Patents

Literature

110results about How to "Less tooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

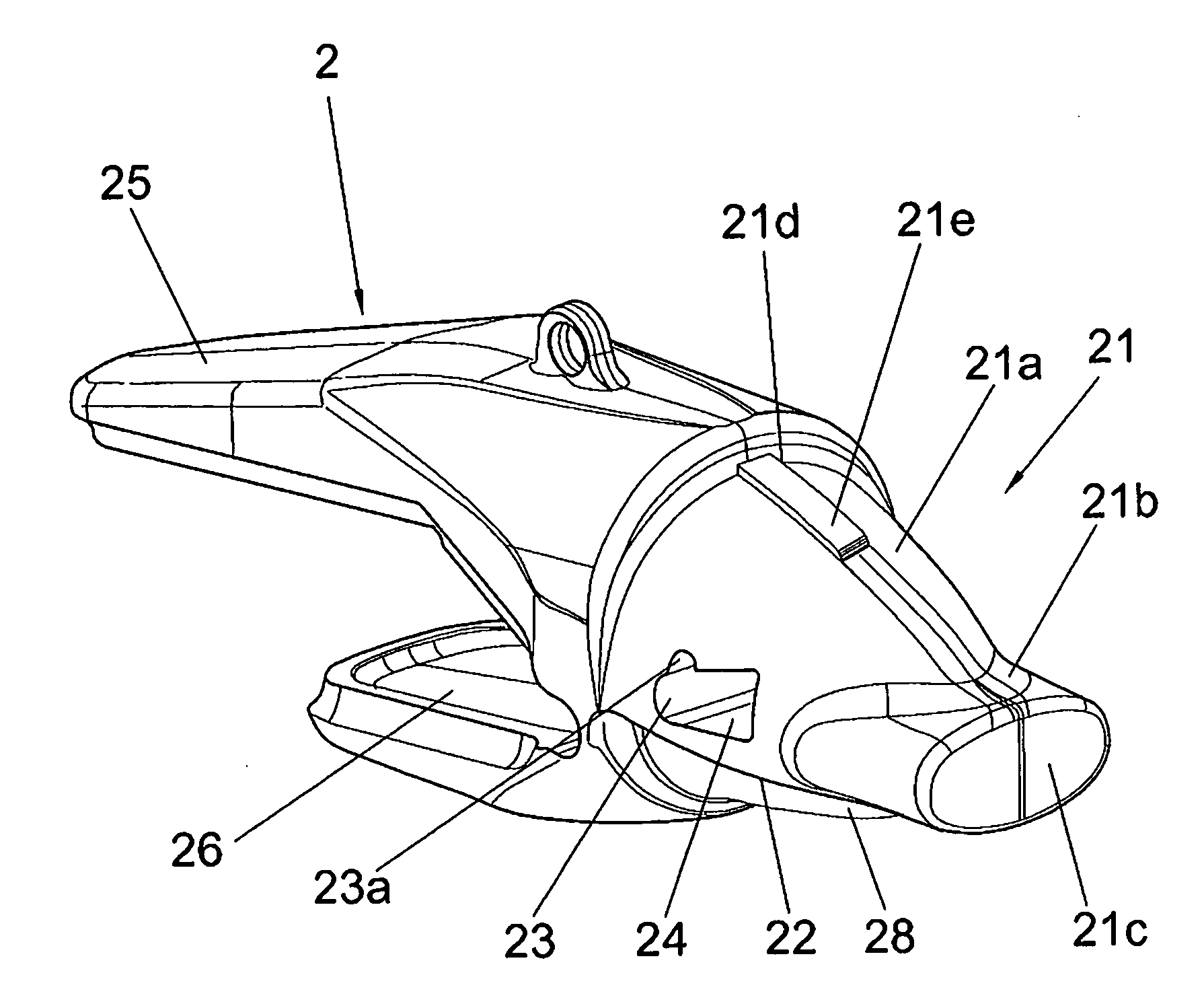

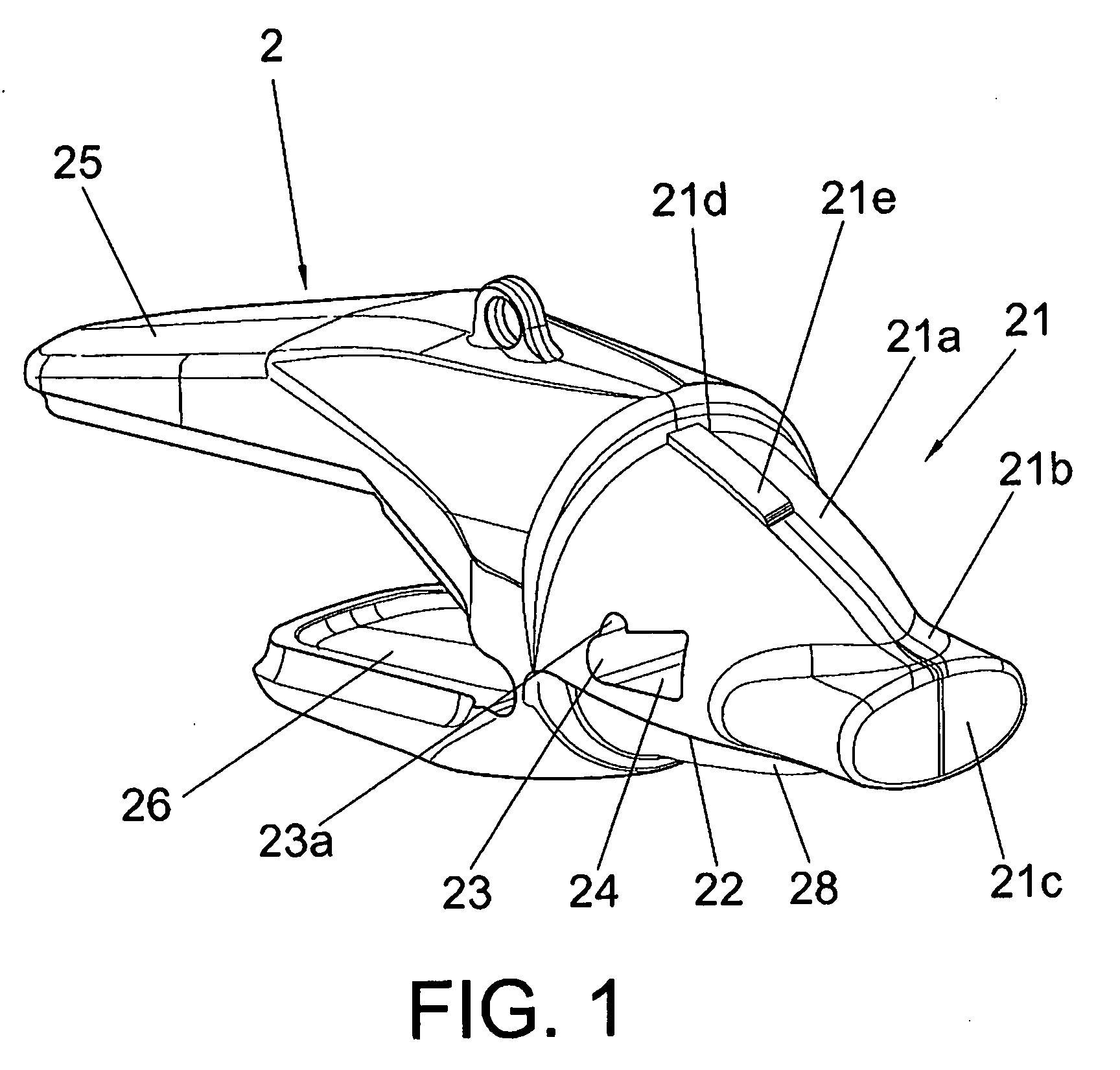

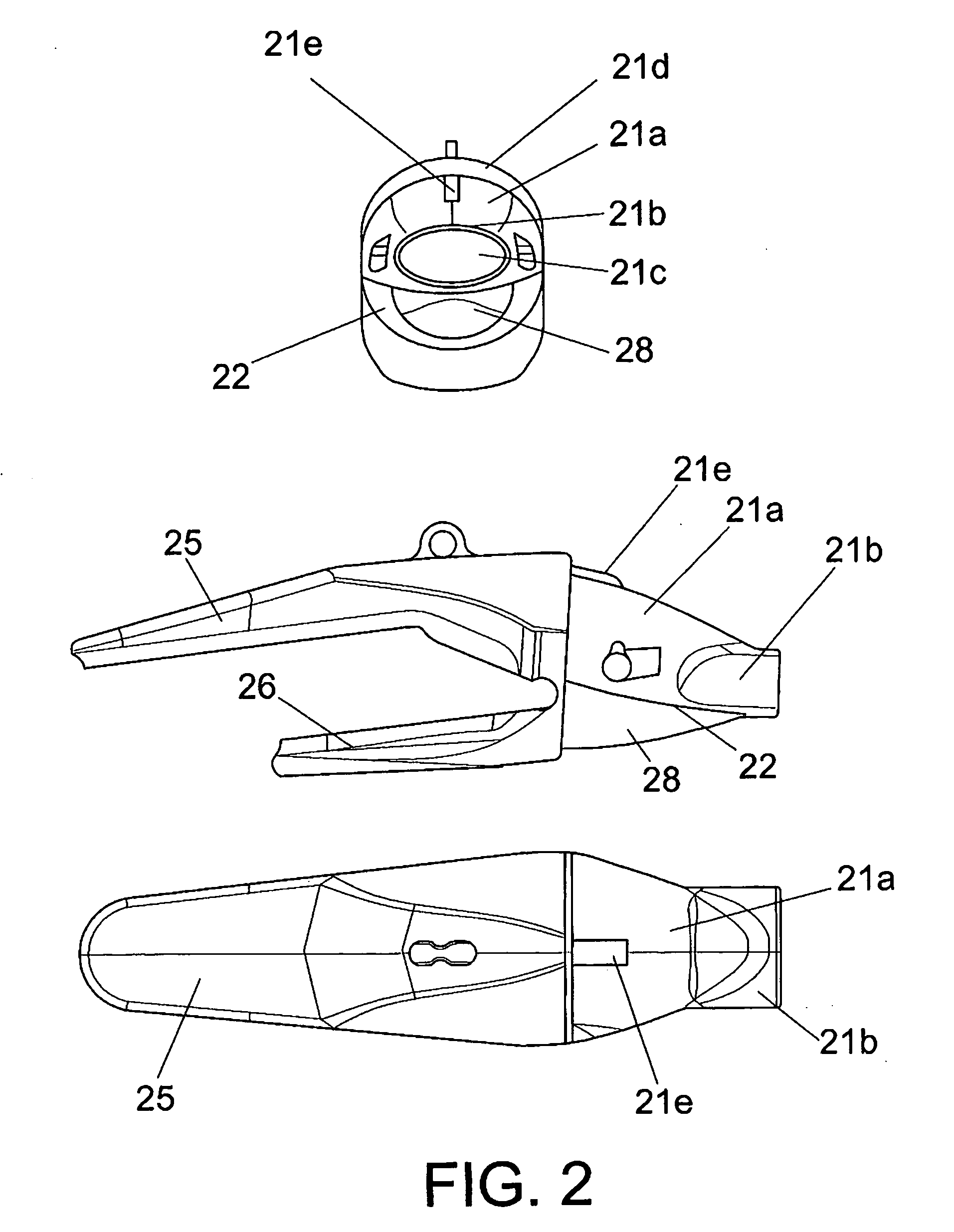

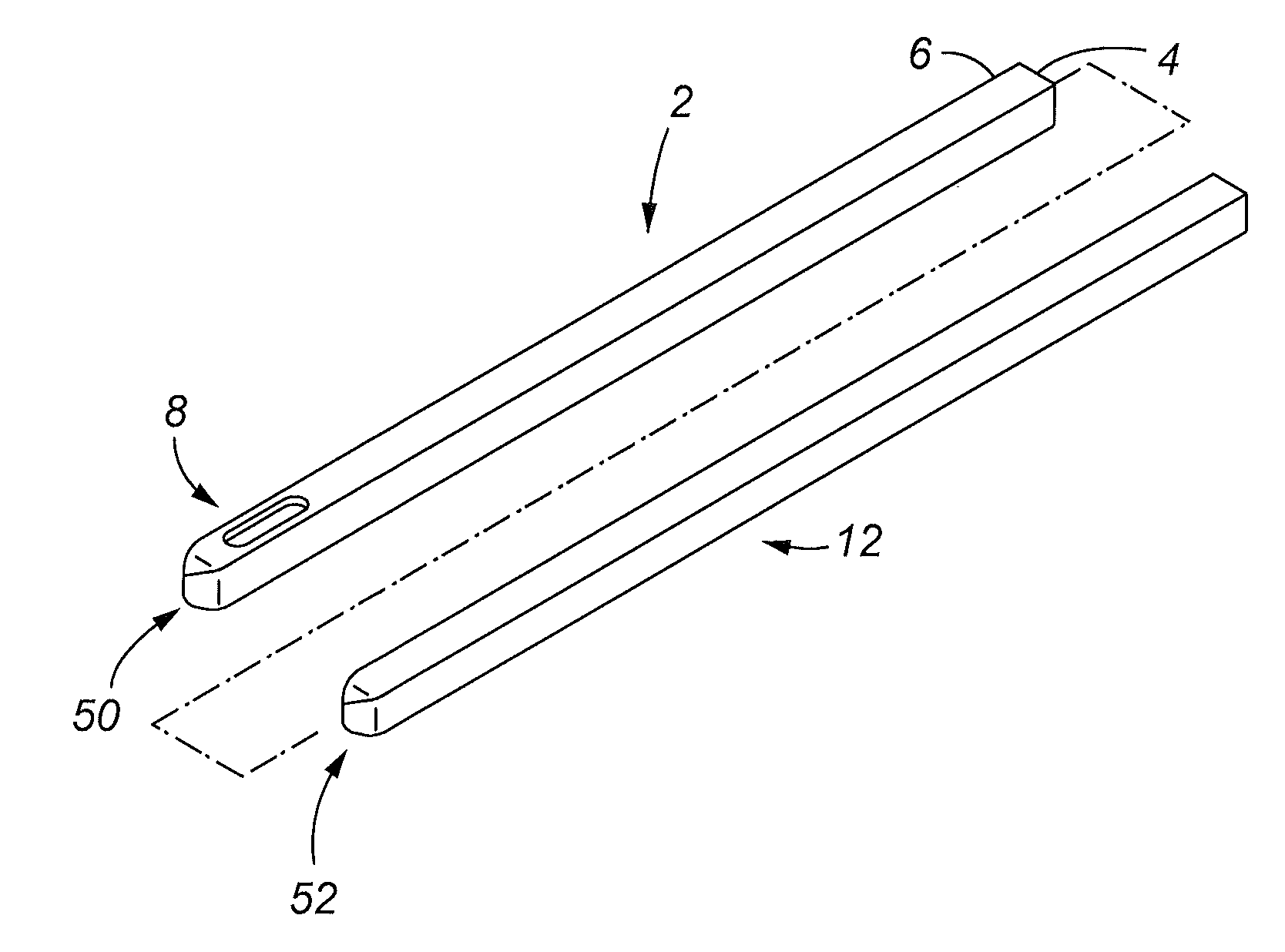

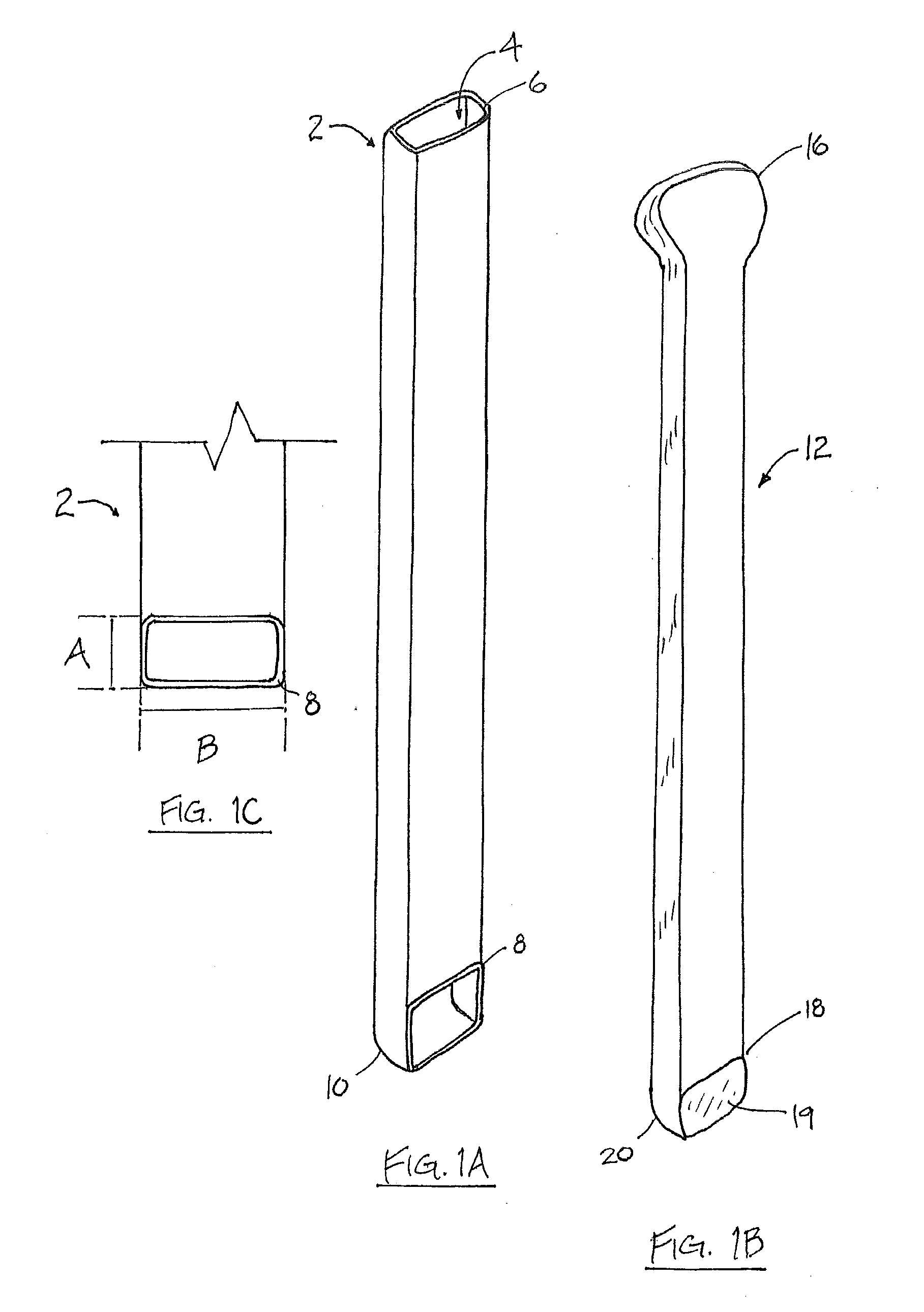

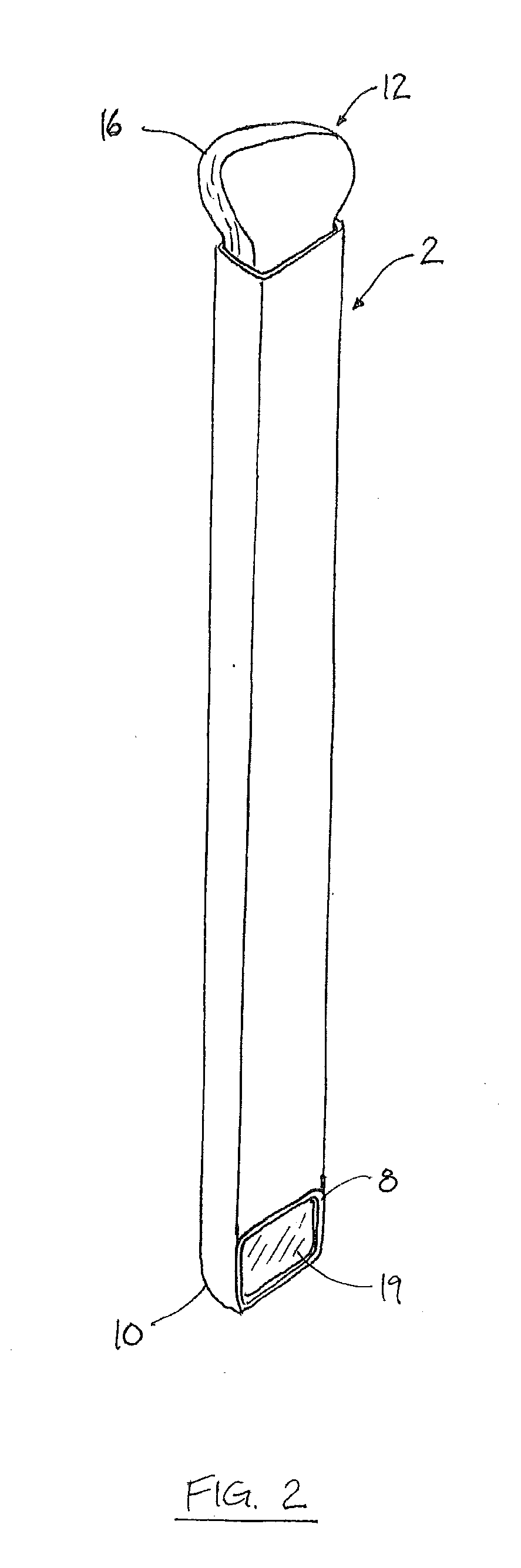

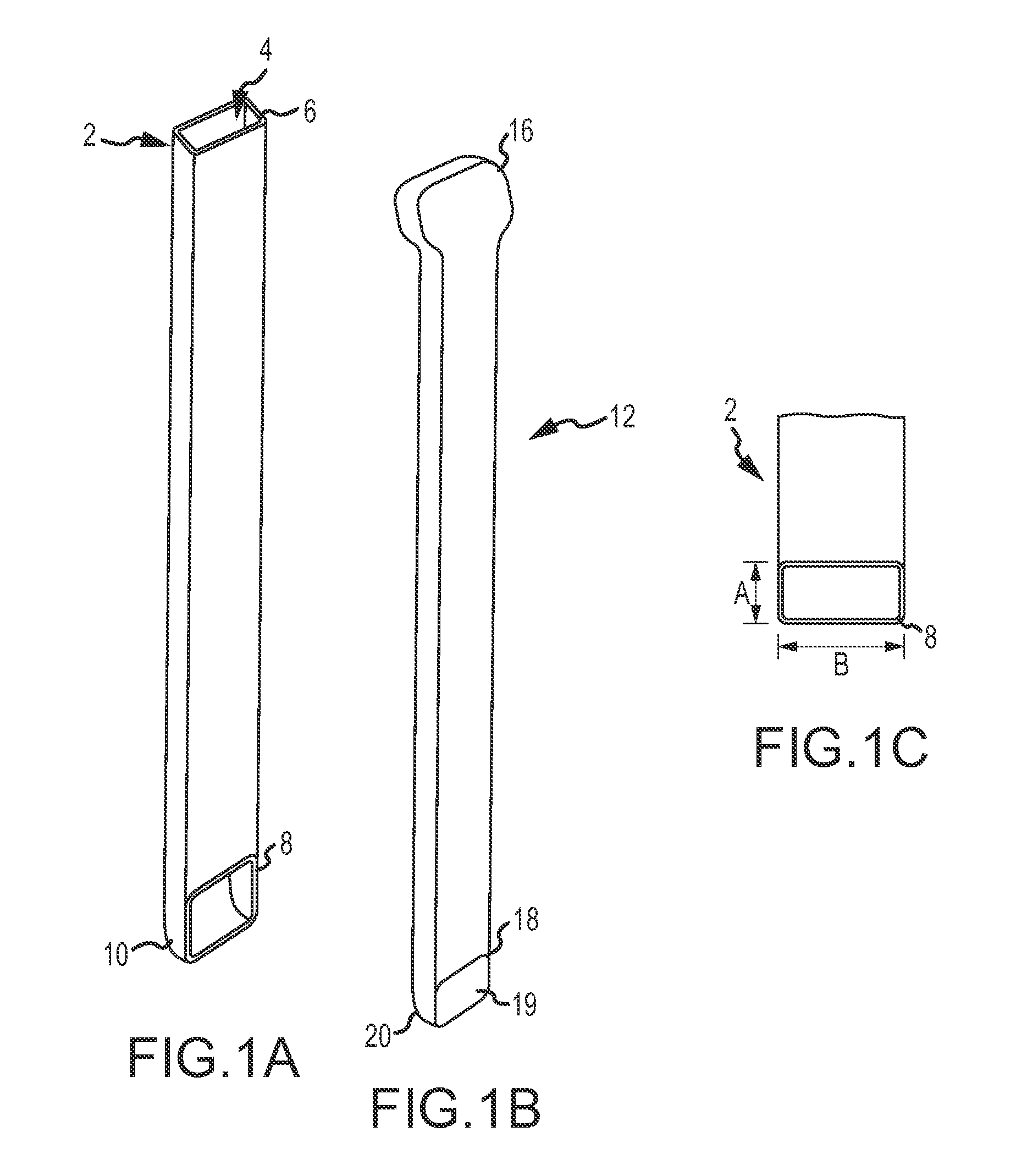

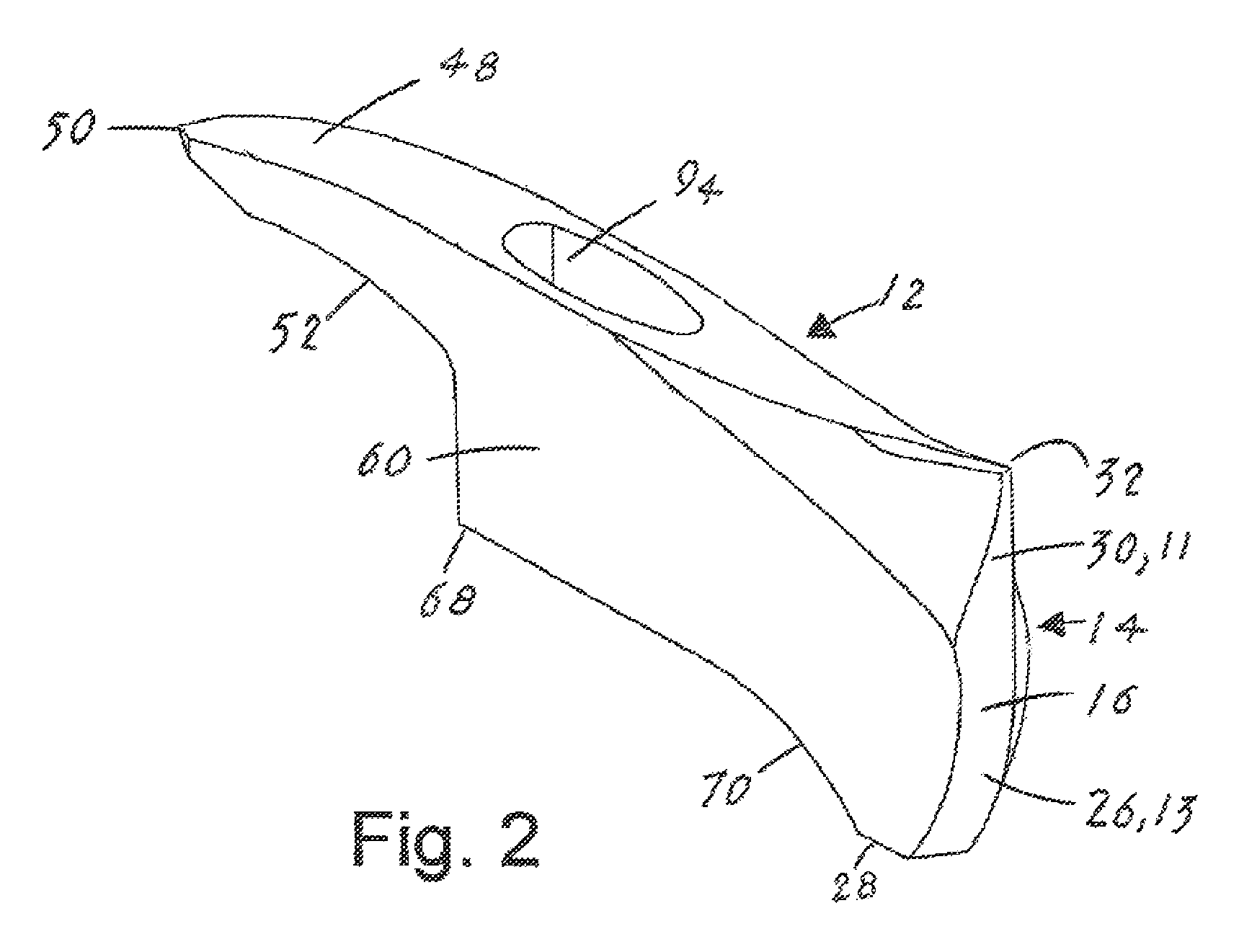

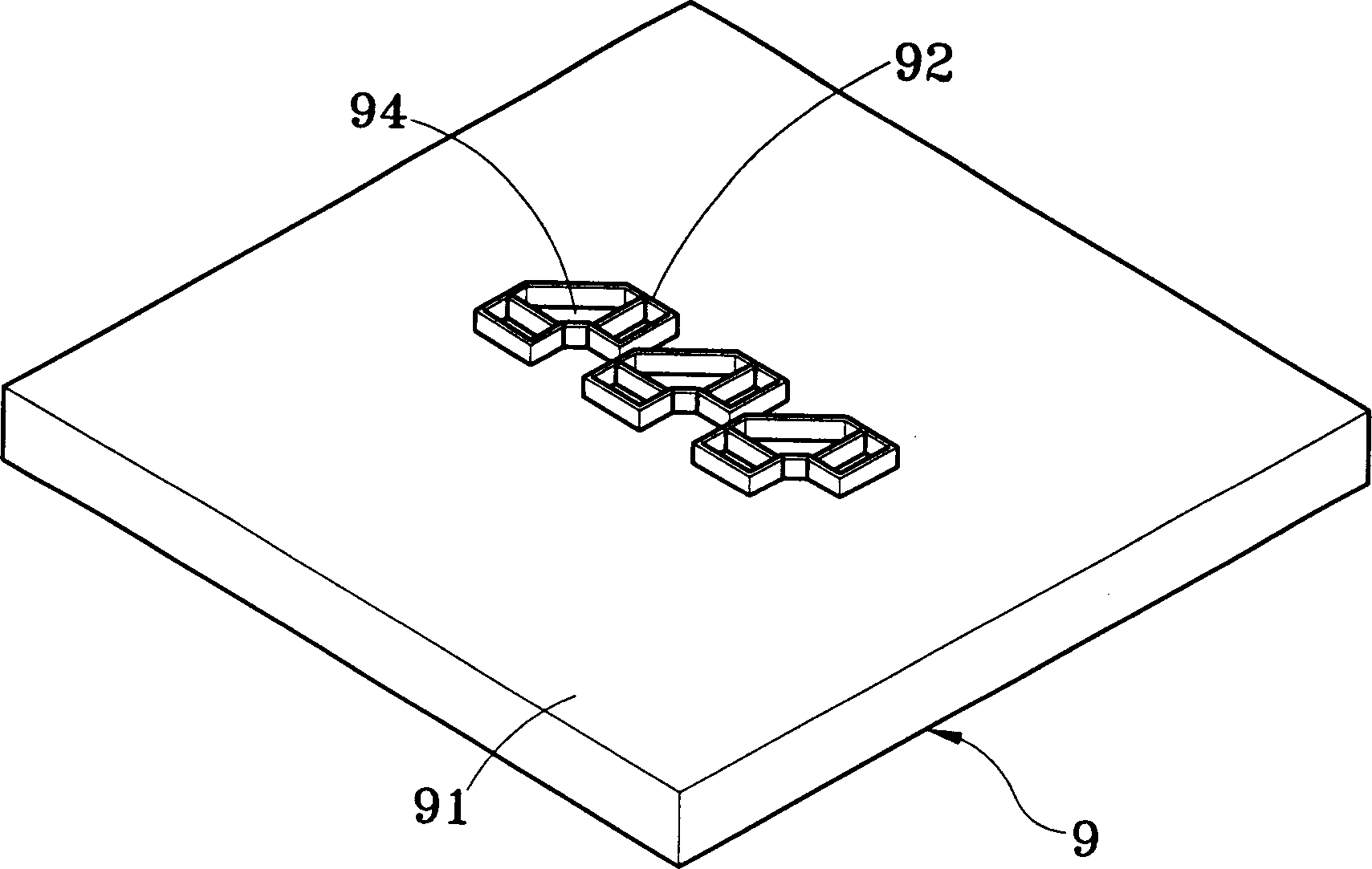

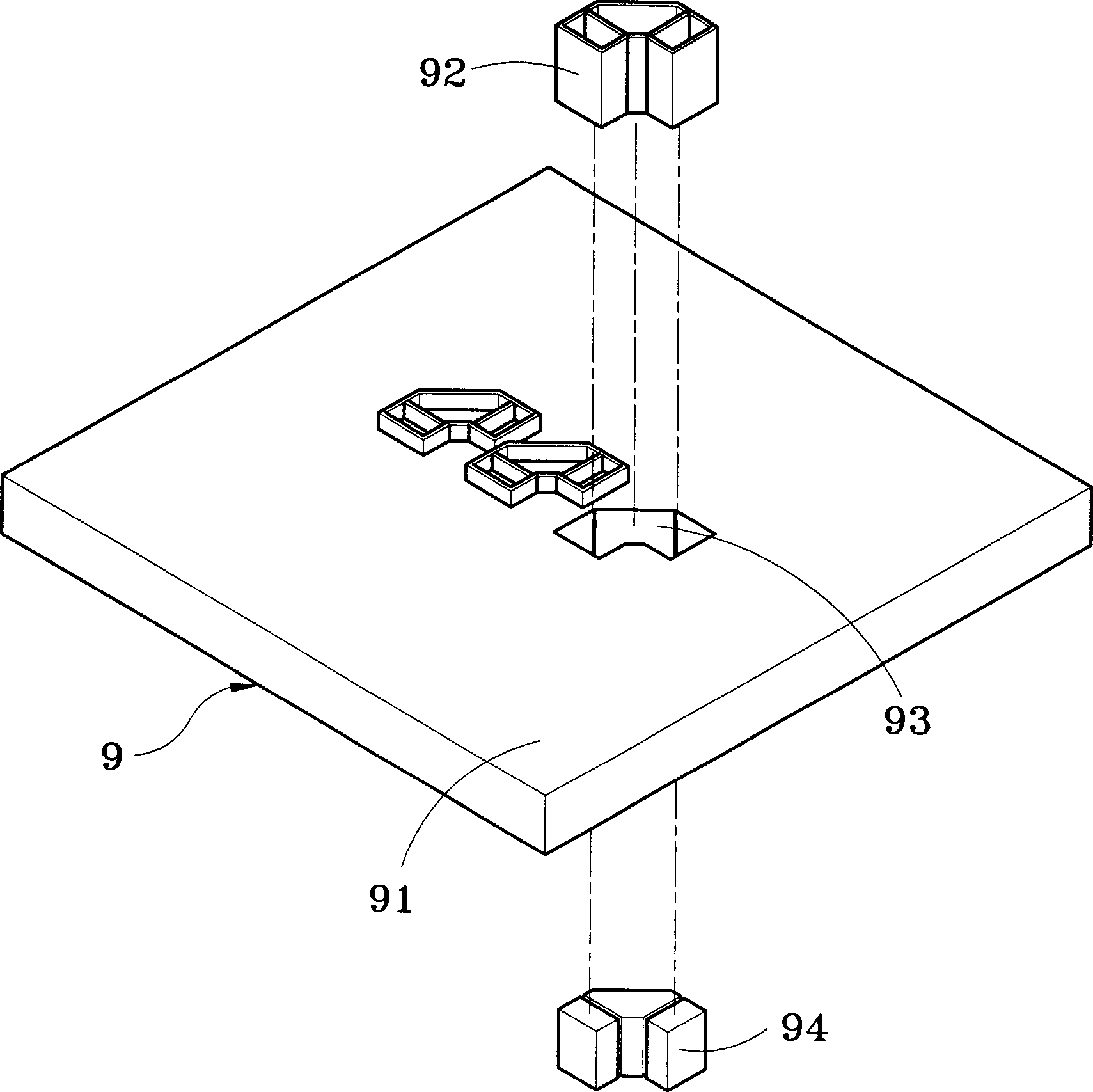

Wear Assembly and Components Thereof, Which is Intended for Machines That Are Used to Move Mateials Such as Earth and Stones

ActiveUS20080028644A1Reduce usageEasy to operateSoil-working equipmentsDragsCoupling systemExcavator

The present invention relates to a wear assembly, as well as to the different components thereof, which comprises a wear member or tooth and an adaptor member or tooth bar for wear applications in a machine for moving materials such as earth and stones.The invention contemplates a wear assembly and particularly a coupling system between the different components to one another by means of a characteristic coupling system and at least one retention system assuring the coupling and anchor between the different components, specifically between the wear member and adaptor, the latter in turn being joined to the blade of a bucket or scoop of a machine for moving materials, such as an excavator or the like.

Owner:METALOGENIA SA

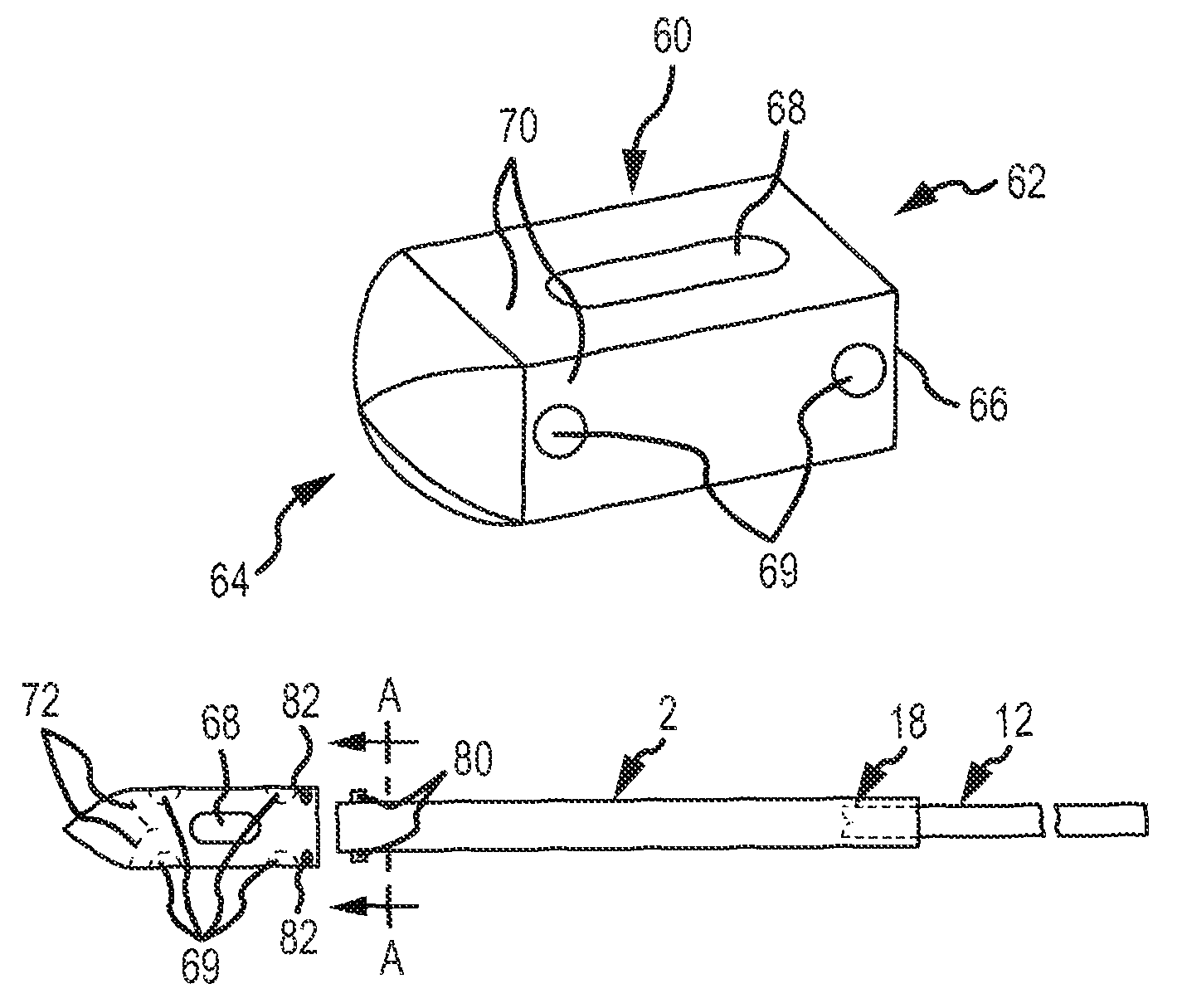

Biological delivery system with adaptable fusion cage interface

ActiveUS20160106551A1Control volumeIncreased traumaBone implantJoint implantsSurgical siteBiological materials

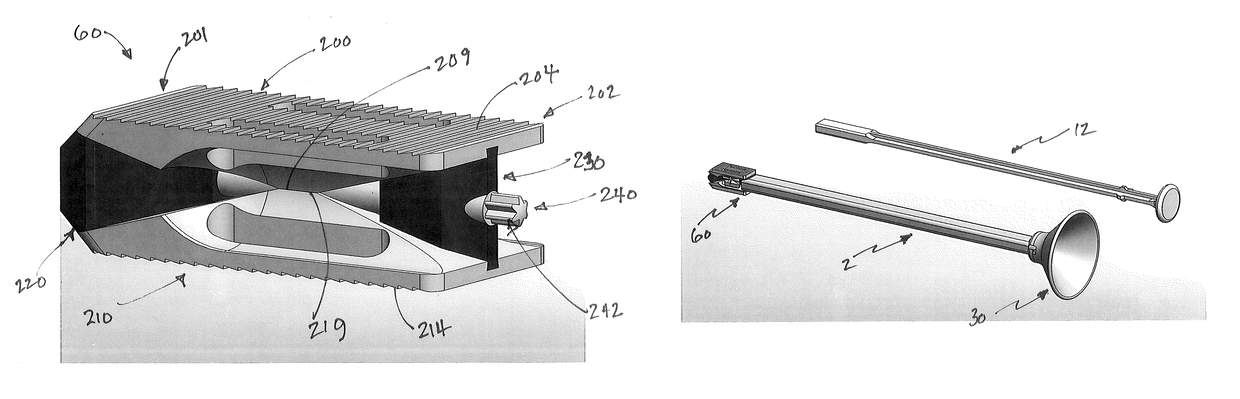

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area. In one embodiment, the integrated fusion cage is an expandable integrated fusion cage.

Owner:SPINAL SURGICAL STRATEGIES INC

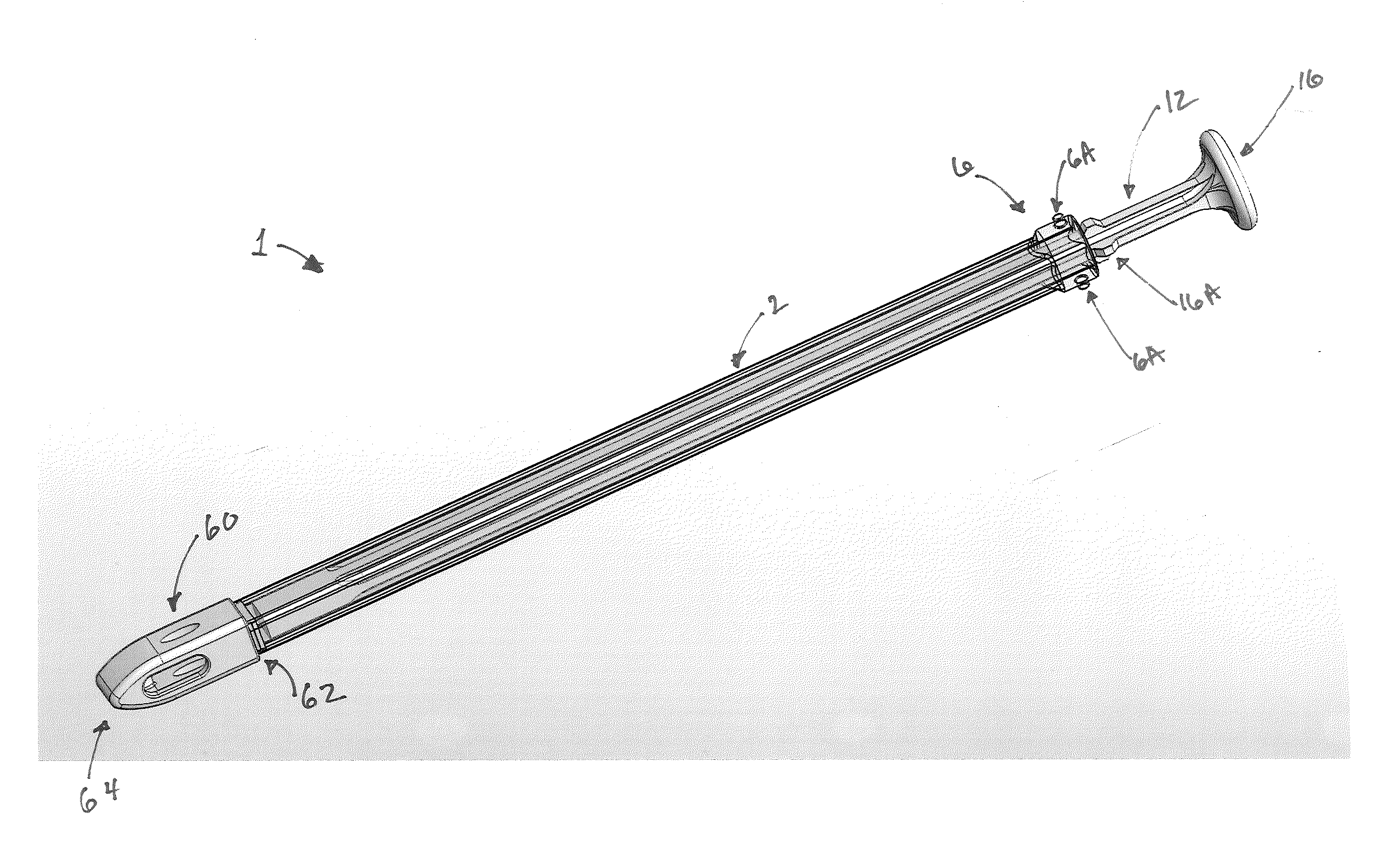

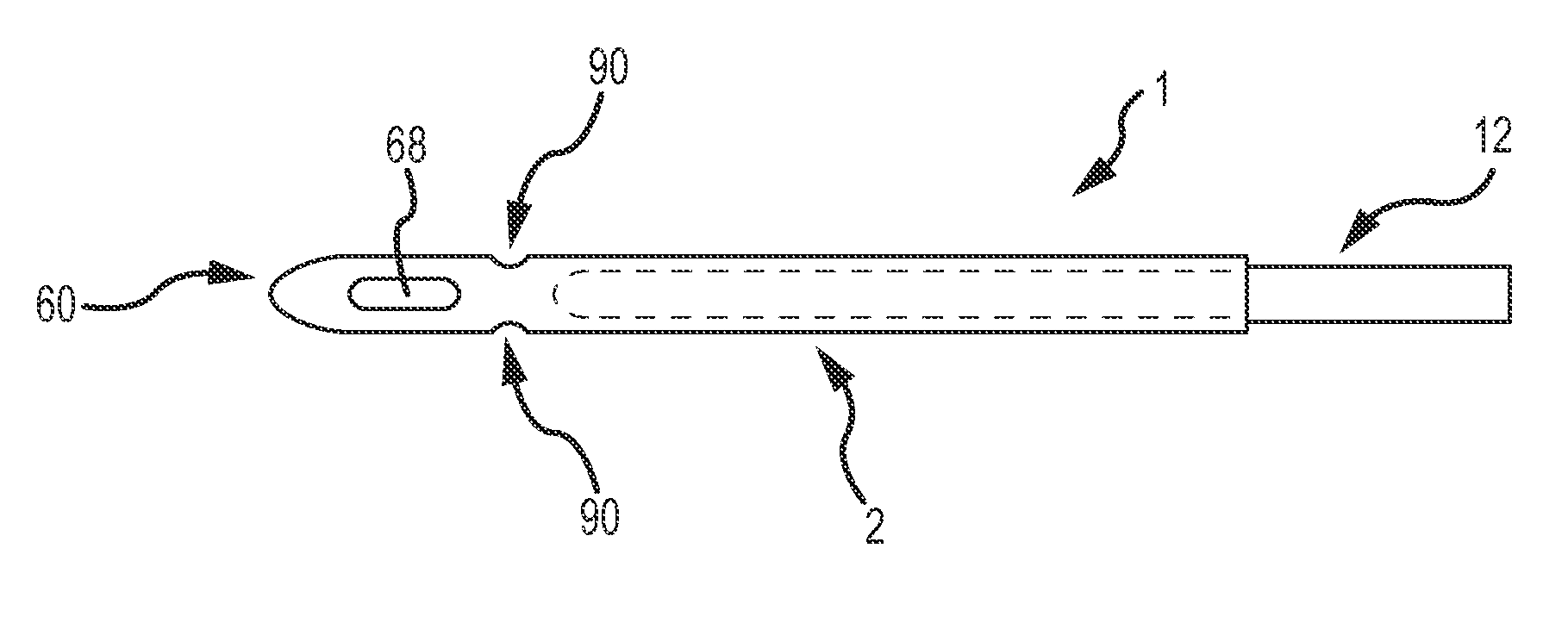

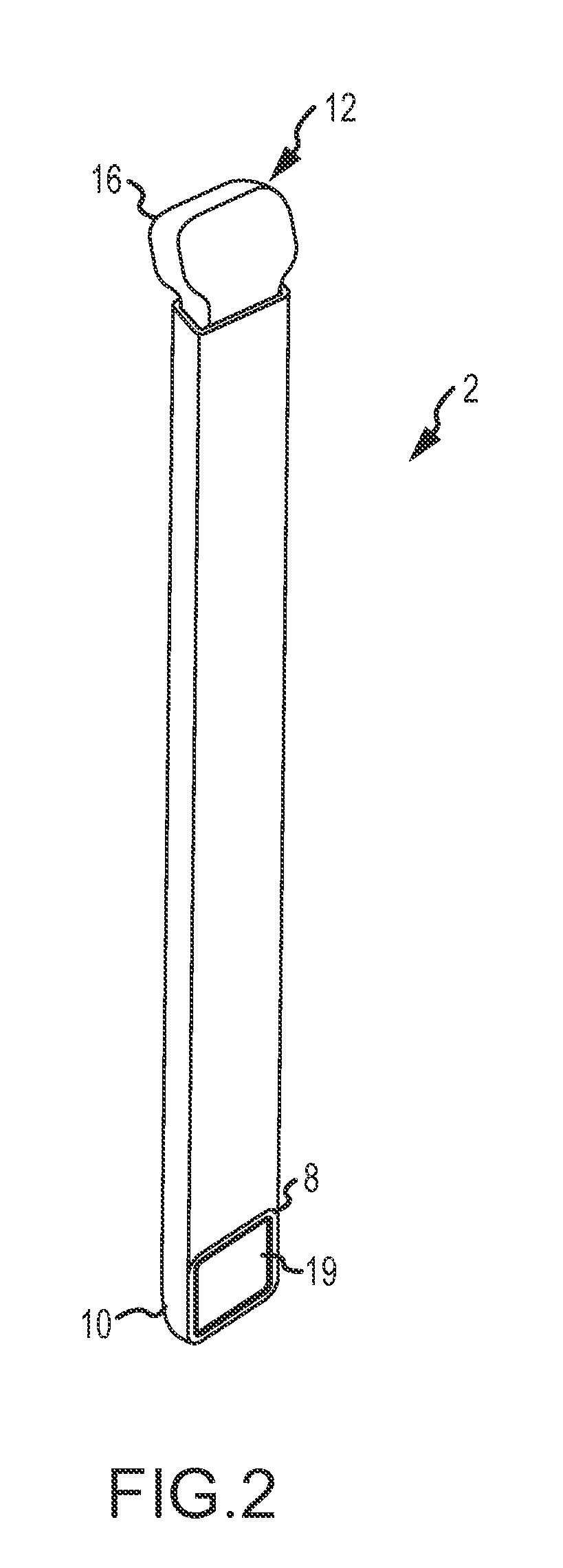

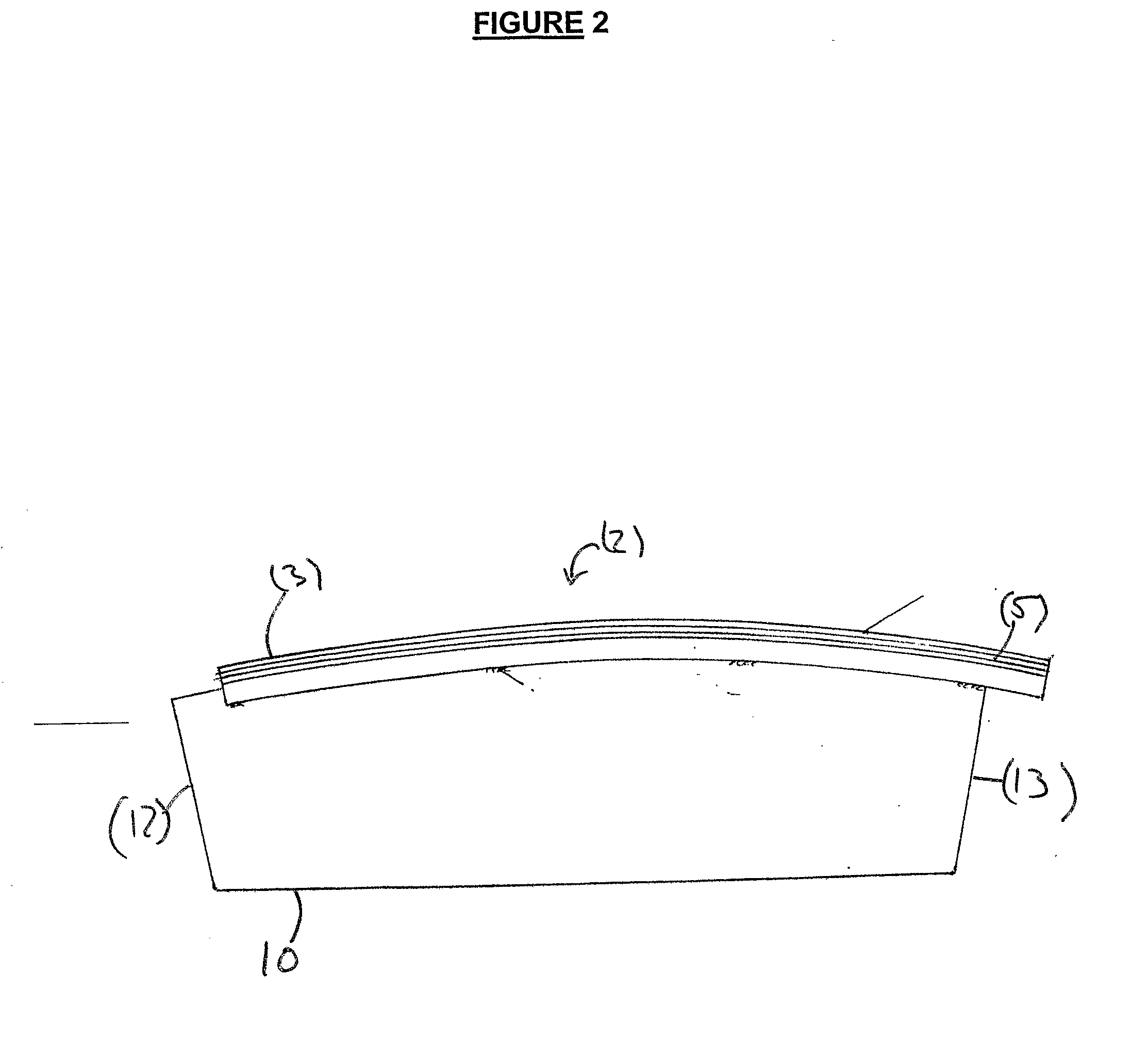

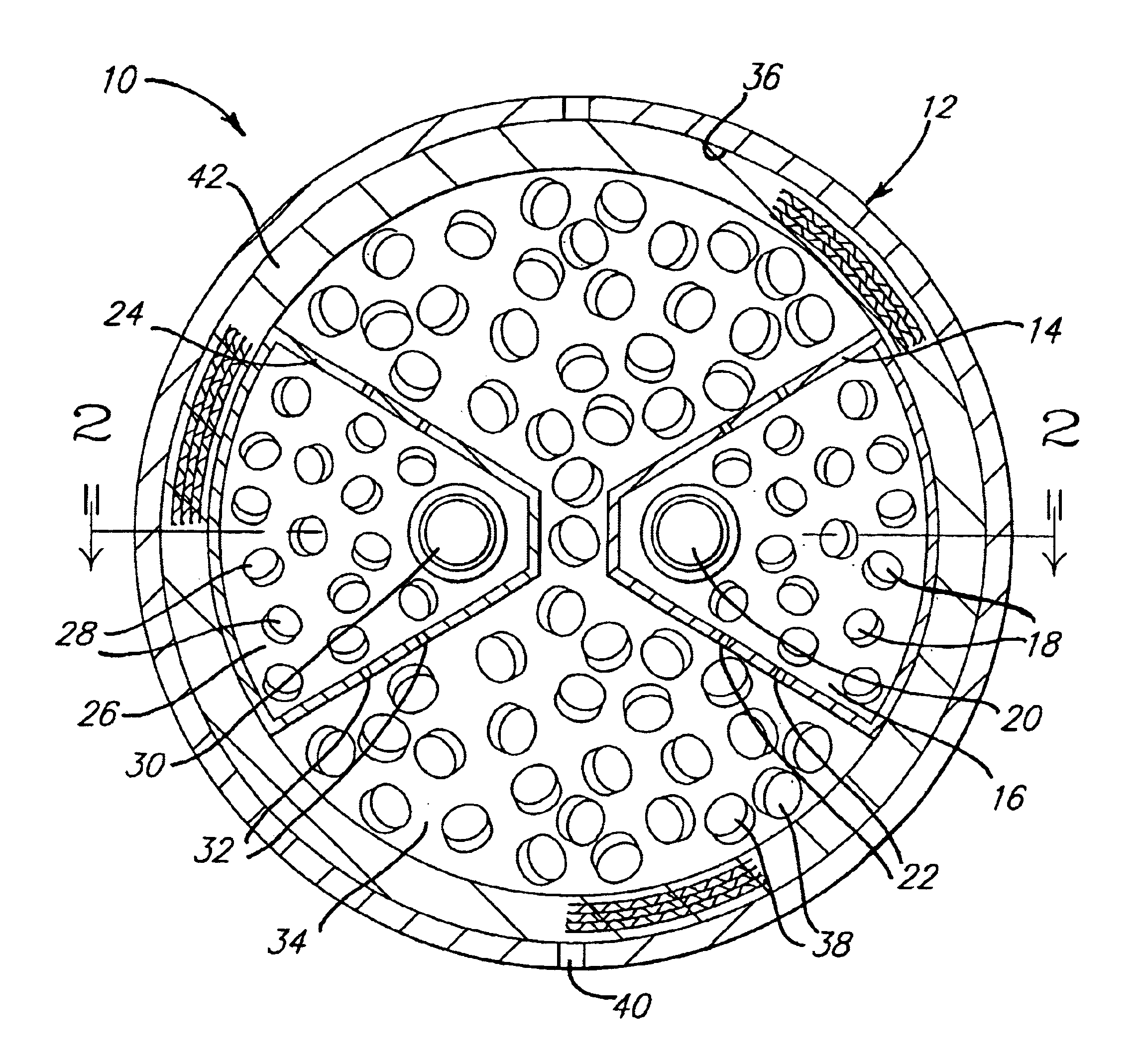

Fusion cage with combined biological delivery system

ActiveUS20120136442A1Accurate maneuveringConvenient to accommodateBone implantSpinal implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

Fusion cage with combined biological delivery system

ActiveUS9186193B2Reduce the risk of infectionReduce the possibilityBone implantJoint implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

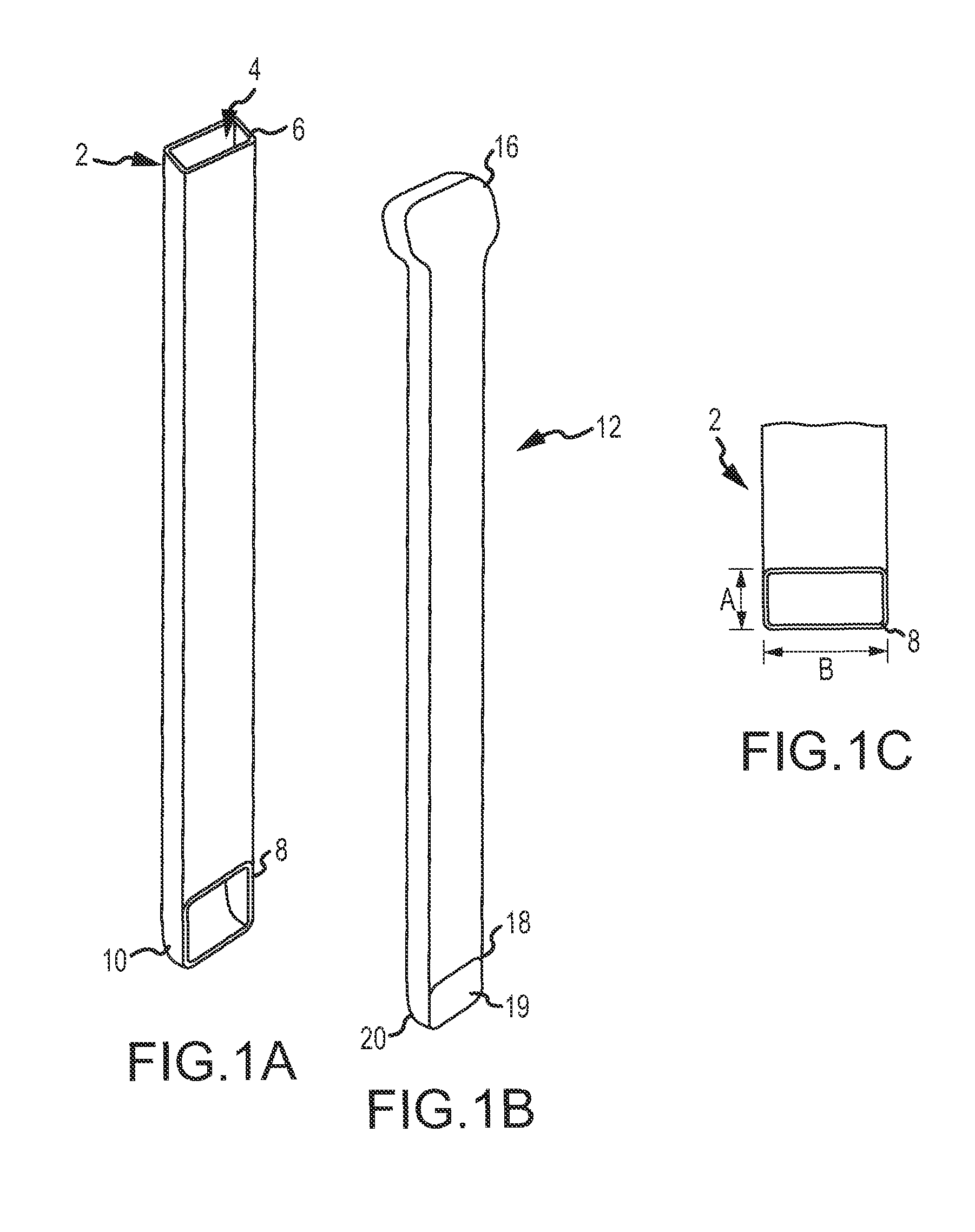

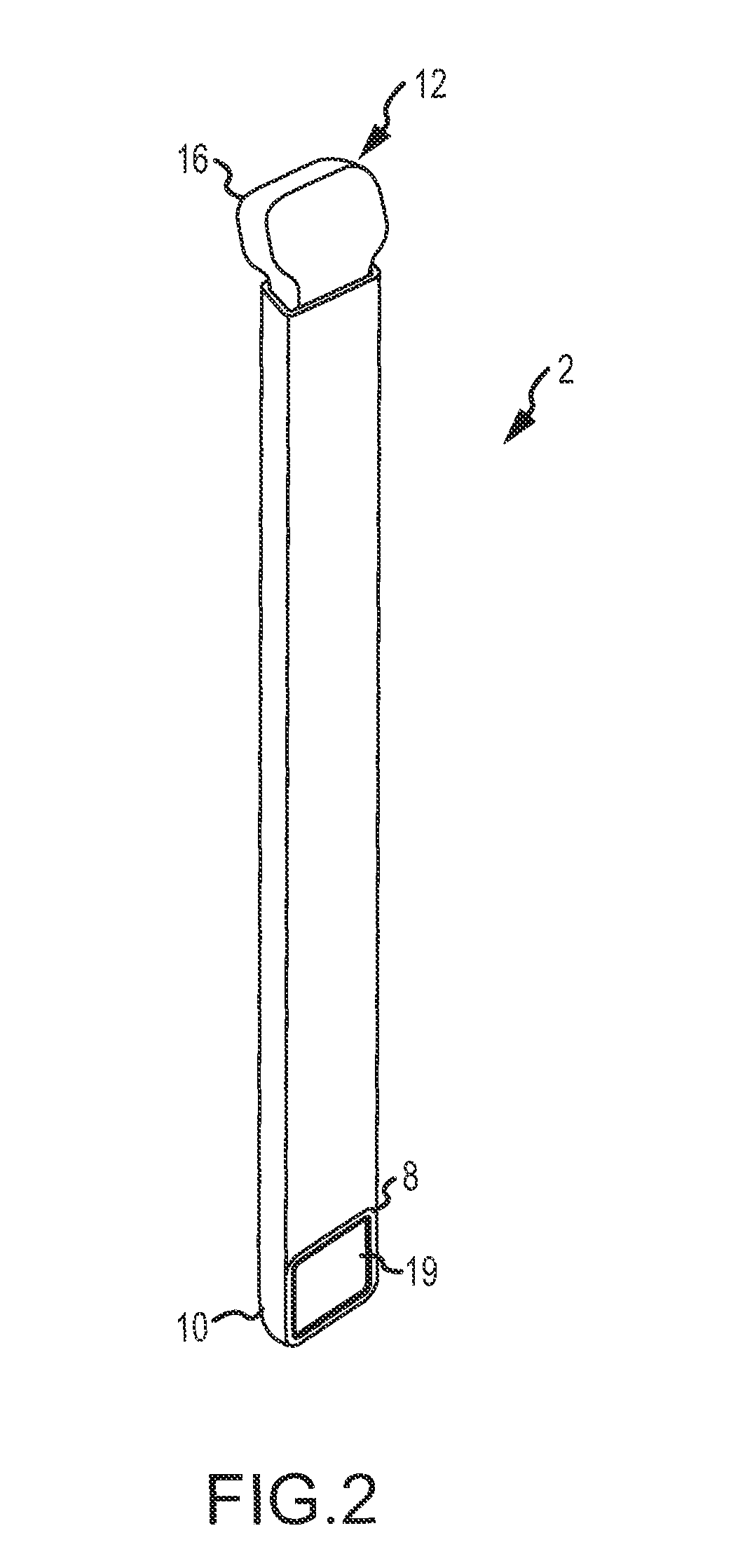

Bone graft delivery device and method of using the same

ActiveUS20110071536A1Accurate maneuveringConvenient to accommodateBone implantSpinal implantsMedicineBone graft materials

The present invention relates to a device and method for delivery of bone graft material to any portion of a patient which requires bone graft material. The device according to various embodiments delivers bone graft to a bone graft receiving area. The bone graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC A NEVADA CORP D B A KLEINER DEVICE LABS

Fusion Cage With Combined Biological Delivery System

ActiveUS20130184822A1Good accommodationPreventing and mitigate risk of injuryBone implantSpinal implantsBone graft materialsBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

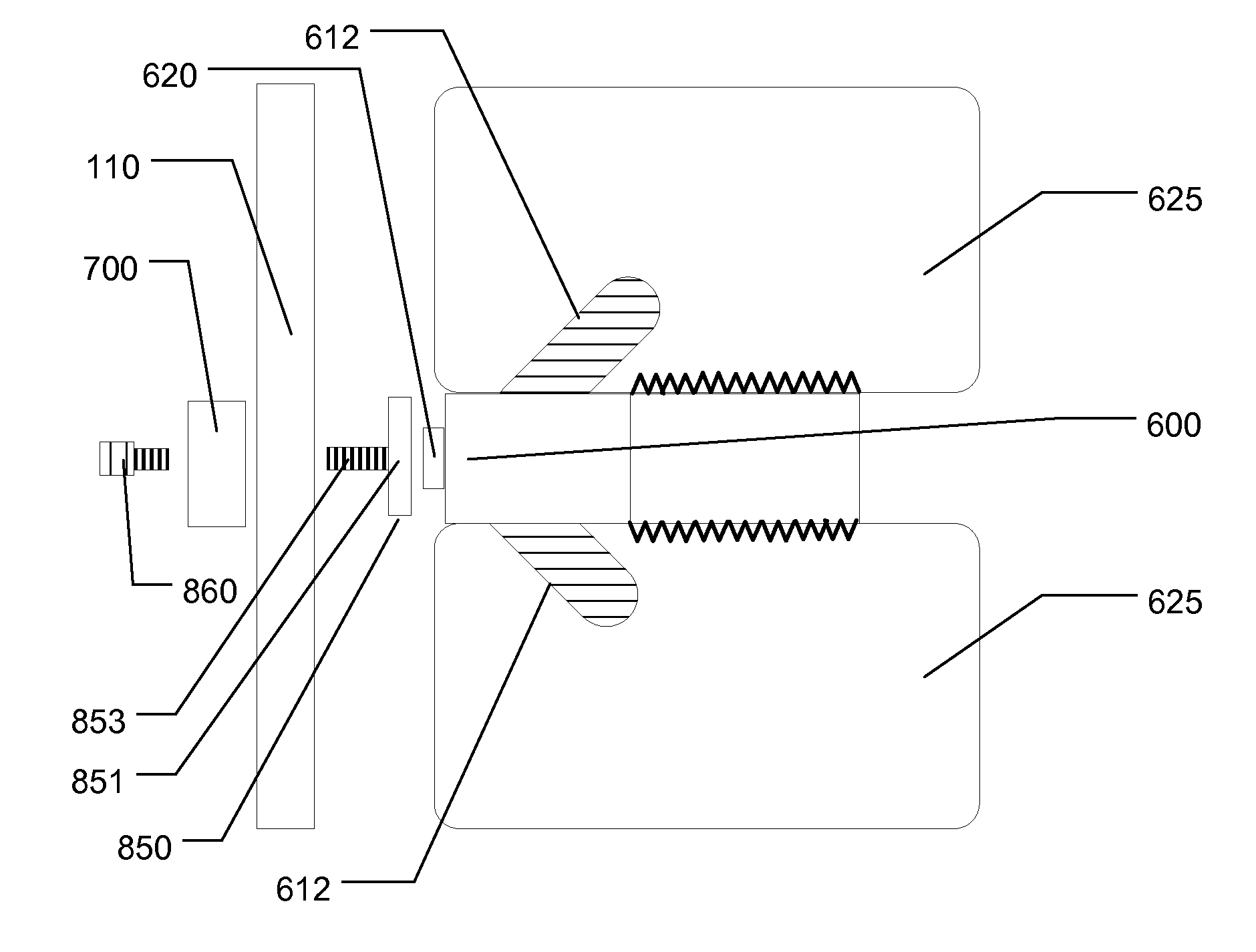

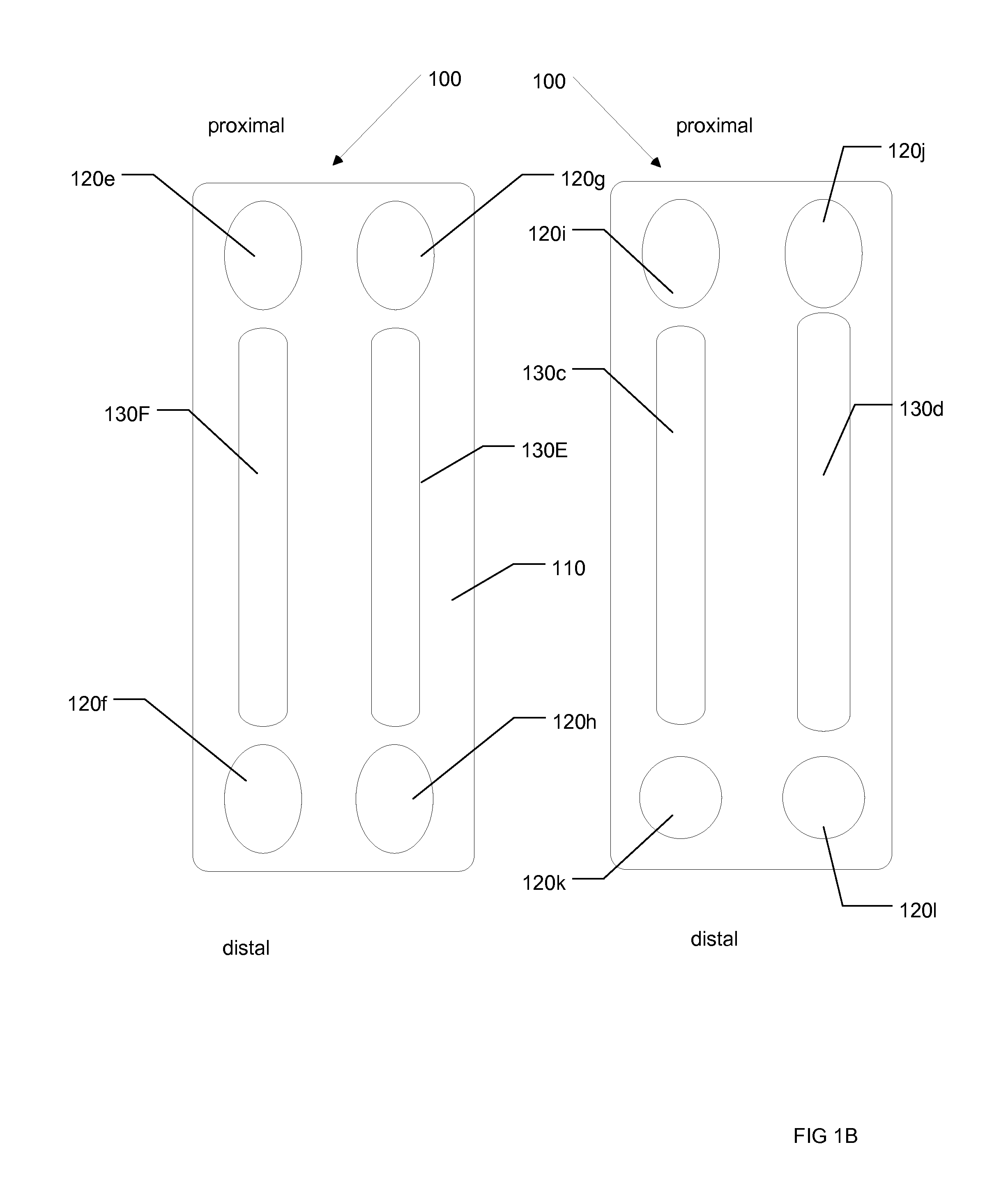

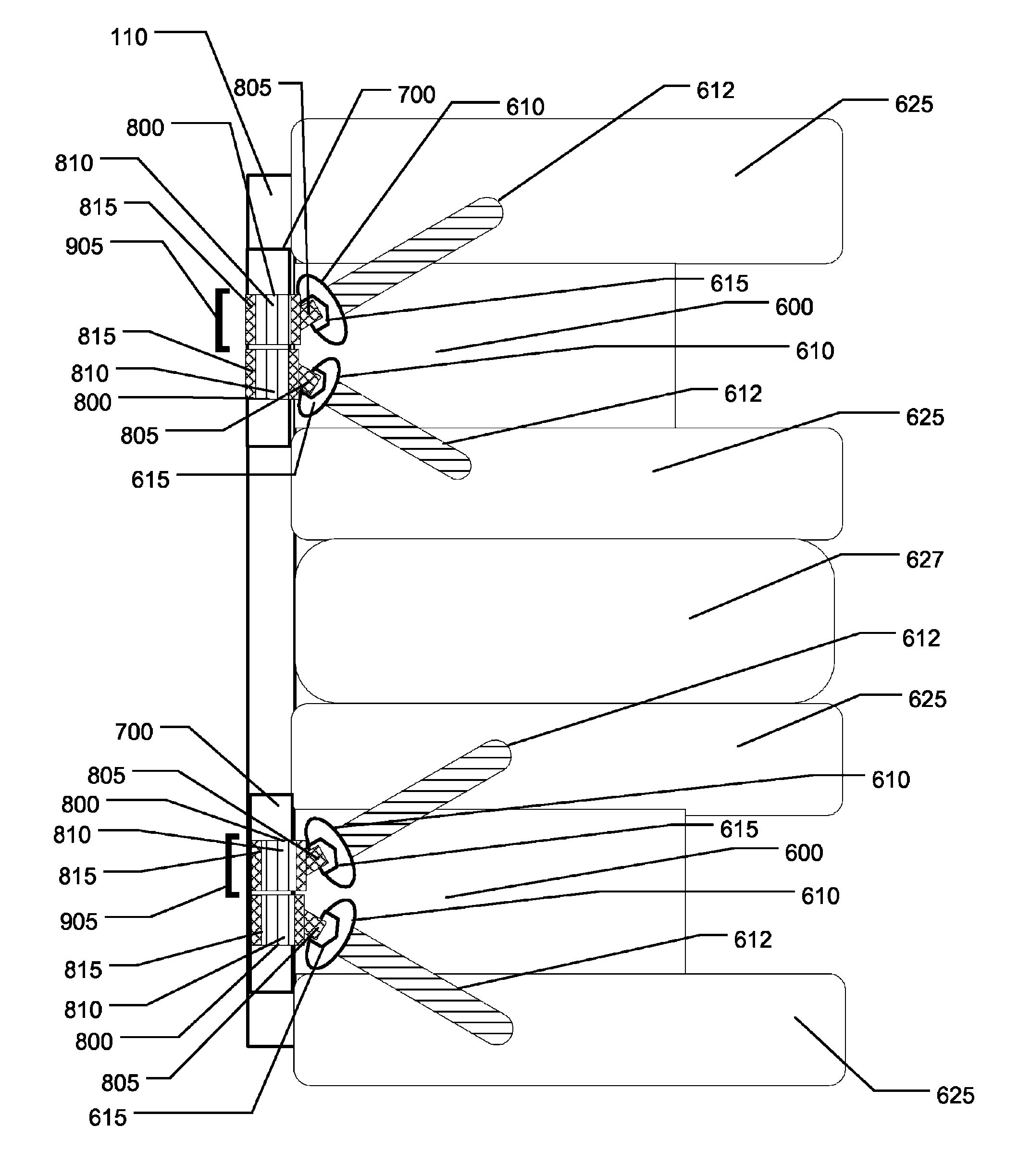

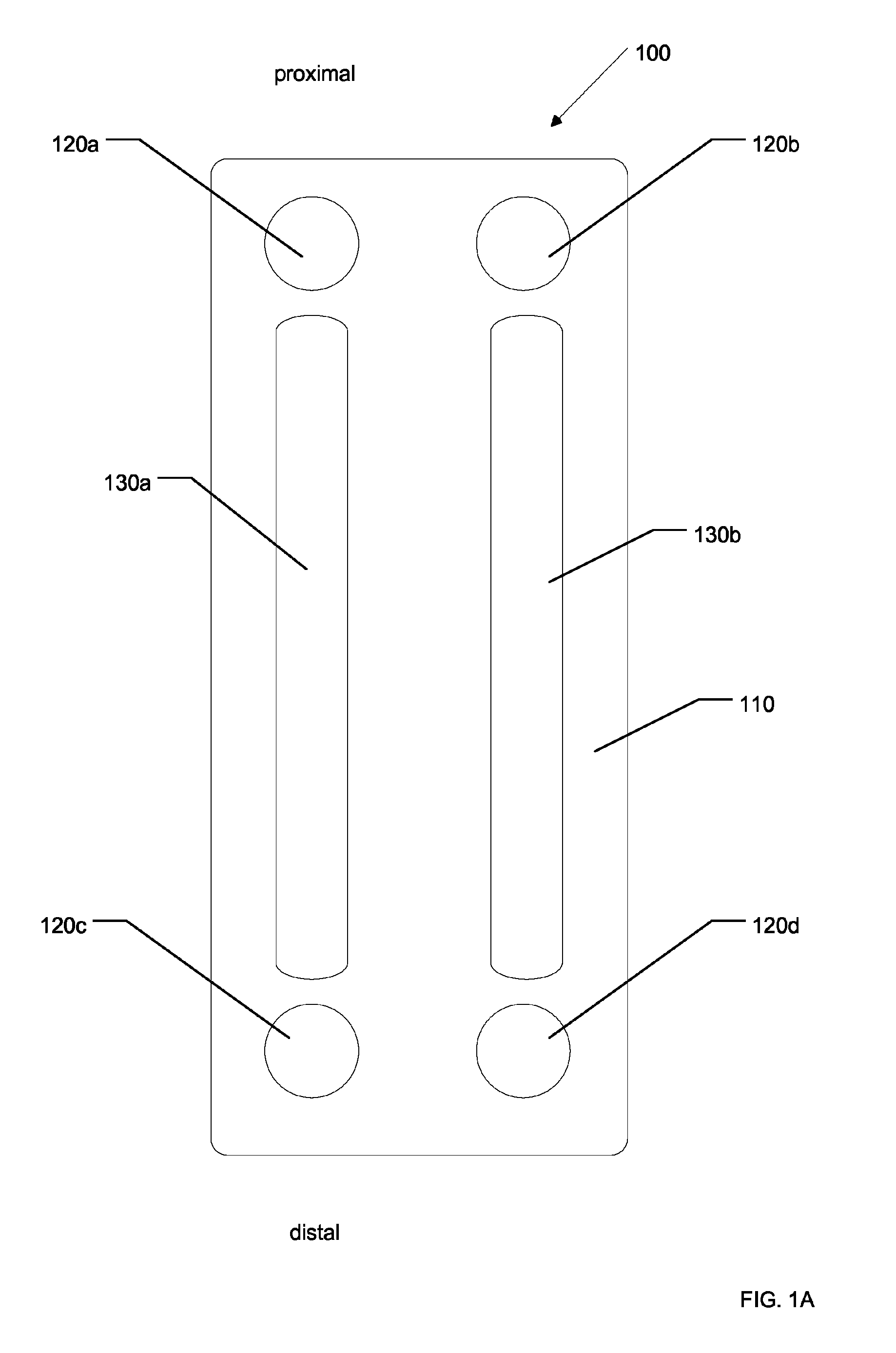

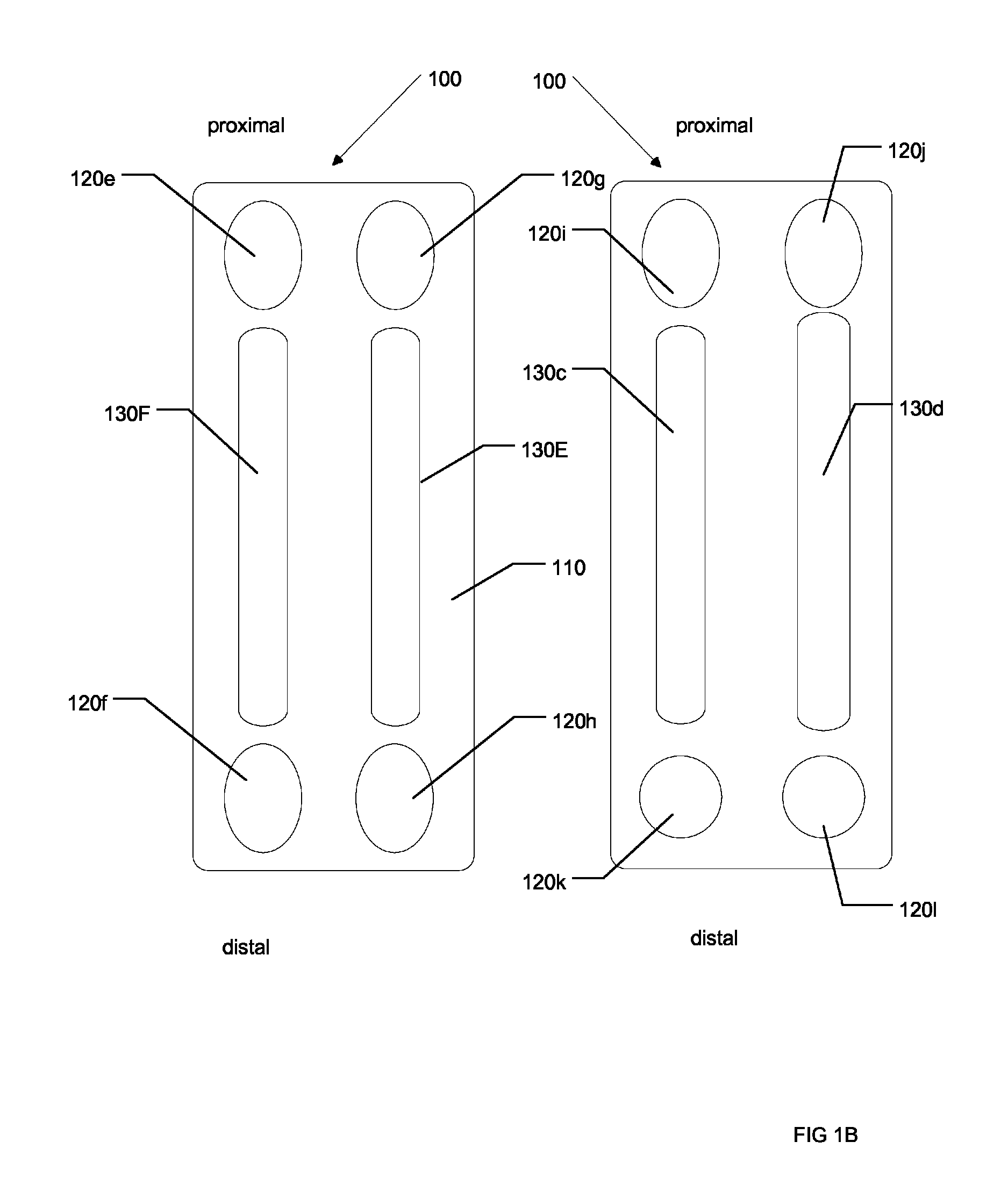

Anterior cervical instrumentation systems, methods and devices

Anterior cervical instrumentation systems, methods, and devices are disclosed. Systems may facilitate immobilizing or providing support for the cervical portion of the vertebral column of a patient. A device may comprise a plate having two channels located in a proximal to distal direction, and may further comprise at least one aperture. The device may further comprise attachment elements such as attachment cross-links and spacer cross-links, and fasteners. The plate and the attachment elements may be secured to the vertebrae by passing fasteners through apertures and channels. The length of the plate, position and number of the attachment cross-links, position and number of spacer cross-links and degree of movement may be intraoperatively selected by the surgeon to provide an optimal application and procedural outcome. Uniform components of the devices and systems allow for a more streamlined and simplified method of treating spinal conditions.

Owner:SPINAL ELEMENTS INC

Fusion cage with combined biological delivery system

ActiveUS9060877B2Reduce the risk of infectionReduce the possibilityBone implantJoint implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

Bone graft delivery device and method of using the same

ActiveUS8906028B2Reduce the risk of infectionReduce the possibilityBone implantJoint implantsBone graft materialsBone transplantation

The present invention relates to a device and method for delivery of bone graft material to any portion of a patient which requires bone graft material. The device according to various embodiments delivers bone graft to a bone graft receiving area. The bone graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC A NEVADA CORP D B A KLEINER DEVICE LABS

Fusion cage with combined biological delivery system

ActiveUS9173694B2Reduce the risk of infectionReduce the possibilityBone implantJoint implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

Biological delivery system with adaptable fusion cage interface

ActiveUS9629729B2Reduce the risk of infectionReduce the possibilityBone implantJoint implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area. In one embodiment, the integrated fusion cage is an expandable integrated fusion cage.

Owner:SPINAL SURGICAL STRATEGIES INC

Fusion cage with combined biological delivery system

ActiveUS20150148907A1Control volumeIncreased traumaBone implantJoint implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

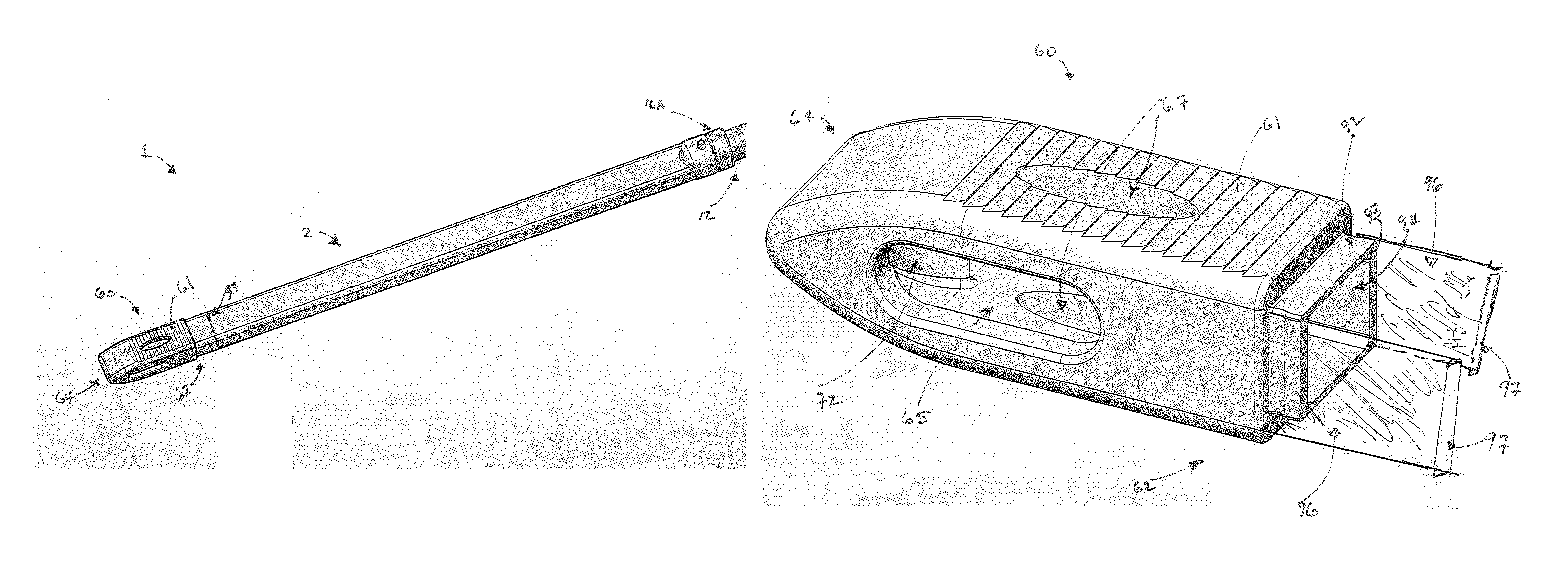

Bone graft delivery device with positioning handle

InactiveUS20170238984A1Reduce the risk of infectionReduce the possibilityBone implantJoint implantsSurgical siteBiological materials

The present disclosure relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material and placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may detach the fusion cage for deposit. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area. In certain embodiments, the integrated fusion cage is an expandable integrated fusion cage.

Owner:SPINAL SURGICAL STRATEGIES

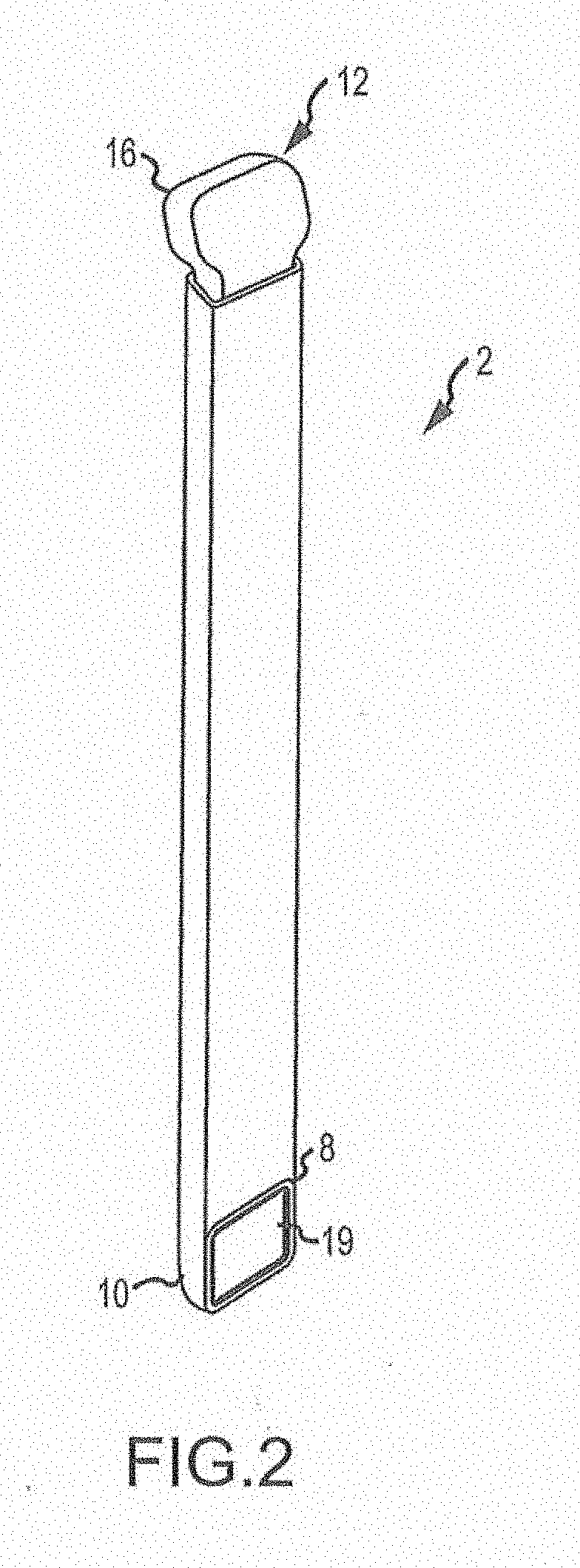

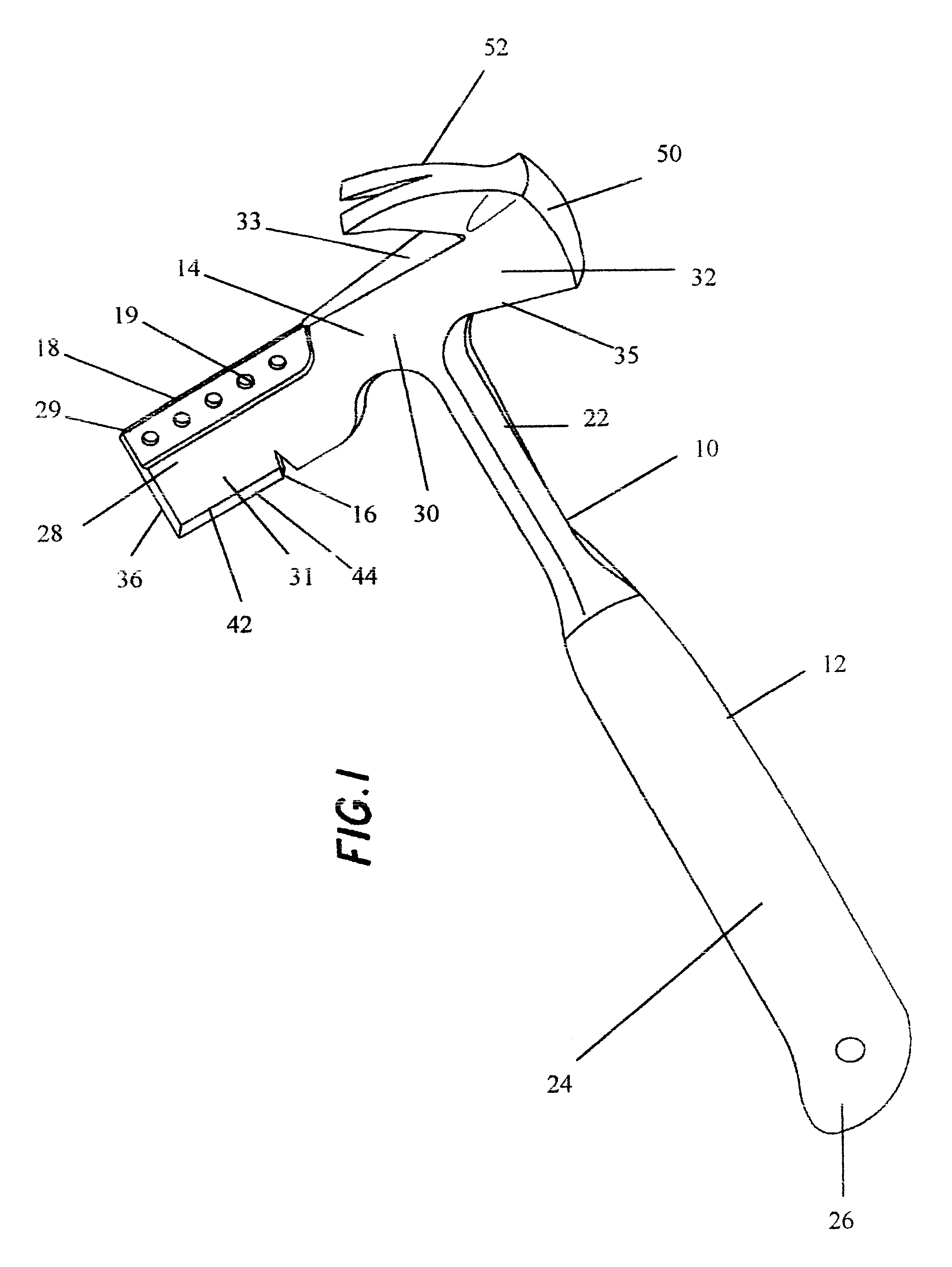

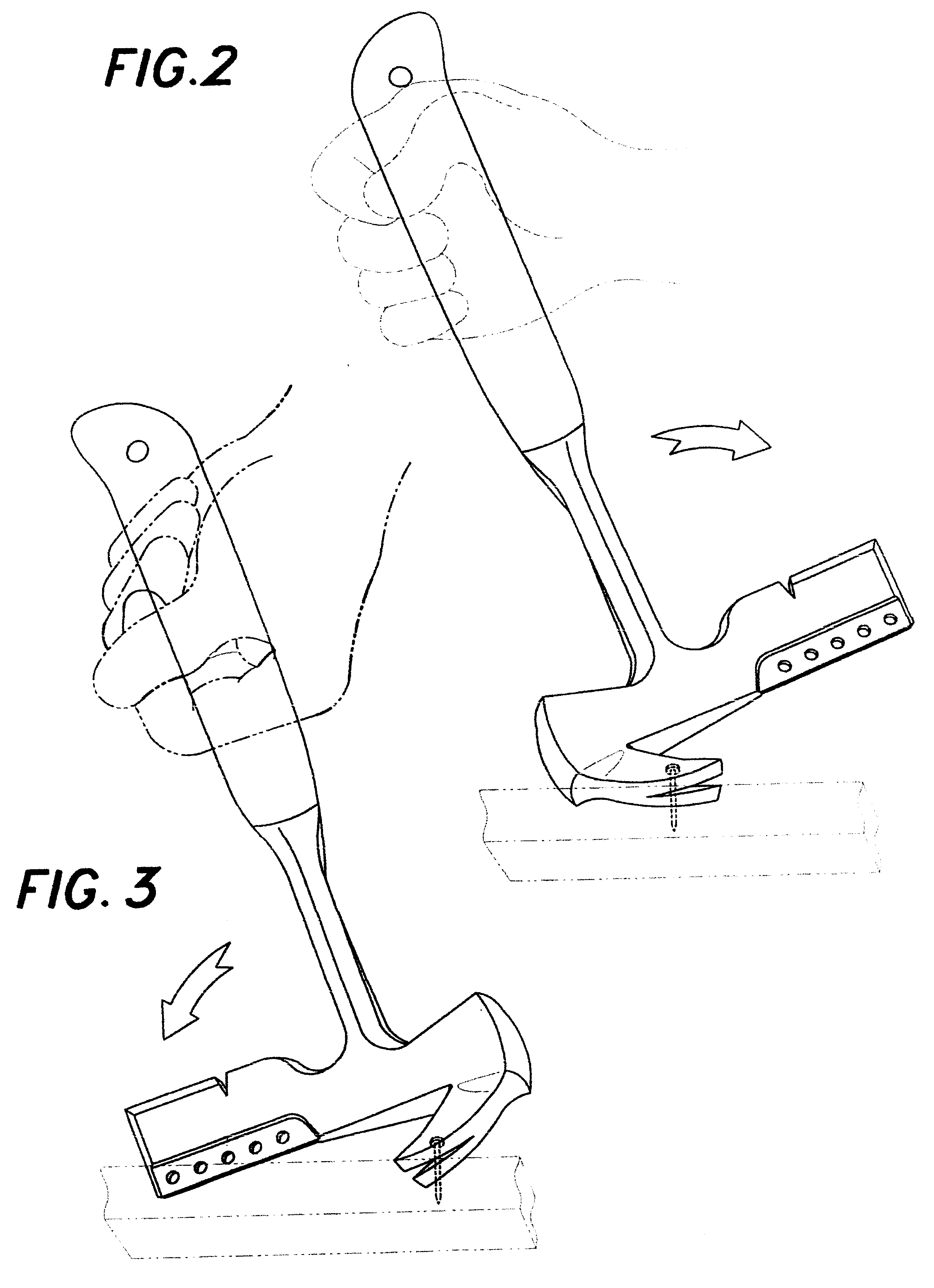

Multi-functional roofing tool

InactiveUS6266834B1Easy and efficient to manufactureDurable and reliable constructionNail extractorsRoof toolsHand heldEngineering

A multipurpose hand-held tool having a handle and a head wherein the head has a plurality of implements. The head has a middle portion, which is connected the handle, a first head end and a second head end. The first head end has three cutters such that there is a cutting edge on the top side, the end, and the bottom side of the first head. The first head end also includes a plurality of gauge holes in the top side, and a nail slot on the bottom side. The second head end includes both a hammer head connected to the end and a hammer claw connected to the top side of the second head end. The multipurpose hand-held tool meets a need for roofers to have a multipurpose tool which helps to quickly, efficiently and accurately remove and replace roofing materials.

Owner:PETERSON LEONARD

Bone Graft Delivery System and Method for Using Same

ActiveUS20170224397A1Reduce the risk of infectionReduce the possibilityBone implantJoint implantsSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area. In one embodiment, the integrated fusion cage is an expandable integrated fusion cage.

Owner:SPINAL SURGICAL STRATEGIES INC

Fusion cage with combined biological delivery system

ActiveUS20130345710A1Control volumeIncreased traumaAdditive manufacturing apparatusBone implantSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

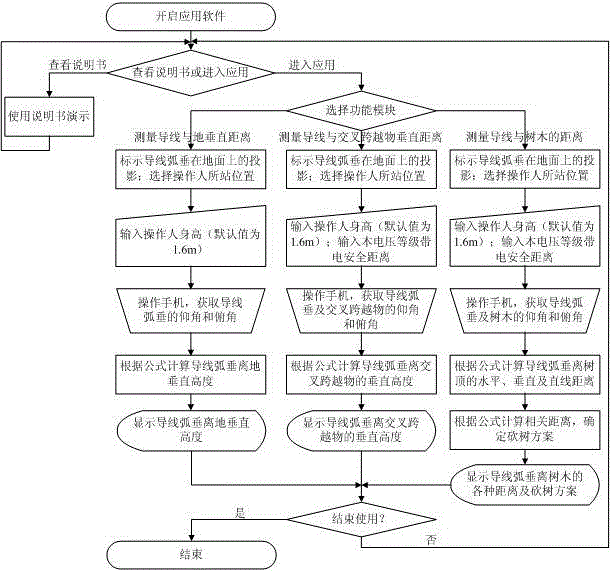

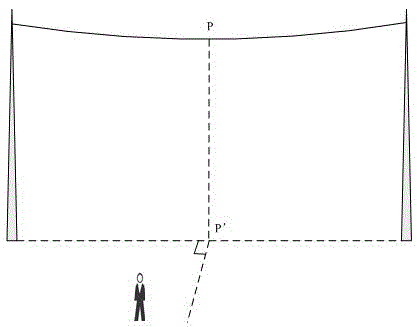

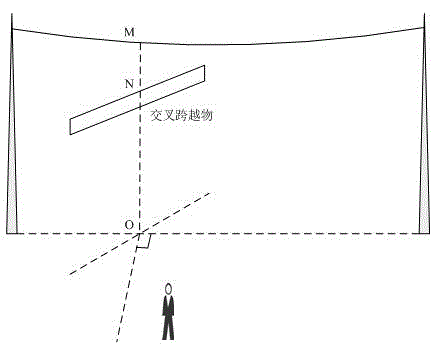

Power line safety distance measurement evaluation method based on smart phone

ActiveCN104535043ALess toolingEasy to operateAngle measurementOptical rangefindersTree distanceRisk evaluation

The invention relates to a power line safety distance measurement evaluation method based on a smart phone. A smart phone which comprises a camera and a gravity sensing device is provided. Firstly, safety distance measurement software is downloaded and mounted through APP and comprises line and ground vertical distance measurement, line and crossing span substance vertical distance measurement, line and tree distance measurement, tree cutting security risk evaluation; and then, line and ground vertical distance measurement, line and crossing span substance vertical distance measurement, line and tree distance measurement, tree cutting security risk evaluation are all carried out. According to the method, manpower waste is reduced, measurement of all power line safety distances can be realized only through the smart phone, the operation is simple, the implementation is easy and no risk exists in the measurement process.

Owner:STATE GRID CORP OF CHINA +3

Low-pressure casting preparing method of as-cast aluminum alloy hub

InactiveCN107952948ASimple production processReduce energy consumptionTransportation and packagingNanotechnologyUltimate tensile strengthToughness

The invention relates to a low-pressure casting preparing method of an as-cast aluminum alloy hub. The method particularly comprises following steps of firstly, aluminum alloy matching and smelting; secondly, aluminum alloy refining; thirdly, strengthened aluminum alloy treatment; fourthly, low-pressure casting forming. According to the technical scheme, aluminum alloy component design, smelting and refining, an Al-5Ti-B intermediate alloy is added for strengthening the aluminum alloy, meanwhile, the content of impurity elements of Fe, Ti and Zn is strictly controlled, and the novel high toughness as-cast aluminum alloy hub free of heat treatment is prepared. The as-cast aluminum alloy hub prepared through the process shows the excellent strength and plasticity, and use needs are met; according to the low-pressure casting preparing method of the as-cast aluminum alloy hub, heat treatment is avoided, a large amount of heat treatment time is saved, and tools, hours and manual work neededby correction after heat treatment are saved, energy consumption is reduced, the production process flow of the aluminum alloy hub is simplified, the preparing cost is reduced, and the important application value is achieved.

Owner:JILIN UNIV

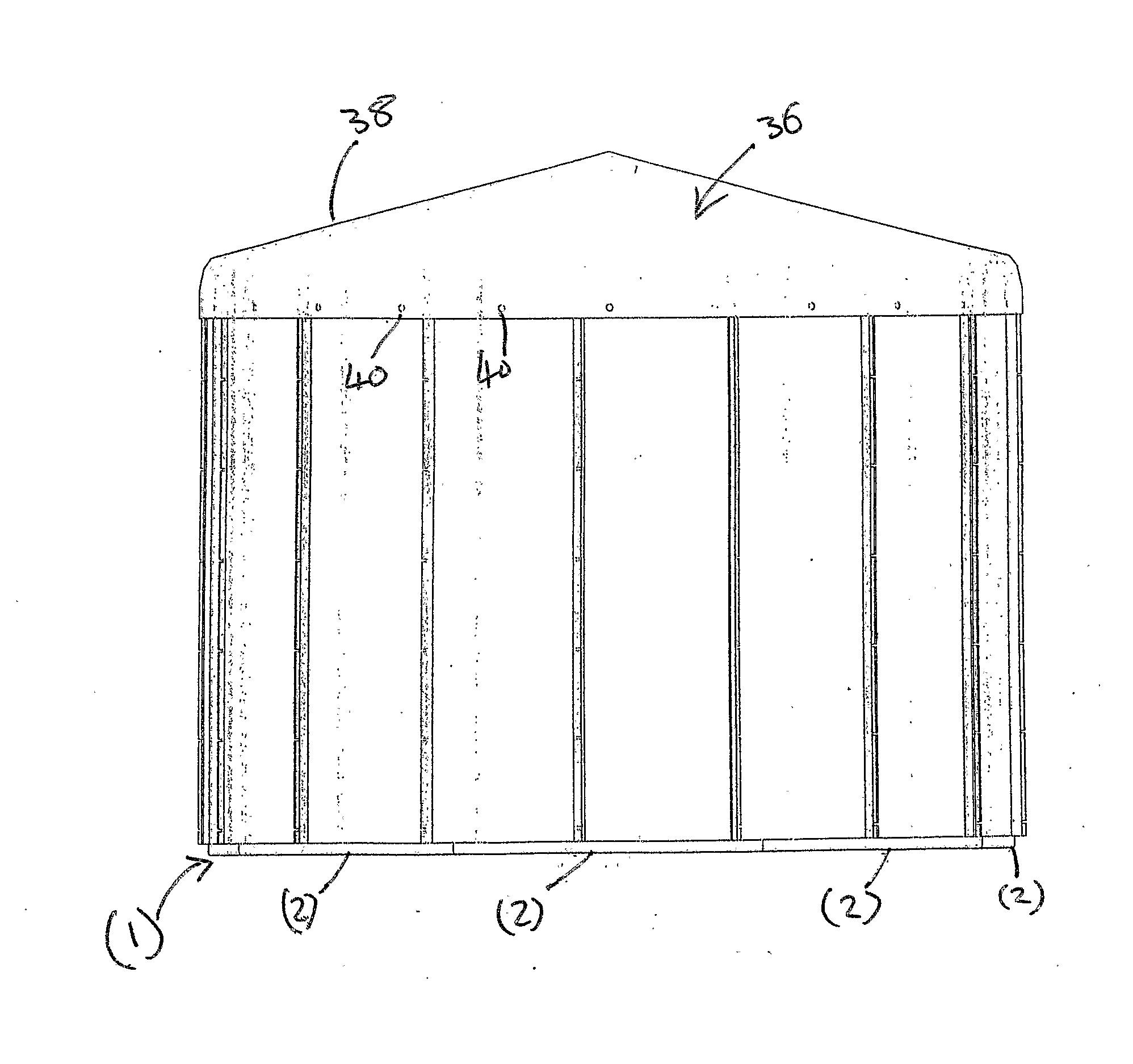

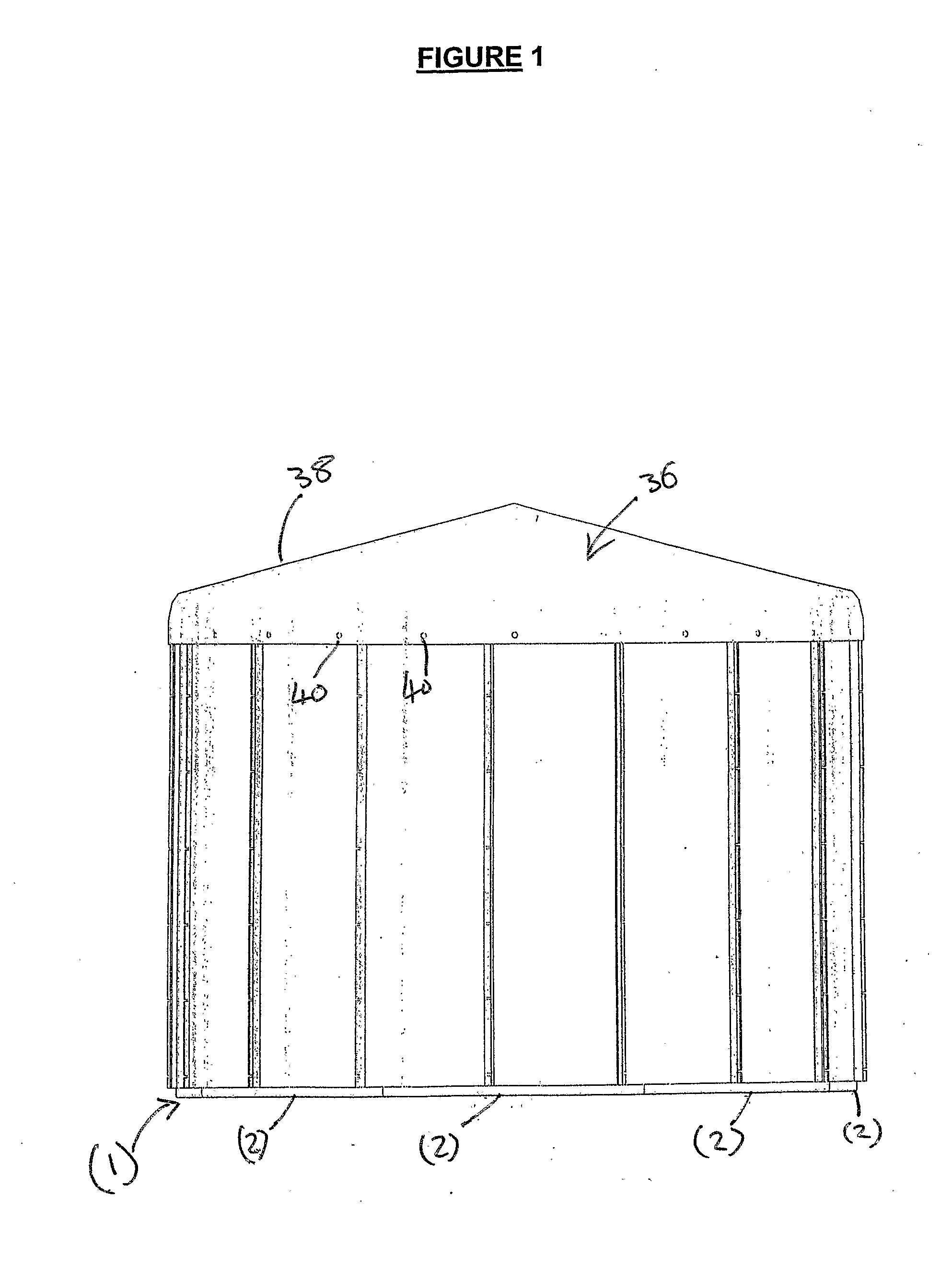

Structure

InactiveUS20110272303A1Avoid damagePrevent unauthorized accessLarge containersBuilding constructionsEngineering

Owner:PETERKEN NEIL TERRY

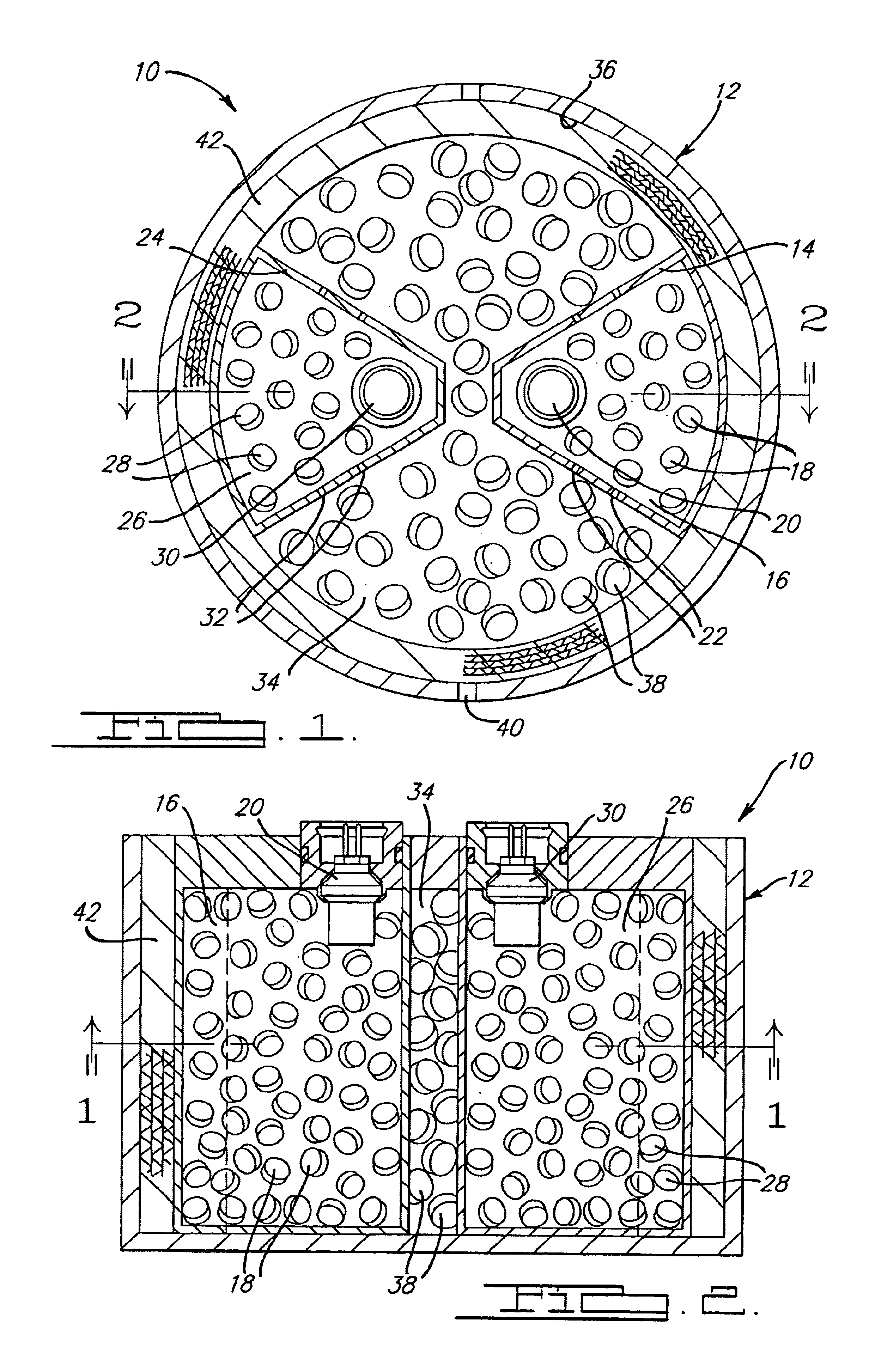

Multiple chamber dual stage inflator

InactiveUS6860511B2Eliminate needLess toolingPedestrian/occupant safety arrangementGas generation devicesCombustion chamberDual stage

A dual stage inflator 10 utilizes a housing 12 having two supplemental propellant combustion chambers 16 and 26, both symmetrically oriented within a primary propellant combustion chamber 34. Chambers 16 and 26 are formed to be substantially equivalent in dimensions and volume thereby simplifying the assembly and manufacturing process.

Owner:AUTOMOTIVE SYST LAB

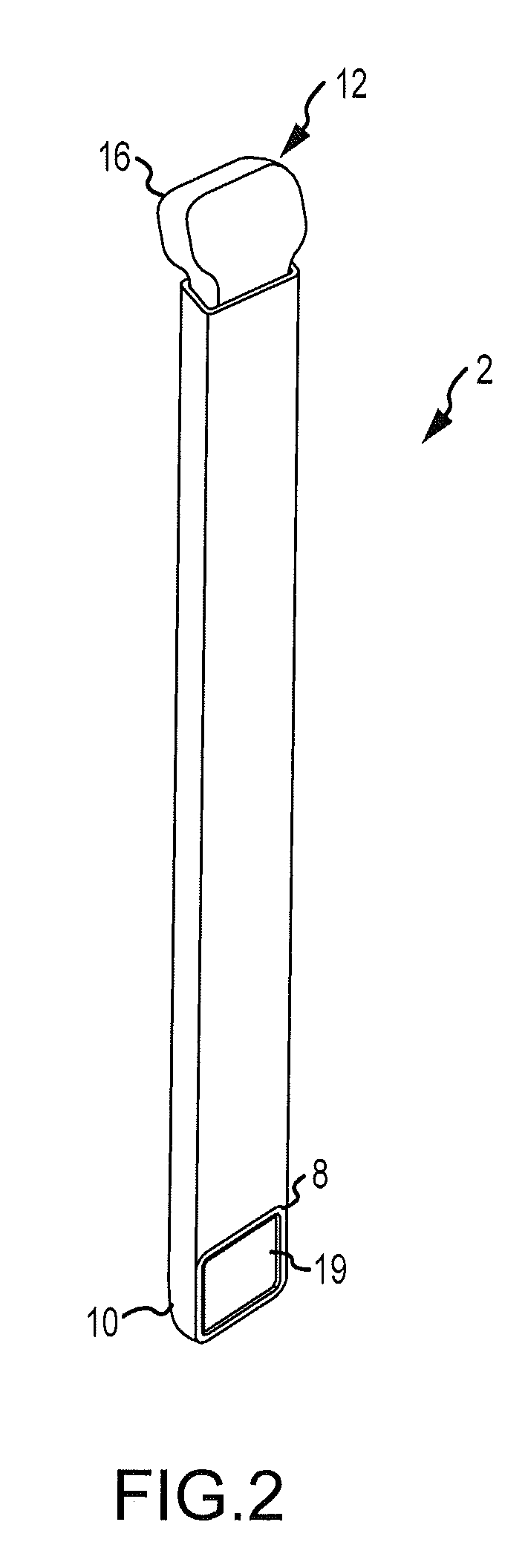

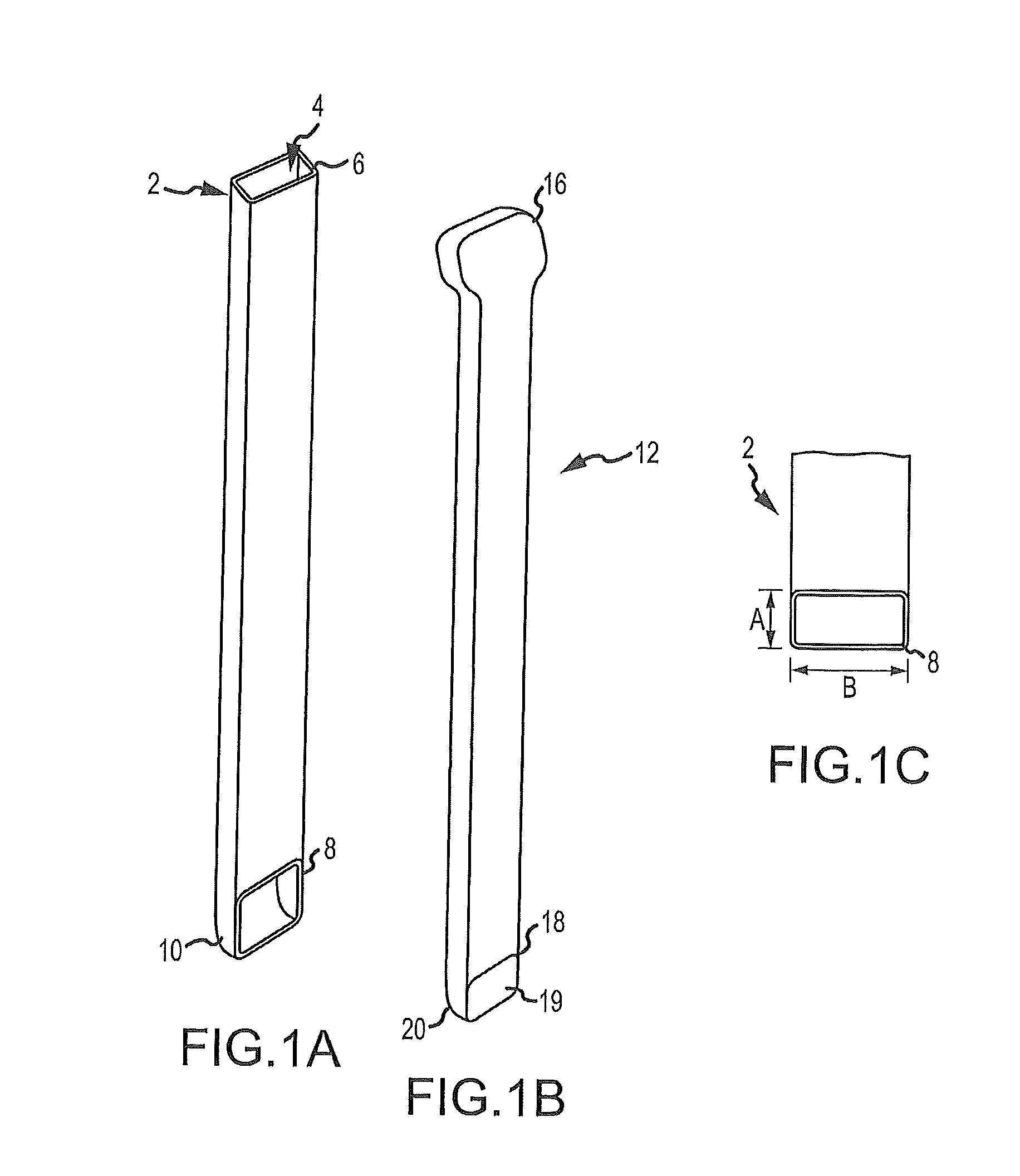

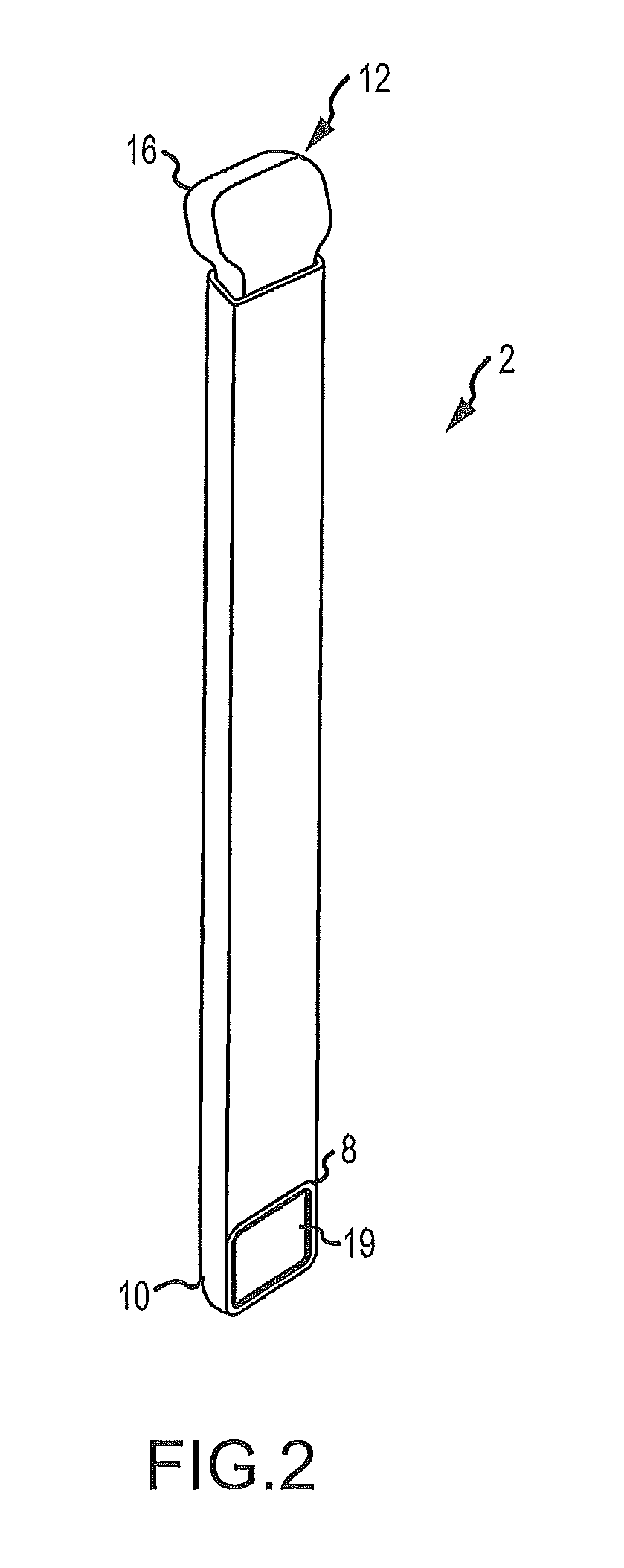

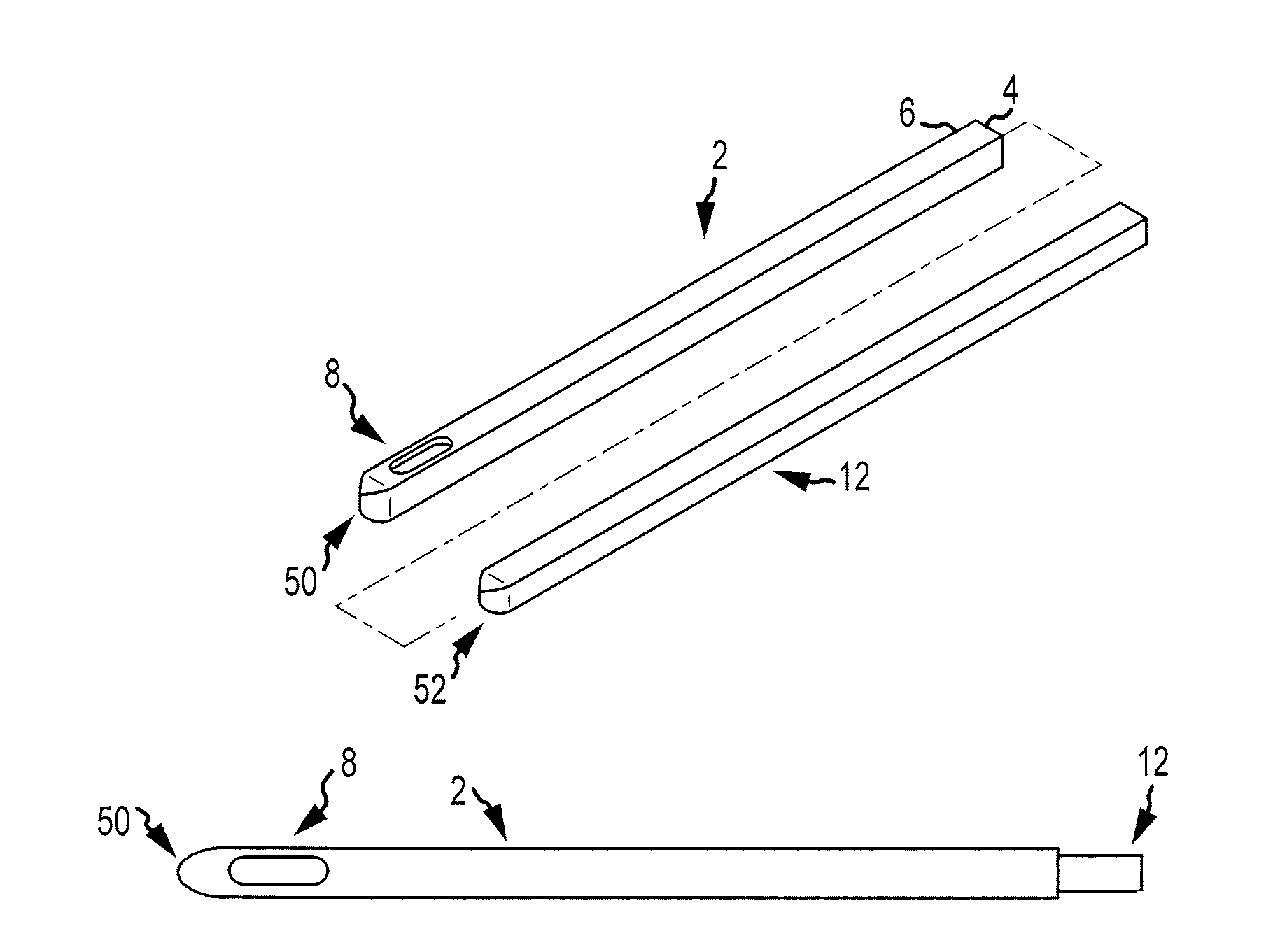

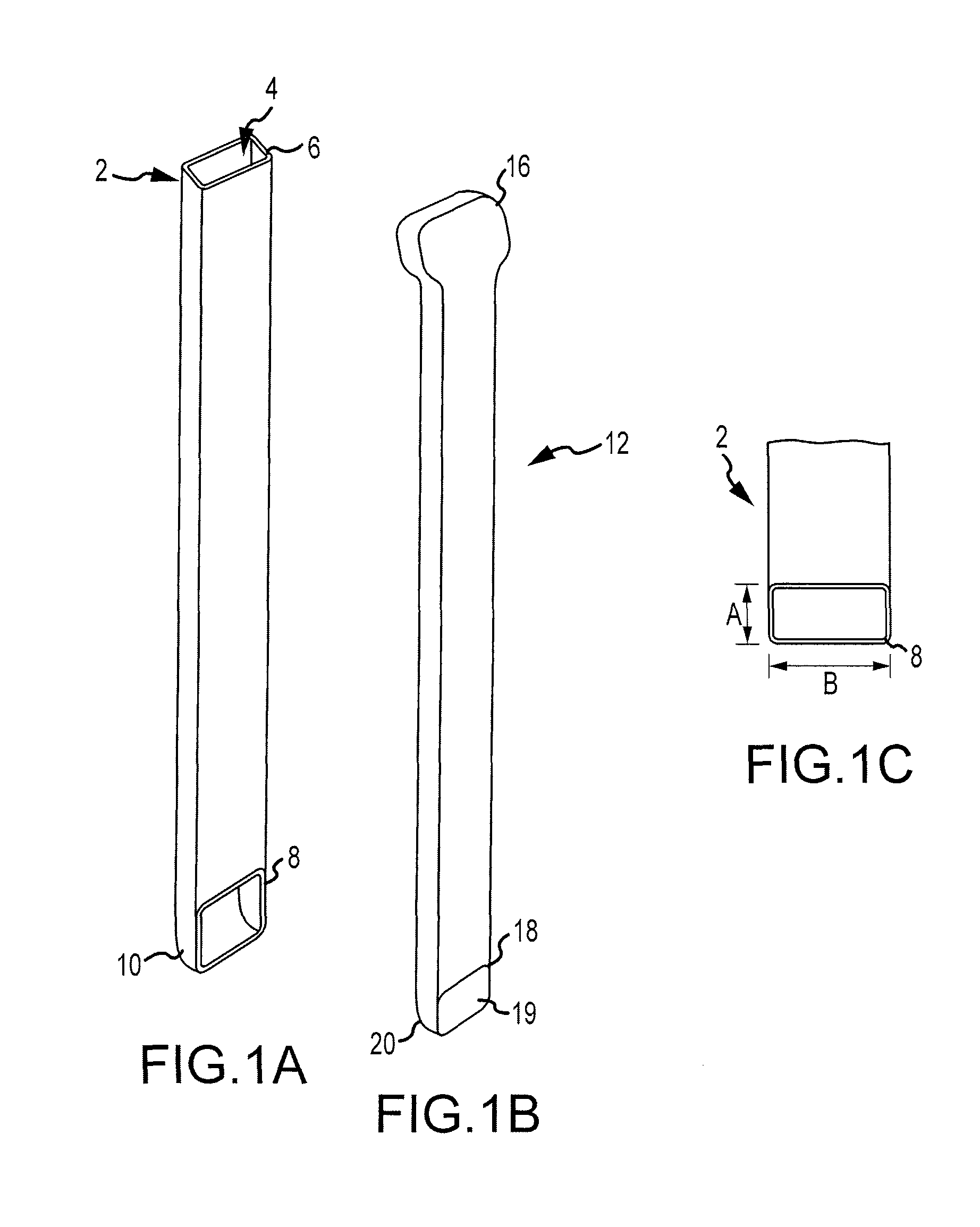

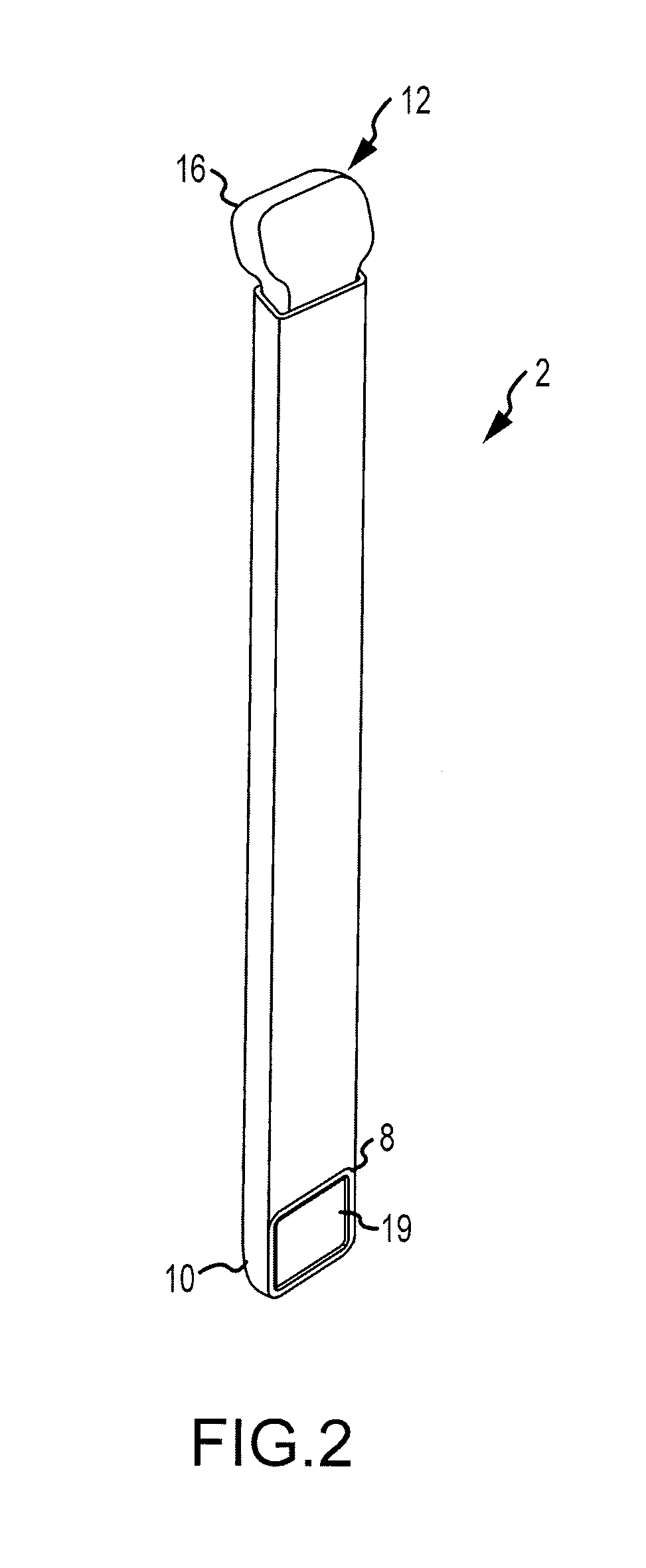

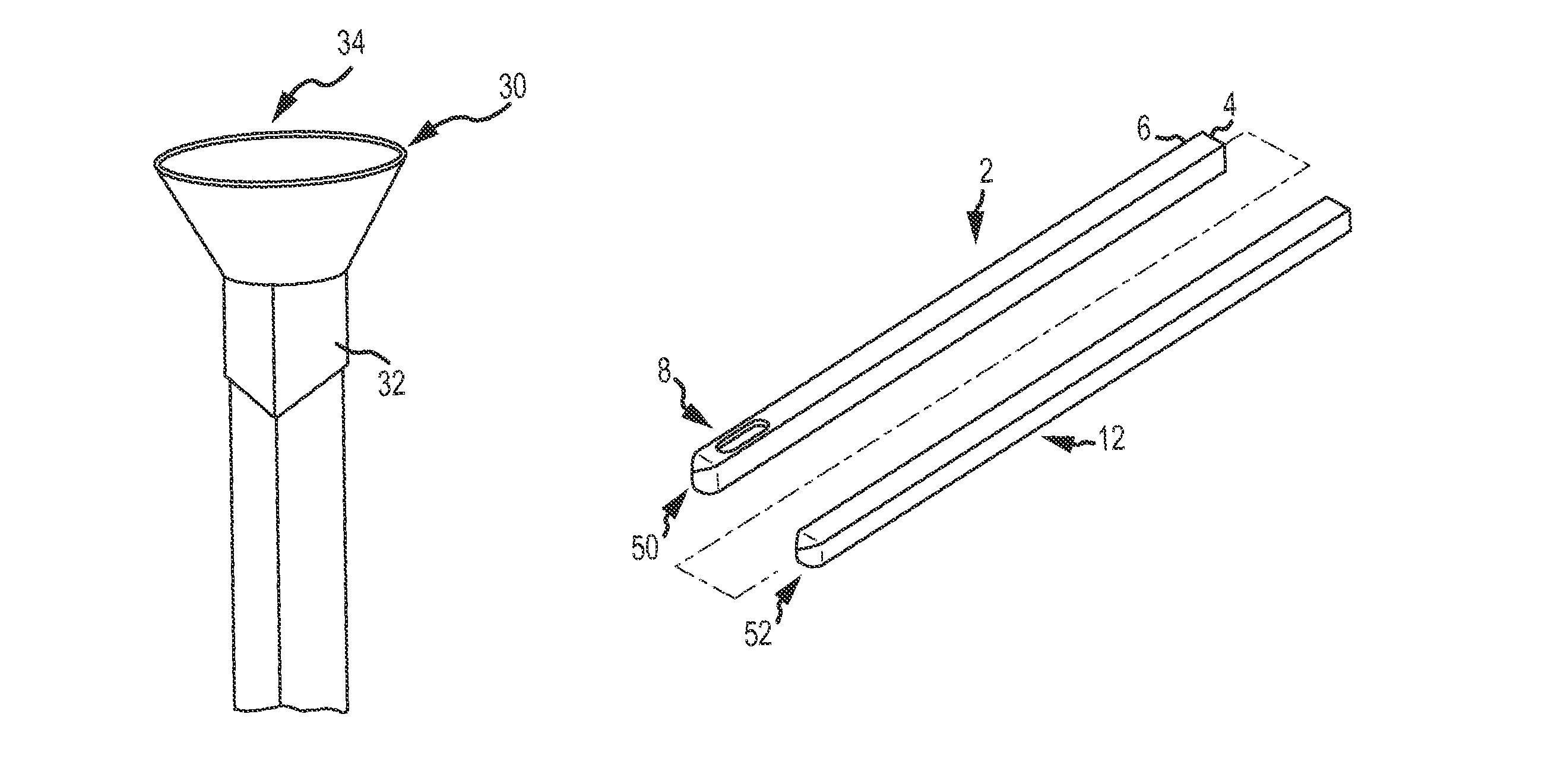

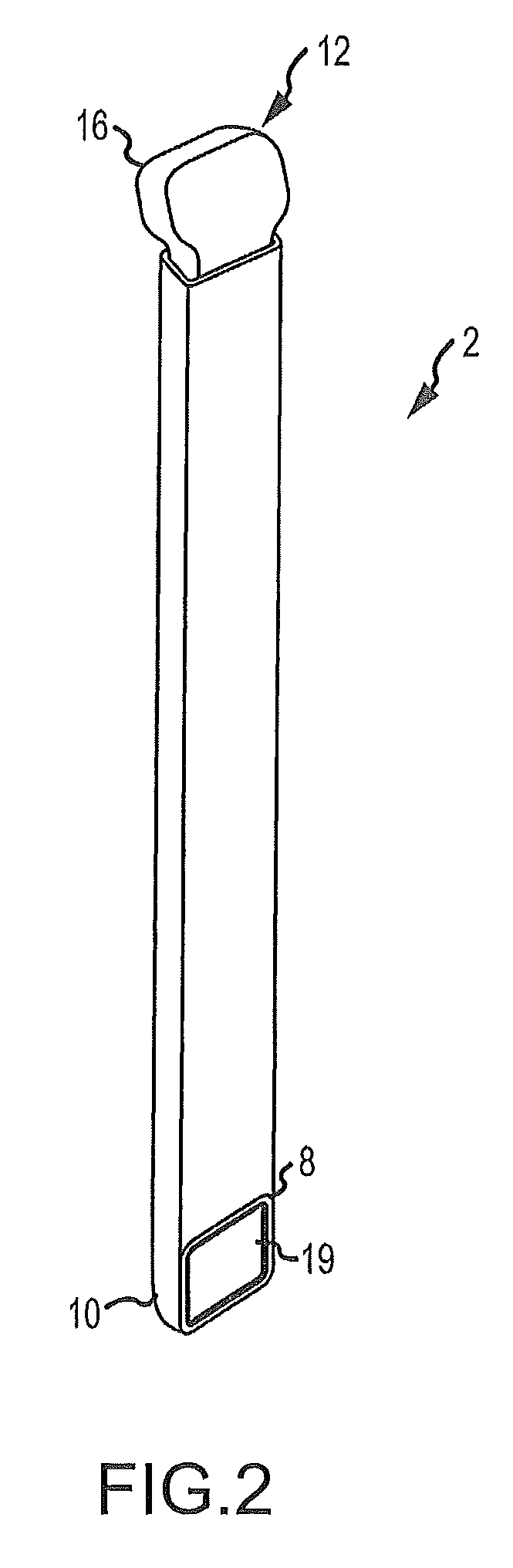

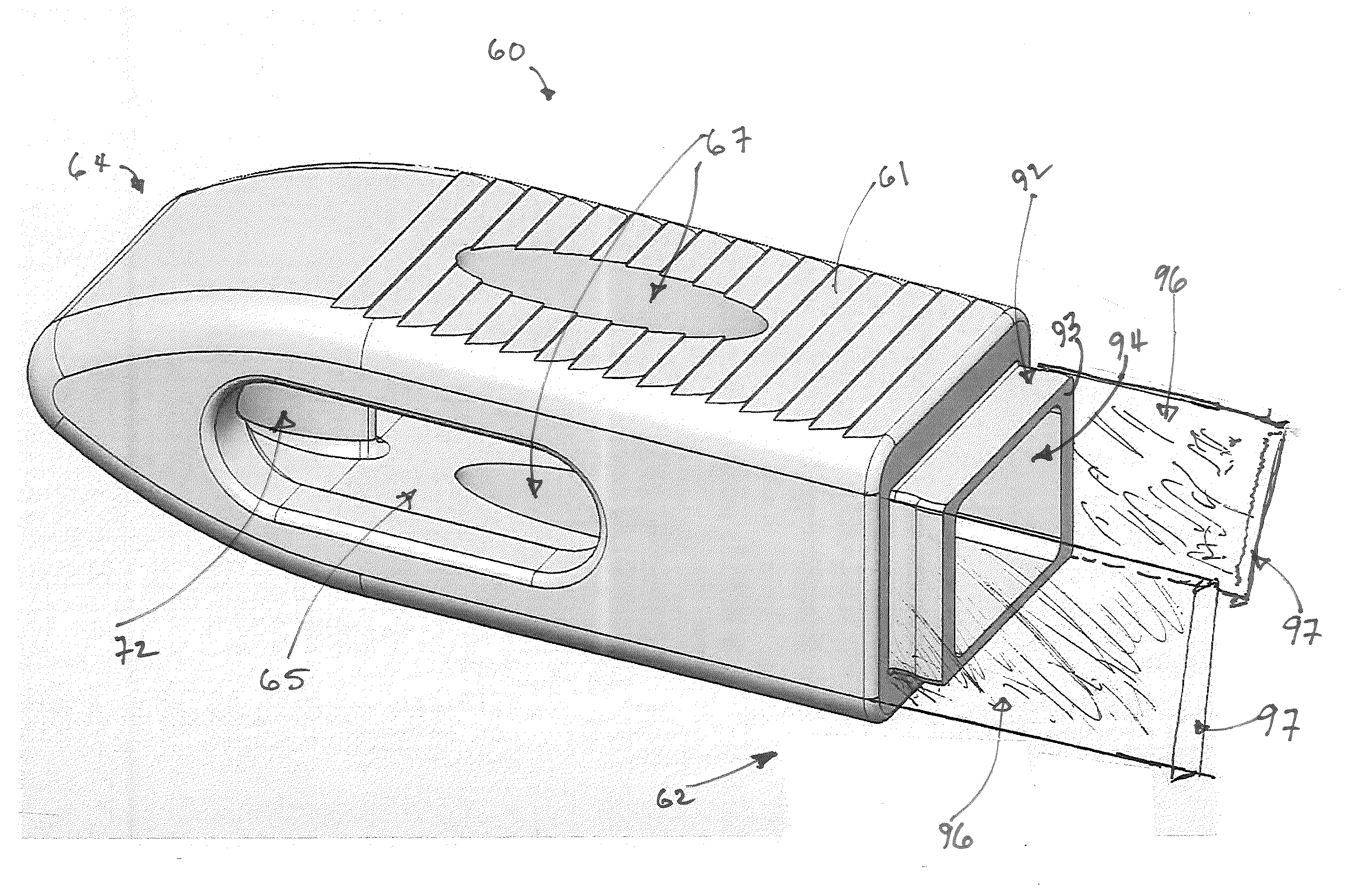

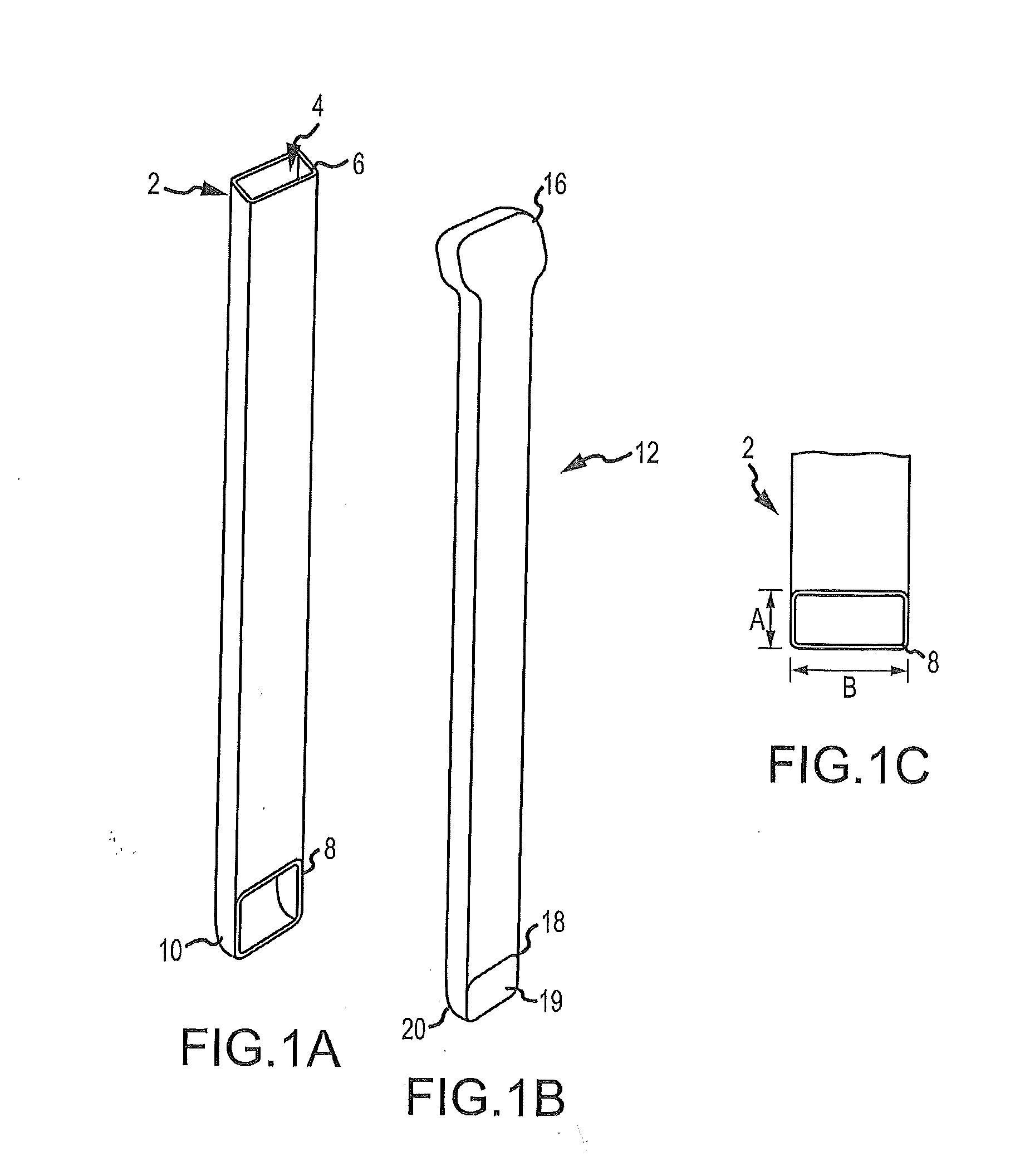

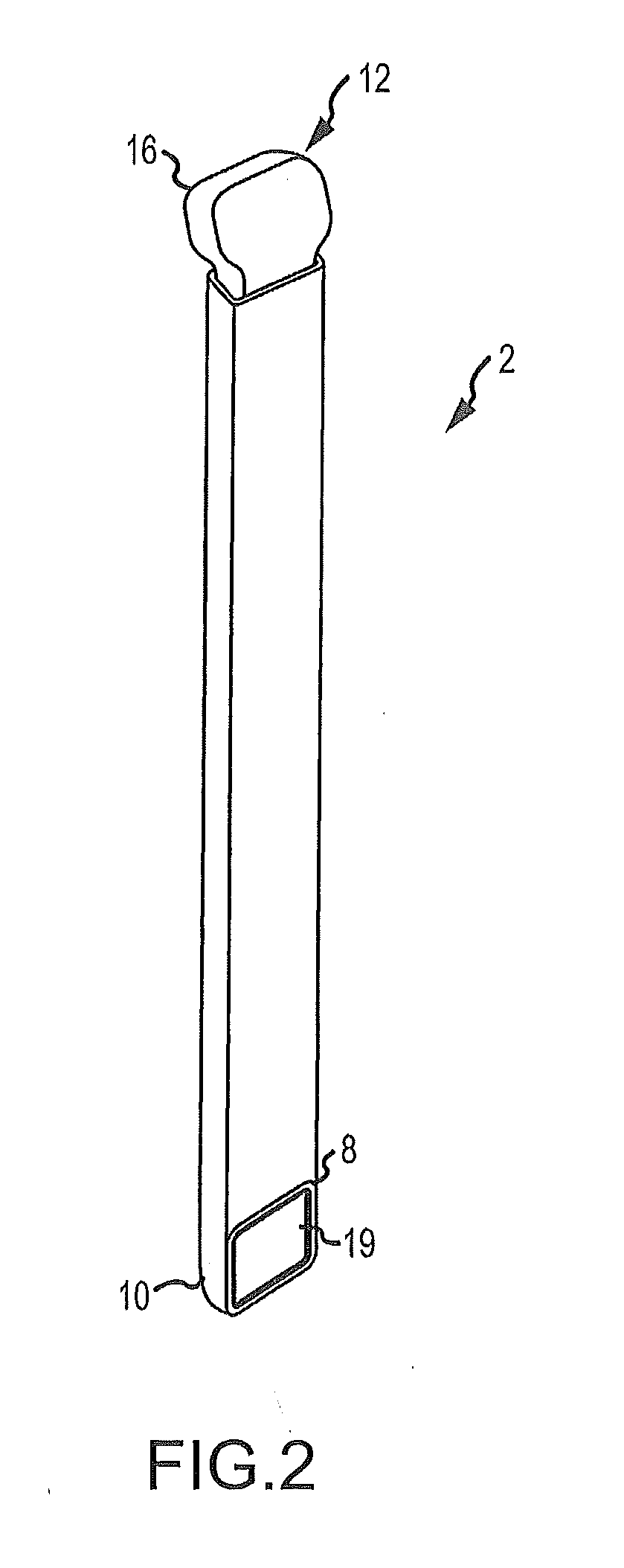

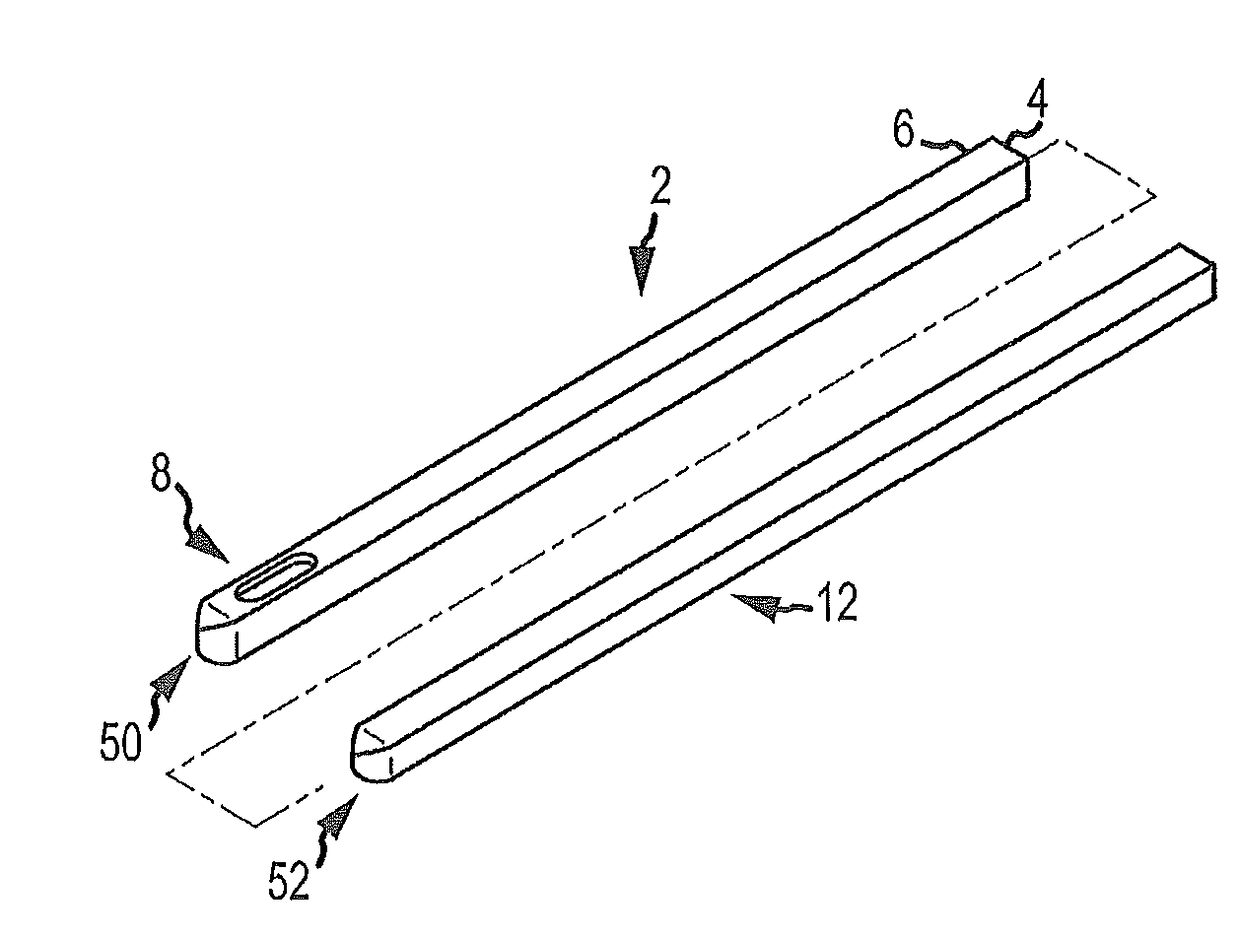

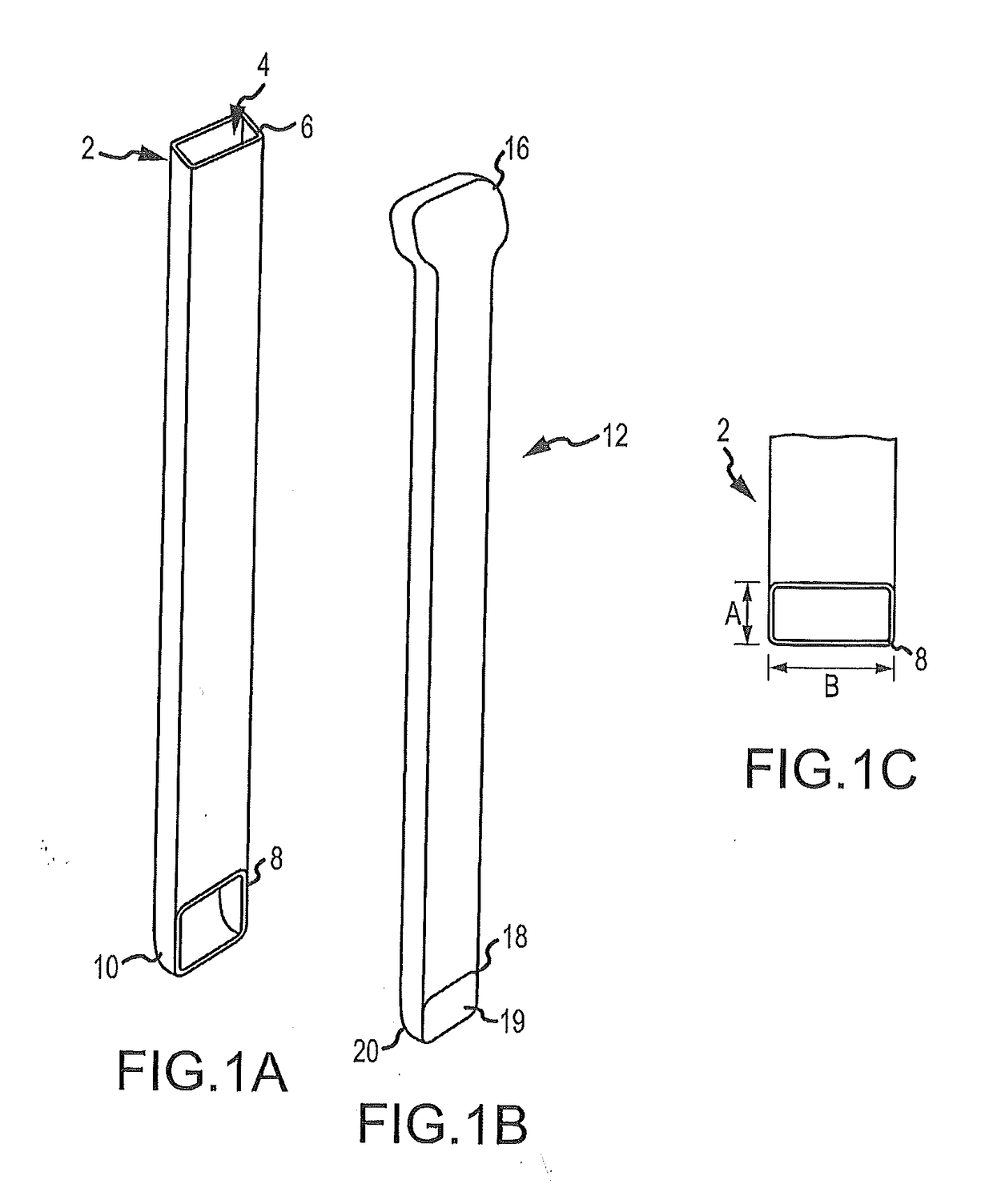

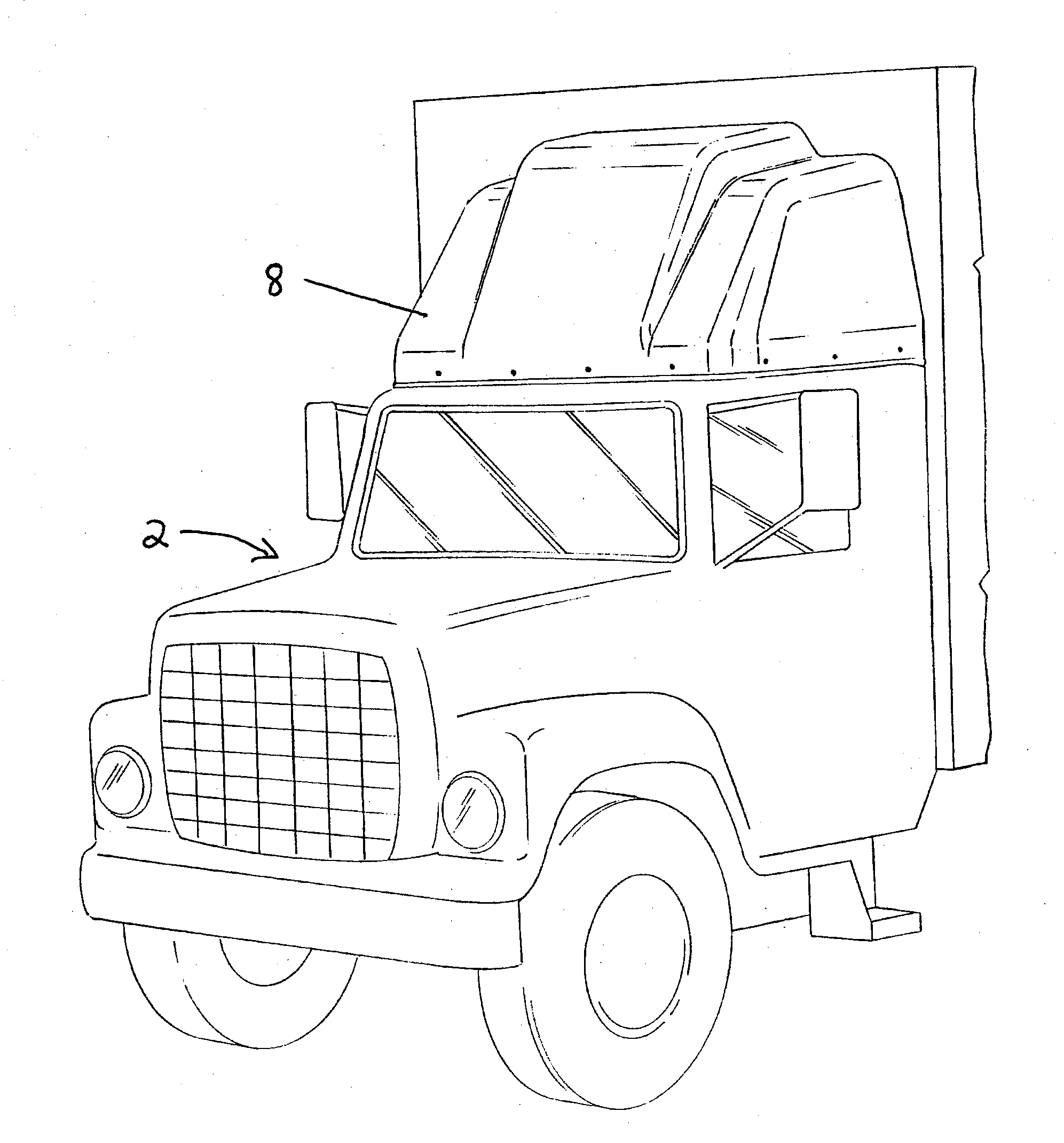

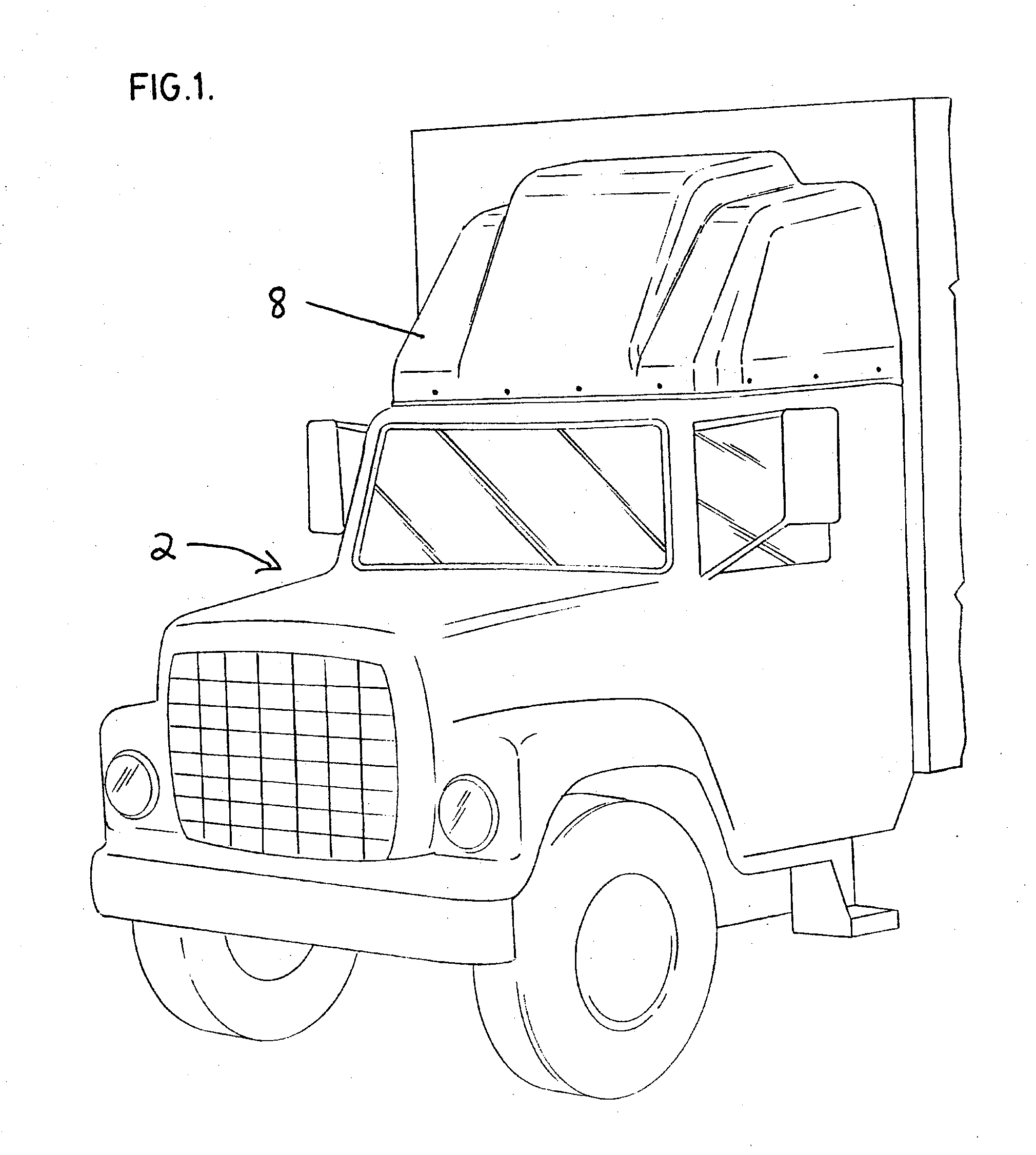

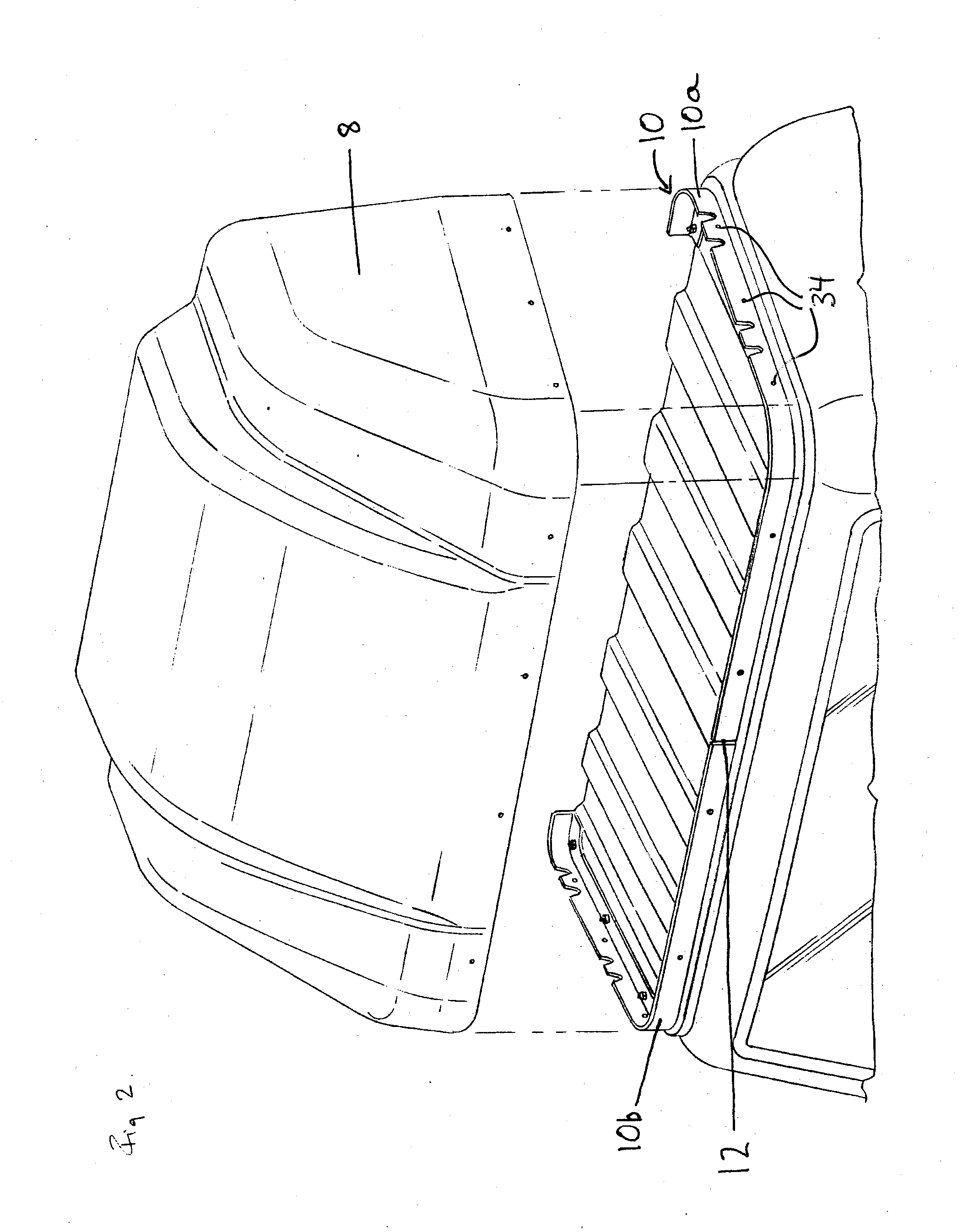

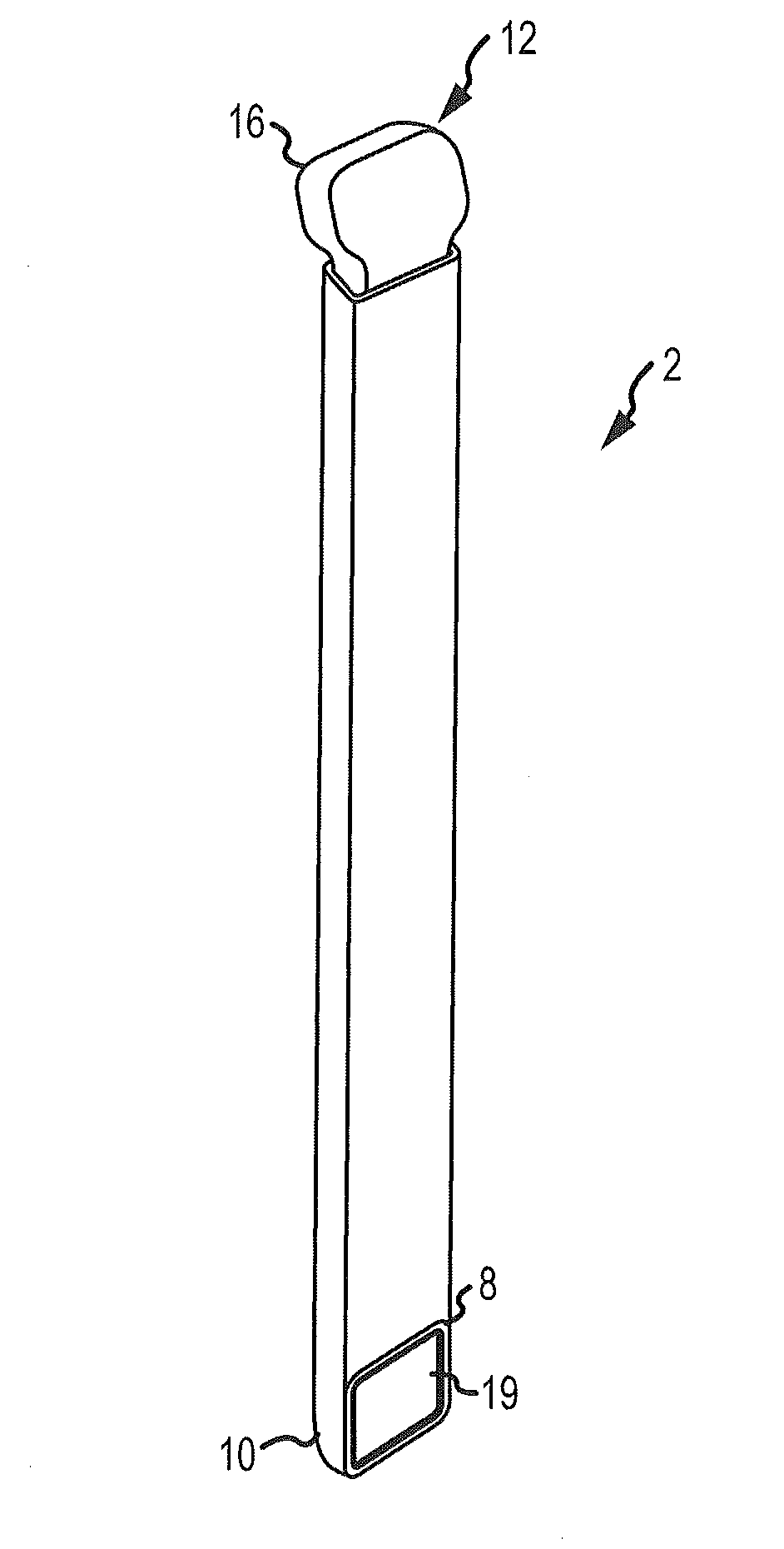

Method of manufacturing a mounting frame for a vehicle wind deflector

Owner:GLOBAL VEHICLE SYST

Fusion cage with combined biological delivery system

ActiveUS20140081279A1Reduce the risk of infectionReduce the possibilityAdditive manufacturing apparatusBone implantSurgical siteBiological materials

The present invention relates to an apparatus and method for near-simultaneous and integrated delivery of bone graft material during the placement of surgical cages or other medical implants in a patient's spine. The integrated fusion cage and graft delivery device according to various embodiments delivers and disperses biologic material through a fusion cage to a disc space and, without withdrawal from the surgical site, may selectably detach the fusion cage for deposit to the same disc space. The integrated fusion cage and graft delivery device is formed such that a hollow tube and plunger selectively and controllably place bone graft material and a fusion cage in or adjacent to the bone graft receiving area.

Owner:SPINAL SURGICAL STRATEGIES INC

Surface treatment technique for aluminum alloy die casting

InactiveCN105862027AImprove mechanical propertiesAccelerated corrosionPressure inorganic powder coatingDie castingPre treatment

The invention provides a surface treatment technique for an aluminum alloy die casting. The technique comprises the following steps that 1, the aluminum alloy die casting is provided; 2, surface pretreatment is conducted on the aluminum alloy die casting; 3, cold spraying is conducted on the aluminum alloy die casting; and 4, alkaline electrolysis polishing treatment is conducted on the aluminum alloy die casting. By the adoption of the surface treatment technique for the aluminum alloy die casting, the defects of the surface of the aluminum alloy die casting are overcome, and an aluminum alloy die-cast product high in surface quality is obtained.

Owner:安徽纯启动力科技有限公司

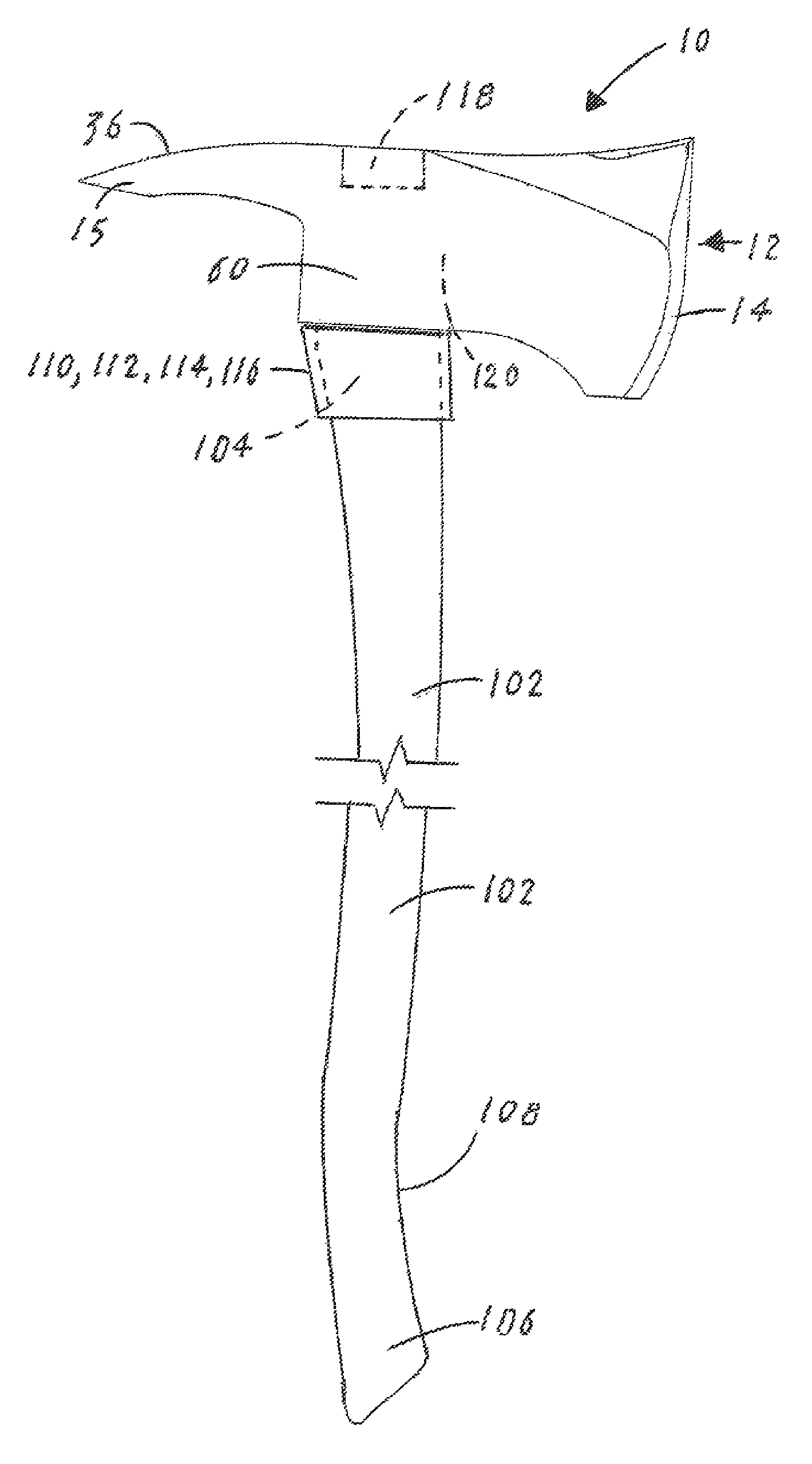

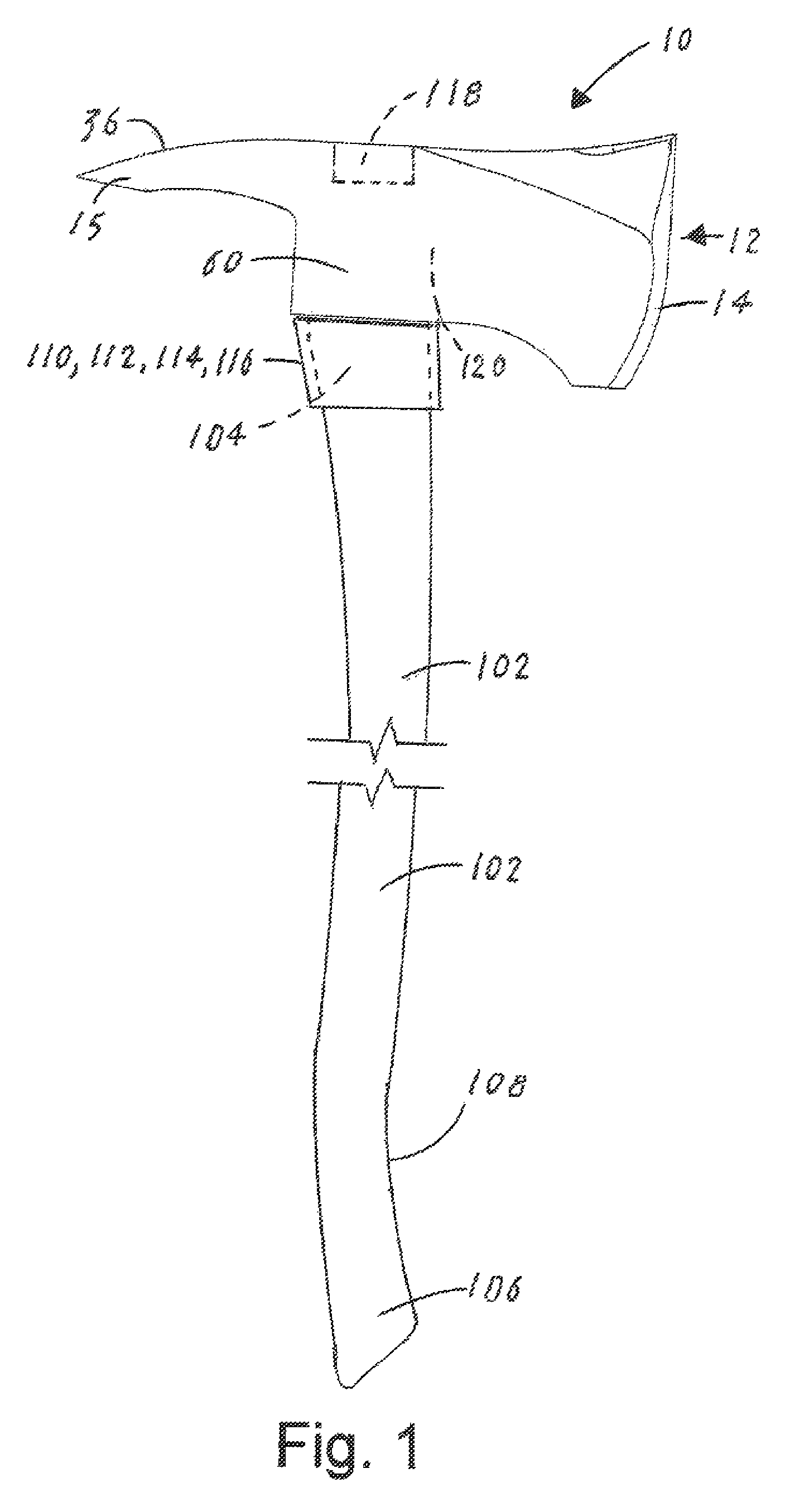

Combination axe, sledge hammer and pick

A combination axe, sledge hammer and pick (CASHP) that is particularly designed for use by firefighters. The CASHP includes a front end and a rear end. The front end has an upper section that functions as an axe blade and the lower section functions as a sledge hammer. The rear section includes a pick that can be utilized for a variety of functions. By incorporating three tools in a single structure the weight that a firefighter carries is lessened. Thus, reducing fatigue and the time that is required to cut through an obstruction to reach fire victims.

Owner:FOX DARIN ANDREW

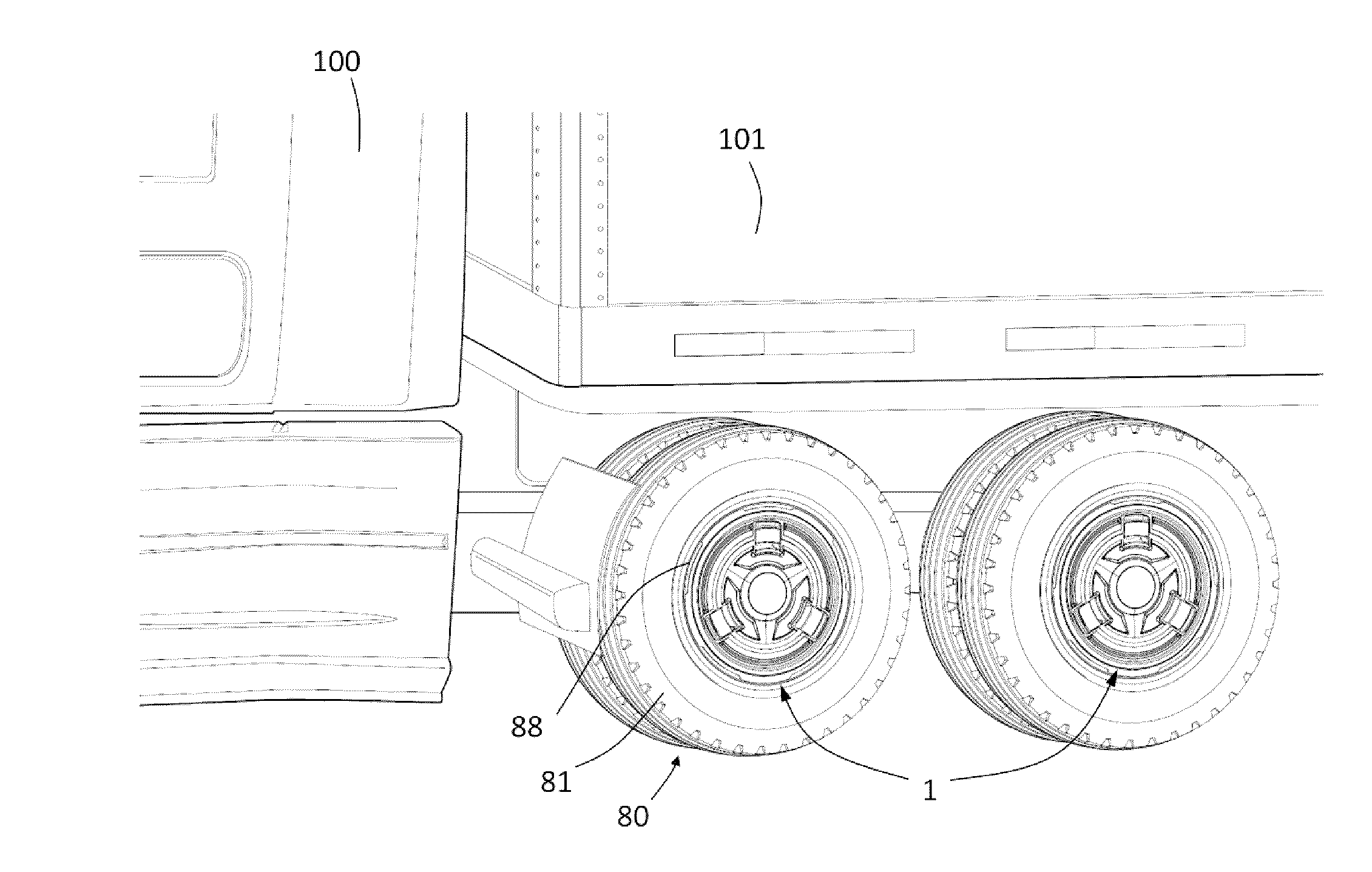

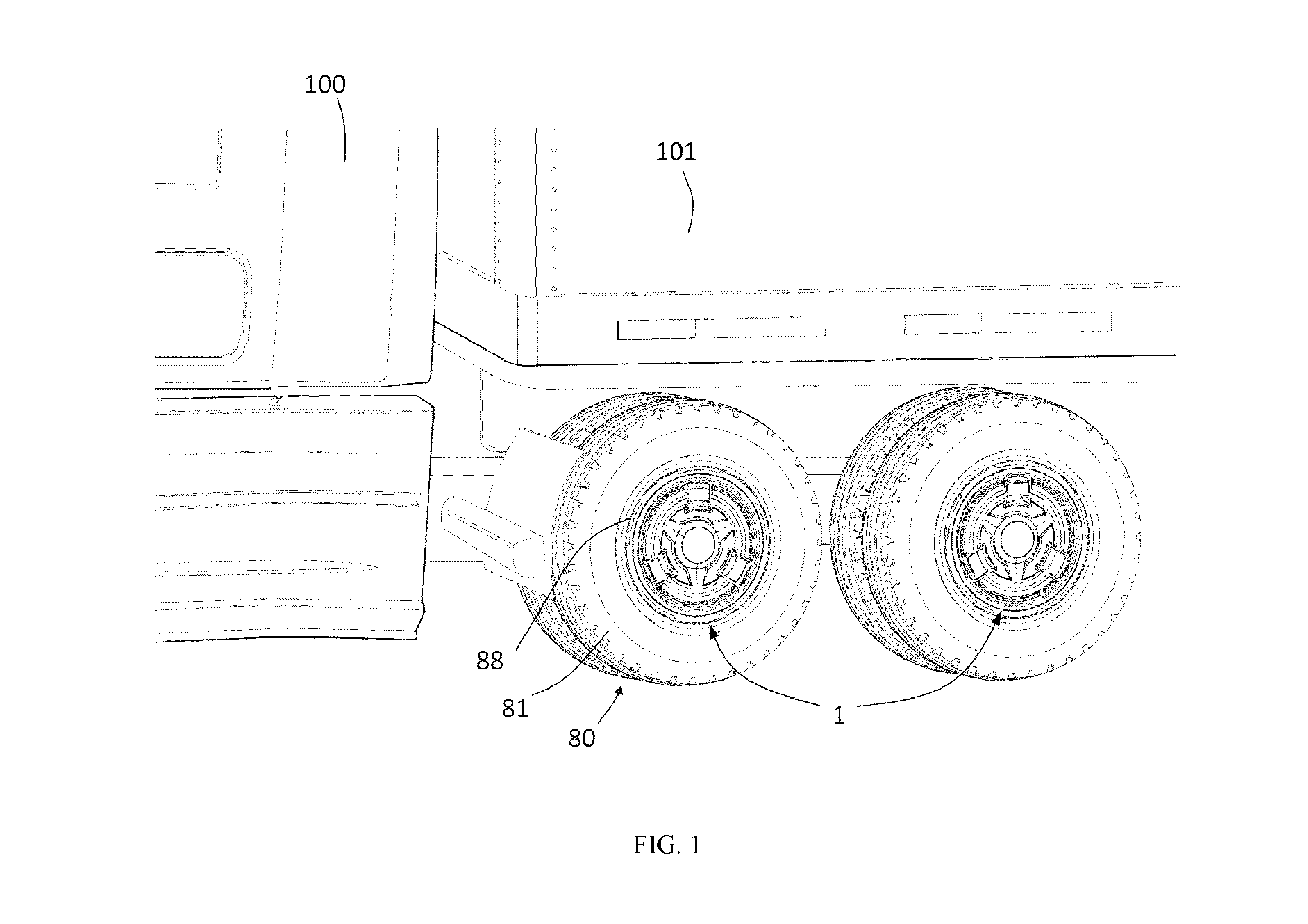

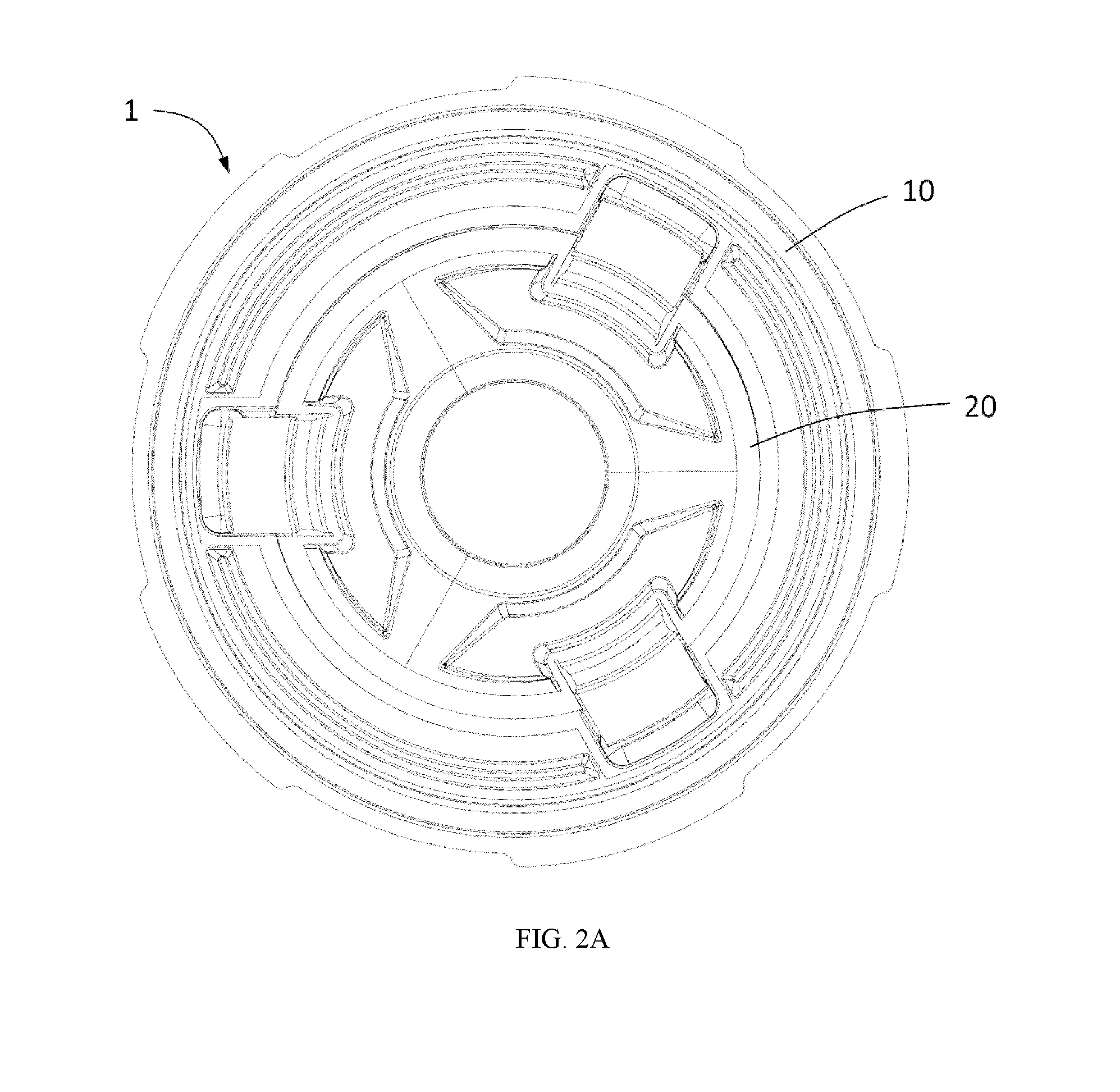

Wheel cover assembly

ActiveUS20150210110A1Improve aerodynamic performanceLess toolingMetal-working apparatusWheel manufactureEngineeringMechanical engineering

The present disclosure relates to a wheel cover assembly for a wheel assembly of a vehicle. The wheel cover assembly can include a bracket configured to be mounted onto the wheel assembly, an outer ring configured to be coupled with the bracket, and an inner cover removably couplable with the outer ring. The inner cover can comprise at least one attachment mechanism having a spring element, a catch and a handle, where the spring element can bias the catch to engage with the bracket or the outer ring to removably secure the inner cover to the outer ring.

Owner:LUND & CO INVENTION LLC

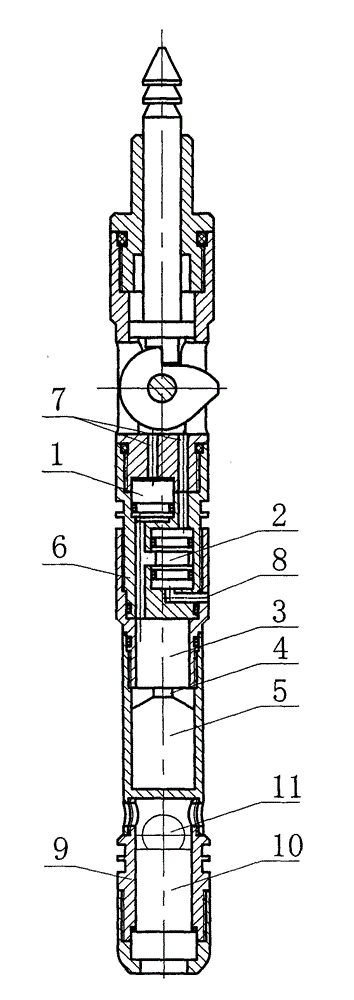

Layered testing and adjustment process for injection well

InactiveCN104863568AAvoid interlayer interferenceReduce distortionSurveyFluid removalInjection pressureSkill sets

A layered testing and adjustment process for an injection well mainly solves the problems that an existing testing and adjustment process is carried out separately under a well shutin circumstance, the number of devices and tools is large, and long time is consumed. The specific testing and adjustment process includes the following steps that firstly, according to an existing throwing and fishing method, blanking plugs in eccentric water distributors in various layers are fished out and then blockage type flowmeters are thrown into the eccentric water distributors in the layers; secondly, different types of injection pressure are adjusted at the mouth of the well, the injection allocation flow of the whole well is 0-150%, and three to six points are selected for pressure adjustment; thirdly, the blockage type flowmeters in the layers are fished out, and testing data are obtained; fourthly, packer seal examining is implemented; fifthly, layered flow adjustment is implemented; sixthly, layered well testing and pressure measurement are implemented. The layered testing and adjustment process for the injection well has the advantages that under a well non-shutin circumstance, layered pressure measurement is completed at the same time, the number of devices and tools is small, operators have no special skill requirements or testing and adjustment experience, and data can be synchronized.

Owner:黑龙江普测科技有限公司

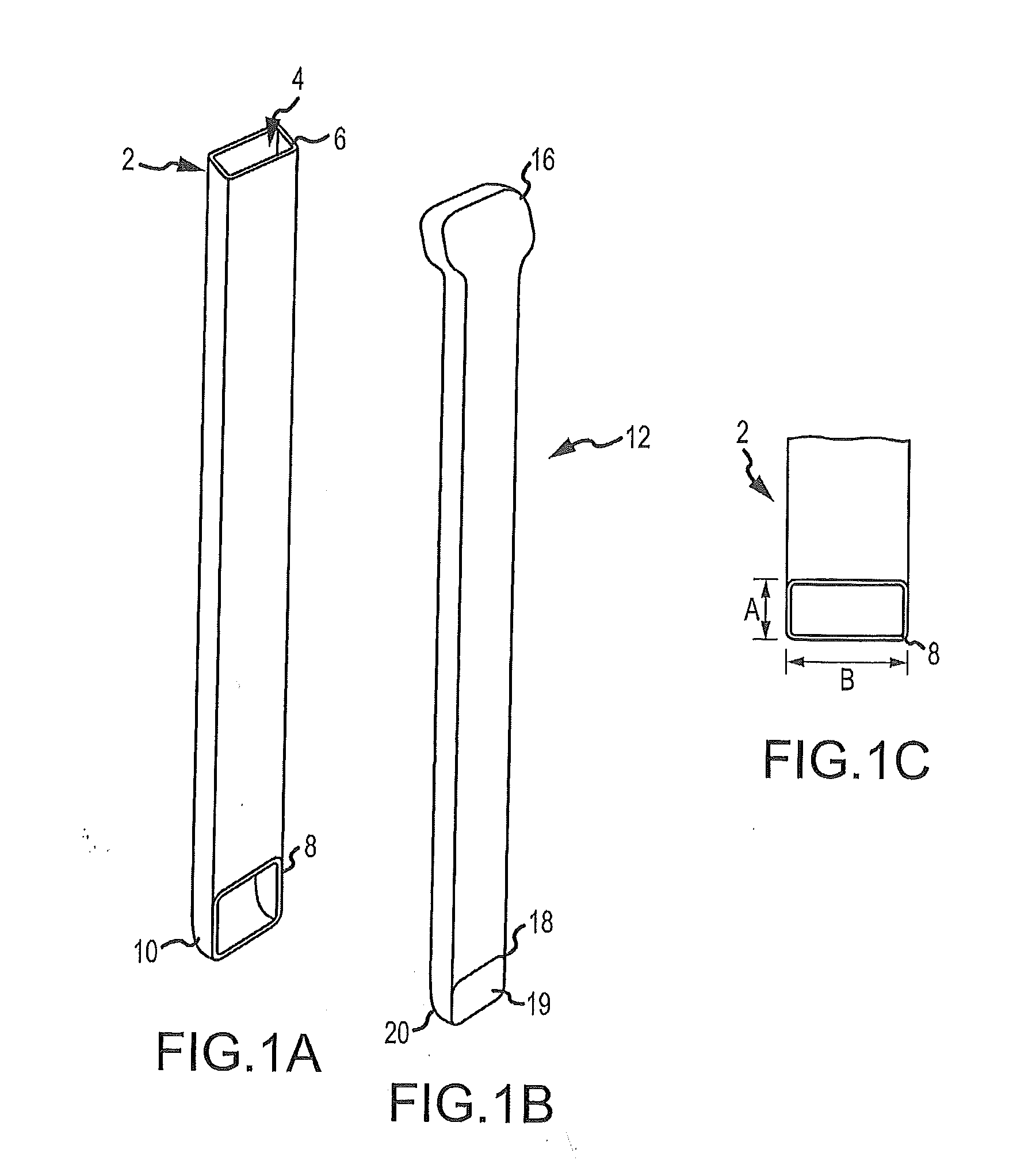

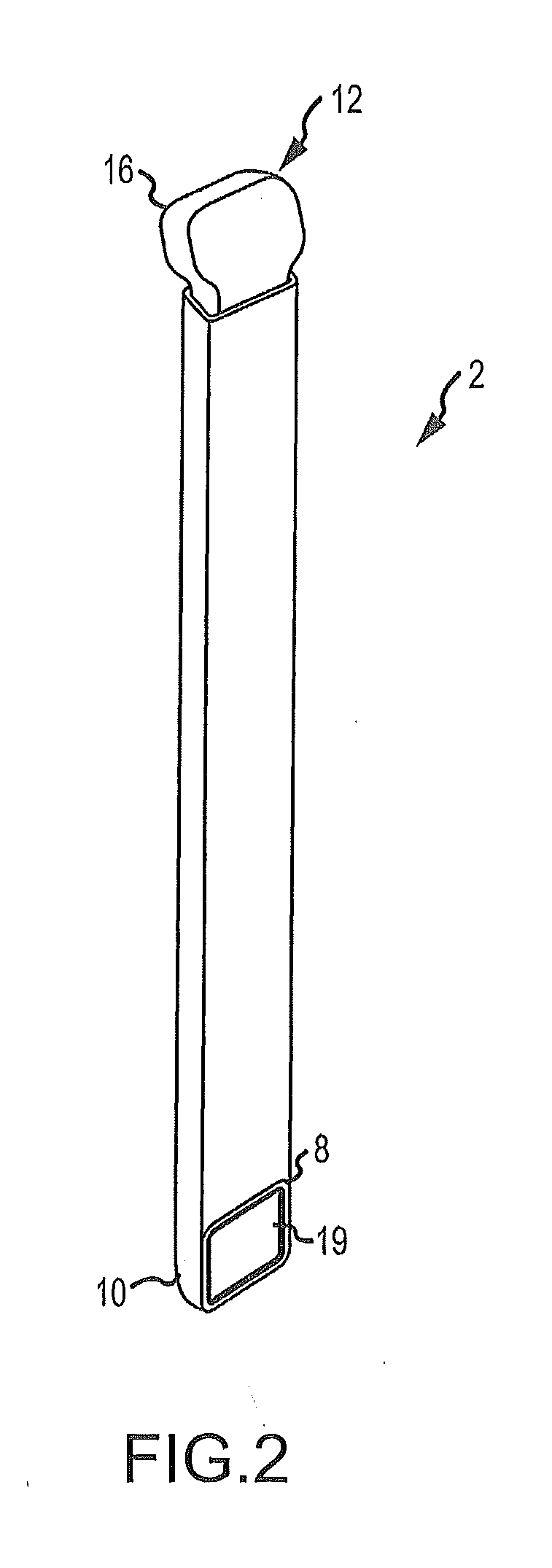

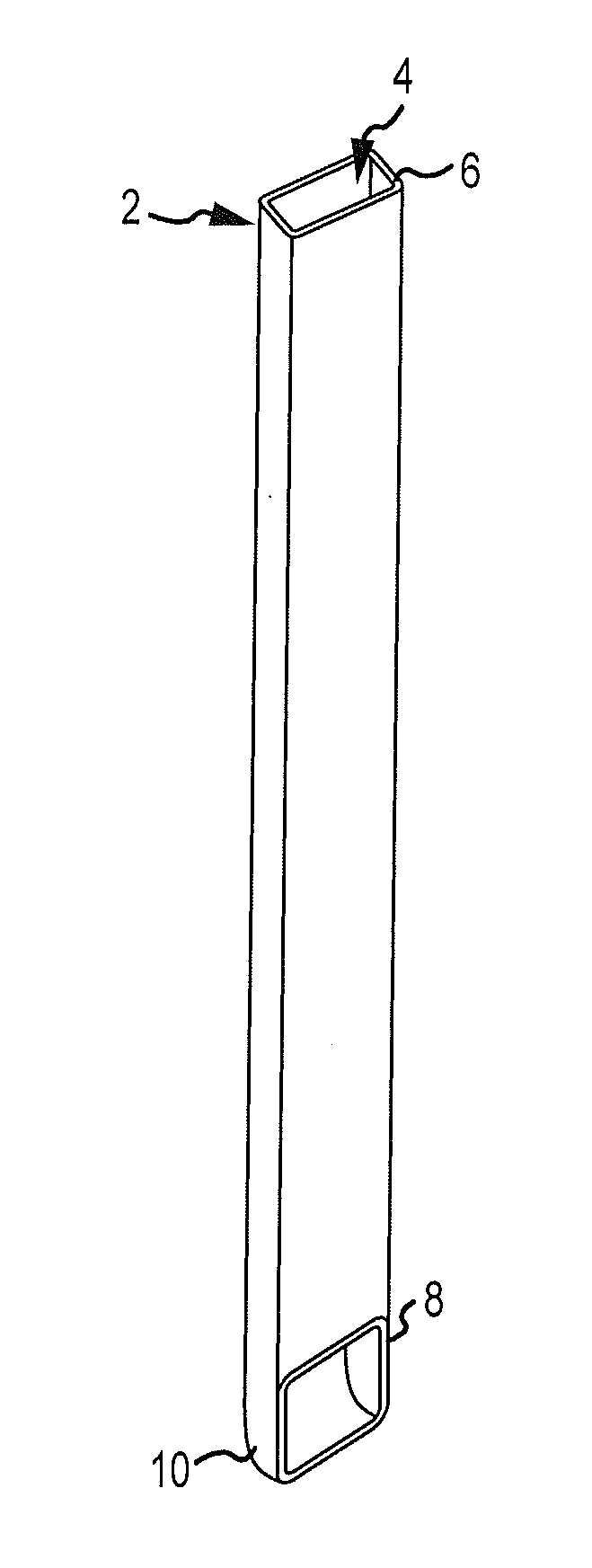

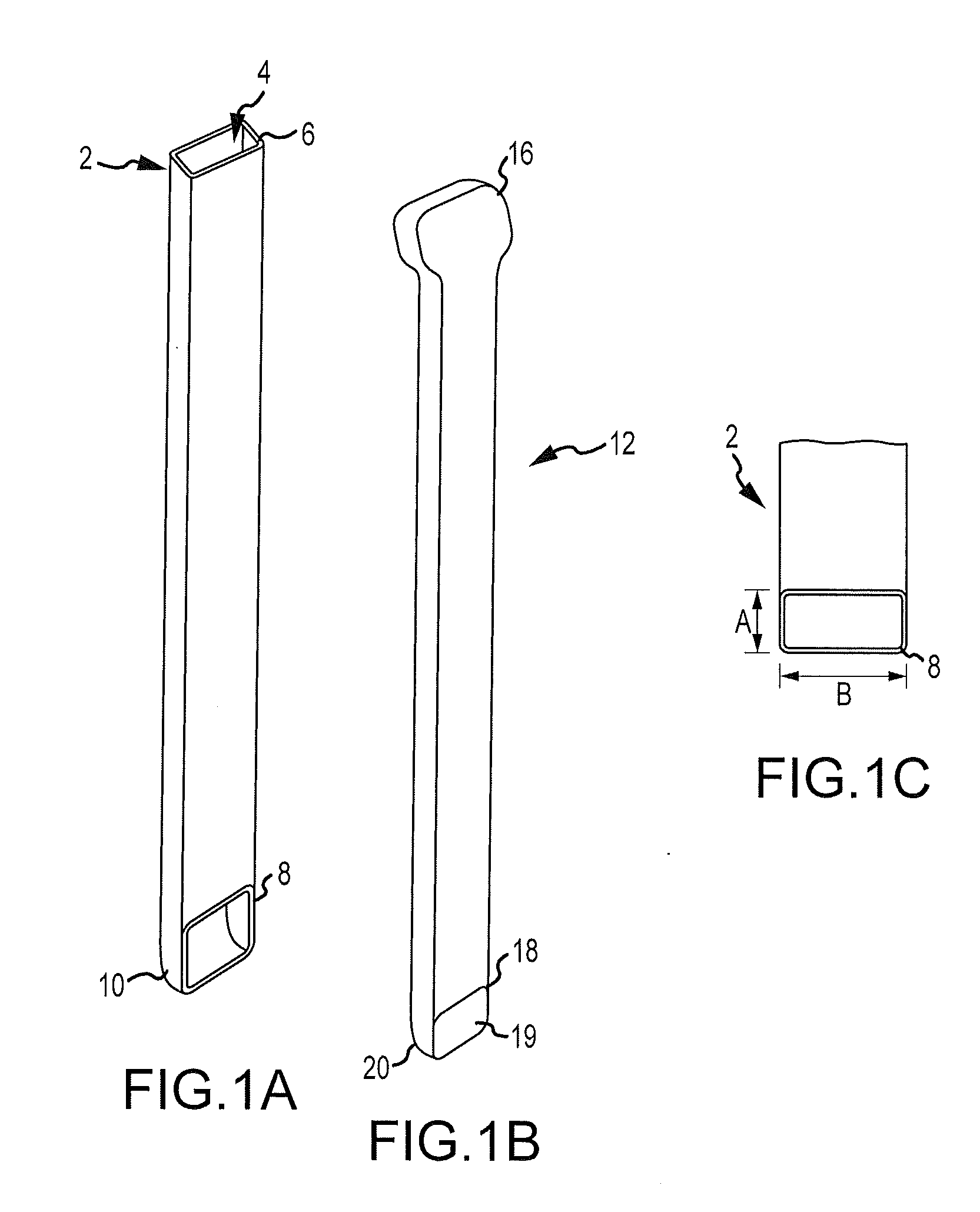

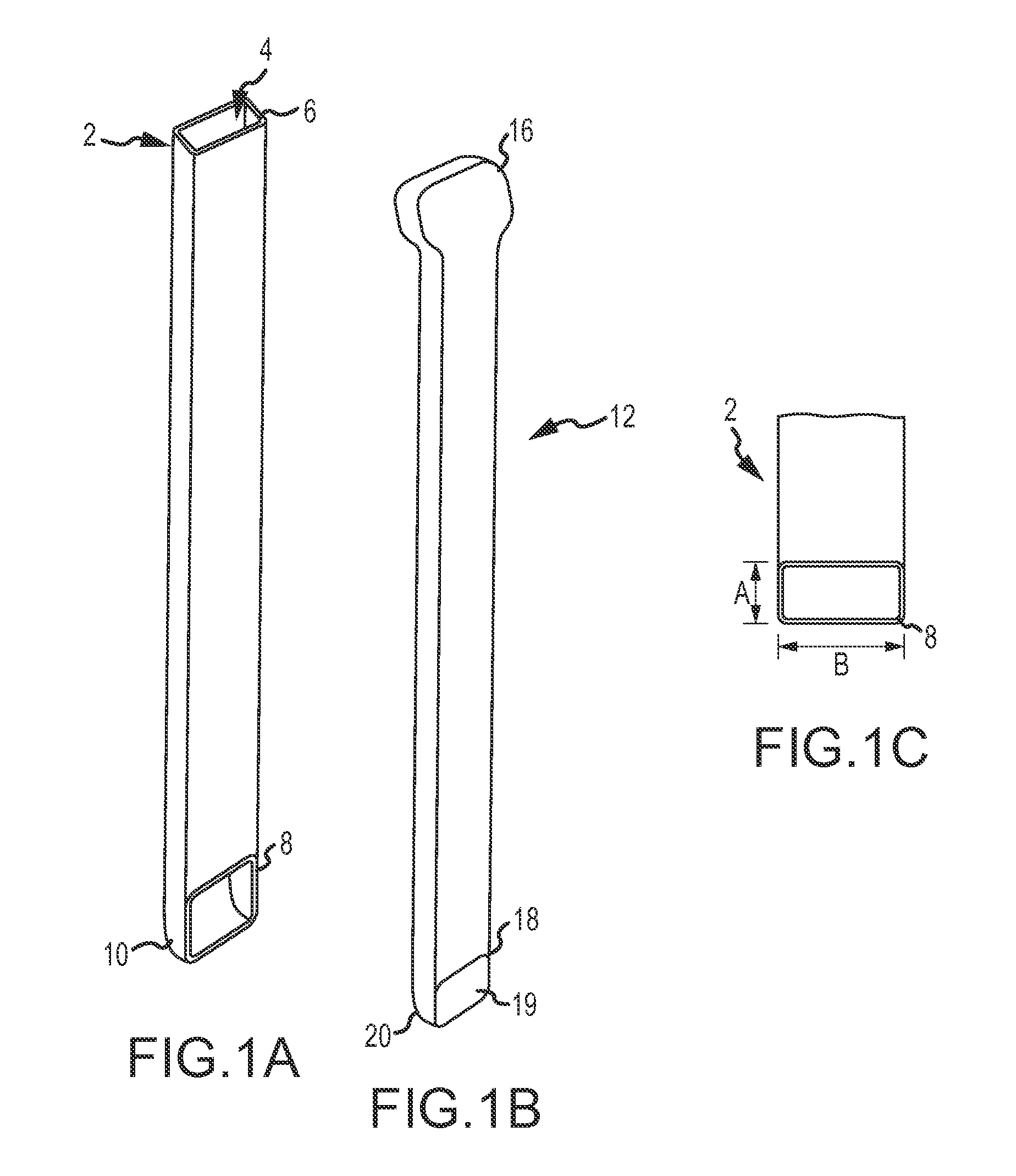

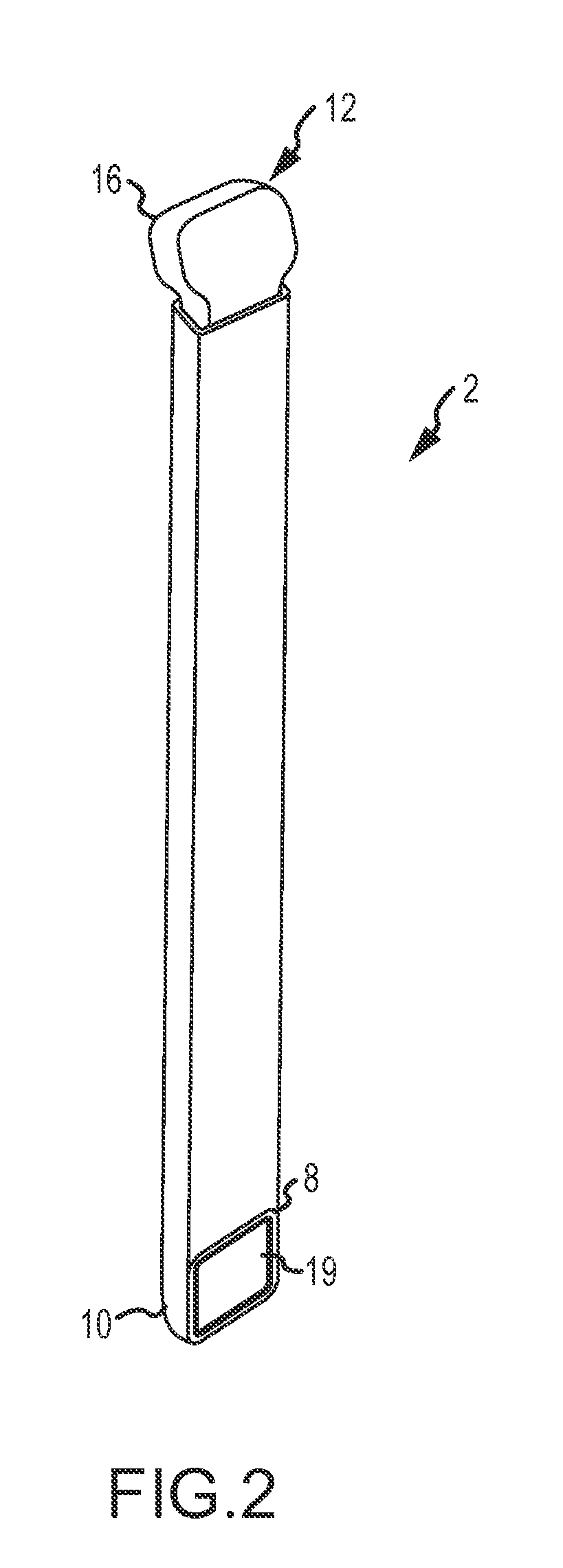

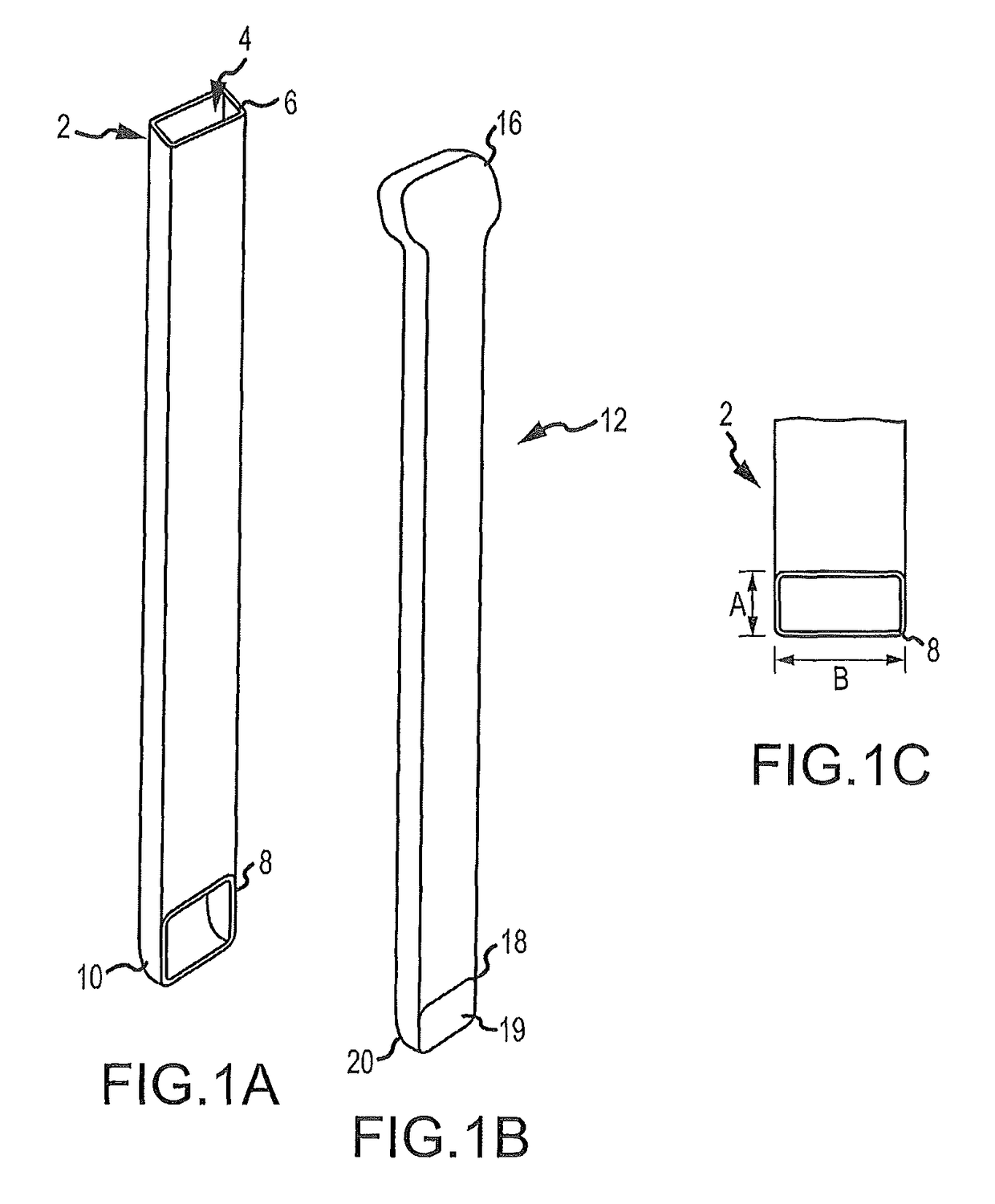

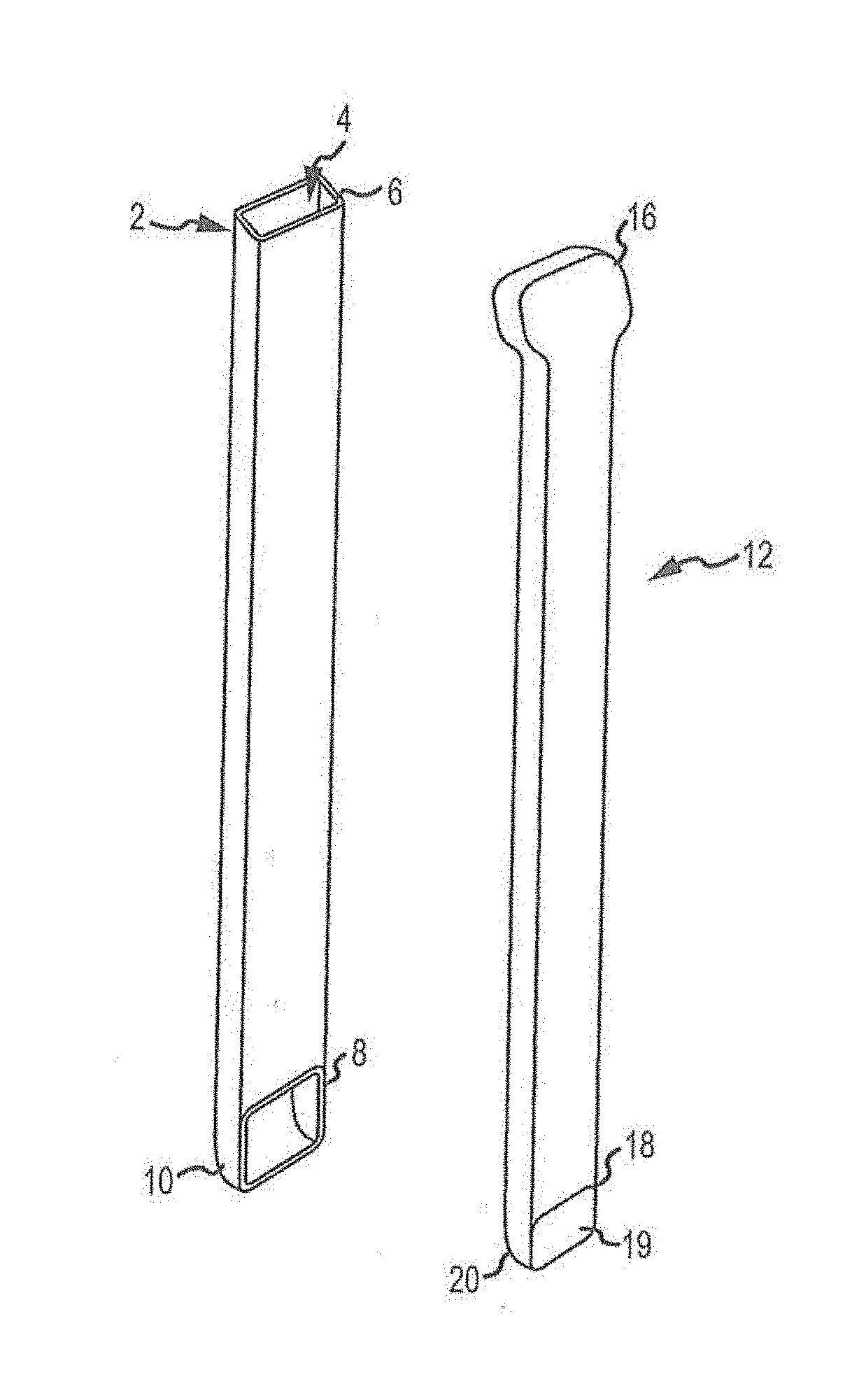

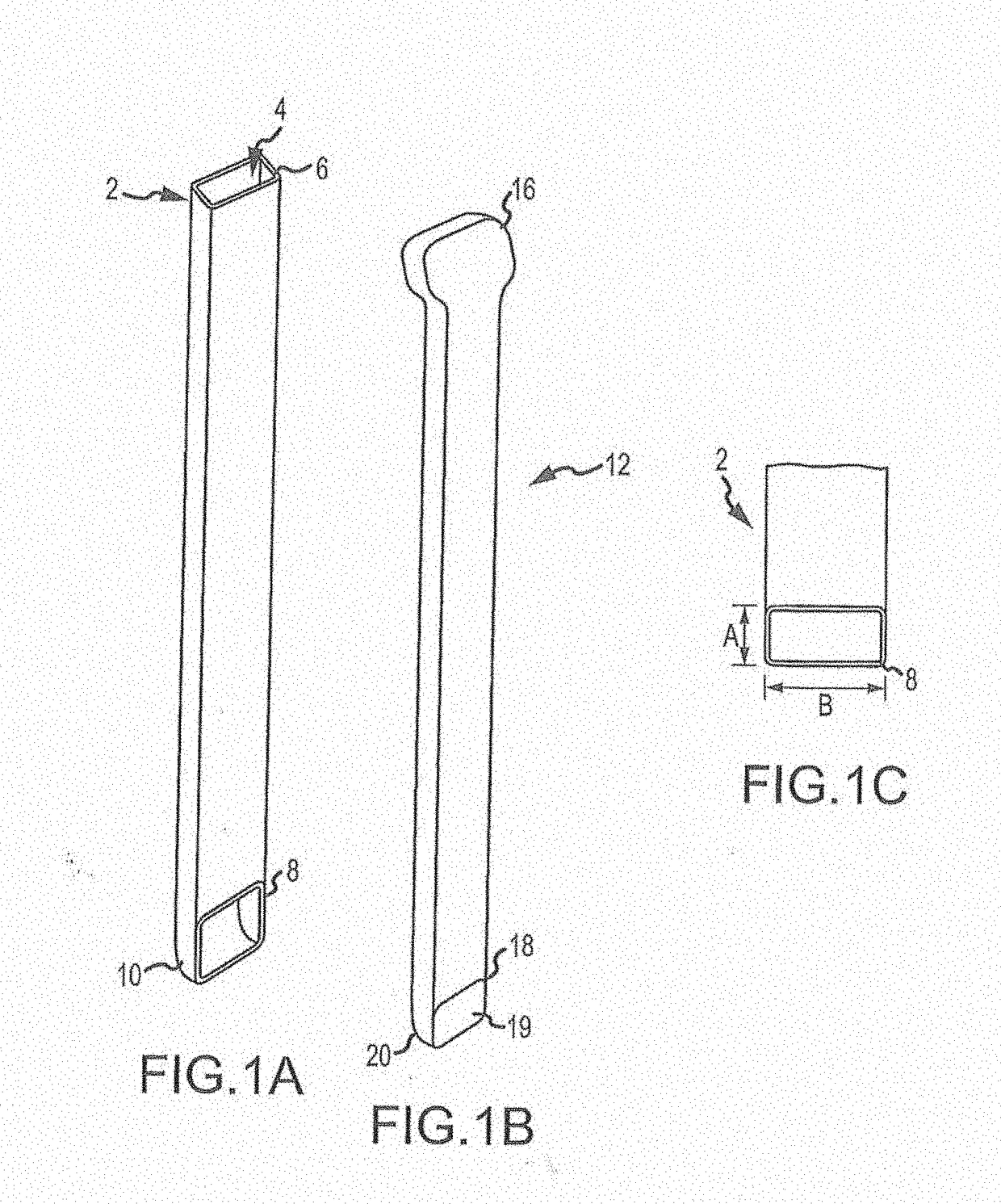

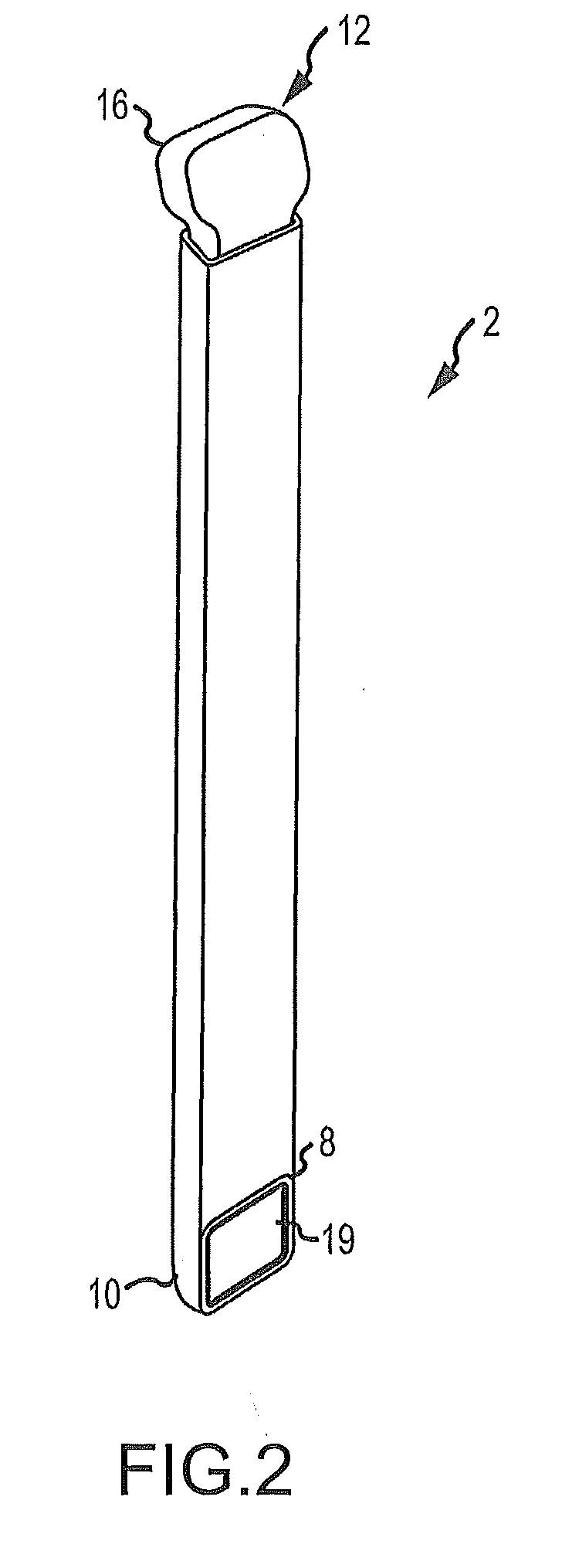

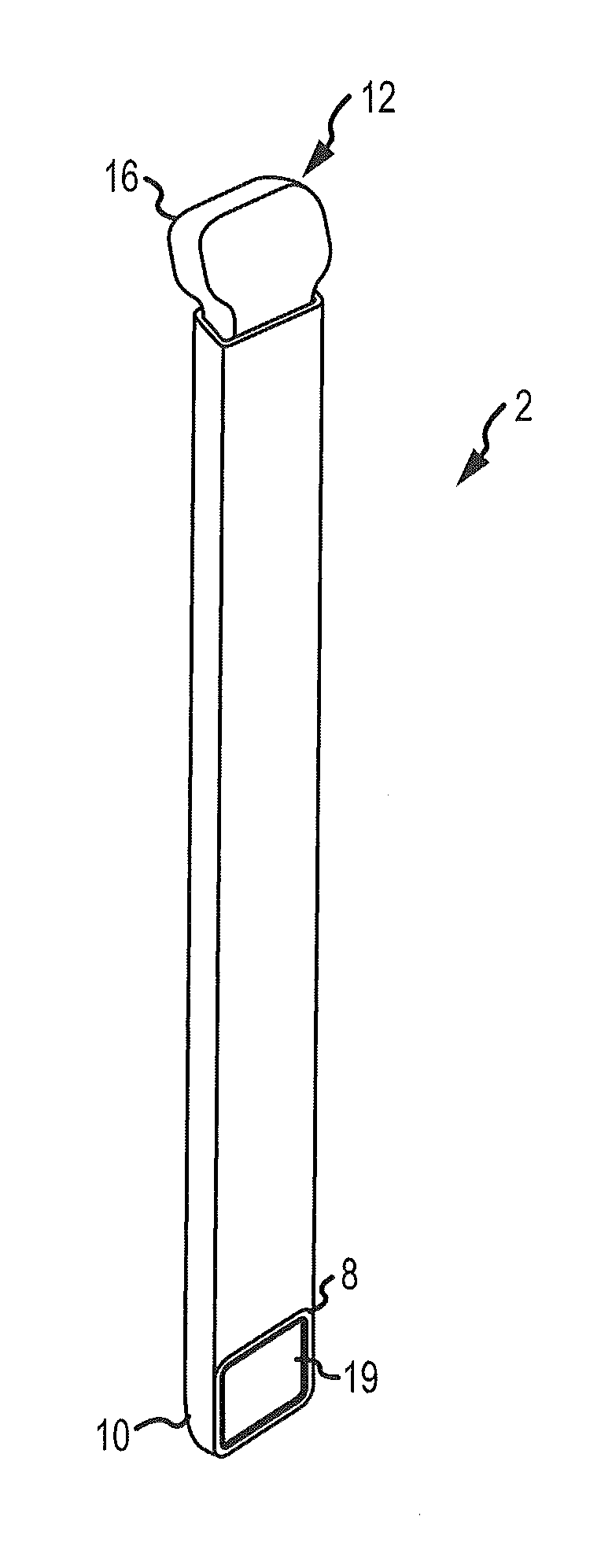

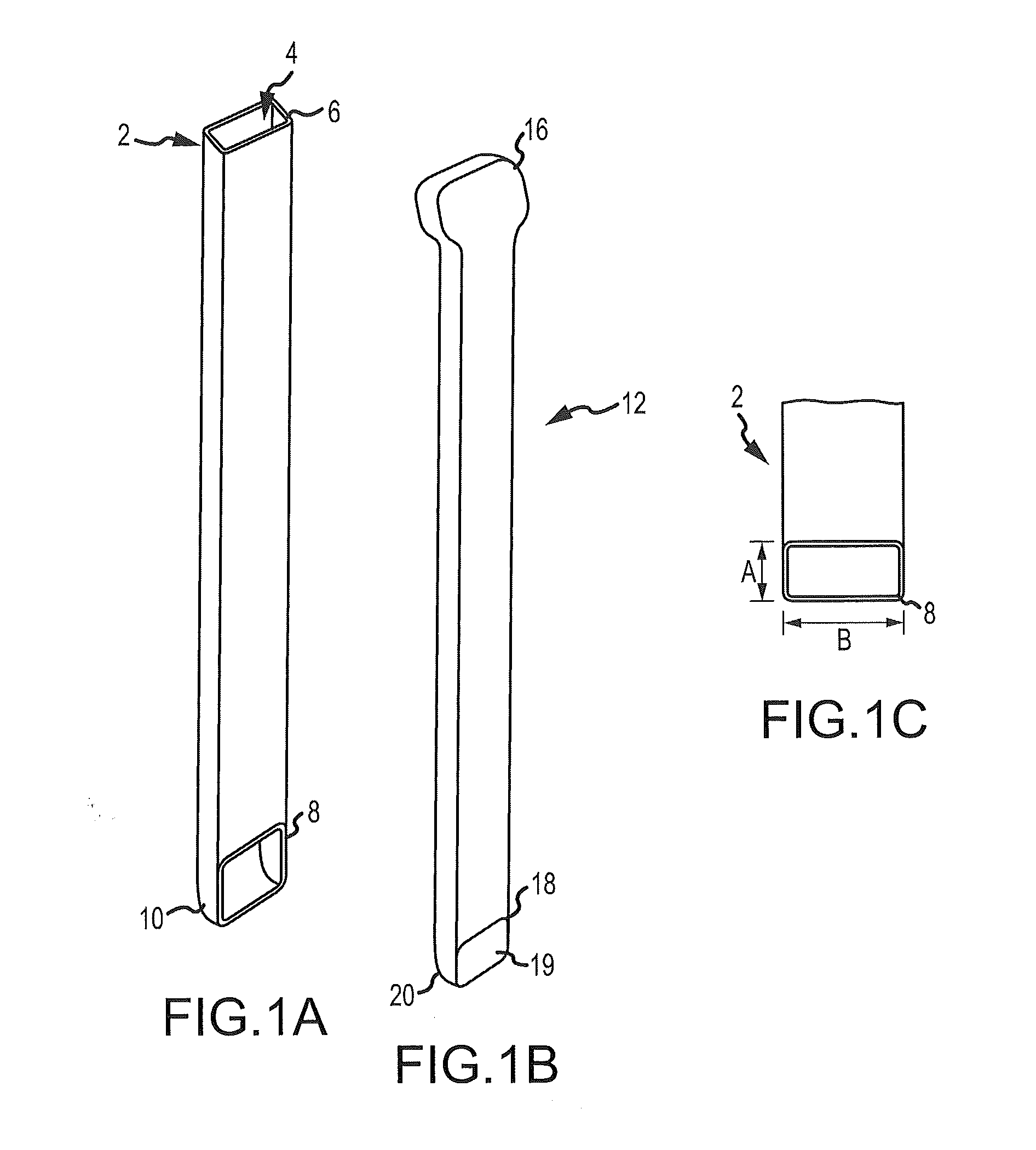

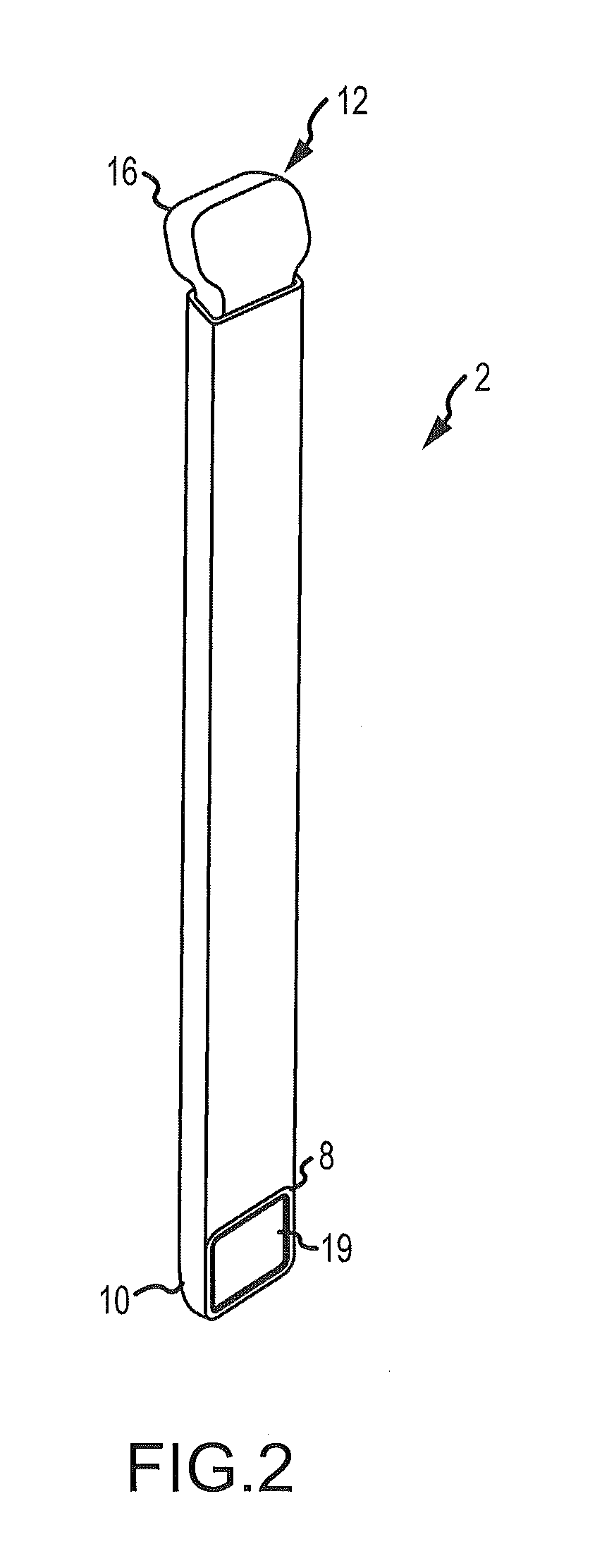

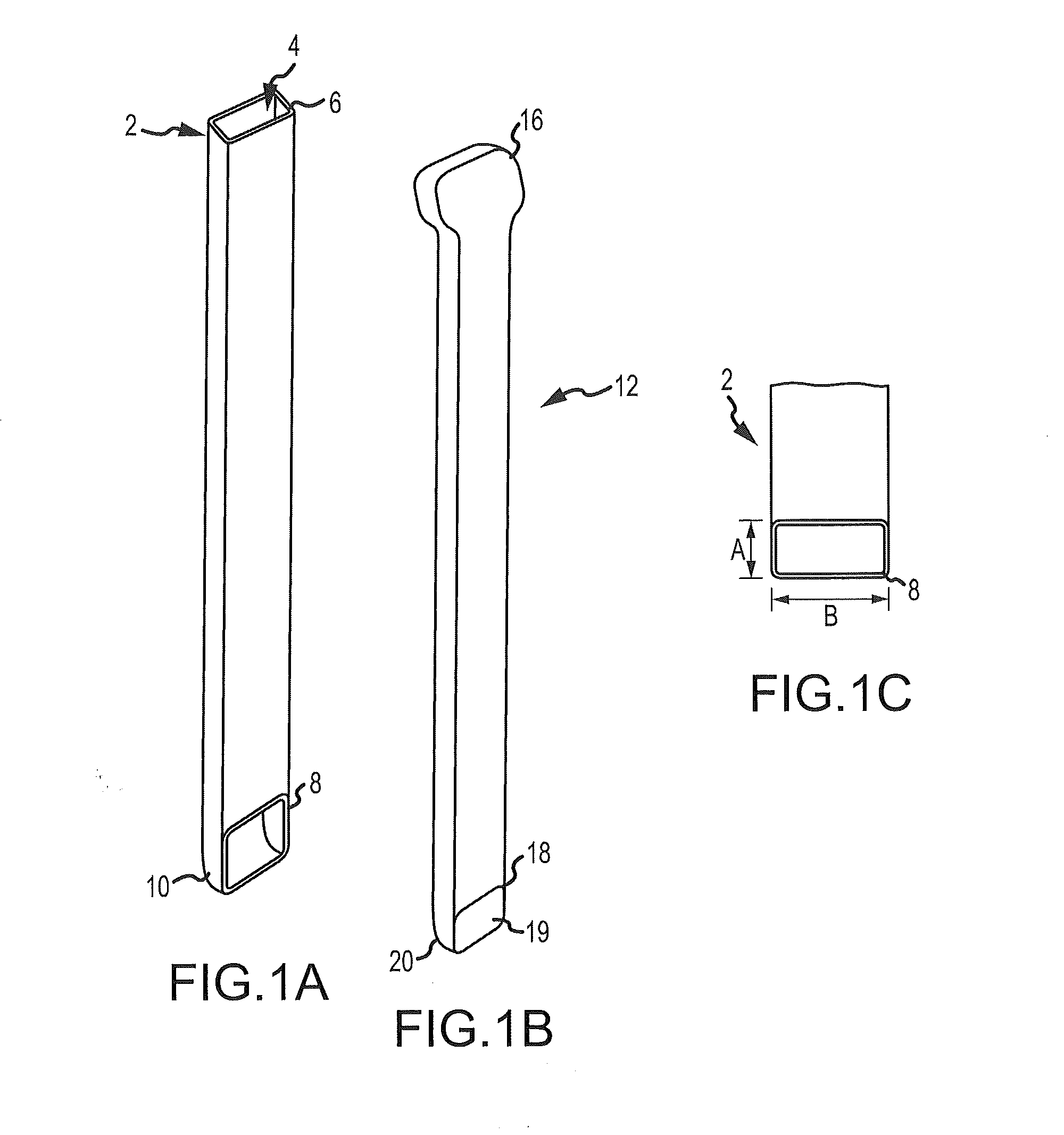

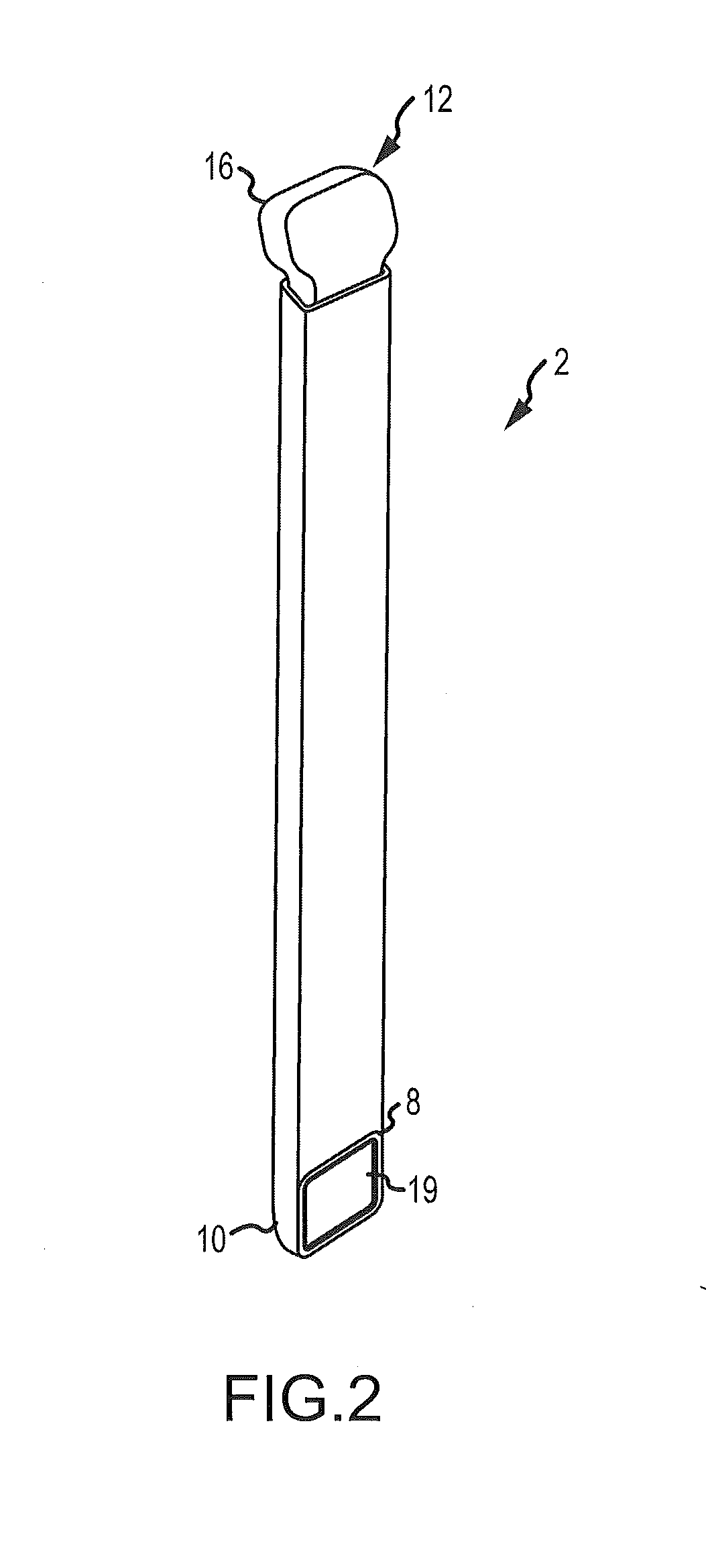

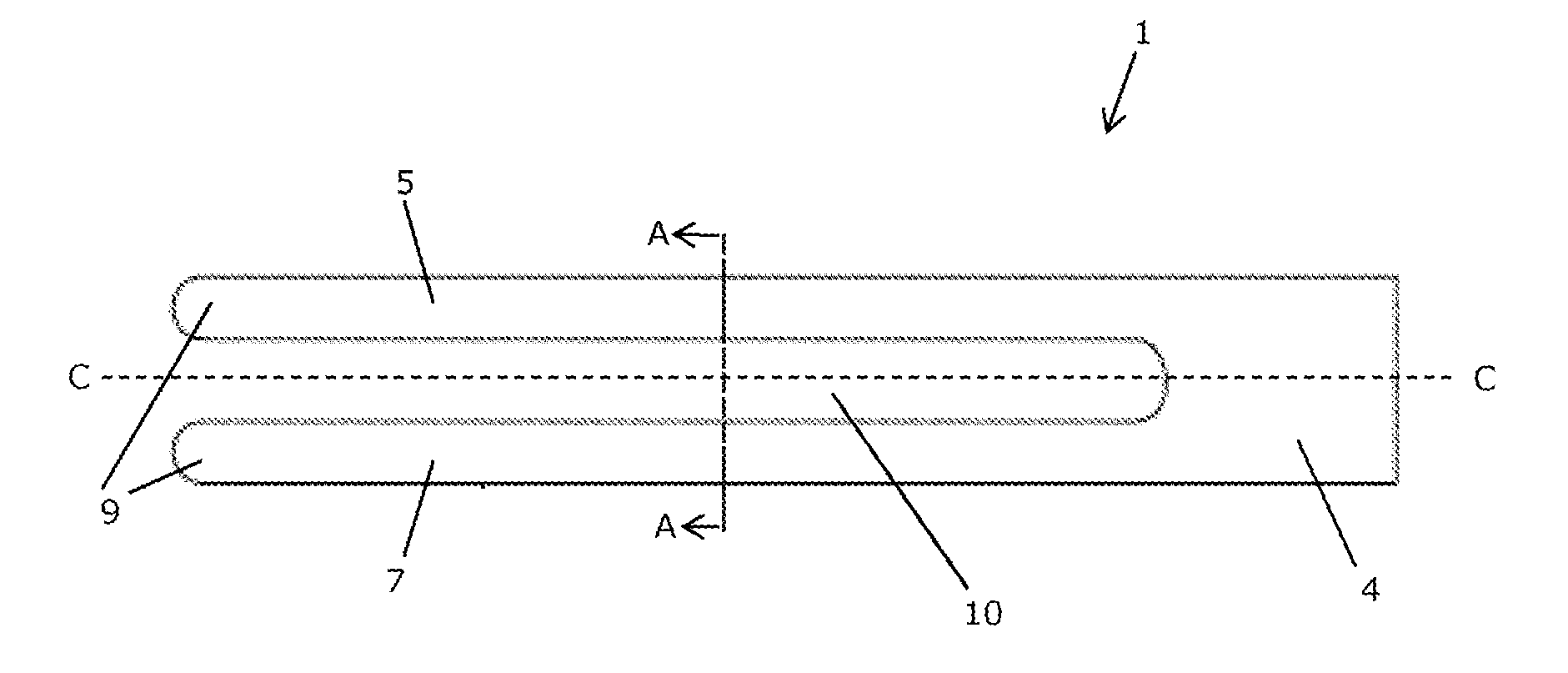

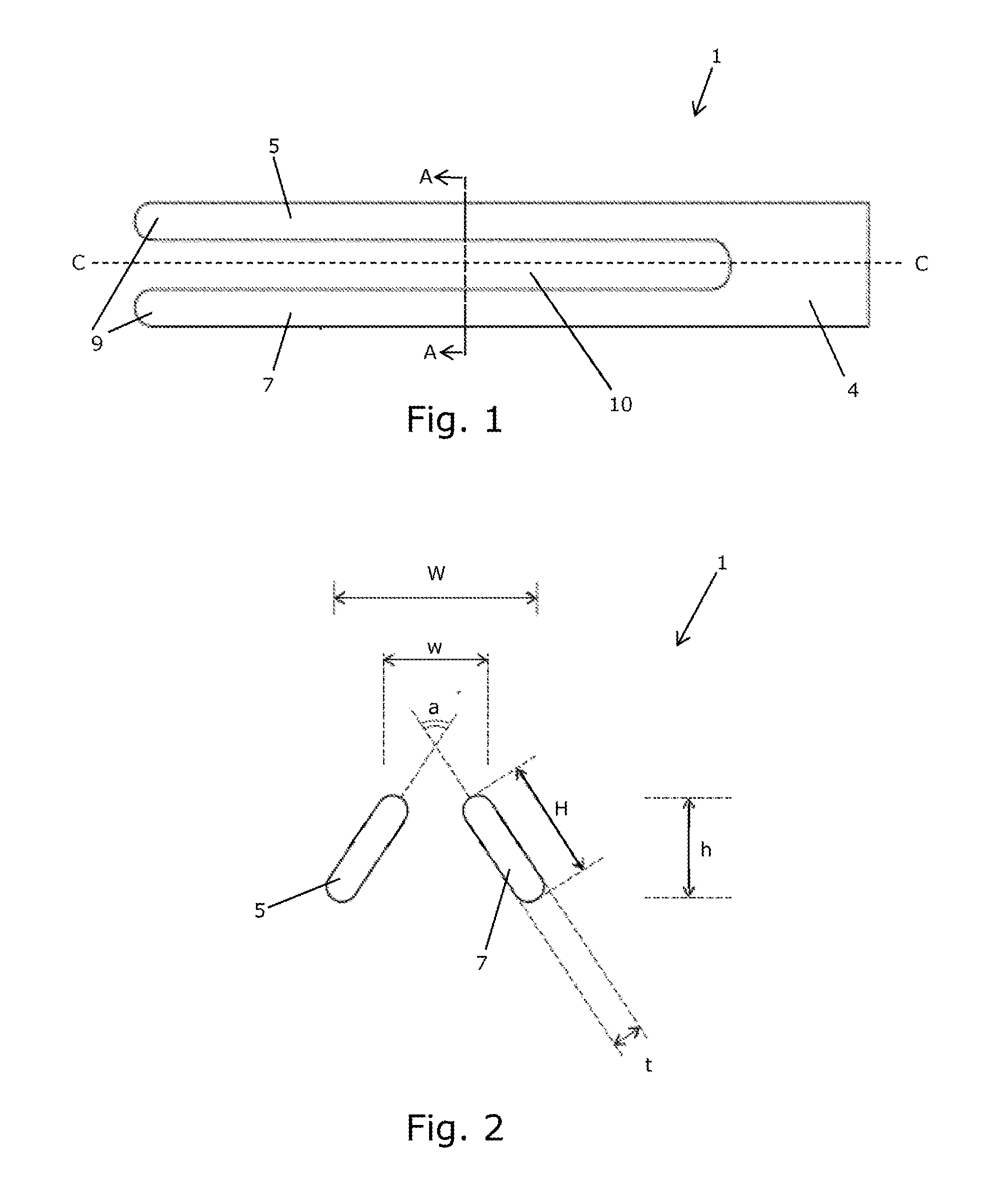

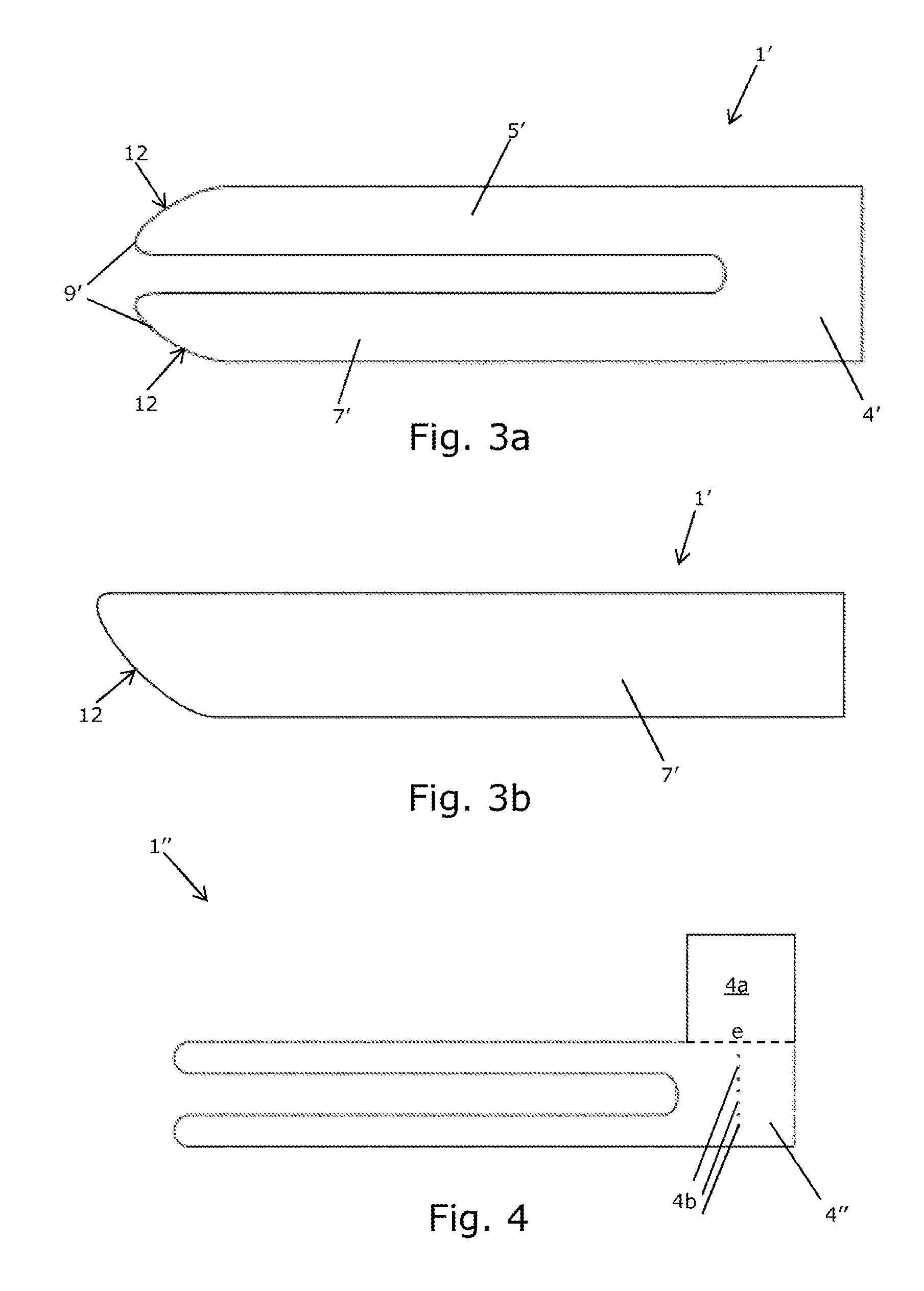

Dental tool

InactiveUS20150282896A1Risk minimizationReduce riskOthrodonticsDam holdersGingival tissueEngineering

The invention provides a dental tool for insertion between two adjacent teeth to provide a-traumatic separation of adjacent teeth of a human being. The tool comprises a base, a first leg for placement in a first gum pocket and for abutting a first one of the two adjacent teeth and a second leg for placement in a second gum pocket and for abutting a second one of the two adjacent teeth. The first and second legs are elongated and extend from the base in an oblong direction towards an end. The legs are separated with an interspace between them for accommodating gum tissue. The invention further provides a method for providing a-traumatic separation of two adjacent teeth of a human being during dental restoration.

Owner:APROXI

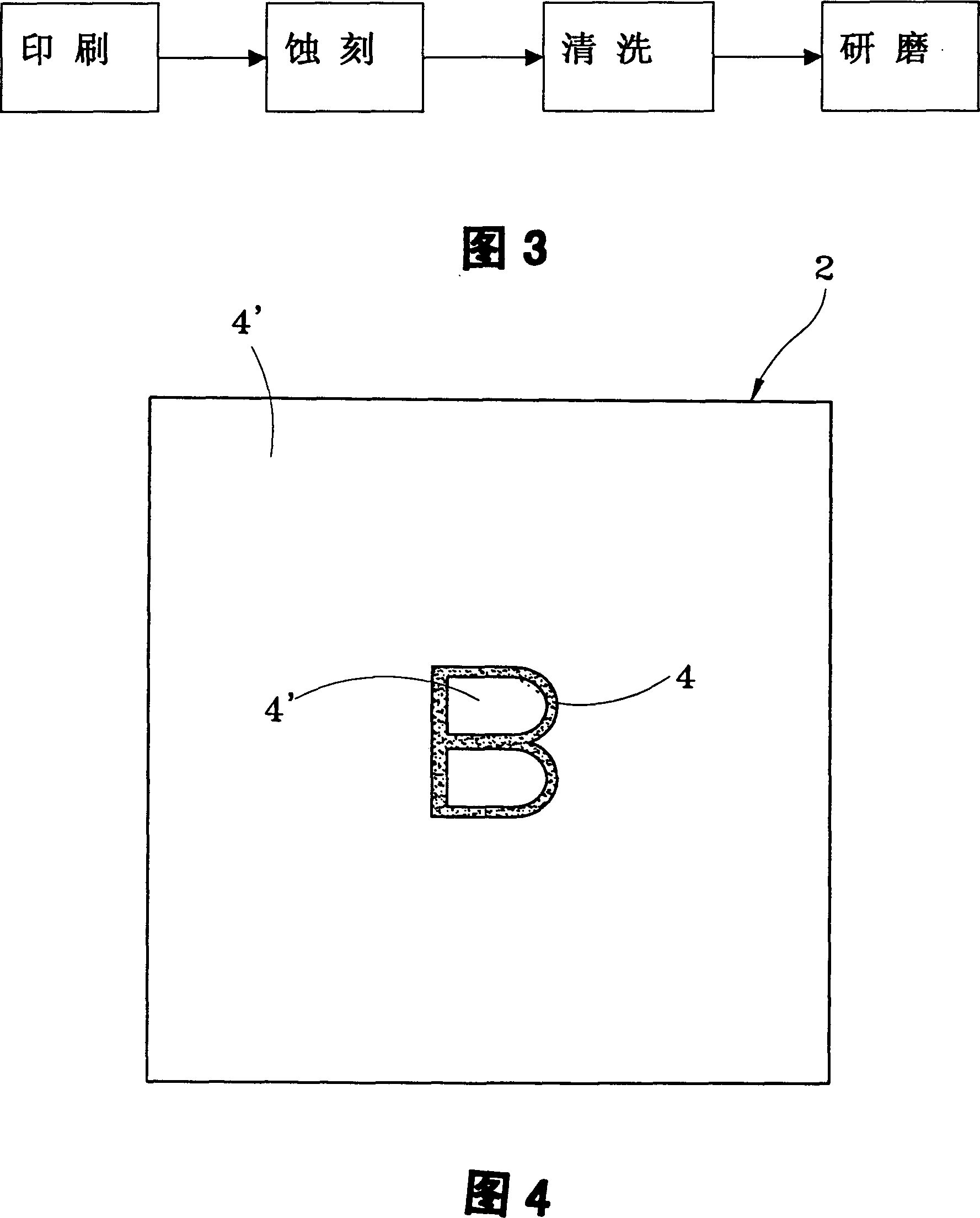

Method for producing cutter

The present invention relates to the production of cutter assembled to cutting bench to cut printed matter, paper and metal board. The production process includes the step of: figure printing of the cut shape with printing ink on metal plate; etching the metal plate through soaking the plate in etching agent solution; cleaning and reaching the required itching depth; and grinding to eliminate theink layer on the metal layer and sharpening the edge of the cutter. In the present invention, cutter is formed together with its seat and this leads to simple, convenient production process suitable for mass production. The cutter has certain toughness for coating to rolling-type cutting bench.

Owner:王金涂

Anterior cervical instrumentation systems, methods and devices

Owner:SPINAL ELEMENTS INC

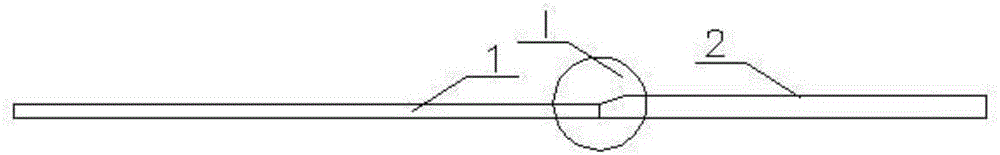

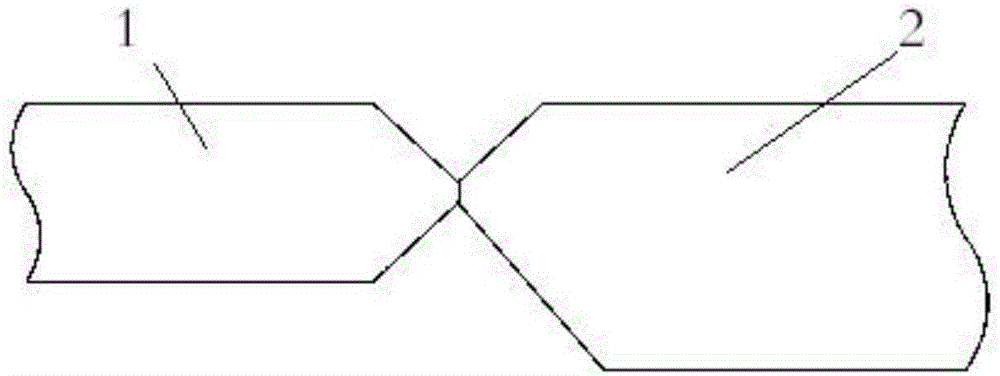

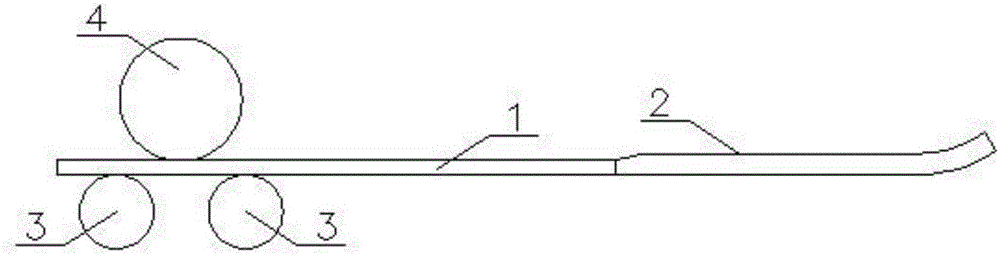

Method for manufacturing unequal thickness steel pipe

A method for manufacturing an unequal thickness steel pipe comprises: firstly, a thin steel plate (1) and a thick steel plate (2) that have different thicknesses are connected as an unequal thickness steel plate by welding; secondly, a roller machine is used to pre-roll two external ends of the thick steel plate and the thin steel plate that are constituted of the unequal thickness steel plate; through reciprocating roll of a lower roll wheel (3) and an upper roll wheel (4), two ends of the unequal thickness steel plate are rolled to warp upwardly; thirdly, areas except the two warped ends of the unequal thickness steel plate are rolled to make the steel plate gradually roll as a pipe shape; fourthly, misaligned edges (6) at two end ports of longitudinal seams (5) that are about to be closed and misaligned edges (7) of an outer round camber at two ends of the abutted unequal thickness steel plate are rectified and welded and the longitudinal seams are abutted, thus forming an unequal thickness steel pipe; Lastly, the roundness is rectified. According to the invention, the existing conventional roller machine is adopted to roll the unequal thickness steel plate as an unequal thickness steel pipe with arc shape.

Owner:YCIH STEEL STRUCTURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com