Semiconductor device

A semiconductor and device technology, applied in the field of semiconductor devices using gallium nitride-based semiconductors, can solve problems such as limited withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

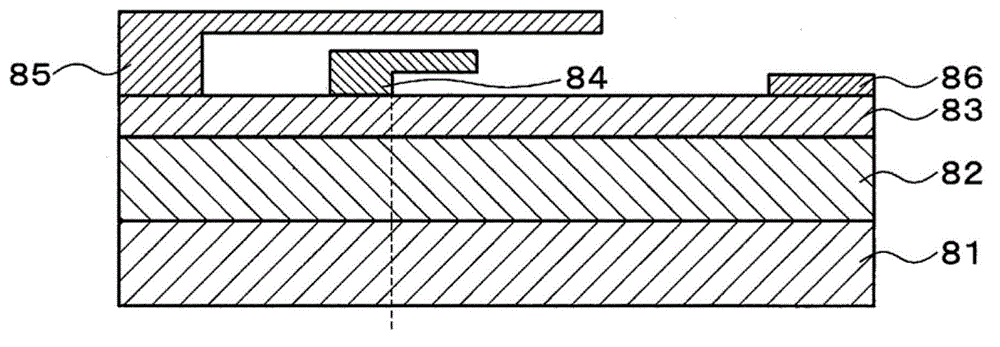

[0109] The GaN-based semiconductor device of the first embodiment will be described.

[0110] The basic structure of the GaN-based semiconductor device is shown in Image 6 .

[0111] Such as Image 6 As shown, in this GaN-based semiconductor device, undoped In is sequentially stacked on a base substrate (not shown) such as a C-plane sapphire substrate on which a GaN-based semiconductor is grown on a C-plane. z Ga 1-z N layer 11 (0≤zx Ga 1-x N layer 12 (0y Ga 1-y N layer 13 (0≤yw Ga 1-w N layer 14 (0≤w<1).

[0112] In this GaN-based semiconductor device, when not in operation, the In near the base substrate is z Ga 1-z N layer 11 and Al x Ga 1-x Al in the vicinity of the heterointerface between the N layers 12 x Ga 1-x The N layer 12 induces positive fixed charges, and the Al on the side opposite to the base substrate side x Ga 1-x N layer 12 and In y Ga 1-y Al in the vicinity of the heterointerface between N layers 13 x Ga 1-x The N layer 1...

Embodiment 1

[0200] Such as Figure 23 As shown, on the (0001) plane, that is, on the C-plane sapphire substrate 31, TMG (trimethylgallium) was used as a Ga raw material and TMA (trimethylgallium) was used as a Ga raw material by conventionally known MOCVD (metal organic vapor deposition) technology. aluminum) as Al raw material, using NH 3( Ammonia) as nitrogen raw material, using N 2 gas and H 2 Gas is used as a carrier gas, and a low-temperature growth (530°C) GaN buffer layer 32 with a thickness of 30nm is stacked, and then the growth temperature is increased to 1100°C, and an undoped GaN layer 33 with a thickness of 1000nm and an undoped Al layer with a thickness of 47nm are continuously grown. x Ga 1-x N layer 34 (x=0.226), undoped GaN layer 35 with a thickness of 10 nm, and Mg-doped p-type GaN layer 36 with a thickness of 30 nm. The Mg doping amount becomes 3×10 according to the Mg concentration 19 cm -3 way to set.

[0201] The 4-terminal Hall measurement was carried out o...

no. 2 Embodiment approach >

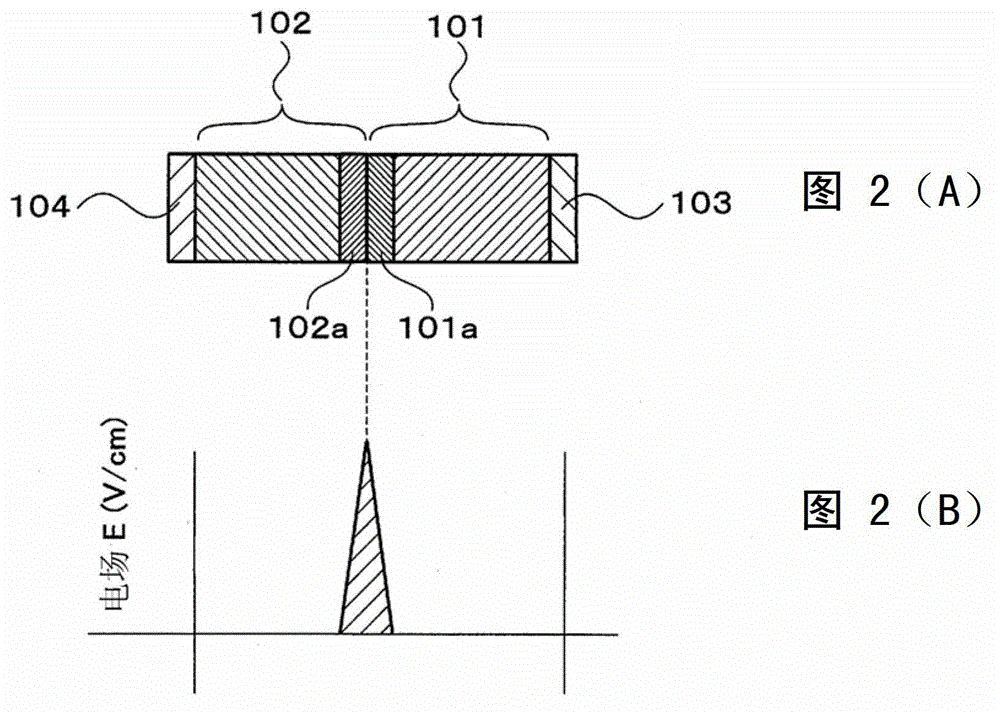

[0211] The GaN-based diode of the second embodiment will be described.

[0212] Figure 24 represents the GaN-based diode.

[0213] Such as Figure 24As shown, in this GaN-based diode, an undoped GaN layer 41, an undoped AlGaN layer 42, an undoped GaN layer 43, and p-type GaN layer 44 . The upper portion of the undoped AlGaN layer 42, the undoped GaN layer 43, and the p-type GaN layer 44 are patterned into a predetermined shape to form a mesa. An anode electrode 47 is formed extending from the top surface and the side surface of one end of the mesa to the undoped AlGaN layer 42 adjacent to the mesa. The anode electrode 47 is formed of, for example, Ni or the like. In addition, a cathode electrode 48 is formed on the undoped AlGaN layer 42 apart from the mesa portion. The cathode electrode 48 is formed of, for example, a Ti / Al / Au laminated film or the like. In this GaN-based diode, a 2DHG 45 is formed in the undoped GaN layer 43 near the heterointerface between the undop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com