Patents

Literature

31results about How to "Expansion of mining area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep low penetrating oil layer thin oil fire flooding horizontal well gas-injection horizontal well oil production process technology

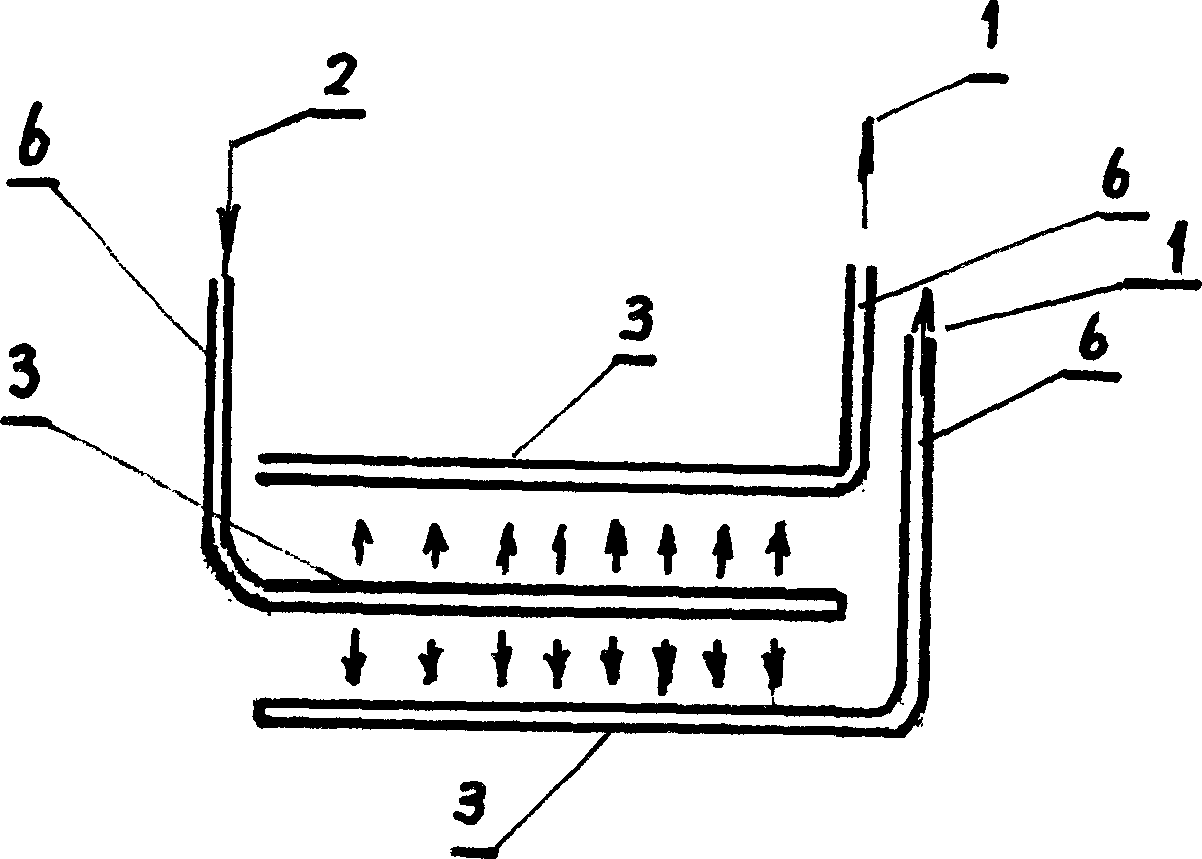

The present invention relates to a deep-layer low-permeability oil reservoir thin oil combustion drive horizontal well air injection horizontal well oil production technique. It is characterized by that said invention utilizes the heat quantity produced in air injection horizontal well section as firing drive oil reservoir and transfers the heat quantity into the horizontal oil-producing wells distributed at two sides of the air injection horizontal well section so as to make the thin oil be recovered from the oil-producing wells.

Owner:尤尼斯油气技术(中国)有限公司

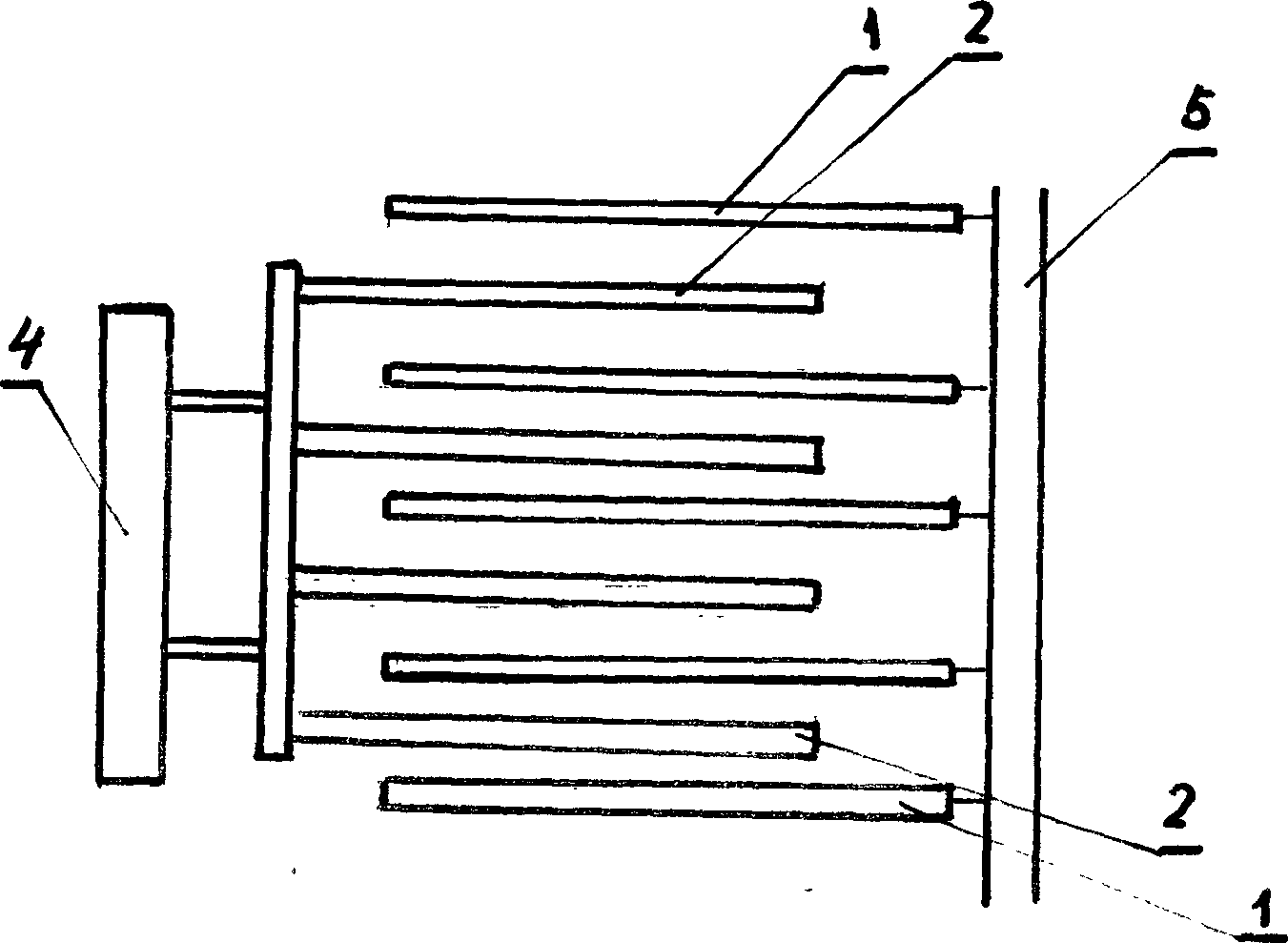

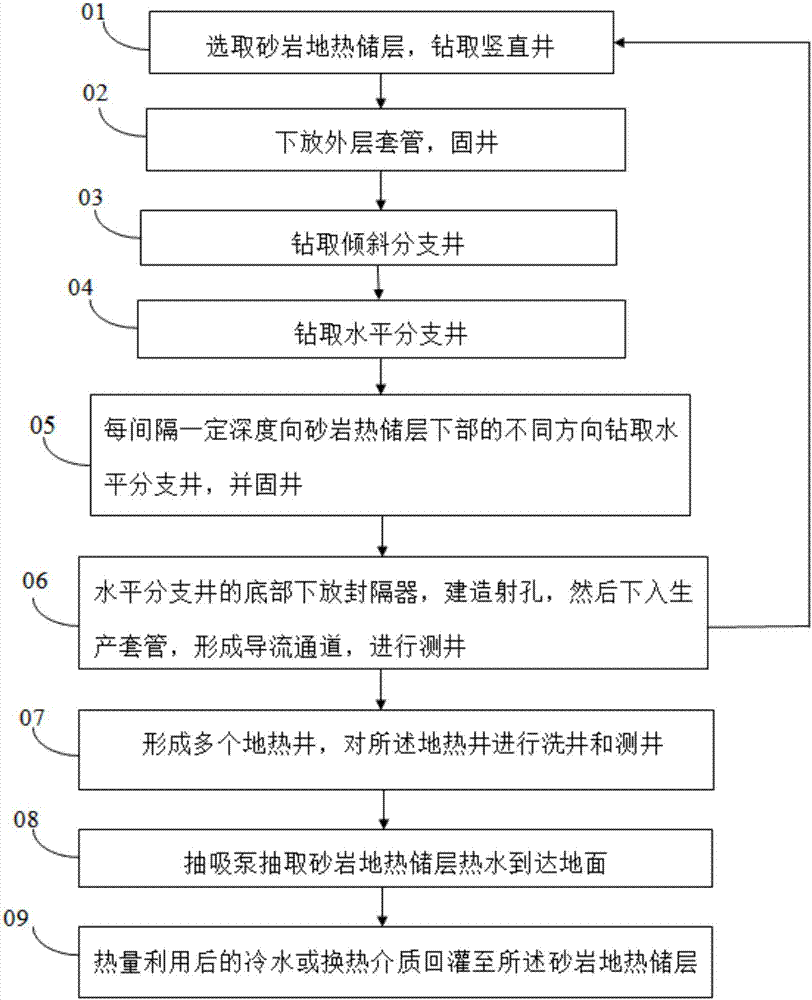

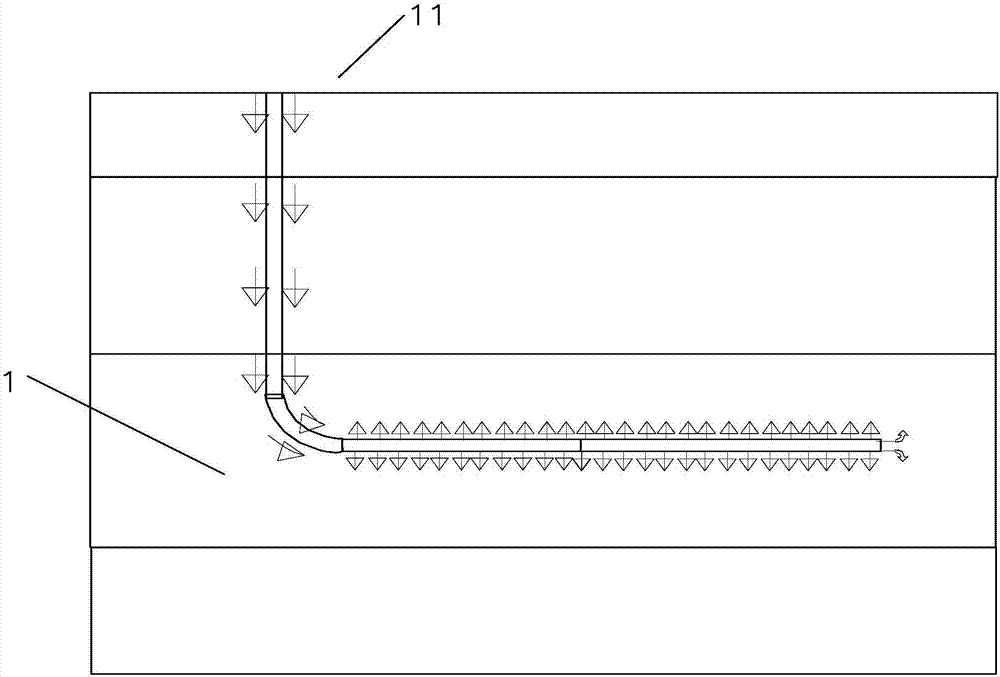

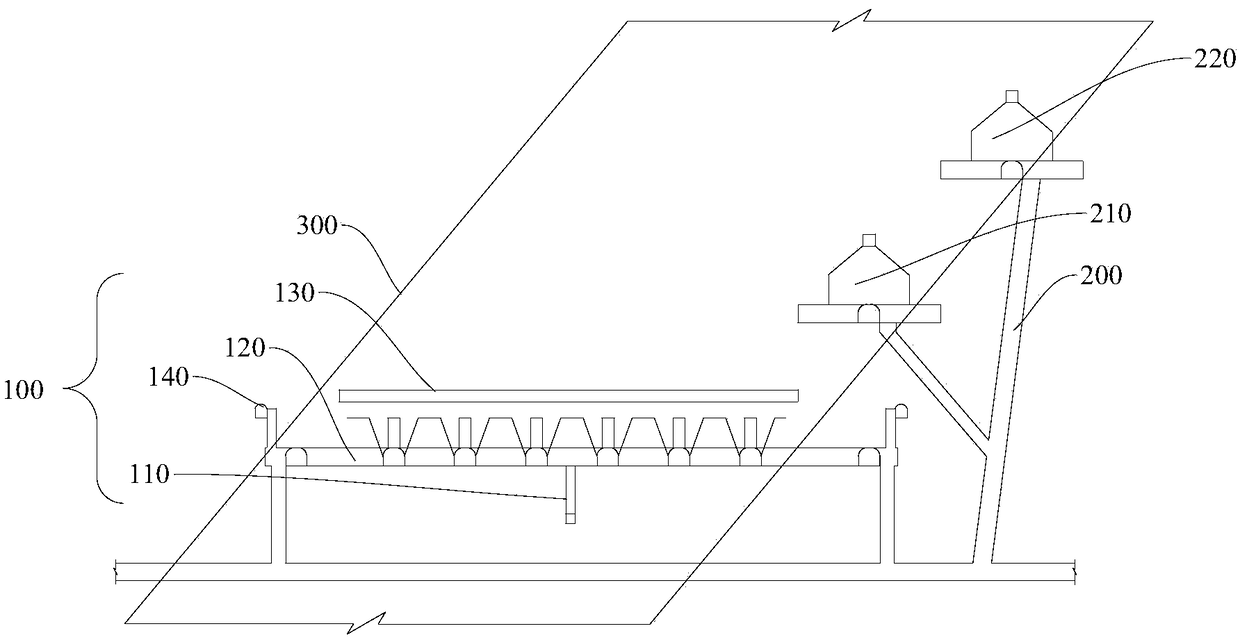

Medium-deep sandstone geothermal horizontal level exploitation method and structure

PendingCN106978993AIncrease geothermal mining productionSpeed up miningOther heat production devicesGeothermal energy generationWell drillingHorizontal wells

The embodiment of the invention discloses a medium-deep sandstone geothermal horizontal level exploitation method and structure. A horizontal well is built on a sandstone geothermal reservoir, a production well composed of a vertical well and the horizontal well is formed, and finally, the novel technology and method for exploiting and recharging the geothermal generation well are formed; the horizontal well is a single horizontal well or a plurality of parallel horizontal wells; the effective contact superficial area of the drilled well and the reservoir is increased, the exploitation and recharging efficiency is improved, the geothermal well yield is greatly increased, and economic benefits are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

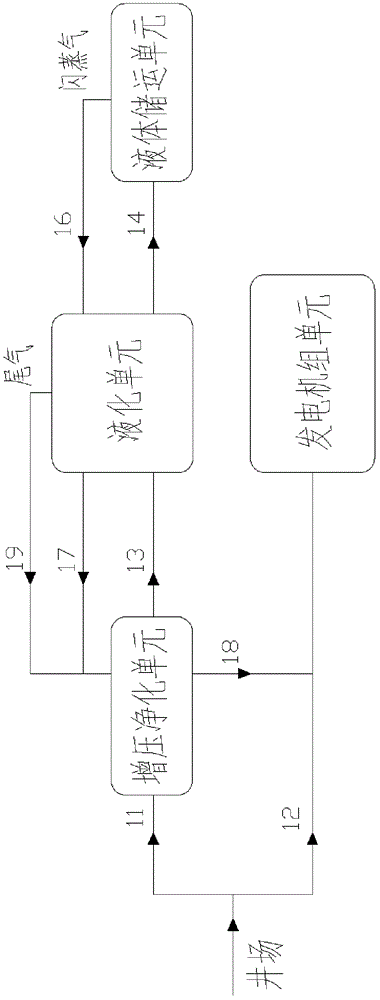

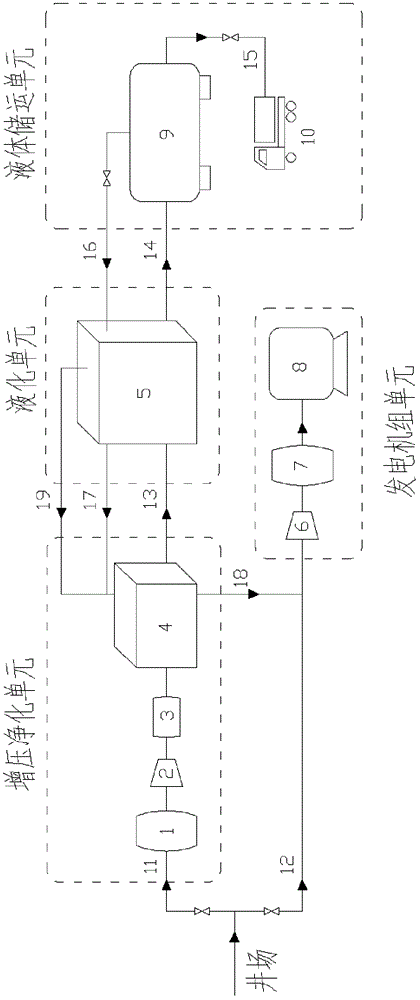

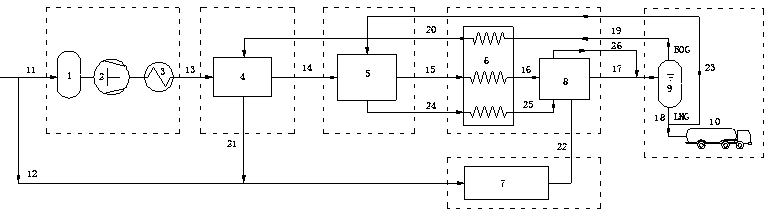

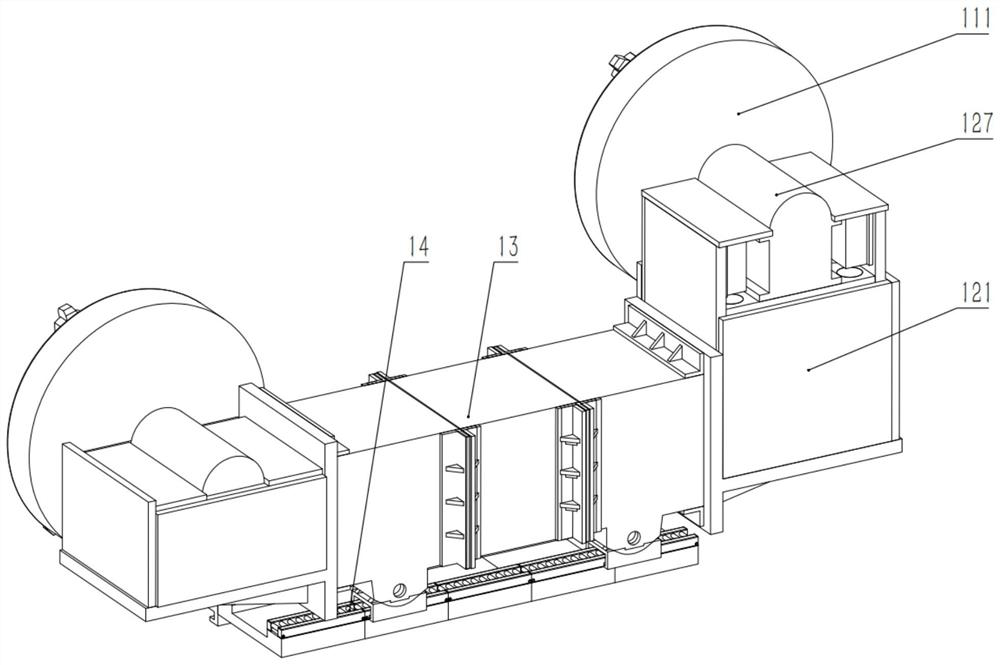

Method and system for coalbed methane liquefaction

InactiveCN103060036AIncrease profitExpansion of mining areaSolidificationLiquefactionCooling capacityElectric power

A method and a system for coalbed methane liquefaction. The system comprises a pipeline pressurizing purification unit, a liquefaction unit, a liquid storage and transportation unit and a power unit, which are connected through pipelines. Coalbed methane extracted from well site is subjected to supercharging purification and low temperature liquefaction separation and enters into the liquid storage and transportation unit; a the power unit uses untreated coalbed methane and exhaust gas generated from each unit as raw materials for combustion power generation, so as to supply power for the whole system and achieve power self-sufficiency. The system is suitable for field environment without power supply conditions. Exhaust gas from the supercharging purification unit, the liquefaction unit, the storage and transportation unit and the power unit is employed for multiple functional utilization among units; the exhaust gas exchanges heat with a variety of media in different temperature ranges, so as to fully recover and utilize low temperature cooling capacity; pure gas is used as a regeneration gas for regeneration in the purification unit; and the part unable to be reuses is sent into the power unit for generating. The invention can reduce the system energy consumption, improve liquefaction rate of coalbed methane and reduce pollutant emissions.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

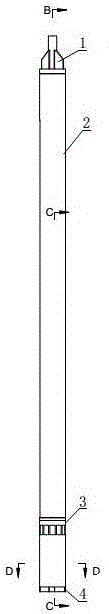

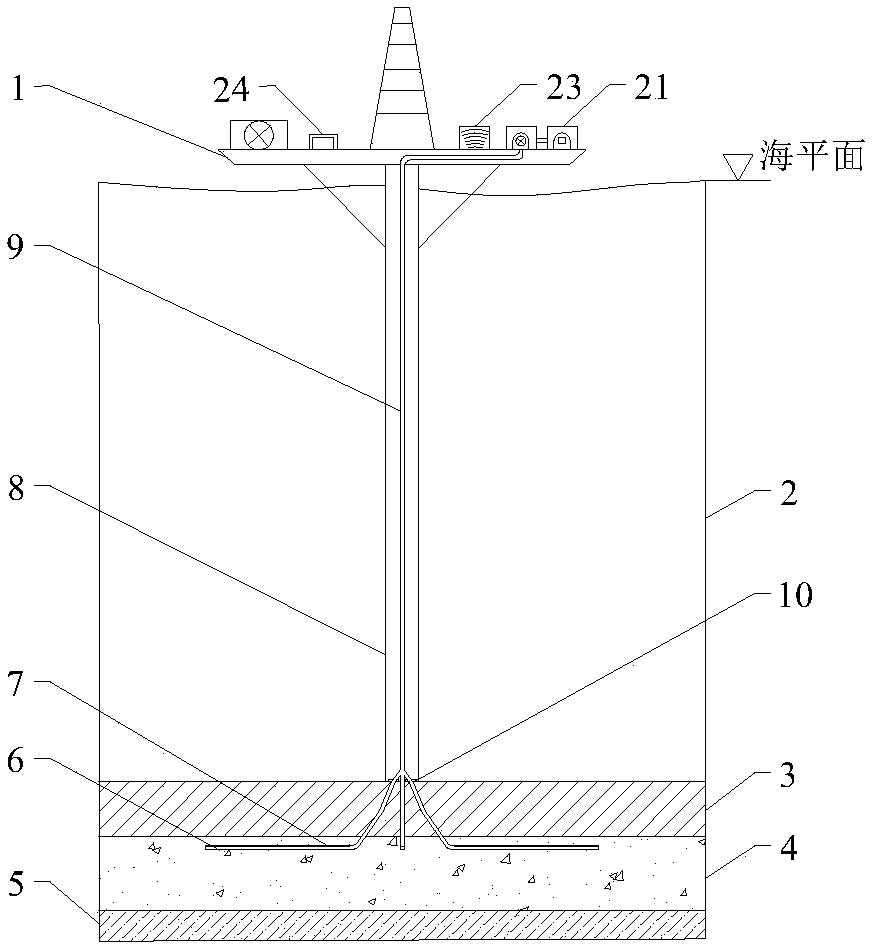

Suction type hydrate mining device and method

ActiveCN103046930ARealize large-scale commercial miningExpansion of mining areaMineral miningPipeflowSoft clay

The invention discloses a suction type hydrate mining device and method. The suction type hydrate mining device comprises a rubbing device, a hose, a piston type pushing device, a suction device, a water pipeline, a seawater injection system and a mining platform. The suction type hydrate mining device can suck soft mixtures of hydrate sediments, gas and water into the pipeline; hot water doping and stirring, hydrate decomposing, gas swelling and work doing and sediment separation can be carried out in the pipeline; and the gas can be collected through the mining platform. By the suction type hydrate mining device, no machine is used for dipping in deep water, so that the mining range is expanded; therefore, relatively high mining efficiency is realized; and hydrates in soft clay sediments can be commercially mined in large scale. A new way is supplied to mining of hydrate stratums with high hydrate content of soft clay sediments in the South China Sea and other areas; and a new method is supplied to mining of energy in the soft clay sediments.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

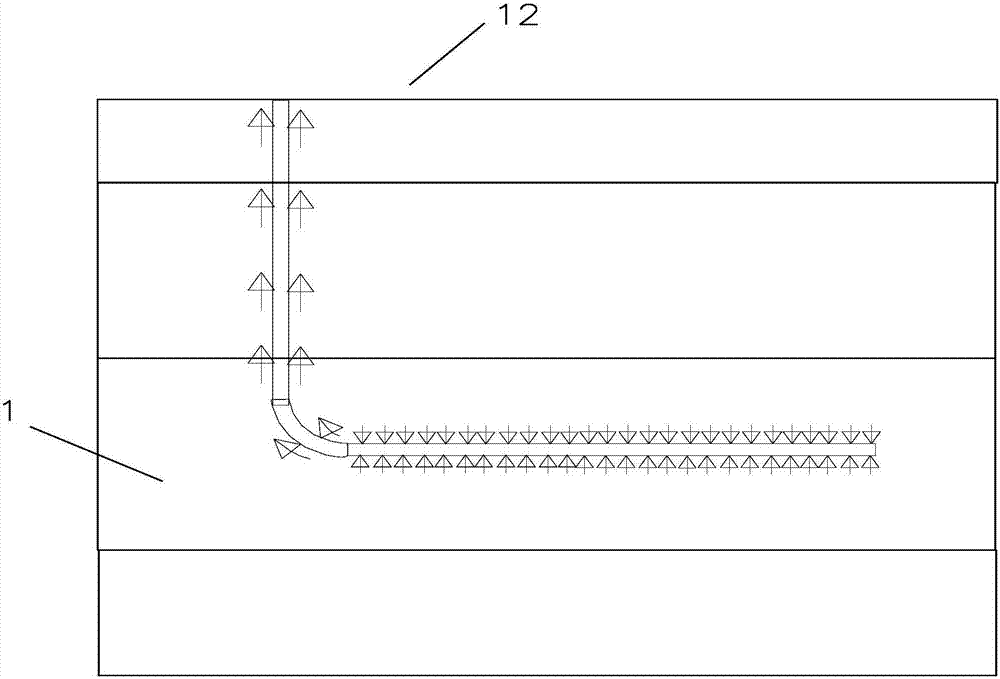

Method for coal bed gas exploitation of full working face through down-hole system

InactiveCN106677746AExpansion of mining areaSolve the problem that the exhaustion of the whole working face cannot be realizedFluid removalLine tubingGeomorphology

The invention provides a method for coal bed gas exploitation of a full working face through a down-hole system. The method comprises the following steps that a plurality of vertical wells are dug in the positions, a preset distance away from a main roadway along the full working face, on the ground, and all the vertical wells penetrate through a coal mine layer; horizontal wells are dug, the horizontal well sections of the horizontal wells are located in the coal mine layer, and the left-right deviation distances, relative to the vertical wells, of the horizontal well sections are between 0.3 m and 0.6 m; after the ground horizontal wells and the vertical wells are all completed, a down-hole horizontal well is dug in the main roadway along the coal mine layer, and the left-right deviation distance, relative to the vertical well nearest the main roadway, of the down-hole horizontal well is between 0.3 m and 0.6 m; a control pipe line is mounted on a well mouth of the down-hole horizontal well; cavity expansion is conducted on coal mine layer sections allowing the vertical wells to penetrate through reamer bits, and all the ground horizontal wells and the down-hole horizontal well communicate with all the vertical wells; and coal gas exploitation of the down-hole full working face is conducted through the control pipe line mounted on the well mouth of the down-hole horizontal well. According to the method for coal bed gas exploitation of the full working face through the down-hole system, the problem that pumping and drainage of the full working face cannot be achieved in the exploitation process of coal bed gas is solved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

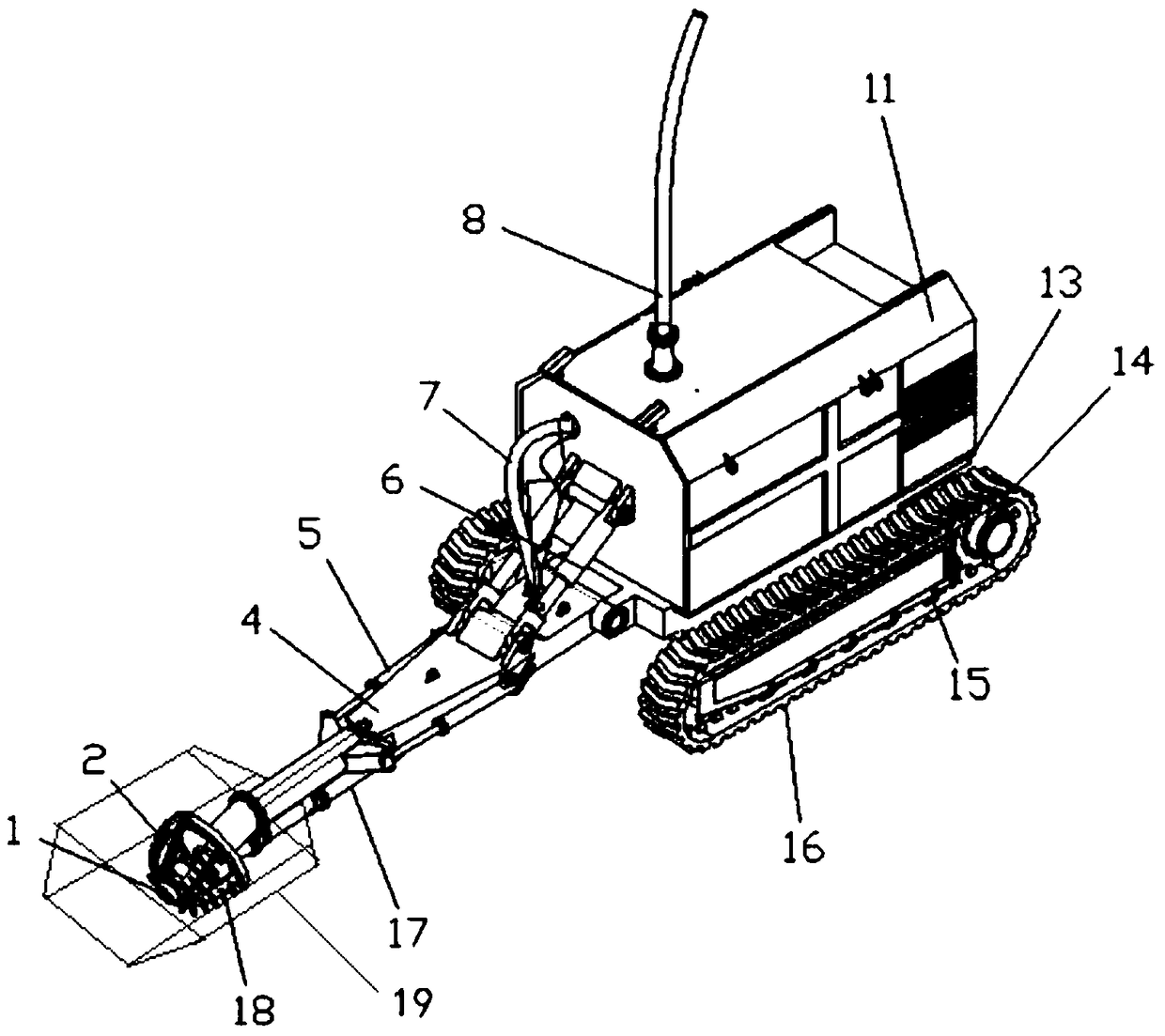

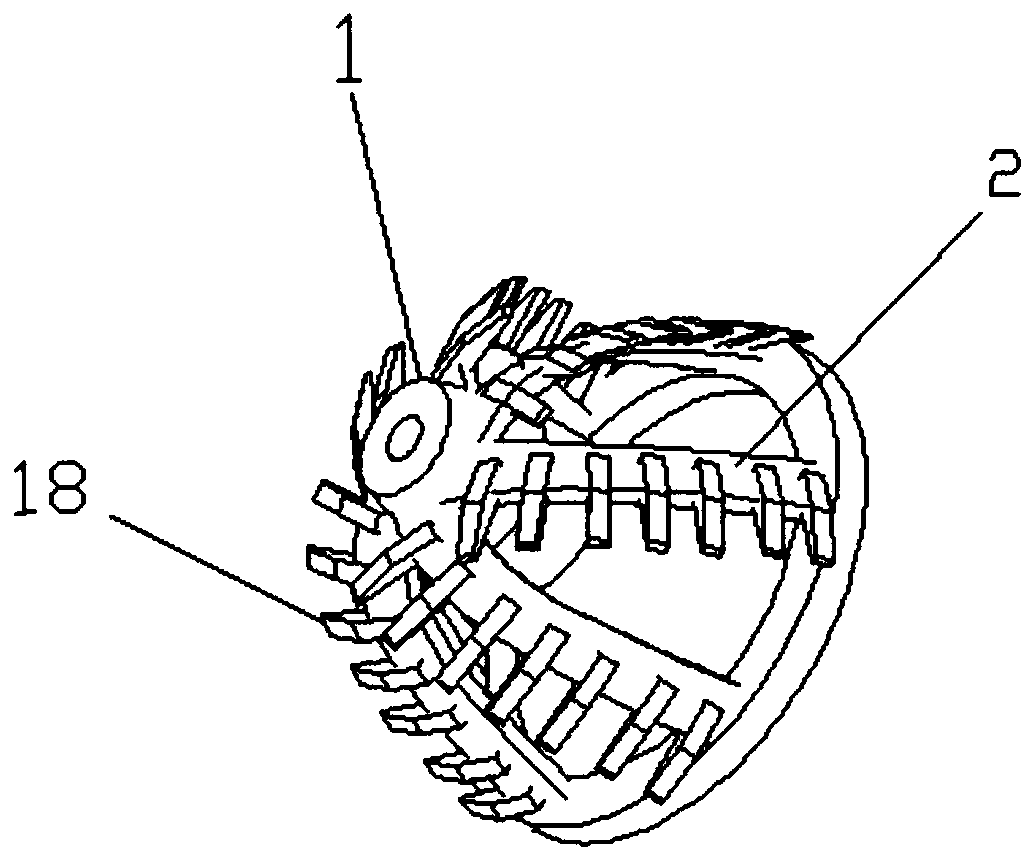

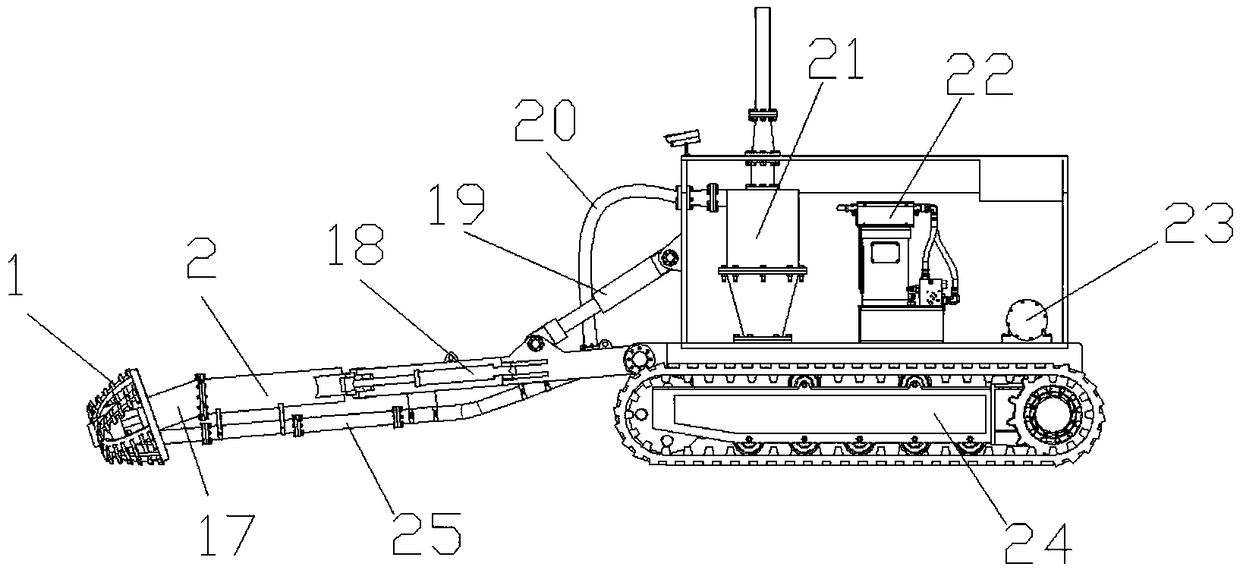

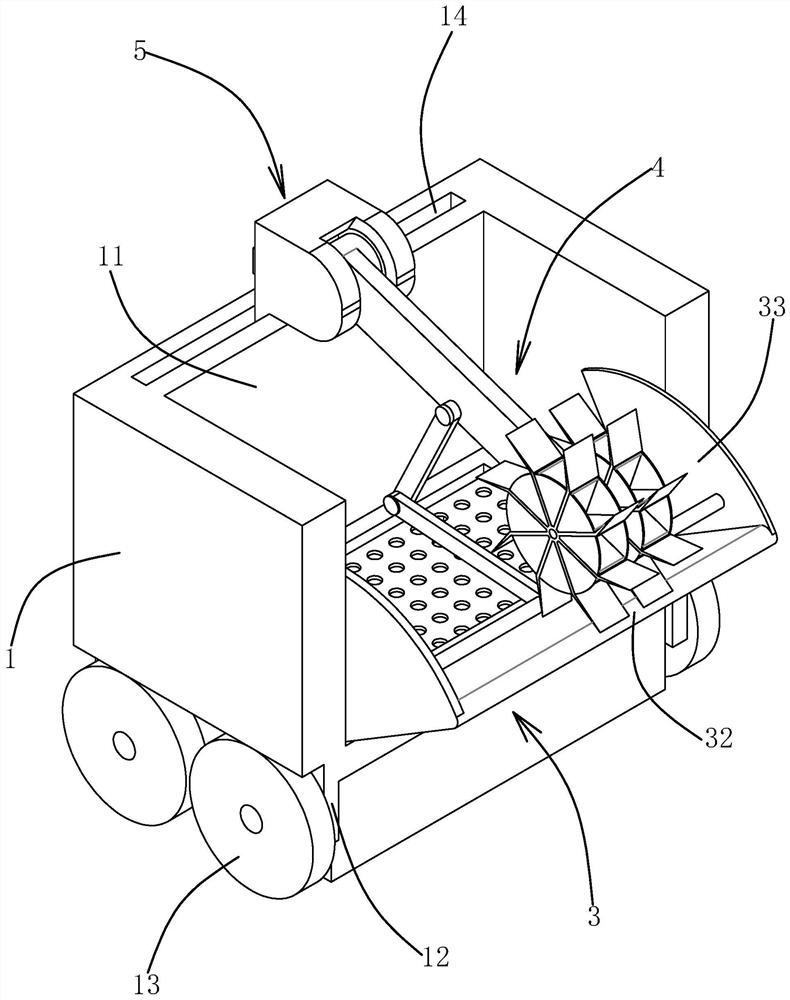

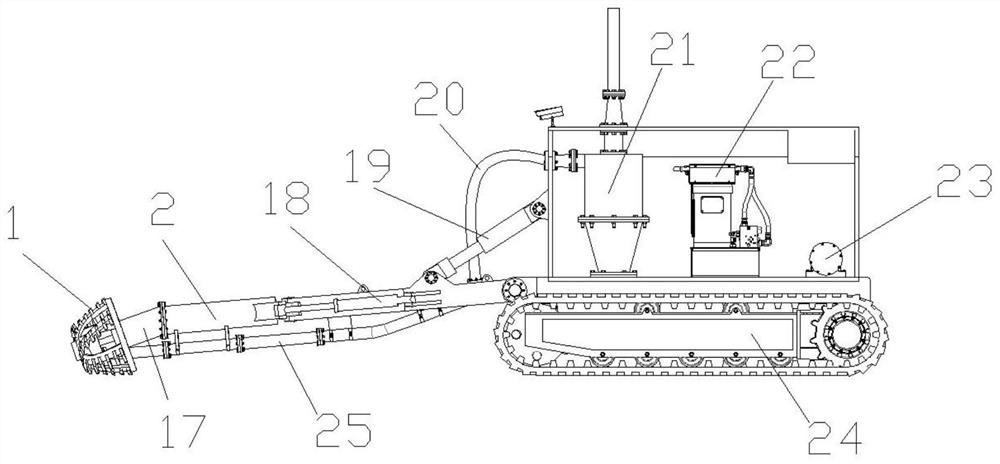

Cutter-suction natural gas hydrate collecting system

InactiveCN108871881AExpansion of mining areaIncrease the areaWithdrawing sample devicesNew energyHydraulic pump

The invention discloses a cutter-suction natural gas hydrate collecting system, which belongs to the technical field of new energy exploitation. The cutter-suction natural gas hydrate collecting system comprises a trolley, which comprises a cutter-suction head, a lever arm, a trolley body and a chassis, wherein the cutter-suction head is connected to bottom of front end of the trolley body with the lever arm; a pipeline is arranged under the lever arm for connecting cutter-suction head and trolley body; the trolley body is mounted on the chassis and is a hollow structure; a separator, hydraulic pump station and an electronic storehouse are provided in the trolley body; band tracks are provided on both sides of the chassis; the cutter-suction natural gas hydrate collecting system solves theproblems of small mining area for natural gas hydrate in current seabed and low efficiency of mining, integrates collection, transport and separation, has more reasonable lever arm structure for balanced stress, and is able to recycle major gasified combustible ice to protect the environment.

Owner:SOUTHWEST PETROLEUM UNIV

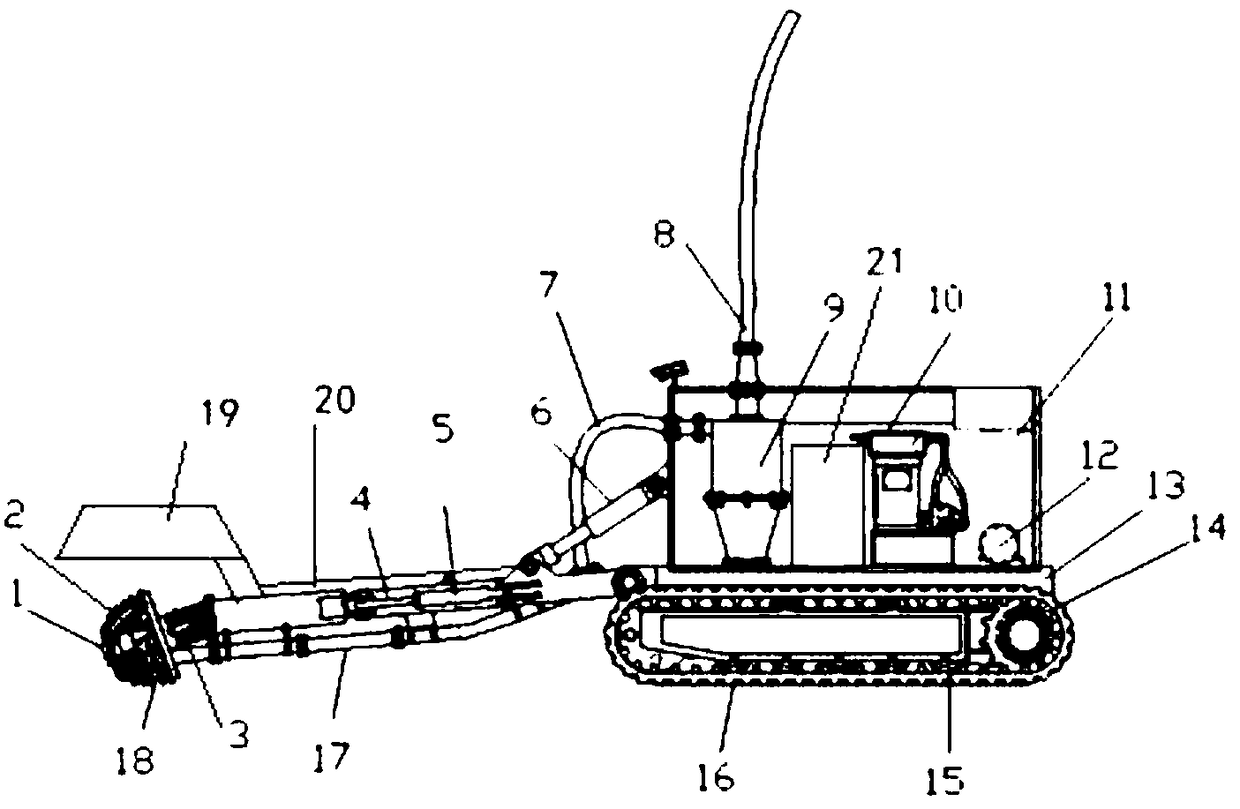

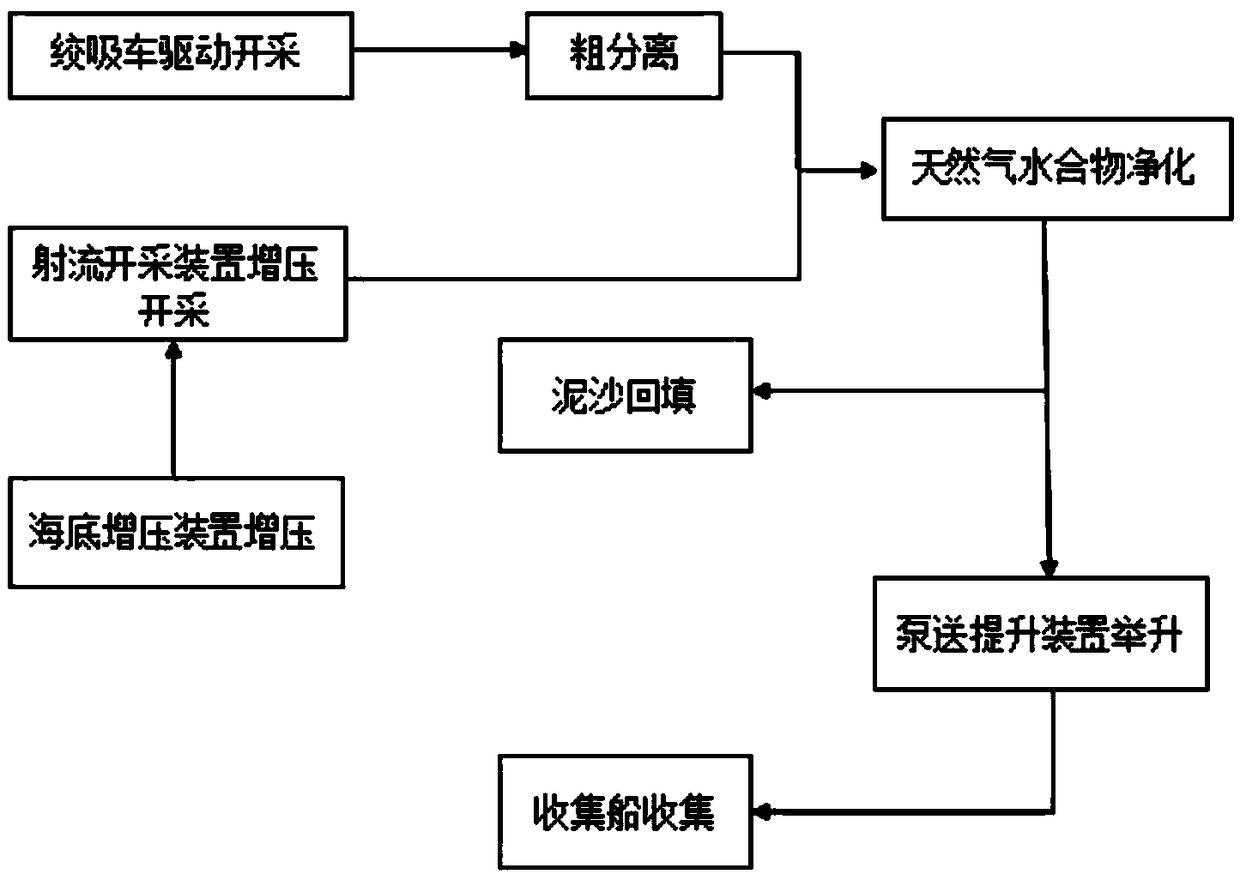

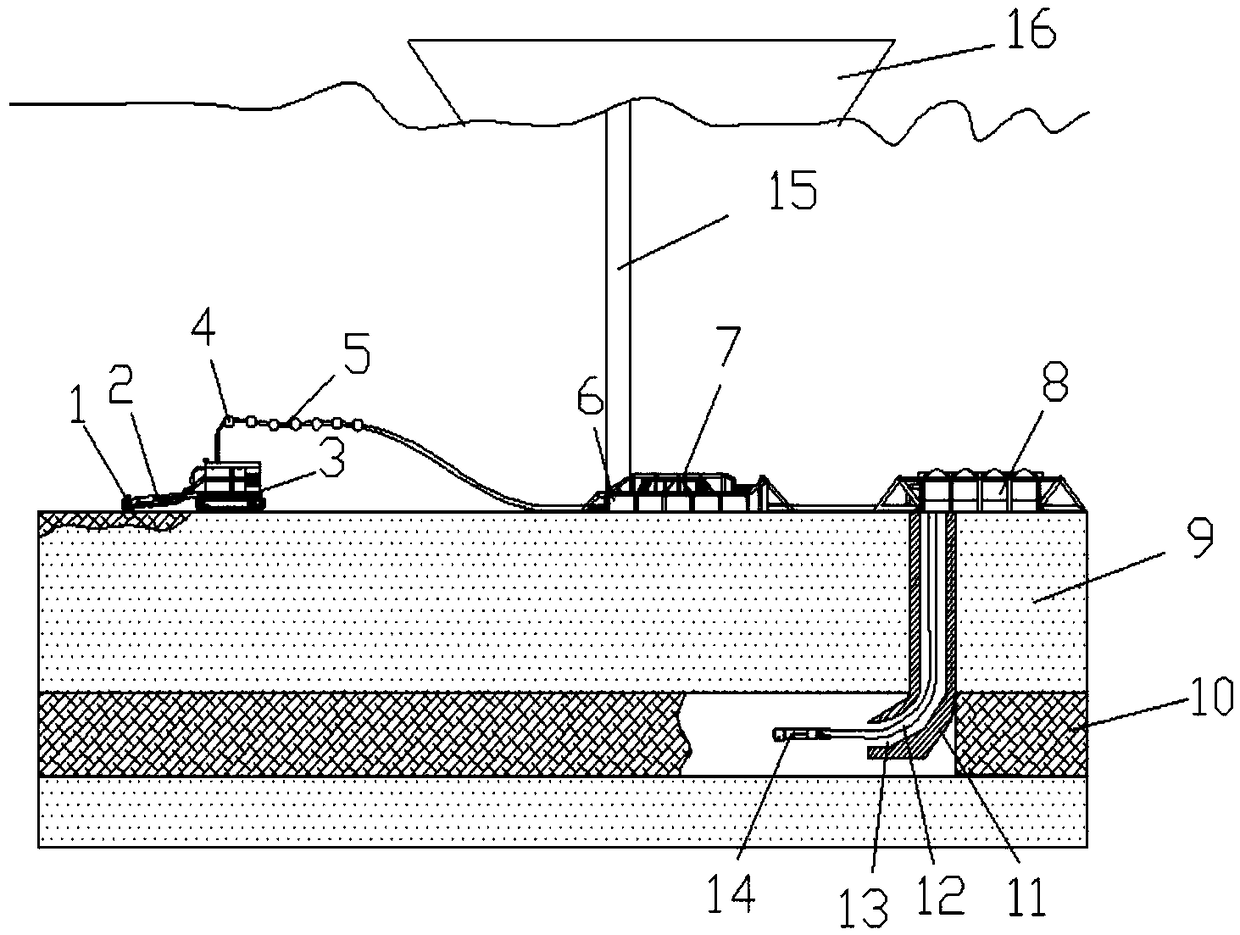

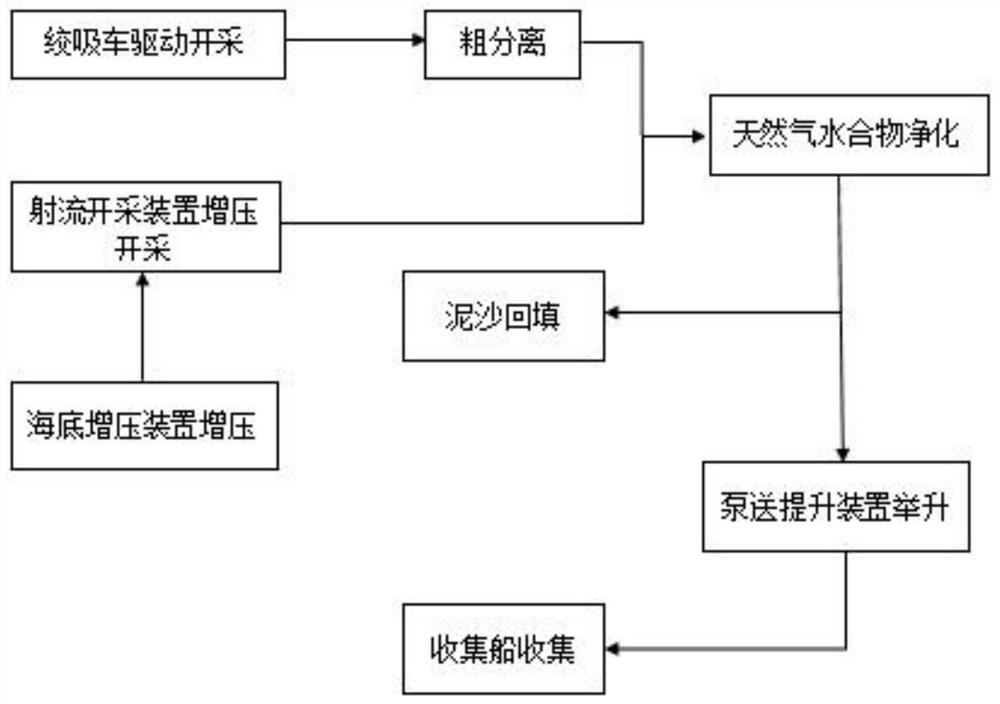

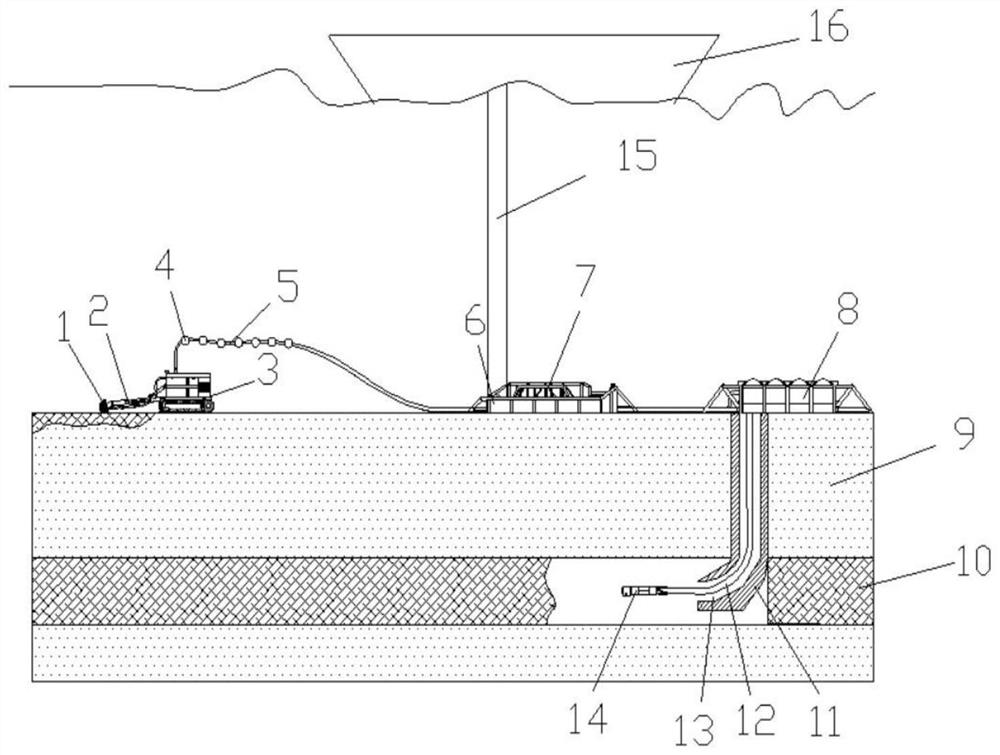

Seafloor natural gas hydrate mining system and method

InactiveCN108894755AImprove work efficiencyWide range of miningConstructionsFluid removalMineralogyNatural gas

The invention discloses a seafloor natural gas hydrate mining system and method, and belongs to the technical field of new energy mining. The system comprises a natural gas hydrate mining device, a driving device, a natural gas hydrate purifying device, a seafloor pressurizing device, a pumping lifting device, an L-shaped pipeline and a collecting ship; the natural gas hydrate mining device comprises a cutter suction mining device and a flow jetting mining device; the mining method comprises the steps of driving mining of a suction vehicle, pressurizing of the seafloor pressurizing device, pressurizing mining of the flow jetting mining device, purifying of natural gas hydrate, mud and sand refilling, lifting of the pumping and lifting device and the collection of the collecting ship; a coarse separating device is arranged in the cutter suction mining device. The method in which two mining manners are combined is adopted, mud and sand in the natural gas hydrate are removed while miningis conducted, each working procedure is operated independently, the recovery ratio of natural gas hydrate is effectively improved, and the system has better application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

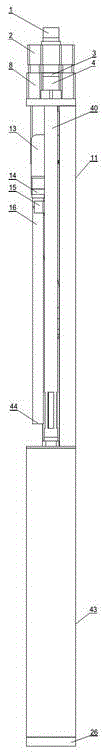

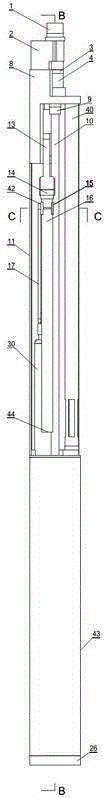

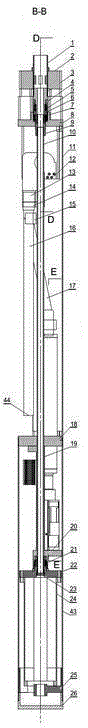

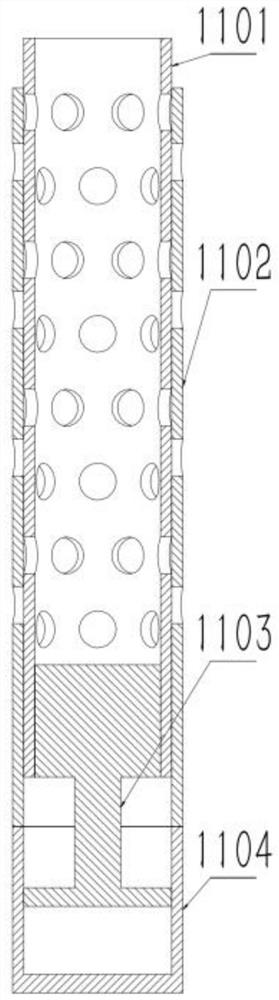

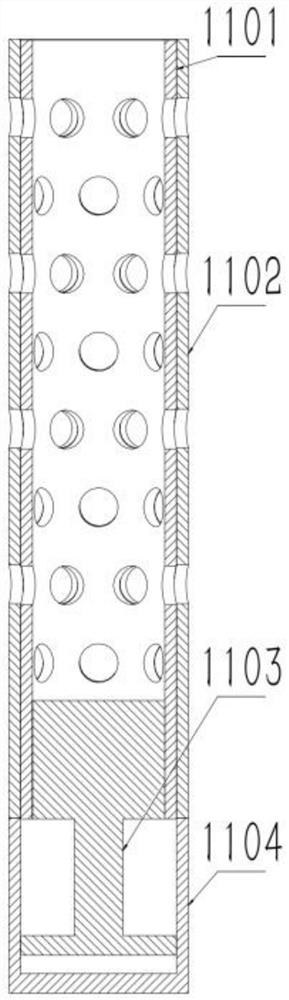

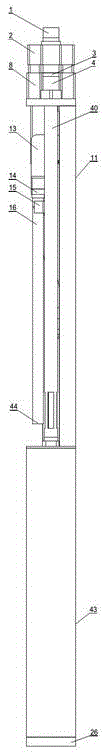

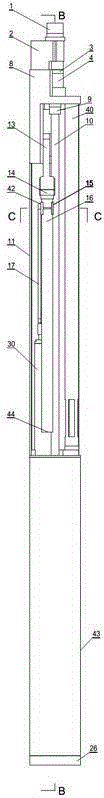

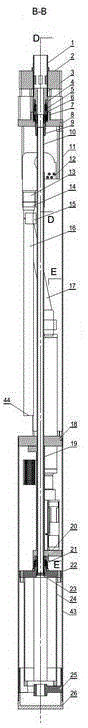

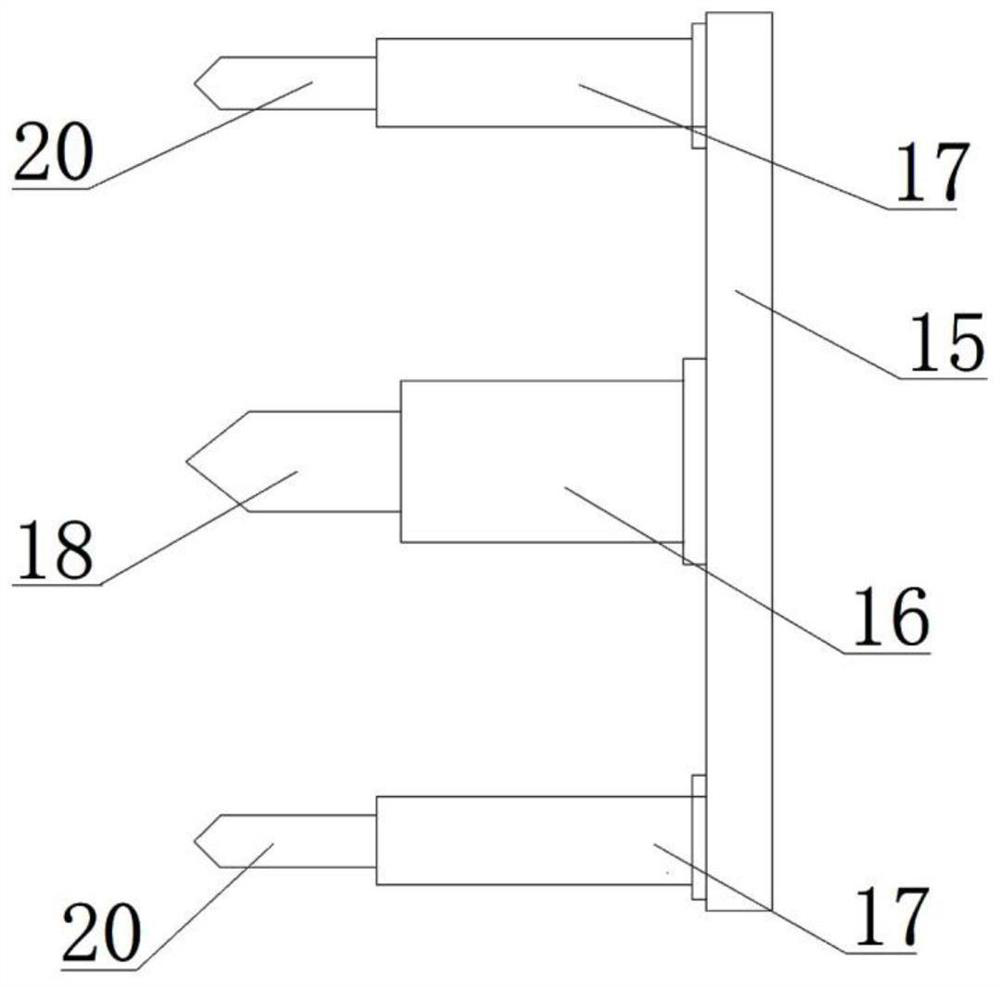

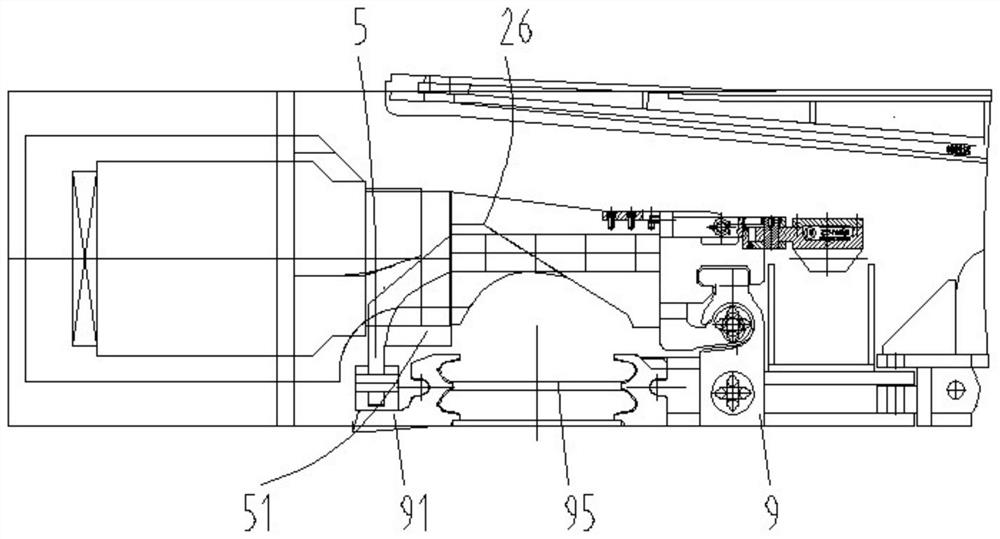

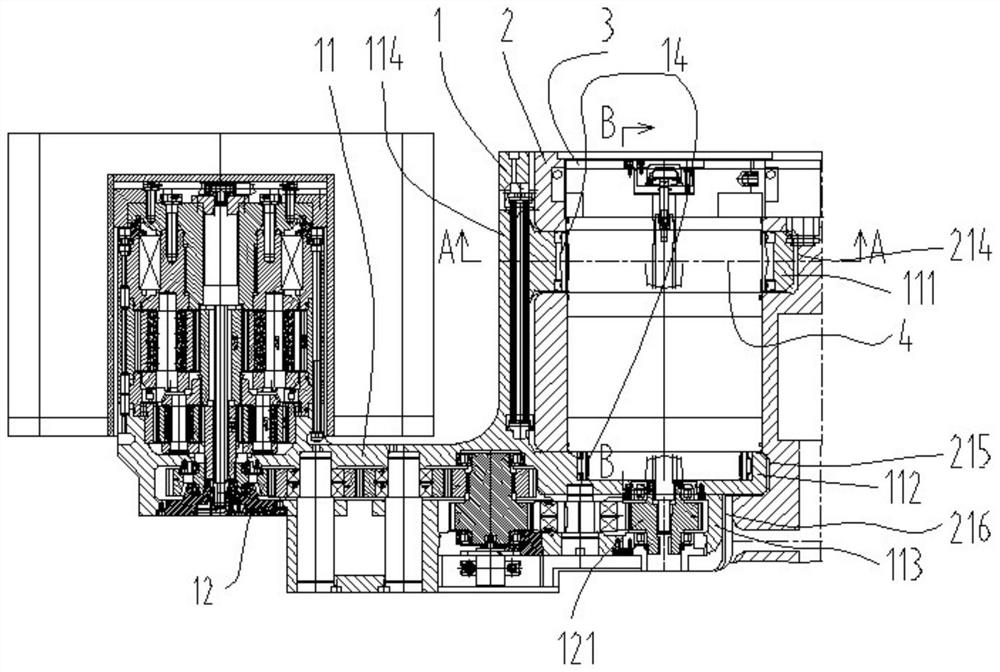

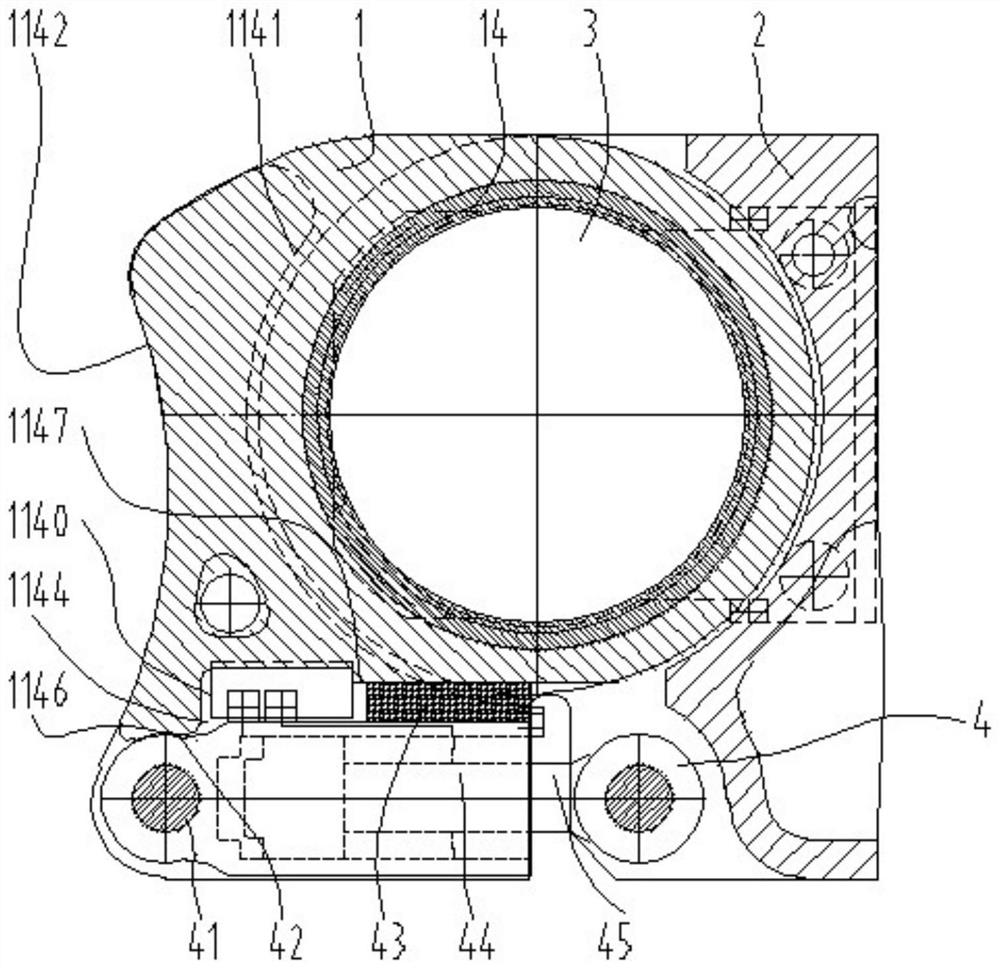

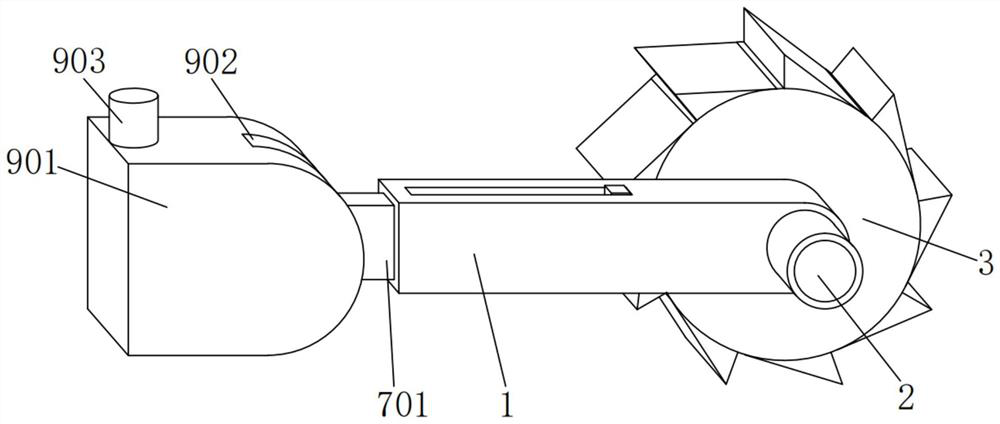

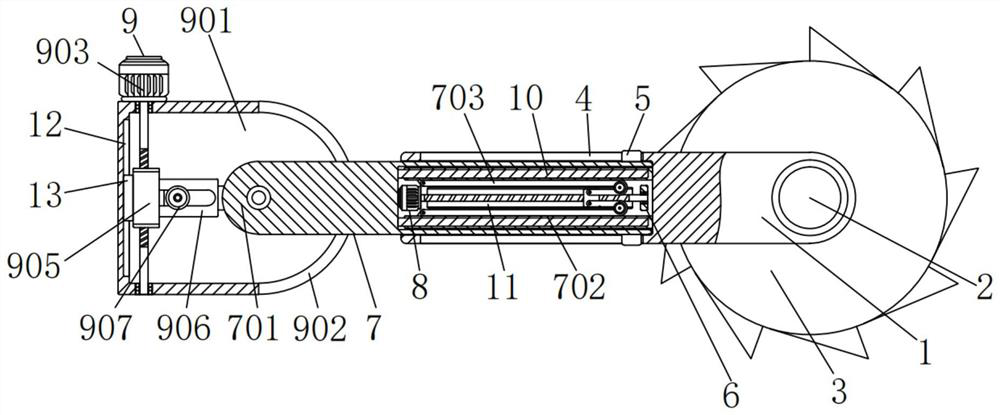

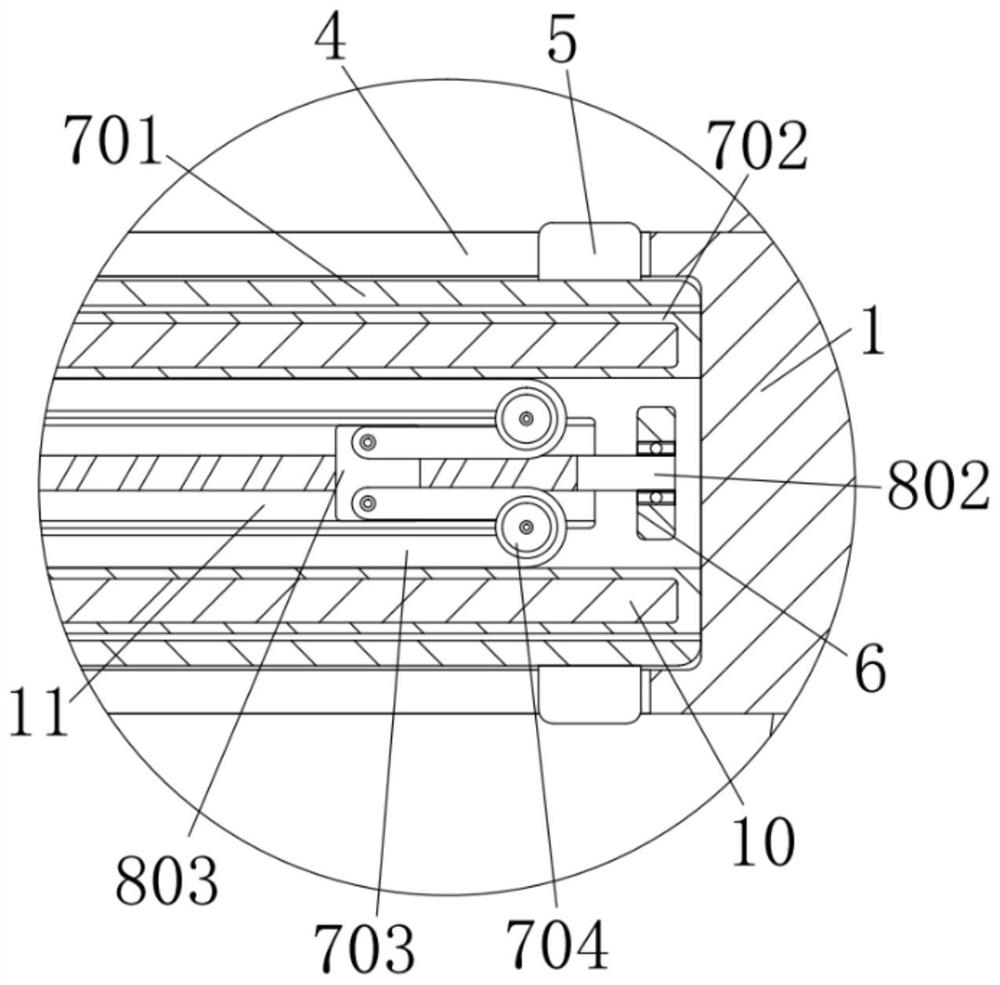

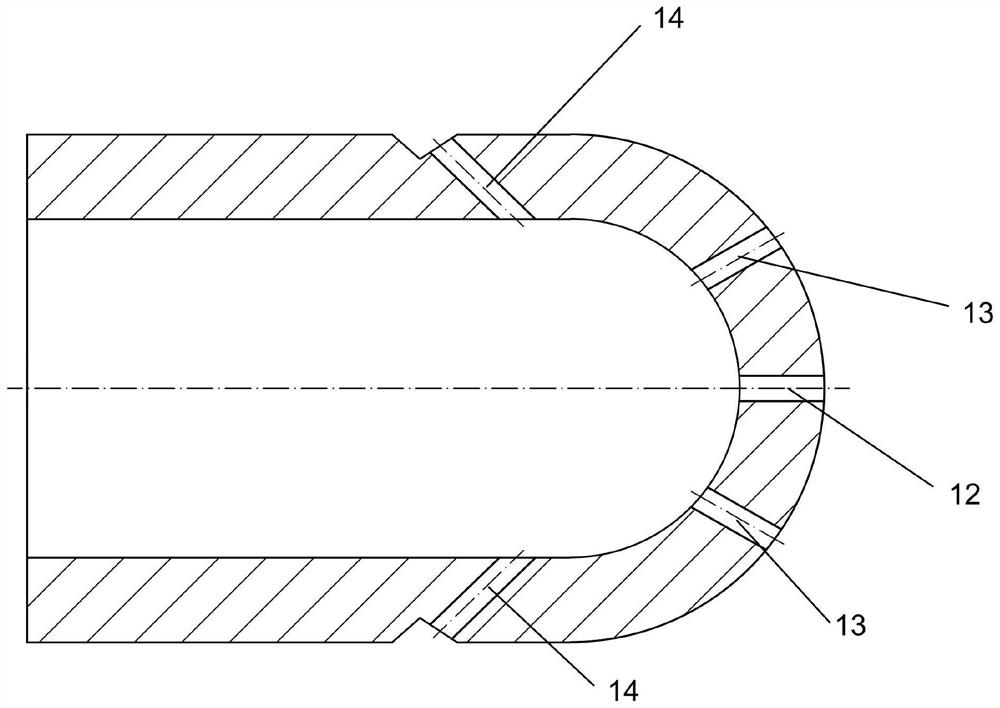

An electronically controlled single-action retractable drilling tool for hydraulic mining of boreholes

InactiveCN104018838BExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningBall screwDrivetrain

The invention discloses an electrically controlled single-action telescopic drilling tool for borehole hydraulic mining. The telescopic drilling tool consists of a high-pressure water delivery system, a power transmission system, an electrically controlled single-action system, a water gun arm extending-retracting system and a slag discharging pipeline. The designed water gun can stretch out for the design distance along the radial direction, so that the range of borehole hydraulic mining is greatly widened, and the production efficiency is improved. According to the power transmission system, the rotating angle and speed of a stepping motor can be accurately controlled by a computer, so the opening angle of the water gun can be accurately controlled, and the water gun can stably extend and retract by utilizing a transmission mode of a ball screw. Moreover, the drilling tool is provided with the electrically controlled single-action system, the rotation torque of the drilling tool is provided by the stepping motor of the electrically controlled single-action system instead of a drill stem, and a phenomenon that a power transmission cable is damaged in the process of rotating the drill stem is avoided.

Owner:JILIN UNIV

An electronically controlled telescopic drilling tool for hydraulic mining of boreholes

InactiveCN104005767BExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningBall screwDrivetrain

The invention discloses an electronic control telescopic drilling tool for borehole hydraulic mining. The electronic control telescopic drilling tool for the borehole hydraulic mining is composed of a high pressure water conveying system, a power transmission system, a hydraulic giant telescopic system and a deslagging channel. A hydraulic giant of the electronic control telescopic drilling tool can stretch out for a designed distance in the radial direction, the range of the borehole hydraulic mining is enlarged greatly, and production efficiency is improved. The electronic control telescopic drilling tool for the borehole hydraulic mining has the advantages that the rotating angle and speed of a stepping motor can be controlled accurately through a computer, the opening angle of the hydraulic giant can be controlled precisely, and the stretching and retracting actions of the hydraulic giant are stable through the transmission mode of a ball screw.

Owner:JILIN UNIV

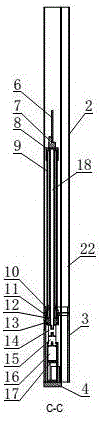

Method for extracting natural gas hydrates through directional drilling and depressurization

InactiveCN107701151AExpansion of mining areaIncrease productionConstructionsFluid removalDirectional drillingProduction area

The invention discloses a method for extracting natural gas hydrates through directional drilling. The method comprises the steps that directional drilling is conducted on a natural gas hydrate layerby arranging a drilling field on the sea bed, and after an existing condition of the hydrate layer is broken, extraction equipment is adopted to extract discomposed hydrates to an offshore productionplatform to be processed. The method is simple and reliable in technical operation, and can adapt to geological conditions of different hydrate layers, the hydrate production area is enlarged, the yield and the recovery rate are improved, and the method has good application prospects.

Owner:CHINA UNIV OF MINING & TECH

Spatial arrangement structure for ore removal level of ore body

PendingCN108952723AExpansion of mining areaSolve efficiency problemsUnderground miningSurface miningMineralogySecondary layer

The invention discloses a spatial arrangement structure for the ore removal level of an ore body. The spatial arrangement structure comprises a primary layer and secondary layers, the secondary layersare located above the primary layer, and the ore removal level of the secondary layers is higher than that of the primary layer. Mining is conducted through combination of the primary layer and the secondary layers, the mining range of the ore body through a natural caving method is effectively enlarged, and the mining benefits of a mine are high; and meanwhile, the difficult problems of continuous caving of high and middle sections of the extremely thick and large gentle dip ore body and heading side ore recovery are further solved, and the ore recovery rate of the heading side ore body is effectively increased.

Owner:CHINA ENFI ENGINEERING CORPORATION

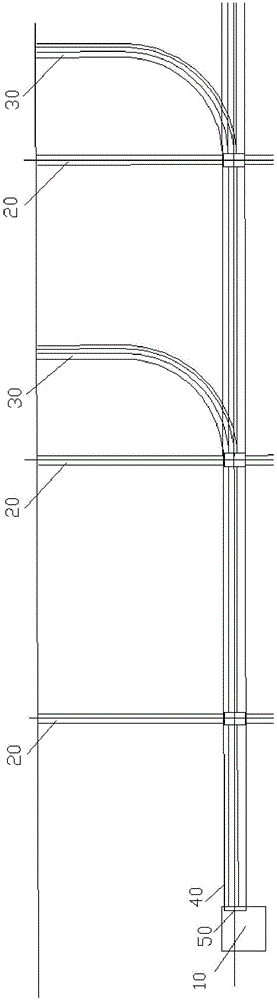

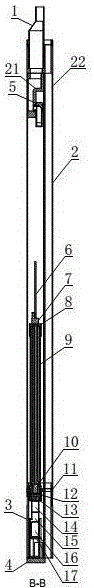

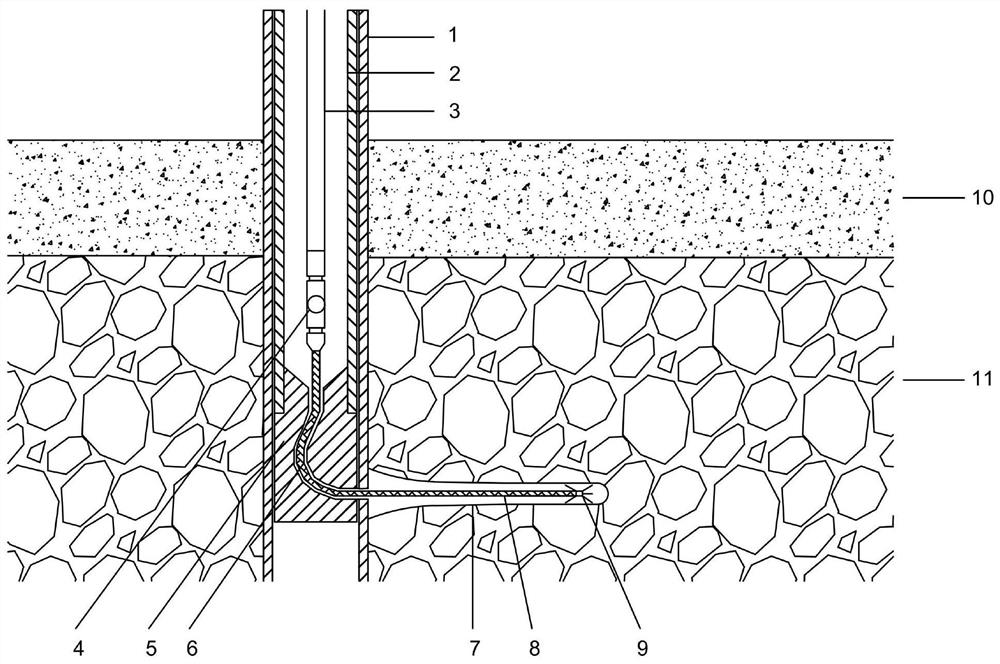

Method for mining underground sodium sulfate decahydrate by drilling hot water dissolving

The invention relates to a method for mining underground sodium sulfate decahydrate by drilling hot water dissolving. The method comprises the following steps of A, well distributing, drilling a vertical well (1) in the area of a sodium sulfate decahydrate mining area near a four-effect vacuum evaporation brine production shop, enabling the well depth to reach a bottom plate of a sodium sulfate decahydrate layer, and drilling two horizontal wells (2, 3) with smaller vertical well depth in the horizontal direction to be communicated with the vertical well; B, cavity dissolving, injecting fresh water with certain temperature from the first horizontal well (2), flowing through the second horizontal well (3), and enabling the brine to flow out of the vertical well (1); C, cavity re-dissolving, after the cavity dissolving is completed, injecting fresh water with certain temperature from the second horizontal well (3), flowing through the first horizontal well (2), and circulating for a period of time repeatedly; D, production, after the cavity re-dissolving is finished, turning to the normal production. The method has the advantage that the three wells are arranged in a triangle way, so the mining area is expanded, the utilization rate of deposits and the concentration of the brine are improved, and the production cost of the brine is reduced.

Owner:INNER MONGOLIA ORIENTAL STAR COAL & CHEM GRP LIMITED

Efficient muddy silt type natural gas hydrate mining system and mining method thereof

PendingCN112127852AEfficient developmentImprove seepage capacityConstructionsFluid removalSlurryFloating platform

The invention provides an efficient muddy silt type natural gas hydrate mining system and a mining method thereof, and belongs to the field of natural gas hydrate mining. The efficient muddy silt typenatural gas hydrate mining system comprises an offshore floating platform, a slurry stirring module, a reaction production module and a product collection module. According to the efficient muddy silt type natural gas hydrate mining system and the mining method thereof, the connectivity of a muddy silt type natural gas hydrate reservoir is transformed by adopting two types of slurry of A type andB type, a gas-water seepage channel in the reservoir is widened, the gas-water seepage capacity is enhanced, the reservoir maintains a good gas-water seepage rate in the process of pressure-reducingmining of natural gas hydrate, generation of ice and secondary hydrate in the reservoir seepage channel is avoided, the long-term effect problem of a pressure-reducing method is solved, and efficientdevelopment of the muddy silt type natural gas hydrate is realized.

Owner:JILIN UNIV

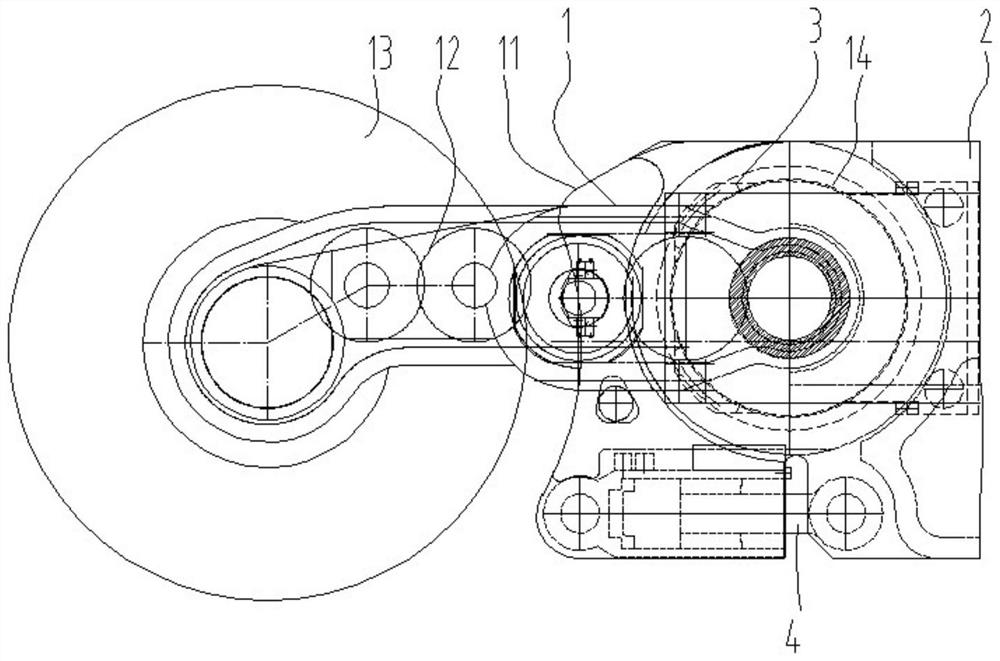

Electrically controlled single-action telescopic drilling tool for borehole hydraulic mining

InactiveCN104018838AExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningDrivetrainBall screw

The invention discloses an electrically controlled single-action telescopic drilling tool for borehole hydraulic mining. The telescopic drilling tool consists of a high-pressure water delivery system, a power transmission system, an electrically controlled single-action system, a water gun arm extending-retracting system and a slag discharging pipeline. The designed water gun can stretch out for the design distance along the radial direction, so that the range of borehole hydraulic mining is greatly widened, and the production efficiency is improved. According to the power transmission system, the rotating angle and speed of a stepping motor can be accurately controlled by a computer, so the opening angle of the water gun can be accurately controlled, and the water gun can stably extend and retract by utilizing a transmission mode of a ball screw. Moreover, the drilling tool is provided with the electrically controlled single-action system, the rotation torque of the drilling tool is provided by the stepping motor of the electrically controlled single-action system instead of a drill stem, and a phenomenon that a power transmission cable is damaged in the process of rotating the drill stem is avoided.

Owner:JILIN UNIV

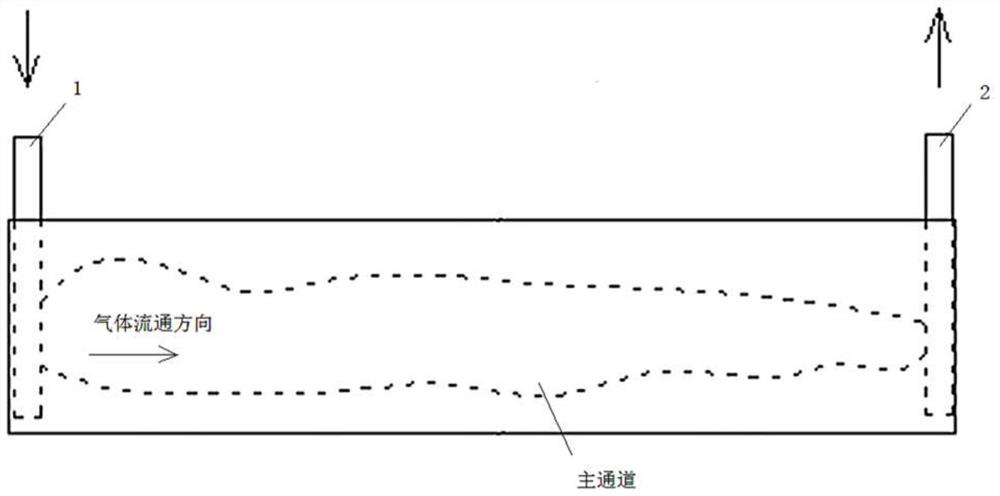

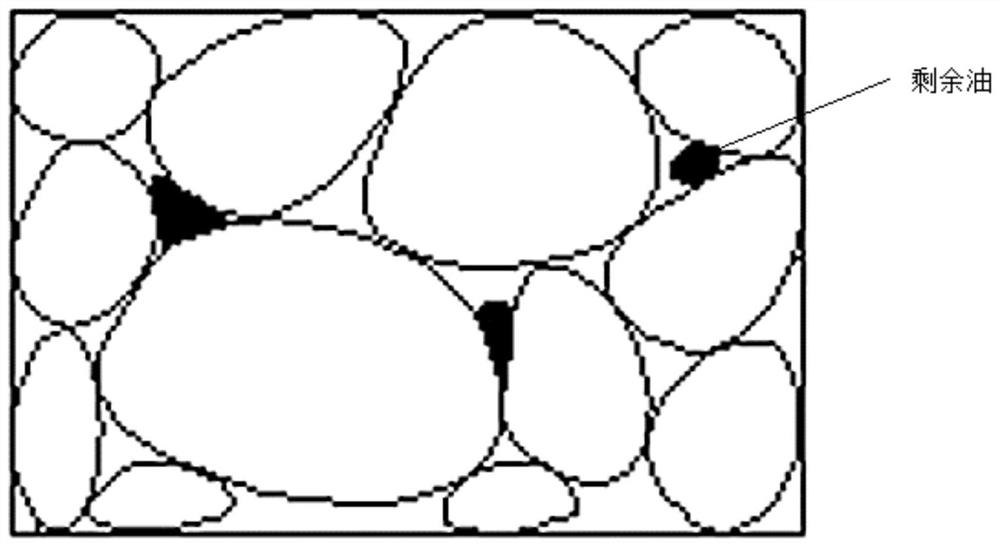

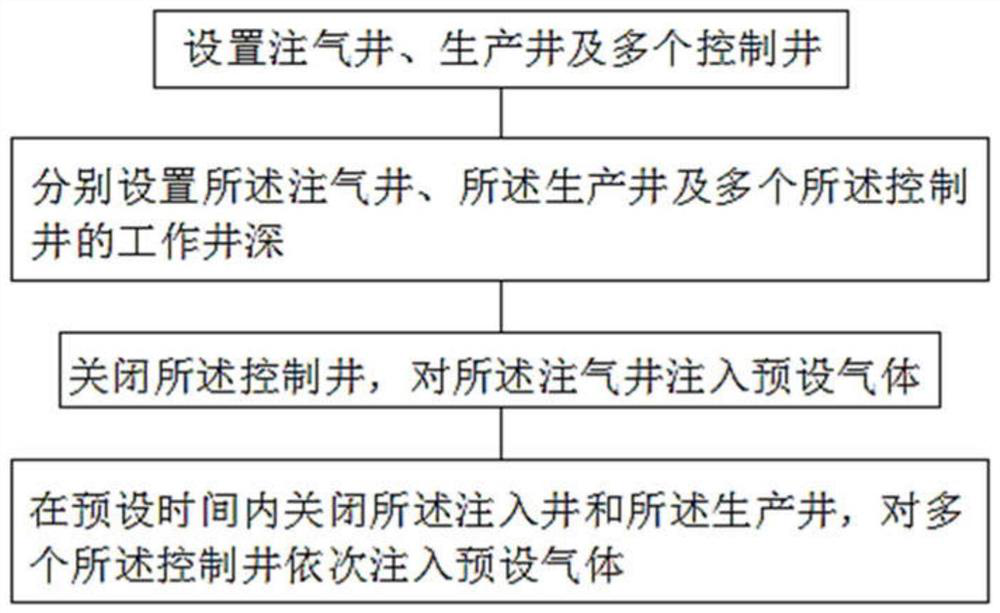

Gas injection oil displacement method and system

PendingCN113153242AReduce residual oil distributionExpand the scope ofFluid removalInjection wellOil distribution

The invention discloses a gas injection oil displacement method and system. The gas injection oil displacement method comprises the following steps of setting the working positions of a gas injection well, a production well and a plurality of control wells, wherein the control wells are used for assisting gas injection, and the multiple control wells are arranged between the gas injection well and the production well at intervals; setting the working well depths of the gas injection well, the production well and the plurality of control wells respectively; closing the control wells, and injecting preset gas into the gas injection well; and closing the injection well and the production well within the preset time, and injecting preset gas into the multiple control wells in sequence. The control wells and the gas injection well are the same in structure; the production well comprises an oil pipe, a casing pipe and a packer arranged between the oil pipe and the casing pipe; each of the gas injection well and the control well comprises a hole oil pipe, a casing pipe, a packer arranged between the hole oil pipe and the casing pipe, and a screwed plug arranged at the tail end of the hole oil pipe. The oil extraction degree can be improved, and remaining oil distribution is reduced.

Owner:PETROCHINA CO LTD

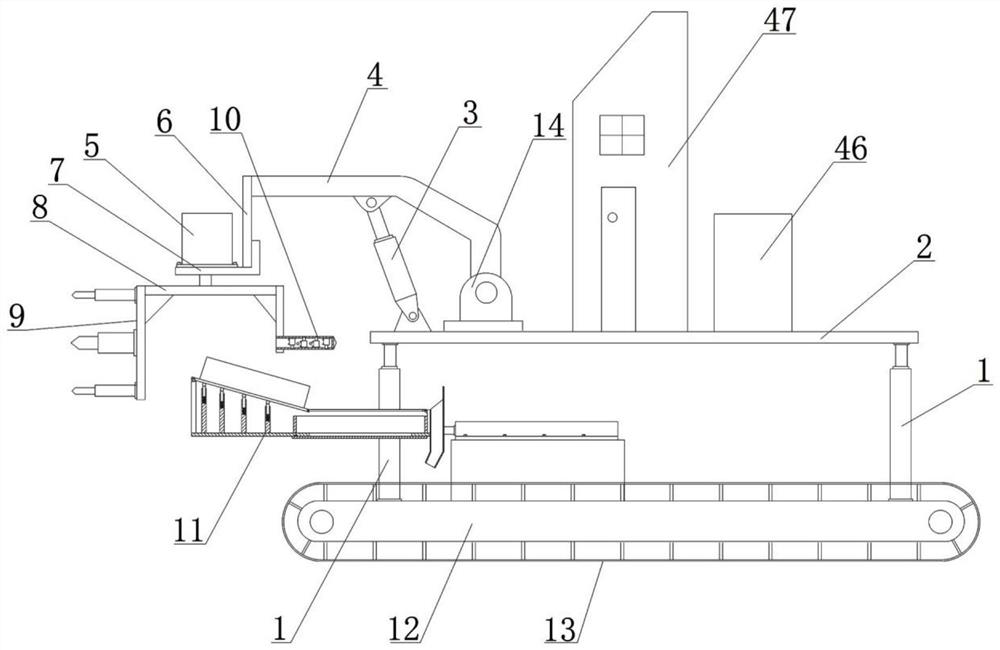

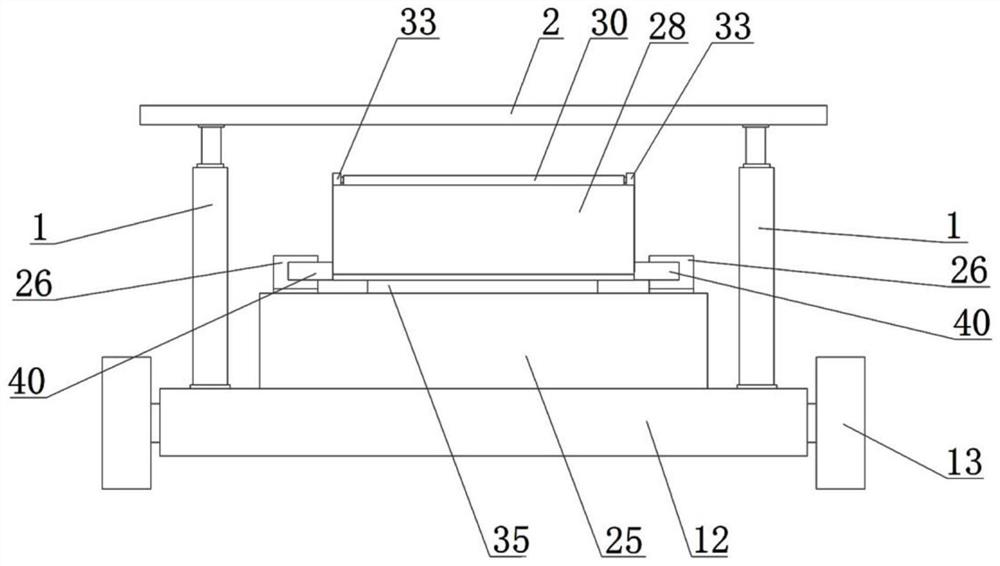

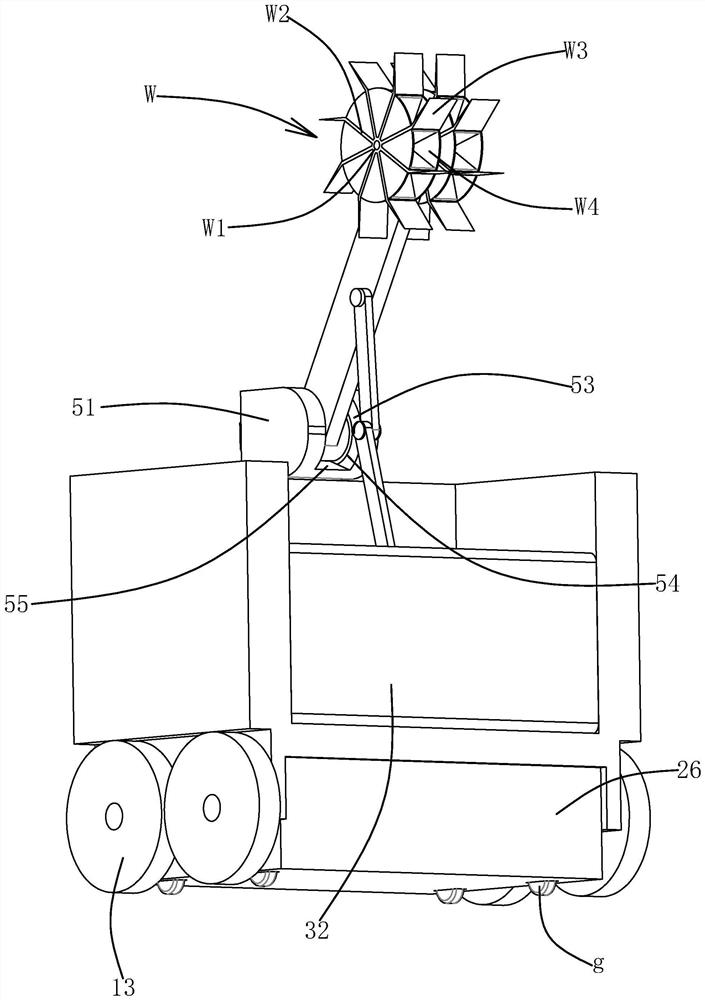

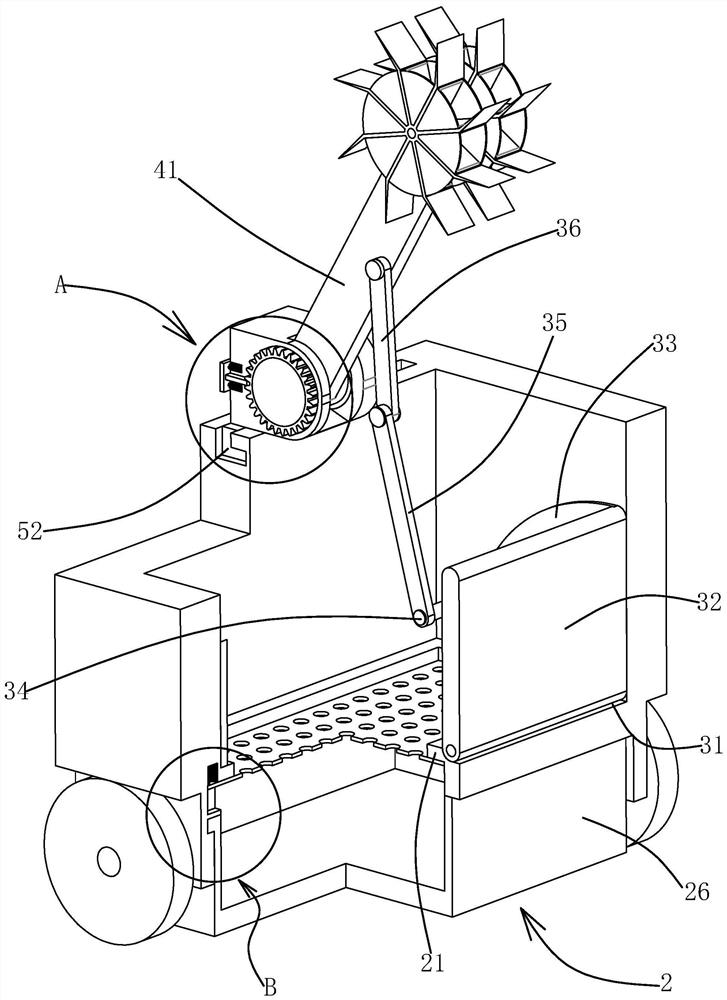

Energy-saving coal mine large-batch mining equipment and method thereof

InactiveCN113389551AShorten mining timeImprove mining efficiencySievingUnderground miningHydraulic motorMining engineering

The invention discloses energy-saving coal mine large-batch mining equipment which comprises a walking mechanism. Lifting oil cylinders are fixedly arranged on a chassis of the walking mechanism and located at the four corners of the chassis, a lifting plate is fixedly arranged on a plane formed by the action ends of piston rods of the lifting oil cylinders, and a feeding swing arm mechanism is further arranged on the lifting plate; the feeding swing arm mechanism comprises a pitching oil cylinder, a swing arm and a hydraulic motor, one end of the swing arm is hinged to the top surface of the lifting plate, the other end of the swing arm extends leftwards to the outer side of the lifting plate, a cylinder barrel of the pitching oil cylinder is hinged to the lifting plate, a piston rod of the pitching oil cylinder is hinged to the swing arm, and a platform is fixedly arranged at the bottom of the mounting plate; and the hydraulic motor is fixedly arranged on the top surface of the platform, an output shaft of the hydraulic motor penetrates through the platform, a truss is installed at the extending end, and a drilling device and a fracturing device are arranged at the left side and the right side of the truss correspondingly. The energy-saving coal mine large-batch mining equipment has the beneficial effects of saving energy consumption, improving the economic benefit of a coal mine plant, mining coal in batches and improving the mining efficiency.

Owner:洪华

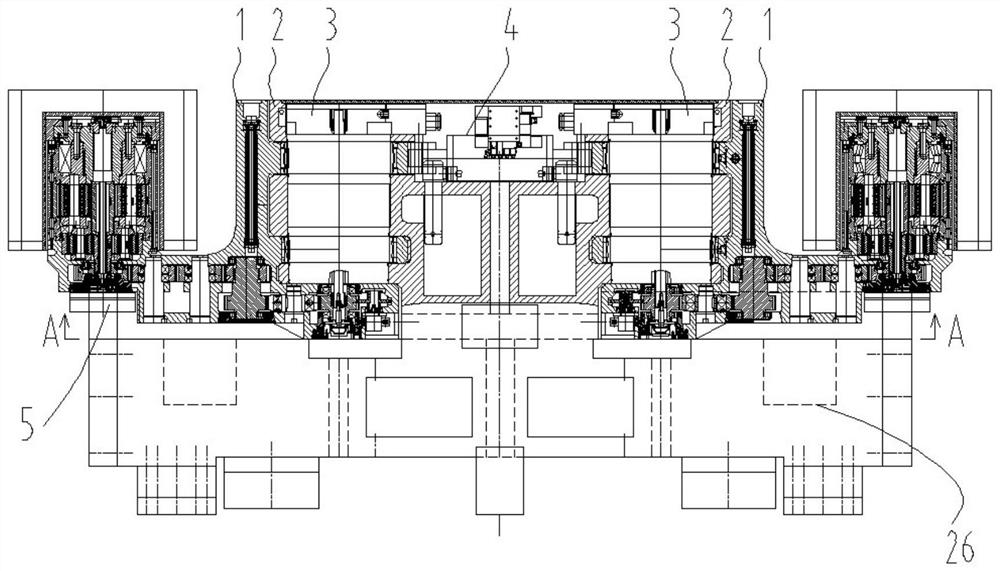

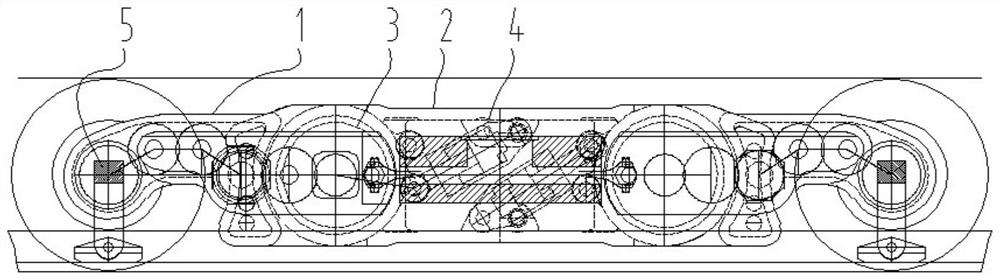

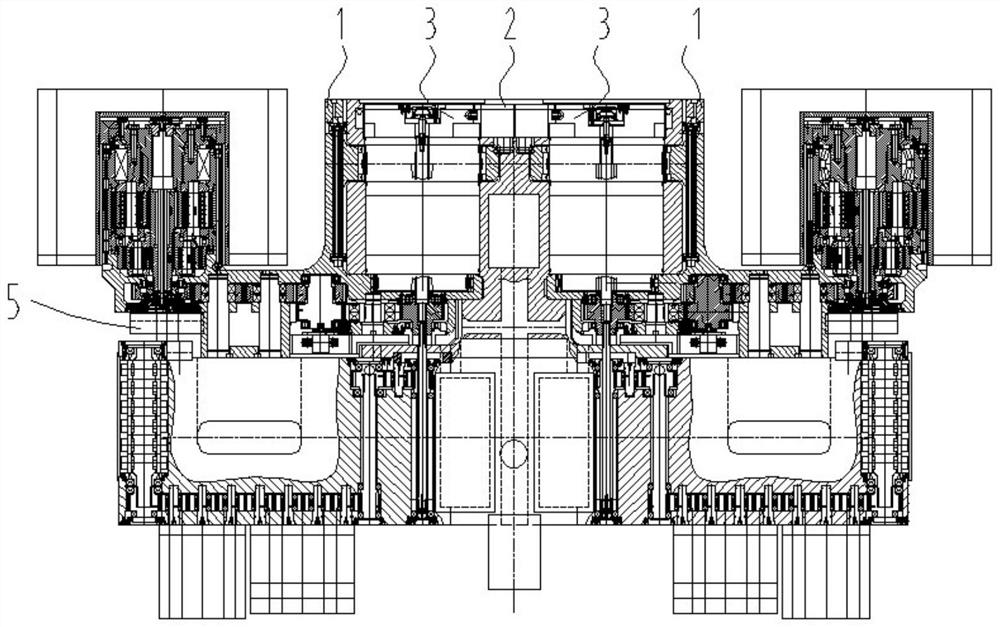

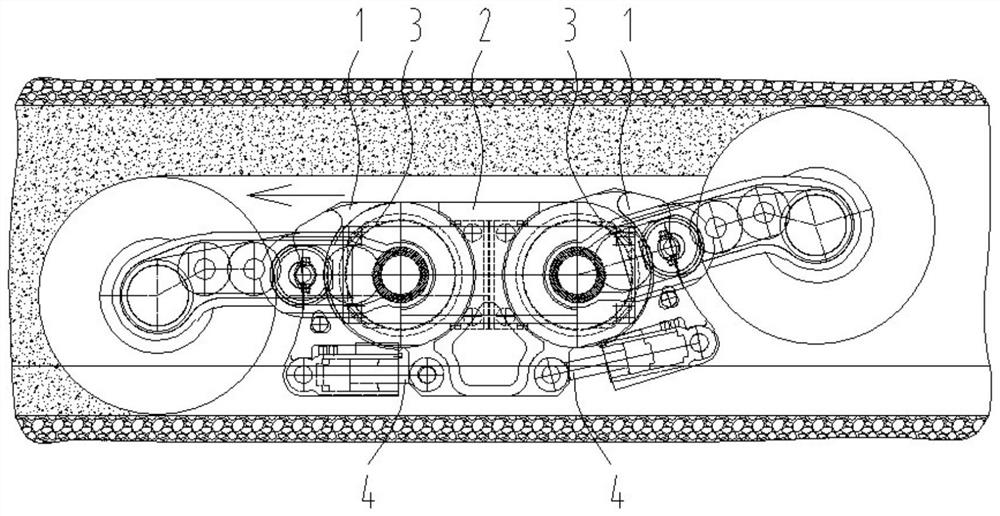

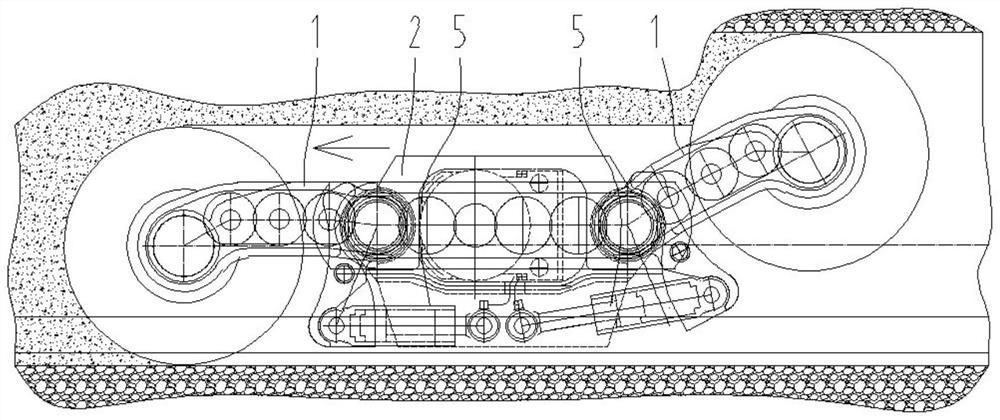

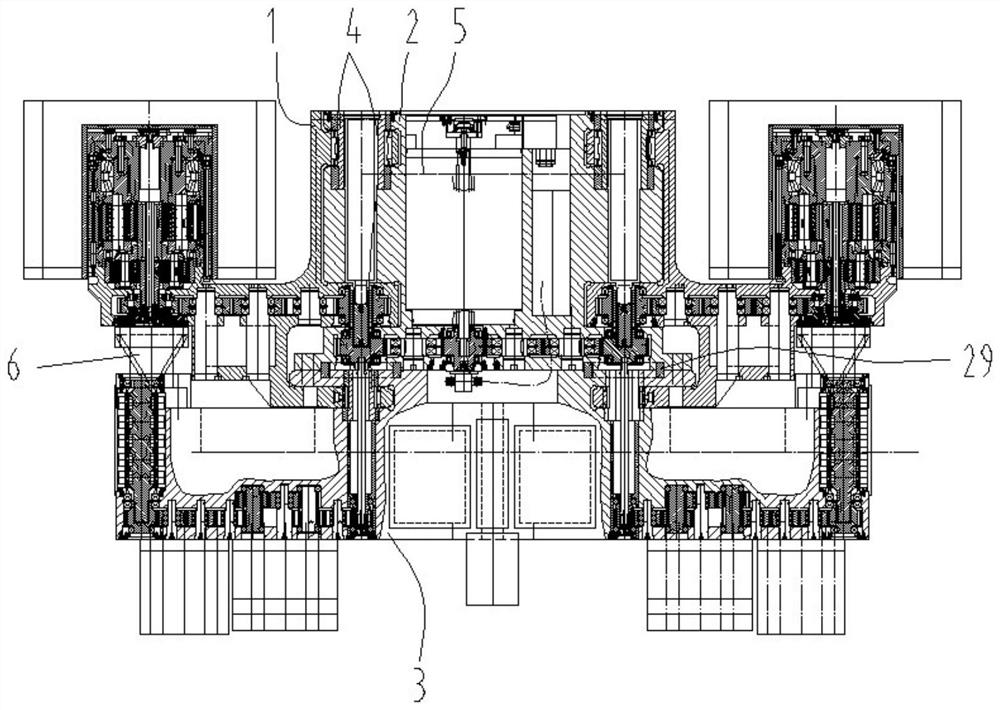

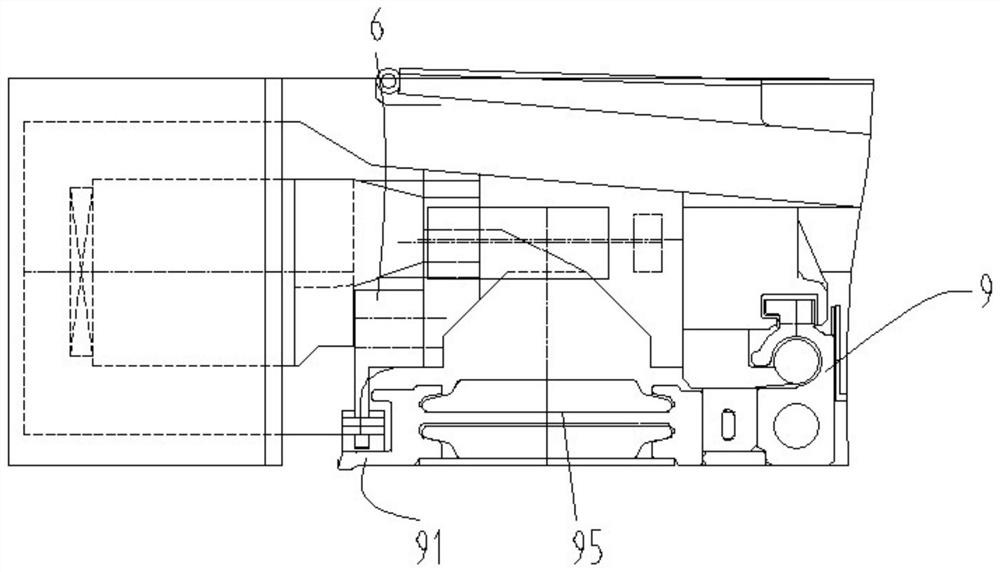

Thin seam coal mining machine

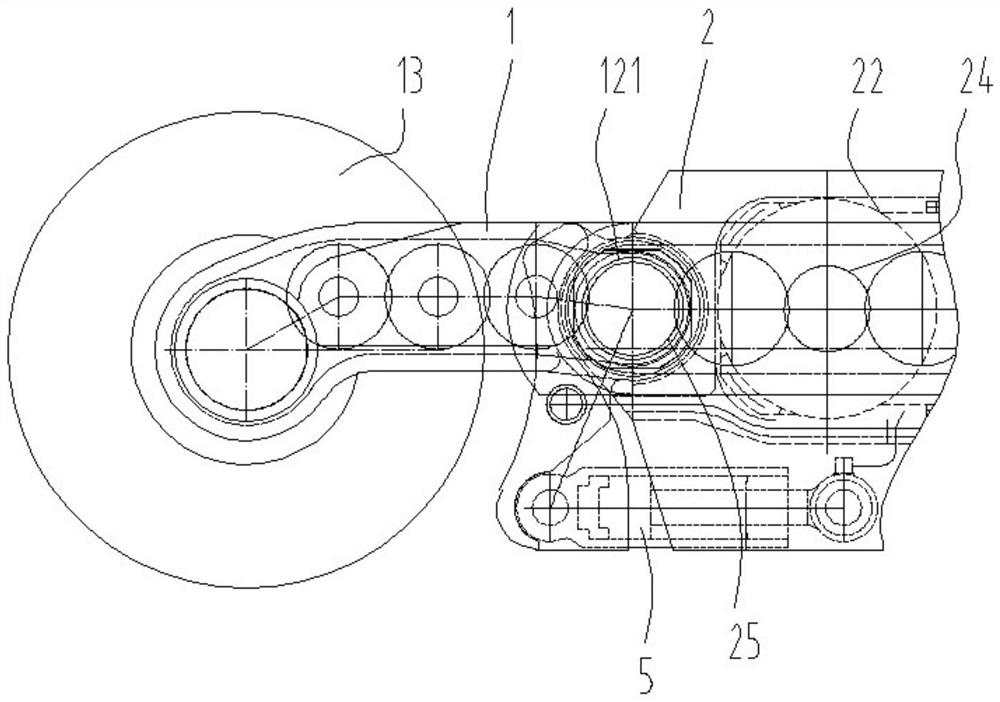

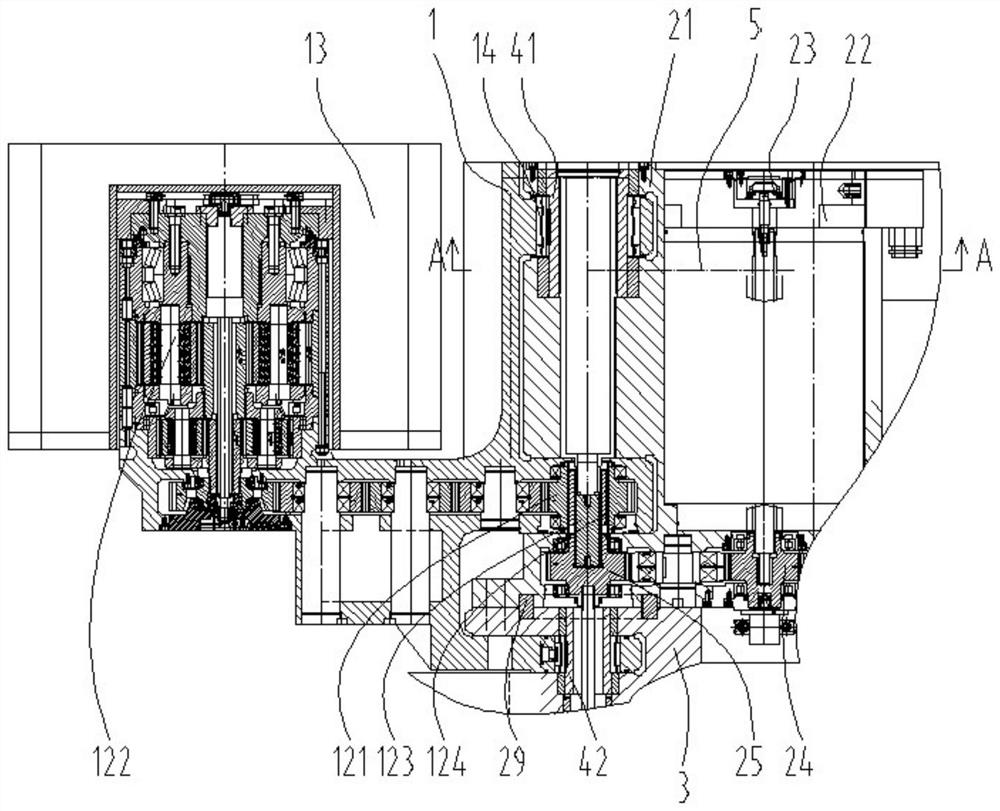

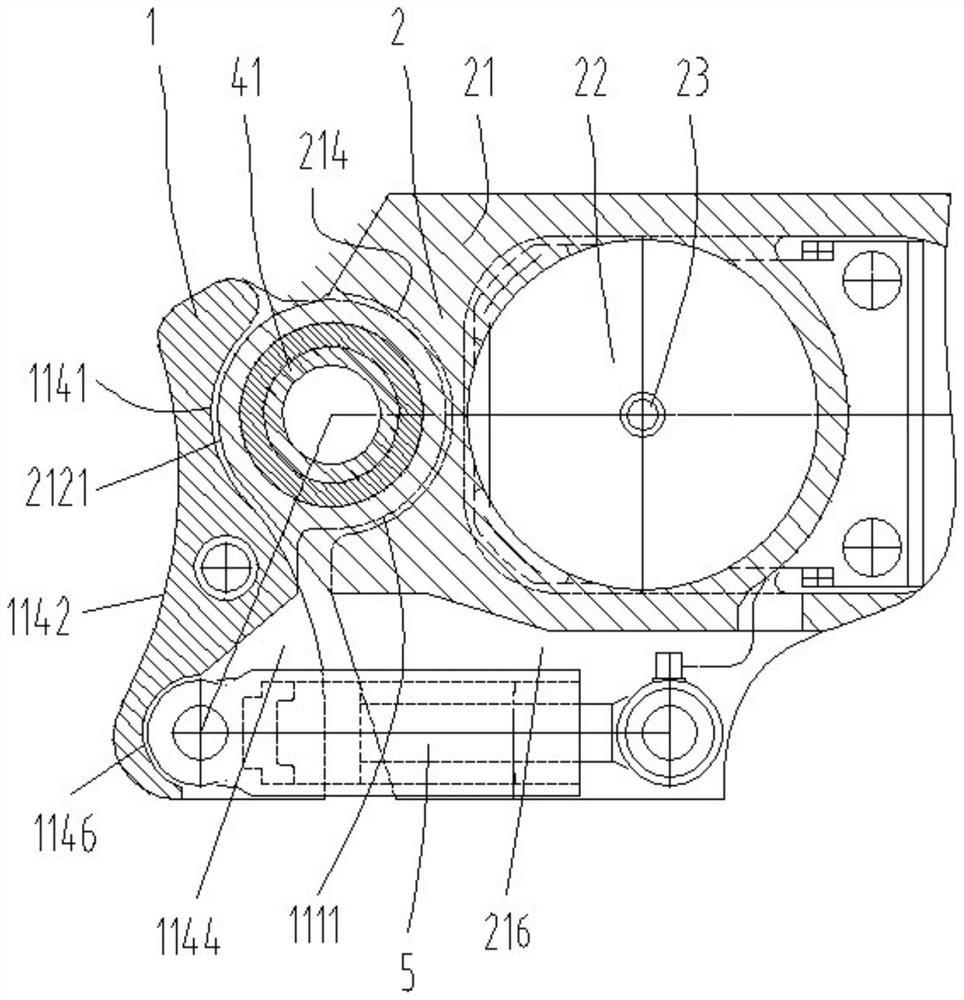

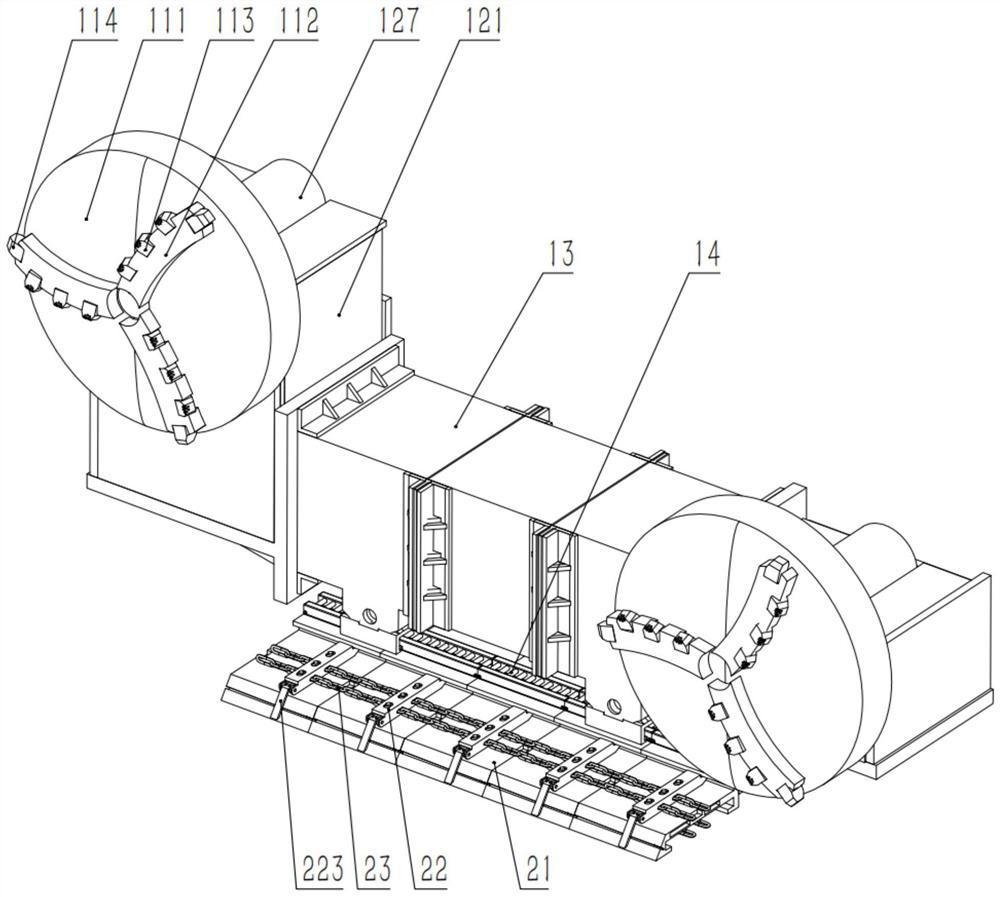

PendingCN114396267AShorten the left and right lengthSimple structureSlitting machinesCutting machinesMining engineeringElectric machinery

The invention relates to a thin seam mining machine which comprises a main body part shell and two swing arm shells hinged to the left end and the right end of the front portion of the main body part shell respectively, a cutting motor is arranged between each swing arm shell and the main body part shell to serve as a hinge pin shaft, and a cover plate is installed at an opening in the front end of the main body part shell. A closed oil cylinder installation cavity is defined by the swing arm shells, the main body shell, the cutting motor and the cover plate, oil cylinders driving the left swing arm shell and the right swing arm shell to swing are installed in the oil cylinder installation cavity, the rear portion of the main body shell is provided with a left coal flow rear channel and a right coal flow rear channel, the coal flow rear channels are grooves which extend from front to back and are provided with downward groove openings, and the coal flow rear channels are communicated with the oil cylinder installation cavity. And the rear end of the groove is closed. The large mining range and the large cutting power can be provided, the machine body can be shortened, and the coal flow loading effect is improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Coal mine excavating equipment

InactiveCN112127397AEasy to minePrevent fallingMechanical machines/dredgersMining engineeringStructural engineering

The invention provides coal mine excavating equipment. The equipment comprises a box body provided with a material bearing area and is characterized in that a material receiving device is arranged atthe lower end of the material bearing area; mounting plates are arranged on the two sides of the material receiving device and symmetrically arranged at the lower end of the box body; wheels are movably mounted on the outer side faces of the mounting plates; an inclined plate device is further arranged on one side of the material bearing area; one side of the inclined plate device is connected with an excavating device; one side of the excavating device is movably installed on an installing base device, and the installing base device is movably installed in an L-shaped sliding groove; and theL-shaped sliding groove is arranged at the side, away from the inclined plate device, of the box body. According to the coal mine excavating equipment provided by the invention, the excavating device,the inclined plate device and the material receiving device are used in cooperation, the excavated coal mine can be directly poured into the material receiving device in the excavating process of theexcavating equipment, action waste is avoided, and the working efficiency of the excavating equipment is improved.

Owner:上海珩鋆机械有限公司

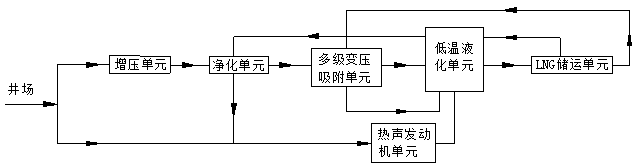

System for preparing LNG from oxygen-bearing coal-bed gas based on thermoacoustic technology and method

PendingCN110747026AImprove recycling efficiencyExpansion of mining areaGaseous fuelsCompression machinesEngineeringAdsorption effect

The invention discloses a system for preparing liquefied natural gas (LNG) from oxygen-bearing coal-bed gas based on a thermoacoustic technology and a method. The system comprises a supercharging unit, a purifying unit, a multistage pressure swing adsorption unit, a low-temperature liquefying unit and an LNG storage and transportation unit which are connected sequentially. The system further comprises a thermoacoustic engine unit connected with the low-temperature liquefying unit, wherein the thermoacoustic engine unit combusts part of the coal-bed gas by using the thermoacoustic technology soas to drive a pulse tube refrigerator to work and provide cold energy required by the low-temperature liquefying unit. A liquefying part does not need external power supply completely, the recovery efficiency of the coal-bed gas is increased, factors of the traditional liquefying process that a mixed refrigerant is difficult to prepare, the varying-load working condition adaptability is poor, andthe like are overcome, and thus, the system and the method are particularly applicable to working conditions that the quantity of disperse coal mine or oil-gas wells is small or electric power supplyis absent. In addition, LNG is optionally introduced into the multistage pressure swing adsorption unit, and thus, an adsorption effect is strengthened; and evaporated gas generated by the LNG storage and transportation unit is subjected to heat exchange and then is applied to regeneration of an adsorptive purifier, so that the energy consumption of the system is further lowered, and pollutant emission is reduced.

Owner:ZHEJIANG UNIV

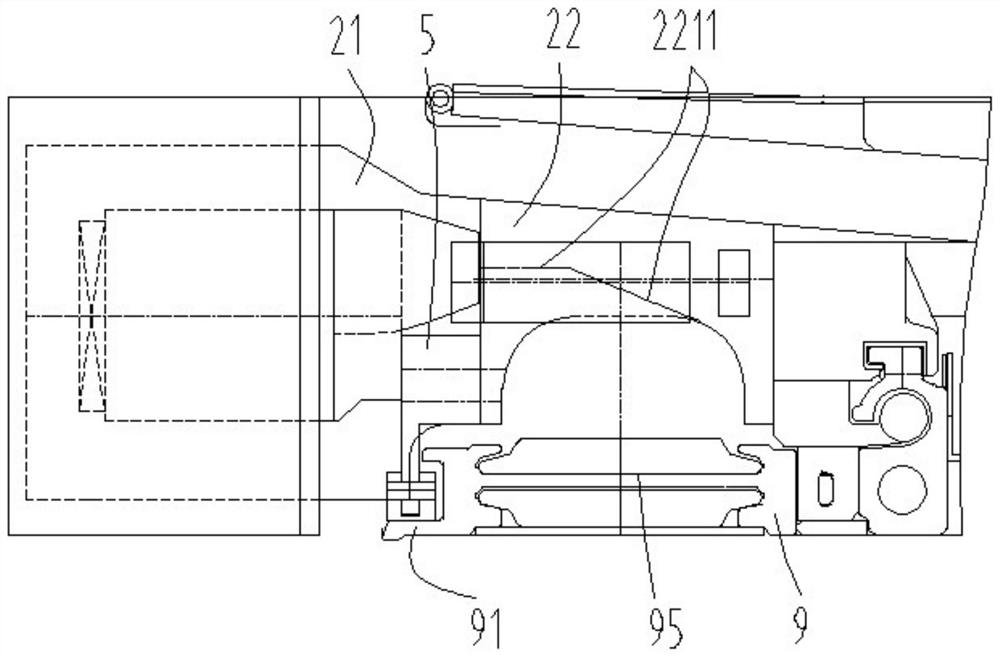

Swing arm and swing arm supporting structure of thin seam short-span coal mining machine

PendingCN114396270AImprove stress stabilityShorten the left and right lengthSlitting machinesCutting machinesGear wheelElectric machinery

The invention relates to a thin seam short-span coal mining machine swing arm and a swing arm supporting structure, a main body of a swing arm shell of the swing arm is an arm frame extending leftwards and rightwards, a connecting arm extending forwards is connected to the middle of the arm frame, a front arm is arranged on the connecting arm, and the front arm is located in front of the high-speed end of the arm frame; the front arm, the front part of the high-speed end of the arm frame and the rear part of the high-speed end of the arm frame are respectively provided with a front pin shaft mounting hole, a rear pin shaft mounting hole and an input end gear of the cutting transmission mechanism, which are coaxial with each other; the supporting structure comprises a front main body part shell, swing arms, cutting motors and a height adjusting oil cylinder, the left end and the right end of the front main body part shell are hinged to the swing arms with the cutting motors as pin shafts correspondingly, and output shafts of the cutting motors are in coaxial transmission connection with input end gears on the left side and the right side on the same side; and a height adjusting oil cylinder is hinged between the front arm of the swinging arm and the shell of the front main body part. The mining machine is compact in structure, a large mining range can be provided, and a short machine body length and a relatively clean oil cylinder installation space can be achieved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +3

Intelligent fully mechanized coal mining face collecting device

PendingCN114396259AIncrease the lengthChange lengthDriving meansCutting machinesElectric machineryScrew thread

The invention discloses an intelligent fully mechanized coal mining face collecting device which comprises a first rod body, a first motor and a cutter, the first motor is installed on the front end face of the first rod body, and the output end of the first motor is rotationally connected with the first rod body through a bearing. According to the intelligent fully mechanized coal mining face collecting device, a second motor in the driving mechanism is connected with an external power source, the second motor can drive a first screw to rotate, when the first screw rotates, a first threaded sleeve can be driven to stably move leftwards on the inner wall of a guide rail, and when the first threaded sleeve moves, a rope body is driven to synchronously move; the rope body drives the second cross rod to move rightwards, the second cross rod drives the first rod body, the first motor and the cutter to move synchronously, then the total length of the first rod body and the second rod body is increased, the total length of the first rod body and the second rod body can be changed according to the actual mining range, and the cutter can conduct mining machining in different ranges.

Owner:中煤华晋集团有限公司王家岭矿

Swing arm and swing arm supporting structure of thin seam compact coal mining machine

PendingCN114396263AIncrease radial floatImprove reliabilitySlitting machinesCutting machinesPhysicsCoal mining

The invention relates to a thin seam compact type coal mining machine swing arm and a swing arm supporting structure, a main body of a swing arm shell of the swing arm is an arm frame extending left and right, a connecting arm extending forwards is connected to the middle of the arm frame, a front arm and a rear arm are arranged in front of and behind the arm frame respectively, and the root of the front arm is connected to the connecting arm; the front arm and the rear arm are respectively provided with a hinged connection hole used for being hinged with a machine body, a rear-stage cutting transmission mechanism is arranged in the arm frame, and an input end gear is coaxial with the hinged connection hole; the supporting structure comprises a front main body part shell, a rear main body part shell, a height adjusting oil cylinder and a swinging arm, the front arm and the rear arm are hinged to the front main body part shell and the rear main body part shell respectively, an output end gear of a front-stage cutting transmission mechanism in the front main body part shell is in coaxial transmission connection with an input end gear of a rear-stage cutting transmission mechanism, and the height adjusting oil cylinder is hinged between the connecting arm and the front main body part shell. The structure is compact, a large mining range can be provided, the length of the machine body is short, and the gravity center of the machine body is improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Hard ore ming and transporting equipment

ActiveCN114017024AExpansion of mining areaImprove mining efficiencyCutting machinesGear wheelMining engineering

The invention relates to the field of coal mining mechanical equipment, in particular to hard ore mining and transporting equipment which comprises milling equipment and semi-open type material transporting equipment which are matched for use, the semi-open type material transporting equipment comprises a non-closed base, an open-close scraper blade and a chain, and the chain drives the open-close type scraper blade to slide on the non-closed type base; the non-closed base comprises a ledge, a scraper supporting plane and a scraper supporting inclined plane which are connected in sequence, the ledge is arranged close to the milling equipment, and the scraper supporting inclined plane inclines towards a coal seam bottom plate in the direction away from the ledge; a baffle is hinged to one end of the open-close type scraper blade and is lapped on the scraper blade supporting inclined surface. A rocker arm and a multi-gear traditional system are replaced by a vertical height adjusting structure, so that the milling equipment can be more suitable for cutting high-hardness ores while the reliability of the equipment is improved. According to the semi-open type material conveying equipment, the range of the falling ore receiving area of the material conveyor is enlarged, and the ore extraction and conveying efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

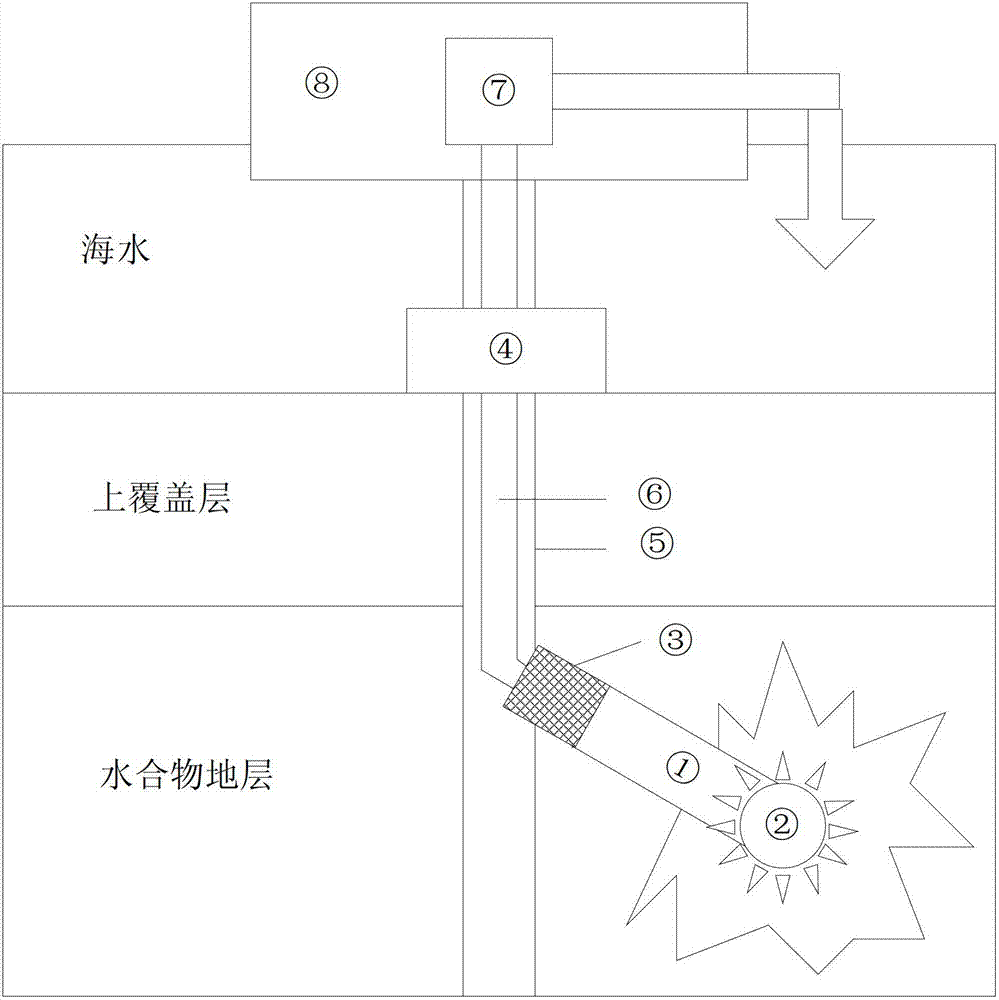

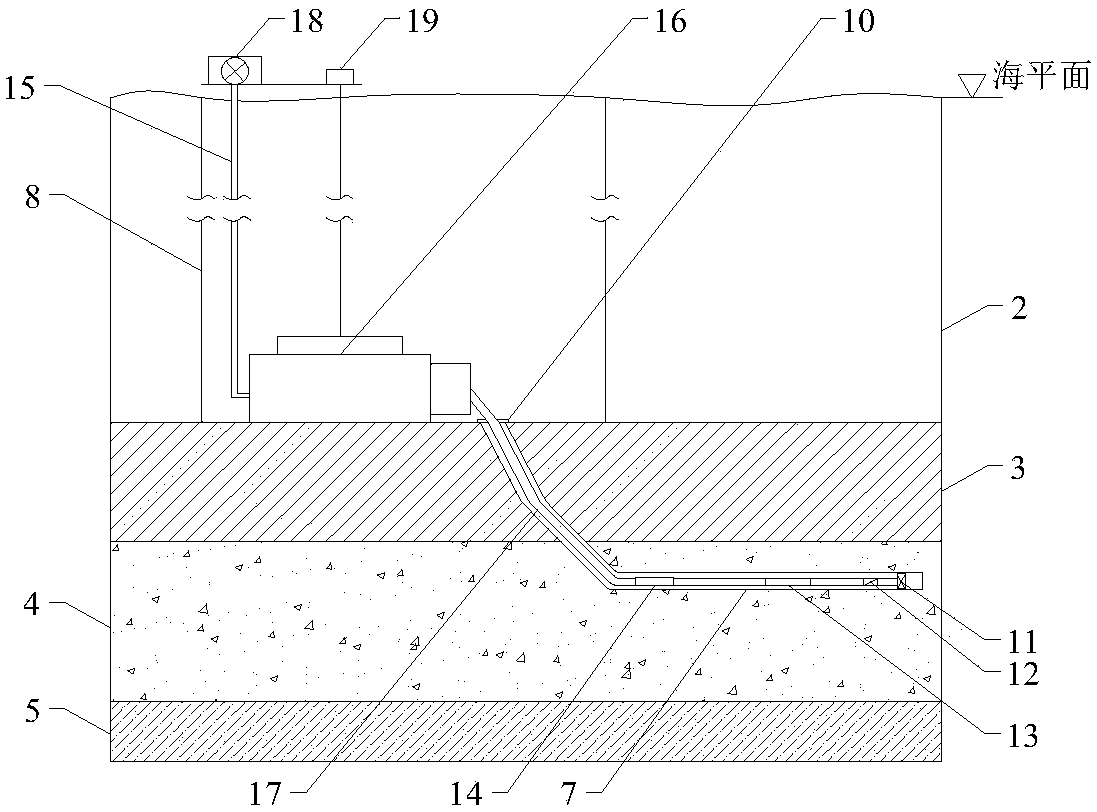

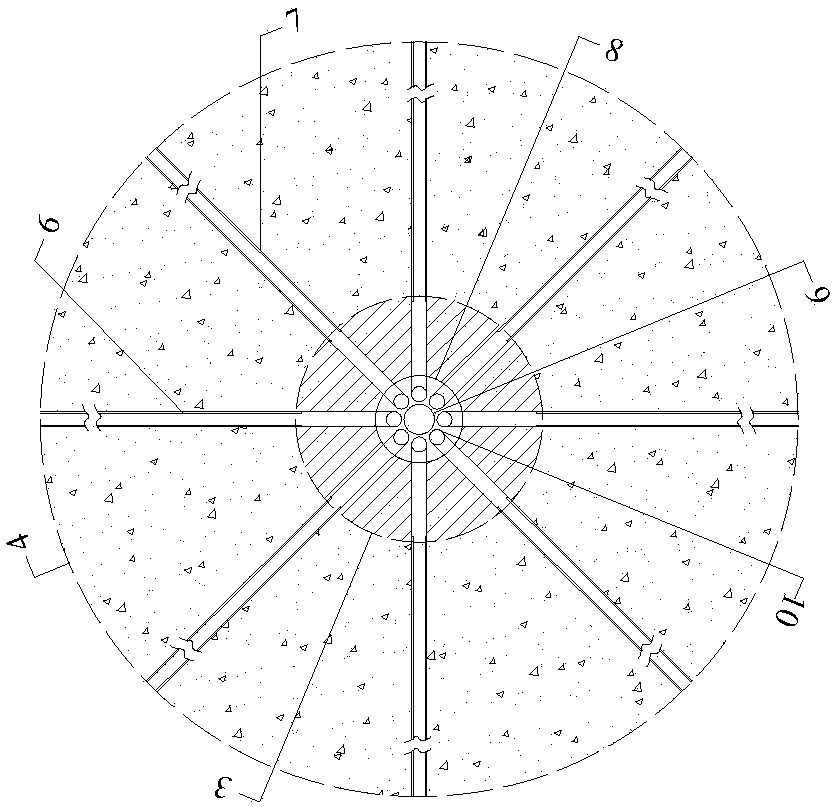

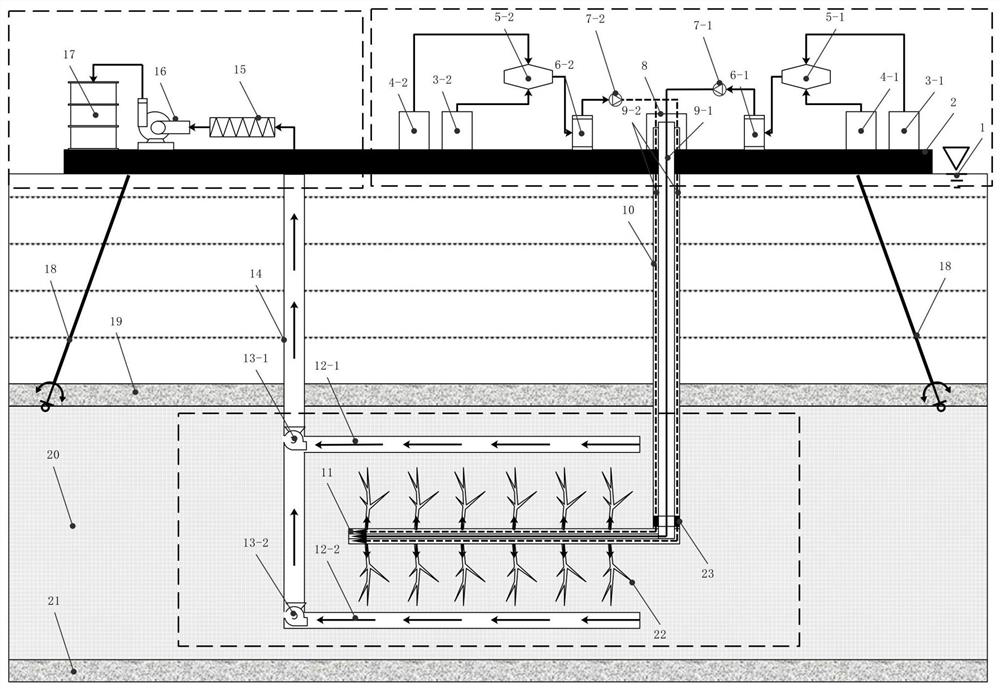

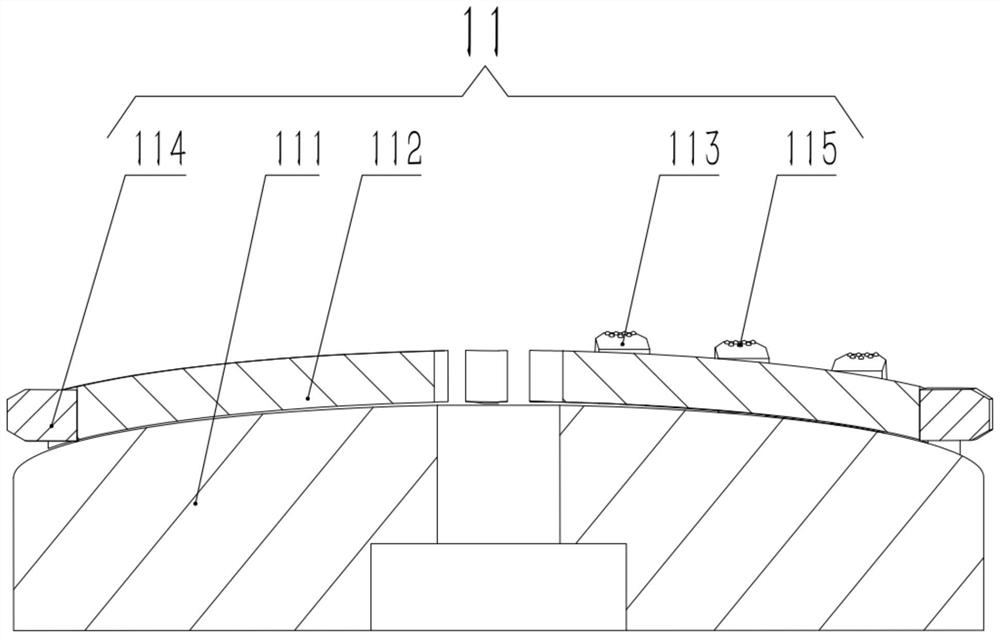

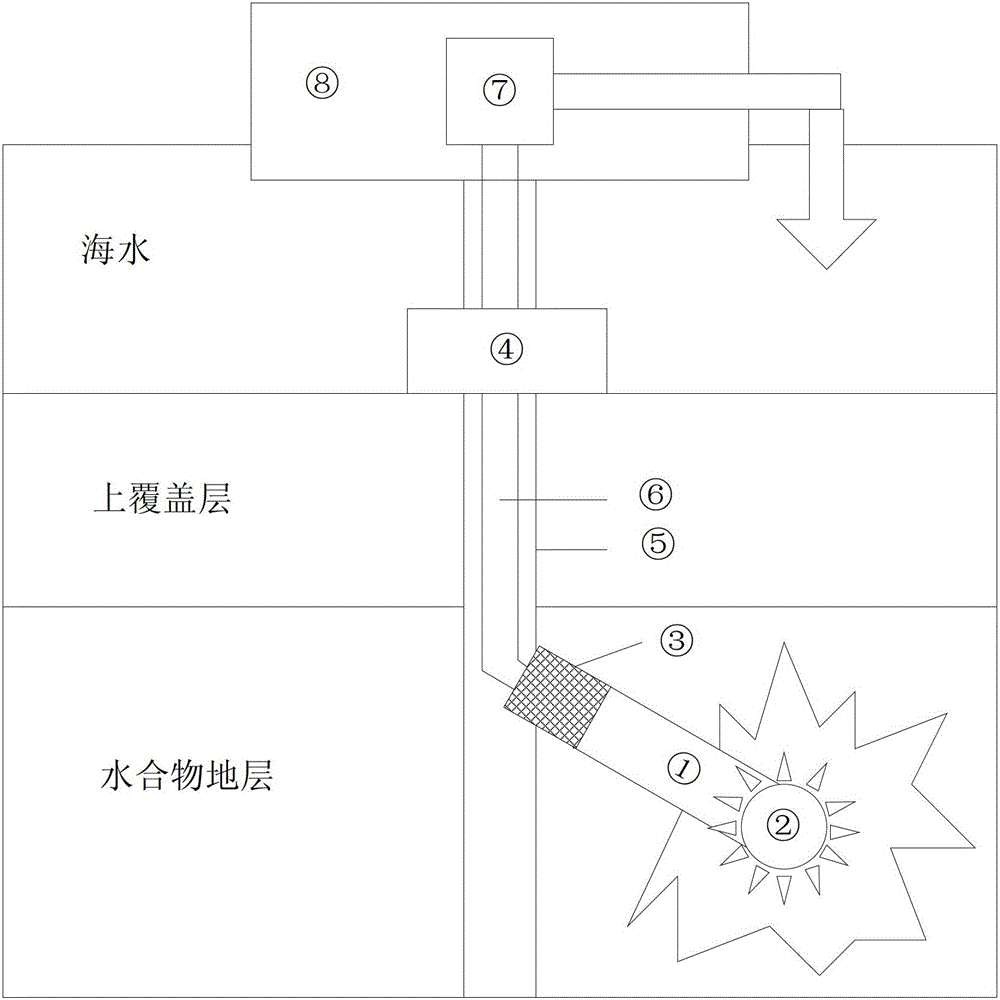

A method for combined exploitation of natural gas hydrate with radial horizontal well and pressure reduction heat injection

ActiveCN109630076BImprove permeabilityImprove efficiencyDrill bitsConstructionsThermodynamicsHorizontal wells

The invention discloses a method for combined exploitation of natural gas hydrate by radial horizontal wells and decompression heat injection, which belongs to the technical field of natural gas hydrate exploitation. On the casing of the formed natural gas hydrate drilling hole, sidetracking is used to open windows The radial horizontal well technology drills multiple horizontal wellbores in a radial shape, and uses high-pressure hot water jets to push the jet drill at the front end of the high-pressure hose to form multiple radial and horizontal mining channels with a length of about 100 meters. The convective heat transfer of the gas hydrate promotes the decomposition of natural gas hydrate, and the convective heat transfer in the far well area is enhanced by the method of joint depressurization. During the drilling process, high-efficiency mining is carried out by means of segmented heating. The invention has the advantages of simple process, low cost, high efficiency and easy realization, and is beneficial to realize large-scale commercial exploitation of natural gas hydrate.

Owner:JILIN UNIV

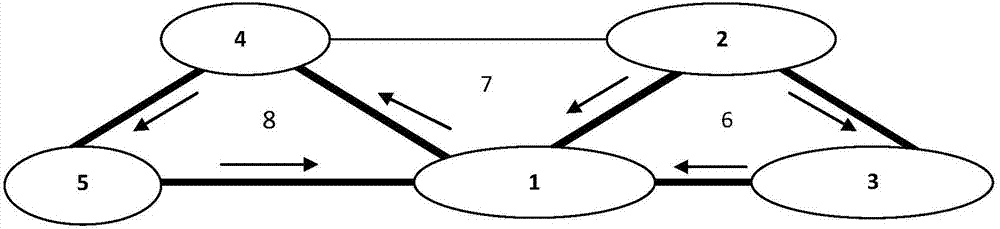

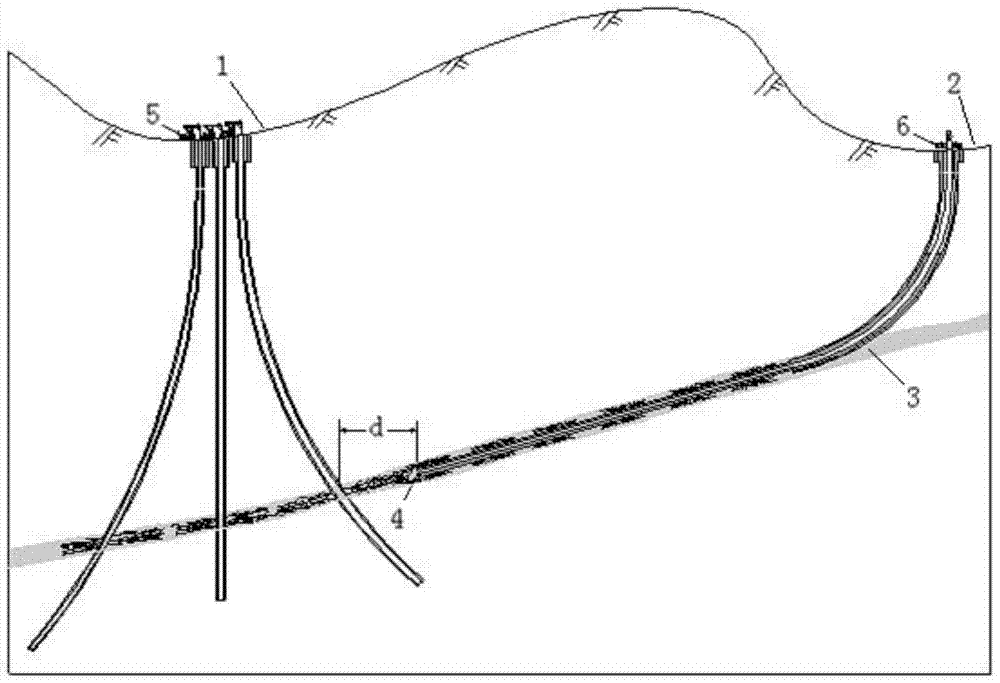

Coal bed methane mining method combined with cluster wells and horizontal wells under complex terrain conditions

InactiveCN104790918BIncrease the range of ground miningExpansion of mining areaFluid removalTerrainHorizontal wells

The invention discloses a method for mining coalbed methane by combining cluster wells and horizontal wells on the ground under complex terrain conditions. The method comprises the following steps: (a) constructing cluster wells and cementing them; (b) constructing horizontal wells and cementing them; (c) Carry out perforation and fracturing construction in sequence in the coal seam section of cluster wells, and install pressure gauges at the wellhead; (d) Carry out staged perforation and fracturing construction in sequence in horizontal wells, and monitor cluster type during the fracturing process Wellhead pressure gauge changes; (e) cluster wells and horizontal wells slowly discharge overflow until the wellhead casing pressure is zero; (f) cluster wells are equipped with drainage and production equipment for drainage and gas production, and horizontal wells are only installed with gas production wellheads. The invention adopts the method of mining coalbed methane on the ground in combination with cluster wells and horizontal wells, which can realize the overall depressurization of coal reservoirs within the control range of cluster wells and horizontal wells, and significantly increase the surface mining of coalbed methane in areas where the buried depth of the target coal seam varies greatly. scope, saving CBM surface development engineering and equipment investment.

Owner:CHINA UNIV OF MINING & TECH

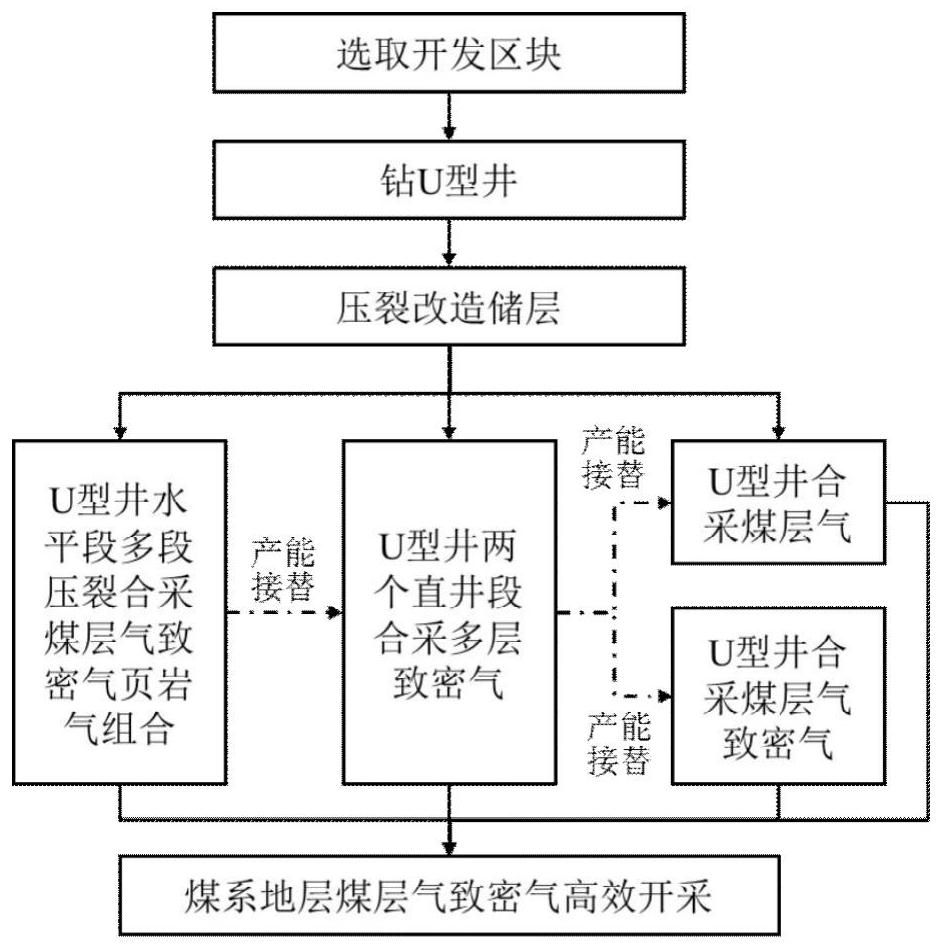

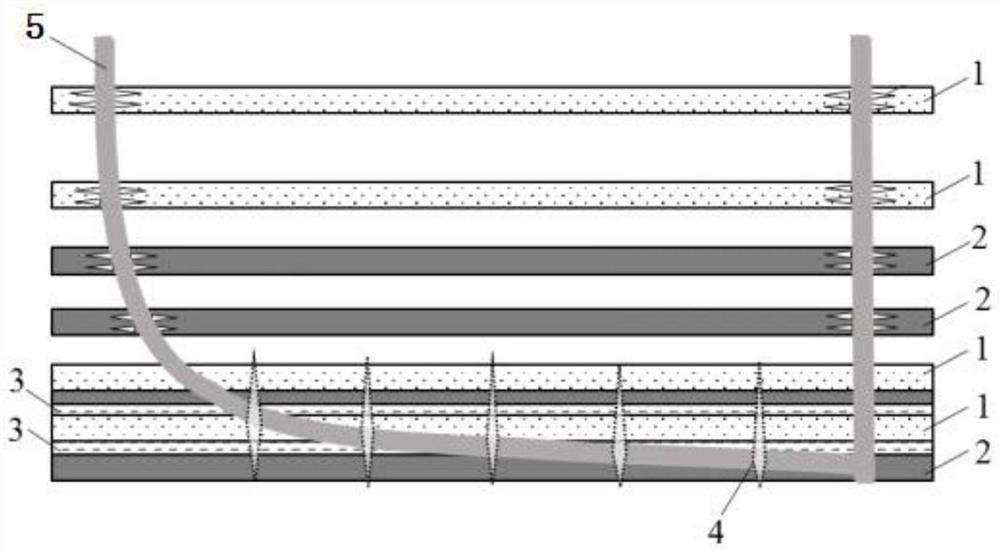

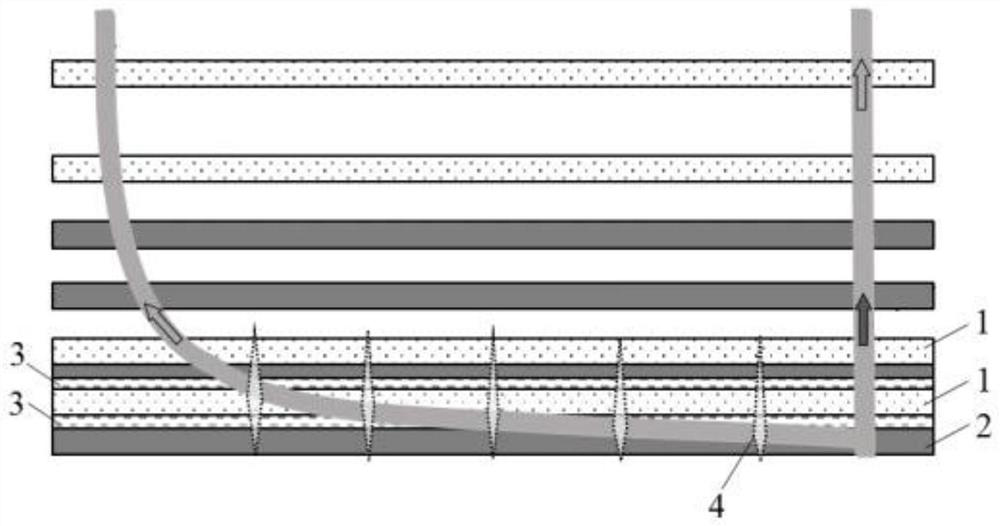

A method for multi-gas co-production and production capacity replacement in coal-measure strata

ActiveCN111894528BExpansion of mining areaRealize three-dimensional developmentFluid removalCoal measuresHorizontal wells

The invention discloses a method for multi-gas co-production and production capacity replacement of coal-measure strata, which comprises the following steps: Step 1, selecting a block in which coal seams and tight sandstone layers are relatively developed in coal-measure strata, and drilling a U-shaped block in the block Well, wherein, the horizontal section of the U-shaped well is in an inclined state, and the horizontal section passes through multiple reservoirs at the same time; step 2, the multiple reservoirs that the horizontal well section passes through are used for joint production by fracturing, and the high Gas production in the vertical well section at the structural position, drainage and fines discharge in the vertical well section at the low structural position and gas production; step 3, when the gas production of the horizontal well section decreases, use a packer to isolate the vertical well section from the horizontal section, and use The two vertical sections of the U-shaped well produce gas from the sandstone layer; step 4, when the gas production in step 3 decreases, all the reservoirs are combined for production. The method proposed by the invention solves the problems of coal seam water production and pressure mismatch between high-pressure and low-pressure reservoirs, reduces the interference of coal seam pulverization, and realizes production capacity replacement in coal-measure gas development.

Owner:SOUTHWEST PETROLEUM UNIV

A subsea natural gas hydrate production system and method

InactiveCN108894755BWon't collapseImprove work efficiencyConstructionsFluid removalMining engineeringNew energy

The invention discloses a seafloor natural gas hydrate mining system and method, and belongs to the technical field of new energy mining. The system comprises a natural gas hydrate mining device, a driving device, a natural gas hydrate purifying device, a seafloor pressurizing device, a pumping lifting device, an L-shaped pipeline and a collecting ship; the natural gas hydrate mining device comprises a cutter suction mining device and a flow jetting mining device; the mining method comprises the steps of driving mining of a suction vehicle, pressurizing of the seafloor pressurizing device, pressurizing mining of the flow jetting mining device, purifying of natural gas hydrate, mud and sand refilling, lifting of the pumping and lifting device and the collection of the collecting ship; a coarse separating device is arranged in the cutter suction mining device. The method in which two mining manners are combined is adopted, mud and sand in the natural gas hydrate are removed while miningis conducted, each working procedure is operated independently, the recovery ratio of natural gas hydrate is effectively improved, and the system has better application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Suction type hydrate mining device and method

ActiveCN103046930BRealize large-scale commercial miningExpansion of mining areaMineral miningPipeflowSoft clay

The invention discloses a suction type hydrate mining device and method. The suction type hydrate mining device comprises a rubbing device, a hose, a piston type pushing device, a suction device, a water pipeline, a seawater injection system and a mining platform. The suction type hydrate mining device can suck soft mixtures of hydrate sediments, gas and water into the pipeline; hot water doping and stirring, hydrate decomposing, gas swelling and work doing and sediment separation can be carried out in the pipeline; and the gas can be collected through the mining platform. By the suction type hydrate mining device, no machine is used for dipping in deep water, so that the mining range is expanded; therefore, relatively high mining efficiency is realized; and hydrates in soft clay sediments can be commercially mined in large scale. A new way is supplied to mining of hydrate stratums with high hydrate content of soft clay sediments in the South China Sea and other areas; and a new method is supplied to mining of energy in the soft clay sediments.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Thin seam short-span coal mining machine

PendingCN114396277AImprove stress stabilityShorten the left and right lengthSlitting machinesCutting machinesThermodynamicsGear wheel

The invention relates to a short-span coal mining machine for a thin coal seam, which comprises a front main body part shell and a rear main body part shell which are fixedly connected front and back, and two swing arm shells which are respectively hinged to the left end and the right end of the front main body part shell, the two ends of an arm frame extending left and right of the swing arm shell are the high-speed end and the low-speed end respectively, a connecting arm overhanging forwards from the arm frame is arranged in the middle of the arm frame, a front arm overhanging leftwards or rightwards is arranged on the connecting arm, and a front pin shaft mounting hole and a rear pin shaft mounting hole are formed in the front portion of the high-speed end of the front arm and the front portion of the high-speed end of the arm frame respectively. An input end gear mounting hole is formed in the rear portion of the high-speed end of the arm frame, the front pin shaft mounting hole and the rear pin shaft mounting hole are coaxial with the input end gear, an oil cylinder containing cavity is formed below the front arm and the lower portion of the connecting arm, and the two ends of a height adjusting oil cylinder are hinged to the connecting arm and the front main body portion shell respectively. According to the invention, a larger mining range and larger cutting power can be provided, the machine body can be shortened, and the gravity center of the coal mining machine can be improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Compact coal mining machine for thin coal seam

PendingCN114396265AImprove reliabilityIncrease radial floatSlitting machinesCutting machinesGear wheelEngineering

The invention relates to a thin seam compact coal mining machine which comprises a machine body and two swing arm shells hinged to the left end and the right end of the machine body respectively, the two ends of an arm frame extending leftwards and rightwards of the swing arm shells are the high-speed end and the low-speed end respectively, a connecting arm overhanging forwards from the arm frame is arranged in the middle of the arm frame, and a front arm and a rear arm are arranged on the front portion and the rear portion of the arm frame respectively. The root of the front arm is connected to the connecting arm, the front arm and the rear arm are hinged to the machine body, an input end gear of a rear-stage cutting transmission mechanism installed in the arm frame is in coaxial transmission connection with an output end gear of a front-stage cutting transmission mechanism installed in the machine body, an oil cylinder outer containing cavity is formed in the lower portion of the connecting arm, and an oil cylinder inner containing cavity is formed in the lower portion of the machine body. The height adjusting oil cylinder is located in the oil cylinder outer containing cavity and the oil cylinder inner containing cavity, and the two ends of the height adjusting oil cylinder are hinged to the connecting arm and the machine body respectively. The coal mining machine can provide a larger mining range, has a more compact machine body, and can improve the gravity center problem of the coal mining machine.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com