Patents

Literature

30results about How to "Eliminate collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

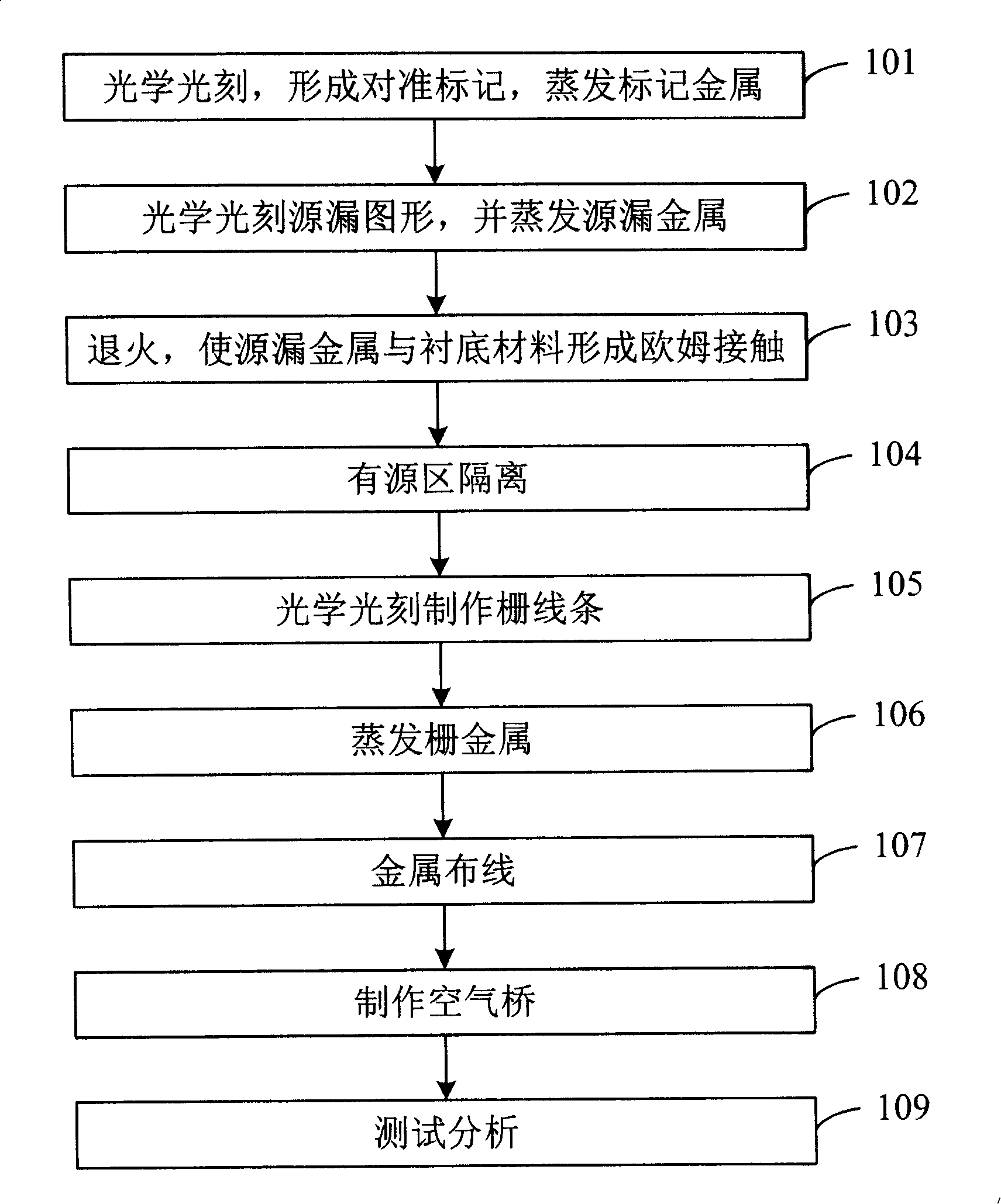

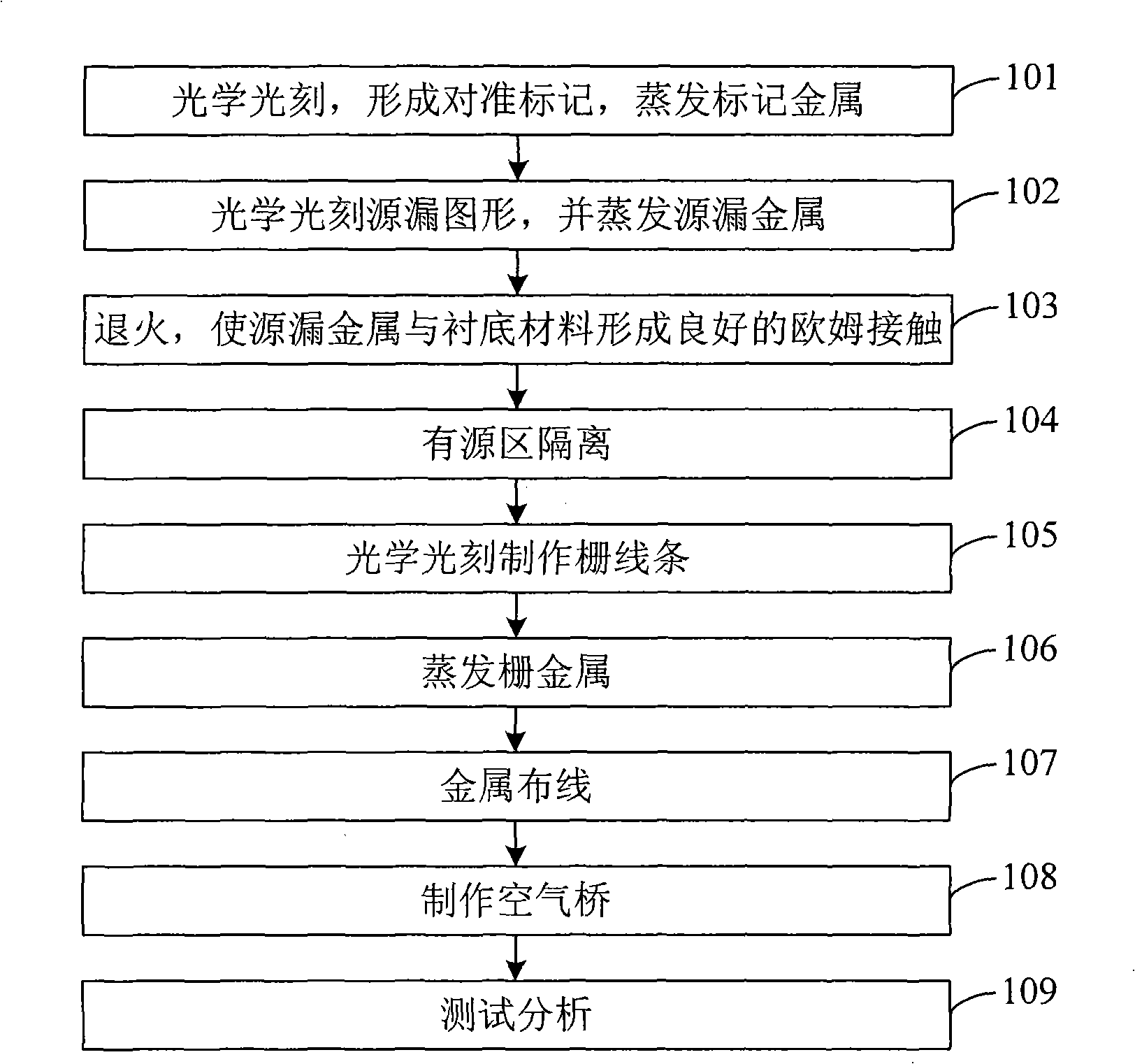

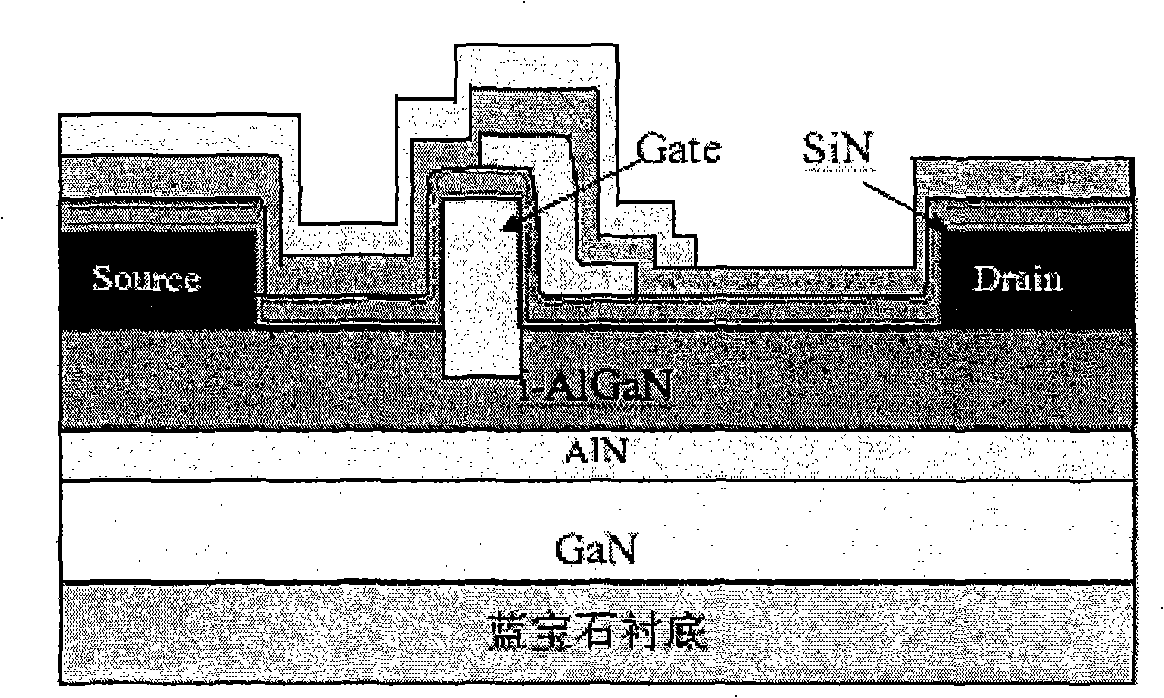

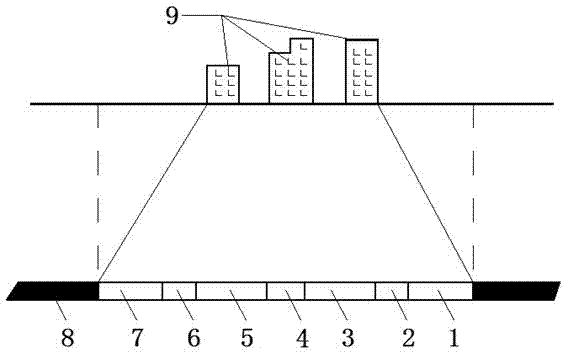

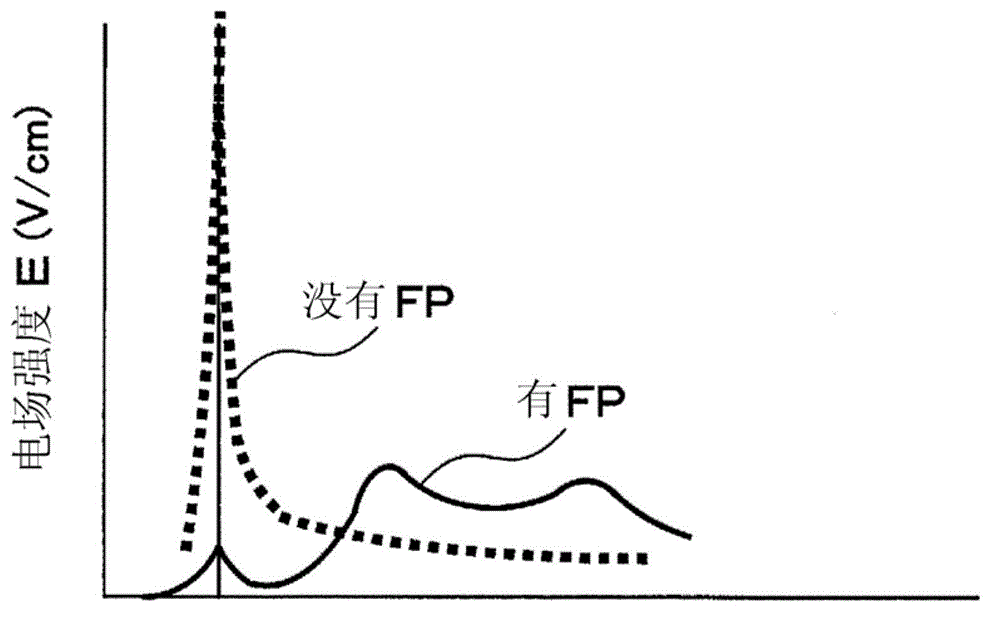

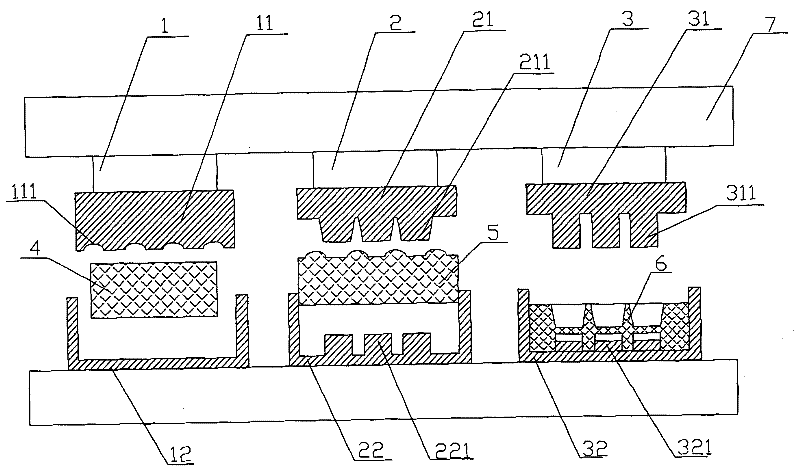

Field effect transistor multi-layer field plate device and method for making the same

InactiveCN101232045AImprove breakdown characteristicsInhibit current collapse phenomenonSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsMicrowave power

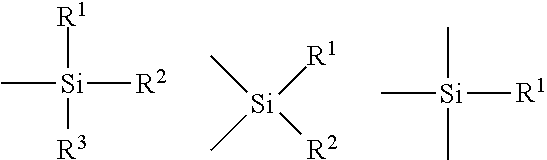

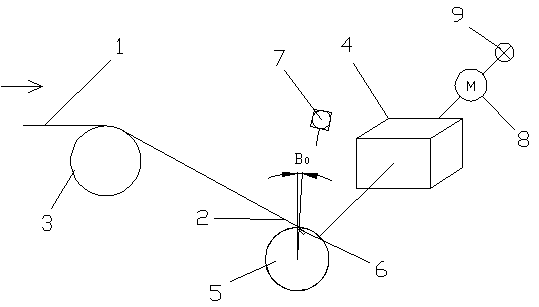

The invention relates to the field of microwave power device technology in semiconductor material and discloses a method for fabricating an AlGaN / GaN high-electron mobility transistor (AlGaN / GaN HEMT) multilayer field plate device. The method comprises, based on common AlGaN / GaN HEMT device fabrication process, firstly fabricating a gate connection field plate after forming a gate metal contact, secondly fabricating a source connection field plate, and forming the AlGaN / GaN HEMT multilayer field plate device. The invention simultaneously discloses an AlGaN / GaN HEMT multilayer field plate device. The invention can greatly improve the breakdown characteristics of the AlGaN / GaN HEMT device and effectively suppress the current collapse of the AlGaN / GaN HEMT device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

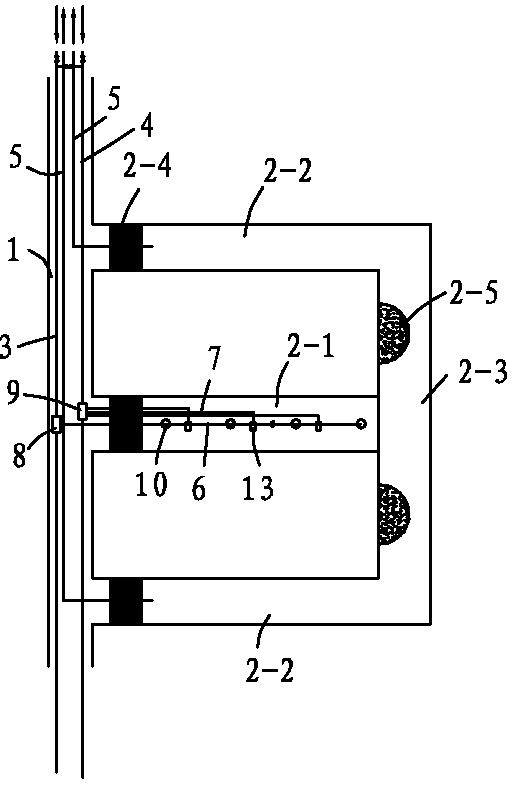

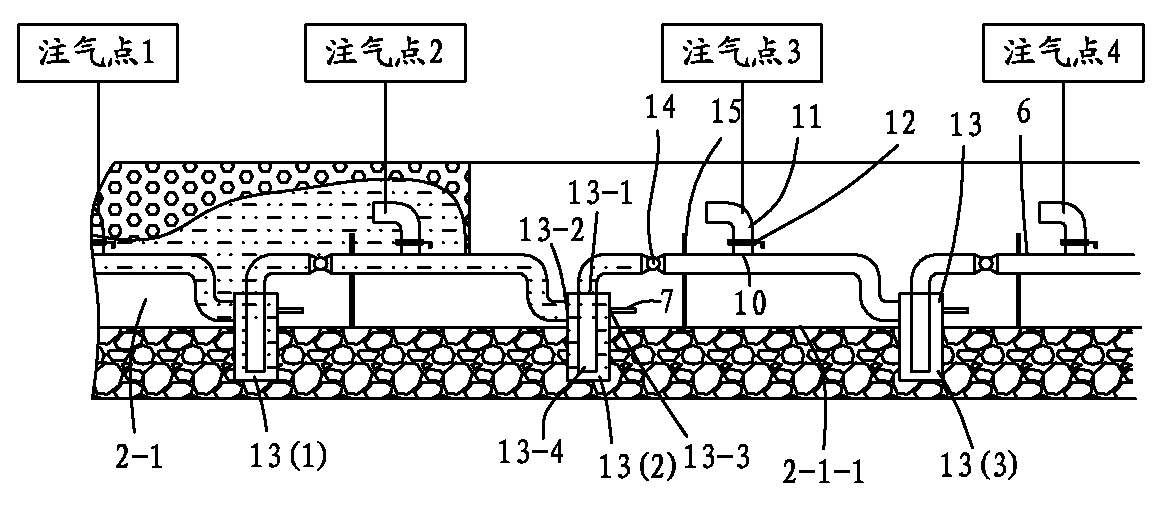

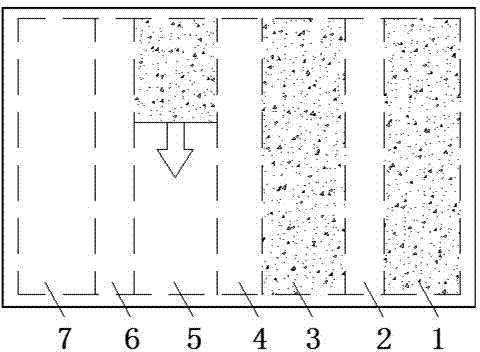

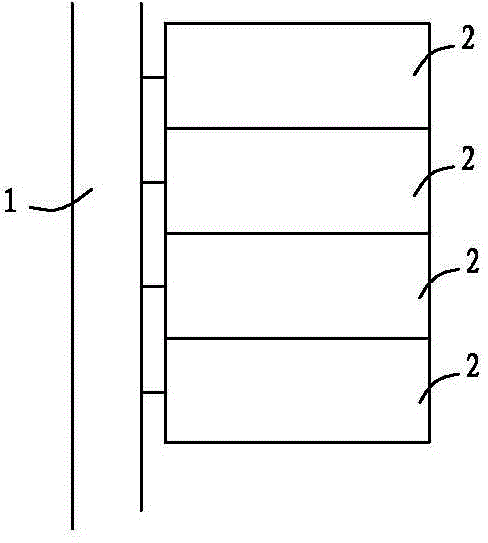

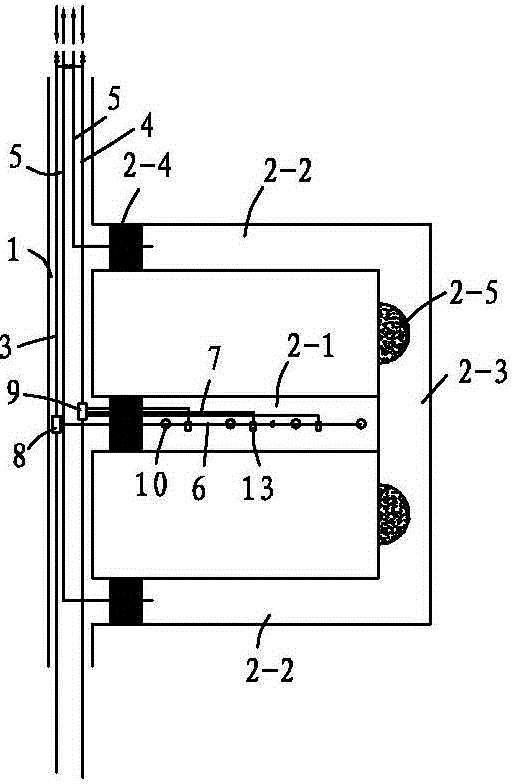

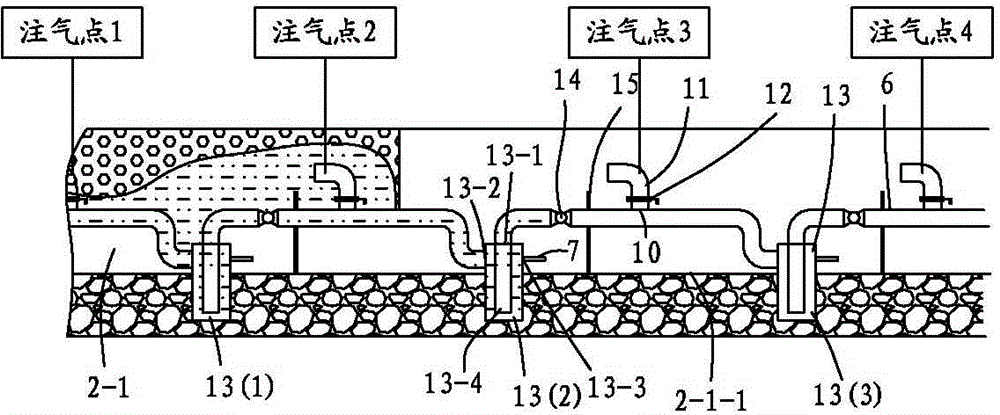

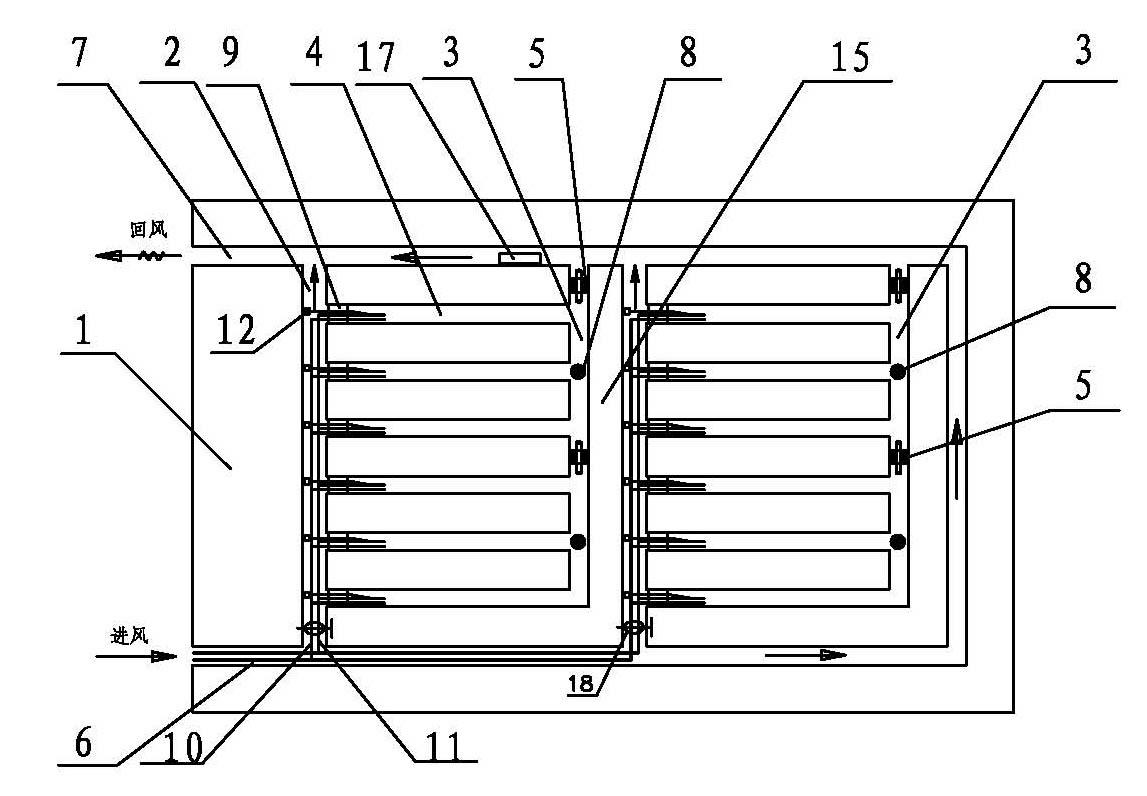

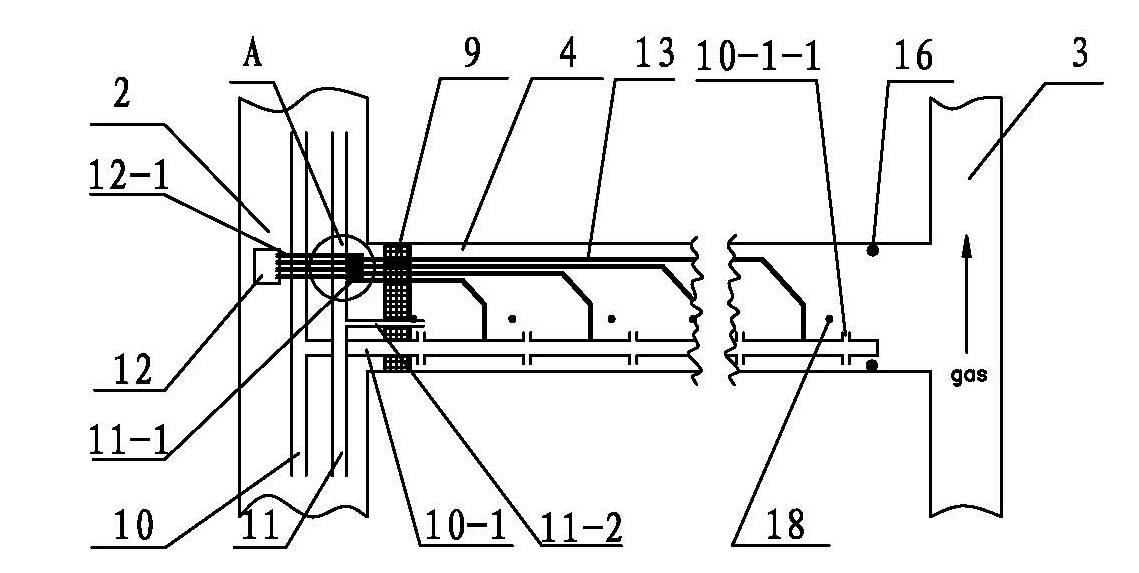

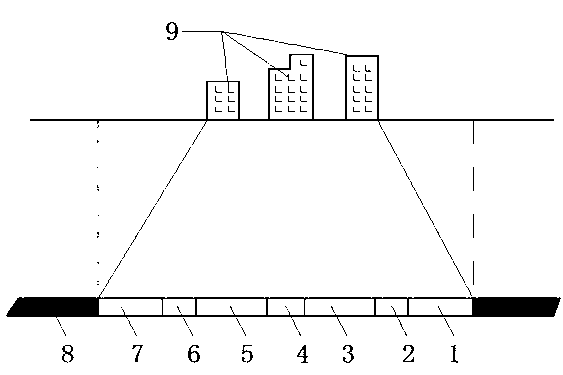

Gas injection point retreating type coal underground gasification system and process

InactiveCN103277082AAvoid cloggingPrevent backflowConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

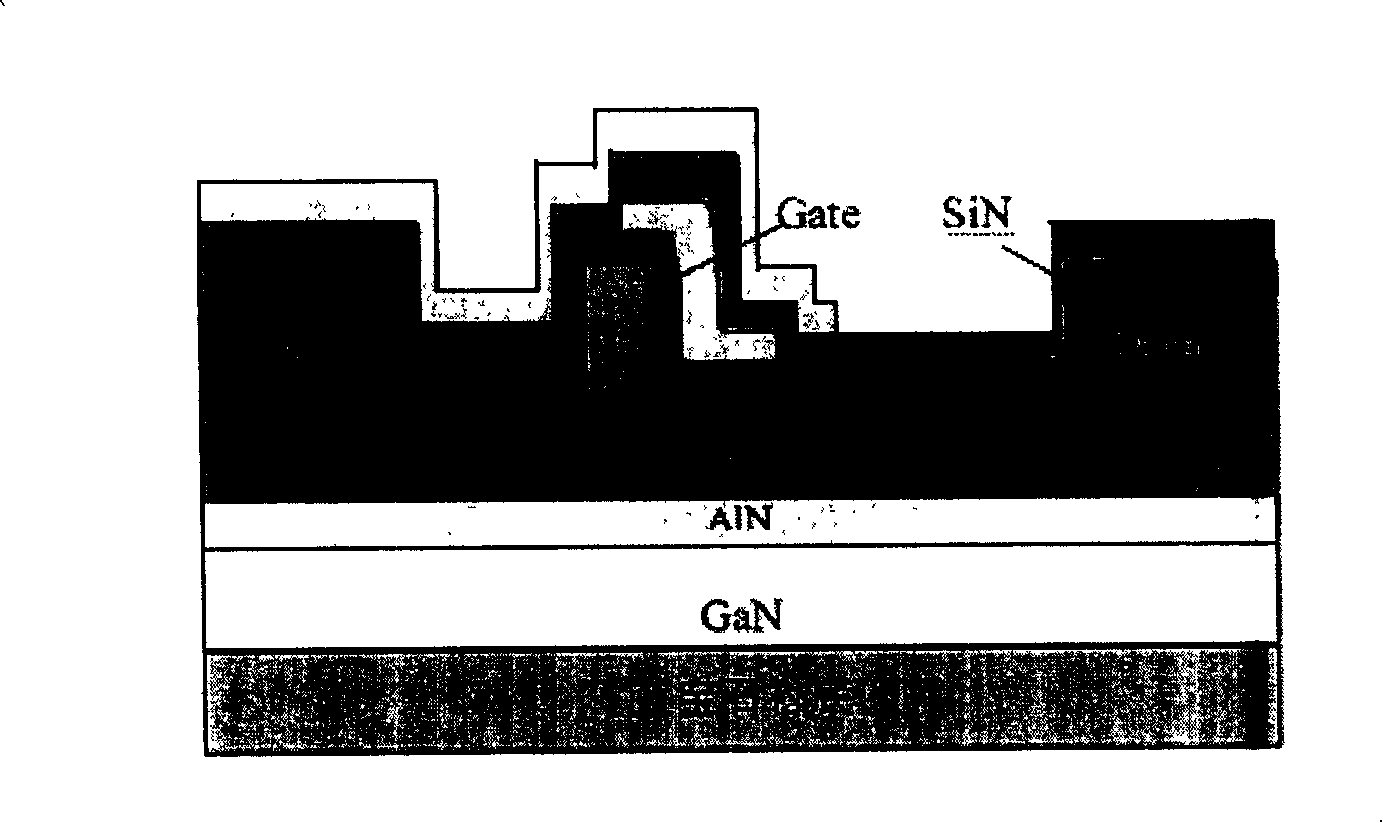

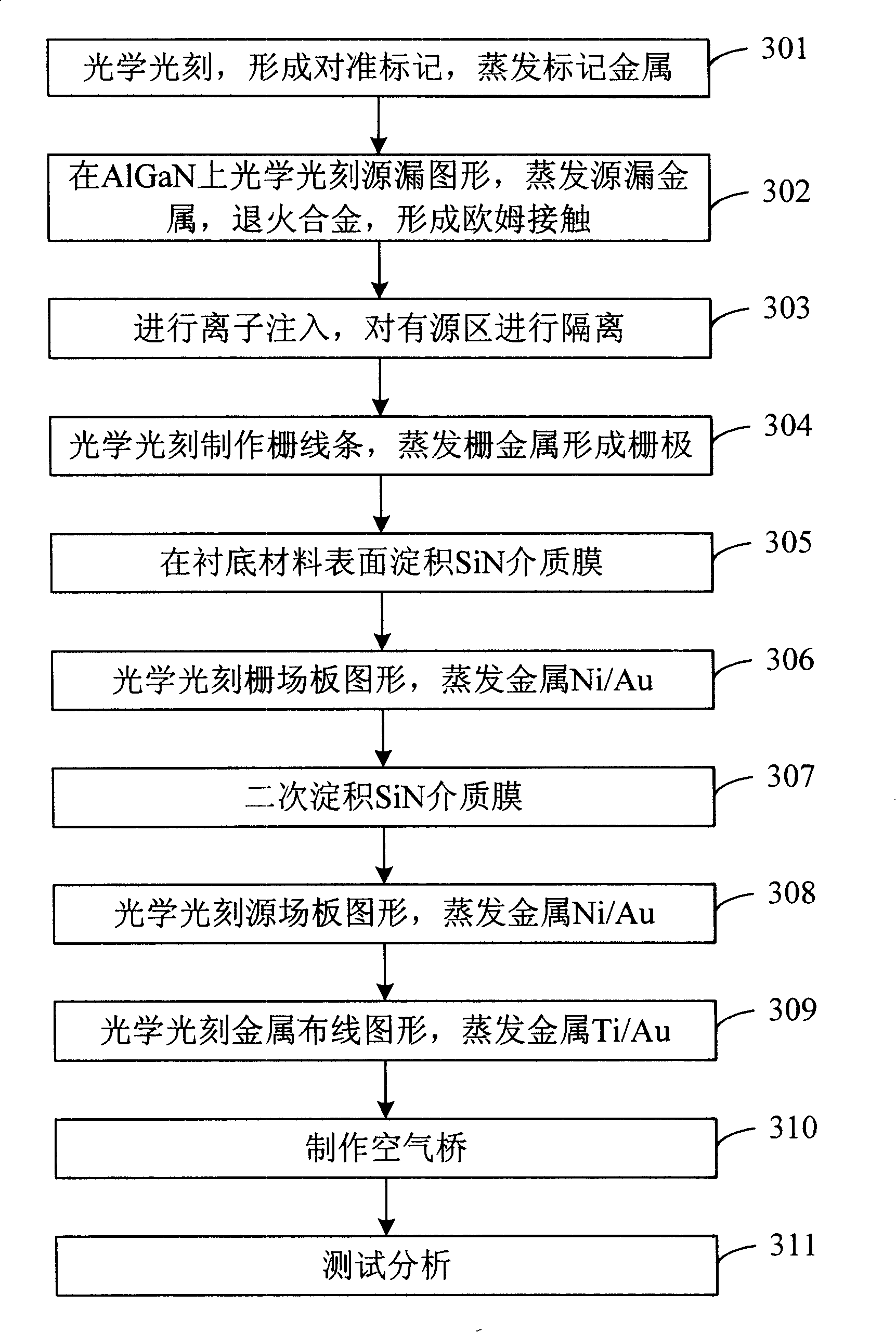

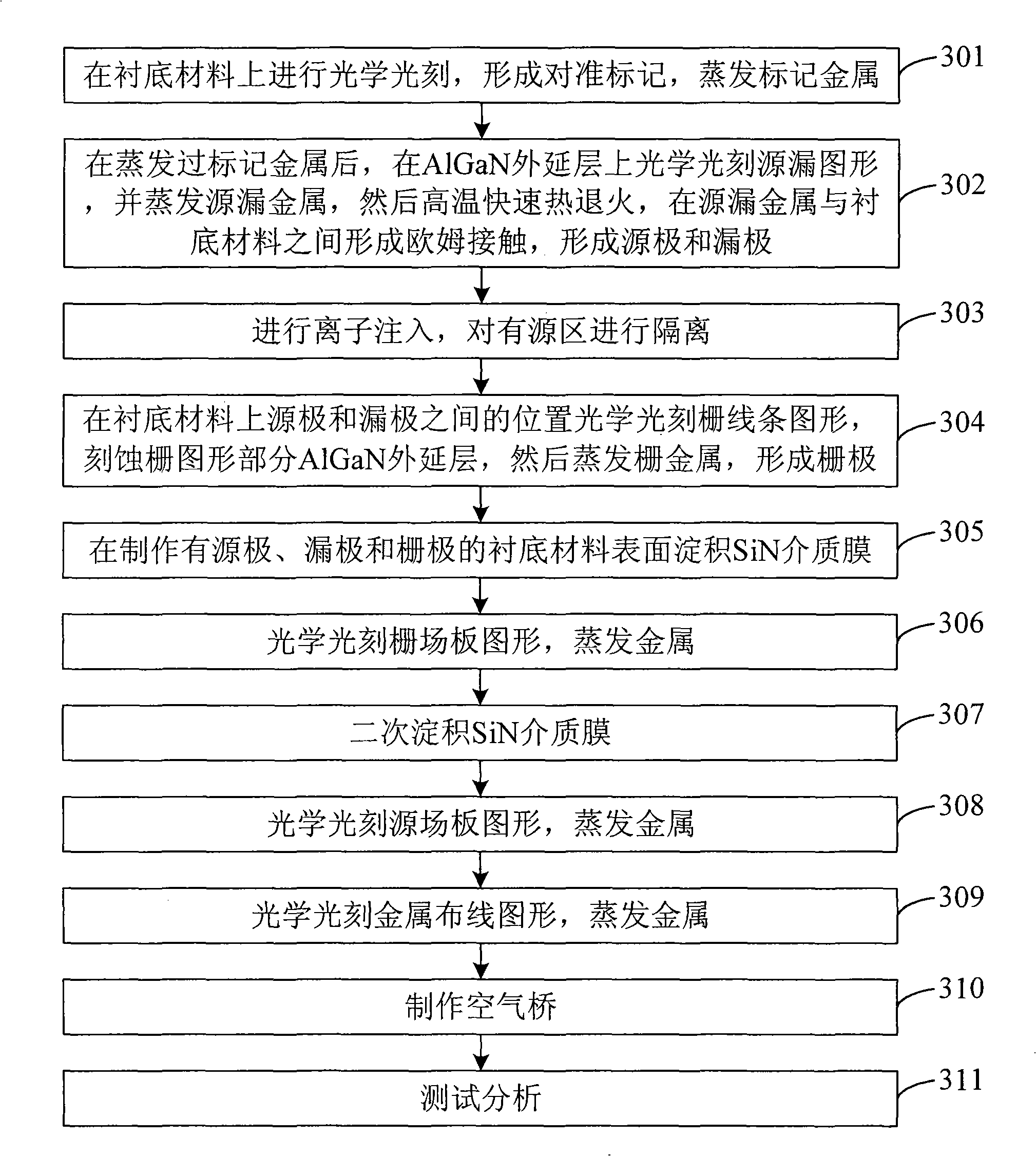

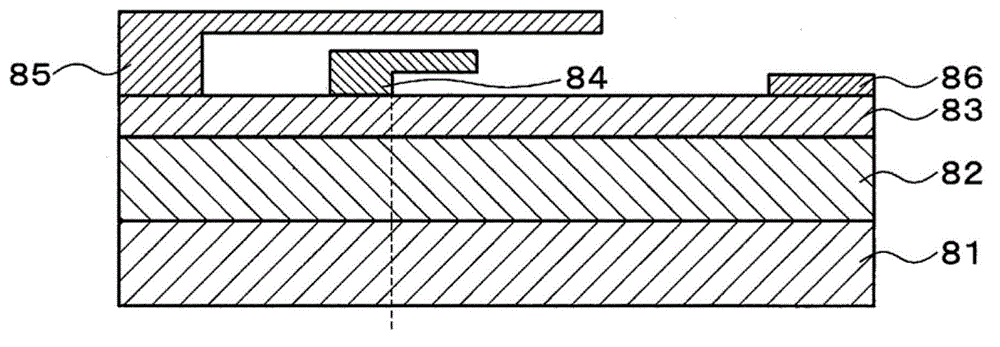

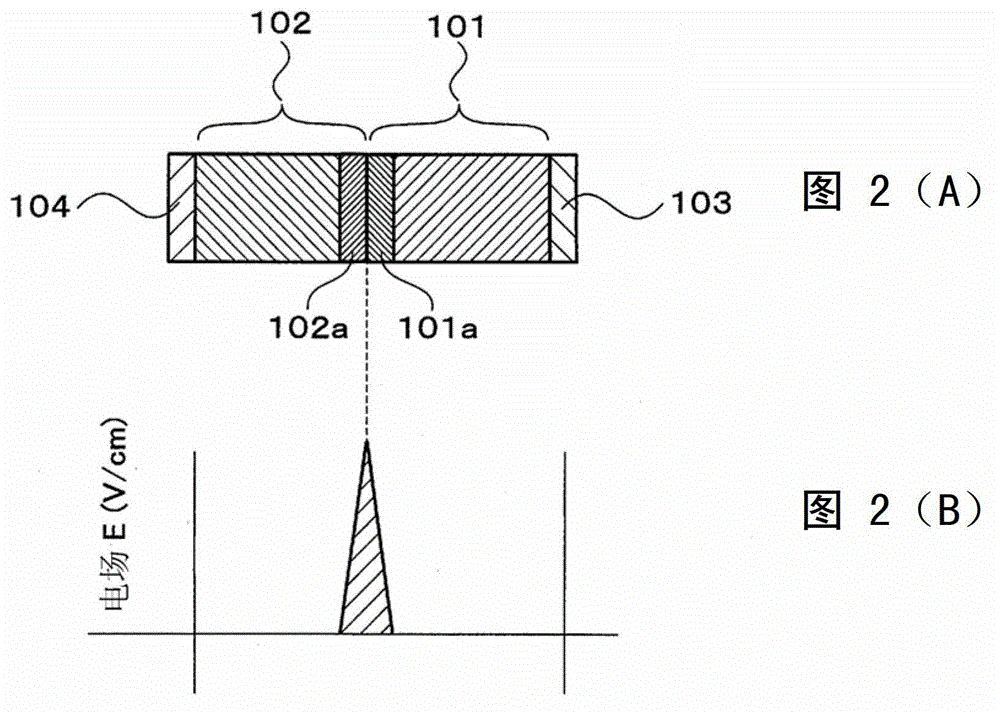

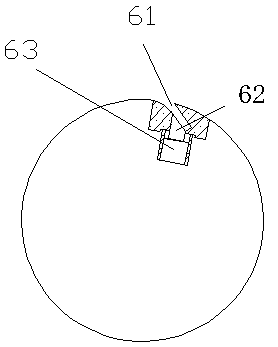

AlGaN/GaN HEMT multilayer field plate device of concave grid groove and manufacturing method thereof

InactiveCN101276837AImprove breakdown voltageEliminate collapseSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsGrid connection

The invention relates to the technical field of microwave power device in semiconductor materials, discloses a AlGaN / GaN HEMT multilayer field board device of recessed grid, and meanwhile discloses a method for manufacturing AlGaN / GaN HEMT multilayer field board device of the recessed grid; on the basis of common AlGaN / GaN HEMT device manufacturing process, the method comprises the steps of photo-etching grid images after forming Ohm contact of a source electrode and a drain electrode, etching AlGaN extension layer of a part of the grid image, after evaporating grid metal, firstly manufacturing a grid connection field board and then a source connection field board to form the AlGaN / GaN HEMT multilayer field board device of the recessed grid. Utilization of the invention can efficiently improve puncturing characteristic, transconductance and threshold value voltage of the AlGaN / GaN HEMT device, and at the same time of improving the device plus, availably suppress phenomenon of current collapse of the AlGaN / GaN HEMT device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

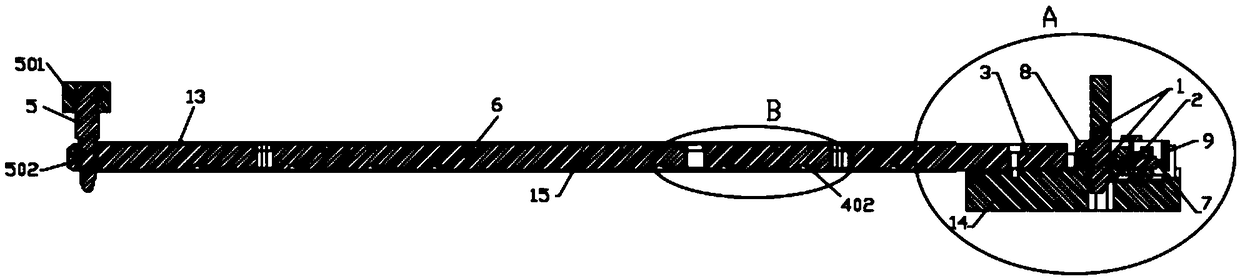

Control method for preventing steel coil inner ring from core pulling during coil stripping of coiling machine

The invention provides a control method for preventing a steel coil inner ring from core pulling during coil stripping of a coiling machine. The control method for preventing the steel coil inner ring from core pulling during coil stripping of a coiling machine comprises the steps that the position of a tong opening is detected after coiling is finished; an ideal shearpoint of strip steel is calculated; a strip tail is positioned; and automatic coil stripping is conducted. The phenomena of jamming of a strip head, scratching of the steel coil inner ring and core pulling during coil stripping can be completely eliminated by adopting the control method for preventing core pulling of the steel coil inner ring during coil stripping of the coiling machine.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

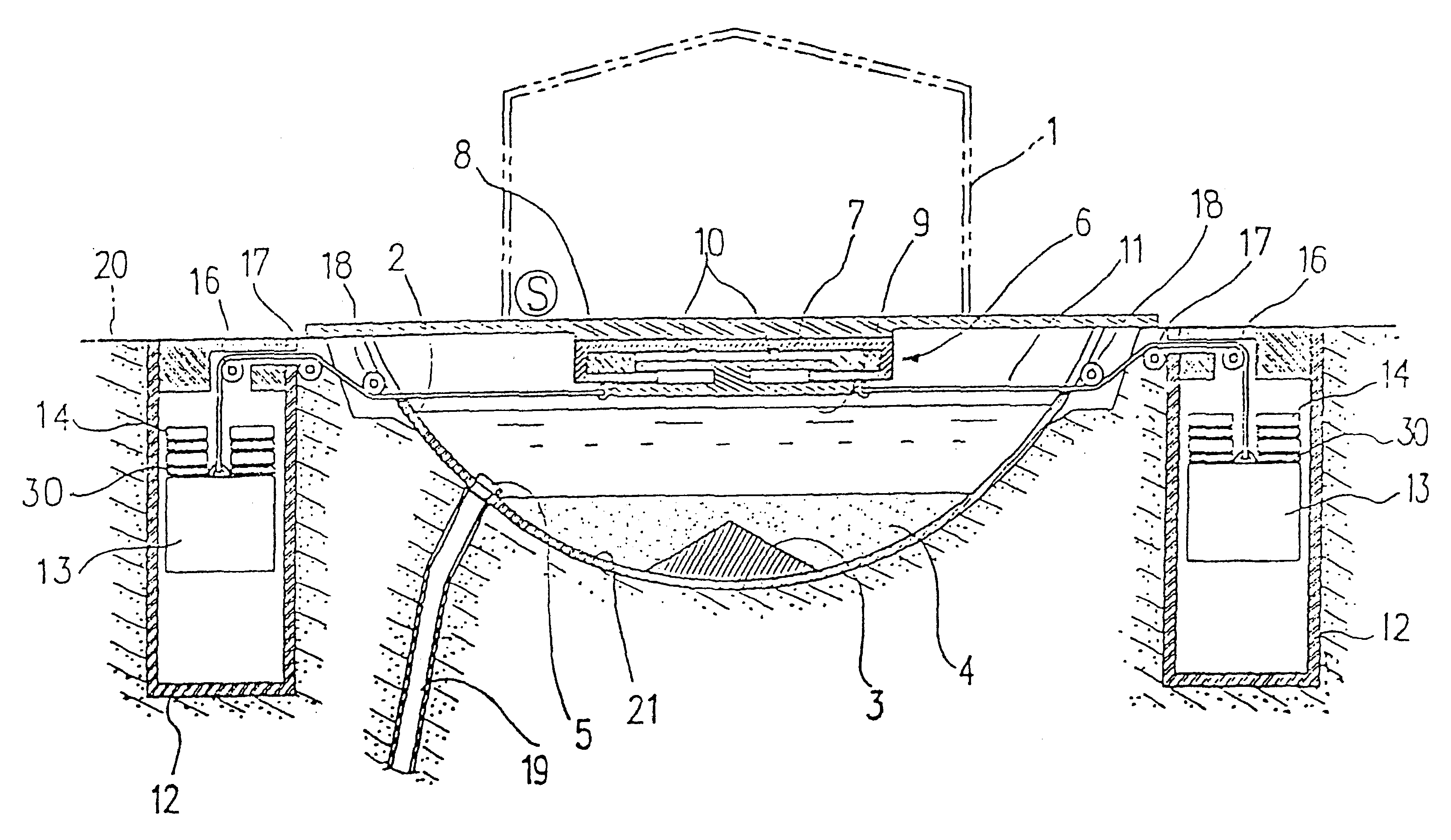

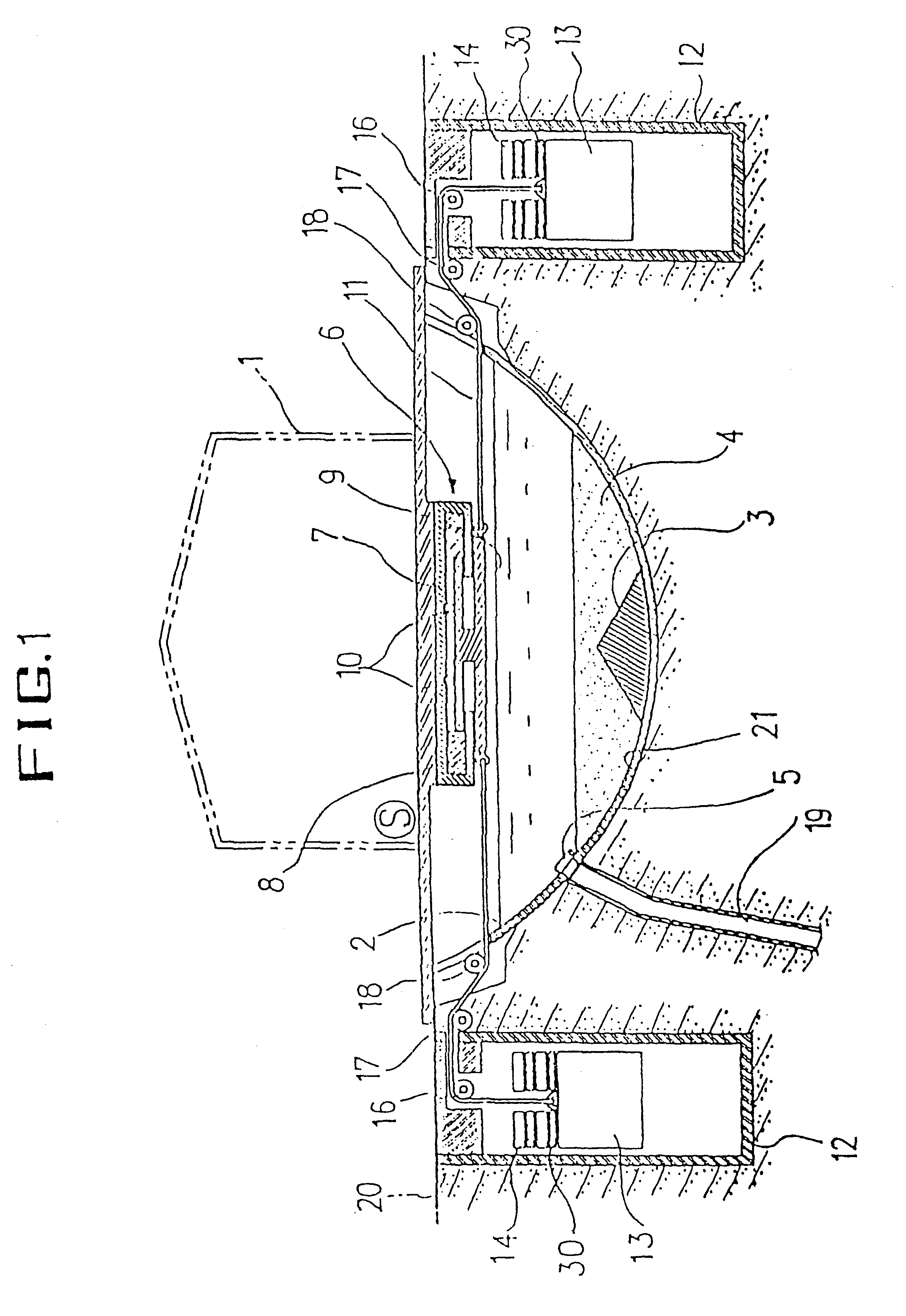

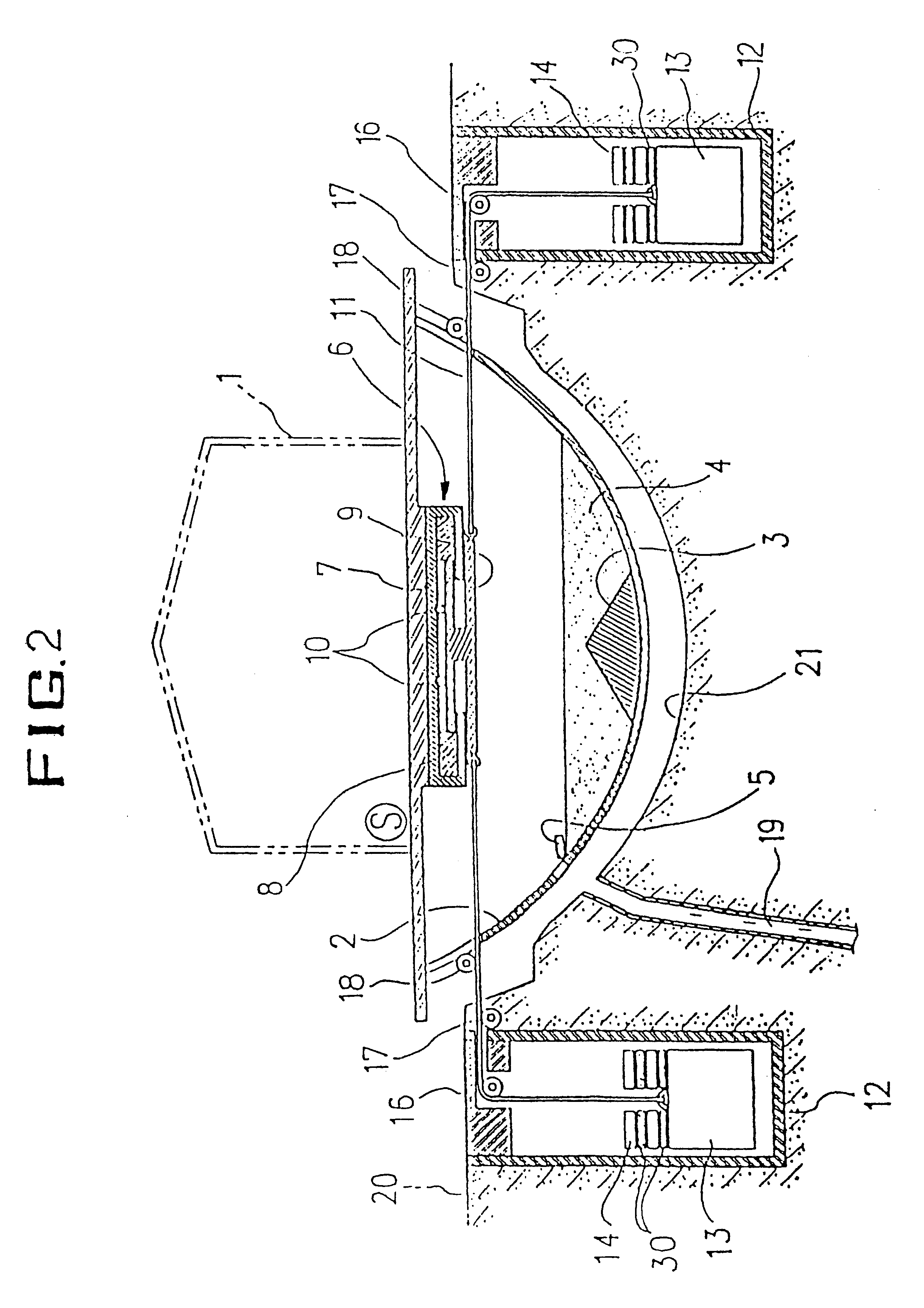

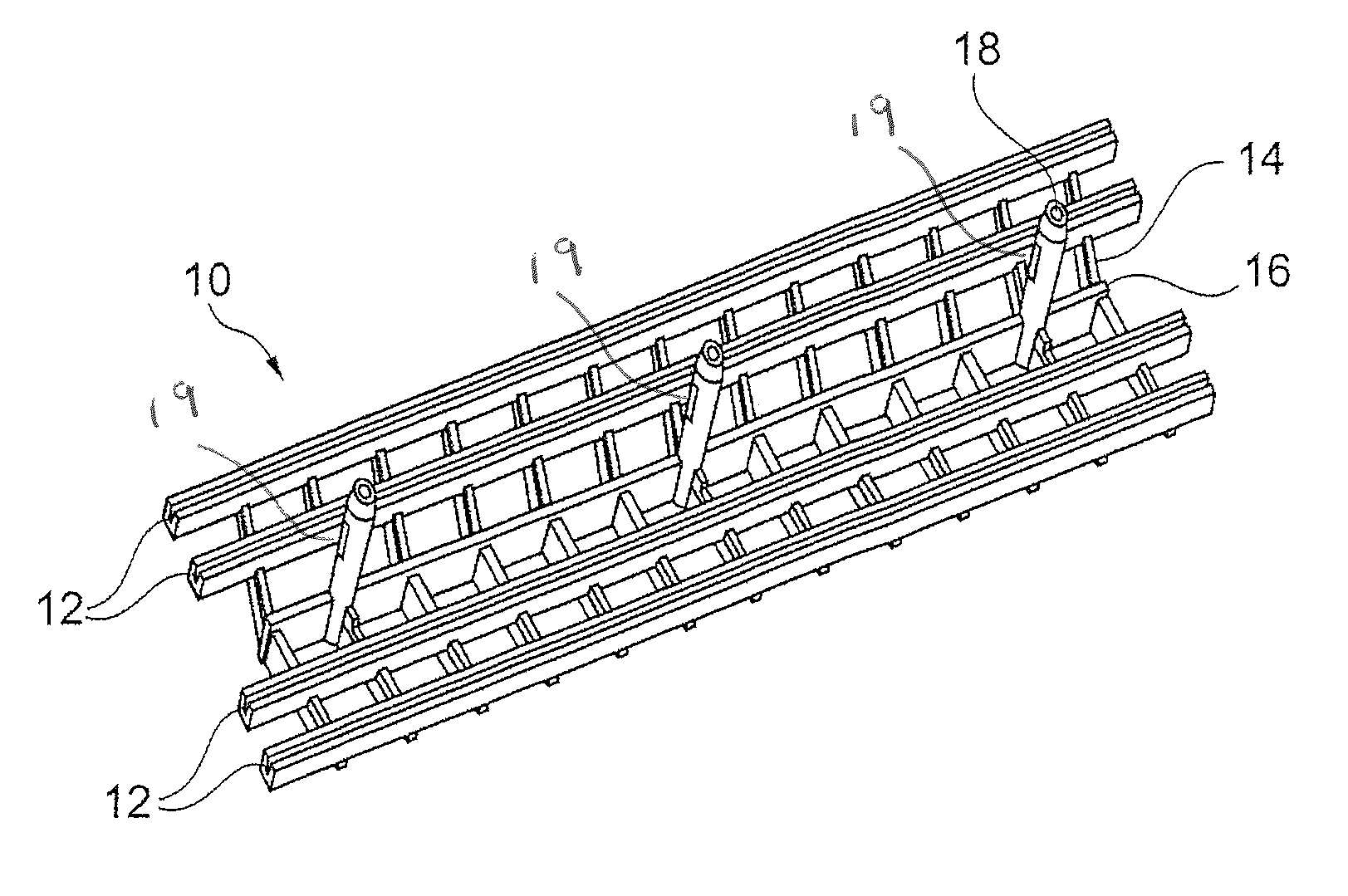

Method of and apparatus for preventing structure from collapsing due to earthquake

InactiveUS6484458B1Prevent collapseIncrease weightProtective foundationProtective buildings/sheltersEngineeringVariable weight

Owner:PARK JANG HO

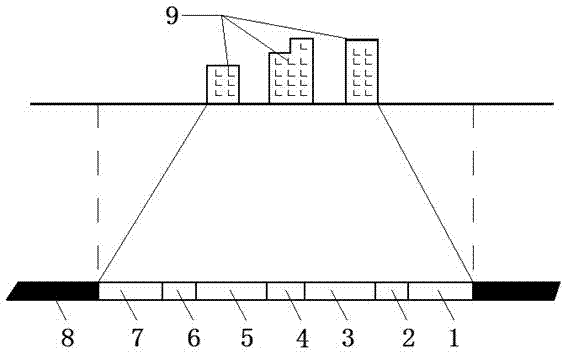

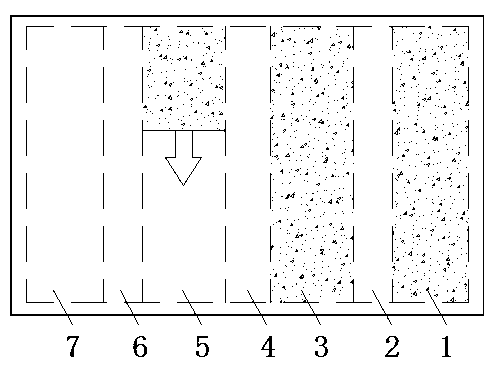

A secondary coal mining method with strip reverse paste filling

ActiveCN102261247AWell deformedImprove securityUnderground miningSurface miningCoal gangueCoal pillar

The invention relates to a secondary coal-mining method for reversely filling paste in stripes. The secondary coal-mining method is suitable for the safe recovery of coal resources under buildings, railways and water bodies. The secondary coal-mining method comprises the following steps of: determining the range of mining coal under building groups according to regulations, and alternatively partitioning paste filling stripes and recovery stripes in the determined coal mining range; sequentially mining the partitioned paste filling stripes and filling mine-out areas of the partitioned paste filling stripes; and sequentially drilling without section pillar along the two paste filling strips and mining the recovery stripes by a caving method after a filler in the past filling stripes is completely solidified. Under usual conditions, the paste filling stripes are wider, and normal recovery stripes are narrow. By the method, the damage to the surface buildings caused by mining subsidence can be effectively reduced, the safety of coal mining can also be ensured without reserving narrow coal pillars, so that the coal resource is completely recovered; and simultaneously, coal resources utilization of solid wastes such as coal gangues and fly ash is realized.

Owner:CHINA UNIV OF MINING & TECH

Semiconductor device

ActiveCN102947921AEliminate collapseReduce lossTransistorSemiconductor/solid-state device manufacturingPower semiconductor devicePower flow

Owner:UNIV OF SHEFFIELD +1

A kind of underground coal gasification system and process with retreating gas injection point

InactiveCN103277082BImplement fixed-point injectionImprove stabilityConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

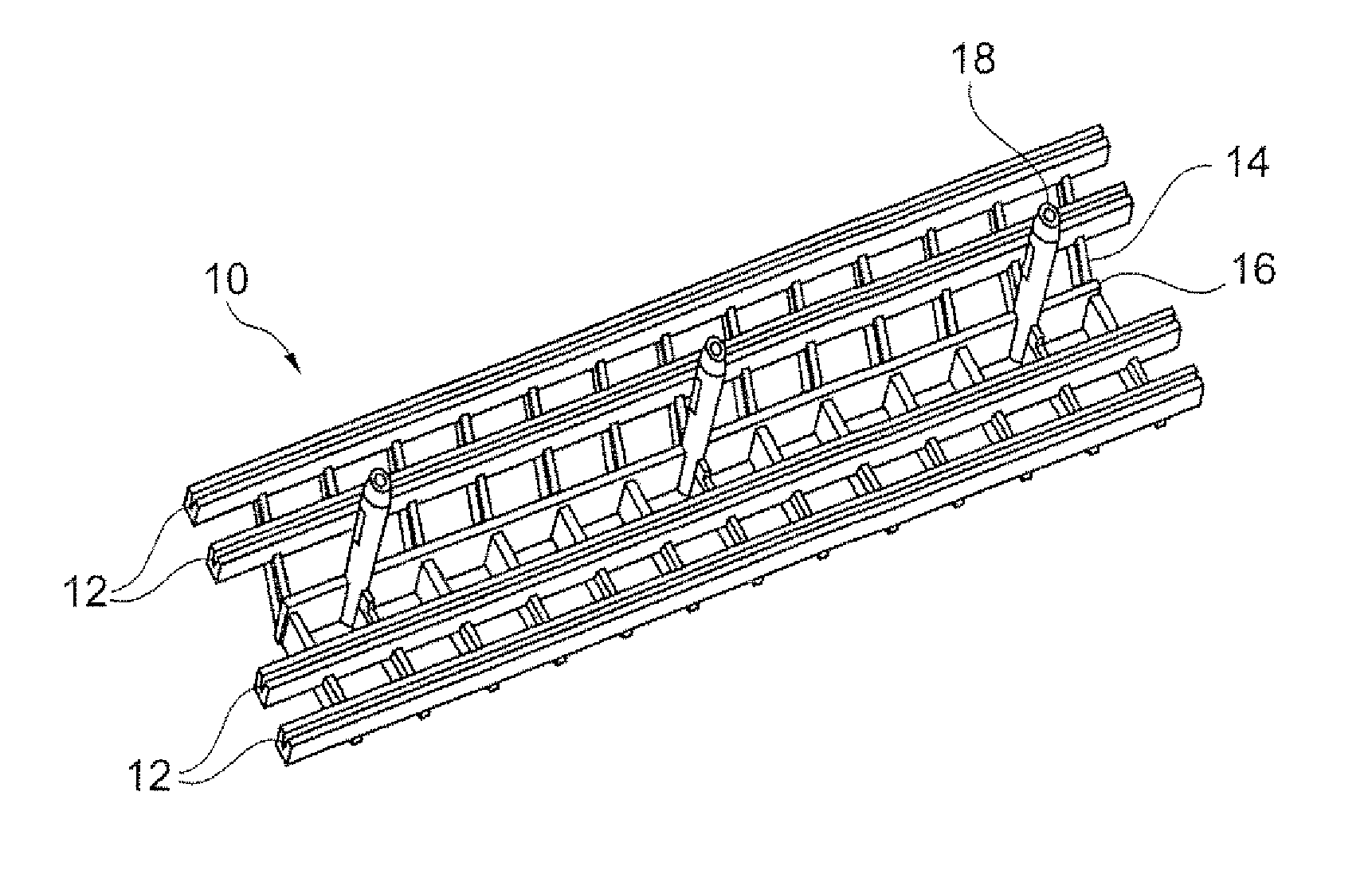

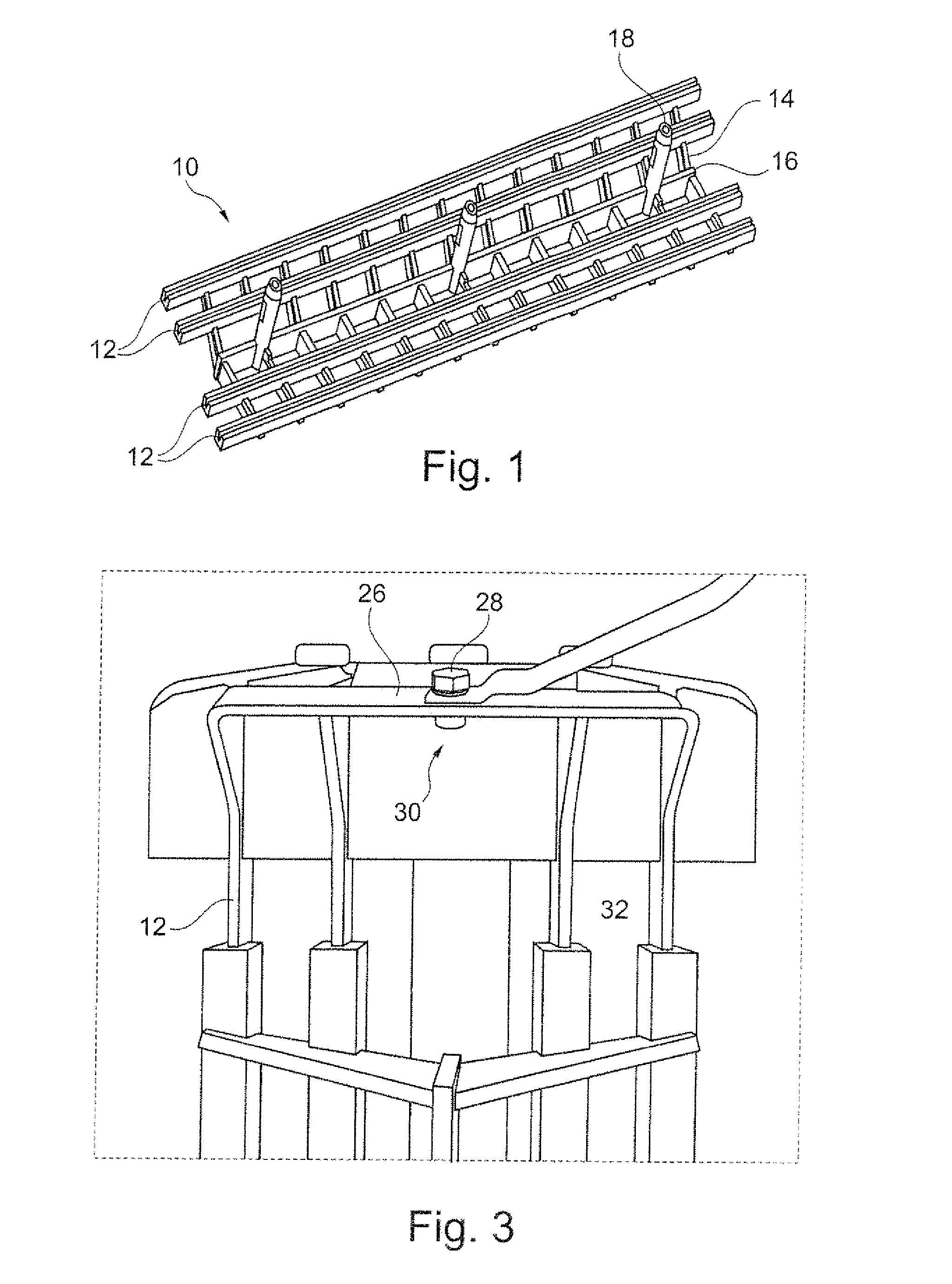

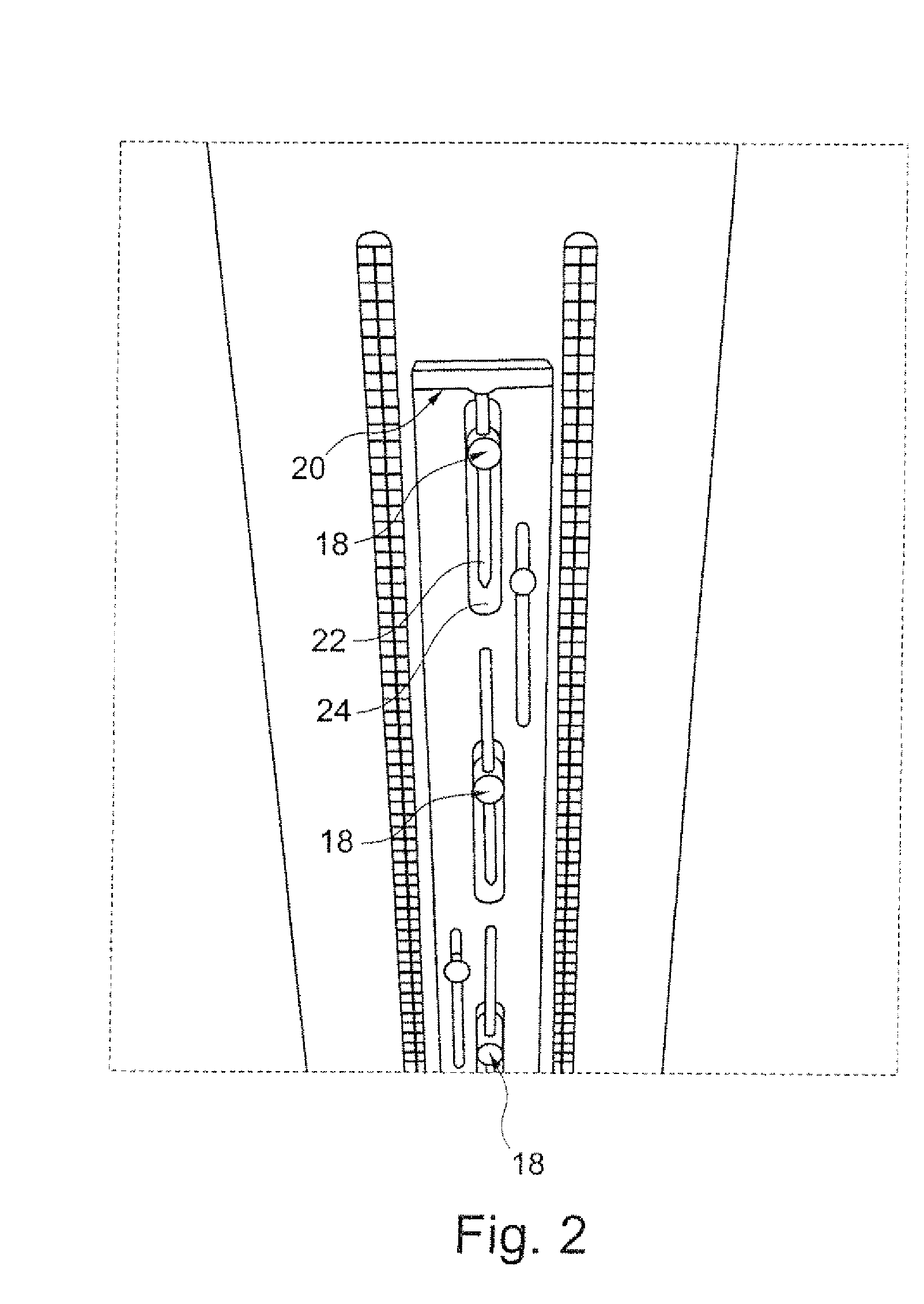

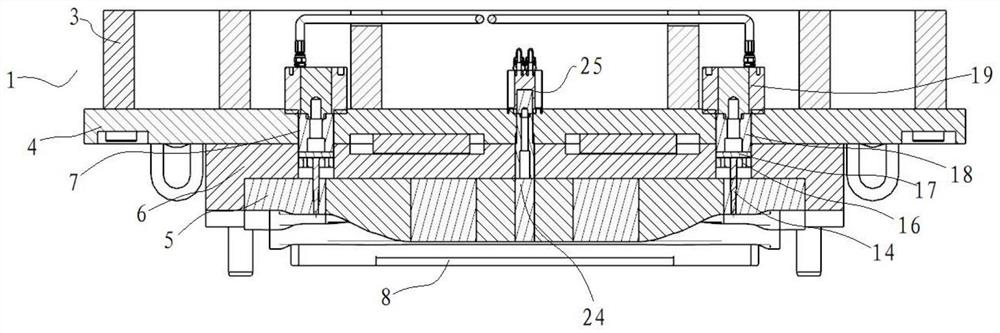

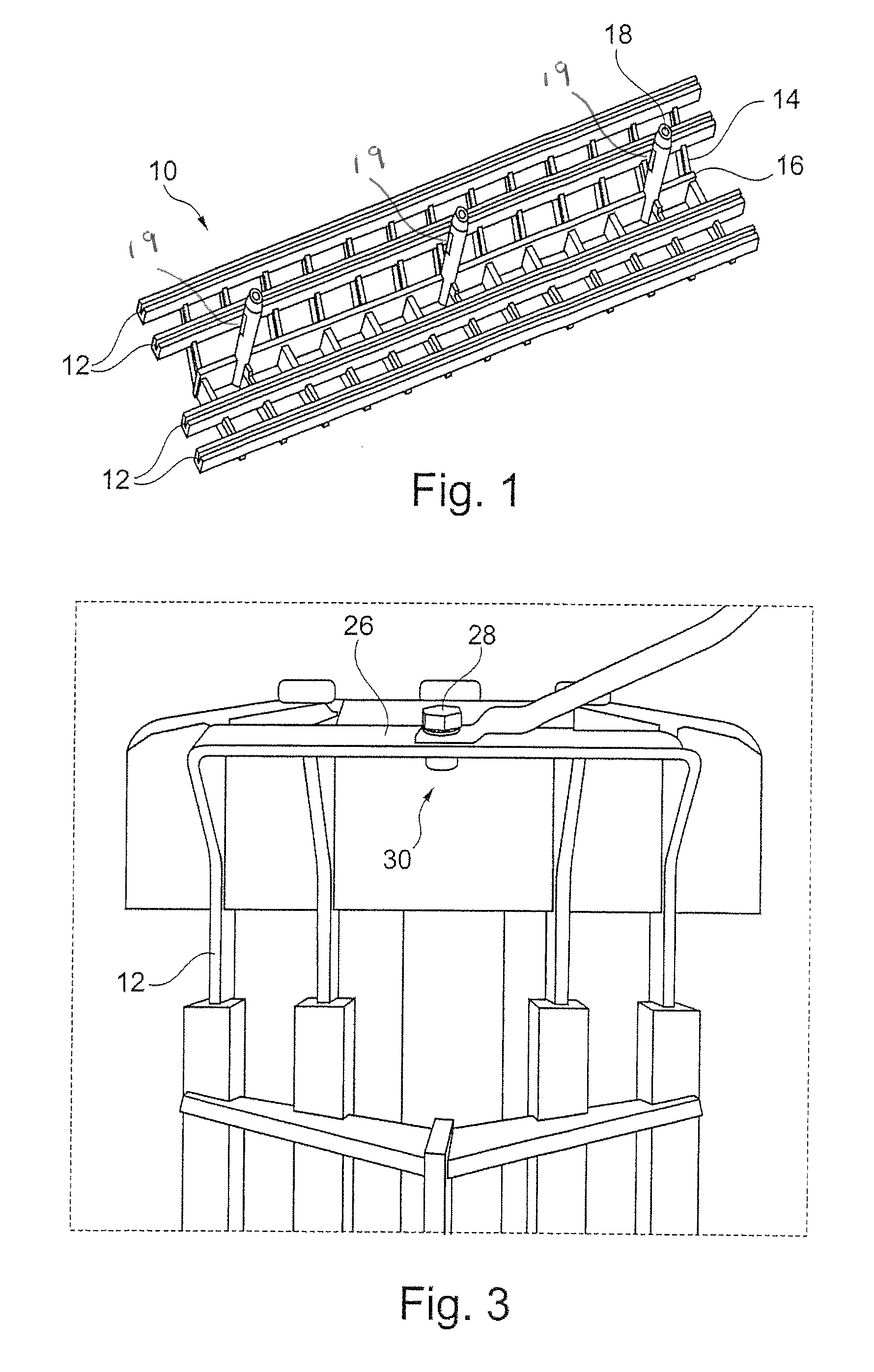

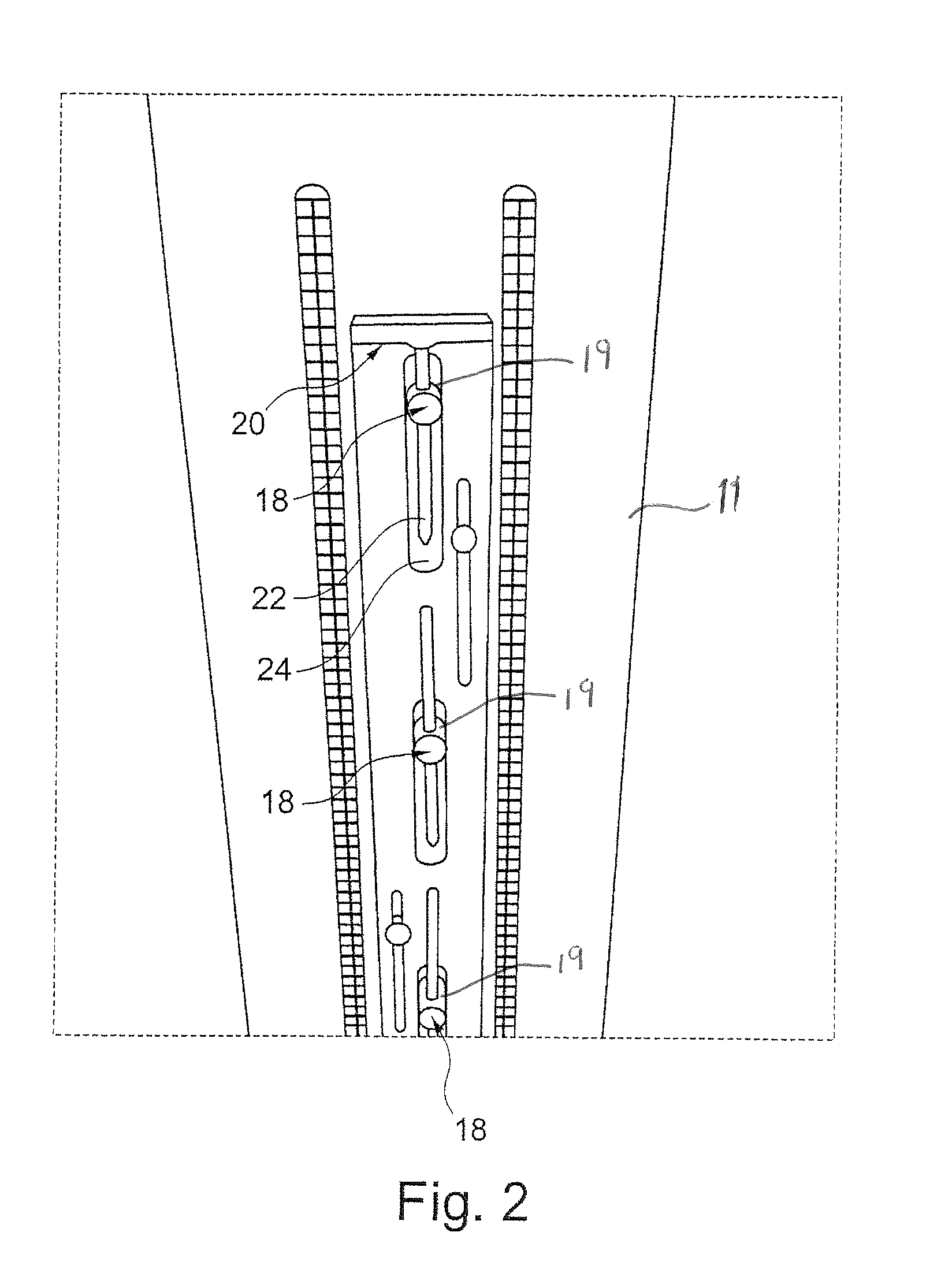

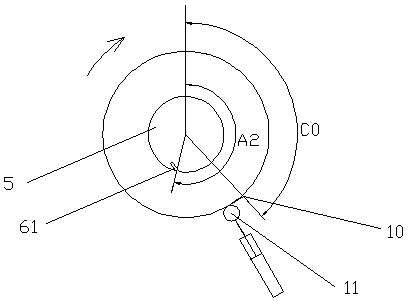

Tool for galvanically coating sliding bearings

InactiveUS20130032475A1Reduce riskUndesirable coating can be preventedMachining electrodesCurrent conducting devicesEngineeringMechanical engineering

The invention relates to a tool for galvanically coating sliding bearings comprising at least one cover, to which a thief is attached.

Owner:FEDERAL MOGUL WIESBADEN

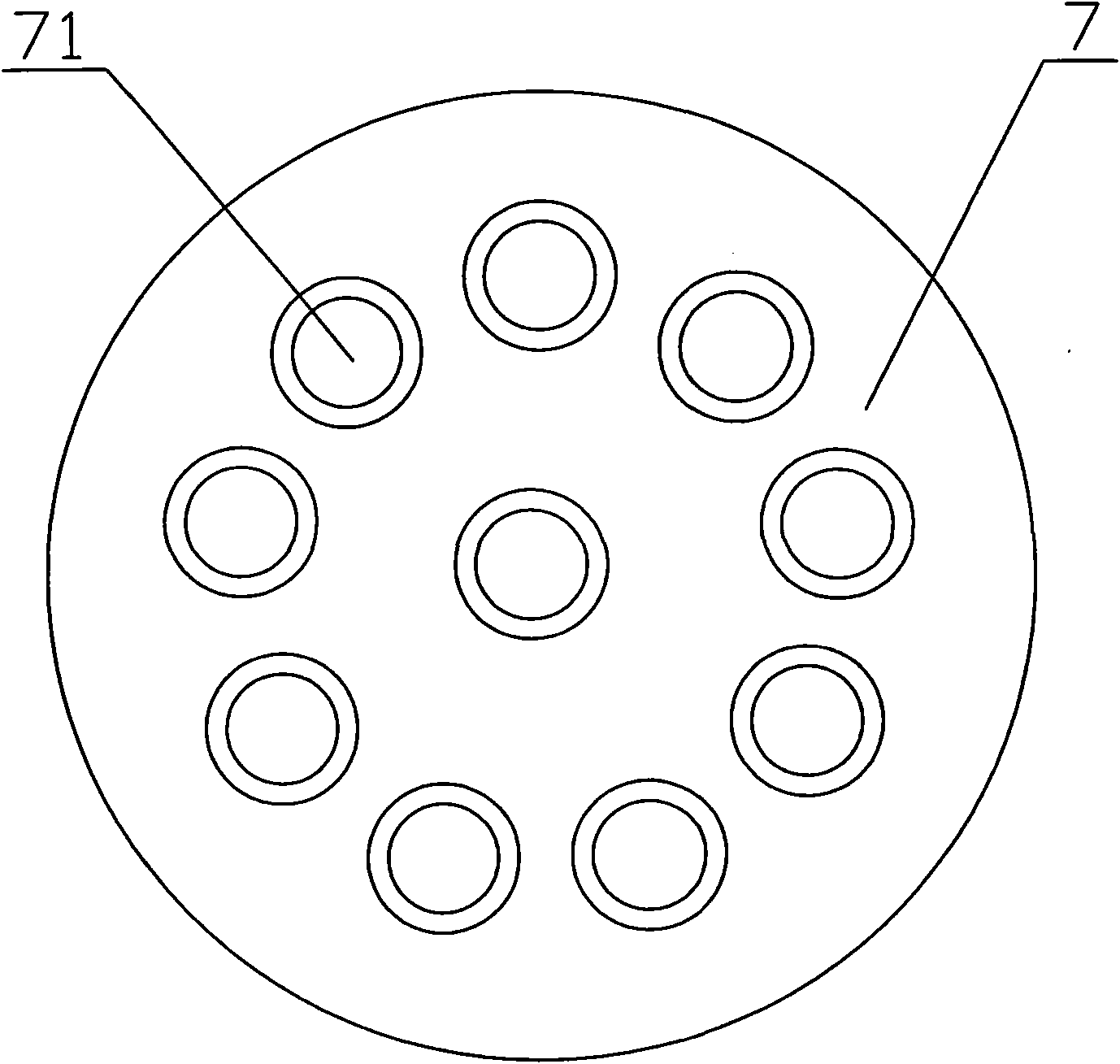

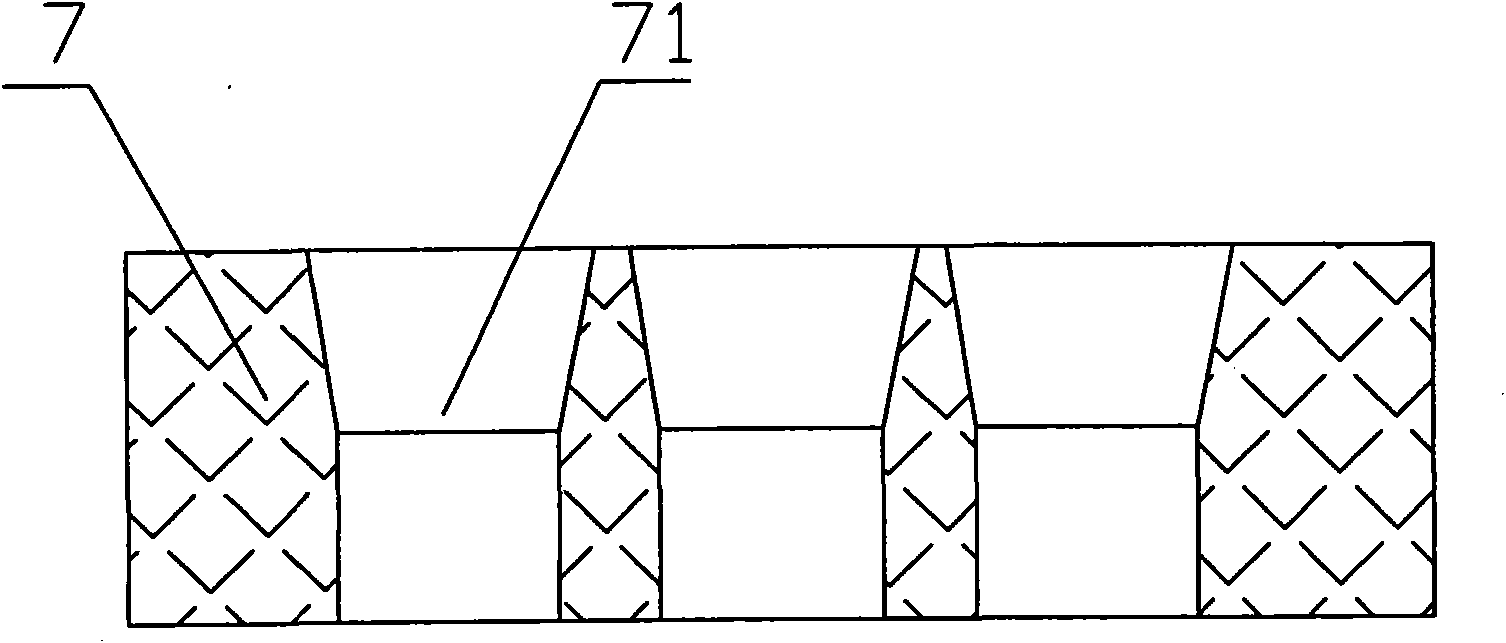

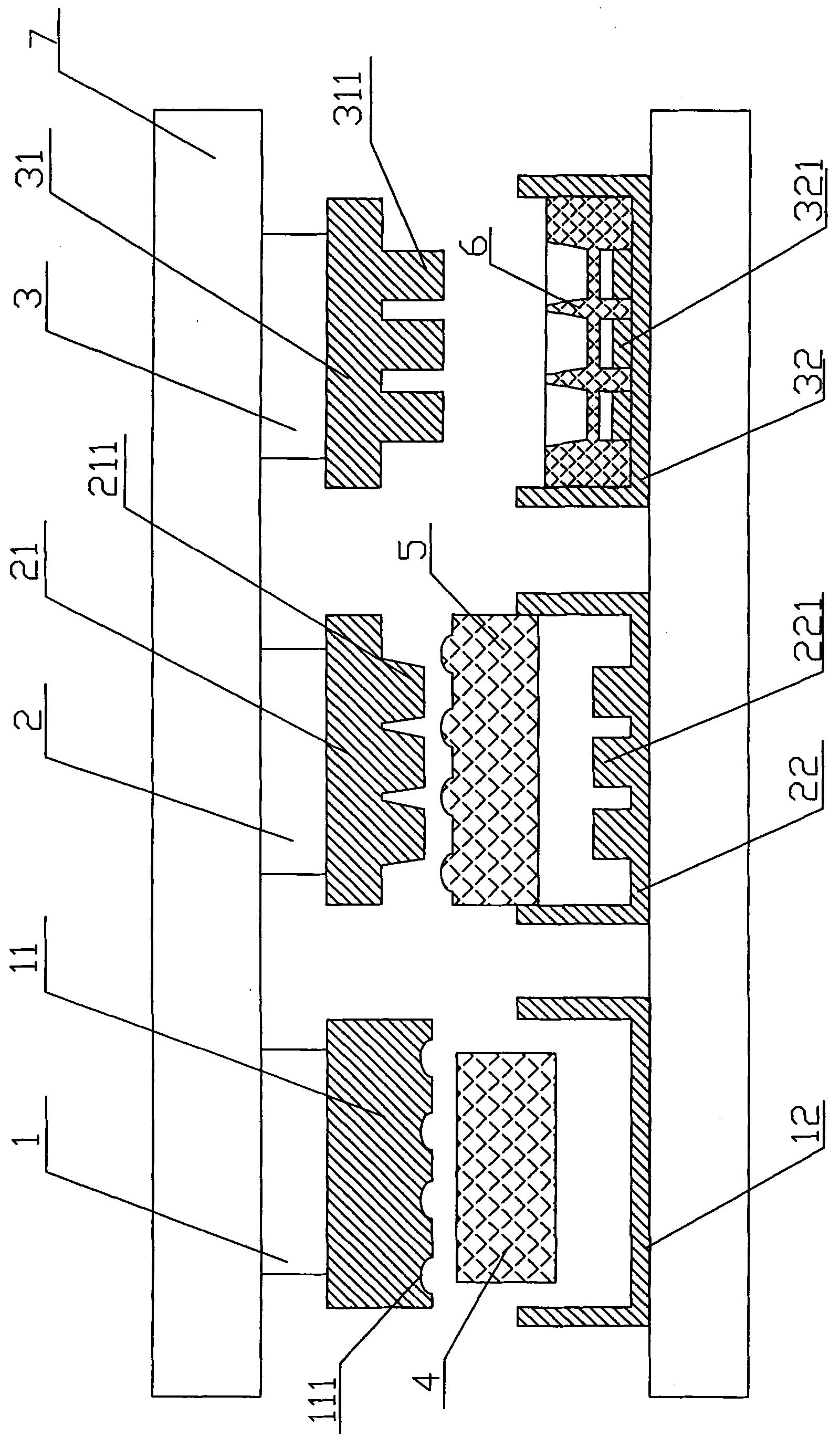

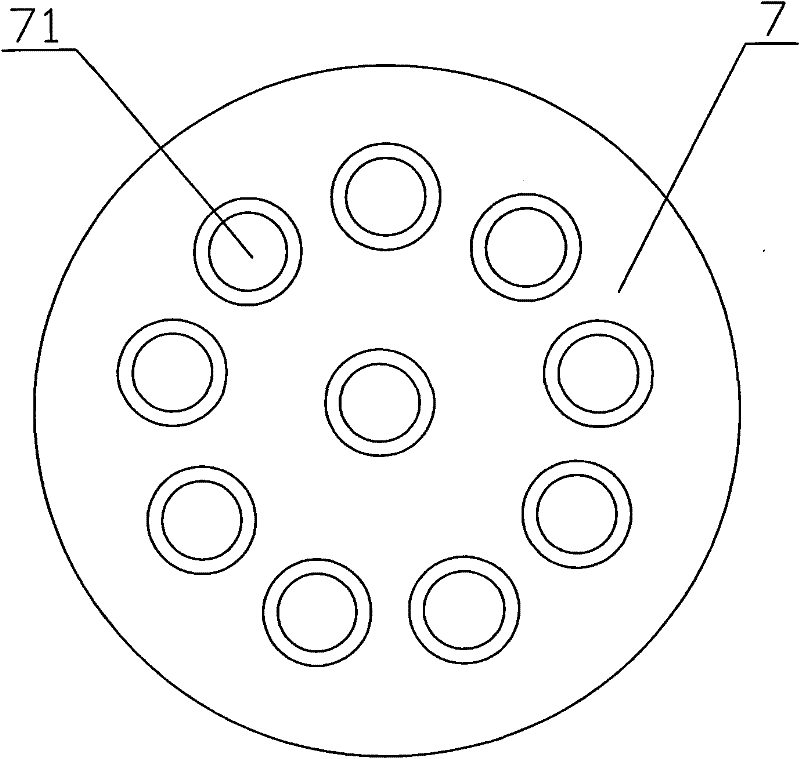

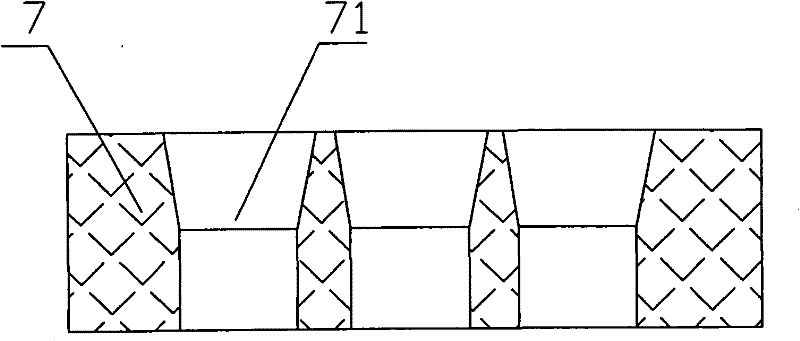

Manufacturing method of prestressed porous anchor plates

The invention relates to a manufacturing method of prestressed porous anchor plates, which is used for manufacturing anchor plates. A plurality of anchor holes (71) are arranged on an anchor plate (7), wherein the upper end of each anchor hole (71) is a tapered hole, and the lower end of each anchor hole (71) is a straight hole. The manufacturing method of prestressed porous anchor plates comprises the following steps of: (1) heating; (2) preparing blanks; (3) punching; (4) perforating; (5) quenching; and (6) atomizing. The manufacturing method of prestressed porous anchor plates has low energy consumption and enables products to have good hardness consistency and beautiful appearance.

Owner:JIANGYIN FASTEN ALGA ENG MATERIAL +1

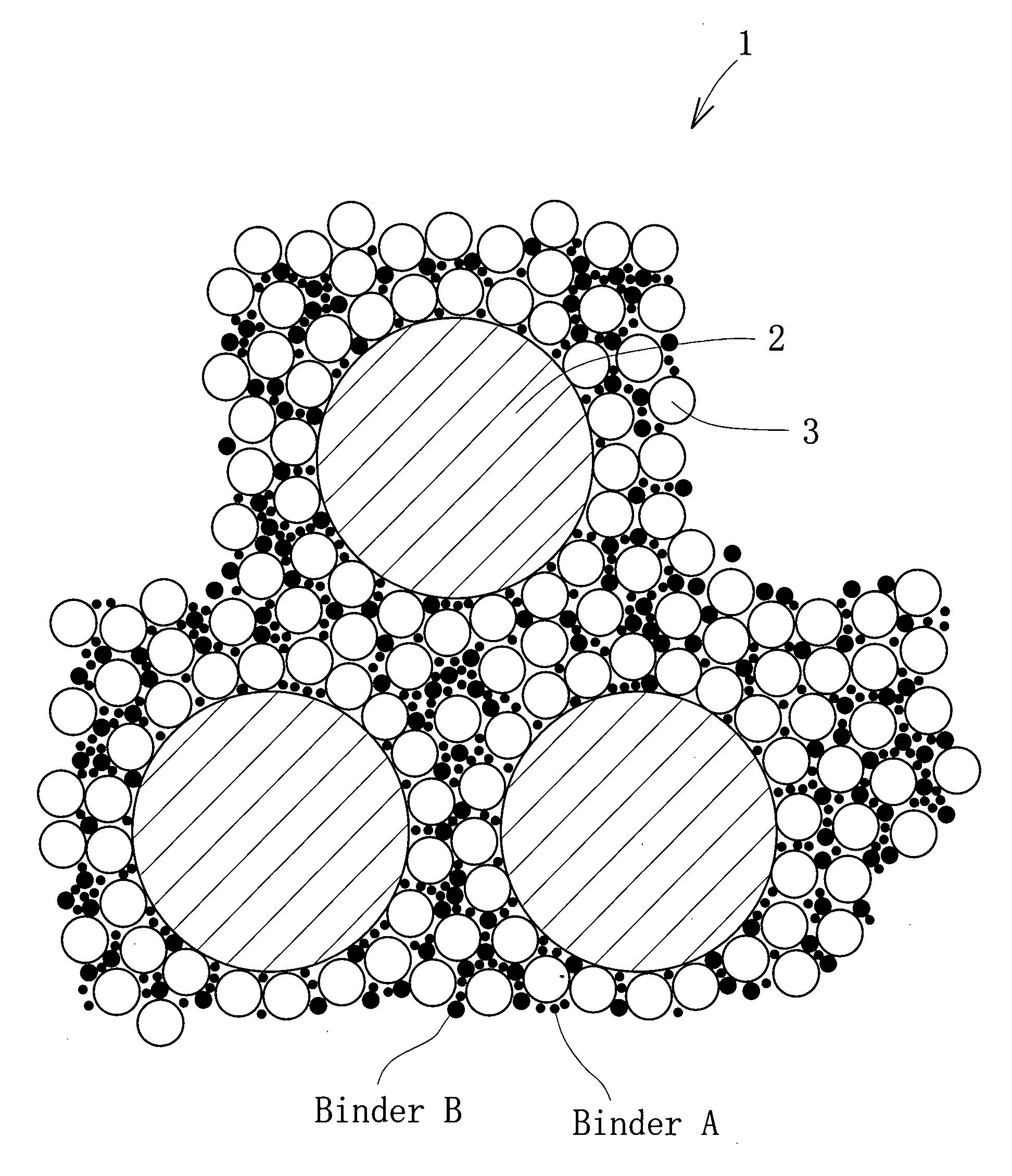

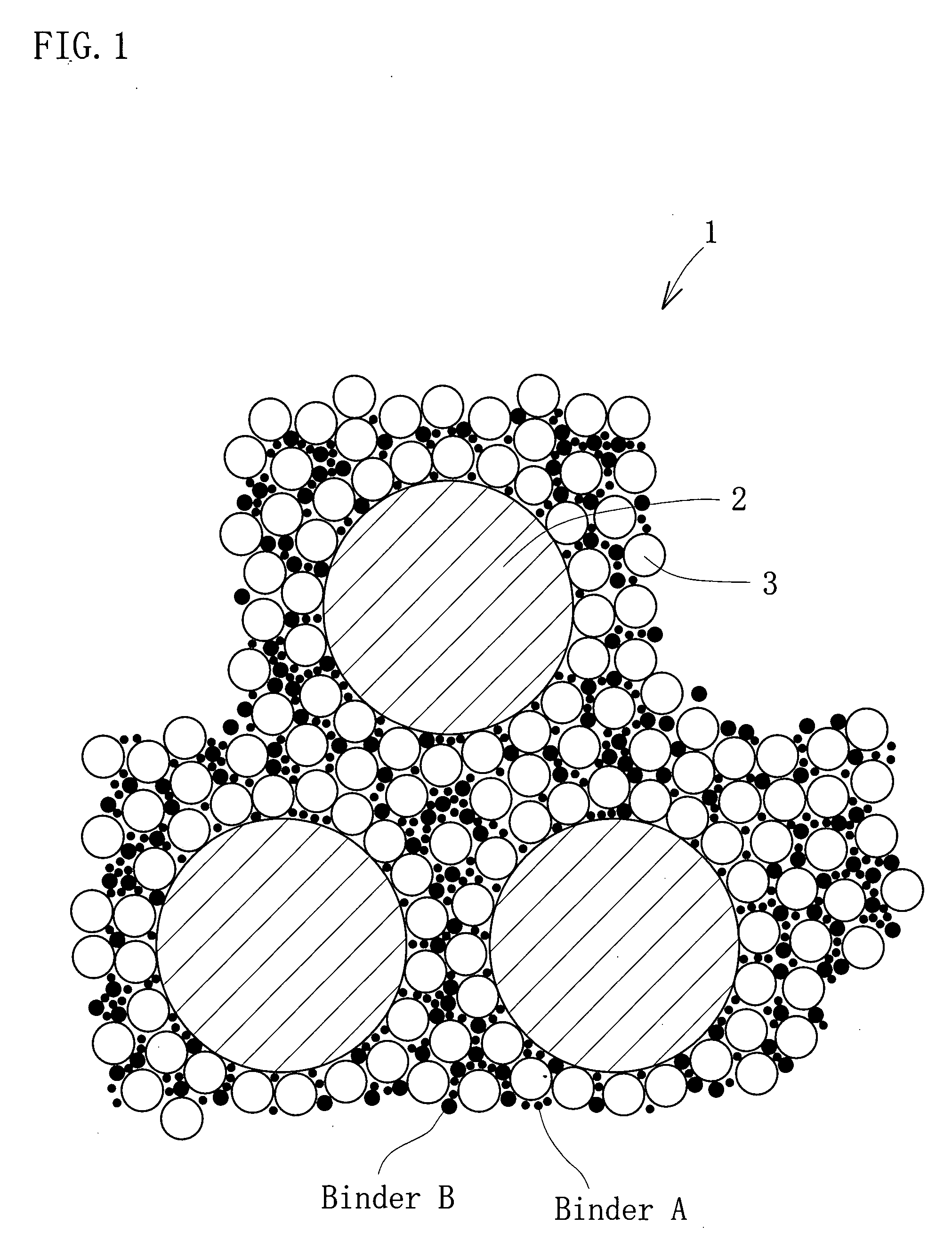

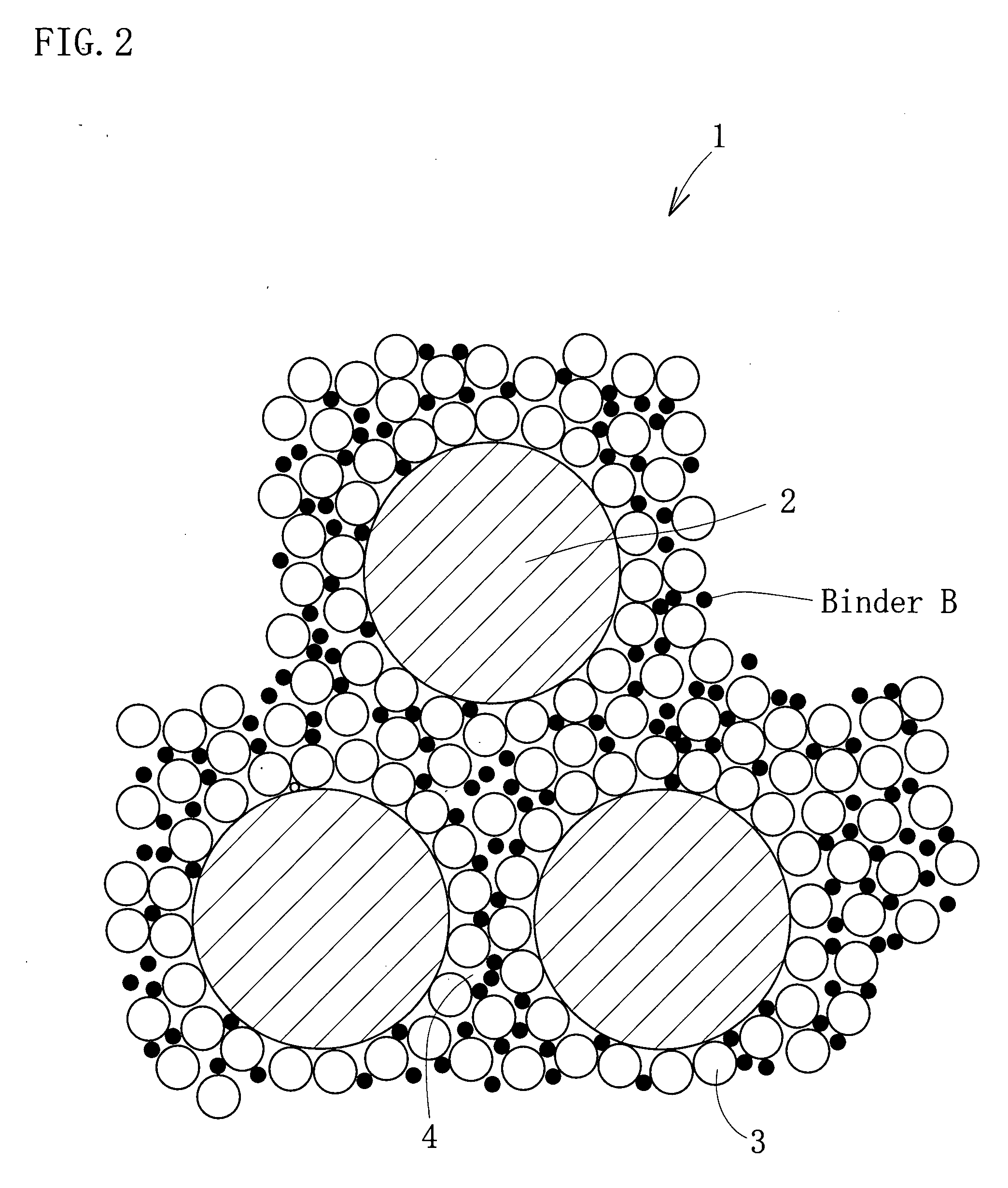

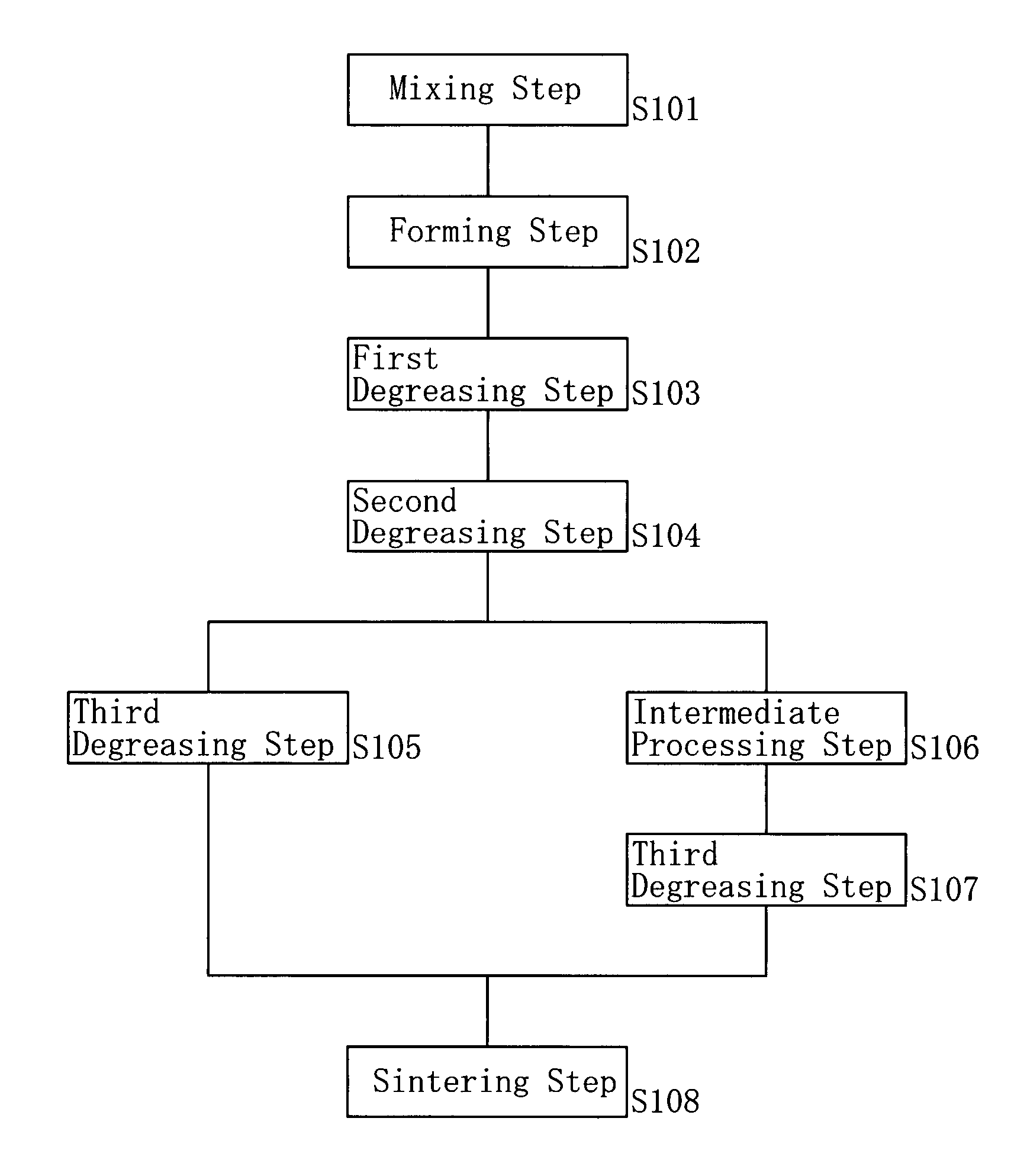

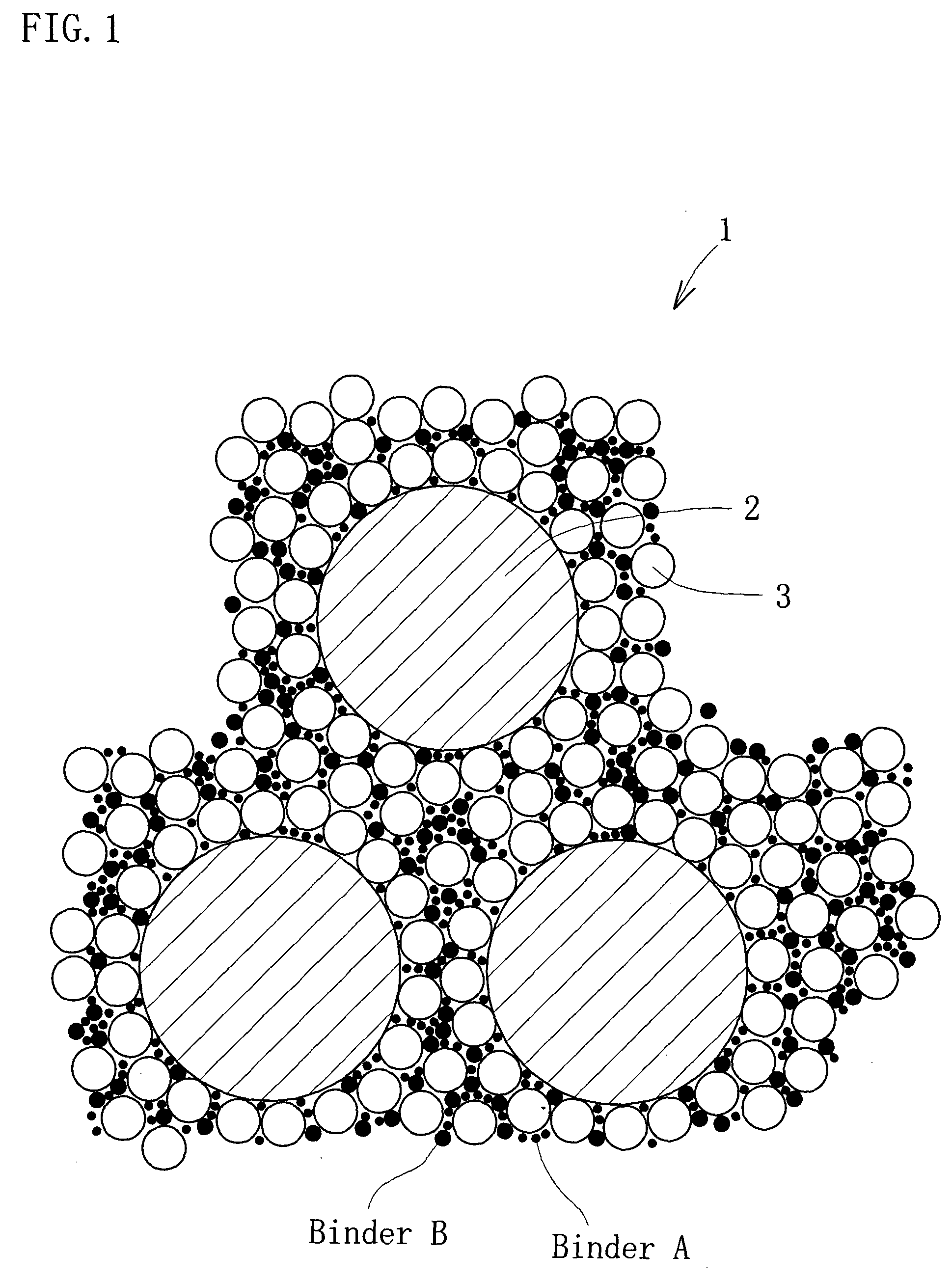

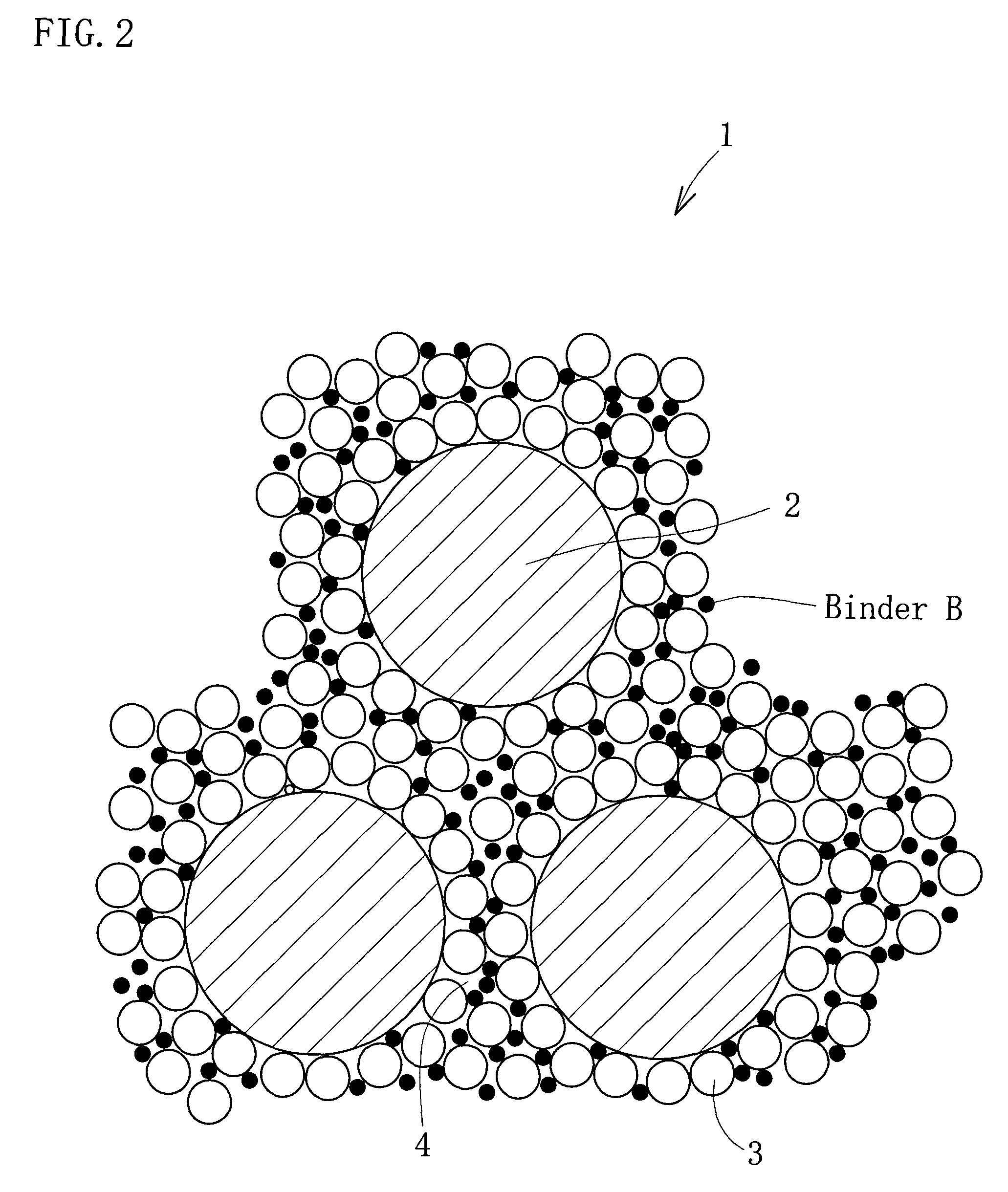

Method of making a porous sintered body, a compound for making the porous sintered body, and the porous sintered body

ActiveUS20090202821A1Maintain level of strength requiredHigh strengthLayered productsMetal-working apparatusMetallurgyHighly porous

A method of making a porous sintered body includes a formation step S102 where a sintering compound which contains a binder and a sinterable powder material is into a predetermined shape; a degreasing steps S103, S104 and S105 where the binder is removed from a formed body obtained in the formation step; and a sintering step S108 where a degreased body after the degreasing step is sintered into a sintered body. The binder contains a component which drains at a temperature higher than a draining temperature of the pore formation material drains. The pore formation material is drained in the degreasing step, with part of the binder remaining un-drained. The present invention enables to manufacture porous sintered bodies which are highly porous, and highly accurate in shape and dimensions. The present invention also enables to manufacture porous sintered bodies which offer functionalities not available before.

Owner:TAISEI KOGYO CO LTD

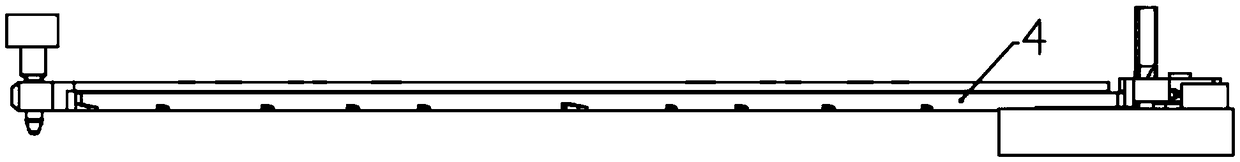

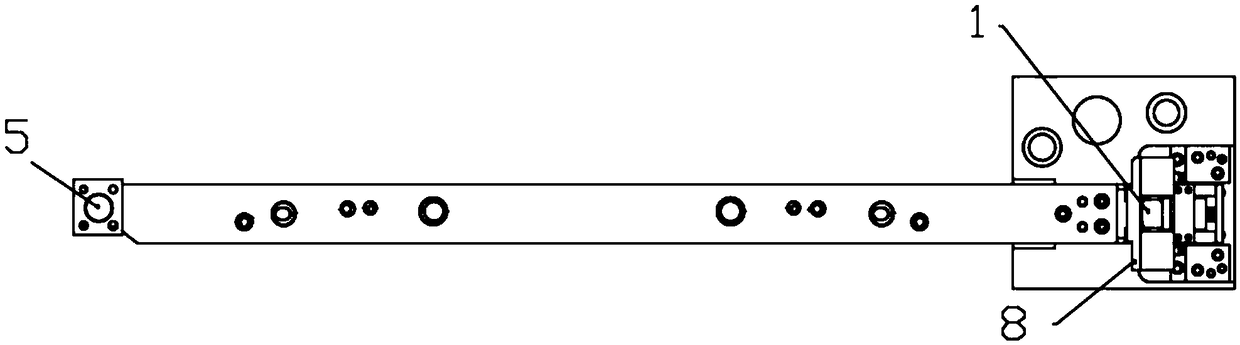

Square tube punching device and process

PendingCN108637078AIngenious ideaCompact and reasonable structurePerforating toolsEngineeringNitrogen

The invention discloses a square tube punching device and process. The square tube punching device comprises a shrinkage mechanism and a driving mechanism, wherein the shrinkage mechanism comprises apunching concave mold core and an oblique sliding block framework; a plurality of sliding block troughs are arranged on the bottom surface of the punching concave mold core; an oblique sliding block is placed in each sliding block trough; a guide pin is arranged one end of the punching concave mold core; the driving mechanism comprises a driving sliding block, a translation sliding block, a nitrogen spring, a connecting moving block and a driving seat; one end of the connecting moving block is connected with one end of the oblique sliding block framework; the other end of the connecting movingblock is movably connected onto the driving seat; the driving sliding block is positioned between the connecting moving block and the translation sliding block; the other side of the translation sliding block is connected with the nitrogen spring; and the translation sliding block is driven by the nitrogen spring to reset. The square tube punching device disclosed by the invention is compact andreasonable in structure; the size of the punching concave mold core is smaller than the inner size of a square tube; and the shrinkage mechanism is driven by the driving mechanism to adjust the position of the oblique sliding block framework. Consequently, the punching concave mold core can closely fit the inner wall of square tube, and the problems about penetration difficulty and collapse duringthe punching process can be solved.

Owner:河北中亿永兴工贸有限公司

Particle containing a hydrophobic region and a hydrophilic region and methods to make same

InactiveUS20120020106A1Prevents permanent shrinkageLow densitySilicon organic compoundsPigmenting treatmentGlass fiberWaveguide

A particle containing a hydrophobic region and a hydrophilic region, products containing the same, a process of making the same, and uses thereof are described. A process of making the particle is also described wherein UV / Ozone techniques can be used to control the depth of organics removal from a porous hydrophobic particle such as an aerogel. The particles can be used in a variety of applications, such as a monolith, a building block, an optical waveguide, a blanket, a matting agent, a structural composite panel, a glass-fiber reinforced panel, a window, a separation wall, a composite wall, a temperature insulation panel, a sound insulation panel, a moisture resistant article, a syntactic foam, or any product of manufacture containing the particles.

Owner:CABOT CORP

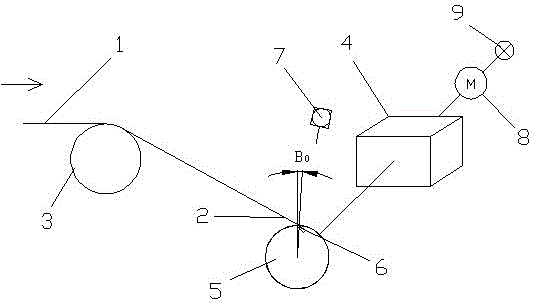

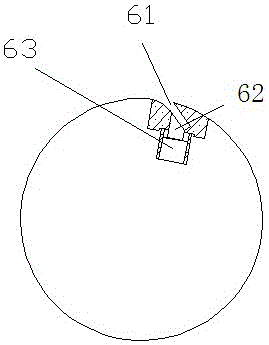

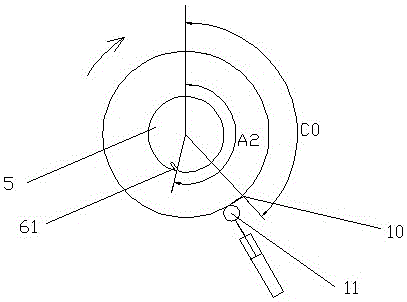

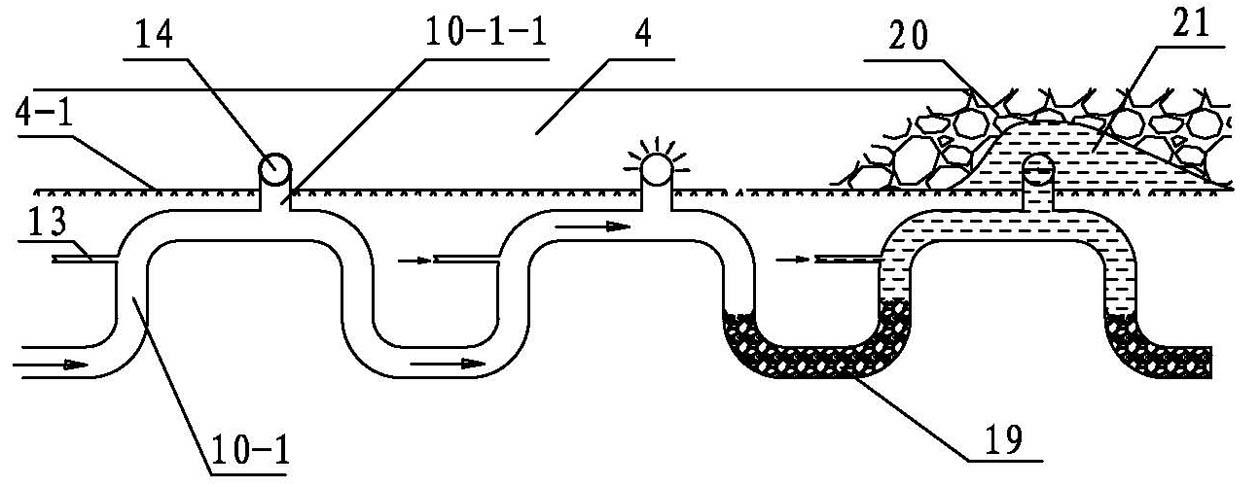

Underground coal gasification system and producing process

InactiveCN101315026BAllow nearby operationMaximize miningConstructionsCoal gasificationThermodynamicsCombustion

The invention relates to an underground coal gasification system and a production process thereof. The system comprises an air course and a gas transmission course which are arranged in a coal seam, a plurality of gasification channels are arranged in the coal seam, the two mutually parallel ends of each gasification channel respectively communicate with the air course and the gas transmission course, and a water drainage closed wall is arranged in the gas transmission course; and the both ends of the air course are respectively connected with an intake airway and a return airway of a mine system. The gasification process comprises the following steps: igniting; judging whether the burning point is required to be moved forward; moving the burning point of the coal seam backwards; plugginga gas passage of a combustion-supporting gas injection branch pipe which is disabled, and filling a burning control area with paste. The coal underground gasification system and the production process have the advantages that the coal seam can be mined to the utmost extent; the leakage of the combustion-supporting gas to the burning control area can be thoroughly cut off when the secure retraction during the coal underground gasification process is realized; the problem that the gasification agent is short-circuited because a passage is formed due to the collapsing of the coal seam floors in the gasification channel and the earlier period gasification area can be solved in the later period of the underground coal gasification, the gas production is secure and reliable, and the gasification rate is high.

Owner:中矿天晟能源科技有限公司

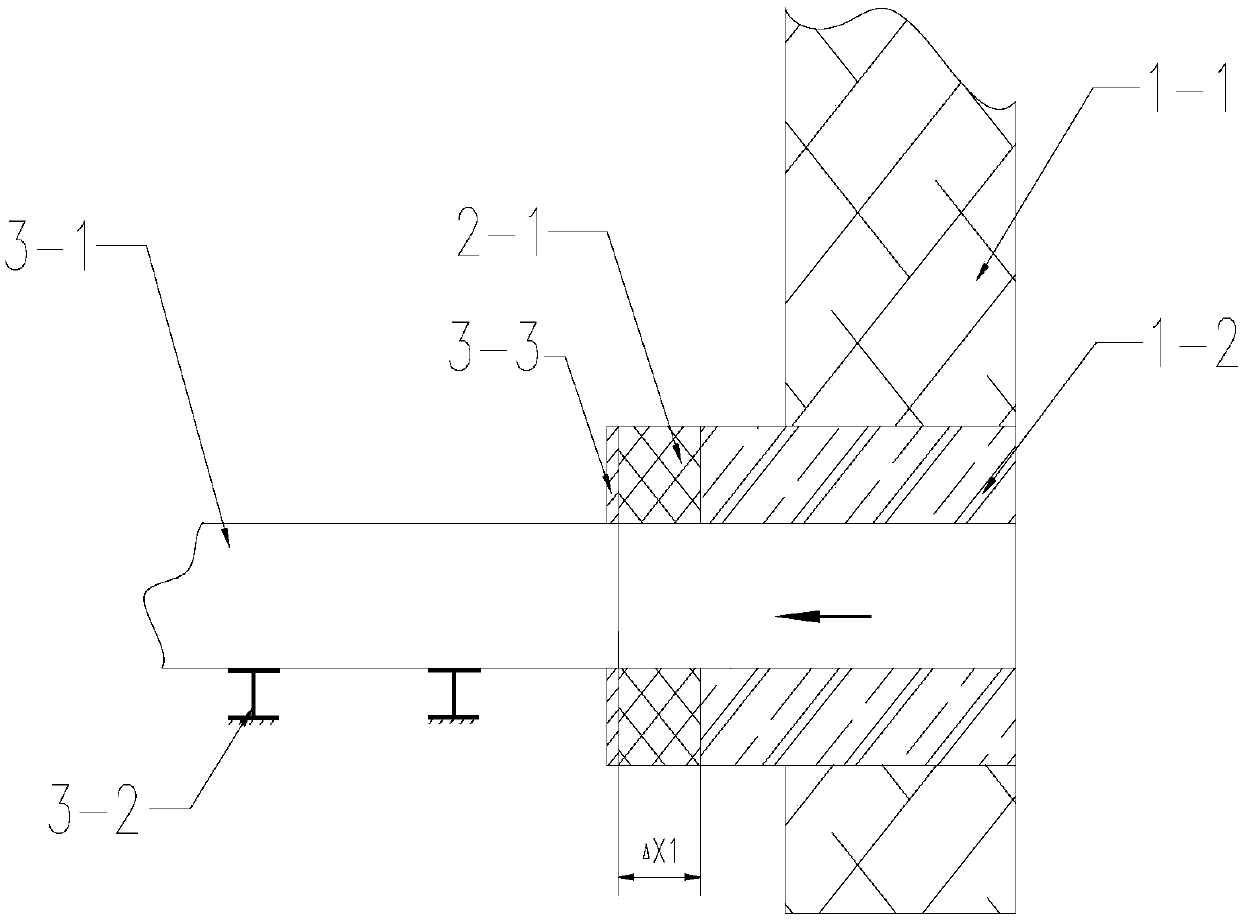

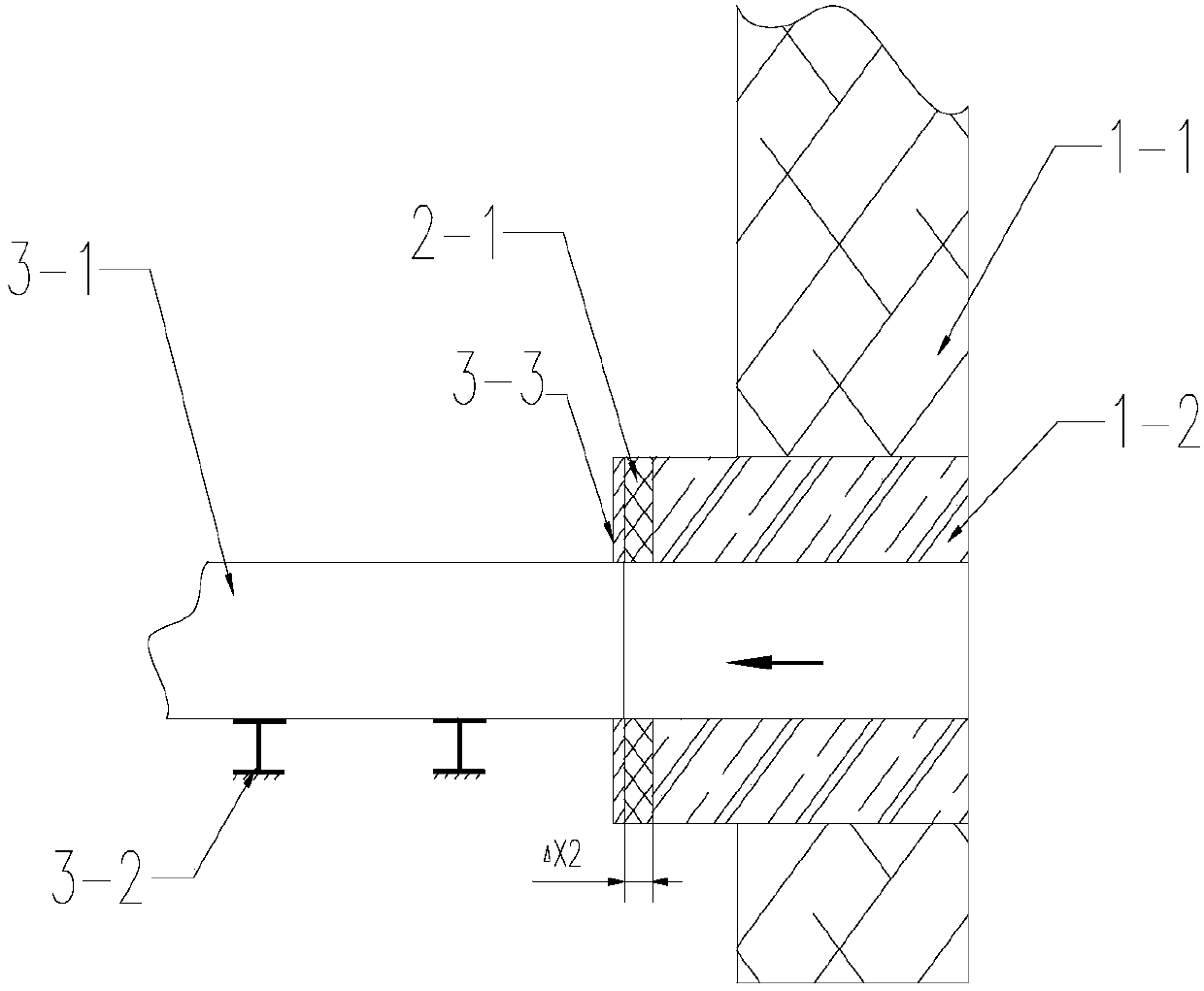

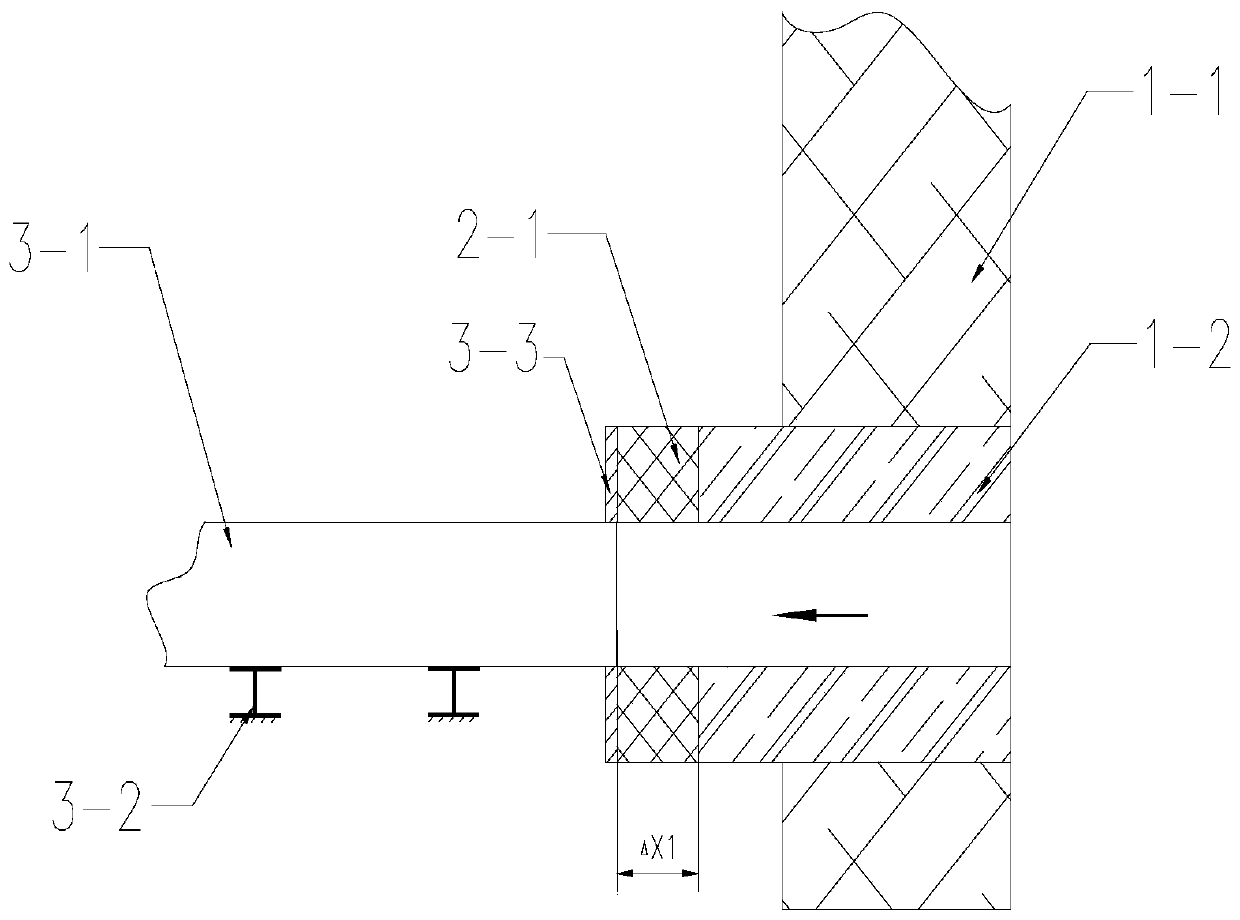

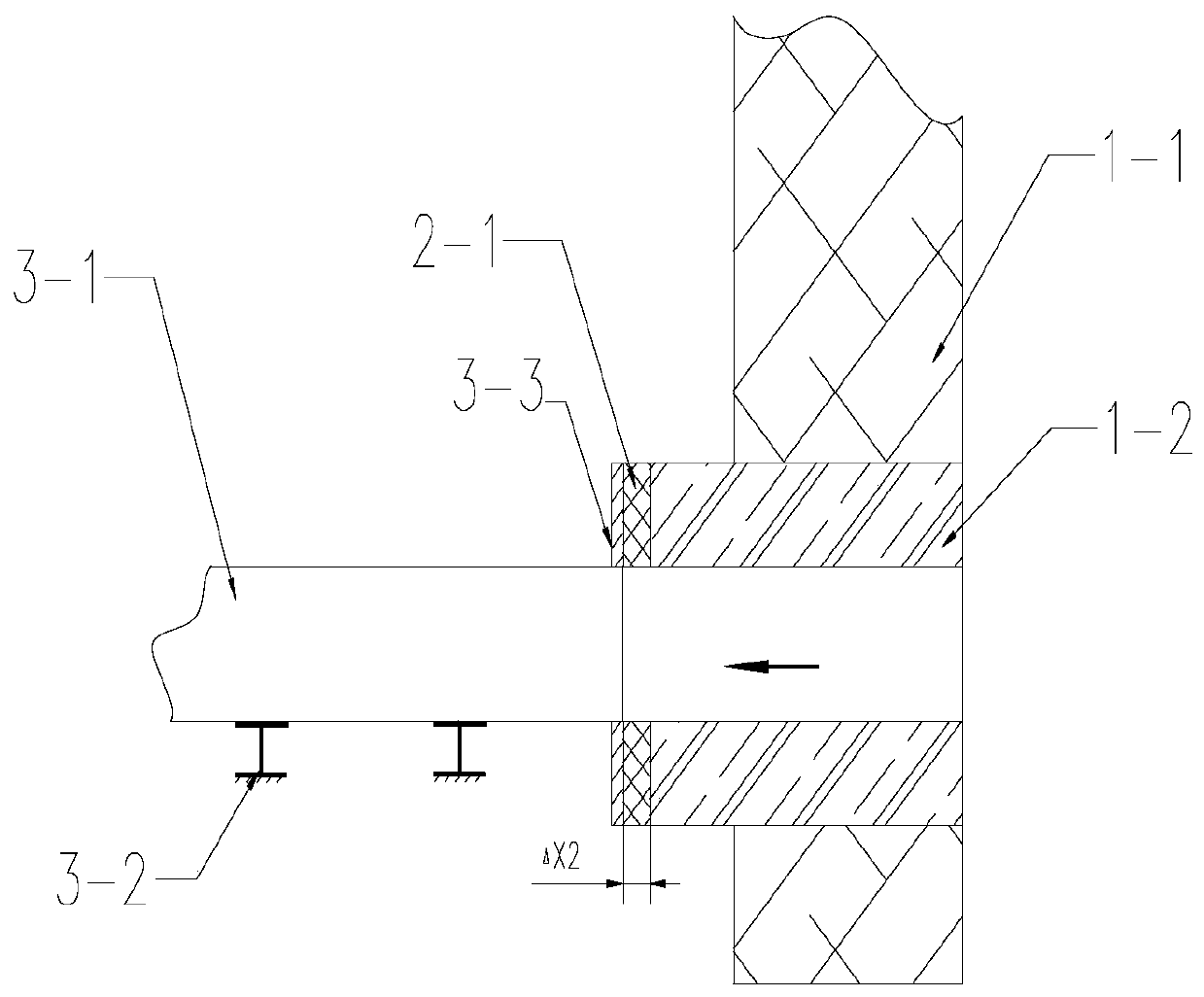

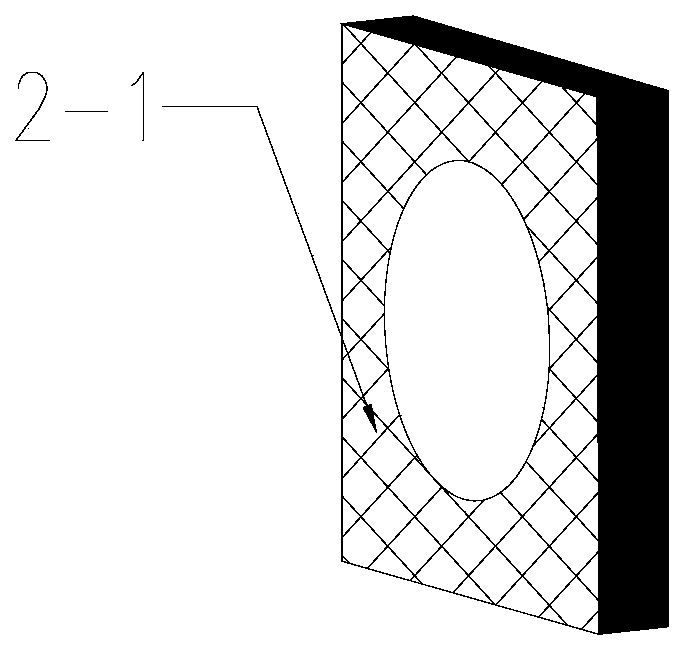

Flue gas outlet structure of glass kiln

The invention relates to a flue gas outlet structure of a glass kiln. The flue gas outlet structure comprises a flue (1-2) and a flue gas pipe (3-1), wherein the flue (1-2) penetrates through a kiln wall body (1-1) from inside to outside; the flue gas pipe (3-1) is positioned outside the kiln wall body (1-1); the adjacent end faces of the flue (1-2) and the flue gas pipe (3-1) are hermetically connected through an expansion ring (2-1) and can realize fluid communication; and the expansion ring (2-1) is made from a material which satisfies the following conditions: the heat resistance temperature is 1260 DEG C or above, and the 24-h linear shrinkage rate at 1000 DEG C is not larger than 1.3%. The flue gas outlet structure of the glass kiln, provided by the invention, is provided with the expansion ring for connecting the flue with the flue gas pipe, thereby effectively preventing extrusion cracking or hogging deformation, caused by thermal expansion, of the flue and the flue gas pipe.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

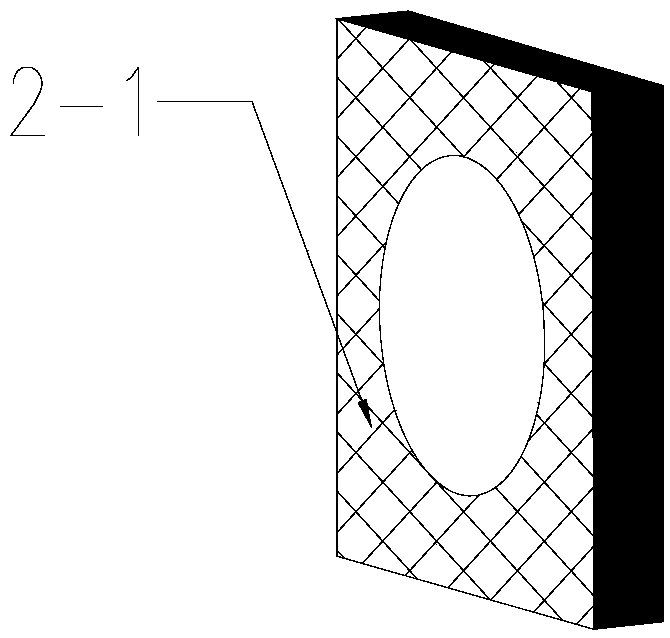

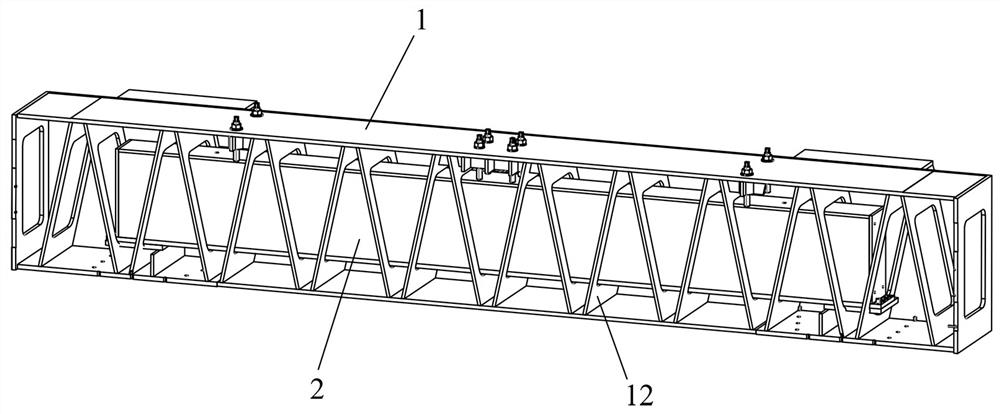

Hidden machine tool cross beam structure with adjustable precision

The invention relates to the technical field of machine tools, in particular to a precision-adjustable hidden machine tool cross beam structure which comprises an outer cross beam frame and an inner cross beam which extend in the left-right transverse direction, an annular rib plate is arranged in a first cavity in the outer cross beam frame, a center hole is defined by the inner edge of the annular rib plate, and the outer edge of the annular rib plate is fixedly connected with the outer cross beam frame. The inner cross beam is located in the first cavity, penetrates through the center hole and is erected on the annular rib plate, and the inner cross beam is fixedly connected with the annular rib plate or the outer cross beam frame body; the outer cross beam frame body comprises a first rear supporting plate and a first upper supporting plate, the inner cross beam comprises a rear supporting face and an upper supporting face, and precision adjusting bolts are arranged on the first rear supporting plate and the first upper supporting plate in a penetrating mode. The precision adjusting bolt can adjust the distance between the first rear supporting plate and the rear supporting face and the distance between the first upper supporting plate and the upper supporting face, and the first rear supporting plate and the first upper supporting plate are each provided with an installation hole for the precision adjusting bolt to penetrate through.

Owner:DEQING TIANMA BEARING CO LTD

Method of making a porous sintered body, a compound for making the porous sintered body, and the porous sintered body

ActiveUS9272333B2Improve liquidityHighly precise shape and dimensionMetal-working apparatusThin material handlingMetallurgyHighly porous

A method of making a porous sintered body includes a formation step S102 where a sintering compound which contains a binder and a sinterable powder material is into a predetermined shape; a degreasing steps S103, S104 and S105 where the binder is removed from a formed body obtained in the formation step; and a sintering step S108 where a degreased body after the degreasing step is sintered into a sintered body. The binder contains a component which drains at a temperature higher than a draining temperature of the pore formation material drains. The pore formation material is drained in the degreasing step, with part of the binder remaining un-drained. The present invention enables to manufacture porous sintered bodies which are highly porous, and highly accurate in shape and dimensions. The present invention also enables to manufacture porous sintered bodies which offer functionalities not available before.

Owner:TAISEI KOGYO CO LTD

Manufacturing method of prestressed porous anchor plates

The invention relates to a manufacturing method of prestressed porous anchor plates, which is used for manufacturing anchor plates. A plurality of anchor holes (71) are arranged on an anchor plate (7), wherein the upper end of each anchor hole (71) is a tapered hole, and the lower end of each anchor hole (71) is a straight hole. The manufacturing method of prestressed porous anchor plates comprises the following steps of: (1) heating; (2) preparing blanks; (3) punching; (4) perforating; (5) quenching; and (6) atomizing. The manufacturing method of prestressed porous anchor plates has low energy consumption and enables products to have good hardness consistency and beautiful appearance.

Owner:JIANGYIN FASTEN ALGA ENG MATERIAL +1

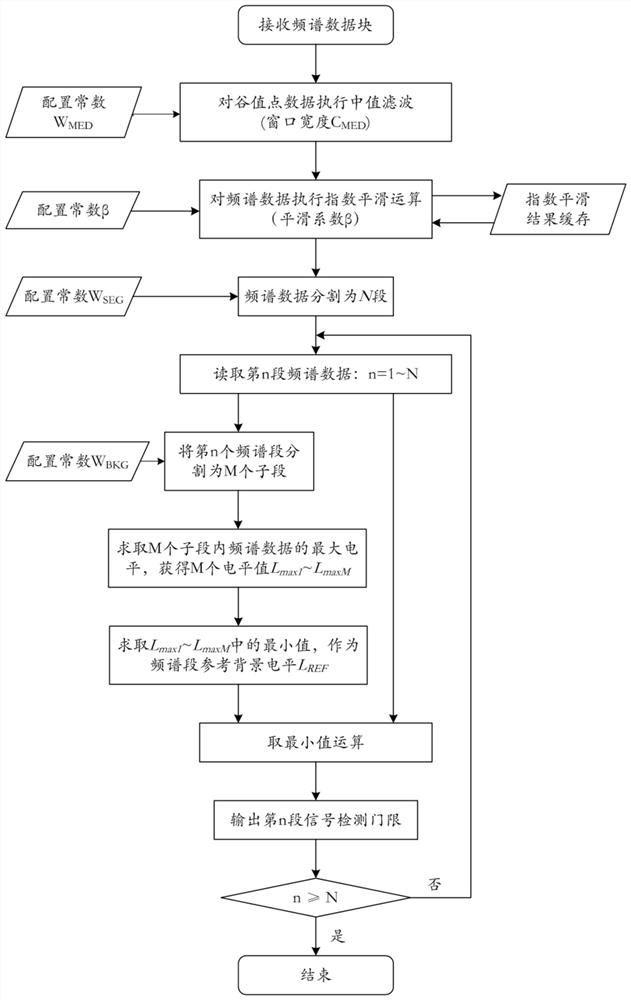

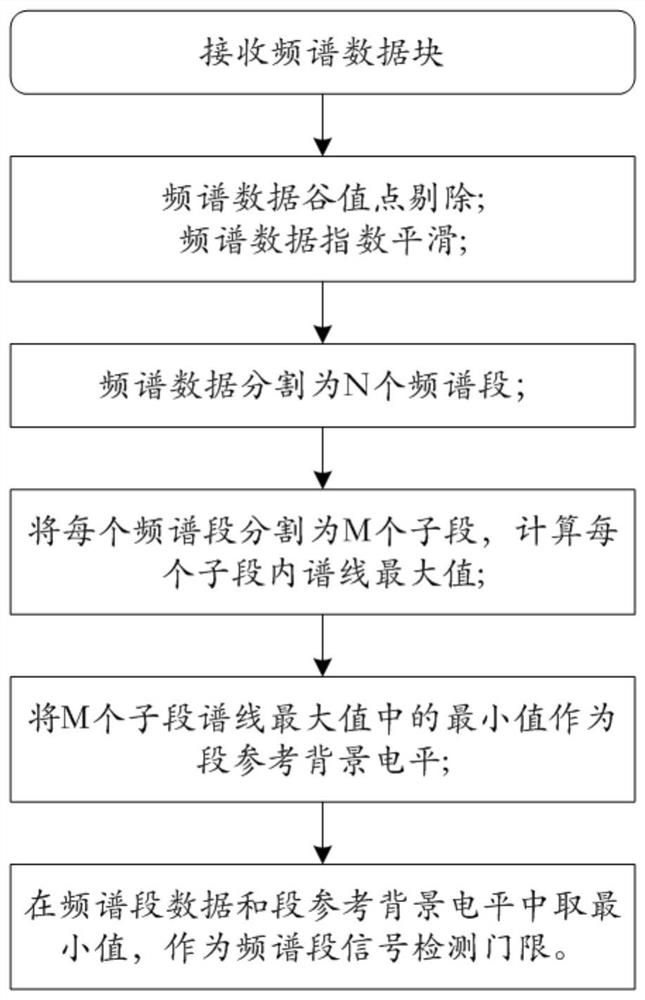

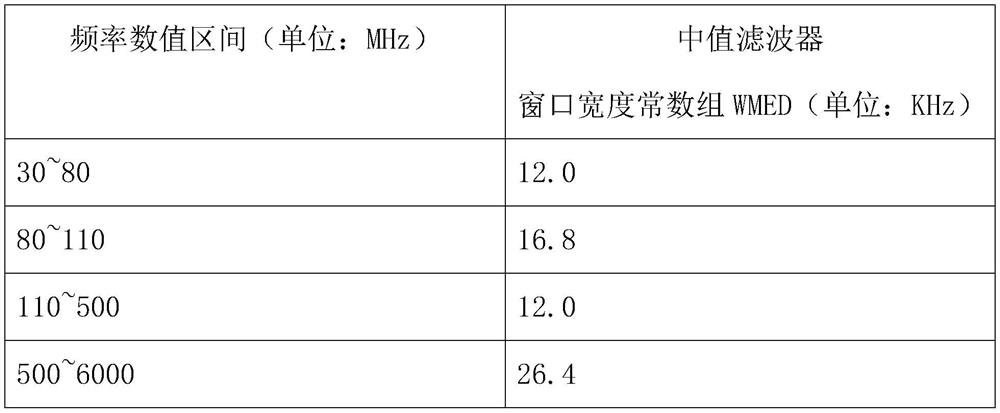

A Calculation Method of Radio Spectrum Signal Detection Threshold

ActiveCN110535543BEliminate collapseEliminate spectral fluctuationsPropogation channels monitoringFrequency spectrumMonitoring system

The invention provides a method for calculating the detection threshold of radio spectrum signals. The method of the present invention performs valley removal and exponential smoothing operations on the spectrum data output by the radio frequency receiver; divides the spectrum data into spectrum segments according to frequency intervals, then divides the spectrum segments into sub-segments, calculates the maximum spectral line level in each sub-segment, and takes The minimum value of the maximum spectral line level of the sub-segment is used as the reference background level of the spectrum segment; finally, the minimum value between the spectrum segment data and the segment reference background level is taken as the signal detection threshold. The signal detection threshold calculated by the method of the present invention can adapt to various bandwidth signals and weak signal detection, the algorithm occupies less memory, and the calculation overhead is low, and is suitable for various fixed, airborne and vehicle-mounted radio monitoring systems for the calculation performance requirements of the signal detection threshold.

Owner:国家无线电监测中心陕西监测站 +1

Injectable type collagen-based soft tissue filling material and preparation method thereof

The invention discloses an injectable type collagen-based soft tissue filling material and preparation method thereof, wherein the filling material mainly comprises collagen 0.5-20%, heparin 0.1%-10%, cell growth factor 0-1%, cushion liquid 70-99.4%, and its preparation comprises extracting soluble collagen from animal connective tissue, cutting off antigen deciding family from the collagen molecules through proteinase hydrolysis, purifying treatment, crosslinking by utilizing safety and nontoxic crosslinking agent, charging biologically active components, kneading the mixture repeatedly into grease form, sealing under asepsis condition and storing at low temperature.

Owner:JINAN UNIVERSITY

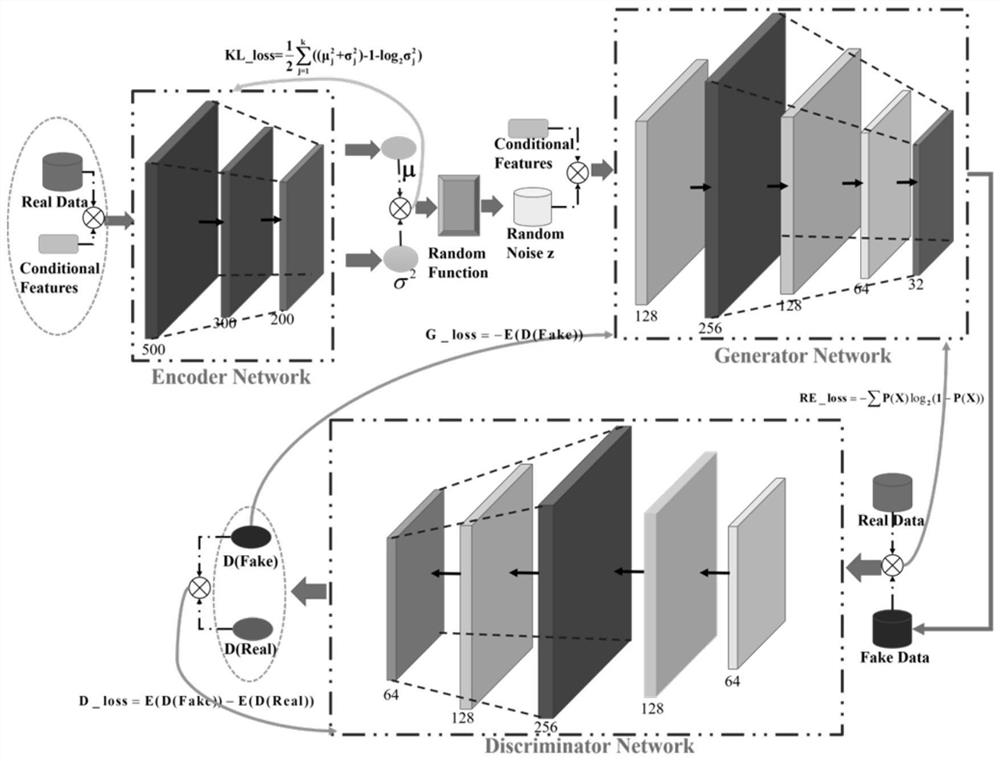

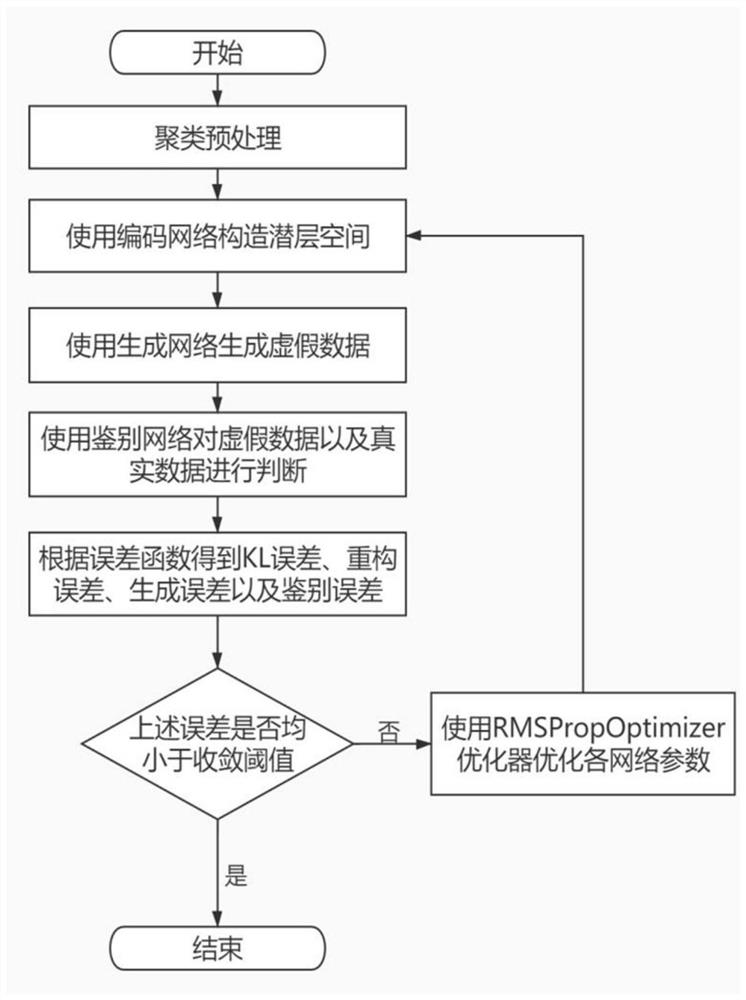

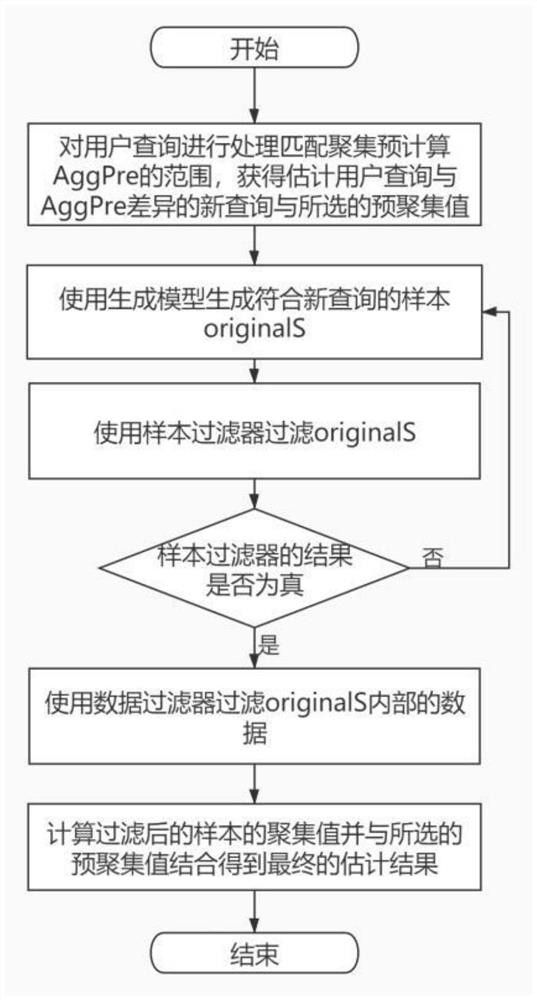

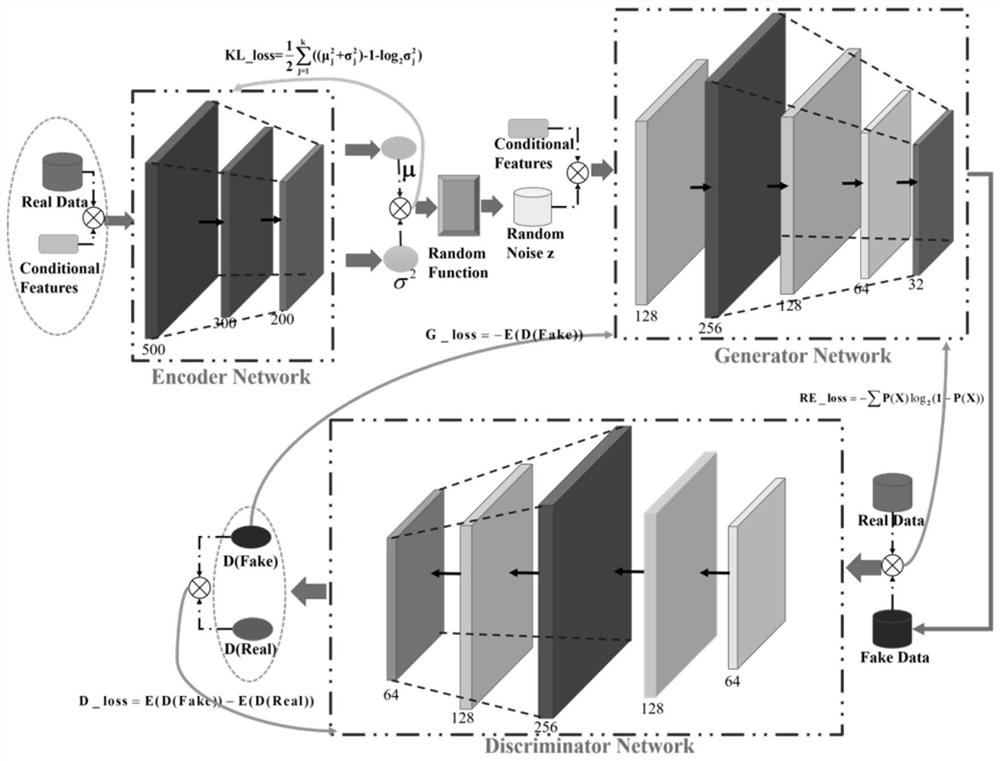

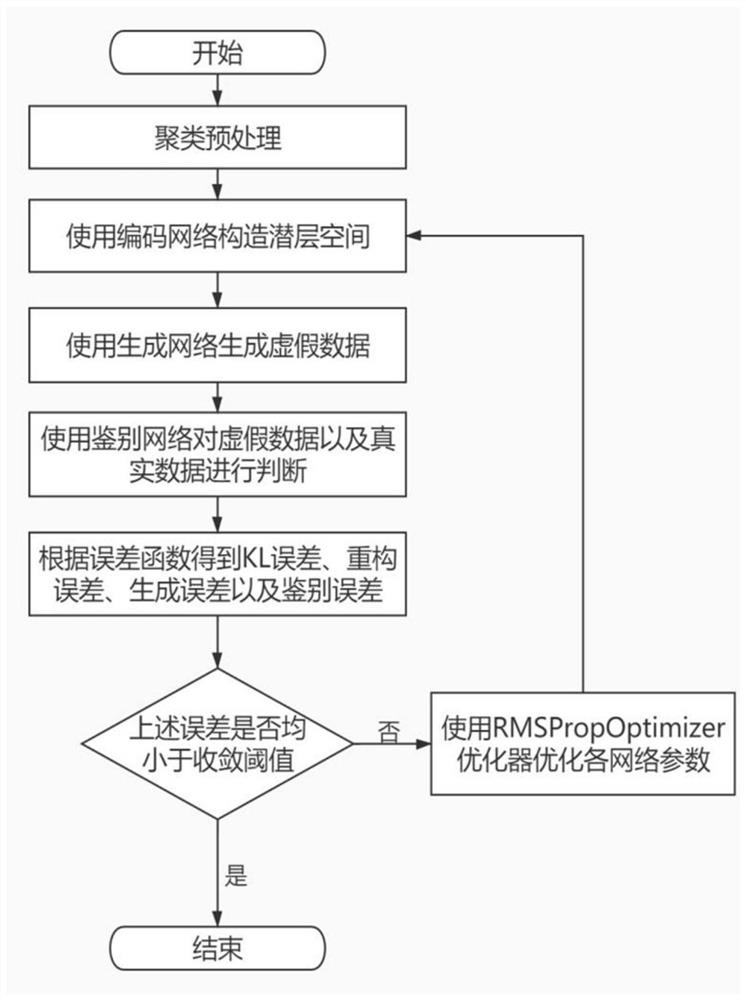

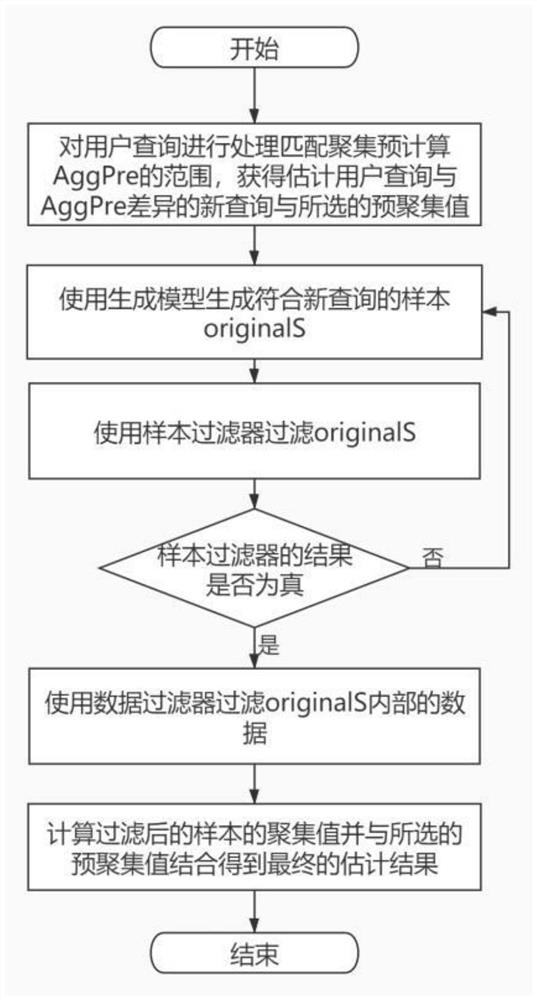

Efficient approximate query processing algorithm based on conditional generative model

ActiveCN113177078AImprove performanceEliminate collapseDigital data information retrievalCharacter and pattern recognitionAlgorithmGenerative adversarial network

The invention belongs to the technical field of information retrieval, and particularly relates to an approximate query processing algorithm. The invention discloses an efficient approximate query processing algorithm based on a conditional generative model. The algorithm comprises the following steps: acquiring a pre-aggregation value of user query by adopting aggregation pre-calculation; processing the user query to obtain a new query newQ for estimating the difference between the user query and the pre-aggregation range and a selected pre-aggregation value; constructing a Wasserstein-based conditional variation generative adversarial network model, and generating a data sample for a new query newQ by using the trained model; and filtering the generated data sample, combining the filtered data sample with the selected pre-aggregation value, and calculating to obtain a final query estimation value. According to the method, an efficient depth generation model is constructed, a Wasserstein distance is introduced as error measurement, and model collapse is eliminated; the model is applied to approximate query and is combined with aggregation pre-calculation, and meanwhile, an approximate query error is reduced by adopting a voting algorithm.

Owner:HARBIN INST OF TECH AT WEIHAI

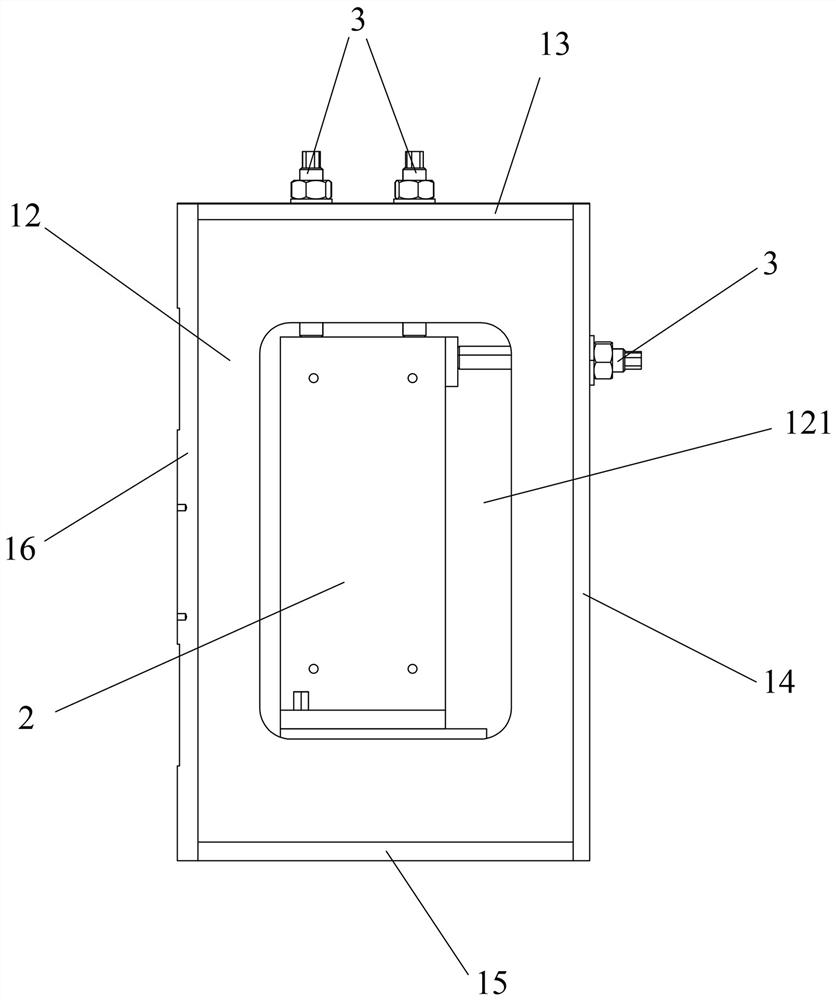

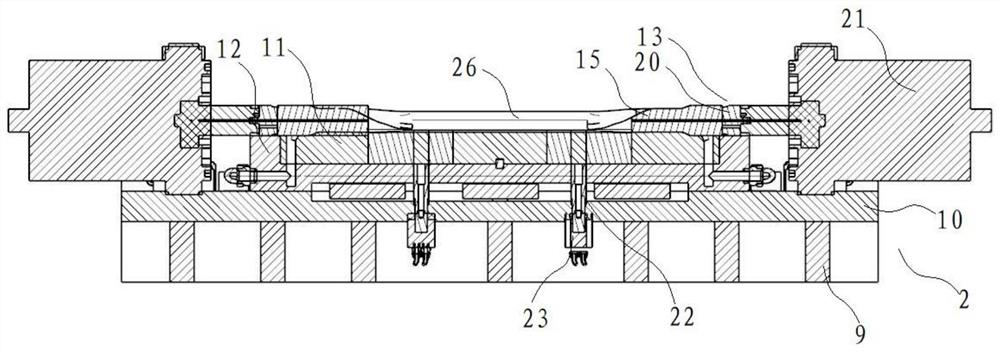

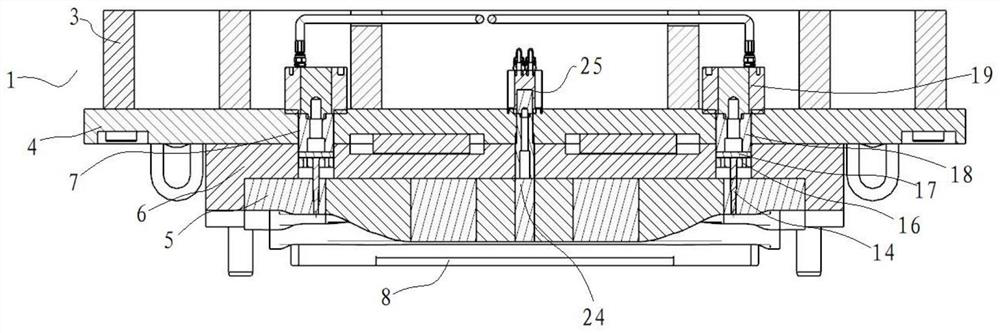

Liquid-filled forming die and liquid-filled forming method

ActiveCN112170610AImprove product accuracy and consistencySave molds and strokesEngineeringLaser cutting

The invention discloses a liquid-filled forming die and a liquid-filled forming method. The liquid-filled forming die comprises an upper die and a lower die, wherein the upper die comprises an upper die support plate, an upper die bottom plate, a punch insert, a punch seat and a punching component; and the lower die comprises a lower die support plate, a lower die bottom plate, a die insert, a diesocket and a liquid filling component. Compared with the prior art, a pre-forming die and the punching frequency are saved, collapse and wrinkles at the two ends are eliminated, hydraulic on-line punching is used as a positioning hole for laser cutting, a tool is simplified, the cutting cost is reduced, the product precision and consistency are improved, punch side collapse is eliminated by punching towards the outside of a pipe, and meanwhile, a punch is rapidly replaced through a skylight and a connecting block, flangings at the two ends are finally formed through a core rod and a die, a pair of outward hole flanging tools is omitted, and seam allowance welding instability and laser cutting cost are avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

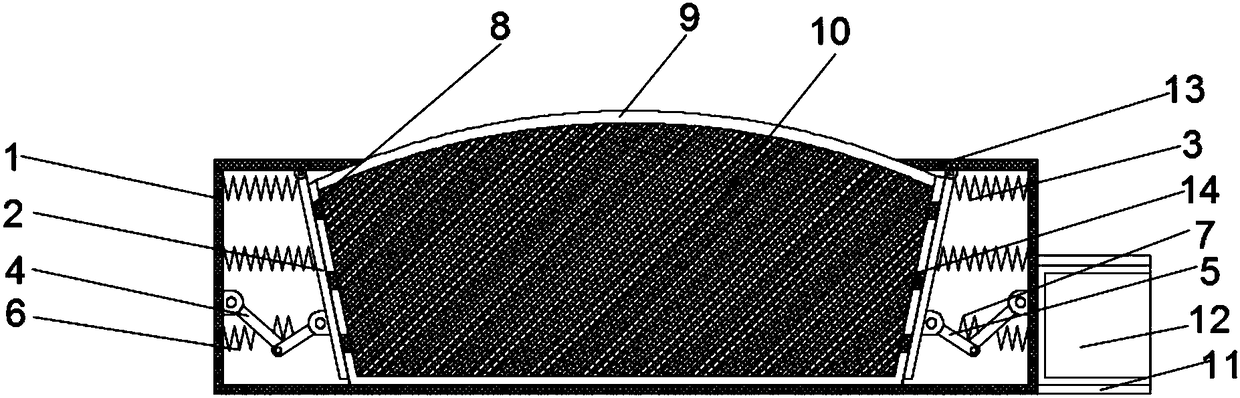

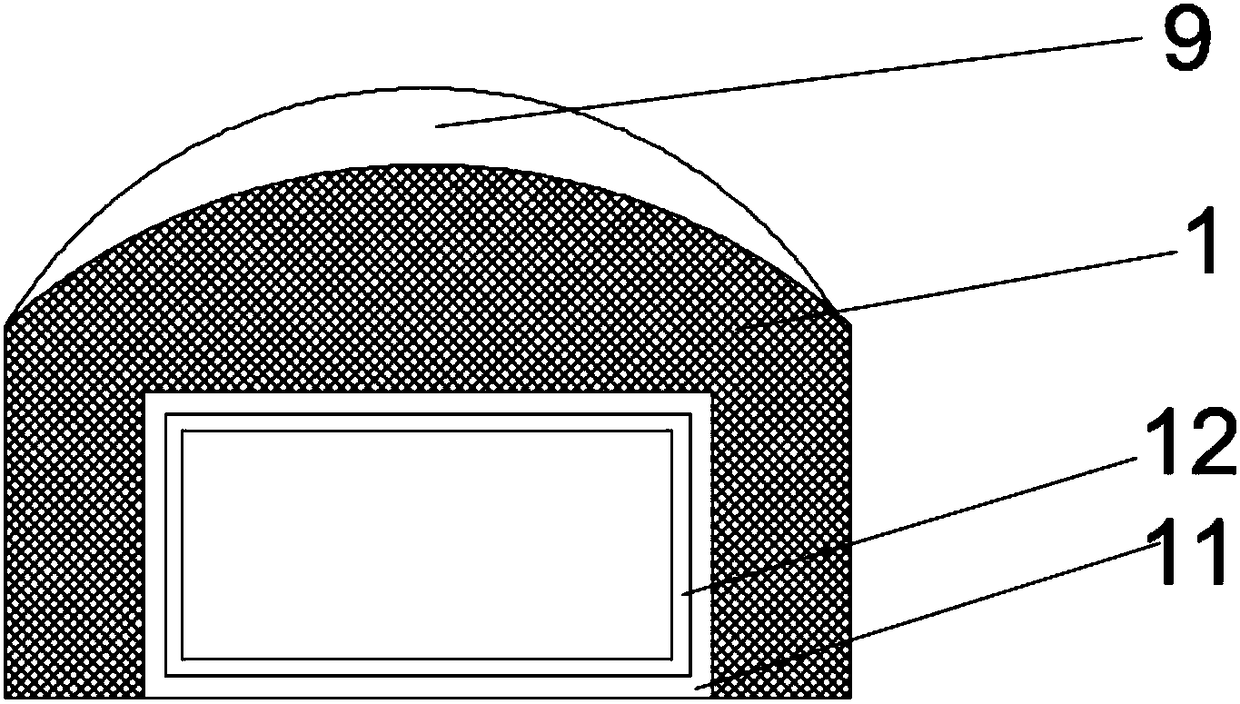

Bamboo fiber pillow

InactiveCN108392041APrevents interference with sleep qualitySolve the problem that there is a certain amount of radiation damagePillowsFiberEngineering

The invention discloses a bamboo fiber pillow and relates to the technical field of bamboo fibers. The bamboo fiber pillow comprises a bamboo pillow housing, limiting plates are rotatably connected tothe two sides of the top of the inner wall of the bamboo pillow housing, and first springs are fixedly connected to the side, close to the bamboo pillow housing, of the outer wall of each limiting plate. The end, away from the corresponding limiting plate, of each first spring is fixedly connected with the bamboo pillow housing; first resetting rods are rotatably connected to the lower end of both sides of the inner wall of the bamboo pillow housing; a second resetting rod is rotatably connected to the end, away from the bamboo pillow housing, of each first resetting rod; a second spring is fixedly connected to one side of the outer wall of each first resetting rod; the end, away from the corresponding first resetting rod, of each second spring is fixedly connected with the bamboo pillowhousing; a third spring is fixedly connected to the side, close to the corresponding first resetting rod, of each second resetting rod. The problems are solved that certain collapse and deformation are formed at head positions of existing bamboo fiber pillows and there is certain radiation damage when mobile phones are placed beside beds.

Owner:安吉竹蕾雅竹纤维有限公司

A liquid-filled molding die and liquid-filled molding method

The invention discloses a liquid-filled molding mold and a liquid-filled molding method. The liquid-filled molding mold includes an upper mold and a lower mold, wherein the upper mold includes an upper mold support plate, an upper mold bottom plate, a punch insert, and a punch seat and punching assembly; the lower die includes a lower die support plate, a lower die bottom plate, a die insert, a die base and a liquid filling assembly. Compared with the prior art, the present invention saves preforming molds and punching times, eliminates collapse and wrinkles at both ends, uses hydraulic online punching as positioning holes for laser cutting, simplifies tooling and reduces cutting costs, and improves product accuracy and consistency. Punching out of the pipe to eliminate the collapse of the punching surface. At the same time, the punch can be replaced quickly through the skylight and the connecting block. The flanging at both ends depends on the mandrel and the die to form the final shape, saving a pair of turning-out tooling and avoiding Seam welding instability and laser cutting costs.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Glass kiln flue gas outlet structure

The present disclosure relates to a flue gas outlet structure of a glass kiln, which comprises a flue (1-2) passing through the kiln wall (1-1) from the inside to the outside and 1) The external smoke pipe (3-1), the adjacent end faces of the flue (1-2) and the smoke pipe (3-1) are sealed and connected by the expansion ring (2-1) and the flue ( 1-2) is in fluid communication with the smoke pipe (3-1); the material of the expansion ring (2-1) meets the following conditions: the heat-resistant temperature is above 1260°C, and the 24-hour linear shrinkage rate at 1000°C is not greater than 1.3% . The flue gas outlet structure of the glass kiln provided by the present disclosure is provided with an expansion ring to connect the flue and the flue, which can effectively prevent the flue and the flue from being cracked or arched due to thermal expansion.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Approximate query processing algorithm based on conditional generative model

ActiveCN113177078BEliminate collapseImprove performanceDigital data information retrievalCharacter and pattern recognitionAlgorithmTheoretical computer science

The invention belongs to the technical field of information retrieval, and in particular relates to an approximate query processing algorithm. An efficient approximate query processing algorithm based on a conditional generation model, including: using aggregated precomputation to obtain the pre-aggregated value of the user query; processing the user query to obtain a new query newQ that estimates the difference between the user query and the pre-aggregated range and the selected pre-aggregated value. Aggregate values; build a Wasserstein-based conditional variational generative adversarial network model, use the trained model to generate data samples for the new query newQ; filter the generated data samples, and compare the filtered data samples with the selected pre-aggregated values Combined, the calculation gets the final query estimate. The method of the present invention constructs an efficient depth generation model, and introduces Wasserstein distance as an error measure to eliminate model collapse; the model is applied to approximate query, combined with aggregate pre-calculation, and a voting algorithm is adopted to reduce approximate query error.

Owner:HARBIN INST OF TECH AT WEIHAI

Tool for galvanically coating sliding bearings

InactiveUS9017531B2Reduce riskUndesirable coating can be preventedCellsReflex reflectorsEngineeringMechanical engineering

Owner:FEDERAL MOGUL WIESBADEN

The control method to prevent the core pulling of the inner ring of the steel coil when the coiler unloads the coil

The invention provides a control method for preventing a steel coil inner ring from core pulling during coil stripping of a coiling machine. The control method for preventing the steel coil inner ring from core pulling during coil stripping of a coiling machine comprises the steps that the position of a tong opening is detected after coiling is finished; an ideal shearpoint of strip steel is calculated; a strip tail is positioned; and automatic coil stripping is conducted. The phenomena of jamming of a strip head, scratching of the steel coil inner ring and core pulling during coil stripping can be completely eliminated by adopting the control method for preventing core pulling of the steel coil inner ring during coil stripping of the coiling machine.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Secondary coal-mining method for reversely filling paste in stripes

ActiveCN102261247BImprove securityHigh recovery rateUnderground miningSurface miningResource utilizationCoal pillar

The invention relates to a secondary coal-mining method for reversely filling paste in stripes. The secondary coal-mining method is suitable for the safe recovery of coal resources under buildings, railways and water bodies. The secondary coal-mining method comprises the following steps of: determining the range of mining coal under building groups according to regulations, and alternatively partitioning paste filling stripes and recovery stripes in the determined coal mining range; sequentially mining the partitioned paste filling stripes and filling mine-out areas of the partitioned paste filling stripes; and sequentially drilling without section pillar along the two paste filling strips and mining the recovery stripes by a caving method after a filler in the past filling stripes is completely solidified. Under usual conditions, the paste filling stripes are wider, and normal recovery stripes are narrow. By the method, the damage to the surface buildings caused by mining subsidence can be effectively reduced, the safety of coal mining can also be ensured without reserving narrow coal pillars, so that the coal resource is completely recovered; and simultaneously, coal resources utilization of solid wastes such as coal gangues and fly ash is realized.

Owner:CHINA UNIV OF MINING & TECH

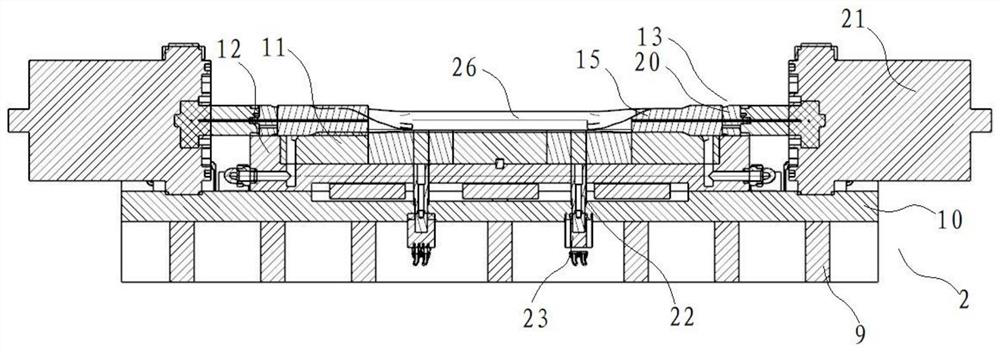

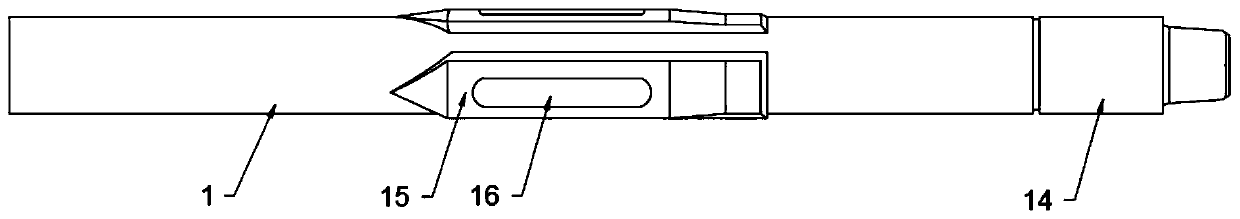

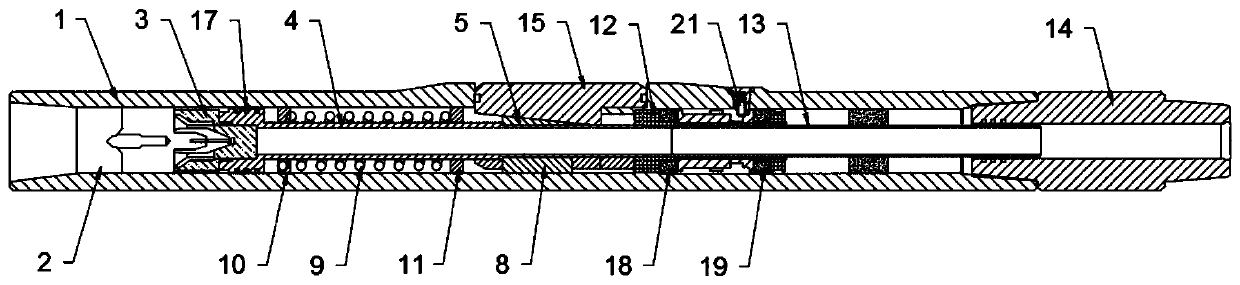

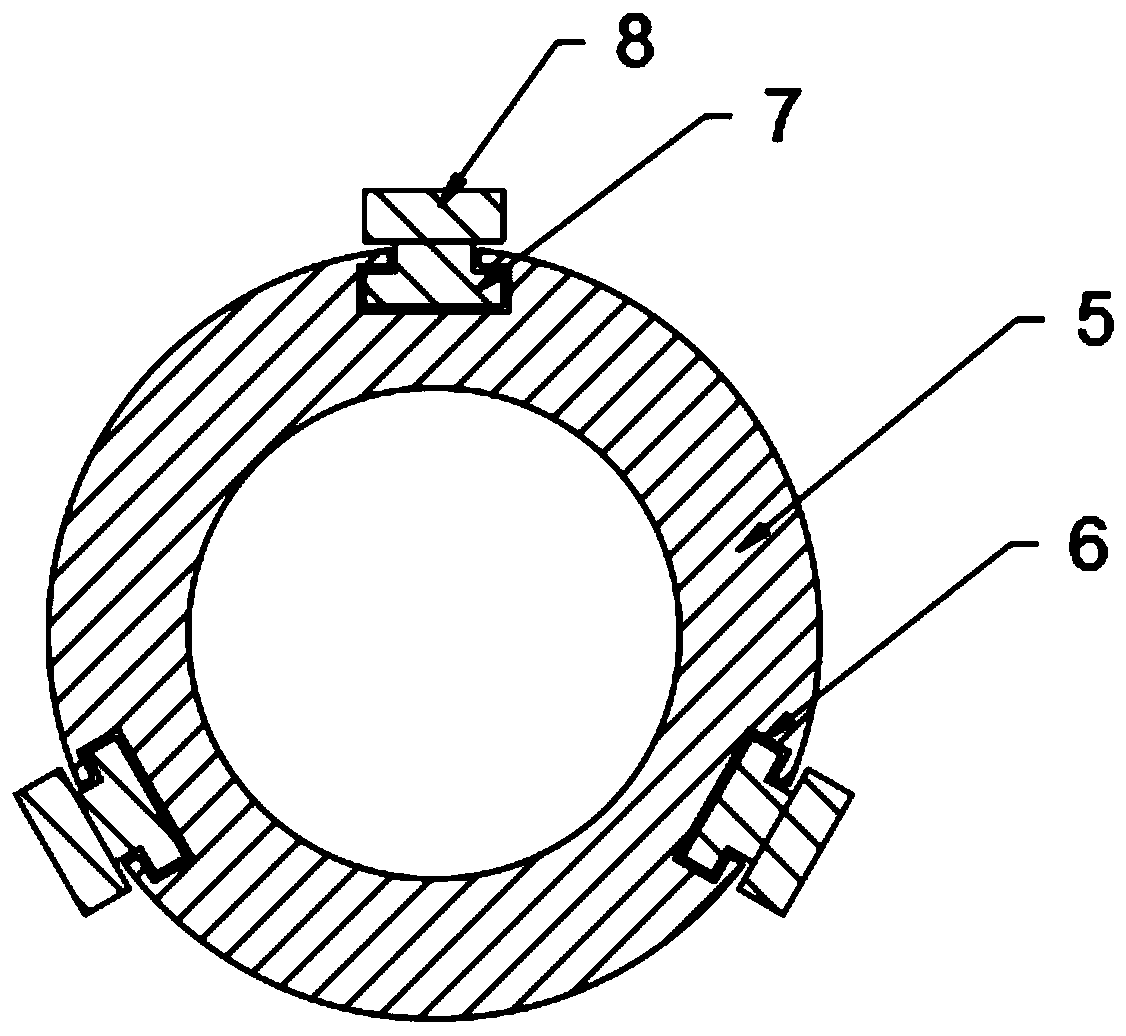

While-drilling adjustable tapered stabilizer

InactiveCN110344773AEffective controlEasy to controlDrilling rodsDrilling casingsDrift angleEngineering

The invention discloses a while-drilling adjustable tapered stabilizer comprising a shell, a signal valve, a first piston column, a bevel body, a chute, a rib, a support block, a spring, a second piston column, a connector, a rotation groove and a pin rod; and one side of the interior of the shell is provided with the signal valve. The while-drilling adjustable tapered stabilizer is arranged, thesize of the stabilizer is adjusted, the well inclination control capability of a lower drilling tool is changed, the hole drift angle of a well is accurately controlled, the small diameter state in the drilling process is kept, the blocking phenomenon is avoided, the problems of blockage and clamping during lower drill lifting of the stabilizer are solved, major accidents such as well collapse andblowout caused by suction of pulling supporting blocks are fundamentally eliminated, safety is ensured, and major economic losses are avoided. By means of the while-drilling adjustable tapered stabilizer, simple and quick adjustment can be carried out by starting and stopping pumps simply, so that well inclination can be precisely controlled. In a horizontal section, the size of the stabilizer isadjusted, and the TVD (deep depth) can be accurately controlled.

Owner:北京众英泰科能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com