Liquid-filled forming die and liquid-filled forming method

A liquid-filled molding and mold technology, which is applied in the field of liquid-filled molding molds and liquid-filled molding, can solve the problems of complex design of laser cutting fixtures, increased mold costs and production costs, and unstable welding of both ends of the seam. The effect of avoiding welding instability, reducing cutting costs, and improving product accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

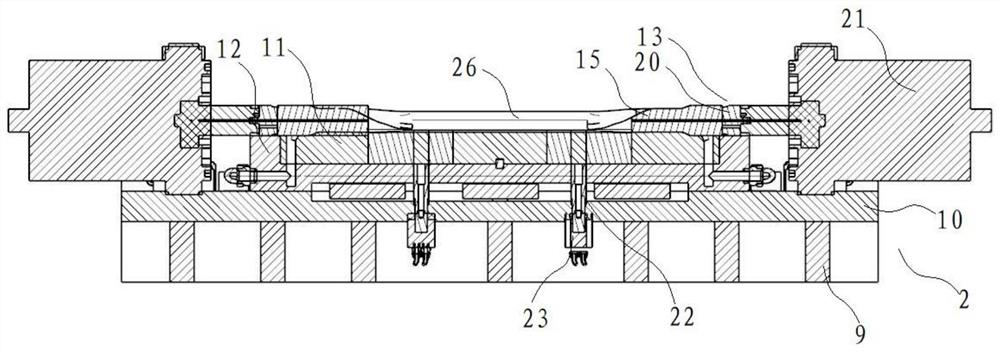

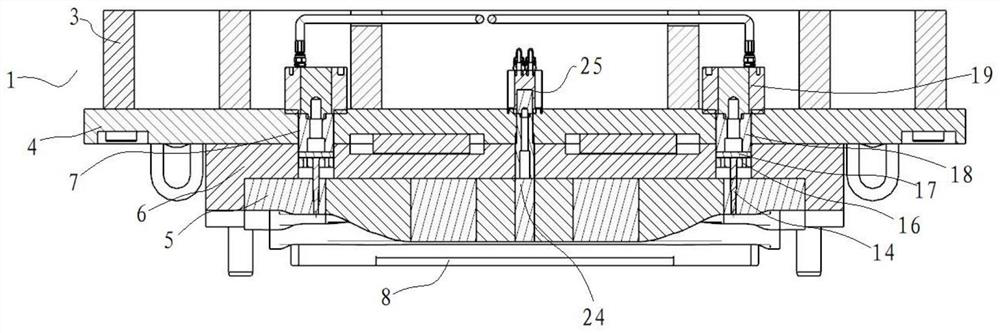

[0028] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a liquid-filled molding die, including an upper die 1 and a lower die 2, wherein:

[0029] The upper mold 1 includes an upper mold support plate 3, an upper mold bottom plate 4, a punch insert 5, a punch seat 6 and a punching assembly 7, and the upper mold bottom plate 4 is fixed on the plate of the upper mold support plate 3 On the surface, the punch insert 5 is fixed in the punch base 6, and the punch base 6 is fixed on the upper mold bottom plate 4, and the top of the punch insert 5 is provided with an upper groove 8. The die insert 11 is installed in the die base 12 through screws and pins, and its surroundings are sealed by trapezoidal encapsulation keys. The surroundings of the die base 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com