Method of manufacturing a mounting frame for a vehicle wind deflector

a technology for wind deflectors and mounting frames, which is applied in the direction of vehicle bodies, monocoque constructions, domestic objects, etc., can solve the problems of high cost, difficulty in achieving wind resistance, and difficulty in achieving custom fairing designs with different lower edge profiles for each tractor styl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

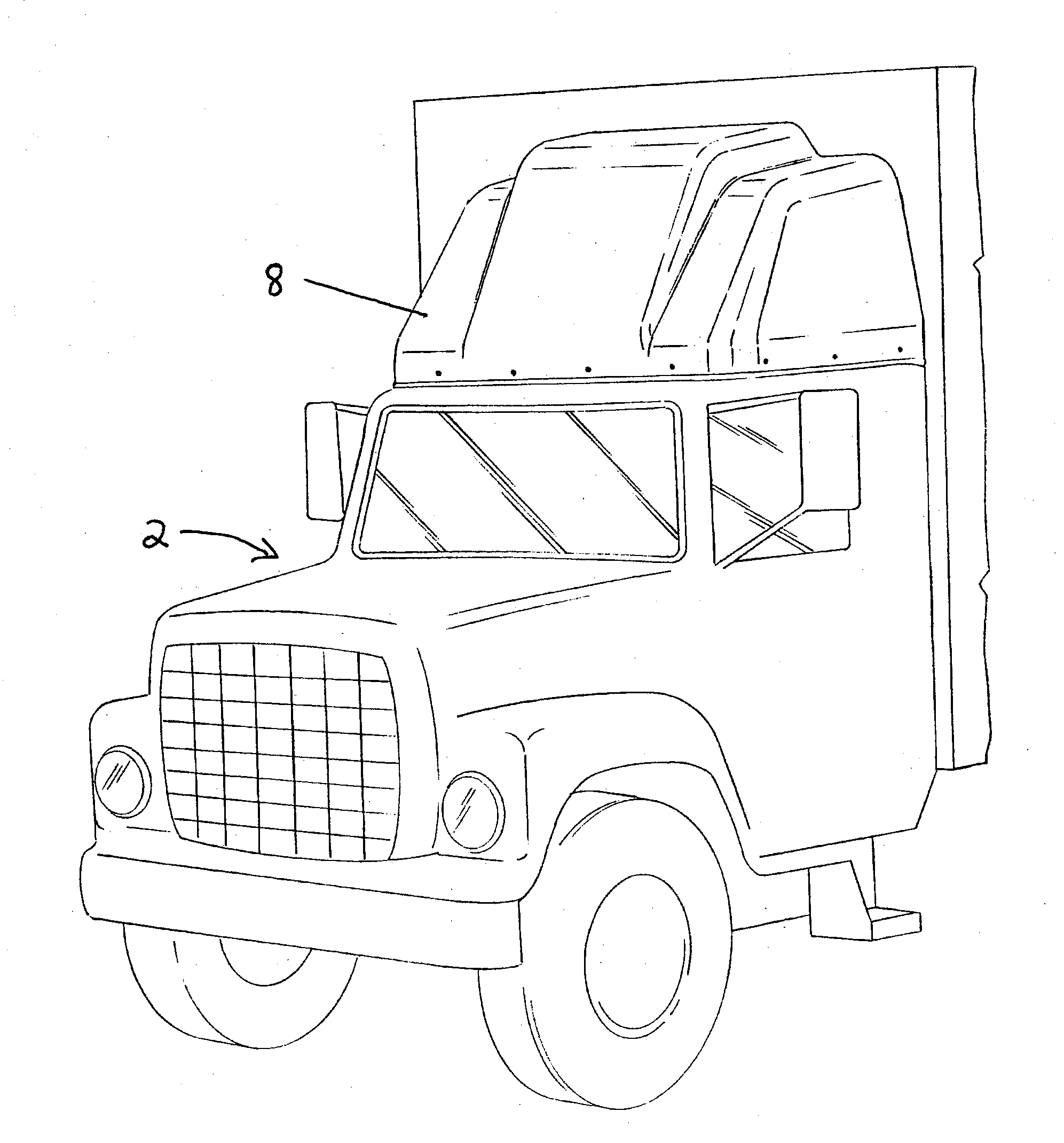

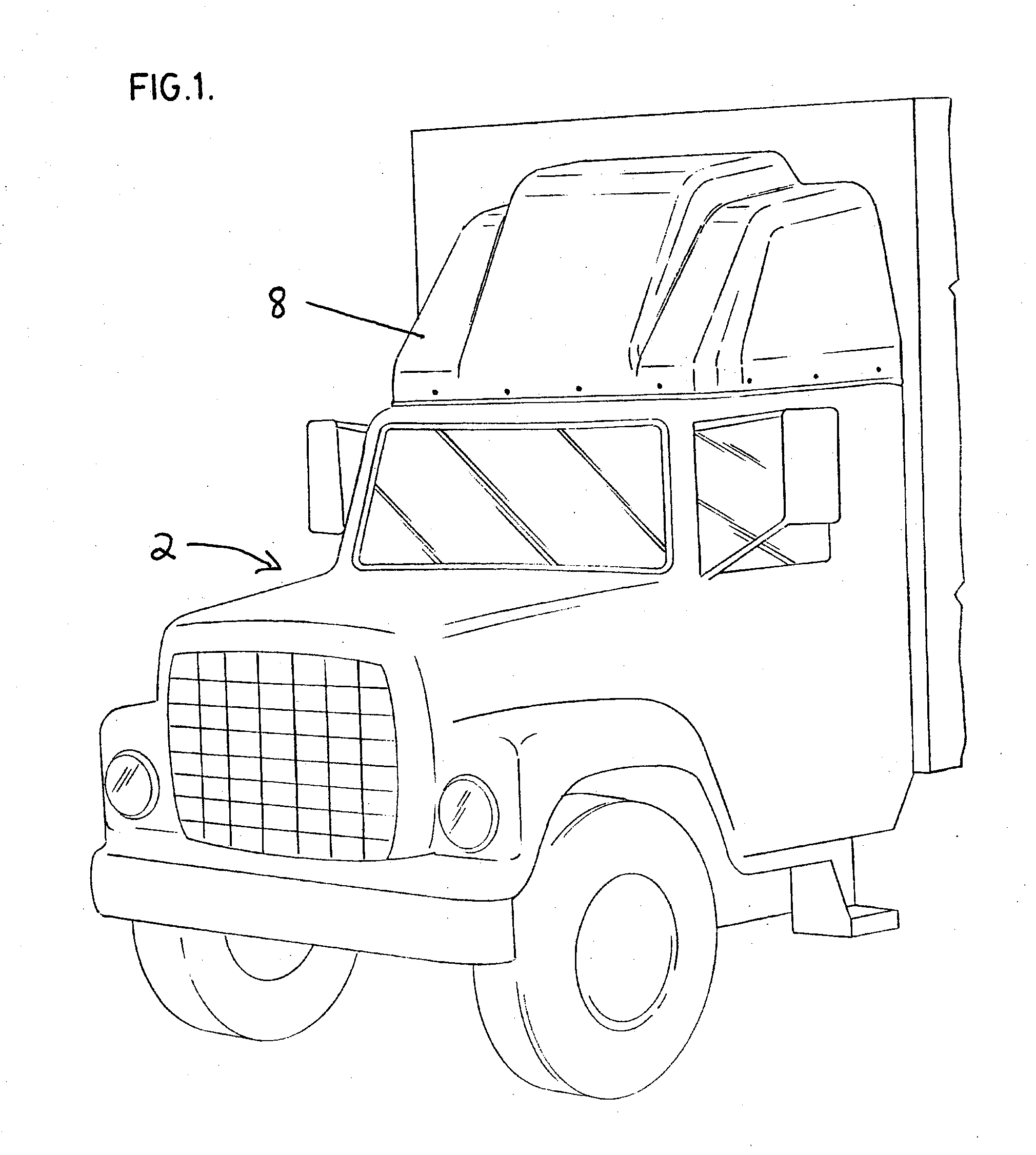

[0011]The present invention provides a method and device for mounting a fairing to the roof of a vehicle, and a method of manufacturing the device.

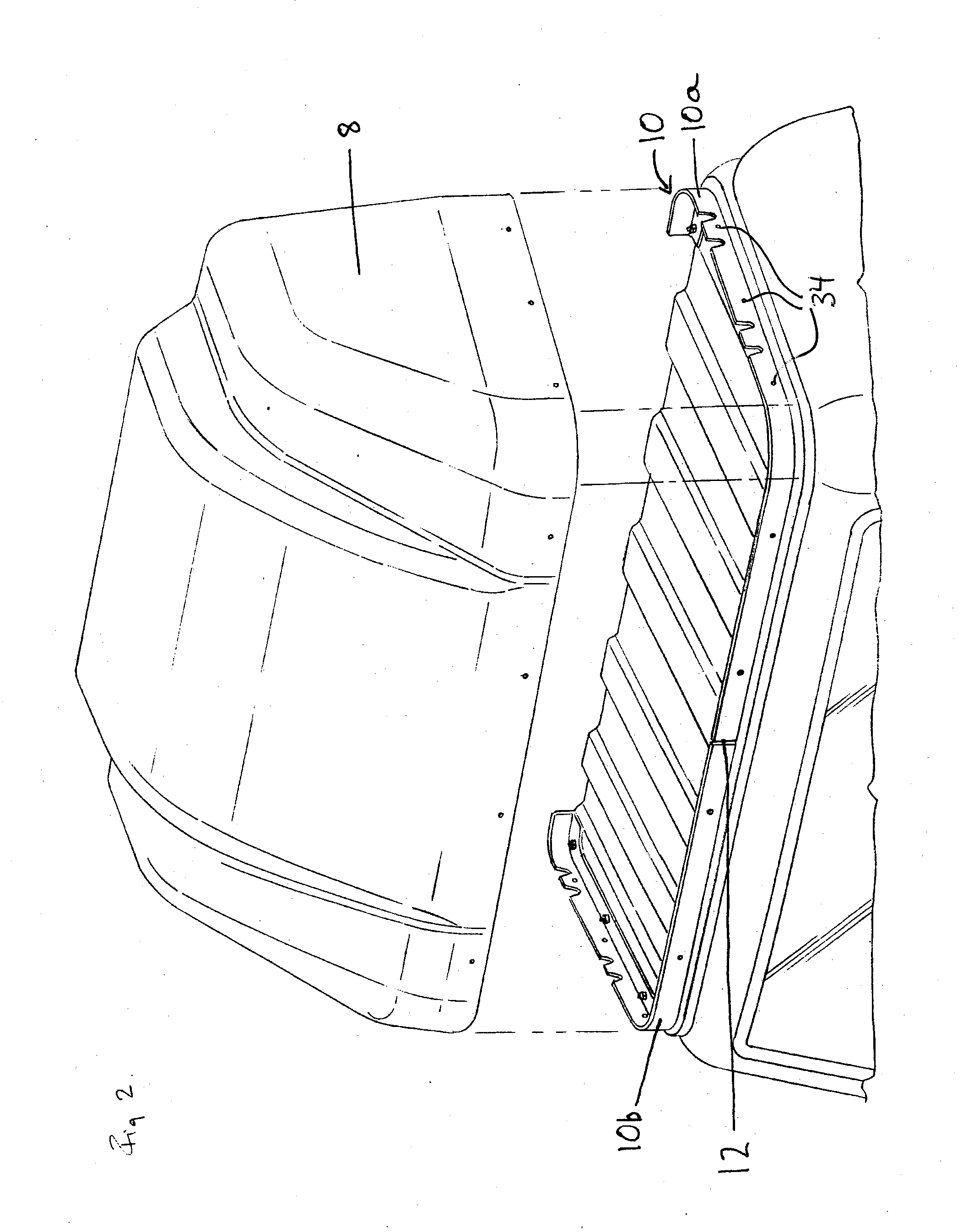

[0012]The invention provides a method of manufacturing a mounting frame for mounting a fairing to a roof of a vehicle, the roof having a mounting surface, the mounting frame having a lower portion for mounting to the roof and an upper portion for securing the fairing, the method comprising the steps of: a. determining a contour of the mounting surface; b. creating at least one mould for moulding a lower portion of the mounting frame having a bottom edge configured generally complementary to the contour of at least a portion of the mounting surface; and c. moulding the lower portion and an upper portion of the mounting frame, the upper portion affixed to or integral with the lower portion and having an outer face configured generally complementary to an interior surface of the fairing.

[0013]The invention further provides a method of mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com