Layered testing and adjustment process for injection well

A technology for layered testing and injection wells, which is used in surveying, wellbore/well components, and production fluids, etc., and can solve the problems of long time consumption, complex operation, and high skill requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

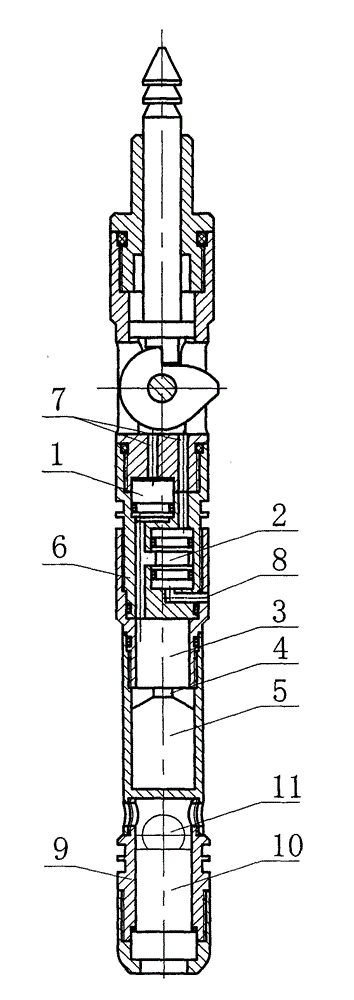

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] As shown in the figure, the injection well layered testing and deployment process includes a built-in tubing pressure sensor in the upper cavity of the upper body, a built-in differential pressure sensor in the upper body cavity at the lower end of the tubing pressure sensor, and a built-in differential pressure sensor in the upper end of the tubing pressure sensor and a differential pressure sensor. The upper body at the upper end has oil pipe pressure transmission holes that communicate with the oil pipe, the upper body at the lower end of the pressure difference sensor has formation pressure transmission holes that communicate with the formation, and the upper end of the lower body is sealed from top to bottom. The circuit board, the communication joint and the battery, a ceramic faucet is built in the lower end of the lower main body, and a plugged flow meter comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com