Patents

Literature

203results about How to "Increase the reaction contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

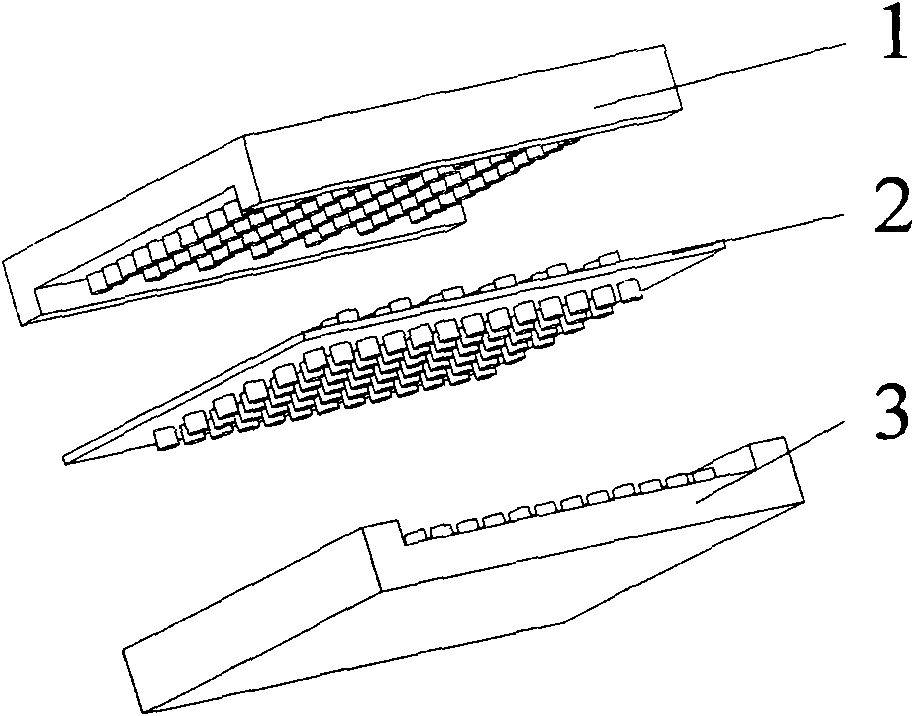

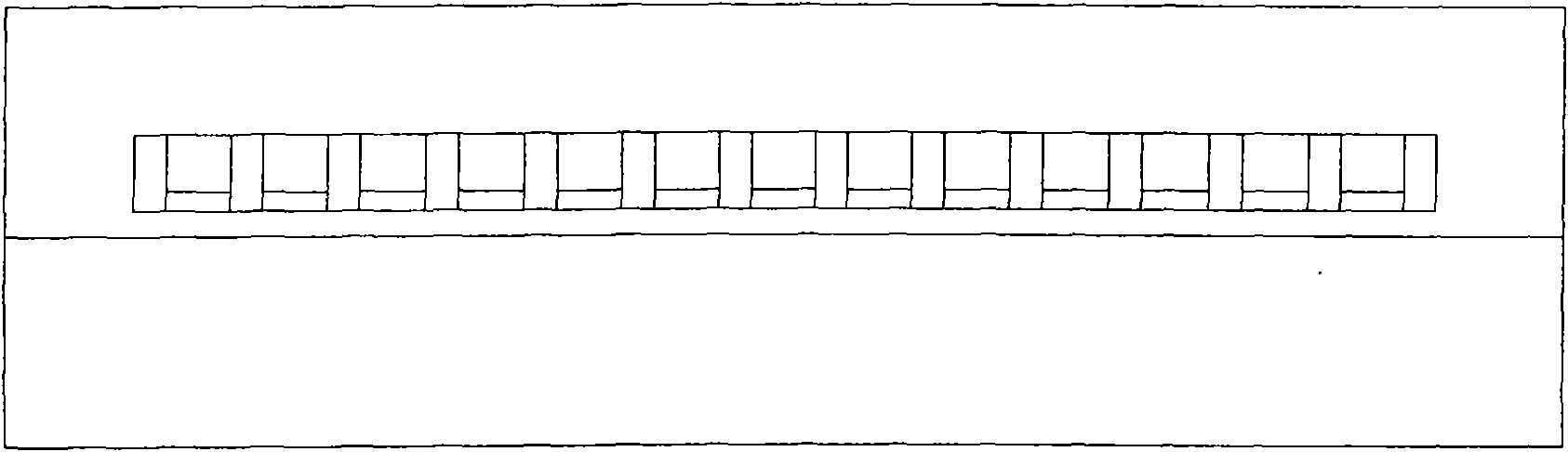

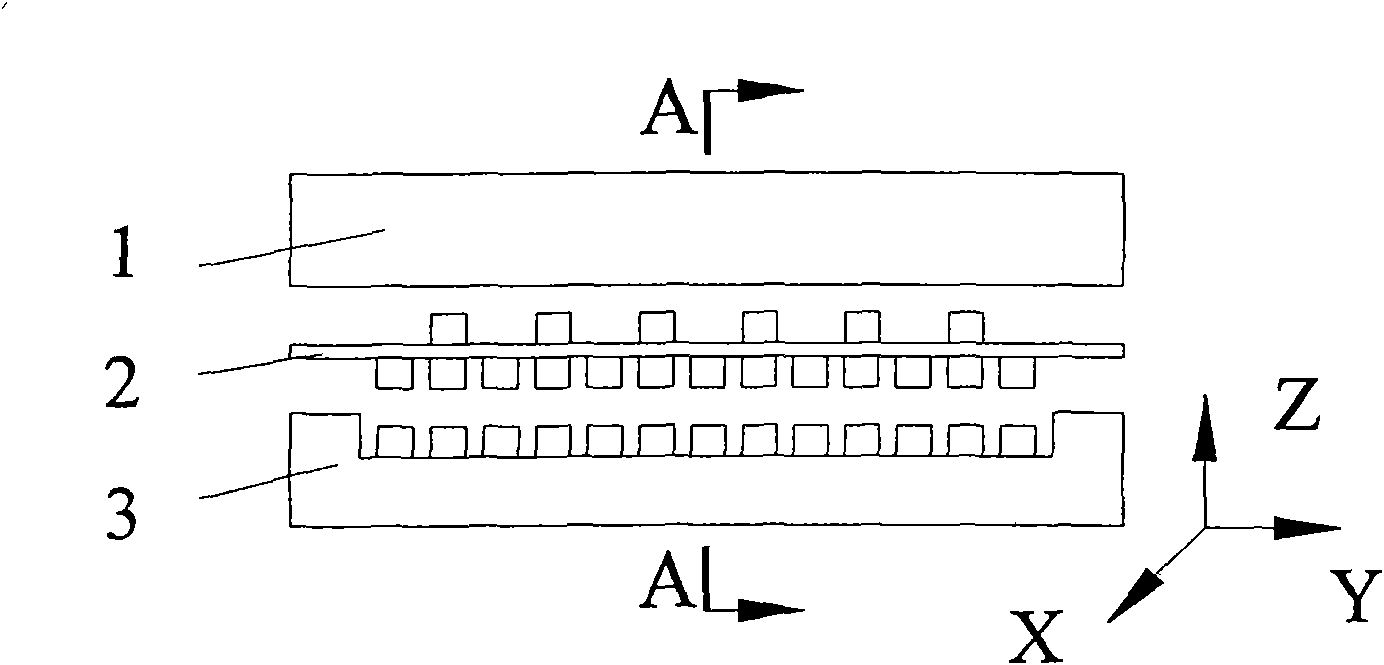

Self-heating type alcohol reforming hydrogen production micro channel reactor with micro-lug boss array structure

The invention discloses a self-heating type alcohol reforming hydrogen production micro channel reactor with the micro-lug boss array structure. Three layers of platy reaction carriers are all provided with micro-lug boss array structures; an upper layer and a lower layer are single-side micro-lug boss array structures; a middle layer is a double-side micro-lug boss array structure; the micro-lug bosses are arranged in the mode of parallel array; the three layers are cascaded to form a reaction channel with an inlet of 90 degrees; both ends of the channel are respectively provided with connector lugs; the gas inlet is provided with a detachable adapter and an outlet is provided with a fixed-type adapter. An upper layer channel is a catalytic reforming hydrogen production channel, and a lower layer channel is a combustion channel. The two layers of channel structures both adopt an open structural type being beneficial for the sediment of the catalytic coating. Fuel gases such as hydrogen and the like are combusted in the combustion channel and generate lot of heat which is transferred into the catalytic reforming hydrogen production channel by the middle layer of the reactor so as to meet the requirement of the steam reforming hydrogen production reaction; the reactor can produce hydrogen in a self-heating type. The invention increases the specific volume of the reactor and increases the yield of the alcohol reforming hydrogen production.

Owner:ZHEJIANG UNIV

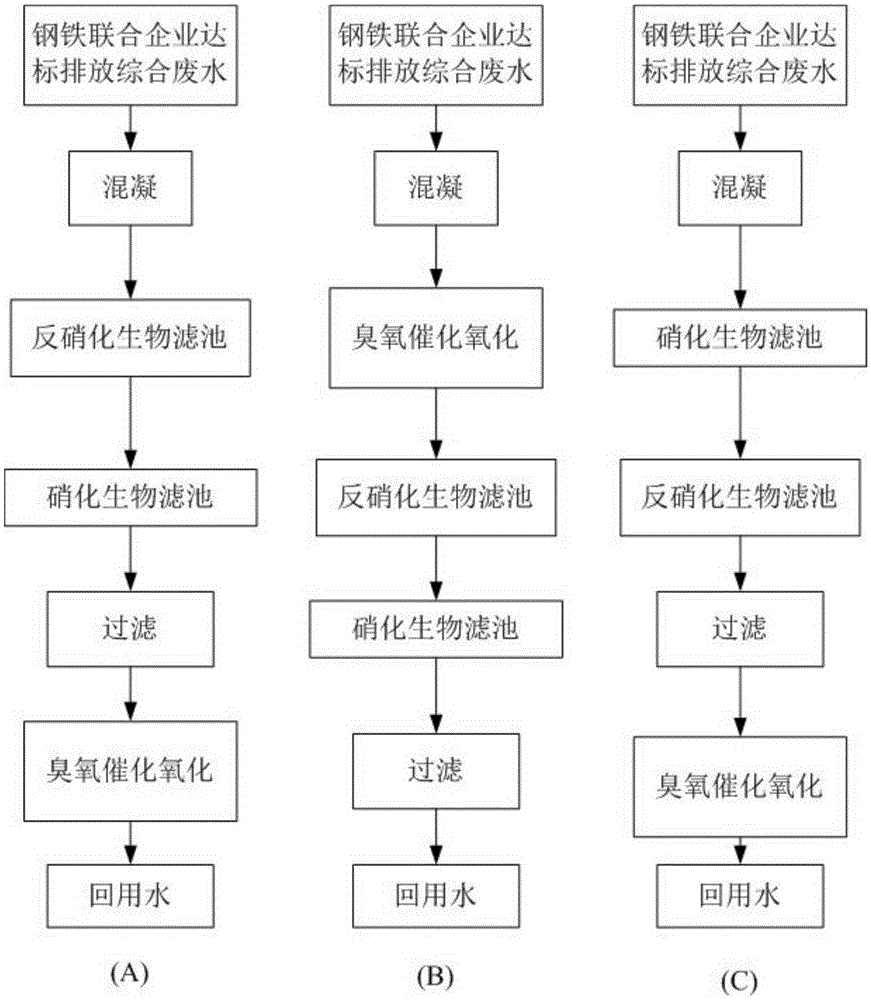

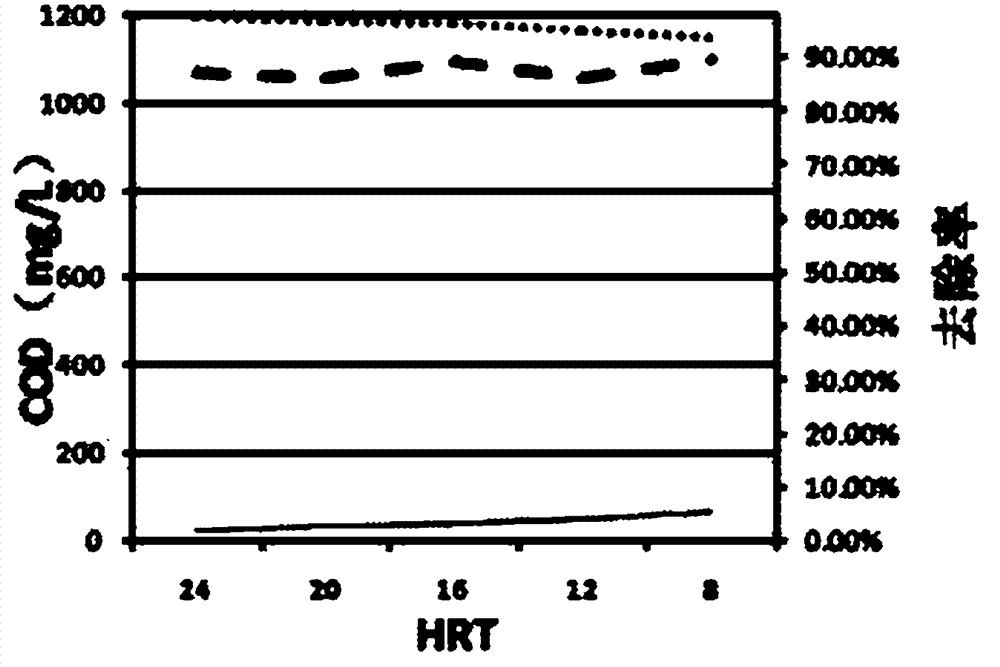

Iron and steel complex comprehensive wastewater treatment device and process

ActiveCN105293833AHigh volume loadIncrease hydraulic loadWaste water treatment from metallurgical processMultistage water/sewage treatmentCatalytic oxidationWater quality

The invention provides an iron and steel complex comprehensive wastewater treatment device and process. The device comprises a coagulation unit, a biochemical treatment unit, a filter unit and an ozone catalytic oxidation unit. The biochemical treatment unit comprises a nitrification biofilter and a denitrification biofilter. The coagulation unit, the denitrification biofilter, the nitrification biofilter, the filter unit and the ozone catalytic oxidation unit are connected in order; or, the coagulation unit, the ozone catalytic oxidation unit, the denitrification biofilter, the nitrification biofilter and the filter unit are connected in order; or, the coagulation unit, the nitrification biofilter, the denitrification biofilter, the filter unit and the ozone catalytic oxidation unit are connected in order. The device can remove COD and ammonia nitrogen from wastewater synchronously at low cost, has the advantages of high treatment efficiency, good stability, strong impact resistance ability and simple operation, can flexibly selects the connection form of the treatment units according to the water quality condition, can realize the whole course flow by gravity, lowers energy consumption, and is conducive to project promotion.

Owner:深圳市锦坚环保科技有限公司

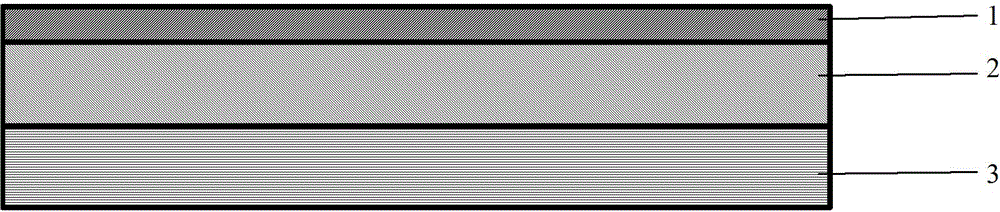

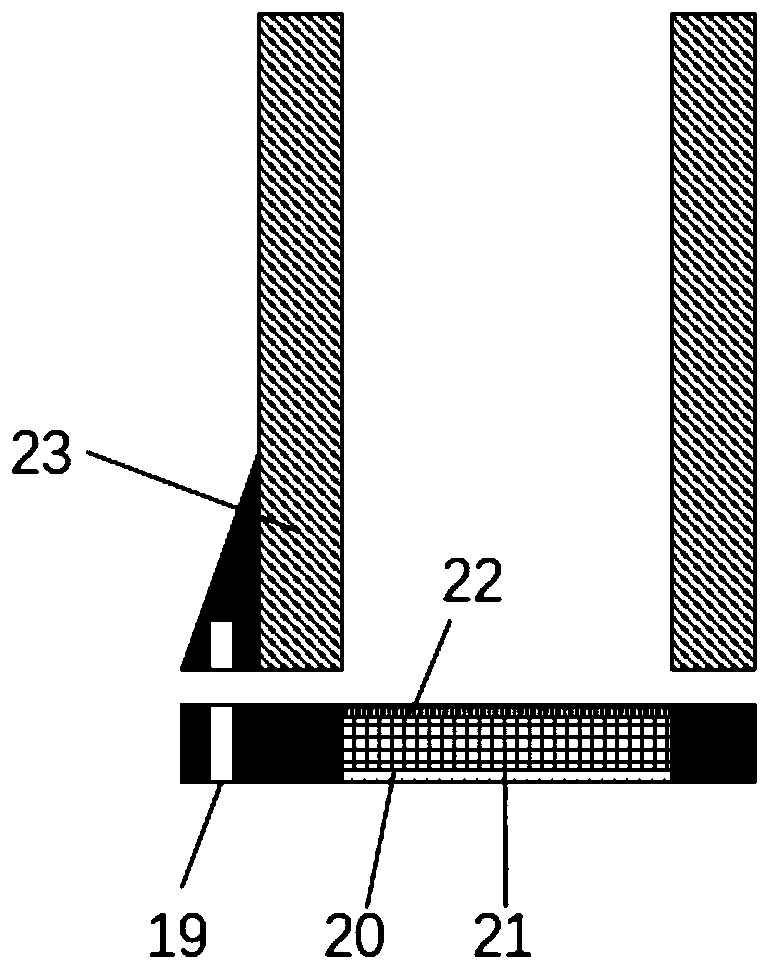

Multilayer composite positive pole piece, method for preparing pole piece and lithium ion battery applying multilayer composite positive pole piece

InactiveCN104466188AIsolated contactImprove immersionSecondary cellsNon-aqueous electrolyte accumulator electrodesPower batteryPole piece

The invention relates to the field of lithium ion batteries and in particular provides a multilayer composite positive pole piece, a method for preparing the pole piece and a secondary lithium ion battery applying the multilayer composite positive pole piece. The composite positive pole piece comprises a current collector layer, a positive active function layer and a safety protection layer formed on the positive active function layer. According to the positive pole piece disclosed by the invention, the condition that inner short circuit occurs because a negative pole material of the lithium ion battery is directly contacted with a positive active material is avoided, the safety performance is good, and the battery of the composite positive pole piece is applied to power batteries.

Owner:JIANGSU QINGTAO ENERGY TECH

Method for smelting medium- and low-carbon ferrochromium by introducing one-step method of carbon dioxide converter

ActiveCN104294002AMeet production requirementsReduce processing costsManufacturing convertersMaterials scienceDecarburization

The invention discloses a method for smelting medium-carbon and low-carbon ferrochromium by introducing a one-step method of a carbon dioxide converter and belongs to the field of metallurgy. The method comprises the following steps: (1) continuously producing high-ferrochromium by using a submerged arc furnace; (2) introducing a CO2 converter to produce medium-carbon and low-carbon ferrochromium; and (3) producing a medium-carbon and low-carbon ferrochromium product. The service life of a fireproof furnace liner is prolonged by introducing the CO2 converter to produce medium-carbon and low-carbon ferrochromium, chromium is prevented from being oxidized during decarburization, the recovery rate of chromium is improved, the grade of converter gas is improved and the smelting cost is lowered.

Owner:UNIV OF SCI & TECH BEIJING

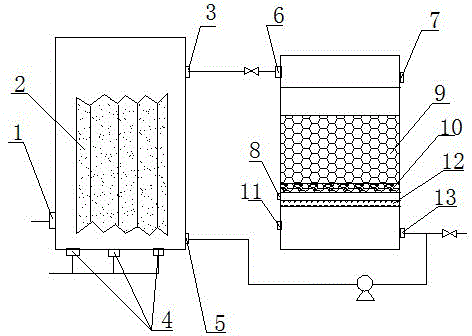

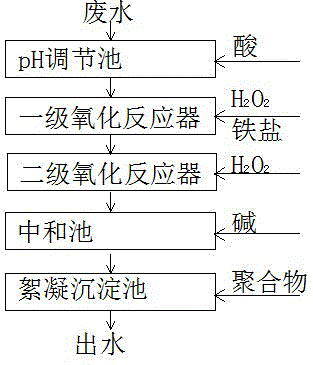

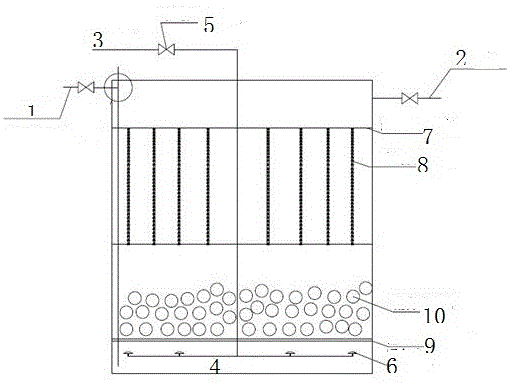

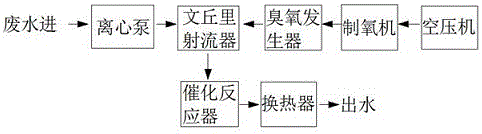

Two-stage catalytic oxidation wastewater treatment system

InactiveCN104445743AIncrease the reaction contact areaPlay the role of diversionMultistage water/sewage treatmentWater/sewage treatment by neutralisationFixed bedCatalytic oxidation

The invention discloses a two-stage catalytic oxidation wastewater treatment system and belongs to the field of wastewater treatment. The two-stage catalytic oxidation wastewater treatment system is connected with a pH adjustment tank, an oxidation reactor, a neutralization tank, and a flocculation-sedimentation tank by virtue of inlet water pipelines, wherein the oxidation reactor comprises a first-stage oxidation reactor and a second-stage oxidation reactor, the water inlet of the first-stage oxidation reactor is connected with the water inlet of the second-stage oxidation reactor by virtue of a pipeline, the first-stage oxidation reactor is a homogeneous oxidation reactor and the second-stage oxidation reactor is a fixed bed oxidation reactor. Compare with the traditional homogeneous reaction and fluidized bed technology, by the two-stage catalytic oxidation wastewater treatment system, the reaction efficiency is increased, the chemical agent addition amount is significantly reduced, the effluent water quality can be significantly improved, the concentration of organic matters in the effluent water is decreased and the two-stage catalytic oxidation wastewater treatment system is applicable to deep treatment of wastewater and has broad practical application prospects.

Owner:王全勇

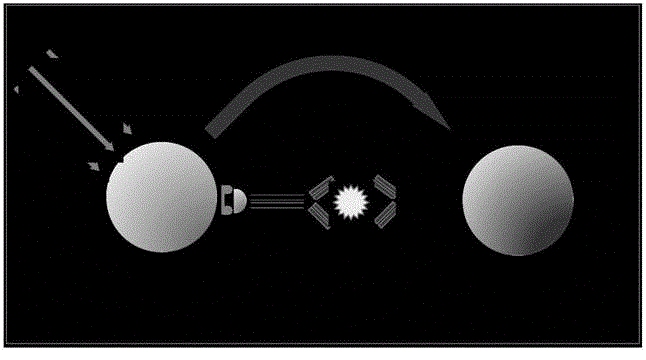

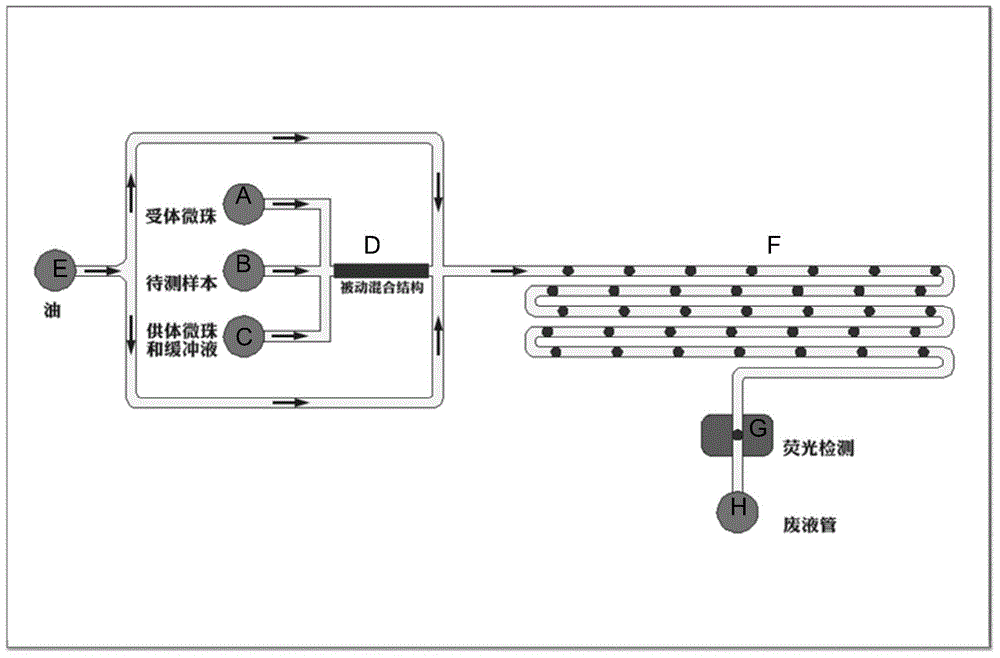

Biological macromolecule detection method based on nano homogeneous time-resolved fluoroimmunoassay and droplet-based micro-fluidic technology

InactiveCN106324236AReduce volumeLow concentration requirementBiological testingFluorescenceEngineering

The invention belongs to the field of micro-fluidic chips, and relates to a biological macromolecule detection method. An alpha-LISA technology and a droplet-based microfluidics technology are combined and optimized to prepare a micro-fluidic chip liquid. A novel biological macromolecule detection method with a high sensitivity is provided. A three-phase mixing technology is adopted. A passive mixing structure is used to fully and evenly mix the reaction liquid. A cross focusing technology is used to form droplets. The generated droplets have the advantage of smaller volume, and thus the reactions become faster. Moreover, the requirements on the samples are lower, the reactions are specific, sensitive, fast, and full; the washing does not need to be carried out after reactions; complicated complexes such as complete proteins, enzyme complex, bacteriophage, and the like, can be detected; the technical bottleneck of conventional commercial liquid chips at present can be broken through; the provided method can be applied to fast clinical biological macromolecule detection; the detection sensitivity and specificity are both improved, and the required sample amount is reduced.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

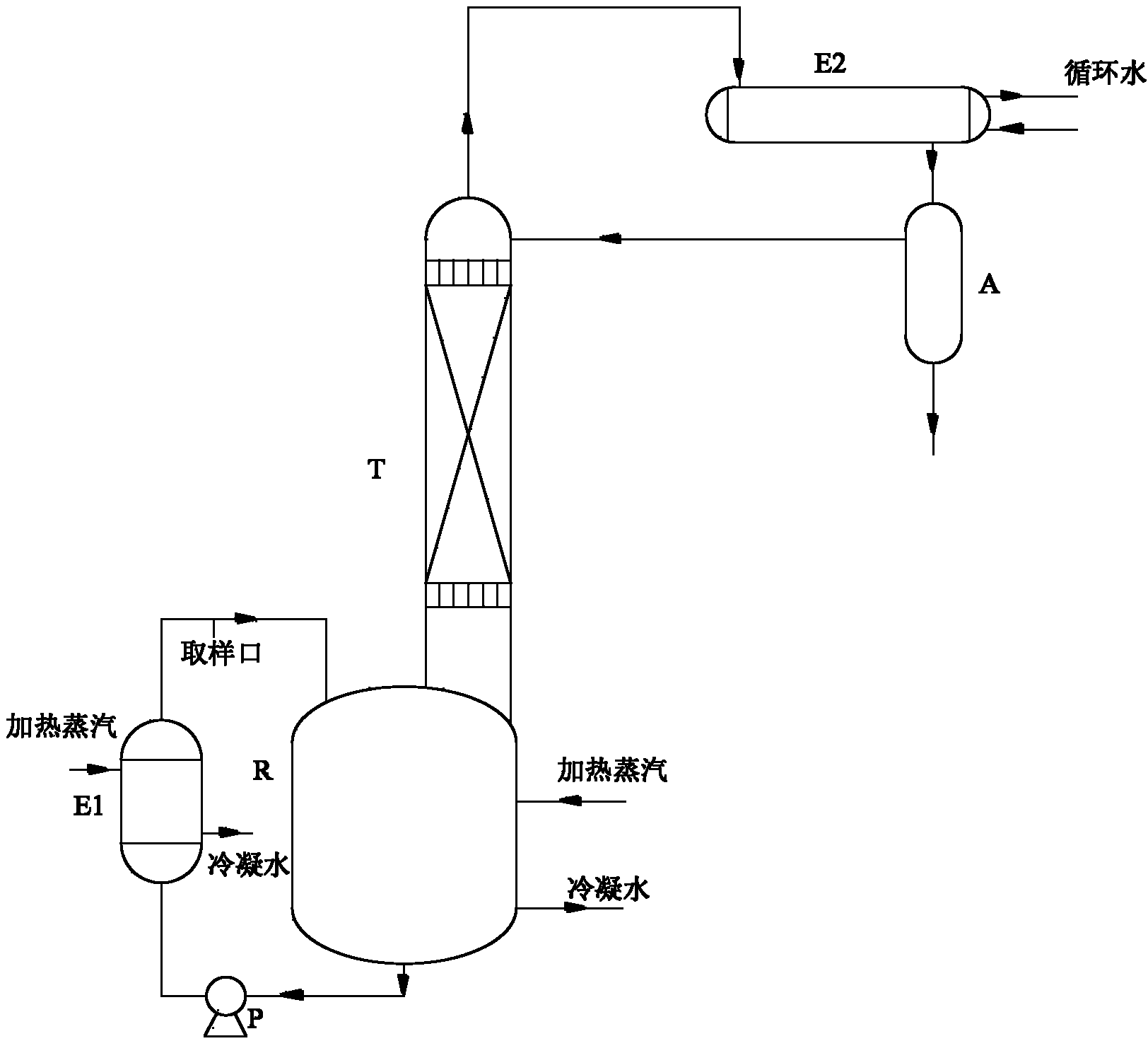

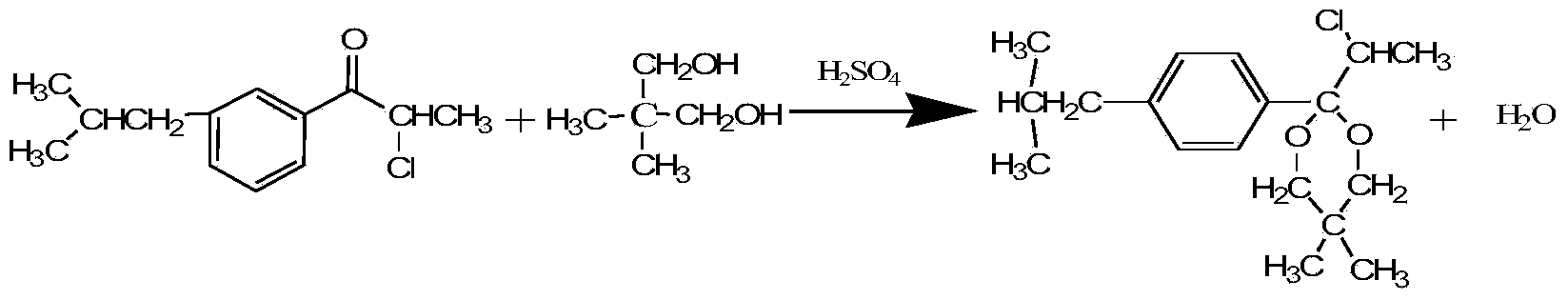

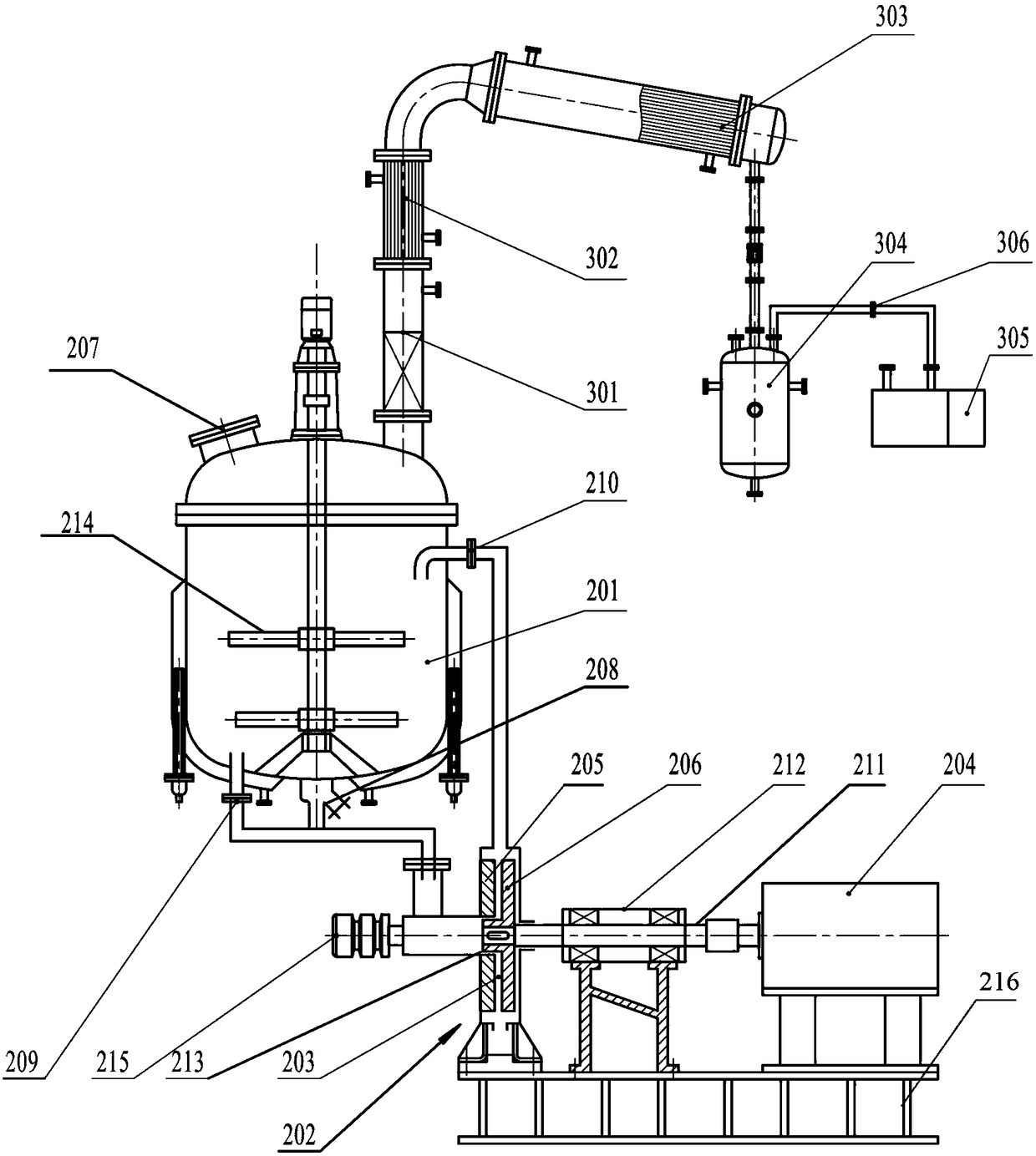

Device and method for shortening ketalation time in ibuprofen synthesis process

The invention relates to a device for shortening ketalation time in an ibuprofen synthesis process through reactive rectification, and a method for shortening ketalation time in an ibuprofen production process. The device consists of a reaction kettle (R), a rectification tower (T), a reboiler (E1), a condenser (E2), a reflux tank (A) and a circulating pump (P). The method comprises the following steps: adding a certain amount of chlorone-containing petroleum ether solution, neopentyl glycol and dilute sulfuric acid into the reaction kettle (R); heating the liquor in the reaction kettle (R) by use of steam in a jacket; introducing gas phase of the heated liquor into the rectification tower (T) to separate; feeding tank liquor of the reaction kettle (R) into the reboiler (E1) through the circulating pump (P) to heat; feeding into the reaction kettle (R); condensing the steam withdrawn on the tower top into condensation water through the condenser (E2) to obtain petroleum ether and water; layering the solution in the reflux tank (A), taking the upper layer of petroleum ether as overhead reflux, and withdrawing and recovering the lower layer of water.

Owner:QINGDAO UNIV OF SCI & TECH

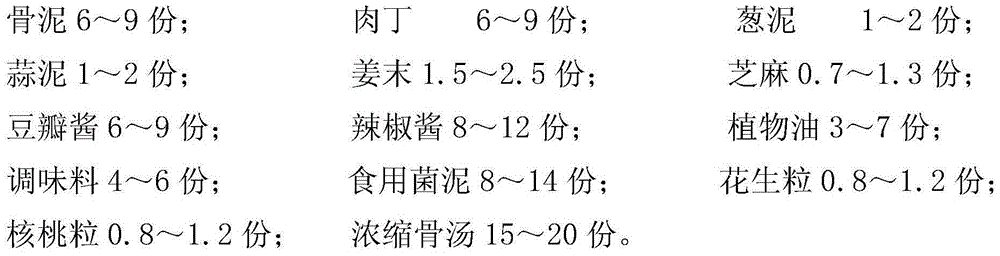

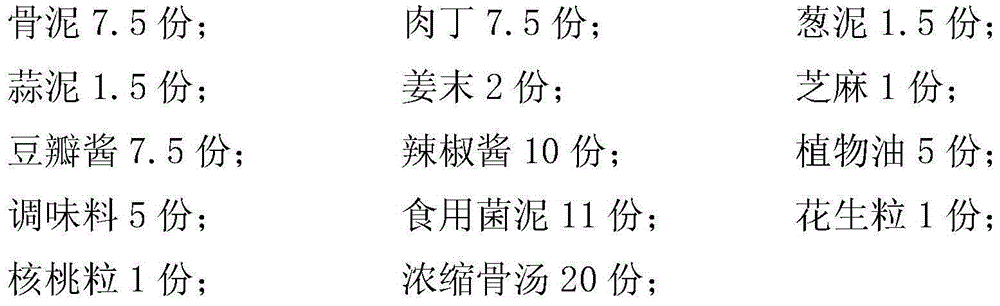

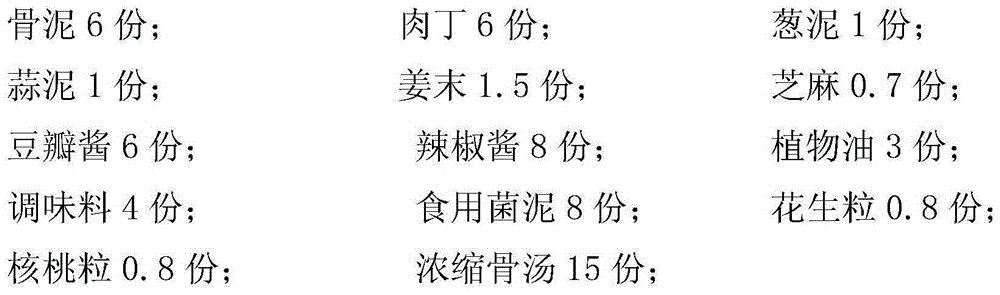

Fresh bone flavor paste of animals and preparation method of fresh bone flavor paste

The invention discloses a fresh bone flavor paste of animals. The fresh bone flavor paste is prepared from the following raw materials: bone paste, diced meat, mashed onion, mashed garlic, bruised ginger, sesame, a thick broad-bean sauce, a chilli sauce, vegetable oil, a seasoner, edible mushroom sludge, peanuts, walnut grains and concentrated bone soup. A preparation method of the fresh bone flavor paste comprises the following steps: (1) raw material pretreatment; (2) preparation of the flavor paste; and (3) canning, exhausting, sterilizing and cooling. The fresh bone flavor paste product of the animals with high additional value is produced by a plurality of technologies with relatively high technological content; by-products in the animal processing industry are changed into treasures; a lot of meat products with abundant nutrient are provided for the consumer market; deep processing and full utilization of animal bones can be promoted; the nutritive value of the mean products is relatively high; the raw material cost is relatively low; the fresh bone flavor paste has a great development prospect.

Owner:XUZHOU UNIV OF TECH

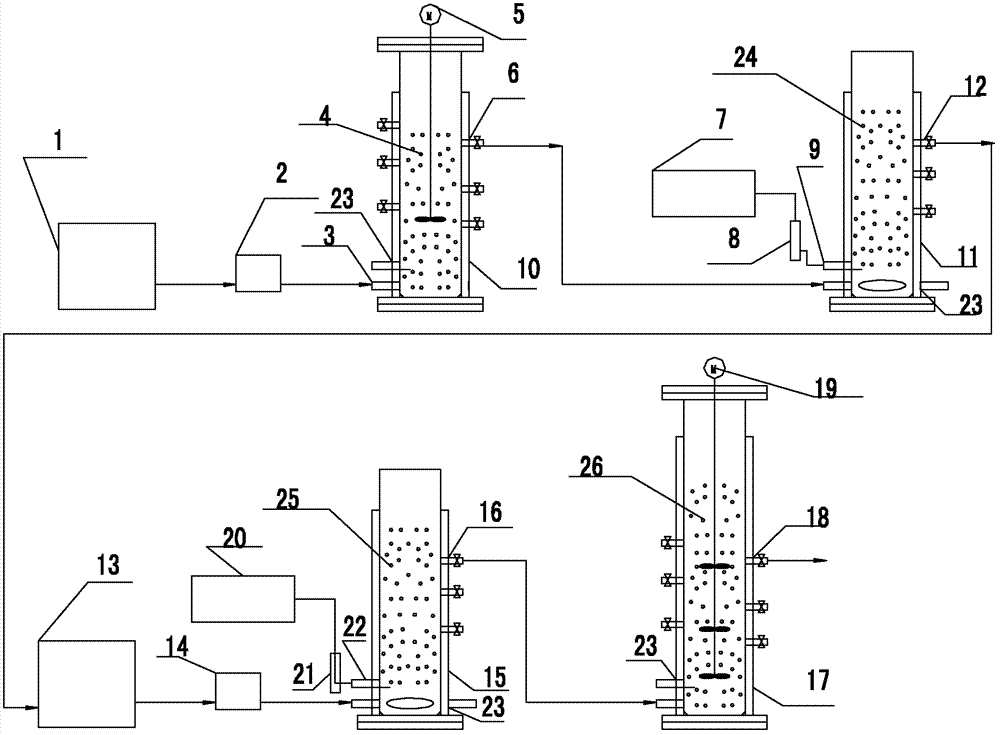

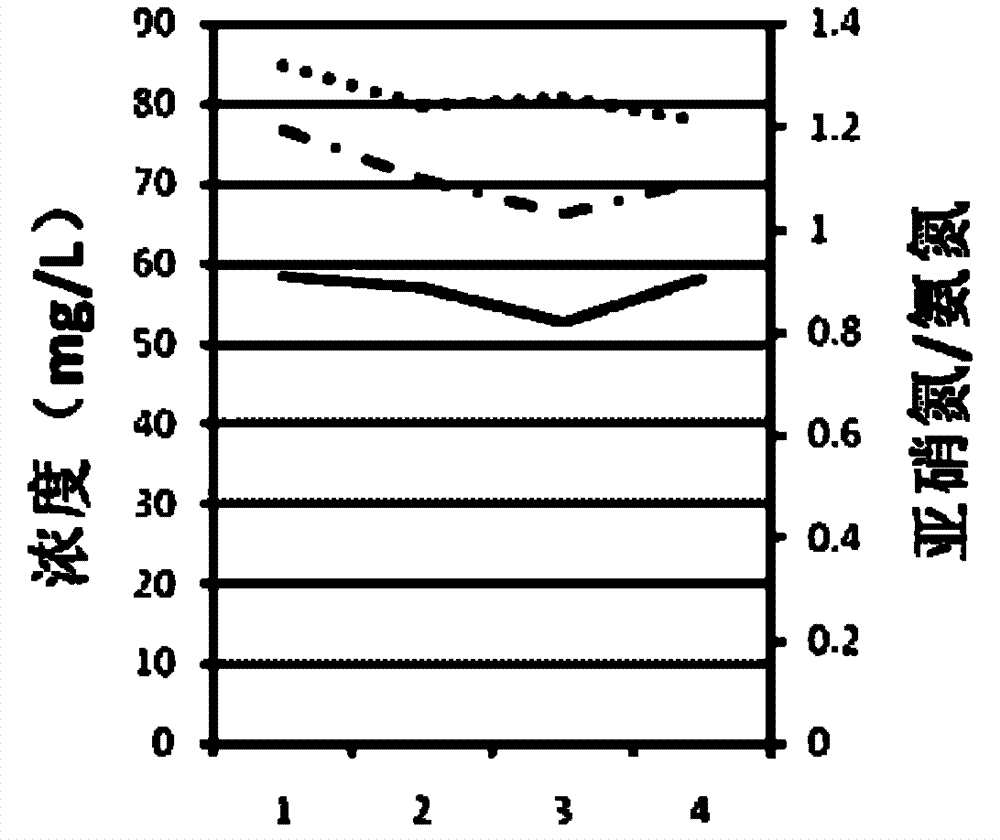

Carbon and nitrogen removal system based on moving bed biomembrane reactor

InactiveCN103086561ASimple structureEasy to operateMultistage water/sewage treatmentNitrogen removalMoving bed biofilm reactor

The invention relates to a carbon and nitrogen removal system based on a moving bed biomembrane reactor. The carbon and nitrogen removal system based on a moving bed biomembrane reactor has the advantages of high reliability, simultaneous implementation of carbon removal and nitrogen removal, and good carbon and nitrogen removal effects. The system comprises an anaerobic tower, an aerobic tower, a shortcut nitrification tower and an anaerobic ammoxidation tower; a first filler is arranged in the anaerobic tower, a second filler is arranged in the aerobic tower, a third filler is arranged in the shortcut nitrification tower, and a fourth filler is arranged in the anaerobic ammoxidation tower; and a water inlet tank is connected with the water inlet of the anaerobic tower, the water outlet of the anaerobic tower is connected with the water inlet of the aerobic tower, the water outlet of the aerobic tower is connected with an intermediate water tank, the intermediate water tank is connected with the water inlet of the shortcut nitrification tower, the water outlet of the shortcut nitrification tower is connected with the water inlet of the anaerobic ammoxidation tower, and the water outlet of the anaerobic ammoxidation tower is connected with a discharge device.

Owner:欧联(北京)环境工程有限公司

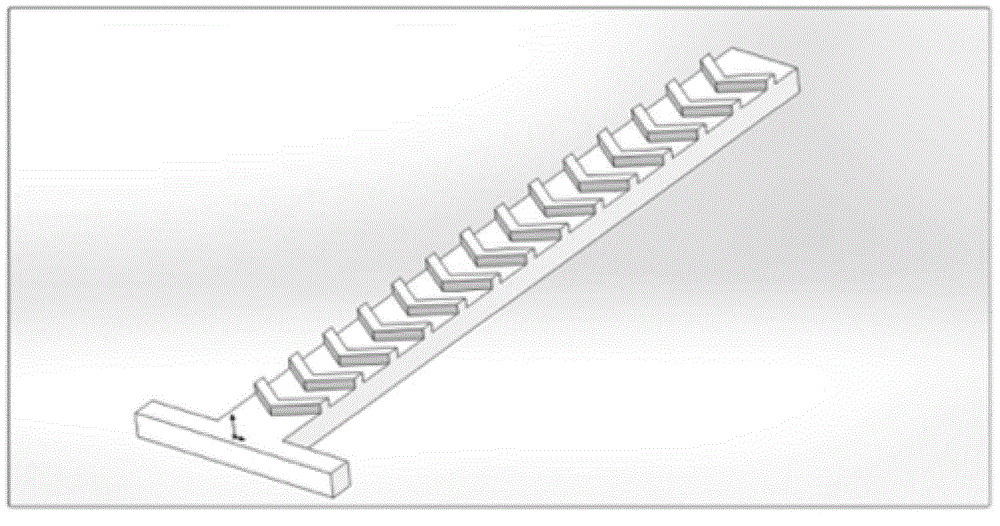

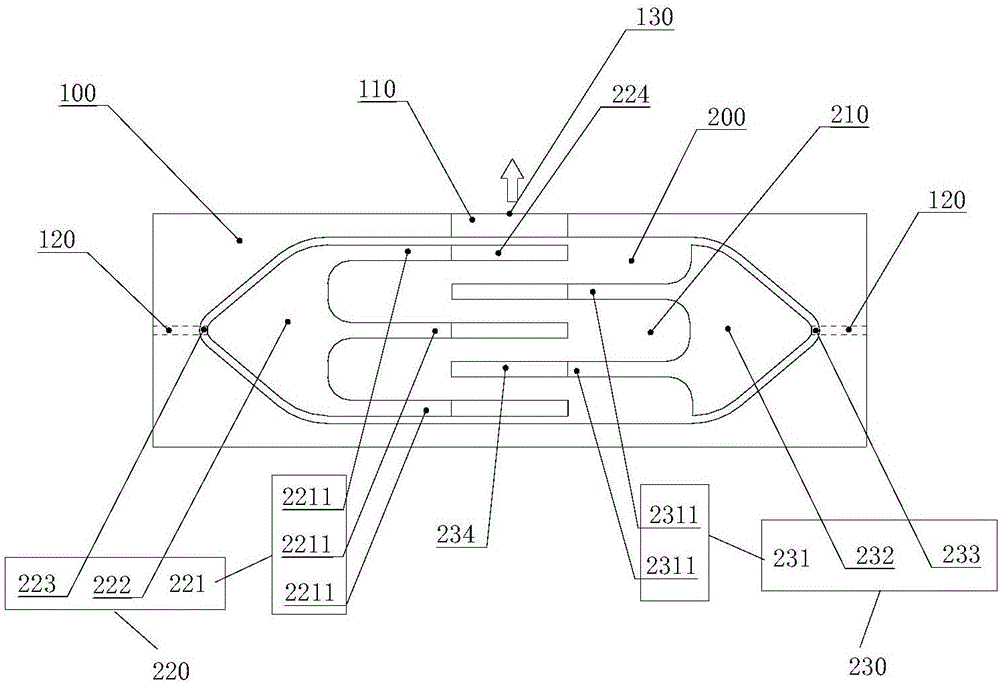

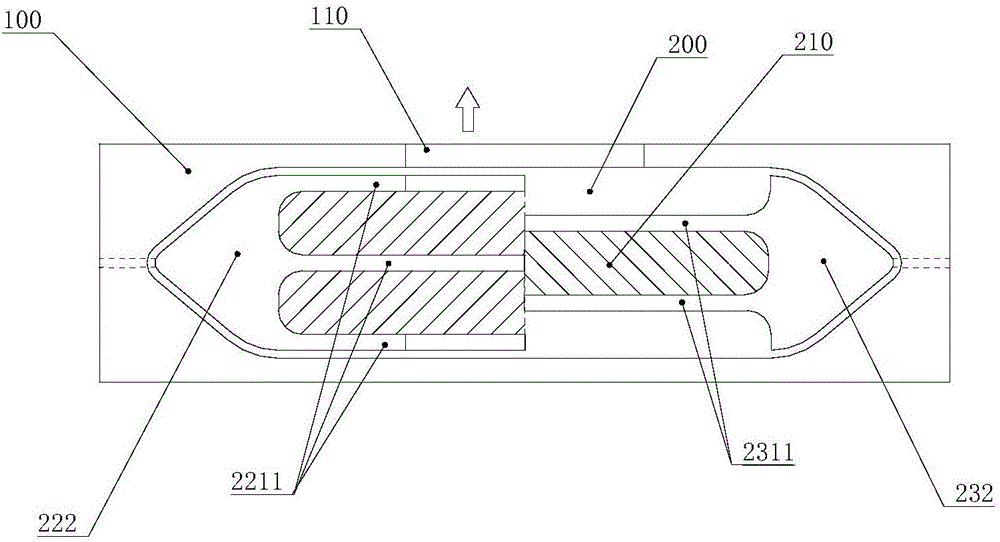

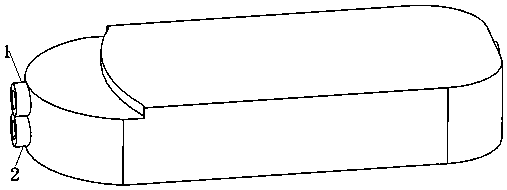

Chip type micro reaction channel and micro reactor

ActiveCN106492718AImprove production efficiencyIncrease the reaction contact areaChemical/physical/physico-chemical microreactorsMicroreactorEngineering

The invention discloses a chip type micro reaction channel and a micro reactor. The chip type micro reaction channel comprises a substrate and a chip, wherein the chip is positioned on the substrate and comprises a diversion structure and a first fluid part and a second fluid part which are partitioned by the diversion structure; the first fluid part comprises a first inlet; the second fluid part comprises a second inlet; meanwhile the first fluid part is partitioned into at least first diversion channels by the diversion structure; the second fluid part is partitioned into at least two second diversion channels by the diversion structure; moreover mixing channels are formed in a connected manner in corresponding positions of the first diversion channels and the second diversion channels on the substrate; the mixing channels are respectively connected with the first diversion channels and the second diversion channels. The micro reactor comprises a first chip type micro reaction channel. By adopting the chip type micro reaction channel and the micro reactor, different reactants in two types of fluid can be sufficiently mixed and reacted, the reaction speed can be increased, the reactant generation efficiency can be improved, and meanwhile the reaction security and reliability can be improved.

Owner:SHANDONG HIMILE CHEM TECH

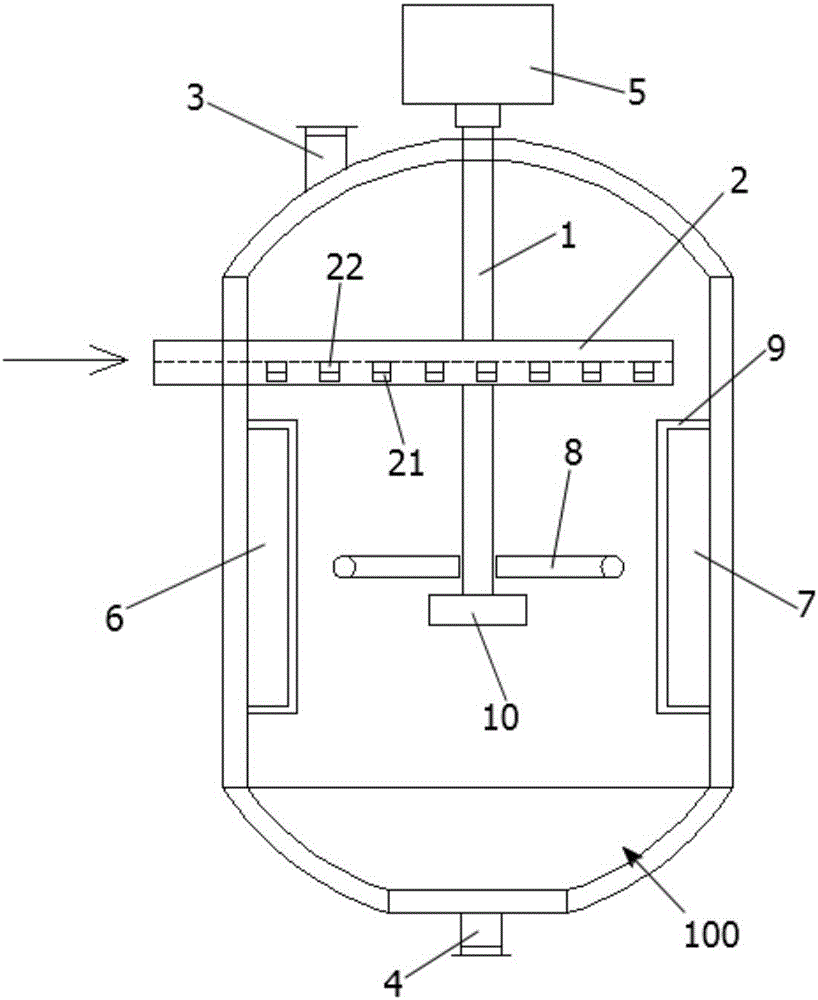

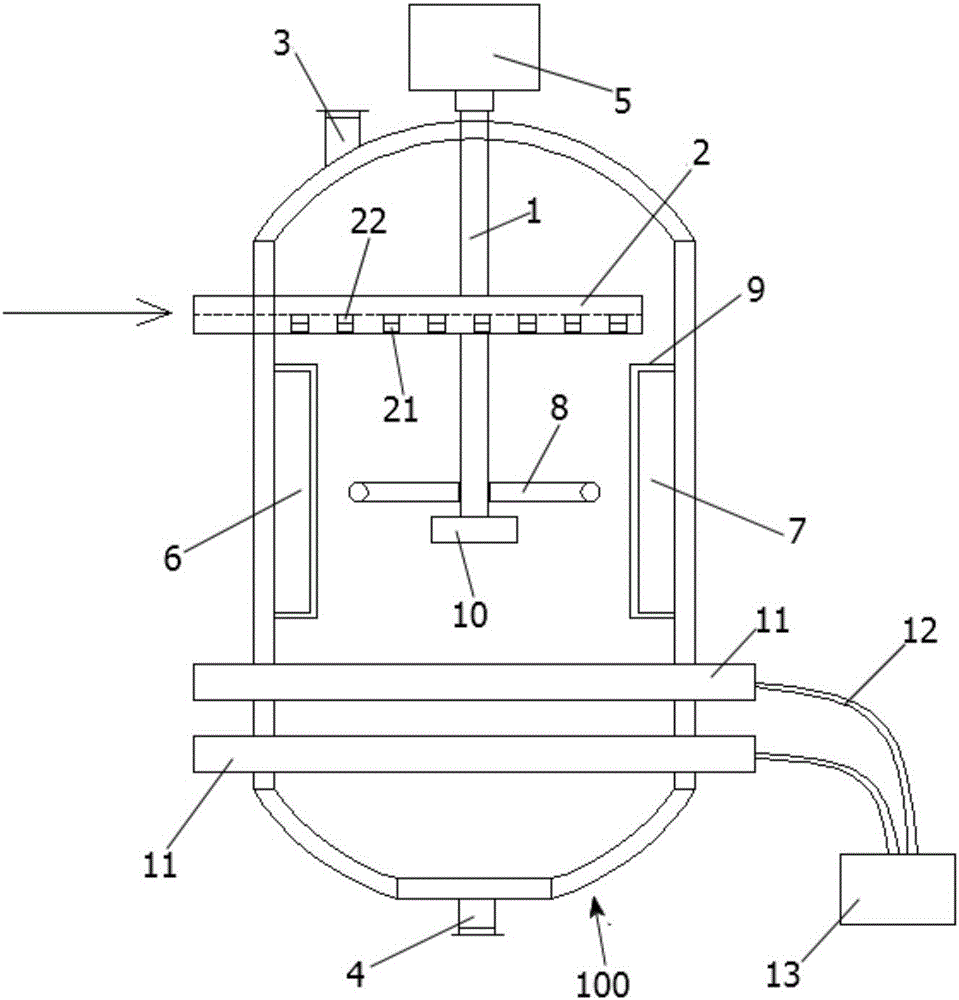

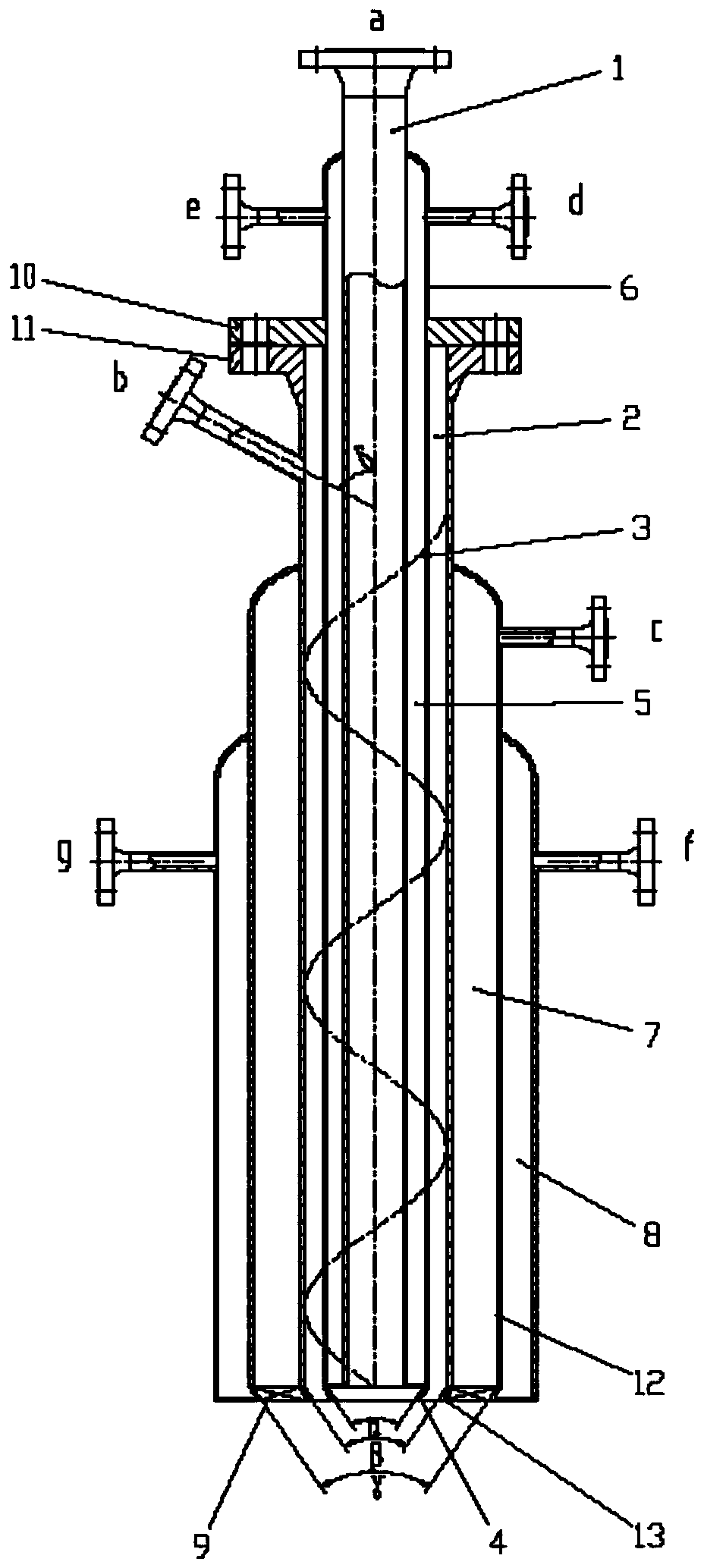

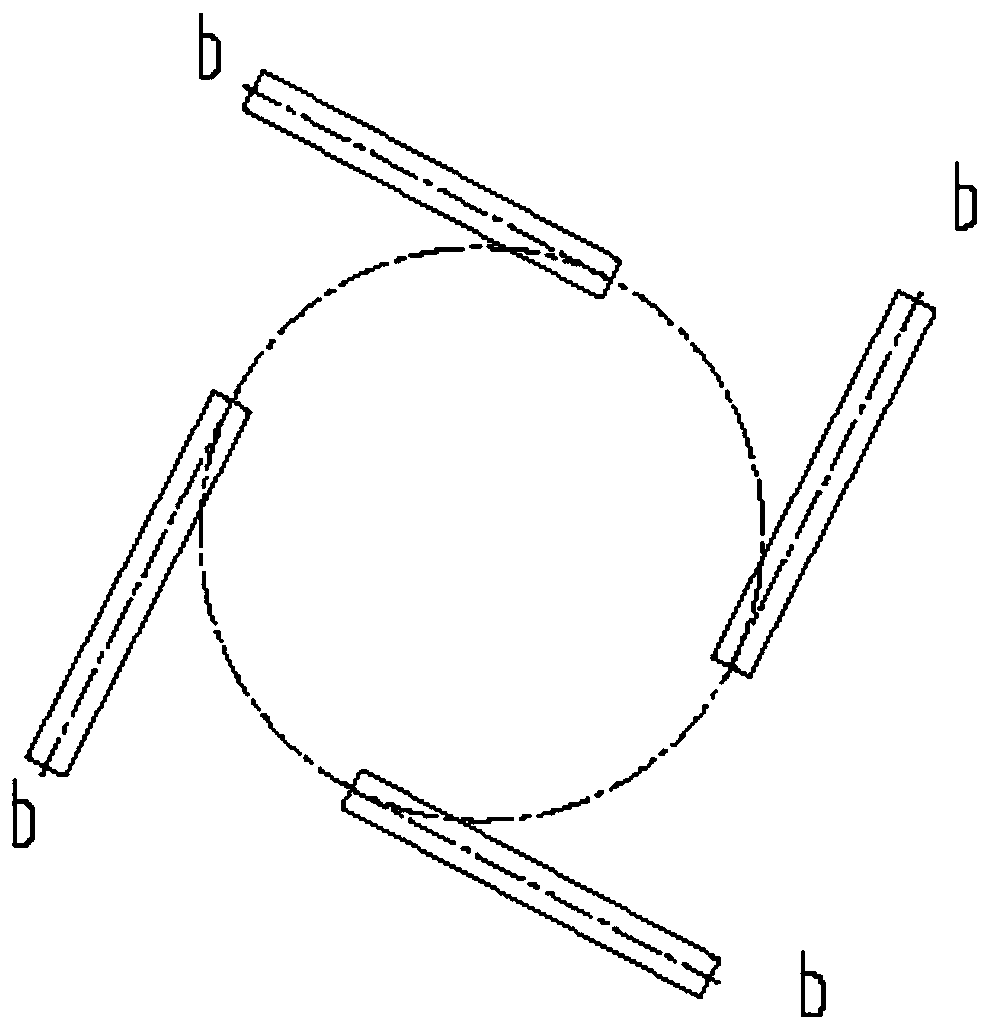

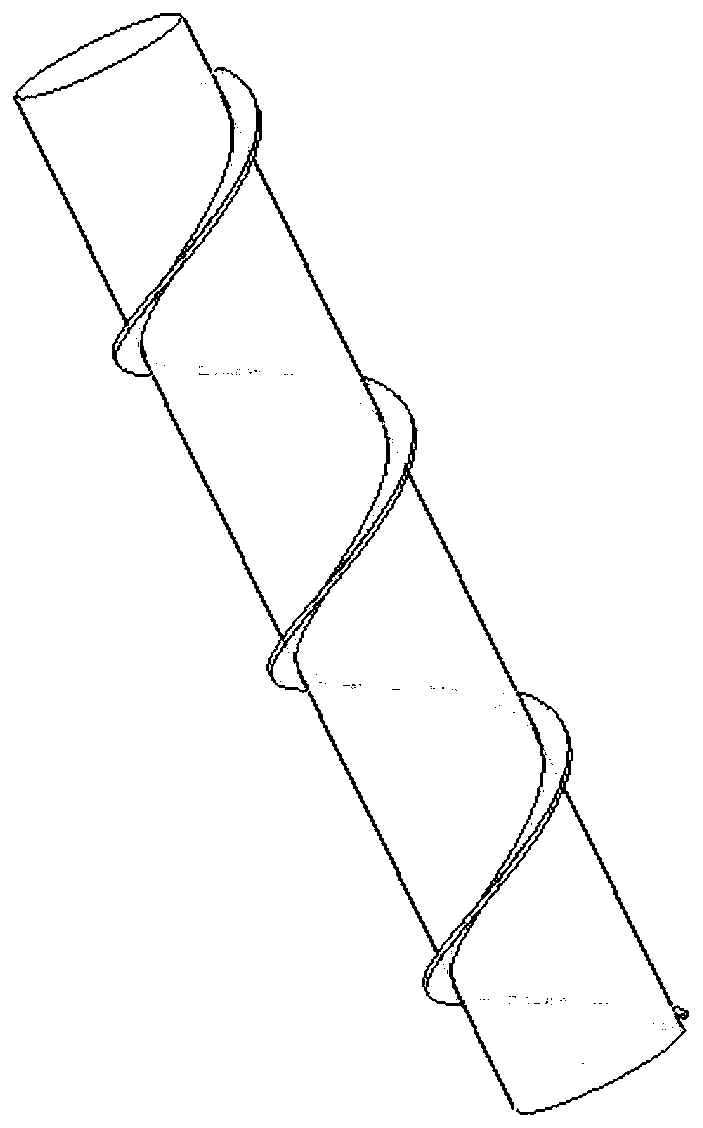

Reaction kettle for producing medical intermediates

InactiveCN106215836AGood dispersionImprove the mixing effectTransportation and packagingMixersBiochemical engineeringMagnetic poles

The invention relates to a reaction kettle for producing medical intermediates. The reaction kettle comprises a tank body, a stretchable rod is arranged in the tank body, and a stop block is arranged at the lower end of the stretchable rod. A feeding annular pipe is arranged at the upper portion in the tank body, the stretchable rod is located in the middle of the annular space of the feeding annular pipe, a feeding inlet is formed in one side of the feeding annular pipe, the pipe wall of the feeding annular pipe is provided with a plurality of spraying openings and a plurality of inclined baffles, the spraying openings correspond to the inclined baffles in a one-to-one mode, and the inclined baffles are downwards inclined. The stretchable rod is sleeved with a magnetic stirrer, the magnetic stirrer is horizontally arranged and located above the stop block, a first electromagnet is arranged on one side of the inner wall of the tank body, a second electromagnet is arranged on the other side of the inner wall of the tank body, the magnetic poles of the first electromagnet and the second electromagnet are opposite, and the first electromagnet and the second electromagnet are controlled through alternating currents and face each other. Due to the structure of the reaction kettle for producing medical intermediates, production efficiency can be effectively improved, and the production cost can be effectively reduced.

Owner:枣阳市众成化工有限公司

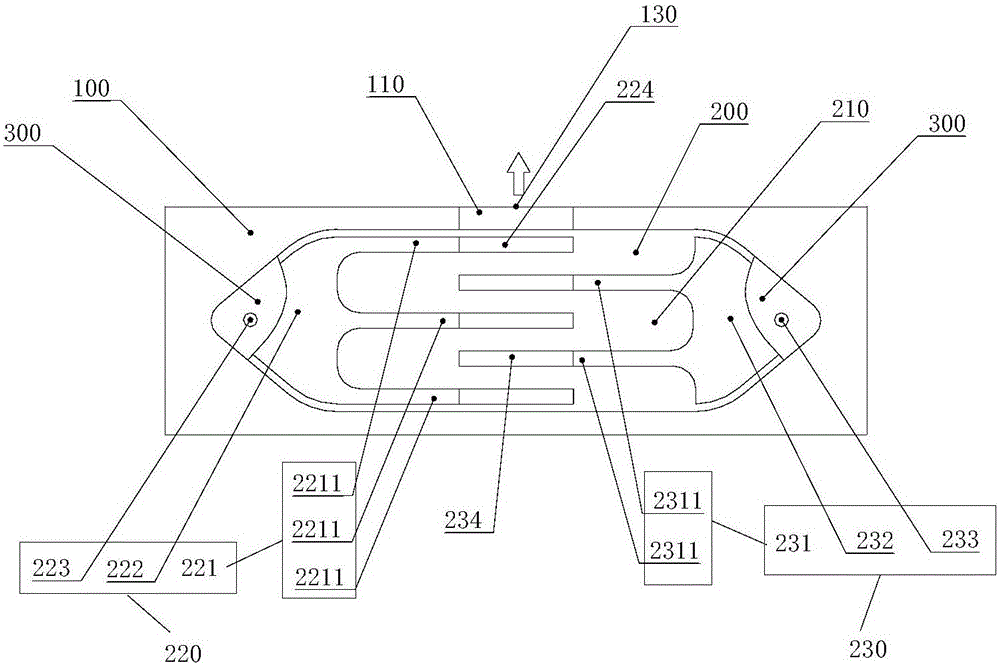

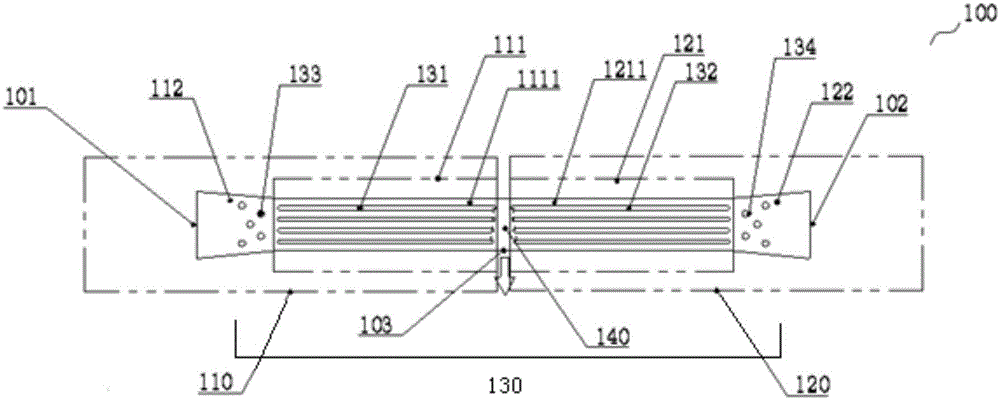

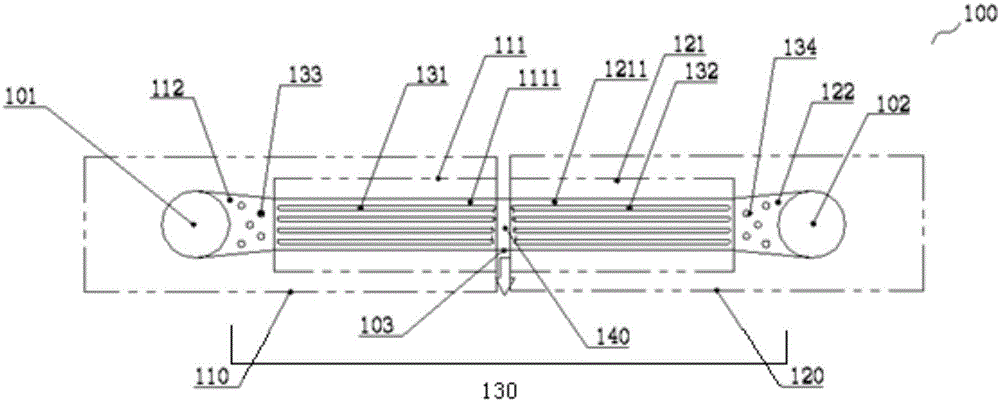

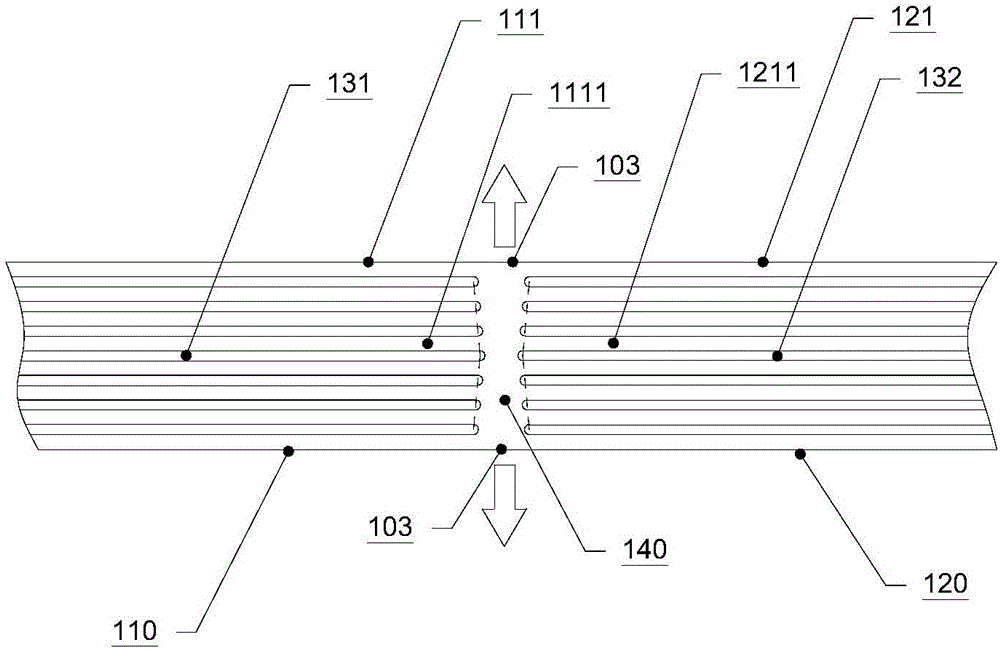

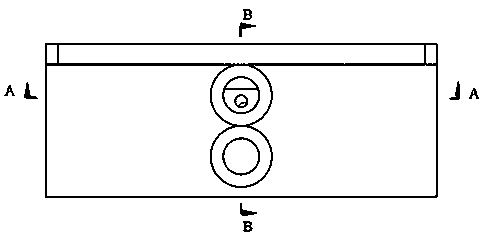

Flow dividing opposite impact microreaction passage and microreactor

InactiveCN106378081AGuaranteed reaction temperatureEnsure stabilityChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical reactor detailsEngineeringReaction speed

The invention relates to a flow dividing opposite impact microreaction passage and a microreactor. The flow dividing opposite impact microreaction passage comprises a reaction body, wherein one end of the reaction body is provided with a first inlet; the other end of the reaction body is provided with a second inlet; the reaction body is also provided with a fluid outlet positioned between the first inlet and the second inlet; a first fluid section is arranged between the first inlet and the outlet; a second fluid section is arranged between the second inlet and the outlet; a flow dividing structure for performing flow dividing on fluid is also arranged in the first fluid section and / or the second fluid section; the first fluid section and / or the second fluid section are / is separated into at least two flow dividing passages through which reaction fluid is allowed to pass by the flow dividing structure; the reaction body also comprises a mixing region which is positioned between the first fluid section and the second fluid section and communicates with the outlet; the mixing region is used for mixing the fluid of the first fluid section and the second fluid section. The microreactor comprises the flow dividing opposite impact microreaction passage. Two kinds of fluid can realize full mixed reaction; the reaction speed is accelerated; the reactant generation efficiency is improved.

Owner:SHANDONG HIMILE CHEM TECH

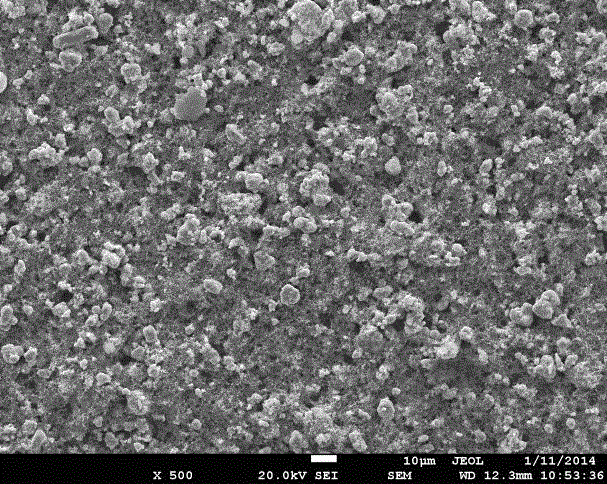

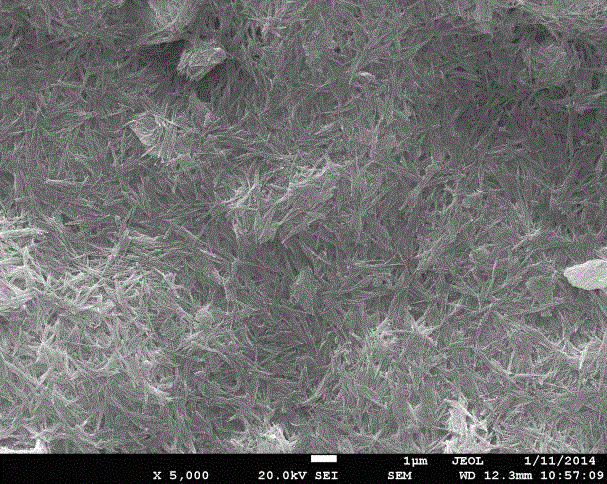

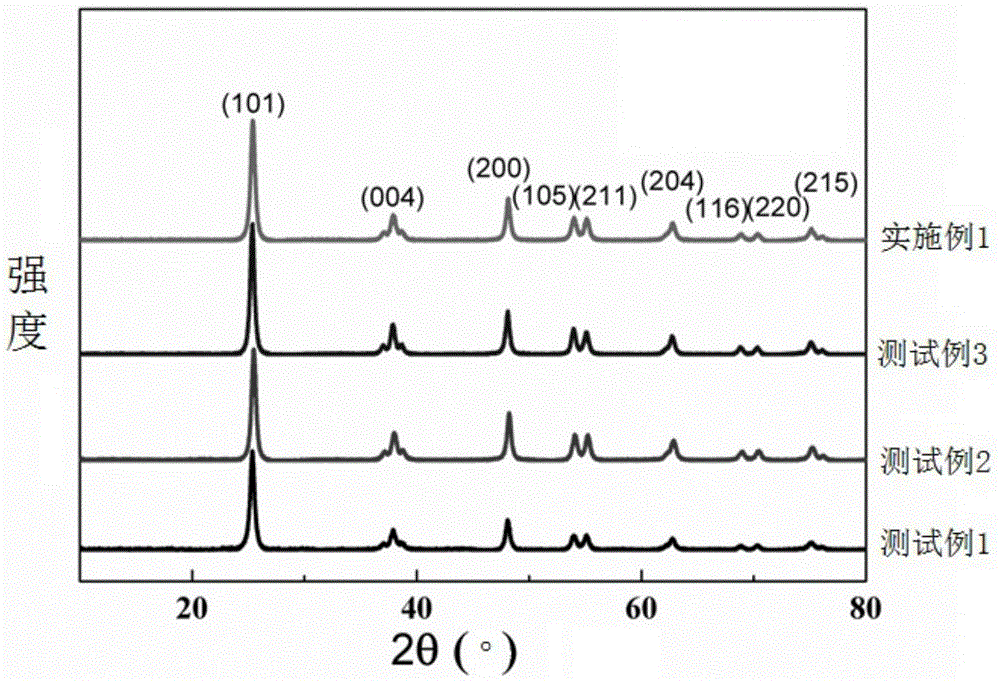

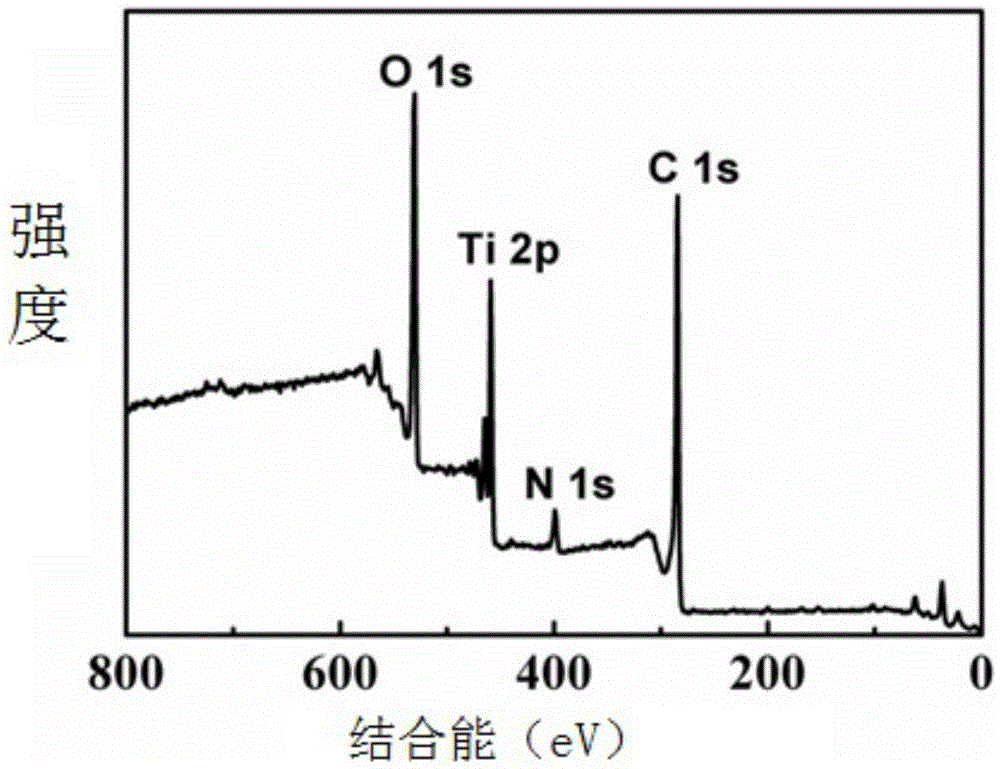

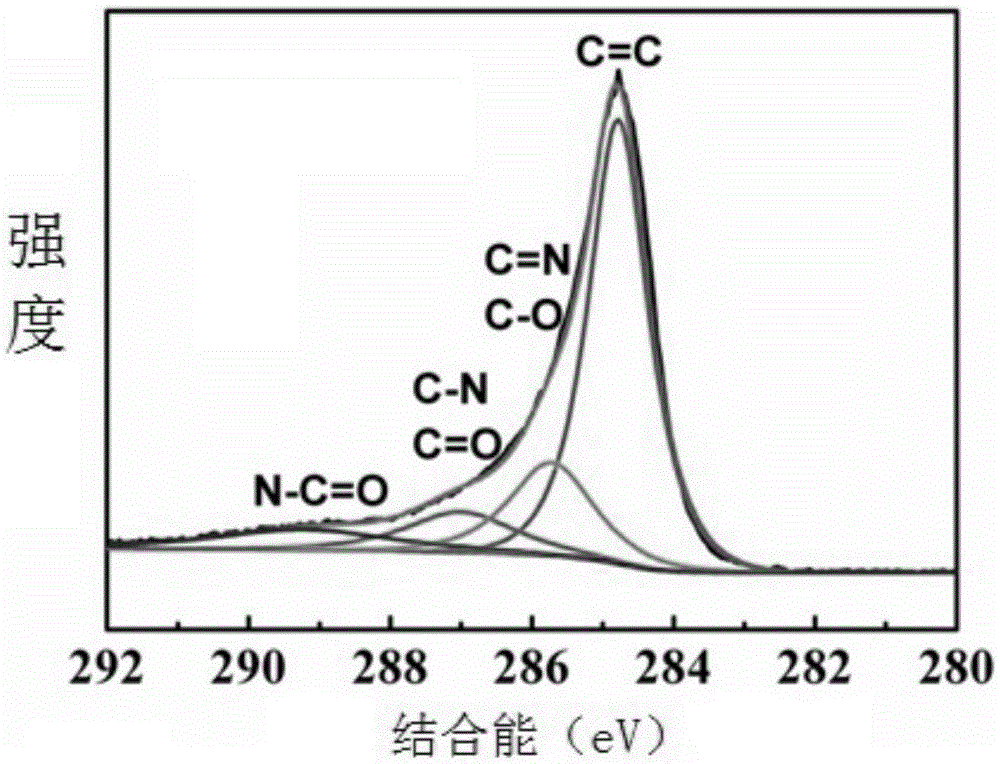

Graphene composite and preparation method thereof

InactiveCN105536848AReduced band gapEfficient degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationElectronic transmissionNanowire

The invention discloses a graphene composite comprising nitrogen-doped reduced graphene oxide and nitrogen-doped titanium dioxide nanowires, wherein the length-diameter ratio of the titanium dioxide nanowires is larger than 10. The one-dimensional titanium dioxide nanowires are selected as an active component, have better electronic transmission channels and are beneficial to acceleration of electronic transmission and increase of the reaction rate. Meanwhile, the one-dimensional titanium dioxide nanowires can better prevent stacking of graphene sheets, more effectively use the characteristic of large specific surface of graphene, enlarge the reaction contact area and increase the catalytic reaction rate. A preparation method of the graphene composite adopts a simple process, raw materials are easy to store, the reaction is mild, energy consumption is lower, and the method is suitable for industrial application. Meanwhile, the titanium dioxide nanowires with controllable morphology are prepared firstly, then the graphene composite is prepared, the product cost is reduced effectively, and product quality controllability can be realized.

Owner:CHANGZHOU MOZHICUI TECH CO LTD

Natural gas hydrate compound exploitation method

ActiveCN111255419AImprove protectionIncrease the reaction contact areaOther gas emission reduction technologiesFluid removalInjection wellCarbon dioxide

The invention discloses a natural gas hydrate compound exploitation method. The natural gas hydrate compound exploitation method comprises the following steps that an exploited well, an injection wellA and an injection well B are arranged at a stratum position of a natural gas hydrate to be exploited, and the injection well A and an injection well B are arranged on the two sides of the exploitedwell; a solid-state crushing drill rig and auxiliary equipment are lowered into a natural gas hydrate storage layer through the injection well B, after the storage layer is drilled, a drill hole is parallel to a horizontal line to continue to drill to crush the storage layer; the exploited well is closed, a carbon dioxide control platform is controlled, and carbon dioxide is injected into the natural gas hydrate storage layer through the injection well A; a drilling liquid control platform is controlled, and drilling liquid is injected into the natural gas hydrate storage layer through the injection well B; and the exploited well is opened, and natural gas generated in the storage layer is extracted to an offshore platform. According to the natural gas hydrate compound exploitation method,the advantage of good stability of the carbon dioxide hydrate is used, the stability of the stratum is ensured, geological disasters and mass decomposition of the hydrate are avoided, and meanwhile,the yield of the natural gas hydrate is effectively improved through favorable reaction conditions provided by the drilling liquid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Pulping reaction device and application thereof

InactiveCN108554342AIncreased chance of collisionQuick responsePlastic recyclingChemical/physical/physico-chemical stationary reactorsFertilizerMotor drive

The invention discloses a pulping reaction device. The pulping reaction device comprises at least one internal pulping reactor and / or at least one external pulping reactor which are connected in series and / or in parallel in any mode, wherein a first main grinding disc and a first auxiliary grinding disc are oppositely arranged in a first reactor body of the internal pulping reactor, and a first main motor drives the first main grinding disc to rotate relative to the first auxiliary grinding disc; and a pulping device of the external pulping reactor comprises a pulping chamber, a second motor,a second auxiliary grinding disc and a second main grinding disc, and the second motor drives the second main grinding disc to rotate relative to the second auxiliary grinding disc. The pulping reaction device integrates the functions of a conventional reactor, pulping and pulverizing functions as well as pulping and high-speed cutting functions, has pulping and liquefying, grinding and pulverizing as well as high-speed cutting effects, obviously increases the reaction speed and reduces the reaction conditions. The invention also discloses application of the pulping reaction device to desulphurization and reproduction of rubber powder, pulping, hydrolysis and production of aquatic organisms and / or terrestrial plants as well as preparation of organic compound fertilizer by phosphorylation.

Owner:RIZHAO XURI COMPOSITE MATERIALS

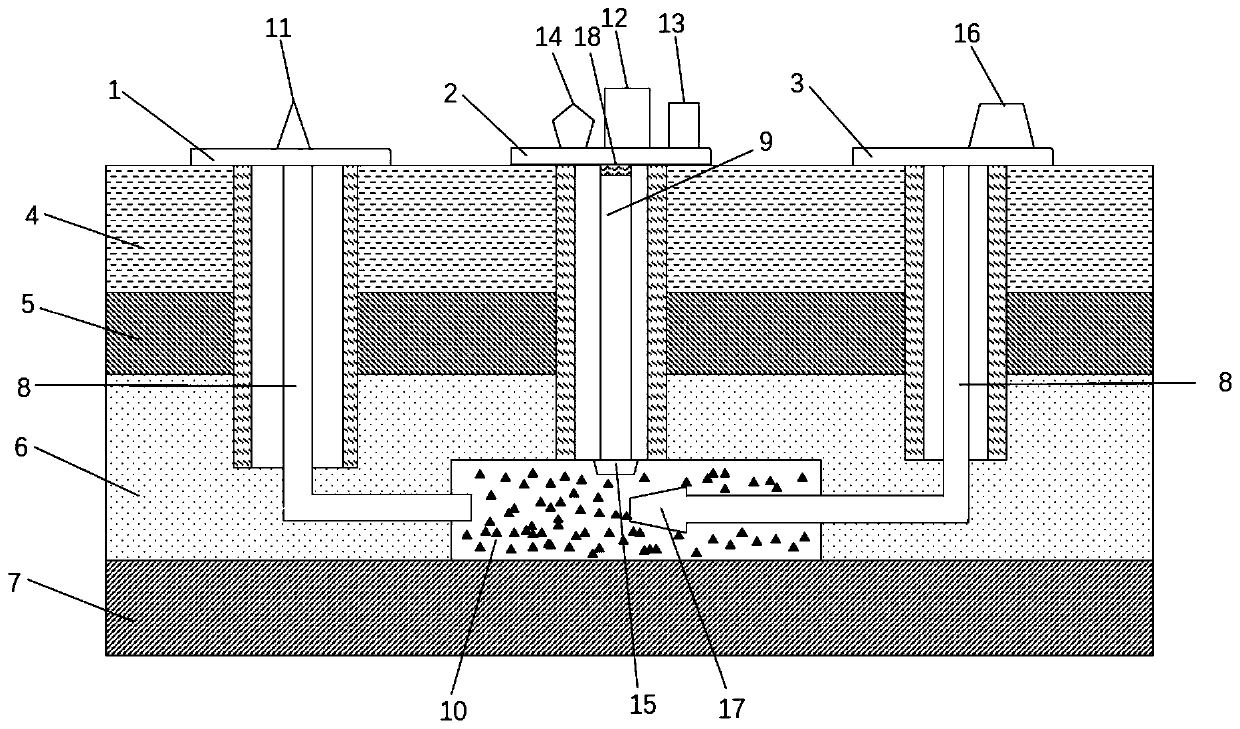

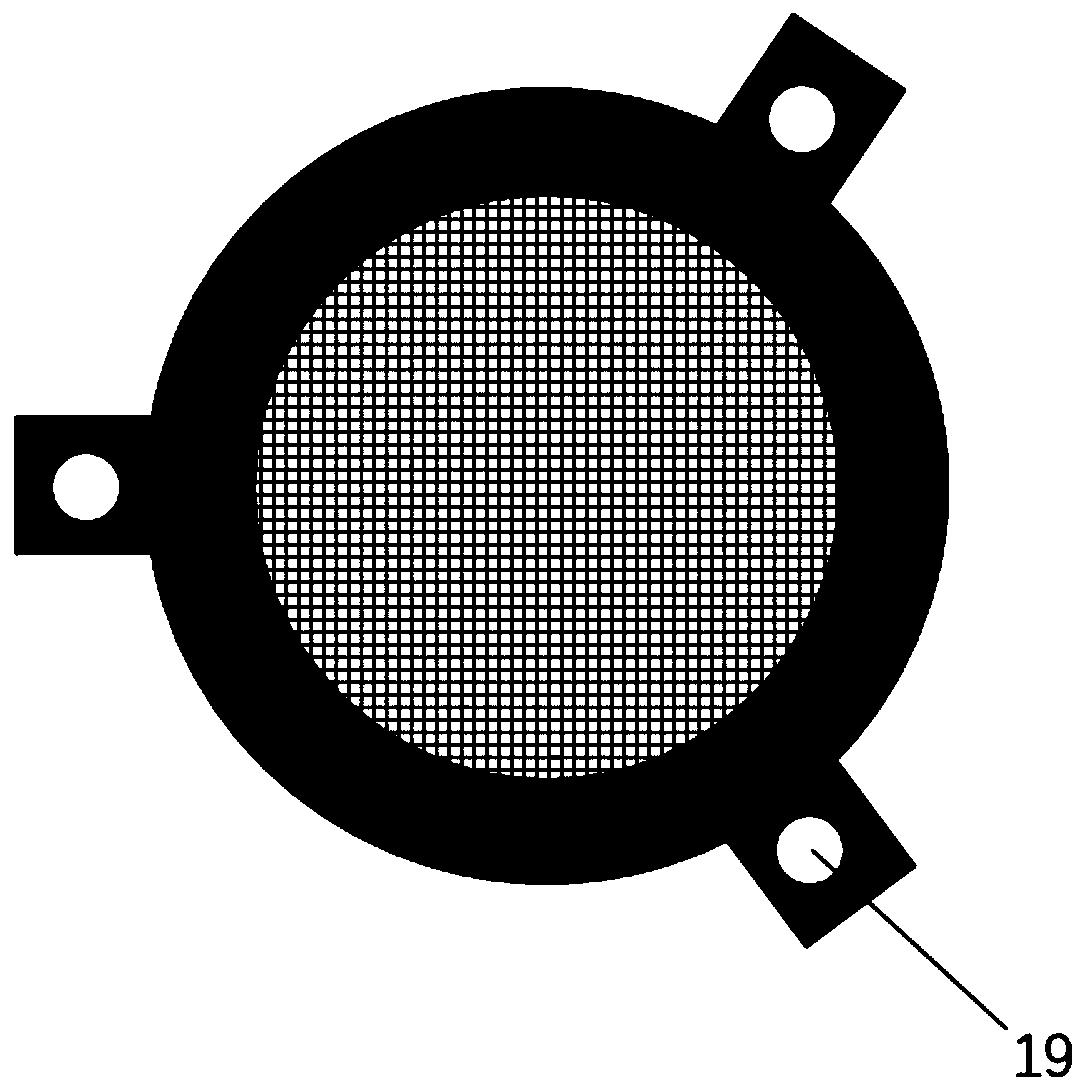

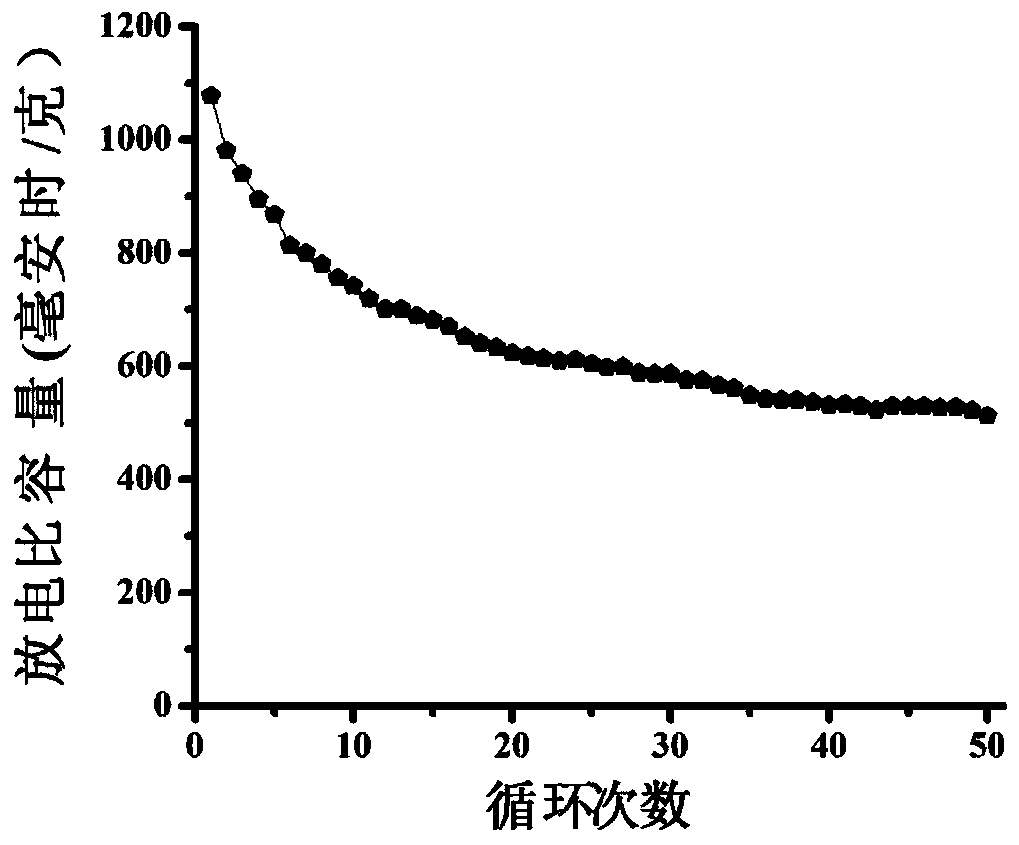

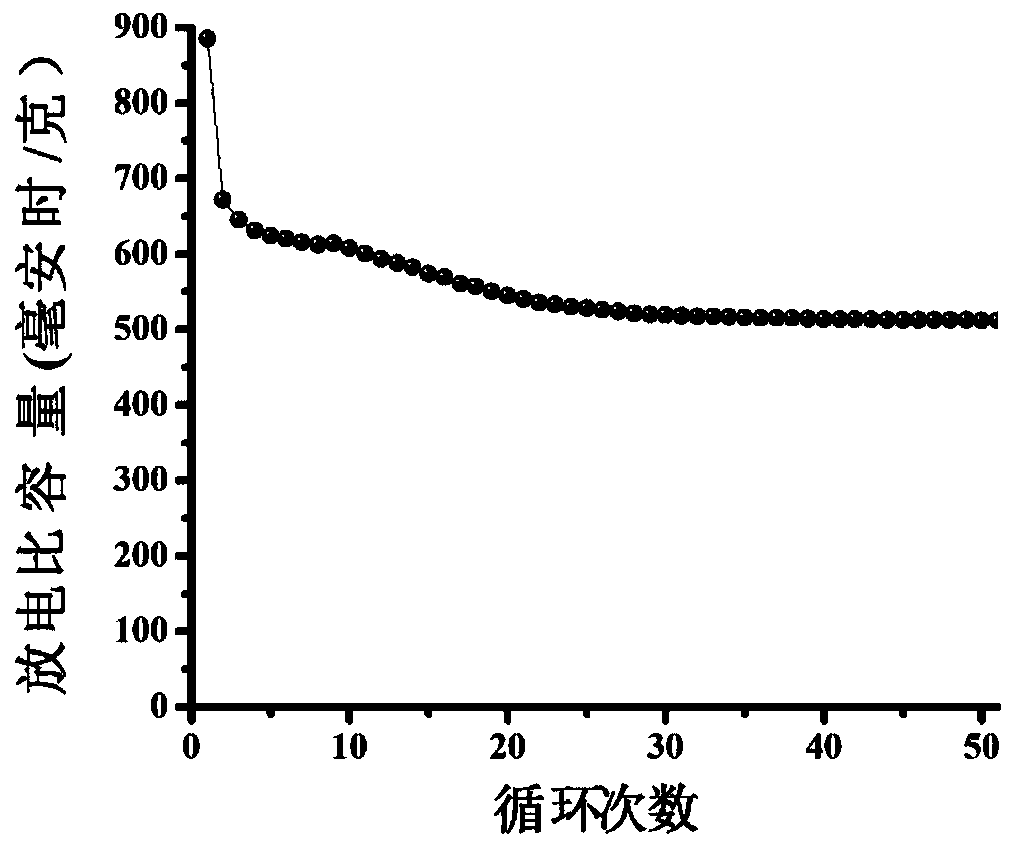

Sodium-sulfur battery positive electrode material and preparation method thereof

ActiveCN109755542ALimit the "shuttle effect"Limit shuttle effectNon-aqueous electrolyte accumulatorsCell electrodesElectrochemical responsePorosity

The invention relates to a sodium-sulfur battery positive electrode material and a preparation method thereof. The sodium-sulfur battery positive electrode material is a sulfur-titanium dioxide-carboncomposite material, and the preparation method includes the following steps: firstly, preparing a metal organic framework material MIL-125, spray-drying and compounding the metal organic framework material MIL-125 with graphene, performing carbonization treatment to obtain a titanium dioxide-carbon composite material, and then doping sulfur to prepare a sulfur-titanium dioxide-carbon composite sodium-sulfur battery positive electrode material by using a ball milling method and a hot melting method. The composite material prepared by using the method has a larger specific surface area and porosity, can limit the 'shuttle effect' of polysulfide, reduces the dissolution of intermediate products, can improve the electrochemical activity of elemental sulfur, shortens the transmission paths ofelectrons and ions, limits the dissolution of polysulfide, and improves the electrochemical reaction speed of active materials adsorbed on the surface of a carrier.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

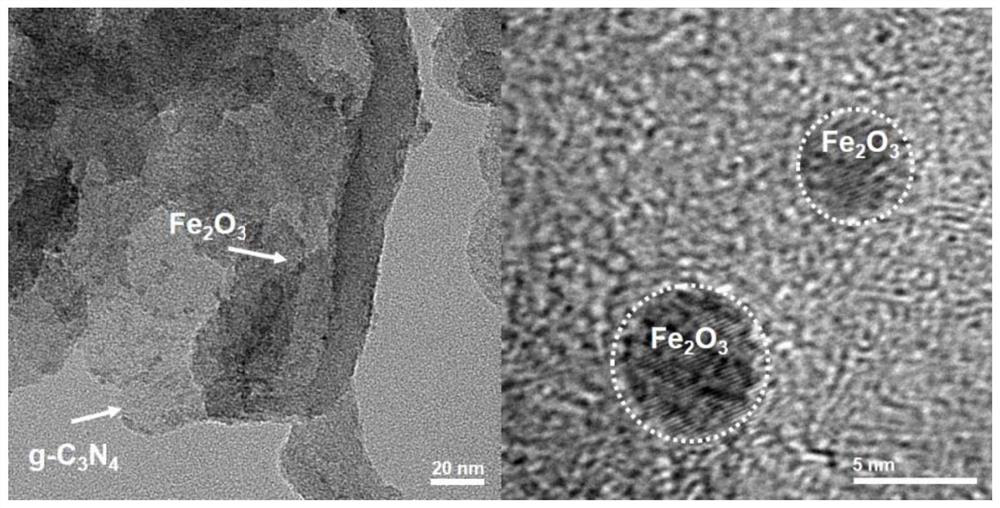

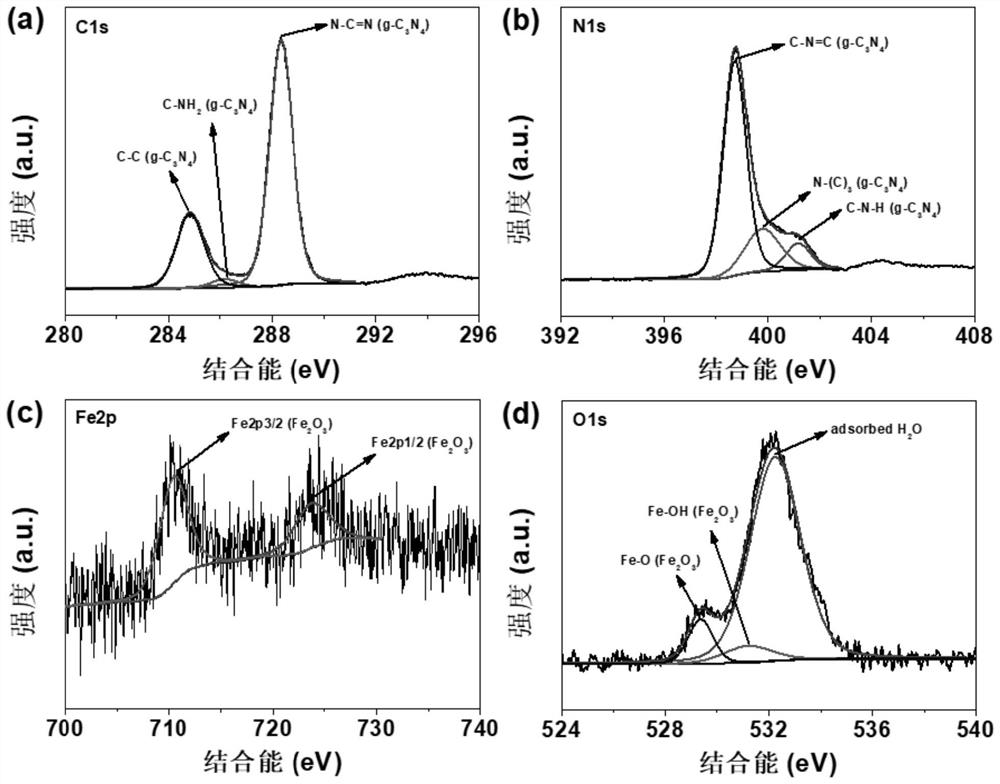

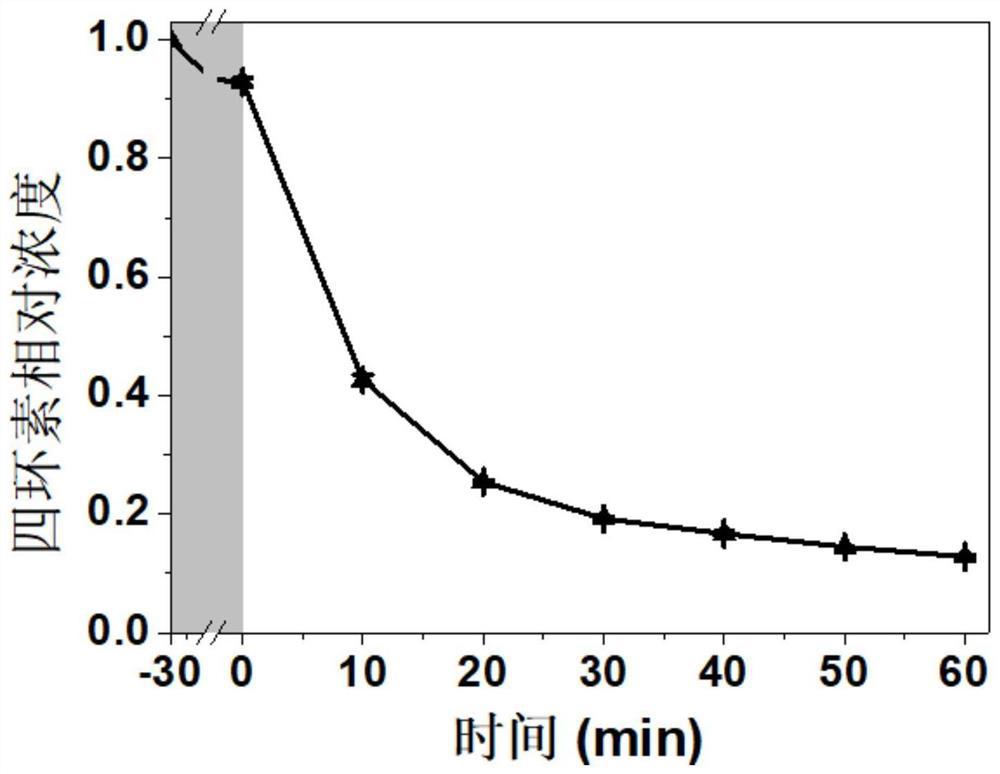

Photo-Fenton catalyst and preparation method thereof and application thereof in water treatment

InactiveCN111659440AGood dispersionSolve reunionWater treatment parameter controlPhysical/chemical process catalystsPtru catalystNitrate

The invention discloses a photo-Fenton catalyst and a preparation method and application thereof in water treatment, and belongs to the technical field of water treatment. The invention provides a method for preparing a g-C3N4 / Fe2O3 compound catalyst. The g-C3N4 / Fe2O3 compound catalyst is used for carrying out photo-Fenton water treatment. The preparation method comprises the following steps: firstly, preparing a g-C3N4 nanosheet, and then carrying out composite modification on the g-C3N4 nanosheet by taking ferric nitrate and ammonium bicarbonate as raw materials to obtain a g-C3N4 / Fe2O3 compound. According to the g-C3N4 / Fe2O3 photo-Fenton catalyst prepared by the method, fe2O3 quantum dots are loaded on the surface of the g-C3N4 nanosheet in a fixed-point deposition manner, and thus morecatalytic active sites and larger reaction contact area are brought about; when the catalyst is used for degrading antibiotic pollutants in water, the catalytic performance is excellent, the degradation efficiency of the antibiotic pollutants is high, the operation cost is low, secondary pollution cannot be caused, and the catalyst has a wide application prospect.

Owner:JIANGNAN UNIV

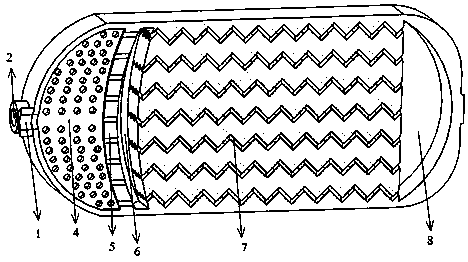

Microfluid extraction expansion reactor for 3D printing and applications of microfluid extraction expansion reactor

PendingCN108486364AIncrease the number of channelsIncrease the reaction contact areaAdditive manufacturing apparatusProcess efficiency improvementGas liquid reactionEngineering

The invention relates to a microfluid extraction expansion reactor for 3D printing and applications of the microfluid extraction expansion reactor and belongs to the technical field of microfluid extraction. The microfluid extraction expansion reactor for 3D printing comprises a water phase inlet, an oil phase inlet, a mixed liquid collection cavity I, a liquid drop cutting sieve plate, a mixed liquid collection cavity partition, a mixed liquid collection cavity II, a mixed reaction microchannel, a mixed liquid collection cavity III and a mixed liquid outlet. The applications of the microfluidextraction expansion reactor for 3D printing comprise single-phase or multi-phase reaction microfluid extraction including a gas-liquid reaction and a liquid-liquid reaction. According to the microfluid extraction expansion reactor for 3D printing, oil-water two phase separating is rapid, the extraction reaction time is short, and an emulsifying phenomenon cannot occur.

Owner:KUNMING UNIV OF SCI & TECH

Waste concrete recycling method with low processing cost

InactiveCN111848006ASoft natureNot easy to changeSolid waste managementGel preparationEnvironmental engineeringSorptivity

The invention discloses a waste concrete recycling method with a low processing cost. The invention belongs to the technical field of concrete processing. The method comprises: arranging hydrogel powder, drying the prepared hydrogel, preparing the hydrogel into a solidified block, crushing the waste concrete into powder with the same size as the waste concrete granular material, at the moment, adding the waste concrete granular material and the hydrogel powder into stirring equipment, and mixing. When adding waste concrete granular materials and hydrogel powder into stirring equipment, stirring equipment needs to be set, stirring directions are the same, the hydrogel is soft in property, the shape is kept, a large amount of water can be absorbed, the mixed modified concrete has certain water absorption performance, the shape of the modified concrete is not easy to change after the modified concrete absorbs water, the internal adhesiveness of the modified concrete is improved, the interior of the modified concrete is not easy to be too dry due to the fact that the hydrogel has certain water absorption performance, and cracks of the modified concrete due to the fact that the interiorof the modified concrete is too dry are reduced.

Owner:汉江城建集团有限公司

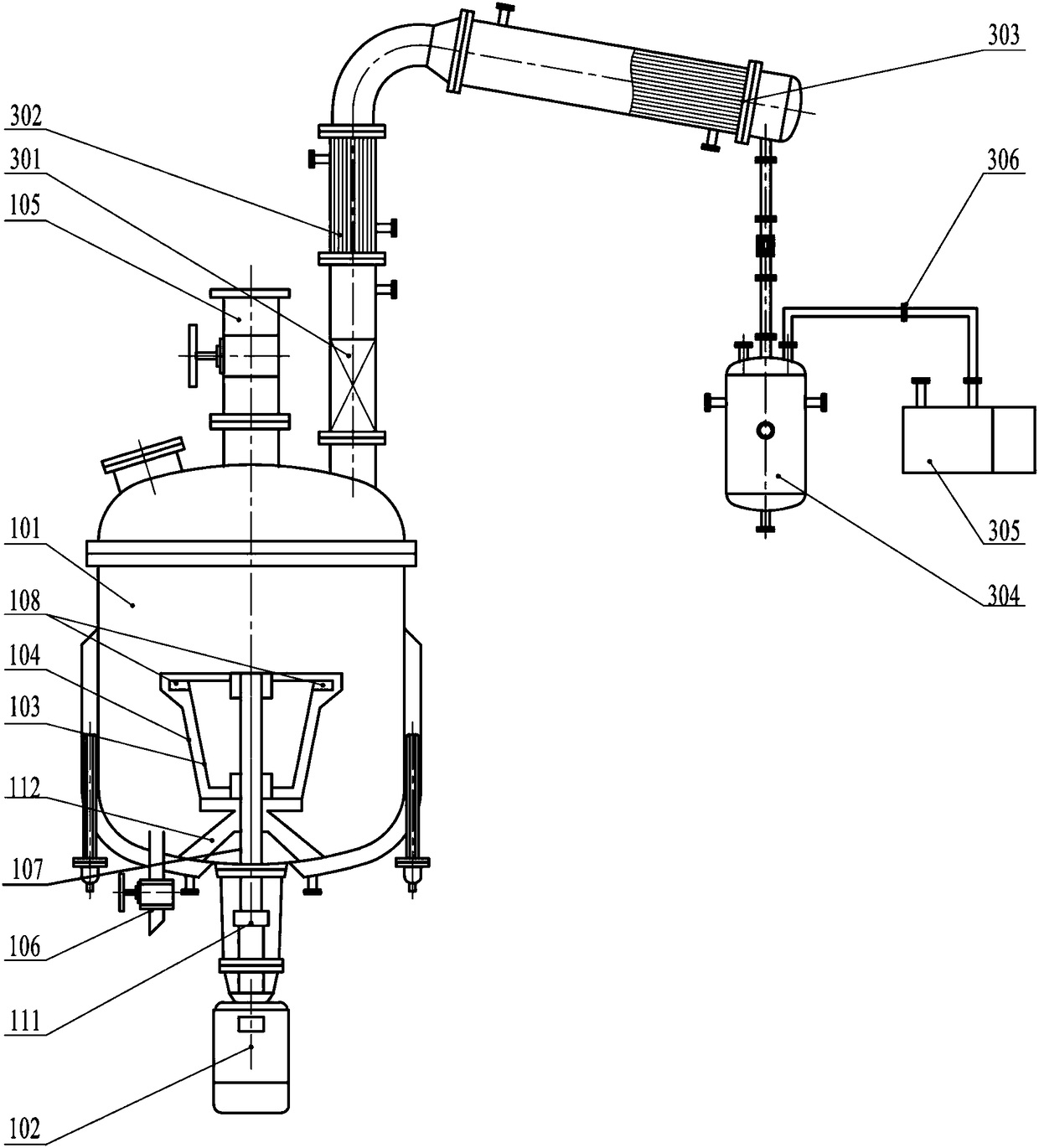

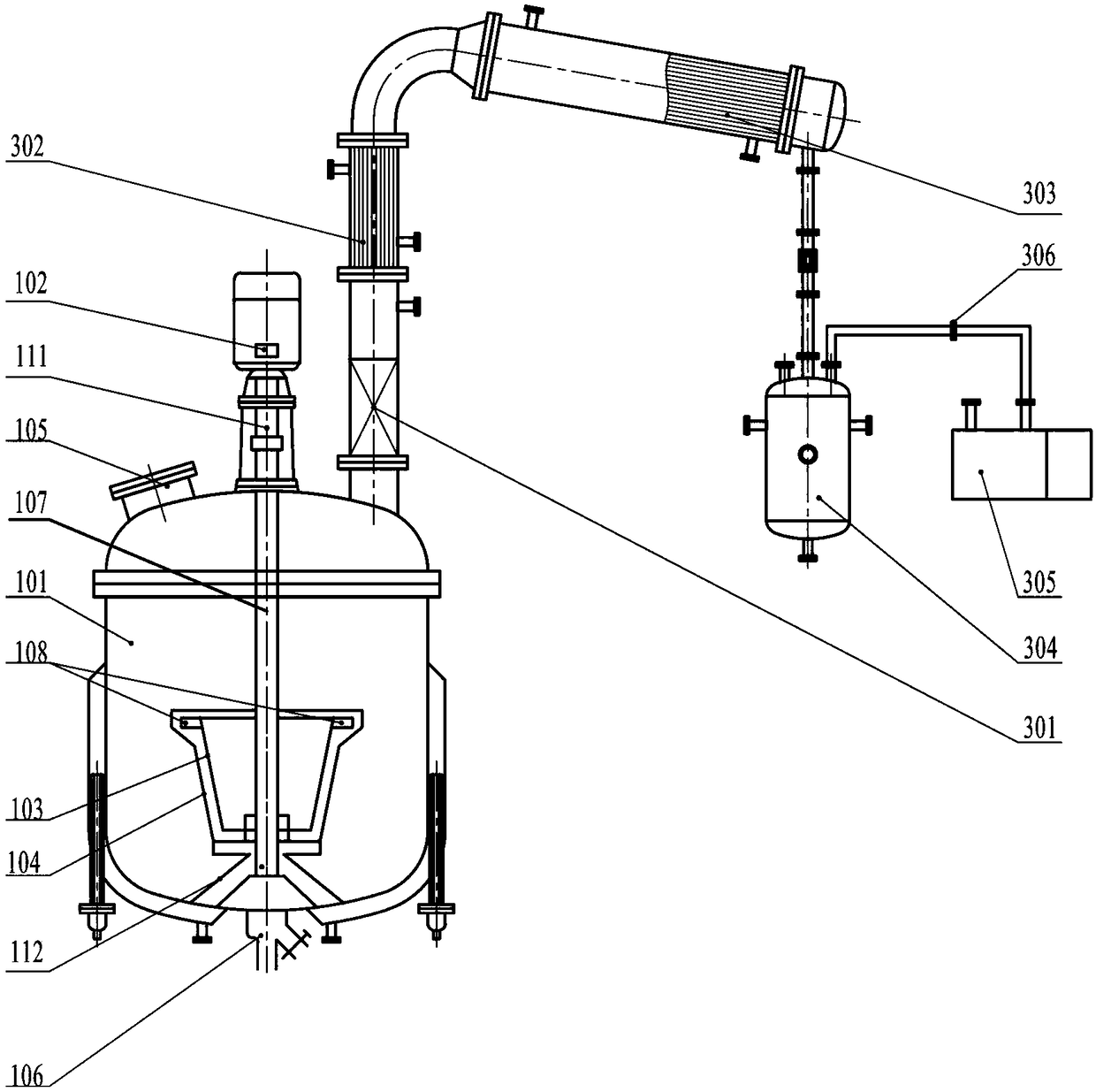

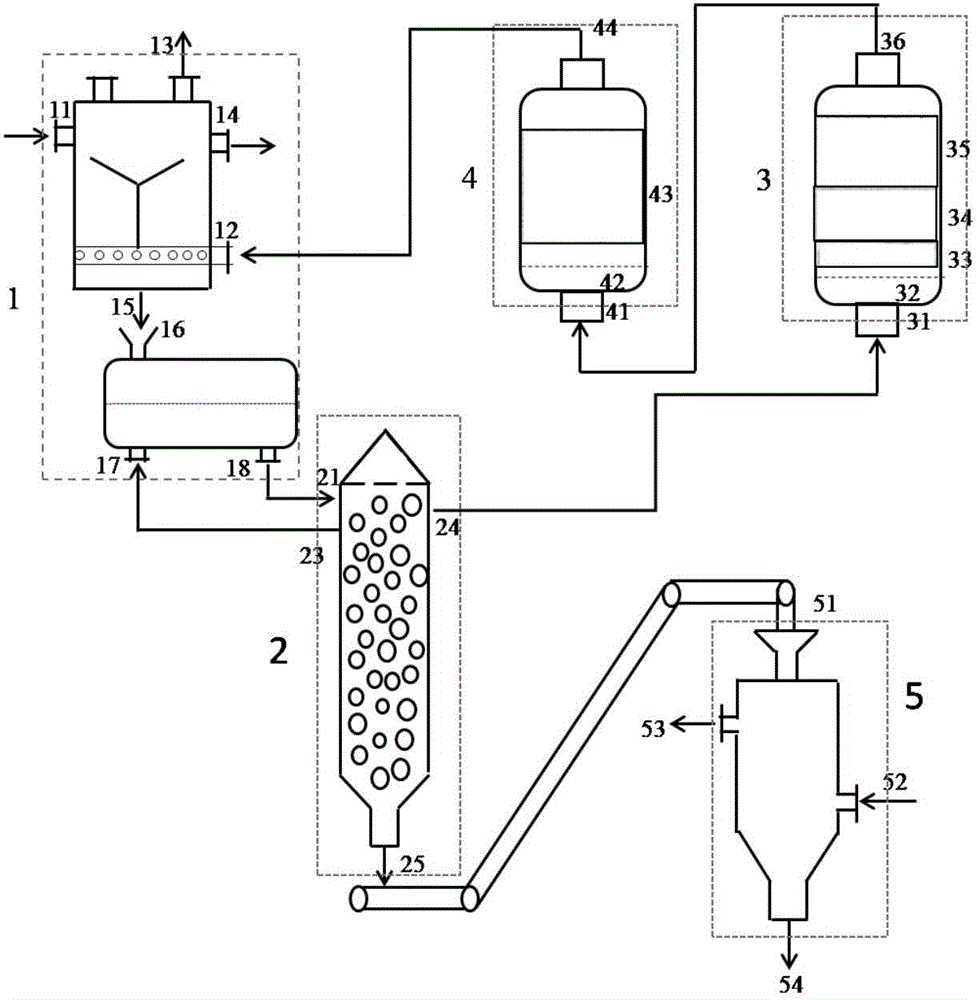

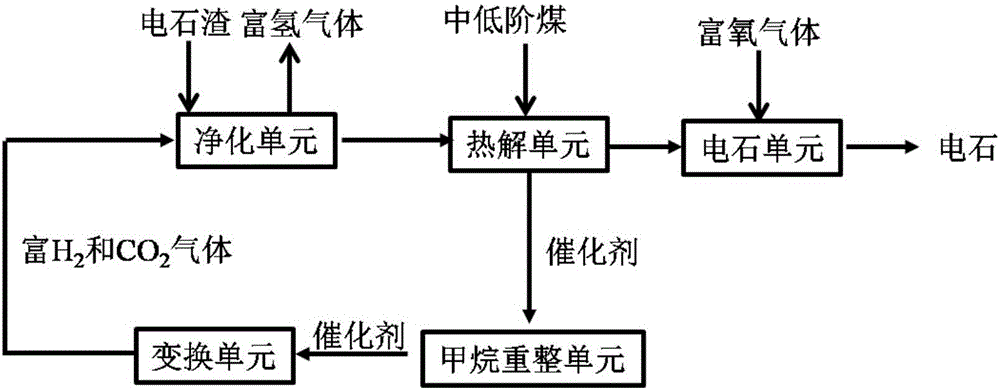

System and method for preparing hydrogen-rich gas and calcium carbide from calcium carbide slag

ActiveCN106241735ASave the step of calcinationLow costHydrogenHydrogen/synthetic gas productionCatalytic reformingSlag

The invention relates to a system and method for preparing hydrogen-rich gas and calcium carbide from calcium carbide slag. The system comprises a calcium carbide slag purification unit, a high-temperature pyrolysis unit, a catalytic reforming unit, a conversion unit and a calcium carbide smelting unit. The calcium carbide slag purification unit comprises a CO2 carbonization unit and a drying unit. The high-temperature pyrolysis unit comprises a pulverized coal inlet, a dried carbonization solid inlet, a crude gas outlet and a high-temperature mixed powder outlet. The catalytic reforming unit comprises a crude gas inlet and a synthetic gas and carbon dioxide outlet. The conversion unit comprises a synthetic and carbon dioxide inlet and a rich CO2 and hydrogen outlet. The calcium carbide smelting unit comprises a high-temperature mixed powder inlet and a calcium carbide outlet and is used for smelting high-temperature mixed powder into calcium carbide. By means of the system and method for preparing the hydrogen-rich gas and calcium carbide from the calcium carbide slag, the calcium carbide slag is utilized, and pyrolysis gas with complex components is converted into the hydrogen-rich gas.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

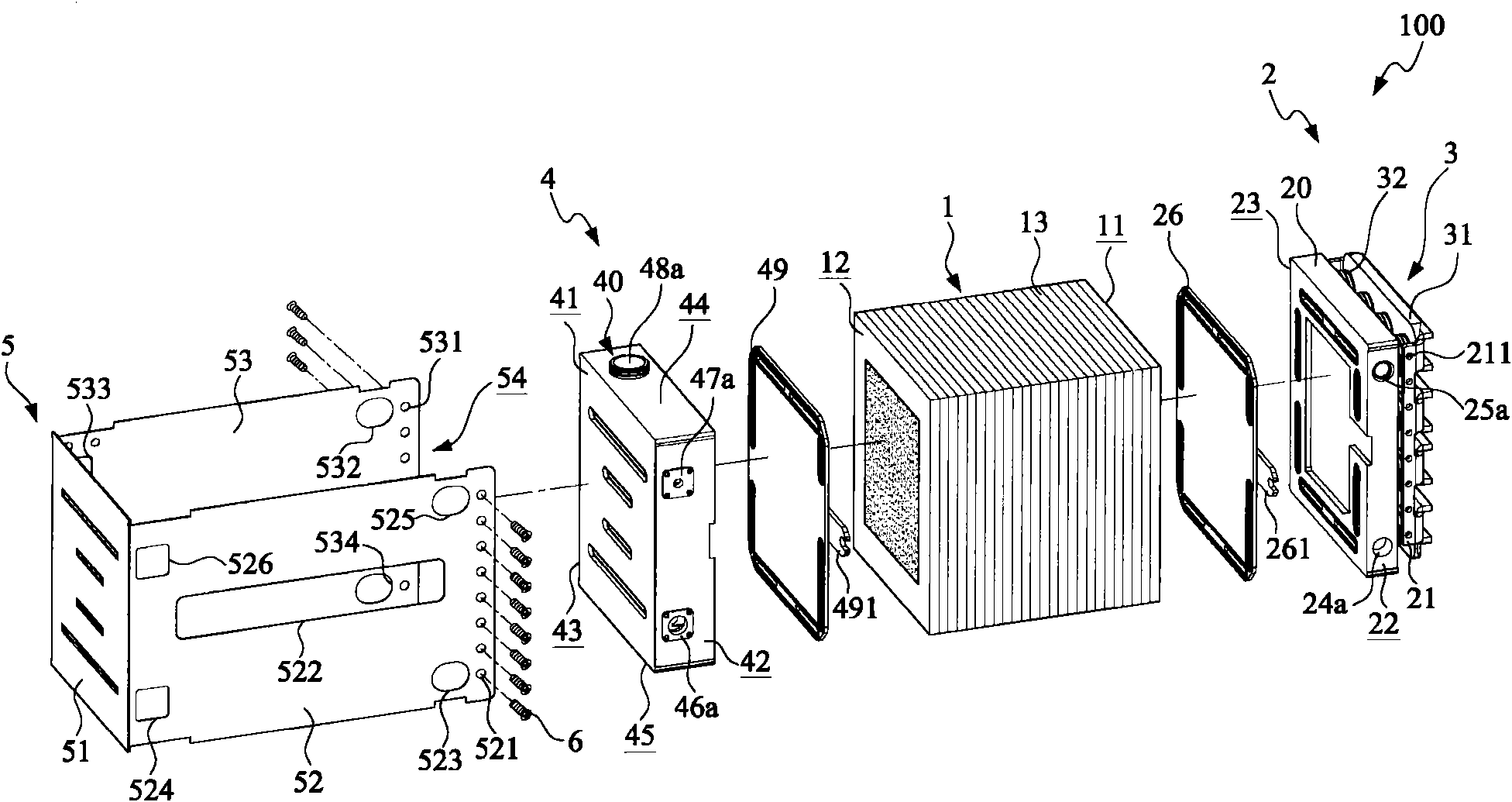

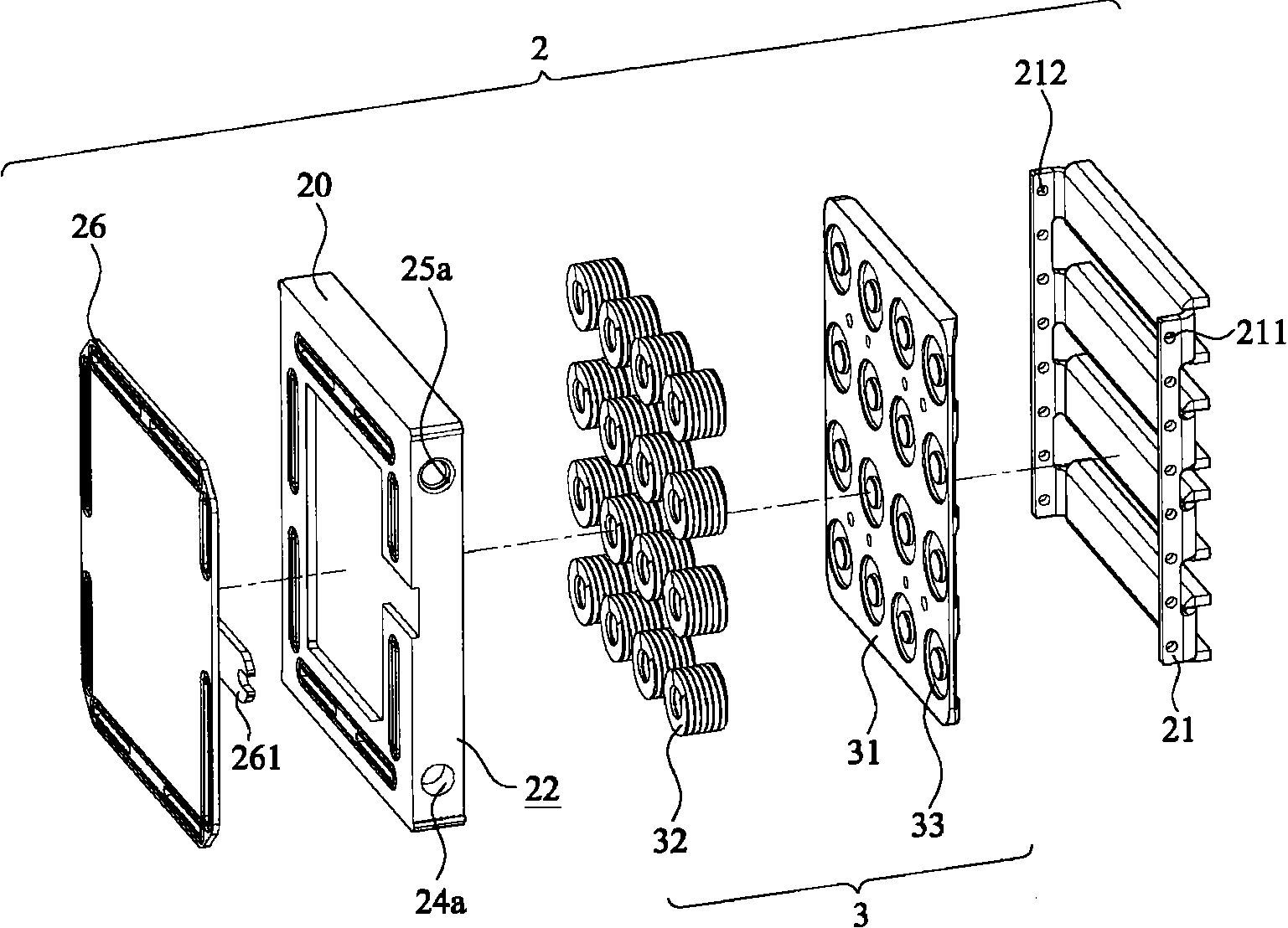

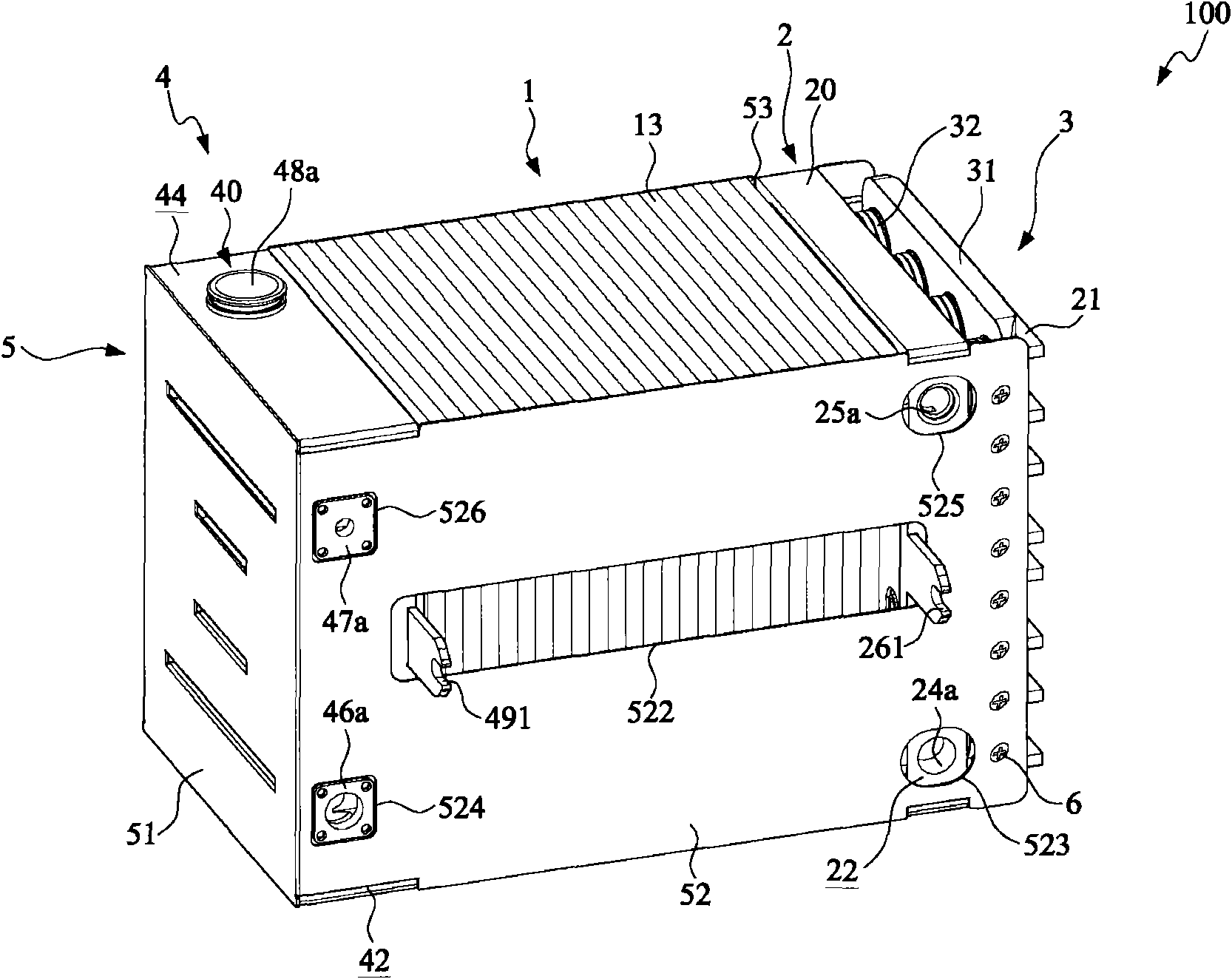

Pressure-bearing assembling structure of fuel cell module

InactiveCN101540413AEasy to assembleAvoid the disadvantages of increased costsFuel cells groupingCell component detailsFuel cellsEngineering

The invention relates to a pressure-bearing assembling structure of a fuel cell module, which comprises the fuel cell module, a first pressure-bearing end plate, a first-pole collector plate, a second pressure-bearing end plate, a second-pole collector plate and a pressing structure, wherein the fuel cell module comprises a first-pole side, a second-pole side and at least one cell monomer; the first pressure-bearing end plate is connected with the first-pole side of the fuel cell module through a first end plate and the first-pole collector plate; the second pressure-bearing end plate is connected with the second-pole side of the fuel cell module through a second end plate and the second-pole collector plate; the pressing structure consists of a pressing plate and a pair of lateral plates, wherein an opening end is formed between the two lateral plates, the pressing plate supports against one plate surface of the second pressure-bearing end plate, and the opening end is positioned at both sides of the first end plate and connected with a combination part of the first end plate through a positioning structure.

Owner:ASIA PACIFIC FUEL CELL TECH

Method for preparing ethoxyabietic amine by spraying process

The invention relates to a method for preparing rosin amine polyoxyethylene ether by spraying method. The reaction is divided into two steps: the first step is to inhale disproportionated rosin amine into a spray reactor, and when heated to 50-60°C, inhale phosphorous acid and pump while Raise the temperature to 170-180°C under vacuum, control the pressure in the kettle to 0.2-0.3Mpa, close the vacuum valve, turn on the magnetic circulation pump, the material is sucked out from the kettle and then sprayed into the kettle, and the valve of ethylene oxide is opened, the material and epoxy Ethane is sprayed out at the same time, such a circular reaction for 0.8-1.5 hours, heat preservation for 30-40 minutes, and cooling to 90-100 °C; the second step is to vacuumize the inside of the above-mentioned kettle, while inhaling potassium hydroxide, while raising the temperature to 120- 130°C, keep warm for more than 20 minutes, replace the air in the kettle with nitrogen, raise the temperature to 165-175°C, close the vacuum valve, turn on the magnetic circulation pump, and spray the material and the remaining ethylene oxide into the spray reactor at the same time, so that the cycle reaction is 1 -2 hours, keep warm for more than 40 minutes. The method of the invention has short reaction time, complete reaction and good compatibility with other surfactants.

Owner:吴金海

Novel reaction kettle for producing pharmaceutical intermediates

InactiveCN106362660AGood dispersionDischarge in timeTransportation and packagingRotary stirring mixersBiochemical engineeringMagnetic poles

The invention relates to a novel reaction kettle for producing pharmaceutical intermediates. The novel reaction kettle comprises a tank, and a telescopic rod is arranged in the tank; a feed ring pipe is arranged on the upper portion of the interior of the tank, and the pipe wall of the feed ring pipe is provided with multiple nozzles and multiple inclined baffles which are arranged in a downwards-inclined mode; the telescopic rod is sleeved with a magnetic stir bar, one side of the inner wall of the tank is provided with a first electromagnet, the other side of the inner wall of the tank is provided with a second electromagnet, the magnetic pole of the first electromagnet is opposite to that of the second electromagnet, and the first electromagnet and the second electromagnet are controlled by alternating currents and oppositely arranged; the outer side of the bottom of the tank is annularly provided with multiple gas transmission main pipes, and each gas transmission main pipe is communicated with the interior of the tank through four gas transmission branch pipes. According to the structure, the novel reaction kettle for producing the pharmaceutical intermediates has the advantages that internal residual materials can be thoroughly removed, the production efficiency can be effectively improved, and the production cost can be reduced.

Owner:枣阳市众成化工有限公司

Method of treating VOCs (volatile organic compounds) and foul gas

InactiveCN109794155AGood processing effectIncrease the reaction contact areaDispersed particle separationMicro nanoVolatile organic compound

The invention discloses a method of treating VOCs (volatile organic compounds) and foul gas. The method comprises the steps of preparing micro-nano bubbles, to be specific, introducing ozone into an aqueous solution containing an oxidant, mixing well, and introducing the mixed solution into a micro-nano bubble generator to generate micro-nano bubbles; degrading, to be specific, introducing the micro-nano bubbles into a catalytic oxidizing column, spraying a liquid to the top of the catalytic oxidizing column, introducing waste gas to be treated into the bottom of the catalytic oxidizing column, subjecting the micro-nano bubbles, the liquid and the waste gas to be treated to contact reaction in the catalytic oxidizing column, and oxidatively degrading the waste gas. The method has the advantages of good treatment effect and basically zero residue.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV +1

Grain dry segmented steam explosion pretreatment method for fermenting liquor by using pure grain in solid state

InactiveCN102115702AGuaranteed puffed floweringSolve the problems of low production efficiency, high energy consumption and loss of fermentable sugarAlcoholic beverage preparationPressure risePretreatment method

The invention discloses a grain dry segmented steam explosion pretreatment method for fermenting liquor by using pure grain in solid state, which belongs to the field of liquor fermentation. The method comprises the following basic steps of: pre-balancing the moisture content of the grain; putting the grain into a two-way air inlet quick-opening steam explosion reaction tank separately or together; introducing superheated steam and high-temperature air until a certain pressure is achieved; and maintaining for a certain period of time, and quickly opening a ball valve at the bottom of the steam explosion tank after the pressure rises to a peak valve to explode a material into a normal-pressure collecting tank. In the grain treated by the method, the cell tissue is completely damaged, the curing degree of starch is high, and the utilization ratio is high in a fermenting process; meanwhile the grain is sterilized, so that bacteria are removed. By adopting the method, the grain treatment energy consumption in a liquor plant can be lowered, the liquor yield and the superior product rate are increased, and the comprehensive benefit is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

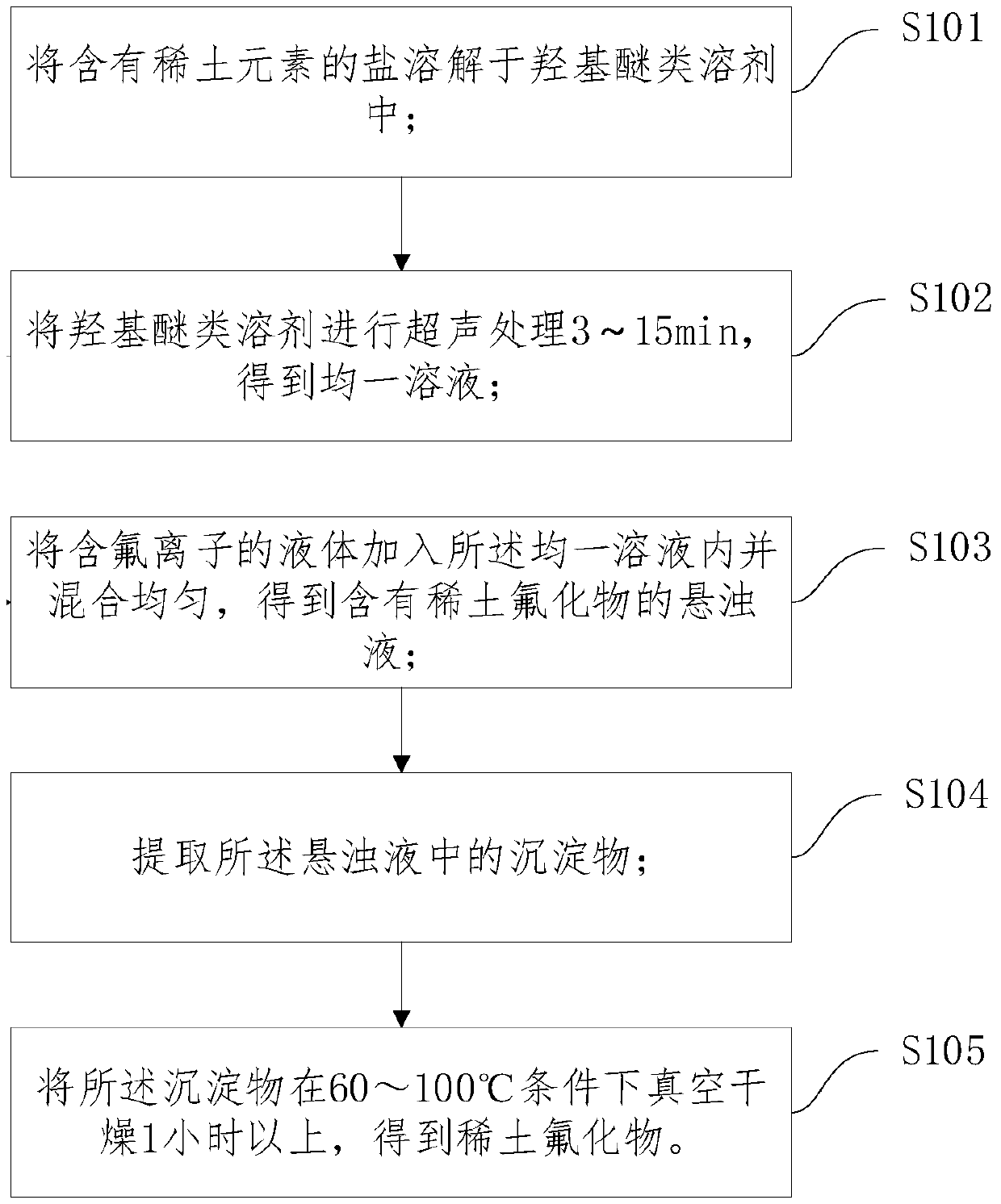

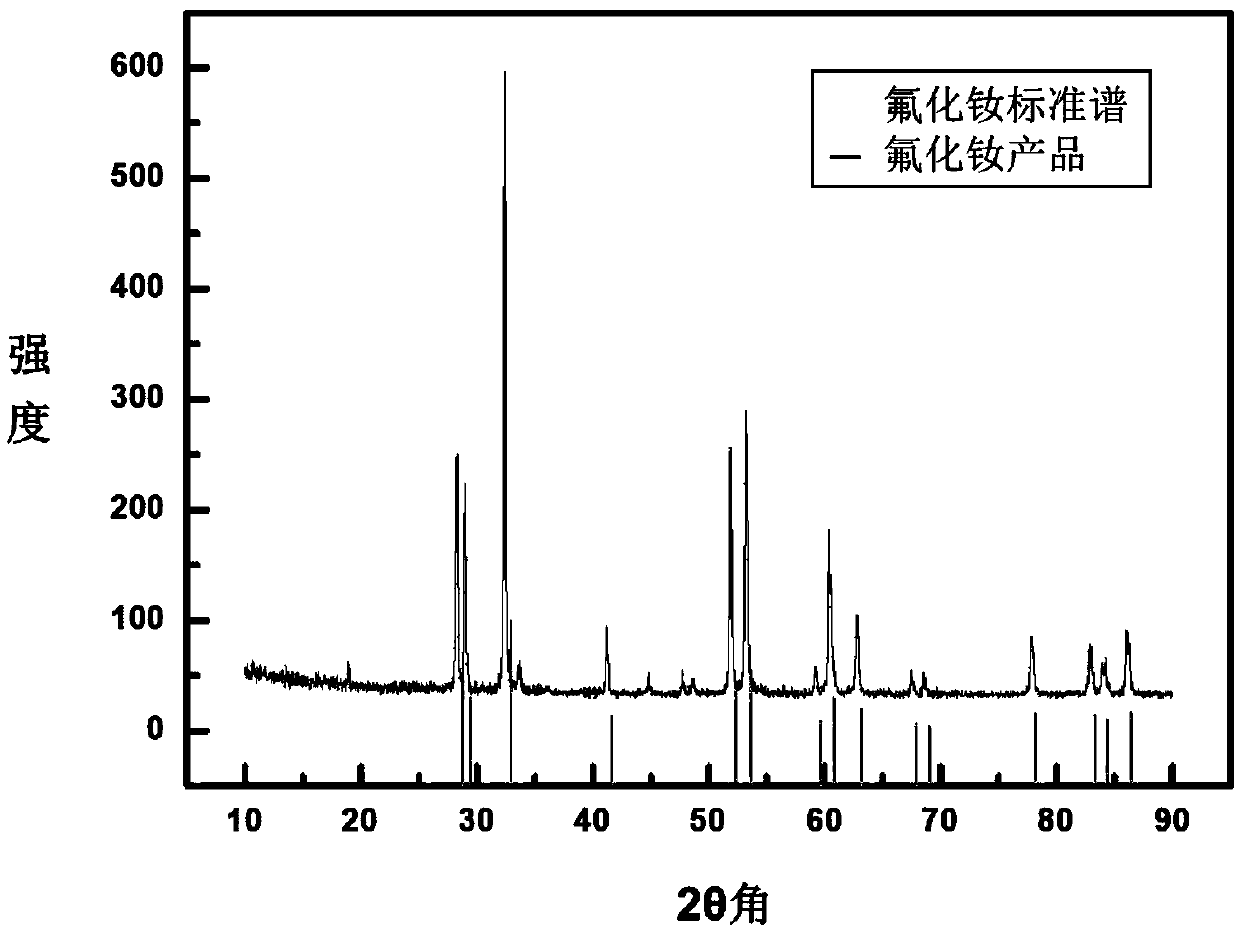

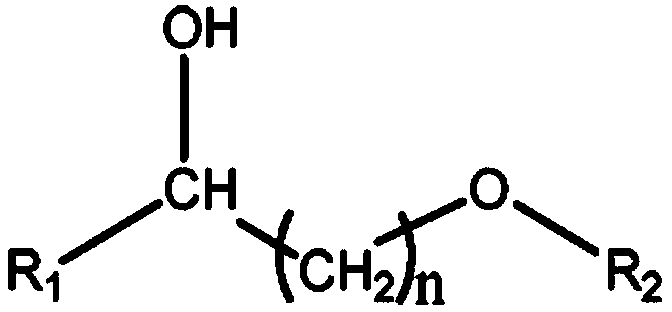

Preparation method of rare earth fluoride

PendingCN111392760AHigh viscosityWon't happenRare earth metal fluoridesHydrogen fluorideRare-earth element

The invention discloses a preparation method of rare earth fluoride. The preparation method comprises the following steps: dissolving salt containing rare earth elements into a hydroxyl ether solvent;carrying out ultrasonic treatment for 3-15 minutes to obtain a uniform solution; adding liquid containing fluorine ions into the uniform solution and uniformly mixing to obtain turbid liquid containing rare earth fluoride; extracting precipitate in the turbid liquid; and vacuum-drying the precipitate at the temperature of 60-100 DEG C for 1 h or longer to obtain rare earth fluoride, wherein the water oxygen content of the rare earth fluoride is smaller than 100ppm. According to the preparation method of the rare earth fluoride provided by the embodiment of the invention, the salt containing rare earth elements is dissolved in the hydroxyl ether solvent, the viscosity of the hydroxyl ether solvent is relatively high, the rare earth fluoride is prepared in a high-viscosity environment, thereaction environment is liquid, the reaction selectivity is relatively high, and the reaction is complete. Moreover, the whole process is carried out in liquid, hydrogen fluoride is not needed, no tail gas is generated, and the reaction process is energy-saving and environment-friendly. No water is contained in the whole reaction process, and the water oxygen content of the product is low.

Owner:GRIREM ADVANCED MATERIALS CO LTD

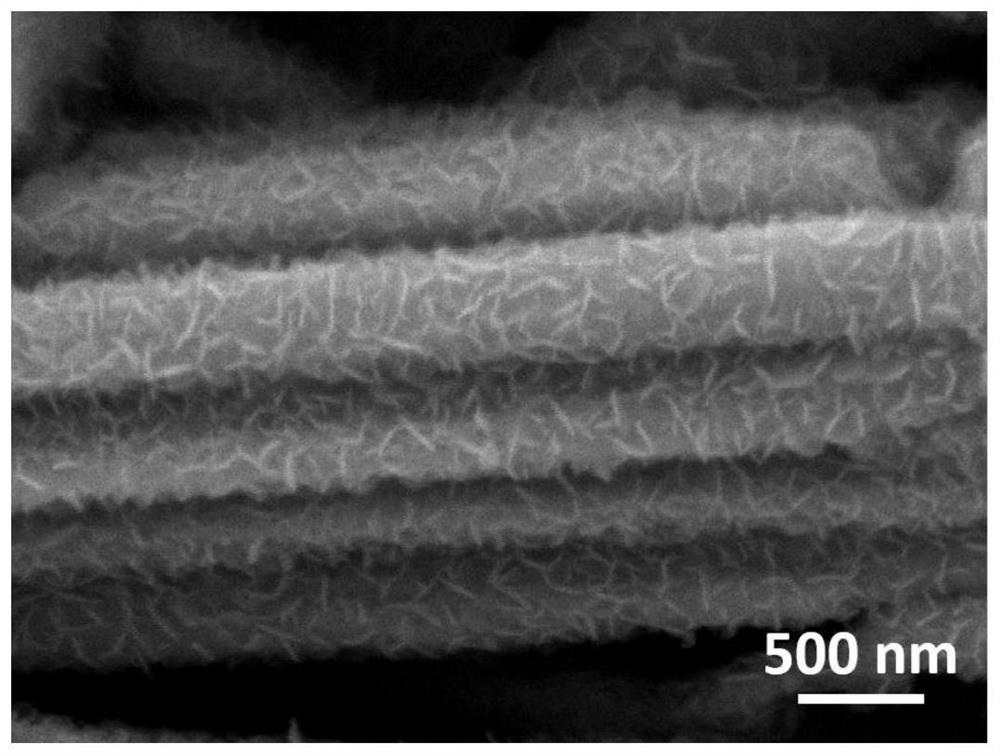

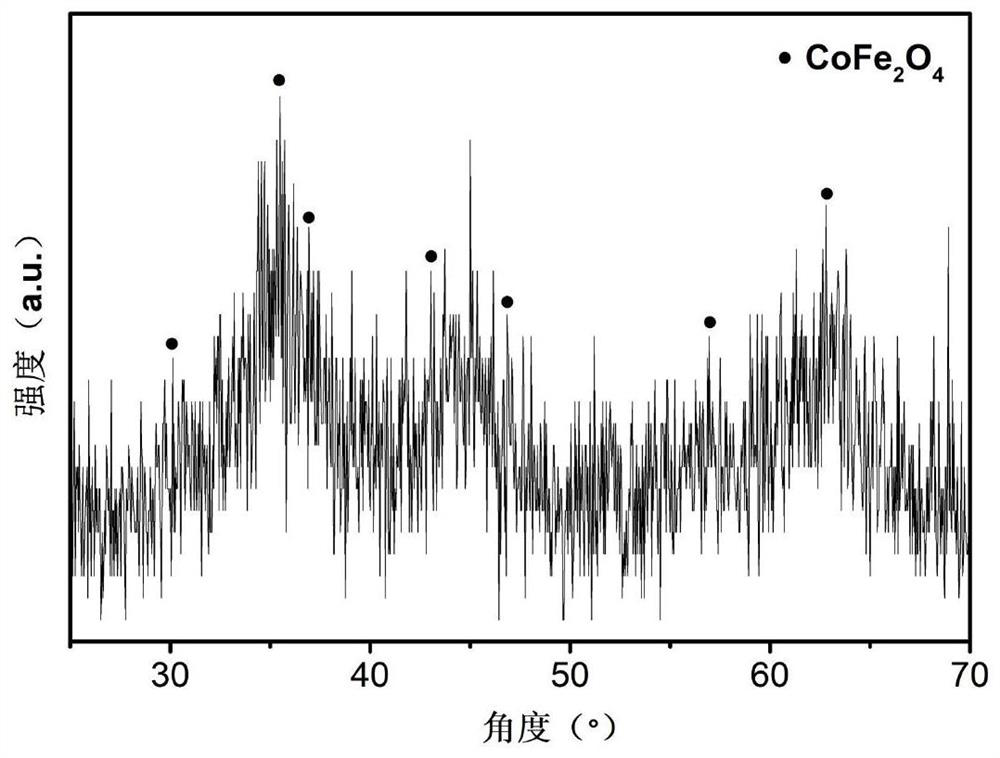

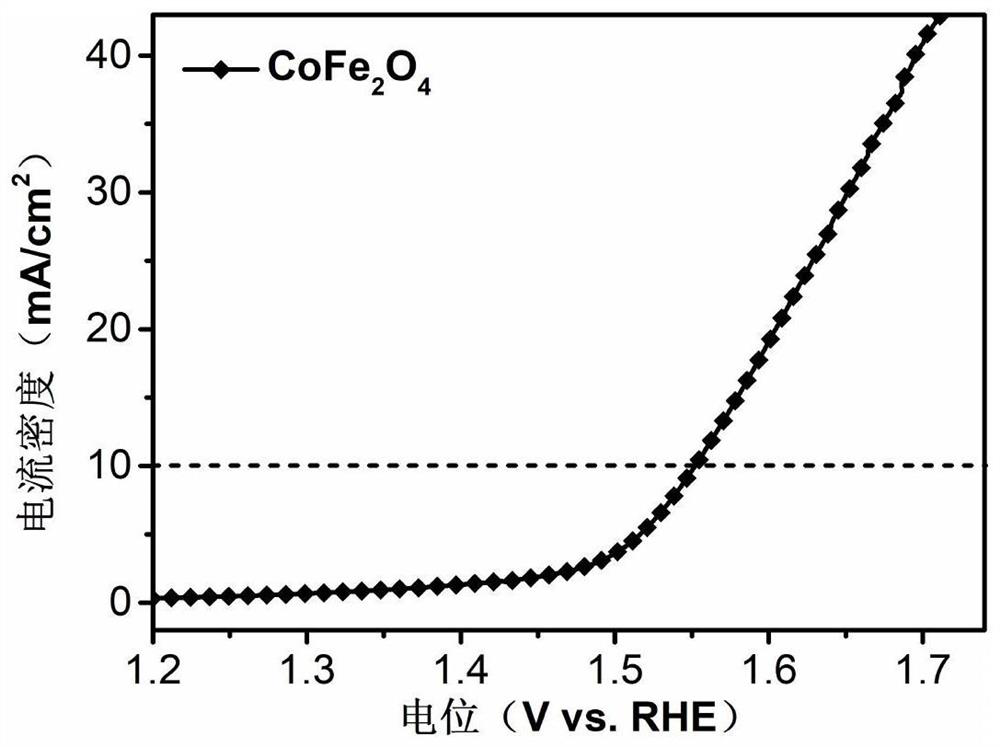

Preparation method and application of spinel type oxide catalyst

PendingCN111841543AReduce manufacturing costRapid coolingMetal/metal-oxides/metal-hydroxide catalystsElectrodesAir atmospherePtru catalyst

The invention discloses a preparation method of a spinel type oxide catalyst. One or two transition metals of cobalt, iron, nickel, manganese, copper, chromium and zinc and aluminum are jointly heatedto a molten state by adopting a vacuum induction melting furnace, cooling is performed to obtain a rod-shaped alloy ingot, a vacuum melt-spinning device is employed for melting for blow casting intoa corresponding alloy strip, carrying out dealloying treatment on the alloy strip in an alkaline solution to obtain a dealloyed product, and in order to improve the crystallinity and stability of thematerial, the dealloyed product is placed in a tubular furnace for high-temperature annealing treatment in an air atmosphere, thus obtaining the spinel type oxide catalyst. The invention also relatesto application of the electrode material. The obtained catalyst has a multi-metal mixed valence state, can significantly enhance the conductivity of the material, shows good electrocatalytic activityto oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) in an alkaline environment, has good stability, and can be used as a cathode catalyst of a chargeable and dischargeable metal-airbattery.

Owner:ZHONGBEI UNIV

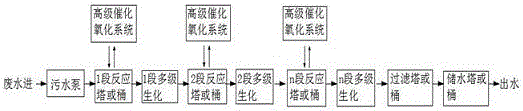

Advanced oxidation and multistage biochemical combination waste water treatment system and technological method

PendingCN106007252AEasy to install and operateEasy to debug and runWater contaminantsTreatment with aerobic and anaerobic processesWaste treatmentEngineering

The invention belongs to waste water treatment, and in particular relates to an advanced oxidation and multistage biochemical combination waste water treatment system and a technological method thereof. The invention provides the advanced oxidation and multistage biochemical combination waste water treatment system, comprising a multistage biochemical combination waste water treatment system; the multistage biochemical combination waste water treatment system consists of a plurality sections of biochemical wastewater treatment systems; each section of biochemical wastewater treatment system consists of a plurality of single-stage biochemical reaction devices; each single-stage biochemical wastewater treatment system is internally provided with an advanced oxidation system which is connected with one of the single-stage biochemical reaction devices. The advanced oxidation and multistage biochemical combination waste water treatment system provided by the invention breaks through thelimitation of a multistage biochemical combination waste water treatment system and enables waste water to be better treated. The invention also provides the method for treating the waste water by utilizing the advanced oxidation and multistage biochemical combination waste water treatment system.

Owner:NANJING DELEI SCI & TECH

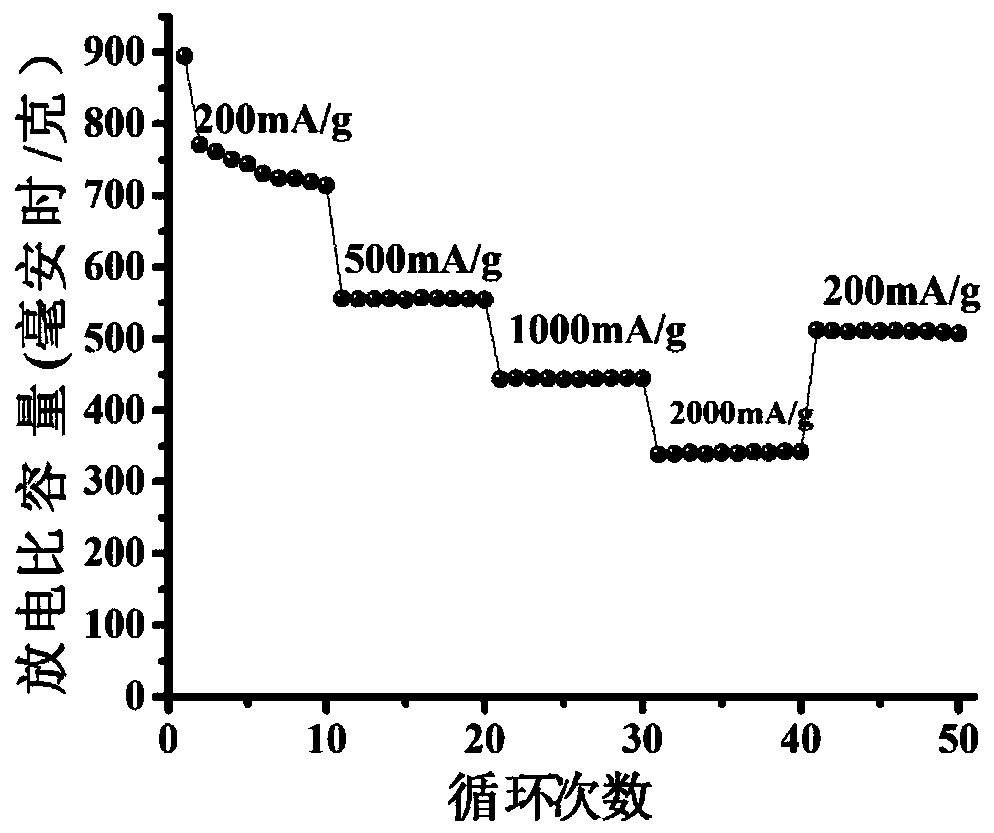

Sodium-ion battery negative electrode material and preparation method thereof

ActiveCN109755543AImprove electrochemical performanceRelieve swellingMaterial nanotechnologyCell electrodesHigh current densitySodium-ion battery

The invention relates to a sodium-ion battery negative electrode material compounded by a nickel oxide-nickel sulfide composite and graphene and a preparation method thereof. The composite material has a double-layer hollow sphere structure. The preparation process includes the following steps: firstly, preparing a nickel oxide double-layer hollow sphere, partially vulcanizing the hollow sphere toobtain the nickel oxide-nickel sulfide composite, and then compounding the nickel oxide-nickel sulfide composite with graphene to prepare the negative electrode material by using a spray drying method. The composite material of the invention can provide more oxidation active sites, obtains higher specific capacity under high current density, shortens the transmission path of electrons and charges, relieves the expansion of materials during charging and discharging, and achieves good cycle life due to good mechanical properties. According to the scheme of the invention, graphene and the nickeloxide-nickel sulfide hollow sphere are compounded, so that the conductivity of the negative electrode material can be enhanced, the volume expansion of active substances in the charging and discharging process can also be alleviated, and the electrochemical performance of the sodium-ion battery can be improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

High-temperature gasification nozzle for petroleum coke

PendingCN110079363AImprove atomization effectIncrease gasification reaction rateGasification processes detailsGranular/pulverulent flues gasificationOxygenInternal temperature

The invention provides a high-temperature gasification nozzle for petroleum coke. The high-temperature gasification nozzle for petroleum coke comprises an oxygen spray pipe, an inner layer cooling jacket and a petroleum coke powder spray pipe which are coaxially arranged front inside to outside, wherein an oxygen inlet is formed in the upper part of the oxygen spray pipe, and the lower part vertically extends to form an oxygen outlet; an inner layer coolant inlet and an inner layer coolant outlet are formed in the upper part of the inner layer cooling jacket, and the lower part vertically extends to the bottom of the oxygen spray pipe and is sealed; petroleum coke guide rotating blades are coaxially arranged outside the inner layer cooling jacket; multiple petroleum coke feed inclined pipes are arranged at the upper part of the petroleum coke powder spray pipe, the lower part of the petroleum coke powder spray pipe vertically extends to the bottom of the inner layer cooling jacket to form annular space, and the inner wall of the petroleum coke powder spray pipe is in radial sealing contact with the petroleum coke guide rotating blades. The inner layer cooling jacket can control internal temperature of the nozzle, prevent overtemperature deformation and wear and prevent non-smooth flowing of petroleum coke powder, and the service life of the nozzle is prolonged.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com