Efficient muddy silt type natural gas hydrate mining system and mining method thereof

A natural gas and hydrate technology, applied in the direction of mining fluids, drilling compositions, chemical instruments and methods, etc., can solve problems such as the inability to form fracture channels, so as to promote molecular thermal movement, widen gas-water seepage channels, and promote decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

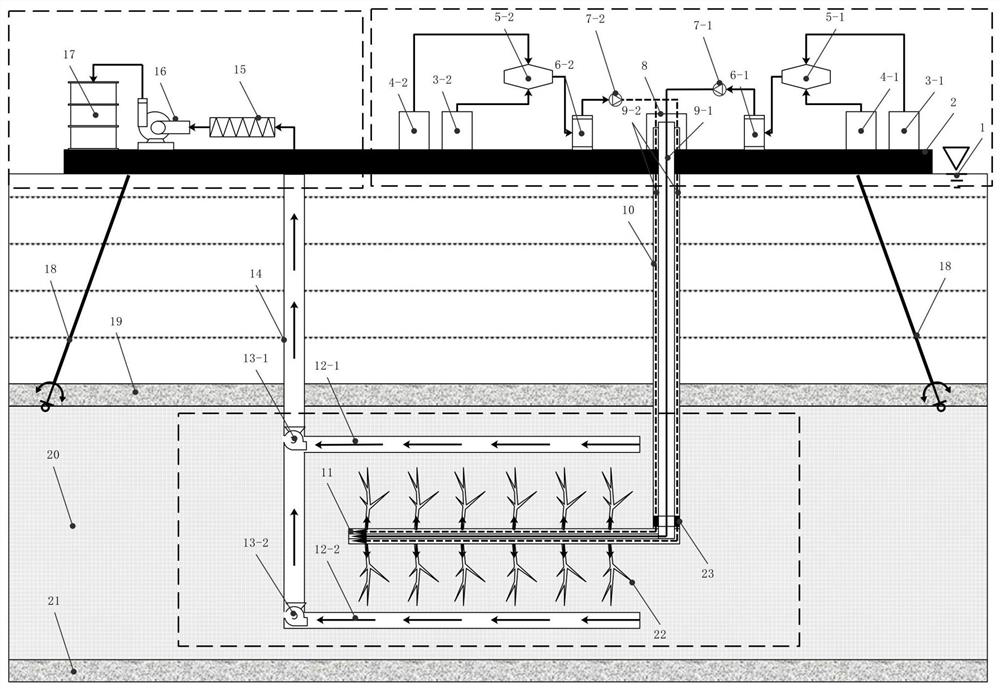

[0031] see Figure 1 to Figure 3 As shown, a high-efficiency argillaceous silt type natural gas hydrate production system includes: an offshore floating platform 2, a slurry mixing module, a reaction production module and a product collection module. The slurry mixing module and the product collection module are located on the floating offshore platform floating on the sea surface Above 2, the slurry stirring module and the product collection module are connected through the reaction production module;

[0032] The offshore floating platform 2 is connected to the seabed through anchor cables 18 to ensure the stability of its position;

[0033] The slurry stirring module includes a type I base liquid storage tank 3-2, a type II base liquid storage tank 3-1, a type I additive liquid storage tank 4-2, a type II additive liquid storage tank 4-1, A-type slurry mixer 5-2, B-type slurry mixer 5-1, A-type slurry storage tank 6-2, B-type slurry storage tank 6-1, A-type slurry mud pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com