Gas injection point retreating type coal underground gasification system and process

A technology of retreating the gas injection point and underground gasification, which is applied in coal gasification, underground mining, construction, etc., can solve problems such as blockage, achieve the effects of improving safety, eliminating ground surface subsidence, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

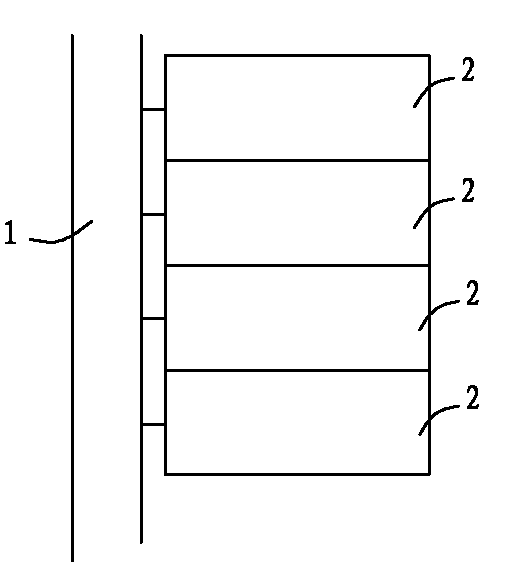

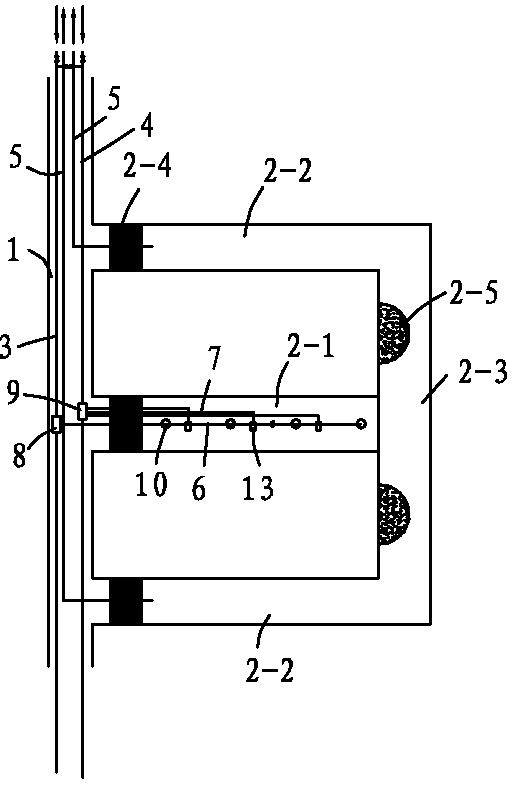

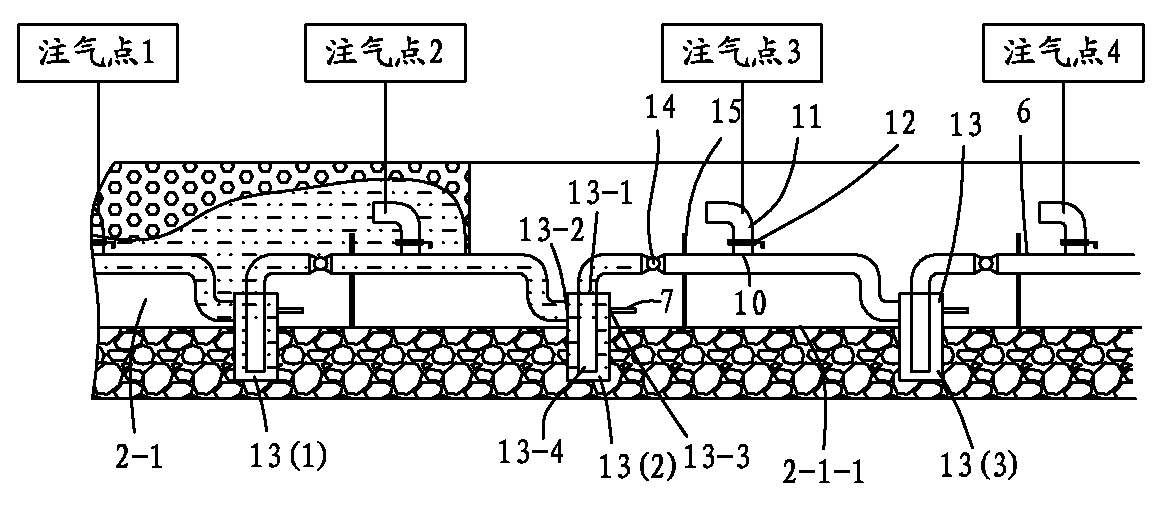

[0046] A kind of underground coal gasification system, see Figure 1 to Figure 4 , the system includes a ventilation roadway 1 and a plurality of underground coal gasification units 2 arranged in the coal seam, and the ventilation roadway connects a plurality of underground coal gasification units; wherein, the underground coal gasification unit includes a gasification unit arranged on a plane agent injection tunnel 2-1 and two gas transportation tunnels 2-2, the two gas transportation tunnels are arranged parallel to both sides of the gasification agent injection tunnel at a certain distance from the gasification agent injection tunnel, the two gas transmission tunnels and the gasification agent injection tunnel One end of the gasification agent injection roadway is connected to each other through the initial gasification roadway 2-3, and the other end of the two gas transportation roadways and the gasification agent injection roadway is isolated from the ventilation roadway t...

Embodiment 2

[0054] An underground coal gasification process is an underground gasification process based on the underground coal gasification system described in Example 1, wherein the sequence of steps of the process comprises: a step of cold test, a step of igniting the gasification working face, a gasification The steps of commissioning of the gasification working face and the steps of retreating the gas injection point for normal production of gasification;

[0055] The steps of the cold test include:

[0056] a. Static pressure relief test on the gasification working face: open the valves of all the inlet pipelines of the gasification working face of the gasification unit, close the valve of the gas outlet pipeline, supply air to the gasification unit, and record the pressure of the gasification working face from the gas outlet Ascent rate, maintain pressure at 60KPa or above, detect leakage;

[0057] b. Dynamic leakage rate measurement: open the inlet valve and outlet valve of one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com