Single-layer multi-point capacitive touch screen

A capacitive touch screen, single-layer multi-point technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as short circuit of lead wires, small distance between welding pads, and low production yield of touch screens. To achieve the effect of improving the production yield rate, improving the production yield rate, and solving the short circuit of adjacent lead wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0056] The following electrode units are arranged side by side, the first electrode group and the second electrode group between the electrode units are arranged side by side, the first electrodes in the first electrode group are arranged in rows, and the electrodes in the second electrode group are arranged in parallel. The second electrodes are arranged in rows. The direction in which the first and second electrodes in each electrode unit are arranged in a column is defined as the first direction, and the direction in which the electrode units are arranged is defined as the second direction, and the second direction is perpendicular to the first direction.

[0057] The term "corresponding" used in the present invention means: along the second direction, the corresponding first electrode and the second electrode have overlapping portions.

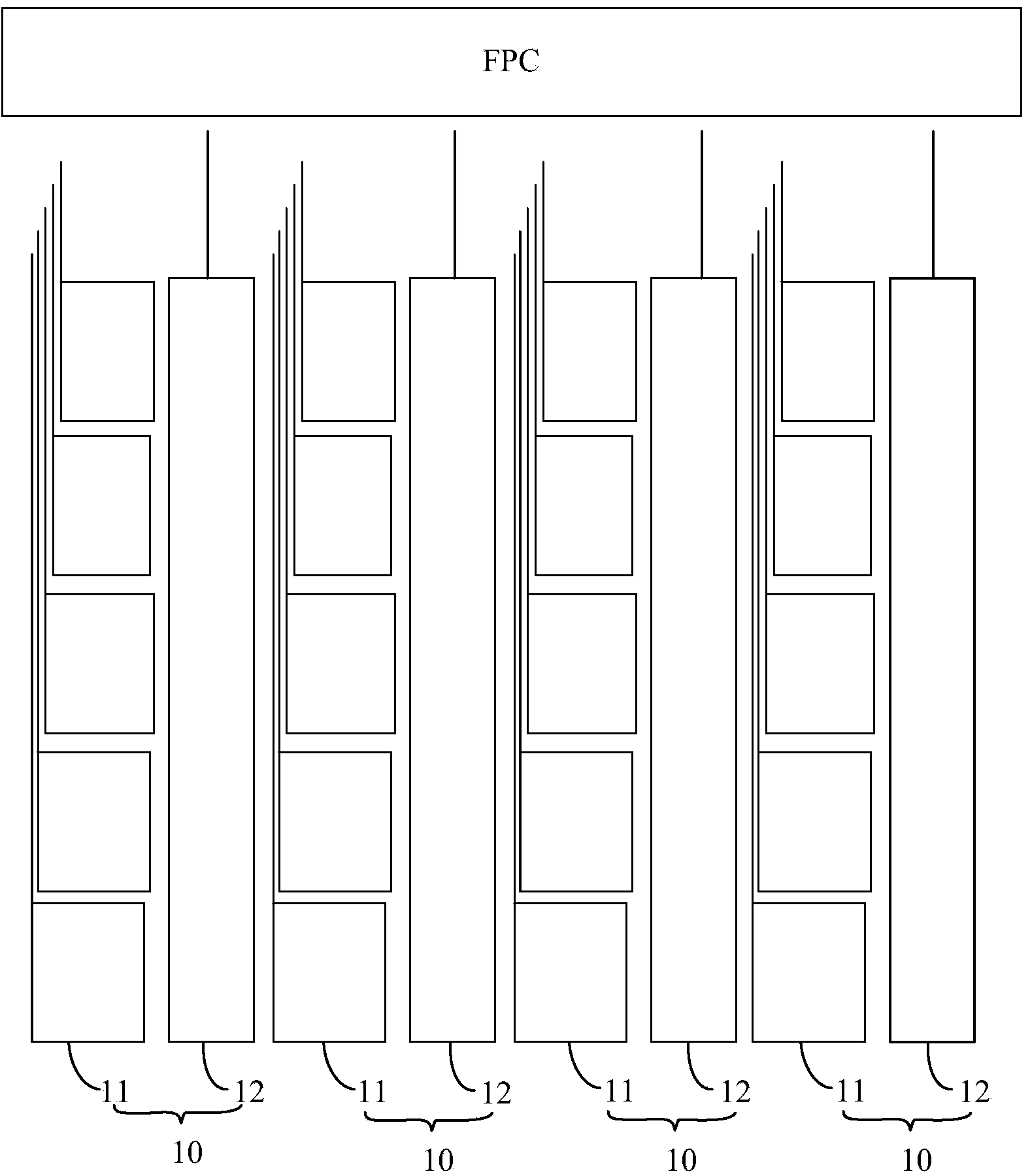

[0058] figure 2 It is a schematic diagram of electrode distribution and lead wires of a single-layer multi-point capacitive touch scree...

no. 2 example

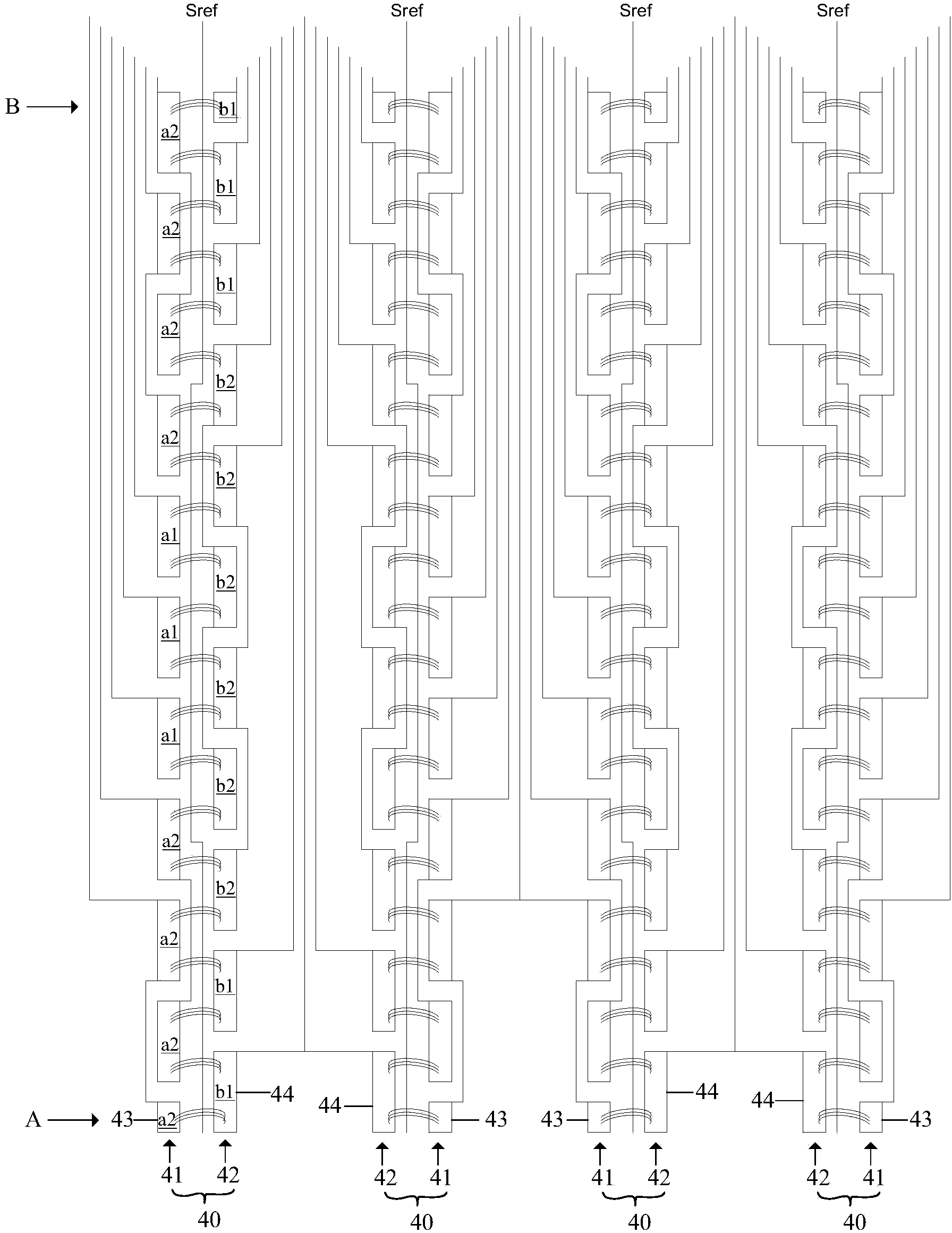

[0083] image 3 It is a schematic diagram of electrode distribution and lead wires of a single-layer multi-point capacitive touch screen in the second embodiment of the present invention, refer to image 3 , the difference between the second embodiment and the first embodiment is:

[0084] The number of electrode units 50; in each electrode unit 50, the numbers of the first electrodes 53 and the second electrodes 54 are 12, which are different from the first embodiment.

[0085] In each electrode unit 50, the corresponding conditions of the first electrode 53 and the second electrode 54 are different:

[0086] In each electrode unit 50, two first electrodes 53 correspond to only one second electrode 54 respectively, and the remaining first electrodes 53 correspond to two second electrodes 54 respectively; the two second electrodes 54 correspond to only one first electrode 53 respectively , the remaining second electrodes 54 correspond to two first electrodes 53 respectively;...

no. 3 example

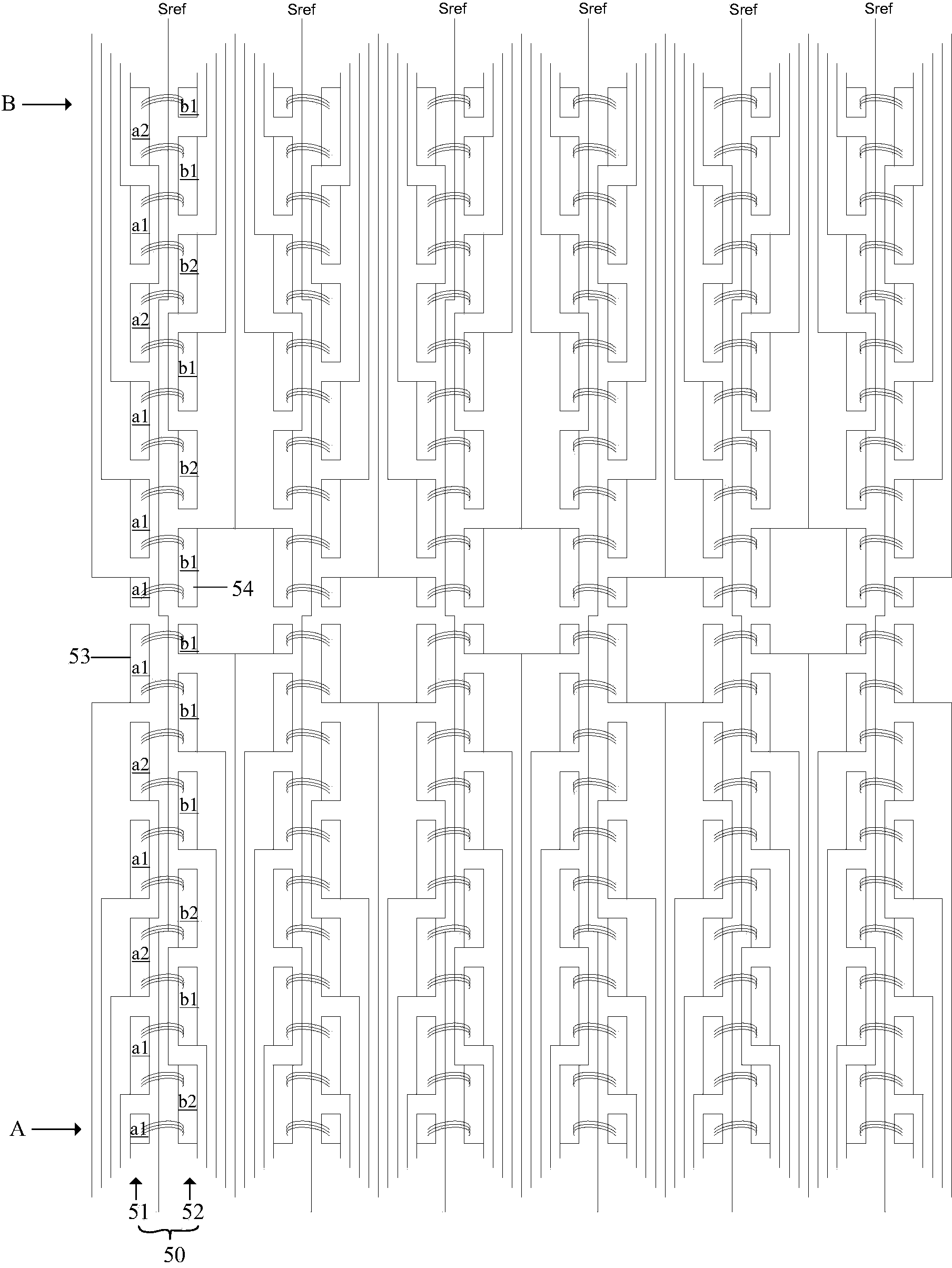

[0100] Figure 4 It is a schematic diagram of electrode distribution and lead wires of a single-layer multi-point capacitive touch screen in the third embodiment of the present invention, refer to Figure 4 , the difference between the third embodiment and the first embodiment is:

[0101] The number of electrode units 60.

[0102] In each electrode unit 60, the distribution of each first-type first electrode a1, the distribution of each second-type first electrode a2, the distribution of each first-type second electrode b1, and the distribution of each second-type second electrode b2 Unlike the first embodiment:

[0103] In the first electrode group 61, the first electrodes 63 located in the first row and the third row are the first electrodes a2 of the second type, and there is a first electrode a1 of the first type between them; the remaining first electrodes 63 are The first type of first electrode a1.

[0104] In the second electrode group 62, the second electrodes 64 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com