Fan, generator and brush yoke component of car radiator

A radiator fan and brush holder technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing material costs, increasing processing costs, and unfavorable heat dissipation, so as to improve reliability, save brackets, and effectively good for fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

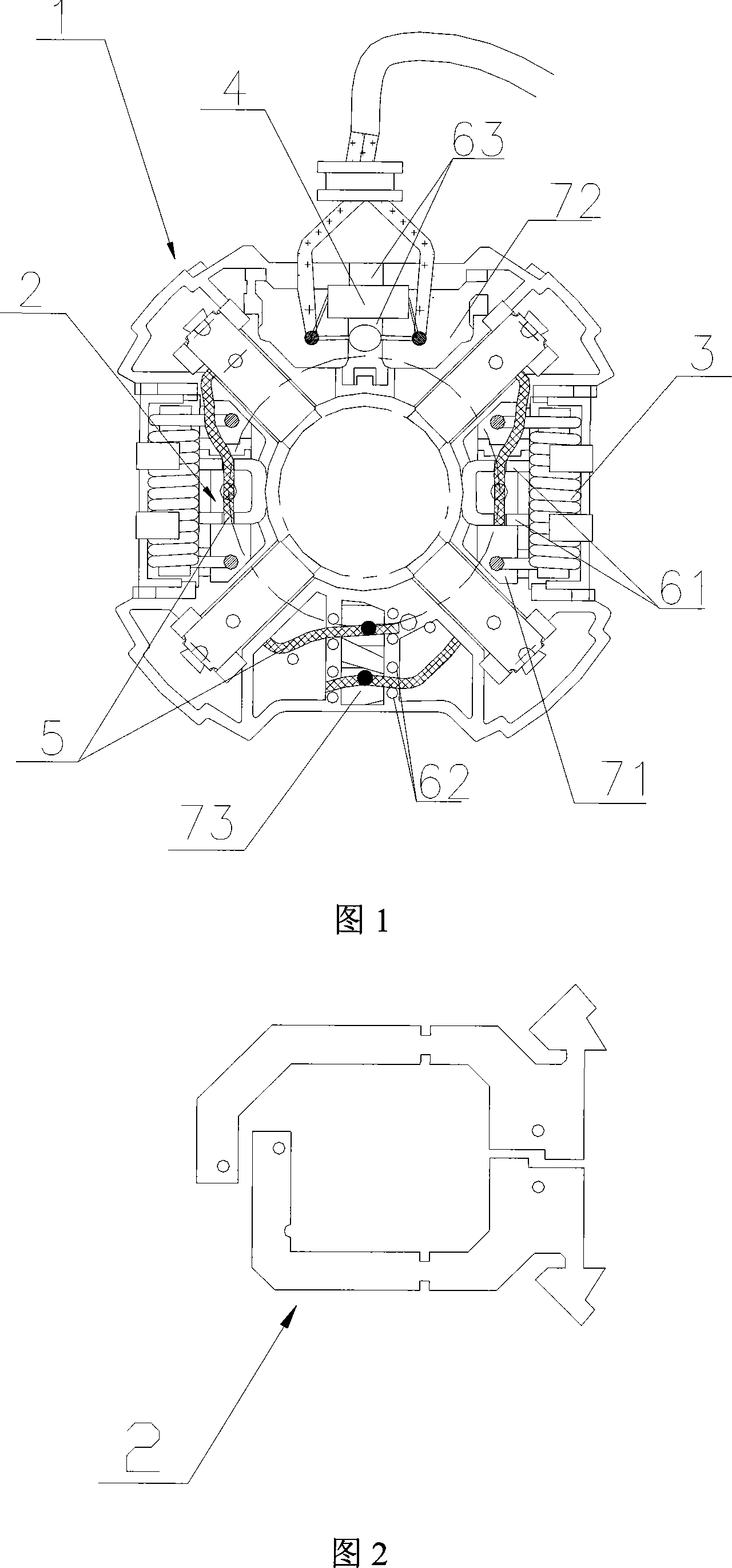

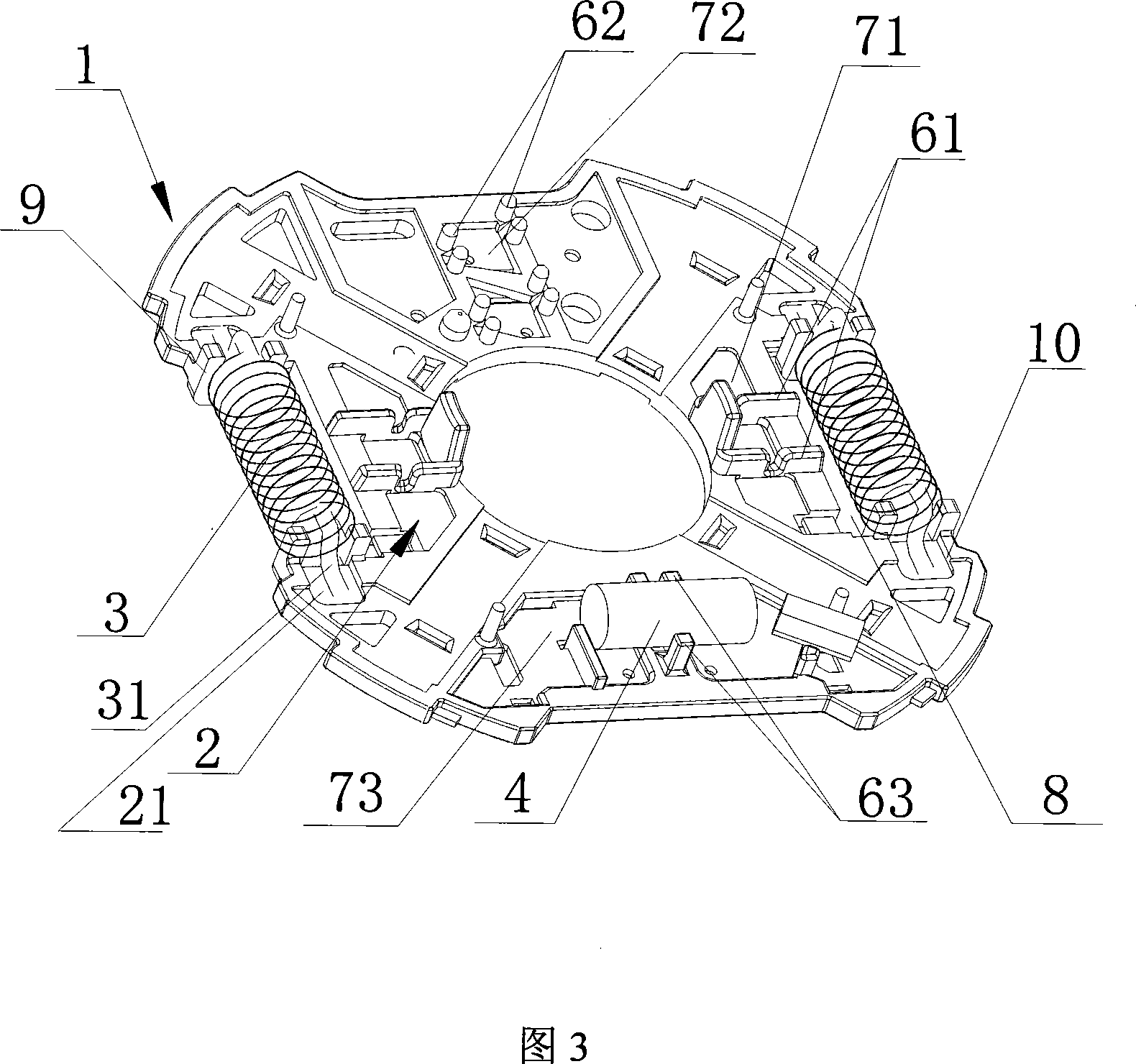

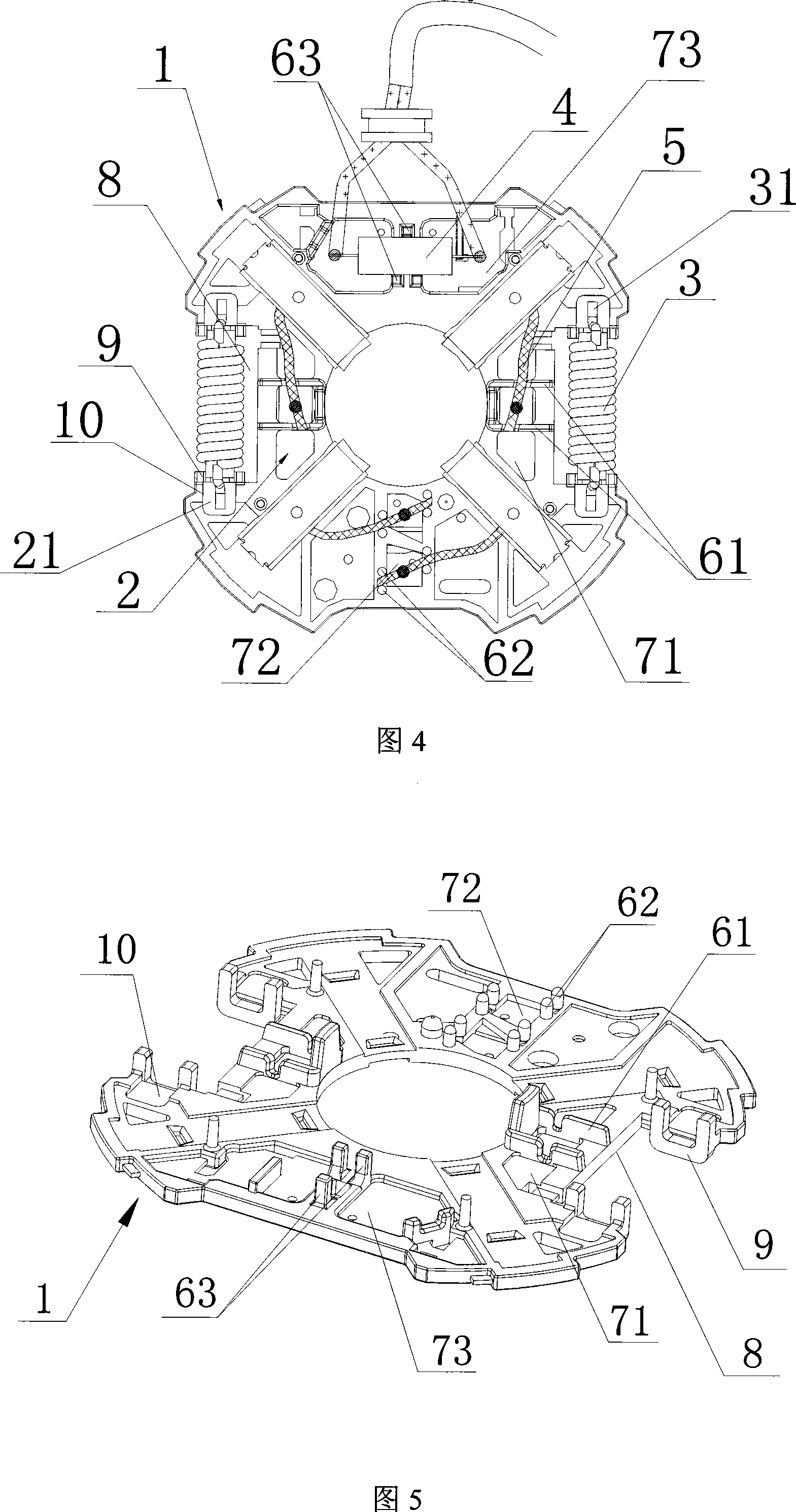

[0016] As shown in Figures 1 to 5, the brush holder assembly of the vehicle radiator fan motor includes a brush holder bottom plate 1, a metal connecting piece 2, a brush holder, a compression spring, a brush, an inductor 3, a capacitor 4, and a brush lead Line 5, the brush holder bottom plate 1 is ring-shaped, the metal connecting piece 2 is ring-shaped corresponding to the brush holder bottom plate, and embedded in the brush holder bottom plate 1, the brush holder bottom plate 1 is integrally provided with protruding structures 61, 62, 63 for fixing the brush lead wires and capacitors, and is provided with bottom plate openings 71, 72, 73 for welding with metal connecting pieces. The spring, the brush and the inductance 3 are fixed on the bottom plate 1 of the brush holder, and the inductance 3, the capacitor 4, and the lead wire 5 of the brush are all welded to the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com