Short circuit-proof electric heating laminating machine

A laminator and electric heating technology, applied in lamination, lamination devices, layered products, etc., can solve problems such as combustion or deflagration of heat transfer oil, potential safety hazards, poor temperature control accuracy, etc., and prolong the service life , Reduce maintenance rate, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

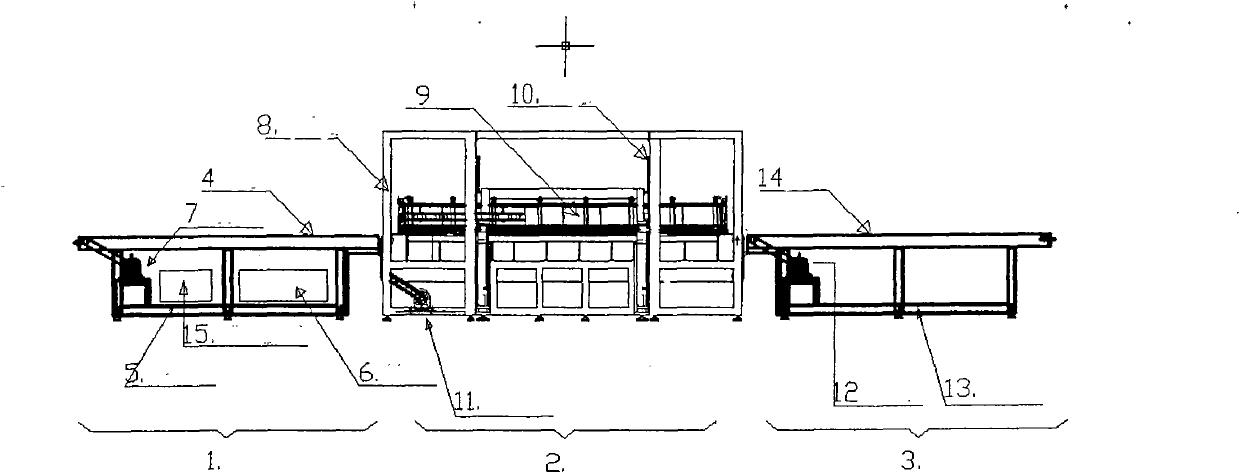

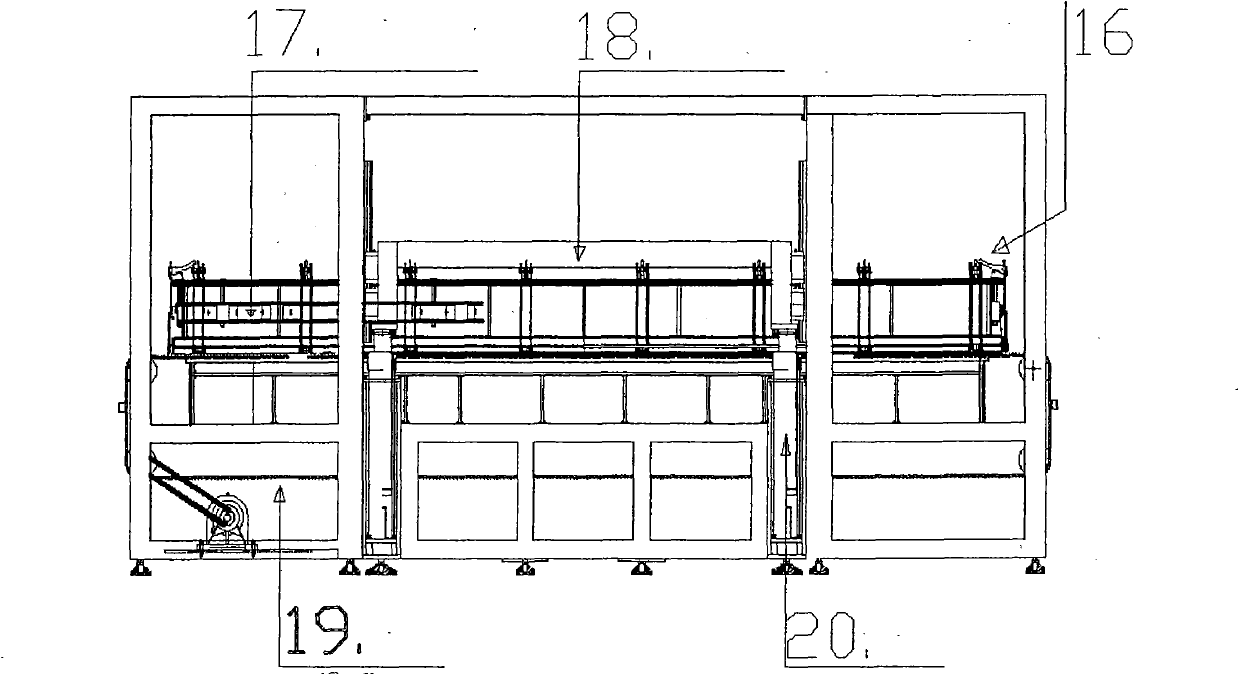

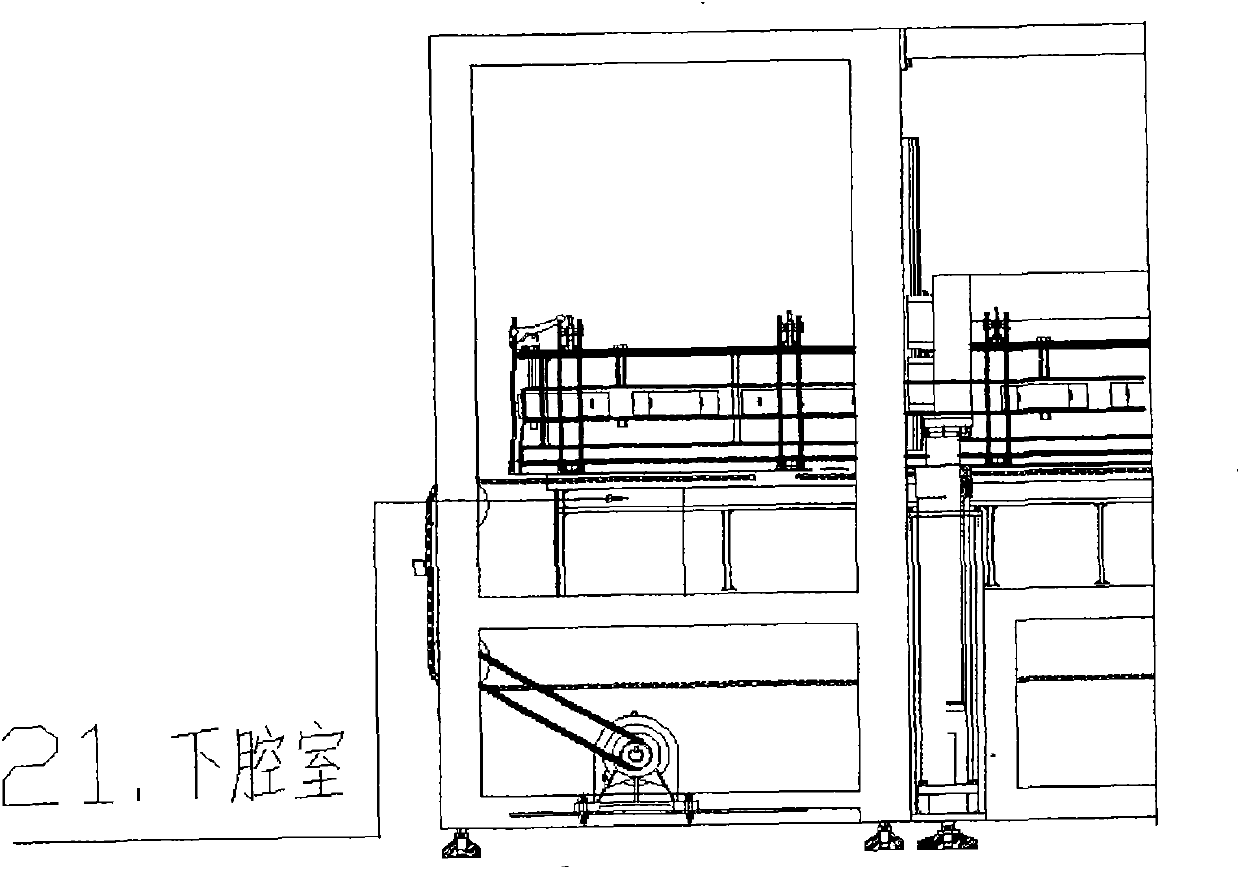

[0017] The following is a specific introduction to the new electric heating laminator: such as ( figure 1 ) is the general assembly drawing of the new type electric heating laminator, where Figure (2) is an enlarged view of the lamination section in Figure (1), and Figure (3) is a partial view of Figure (2), mainly showing the lower chamber.

[0018] As shown in Figure (1), the new electric heating laminator is mainly composed of three sections, namely the feeding table 1, the laminating section 2, and the discharging table 3.

[0019] The function of the feeding platform is to place the installed solar cell components flatly on the feeding platform in advance. Feeding table: feeding table support frame 5 It constitutes the main frame of the feeding table and the control system 6 , thyristor and transformer 15 , feed motor 7 Usually installed inside it. Control System 6 , is the core part of the laminator used to control the mechanical movement and lamination process. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com