Composite scab structure and producing method thereof

A technology of bumps and polymers, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

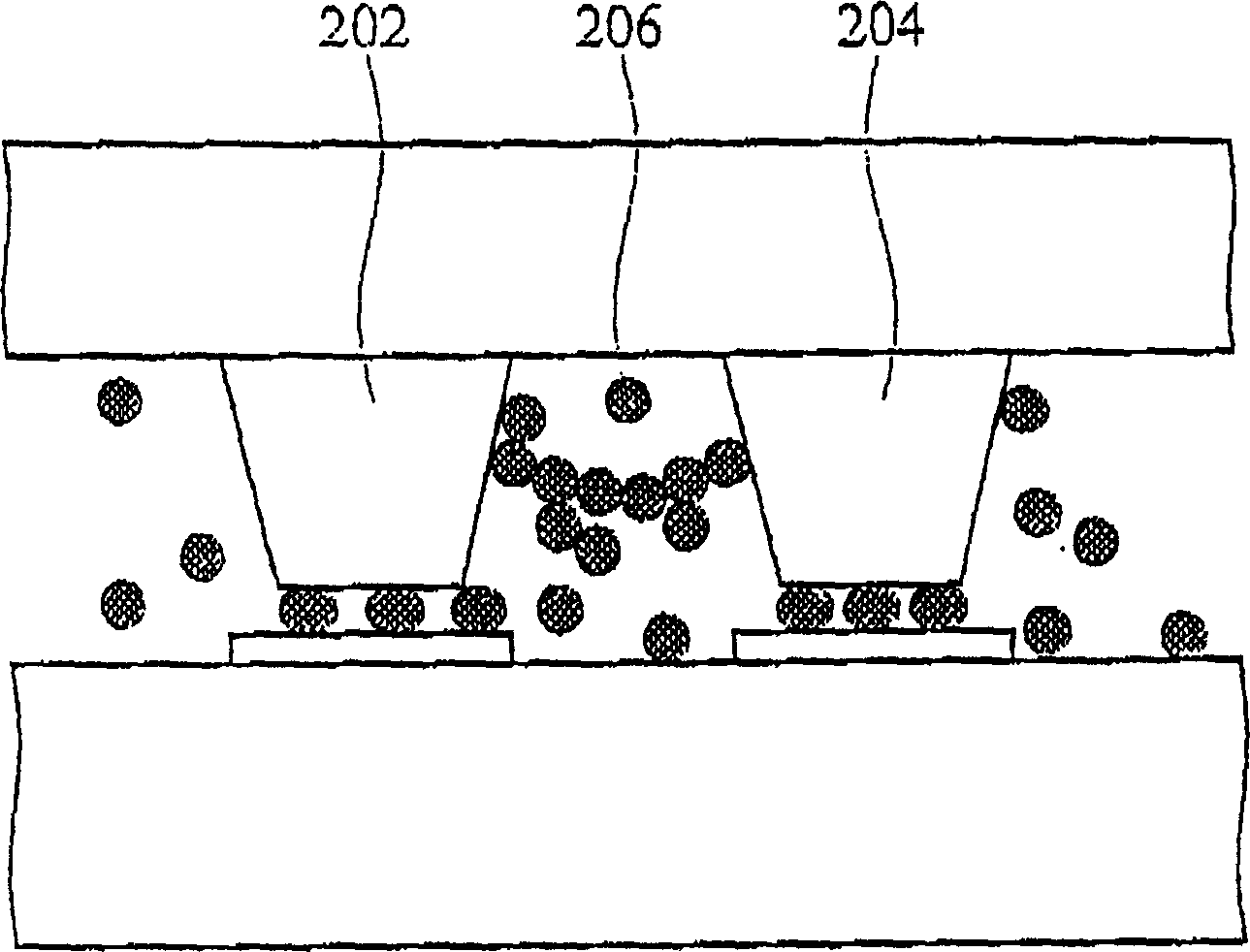

[0039] like Figure 4 As shown, the composite bump structure of this embodiment includes the following elements: a contact pad 402 is located on a substrate 400, such as a semiconductor substrate, electrodes (not shown) are formed on the substrate 400, and the contact pad 402 and The electrodes are electrically connected. The main part 404 is composed of a polymer, located on the substrate 400. The above-mentioned polymer is preferably a high molecular polymer, more preferably a high molecular polymer with a thermal expansion coefficient similar to that of metals such as aluminum and gold, and a good bond with the metal. .

[0040] The composite bump structure of this embodiment further includes at least one conductive plug 406 located in the main body portion 404 . In detail, the above-mentioned conductive plug 406 runs through the entire main body portion 404 ; and a conductive layer 408 is located on the main body portion 404 , wherein the conductive layer 408 is electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com