Oily ceramic slurry, preparation method thereof, positive plate coated with slurry and lithium ion battery

A technology of ceramic slurry and positive electrode sheet, applied in the direction of positive electrode, secondary battery, battery electrode, etc., can solve the problems of large swelling of water-based ceramic coating, easy phase separation and easy detachment of oil-based ceramic coating, etc., to solve the problem of swelling Large, improve flexibility, improve the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

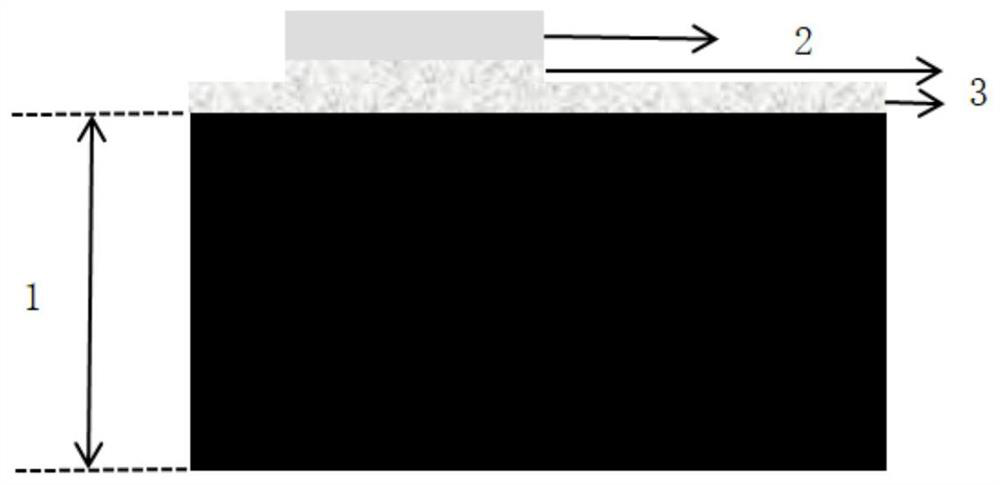

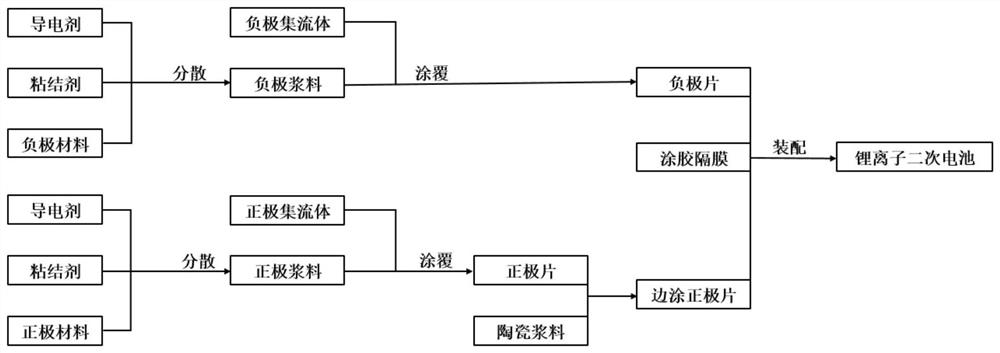

Image

Examples

Embodiment 1

[0053] This embodiment provides an oily ceramic slurry and its preparation method, the raw material components of the oily ceramic slurry include: a first binder, a second binder, ceramic powder and an organic solvent; wherein, the first One binder is polyacrylic acid-polyacrylate copolymer, the molecular weight of the first binder is 600,000, and the glass transition temperature is 65°C; the second binder is polyvinylidene fluoride, and the The molecular weight of the second binder is 1.1 million, and the crystallinity is 42%; the ceramic powder is alumina ceramics (particle diameter D50 is 2 μm); the organic solvent is N-methylpyrrolidone;

[0054] The weight ratio of the first binder and the second binder is 4:1, and the mass ratio of the total mass of the first binder and the second binder to the ceramic powder is 3.5:1.

[0055] The preparation method of described oily ceramic slurry comprises:

[0056] (1) Add the powder solids of the first binder and the second binder ...

Embodiment 2

[0067]This embodiment provides an oily ceramic slurry and its preparation method, the raw material components of the oily ceramic slurry include: a first binder, a second binder, ceramic powder and an organic solvent; wherein, the first One binder is polyacrylonitrile-polyacrylamide, the molecular weight of the first binder is 300,000, and the glass transition temperature is 70°C; the second binder is polytetrafluoroethylene, and the second binder is The molecular weight of the second binder is 900,000, and the crystallinity is 45%; the ceramic powder is zirconia ceramics (particle size D50 is 0.5 μm); the organic solvent is N-methylpyrrolidone;

[0068] The weight ratio of the first binder and the second binder is 7:3, and the mass ratio of the total mass of the first binder and the second binder to the ceramic powder is 6:4.

[0069] The preparation method of described oily ceramic slurry comprises:

[0070] (1) Add the powder solids of the first binder and the second binde...

Embodiment 3

[0074] This embodiment provides an oily ceramic slurry and its preparation method, the raw material components of the oily ceramic slurry include: a first binder, a second binder, ceramic powder and an organic solvent; wherein, the first One binder is polyacrylate-polyamideimide copolymer, the molecular weight of the first binder is 400,000, and the glass transition temperature is 75°C; the second binder is polyhexafluoropropylene , the molecular weight of the second binder is 1.2 million, and the crystallinity is 43%; the ceramic powder is magnesium oxide ceramics (particle diameter D50 is 1 μm); the organic solvent is N-methylpyrrolidone;

[0075] The weight ratio of the first binder to the second binder is 6:1, and the mass ratio of the total mass of the first binder and the second binder to the ceramic powder is 2:1.

[0076] The preparation method of described oily ceramic slurry comprises:

[0077] (1) Add the powder solids of the first binder and the second binder to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com