Manufacturing method of prestressed porous anchor plates

A manufacturing method and prestressing technology, which is applied in the field of anchor plate manufacturing, can solve the problems of internal and external hardness of difficult products, waste of energy consumption, and easy collapse, etc., and achieve the effect of consistent hardness, ensuring product quality, and eliminating collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

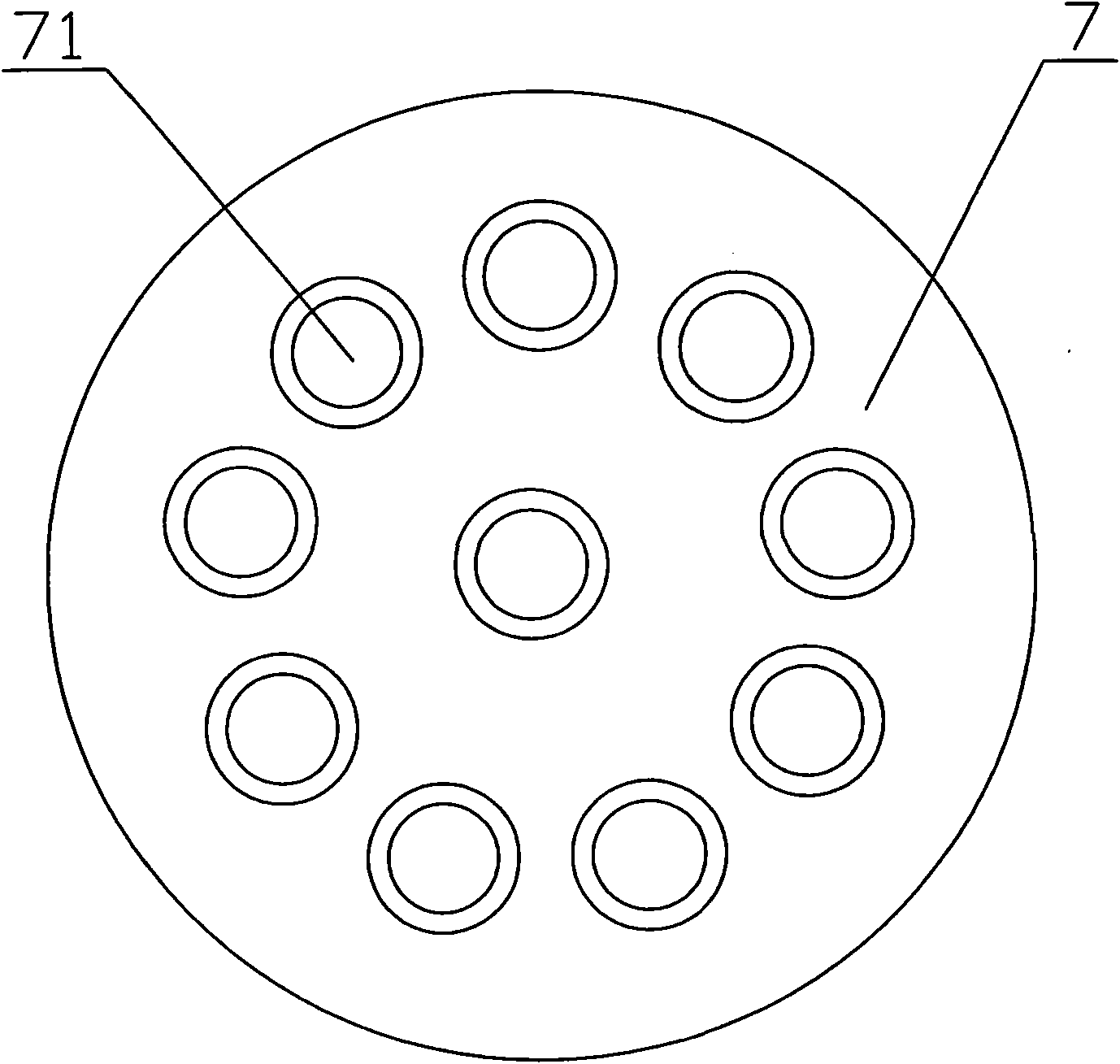

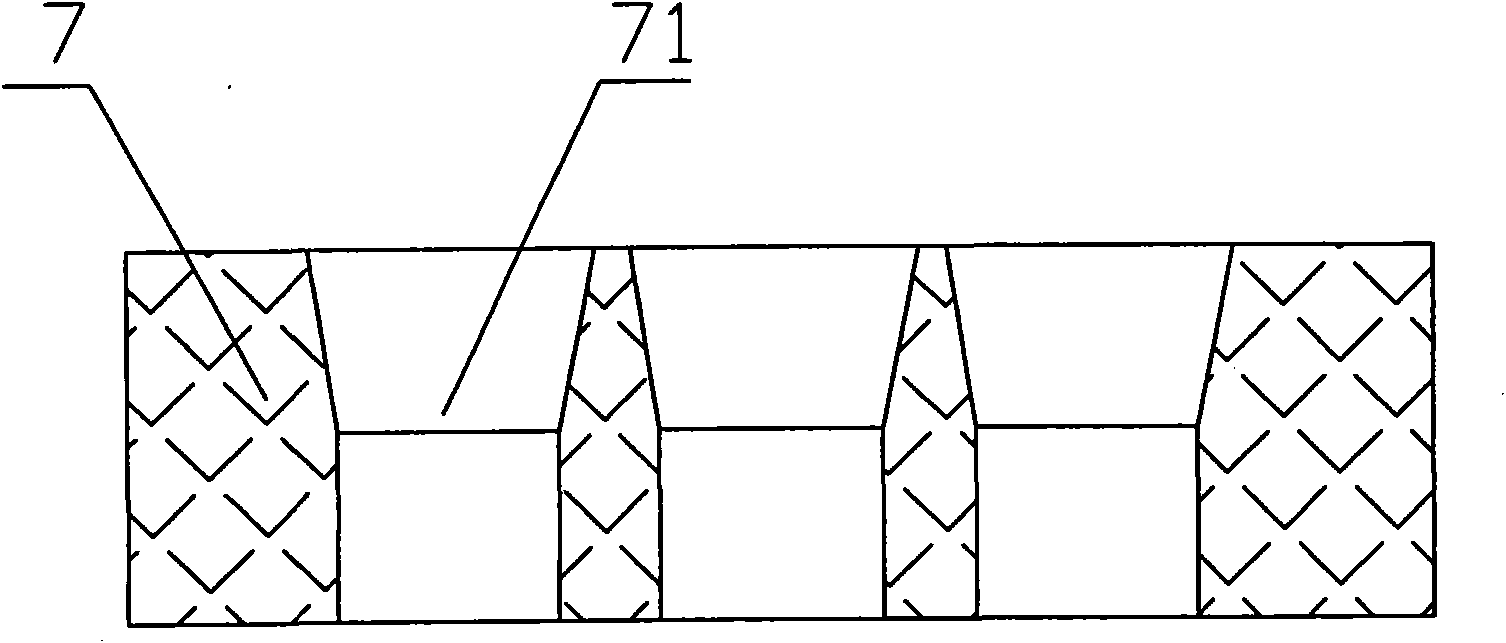

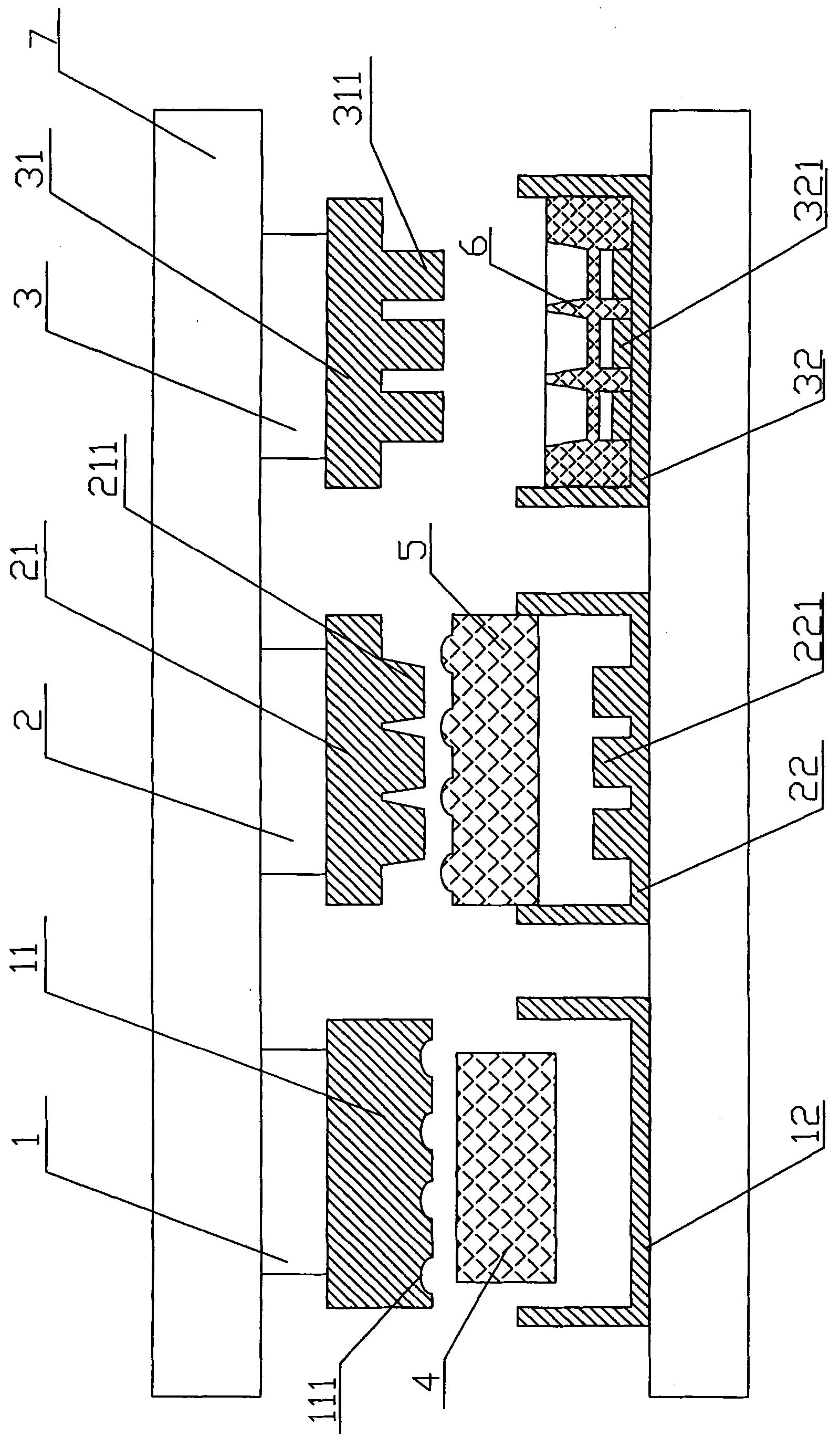

[0032] The present invention relates to a method for manufacturing a prestressed porous anchor plate. The anchor plate 7 is provided with several anchor holes 71, and the upper end of the anchor hole 71 is a tapered hole and the lower end is a straight hole, such as Figure 1~2 As shown, three stations are successively arranged on the stamping plate of the press 8, which are blank making station 1, punching station 2 and piercing station 3 respectively, and the manufacturing method of the prestressed porous anchor plate is as follows:

[0033] 1) Heating: heating the round steel material 4 obtained after cutting the raw material to 1150±20°C.

[0034] 2) Blank making: put the round steel material 4 into the blank mold mold consisting of the blank mold upper mold 11 and the blank mold lower mold 12, and the blank mold upper mold 11 is fixed on the blank making station 1 , the lower mold 12 of the blank-making mold is fixed on the bottom plate of the press 8, and the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com