Square tube punching device and process

A punching device and punching technology, applied in the direction of punching tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in penetrating the punching concave die core and the collapse of punching holes, so as to eliminate the difficulty of penetration and ensure the quality. , compact structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

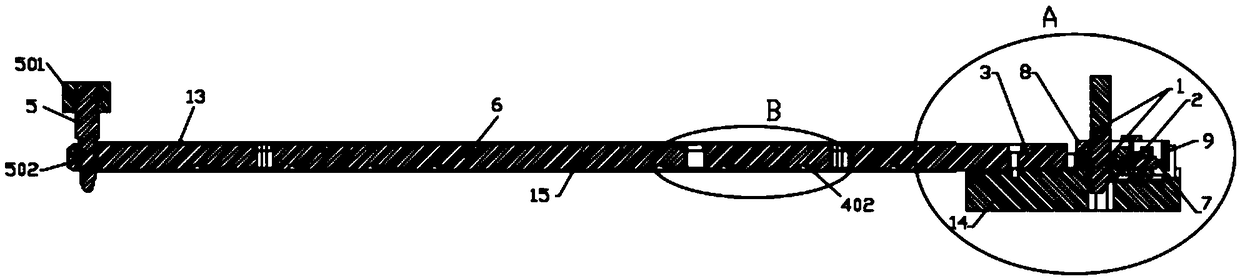

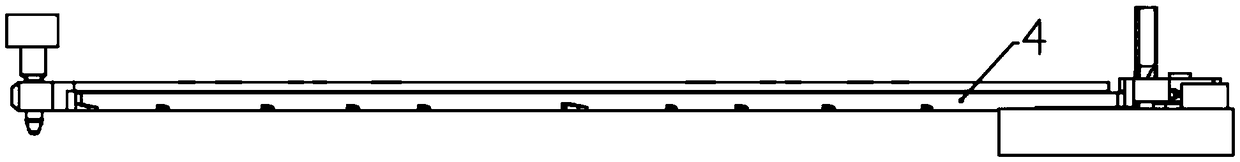

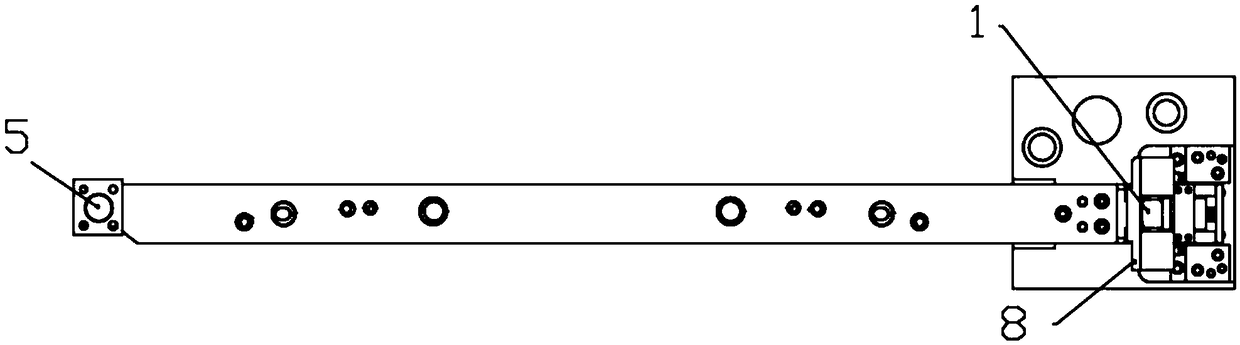

[0029] Such as Figure 1-4 As shown, a square tube punching device includes a shrinking mechanism 3 and a driving mechanism for the positioning of the square tube 13. The shrinking mechanism 3 includes a punching die core 6 and an inclined slider frame 4. The punching The die core 6 is located in the frame of the inclined plane slider frame 4, the punch die core 6 is fixedly connected to the lower template 14 by bolts, and the bottom surface of the punch die core 6 is provided with a plurality of slider grooves 401 , each of the slider grooves 401 is placed with a slope slider 402, and the slope slider 402 is welded and installed on the slope slider frame 4, and the slope slider frame 4 passes through the 2 One or three fixed blocks 15 are positioned and connected; one end of the punching die core 6 is provided with a pilot pin 5 for positioning, and the driving mechanism is arranged at the other end of the inclined plane slider frame 4; specifically , the bottom of the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com