuation structures are mutually crossed. According to the array substrate, the problems of difficult climbing and climbing line breakage of the data line in an overlapping region ofthe grid line and the data line are solved, the problem of short circuit between the grid line and the data line due to coverage of the interlayer insulating layer is solved, and adverse effects caused by lamination between the grid line and the data line are reduced.

Owner:BOE TECH GRP CO LTD +1

Electric core structure of lithium battery

InactiveCN101834318ASolve the problem of short circuitReduce breakageFinal product manufactureSecondary cellsEngineeringOuter core

The invention discloses an electric core structure of a lithium battery. An electric core is positioned inside a cell cartridge, is connected with leading-out terminals of an anode and a cathode of the cell cartridge respectively through conducting connecting pieces, and comprises a battery inner core and a battery outer core, wherein the battery inner core is formed by laminating at least one layer of positive plate encapsulated by a membrane bag and at least one layer of negative plate in turn; and the battery outer core is formed by laminating a positive plate, a membrane and a negative plate in turn, is coiled to be vortex-shaped, and is wrapped on the battery inner core.

Owner:SHANGHAI KENEDE BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com