Method for producing cutter

A manufacturing method and die technology, applied in metal processing and other directions, can solve problems such as reducing manufacturing costs, and achieve the effects of reducing manufacturing die costs, saving man-hours, and saving tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

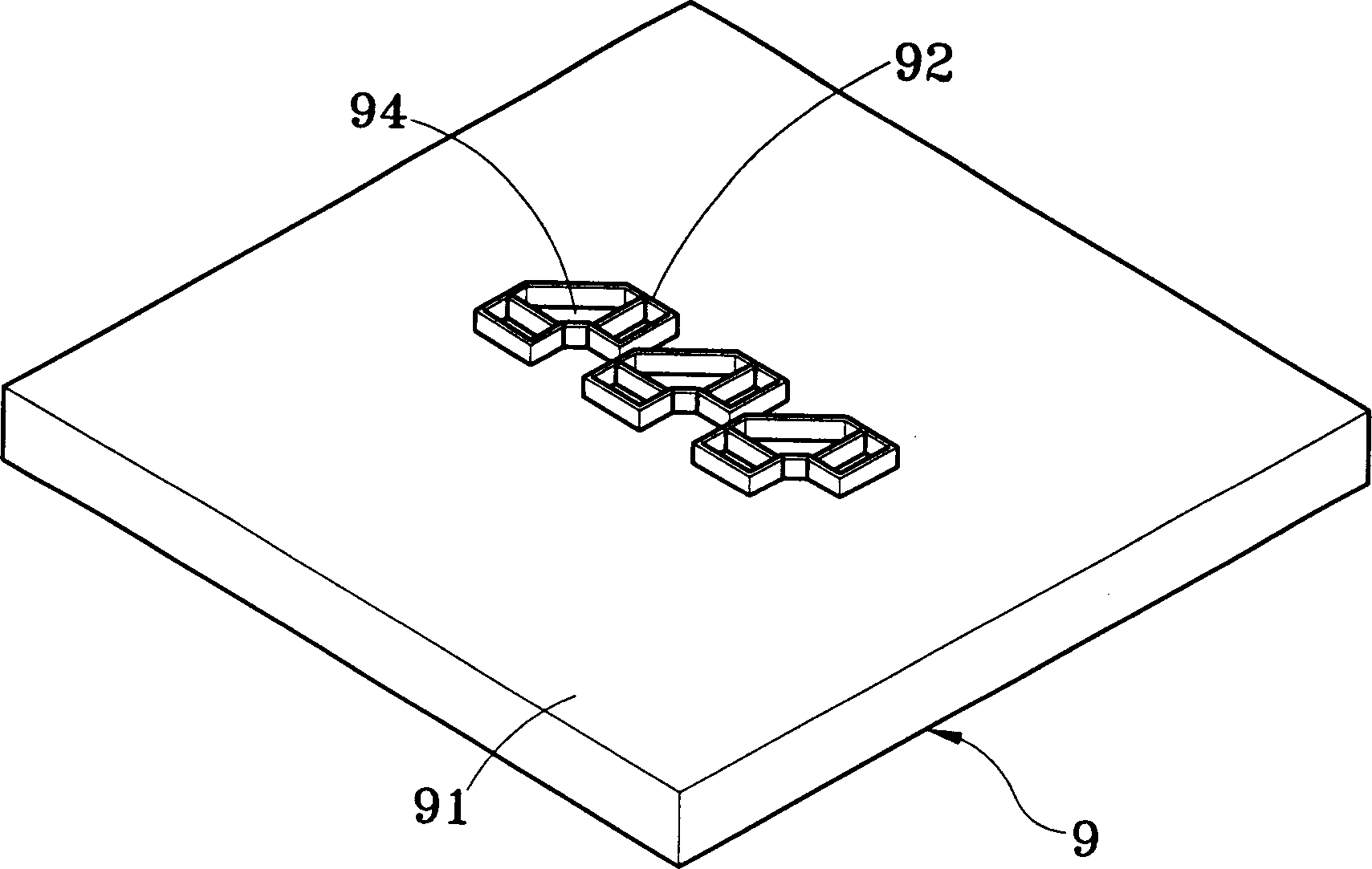

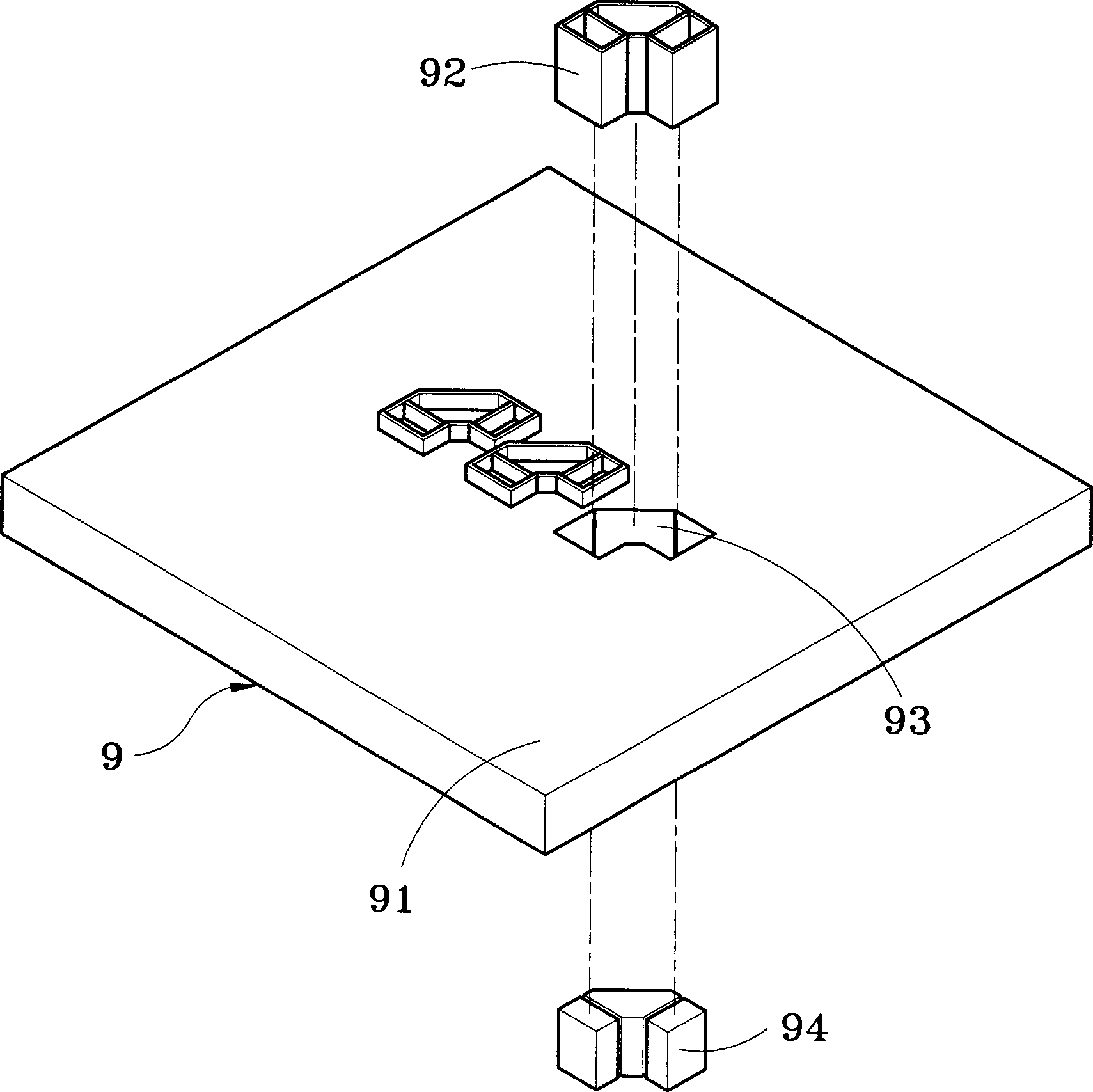

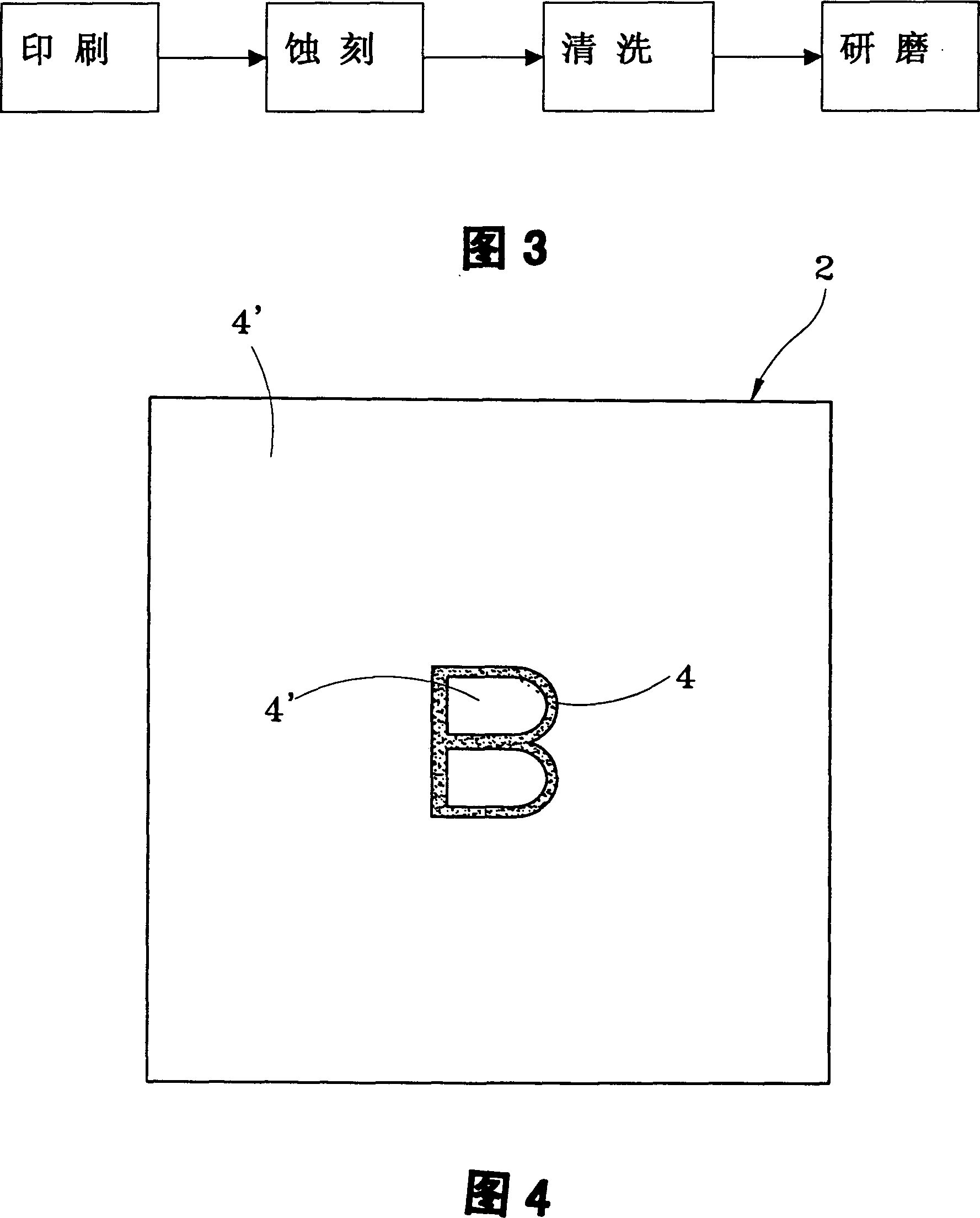

[0031] Please refer to Figure 3, Figure 4, Figure 5 , Figure 6 , Figure 7 As shown, the present invention first gets a metal plate 2 of about 1 mm when making the die 1, and prints a knife pattern formed by an ink layer 4 on the surface of the metal plate 2. After the printing process is completed, it is formed on the surface of the metal plate 2. There are two types of regions, the ink layer 4 and the ink-free layer 4'. After the ink layer 4 printed on the above-mentioned metal plate 2 is dried, carry out the etching process of the second step, and soak the metal plate 2 in a soaking container with an etching agent. The region of the ink-free layer 4 ′ on which no cutter pattern is printed on the surface is etched and sunken by the etchant. The etching speed can be adjusted by selecting and adjusting the type, concentration and temperature of the etching reagent. After the metal plate 2 etching process is completed, the metal plate 2 is immediately taken out and cleane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com