Patents

Literature

98results about How to "Low concentration requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering lead from lead-containing material by matching leaching-electrowinning method

InactiveCN102206750AEasy to separateImprove the efficiency of follow-up operationsPhotography auxillary processesProcess efficiency improvementSlagLead sulfate

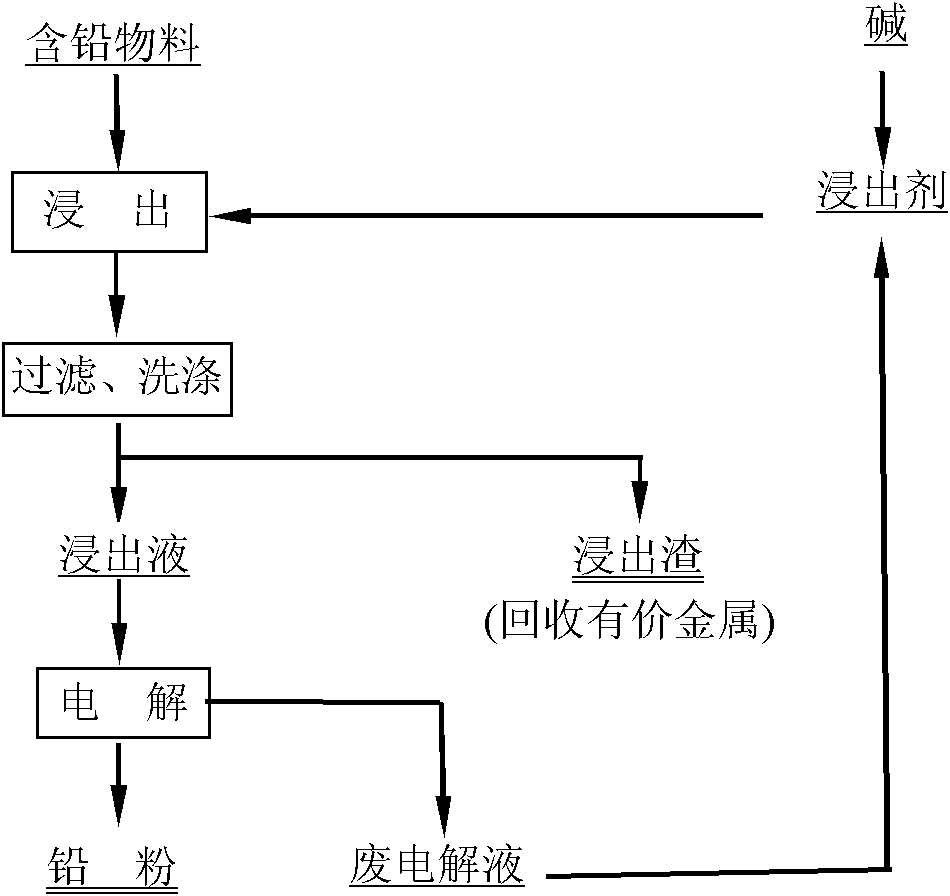

The invention discloses a method for recovering lead from a lead-containing material by matching a leaching-electrowinning method. The method comprises the following steps of: selectively leaching the lead from the lead-containing material at the temperature of -95DEG C by using a mixture of 0.005-0.5M ethylenediaminotetraacetateedetate and 0.05-1.0M alkali as a leaching agent, and filtering and separating to obtain a lead-containing solution; and separating out metal lead powder from the solution by using an electrowinning method, blending electrowinning waste liquor, and returning to the leaching step. By leaching lead from secondary zinc oxide soot, the grade of zinc in secondary zinc oxide and the leaching rate of subsequent leaching can be improved, and subsequent treatment is facilitated; and by leaching lead from low-grade lead slag containing lead oxide, lead sulfate or lead chloride, the leached sewage in the slag piling process never contains lead or contains little lead, environment is not affected, the waste is changed into treasure, and the lead can be recovered from the lead slag. The method has the advantages of simple flow, simple operation, low energy consumption and the like, and can be widely used for treating lead-containing secondary zinc oxide materials and low-grade lead slag.

Owner:CENT SOUTH UNIV

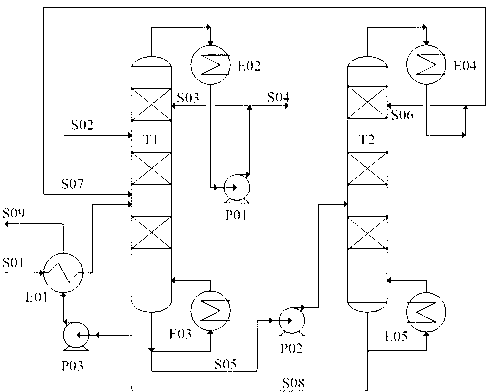

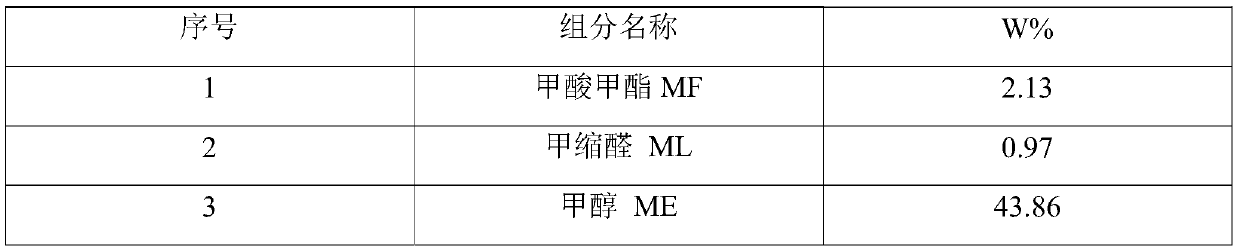

Dimethoxym ethane catalytic distillation production process and production equipment thereof

InactiveCN102070417AContinuous operationReduce production energy consumptionOrganic chemistryOrganic compound preparationCatalytic distillationReaction zone

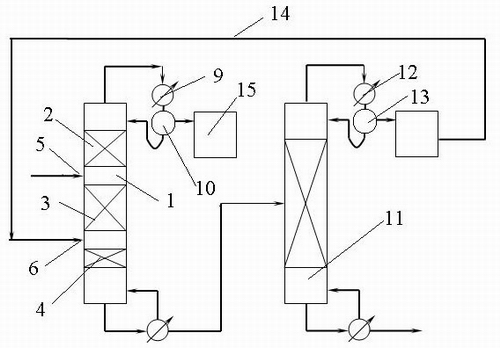

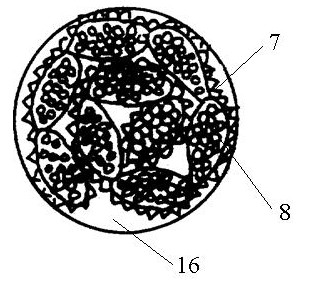

The invention relates to a dimethoxym ethane catalytic distillation production process and production equipment thereof. The process comprises the following steps that: raw materials of methanol and formaldehyde respectively enter a reaction zone from the lower part and the upper part of the reaction zone, the two raw materials carry out aldolization and steam-liquid mass transfer in the reaction zone under the effect of catalysts, and the continuous catalytic distillation process is realized. The production equipment is characterized in that a catalytic distillation device adopts a tower device, cation exchange resin is used as the catalysts, the catalysts of the cation exchange resin are filled in a bundling bag mode to form catalyst structural units, and the structural units form the reaction zone in a rectifying tower, wherein the catalyst structural units are formed through vertical and staggered arrangement. The invention adopts the catalytic distillation tower filled with catalyst bundling bags to produce dimethoxym ethane and has the advantages of high yield, small circulation quantity, low energy consumption and the like.

Owner:FUZHOU UNIV

Treatment method of nitrogen and phosphorus-containing waste water

InactiveCN108002661AStable waterLow concentration requirementWater treatment parameter controlAlkali orthophosphate fertiliserHigh concentrationMagnesium ammonium phosphate

The invention discloses a treatment method of nitrogen and phosphorus-containing waste water. The three-step treatment including magnesium ammonium phosphate reaction, biochemical treatment and deep treatment is sequentially performed on nitrogen and phosphorus waste water phosphorus containing high-concentration ammonium salt and phosphate; a great number of ammonium salts and phosphate can sequentially react with Mg<2+>; MgNH4PO4.6H2O is recovered to be reused as a slow-release fertilizer; through the biochemical treatment on primary treatment liquid supernatant containing low-content ammonium salt and phosphate, ammonia, nitrogen and partial PO4<3-> ions can be removed; finally, through Ca<2+> ions, a small number of PO4<3-> ions remained after the biochemical treatment can be treated;the outlet water stability can be ensured; the standard reaching discharging is reached.

Owner:SHIFANG CHANGFENG CHEM CO LTD

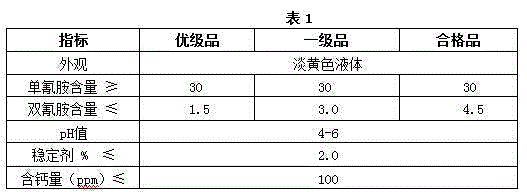

Method for efficiently preparing monocyanamide solution

InactiveCN104445276AFill evenly and effectivelyLow concentration requirementCyanamideO-Phosphoric AcidIon exchange

The invention discloses a method for efficiently preparing a monocyanamide solution, and is used for solving the problems of high equipment investment, high energy consumption, long production period, high production cost, high requirement on concentration of carbon dioxide, high content of calcium ions and incomplete filtration of cyanamide waste residue of an existing production process of the 50% monocyanamide solution. The method comprises the steps of performing a hydrolytic decalcification process step, adding phosphoric acid to regulate pH value, and performing microporous filtration, and evaporation concentration to obtain a monocyanamide product. The monocyanamide solution is prepared by improving a gas inlet way of kiln gas and applying a microporous filtration method, an ion exchange resin decalcification technology and a rotary thin film scraper steam method. Compared with a domestic traditional process, by adopting the method, the requirement of the traditional process on the concentration of carbon dioxide is reduced, the content of the calcium ions in the monocyanamide product is strictly controlled, the product quality is improved, the production period is shortened, the energy consumption is reduced, and the production cost is reduced, so that the method is suitable for industrial large-scale production and has good social and economic benefits.

Owner:GULANG XINHUI CHEM

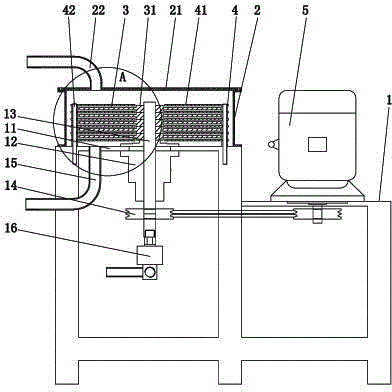

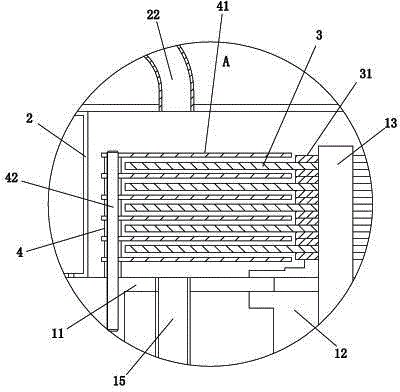

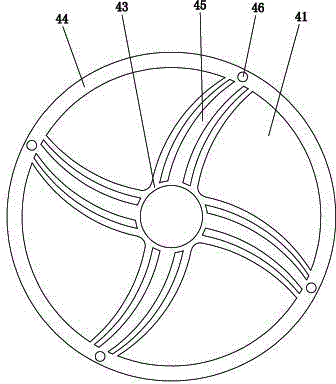

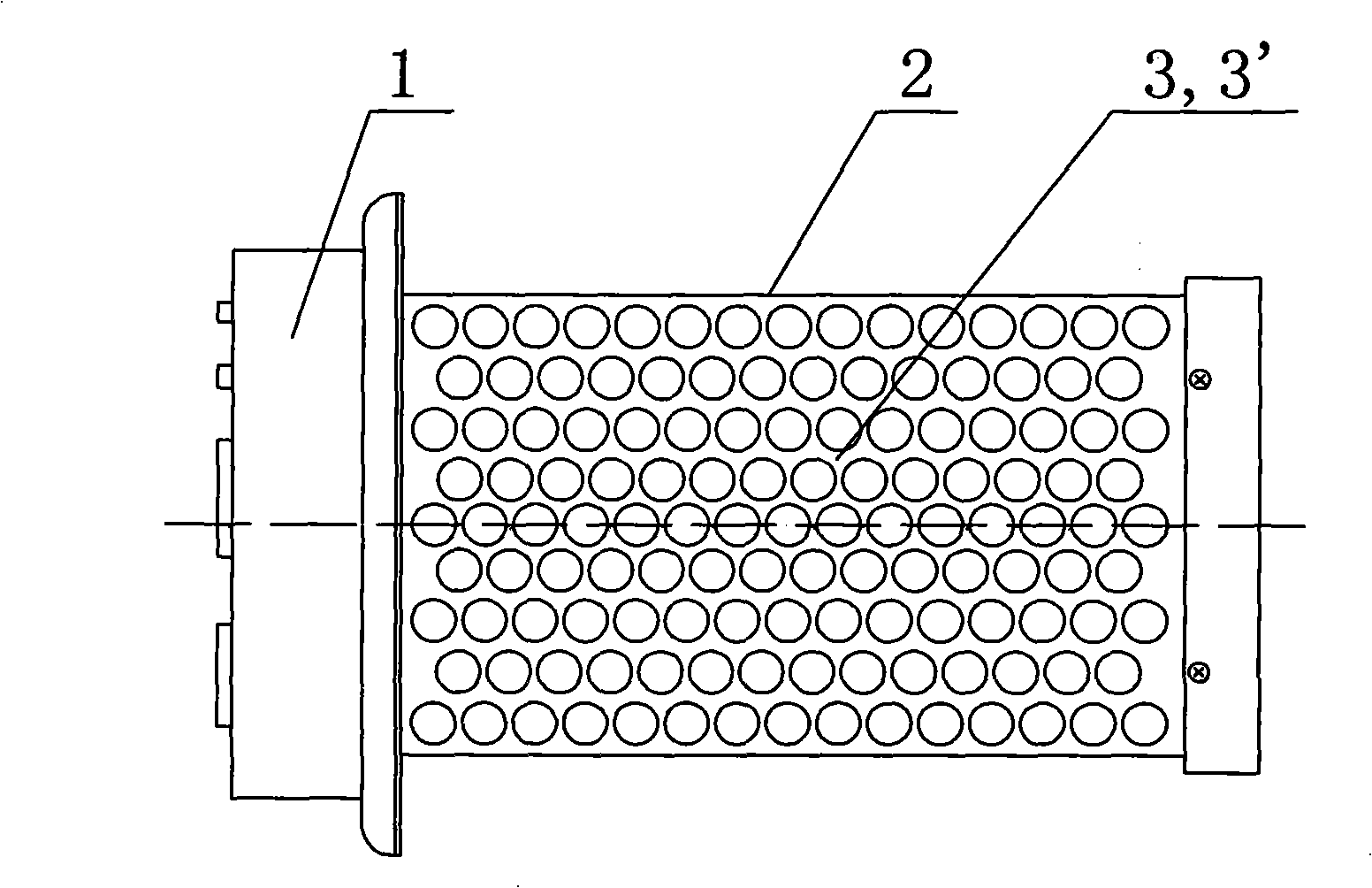

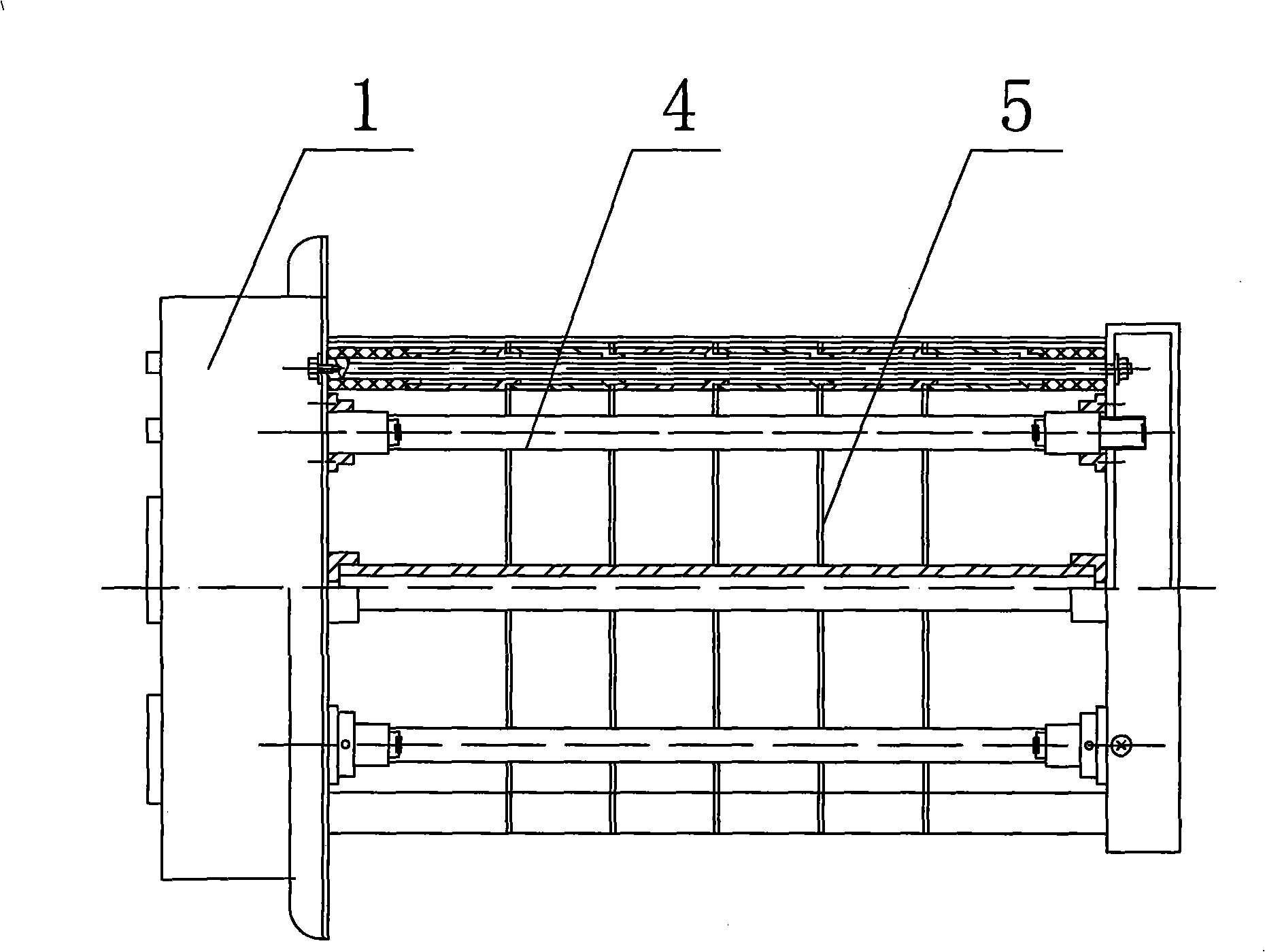

Rotating disc type dynamic membrane separating assembly

InactiveCN104923081AIncrease packing densityLow concentration requirementSemi-permeable membranesConcentration polarizationEngineering

The invention relates to the technical field of filtering separation of membranes, in particular to a rotating disc type dynamic membrane separating assembly. The rotating disc type dynamic membrane separating assembly comprises a machine frame, an outer cylinder and a motor, wherein the outer cylinder is vertically arranged on a mounting plate, the lower port of the outer cylinder is connected with the mounting plate through sealing components, and a separation barrel is arranged in the outer cylinder; a dynamic sealing bearing is arranged on the mounting plate, a hollow shaft is arranged on the dynamic sealing bearing in a rotating manner, and a plurality of filtering discs are arranged in the separation barrel; a belt wheel is arranged on the hollow shaft under the dynamic sealing bearing, and the motor is arranged on the machine frame on one side of the outer cylinder and connected with the belt wheel in a transmission manner. According to the rotating disc type dynamic membrane separating assembly disclosed by the invention, organic filtering materials in various flux specifications can be mounted on the filtering discs, the filtering discs in flat design can improve the filling densities of the organic filtering materials, and hollow flow baffles in fluid flow passage design are arranged among the filtering discs, so that a good hydraulic shear effect and rotary currents are formed on the surfaces of the membranes of the filtering discs by the flow baffles, the membrane pollution can be reduced, the generation of the concentration polarization can be alleviated, the decay speed of membrane flux is lowered, and the cleaning and maintaining period is shortened.

Owner:徐永恒

Metal ore heap leaching, anaerobic enrichment transformation and biological leaching extraction process

InactiveCN102534210ALow concentration requirementEliminate pollutionProcess efficiency improvementLiquid wasteHigh concentration

The invention relates to a metal ore heap leaching, anaerobic enrichment transformation and biological leaching extraction process, which comprises the following steps: utilizing metal sulphate solution with low concentration obtained in the open-air heap leaching operation and treating through a sulfate reduction bacteria process (anaerobic bioreactor) to obtain a metal sulfide precipitate (solid); and obtaining metal sulphate solution with high concentration through bio-leaching (bio-leaching reactor). The invention has the beneficial effects that the environmental risk of external leakage of leaching solution is reduced, the heap leaching period is shortened, the storage capacity of a heap leaching field is greatly reduced, the environmental risk caused by accidental leakage is reduced, and the concentration of metal ions in treated waste liquid is kept below dozens of micrograms per liter so as to be lower than the current environment protection standard requirements.

Owner:JIANGXI UNIV OF SCI & TECH

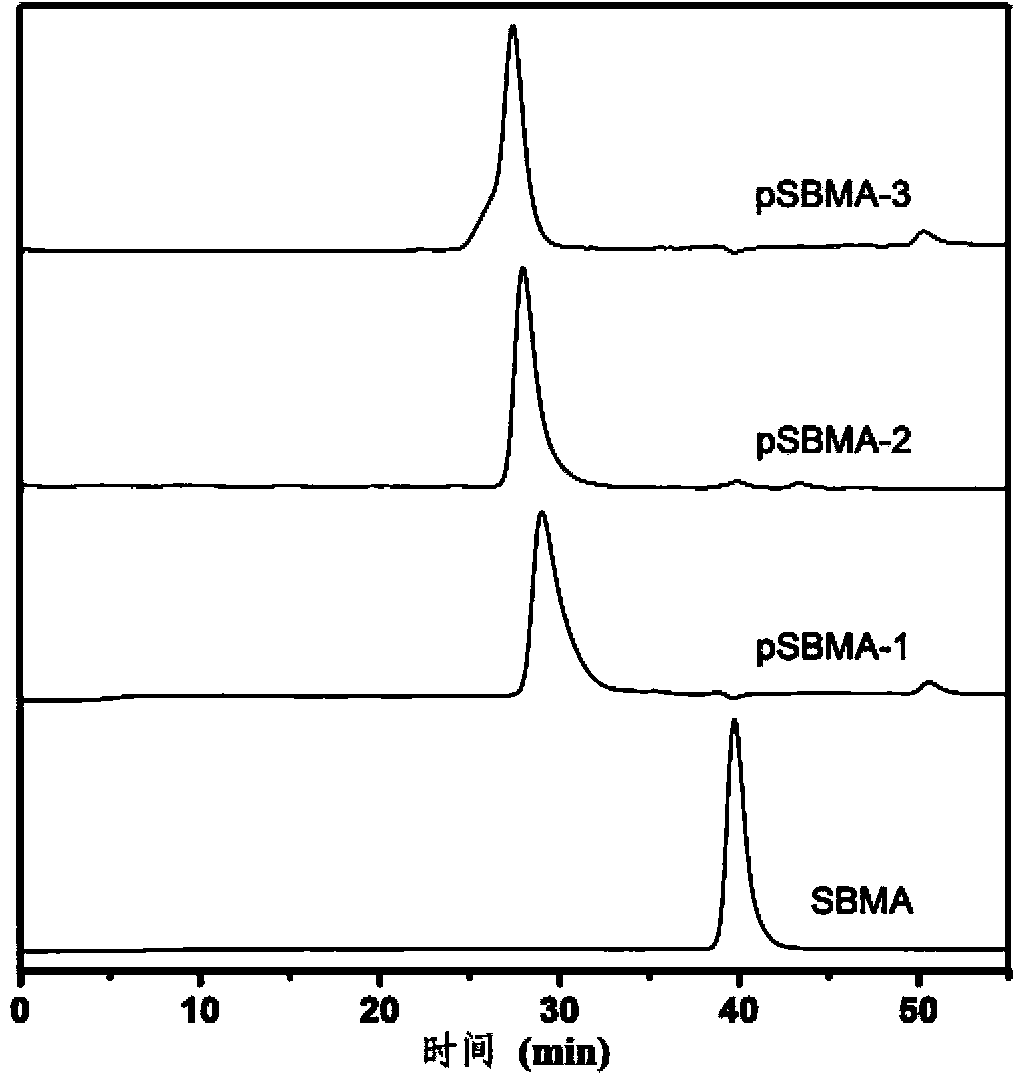

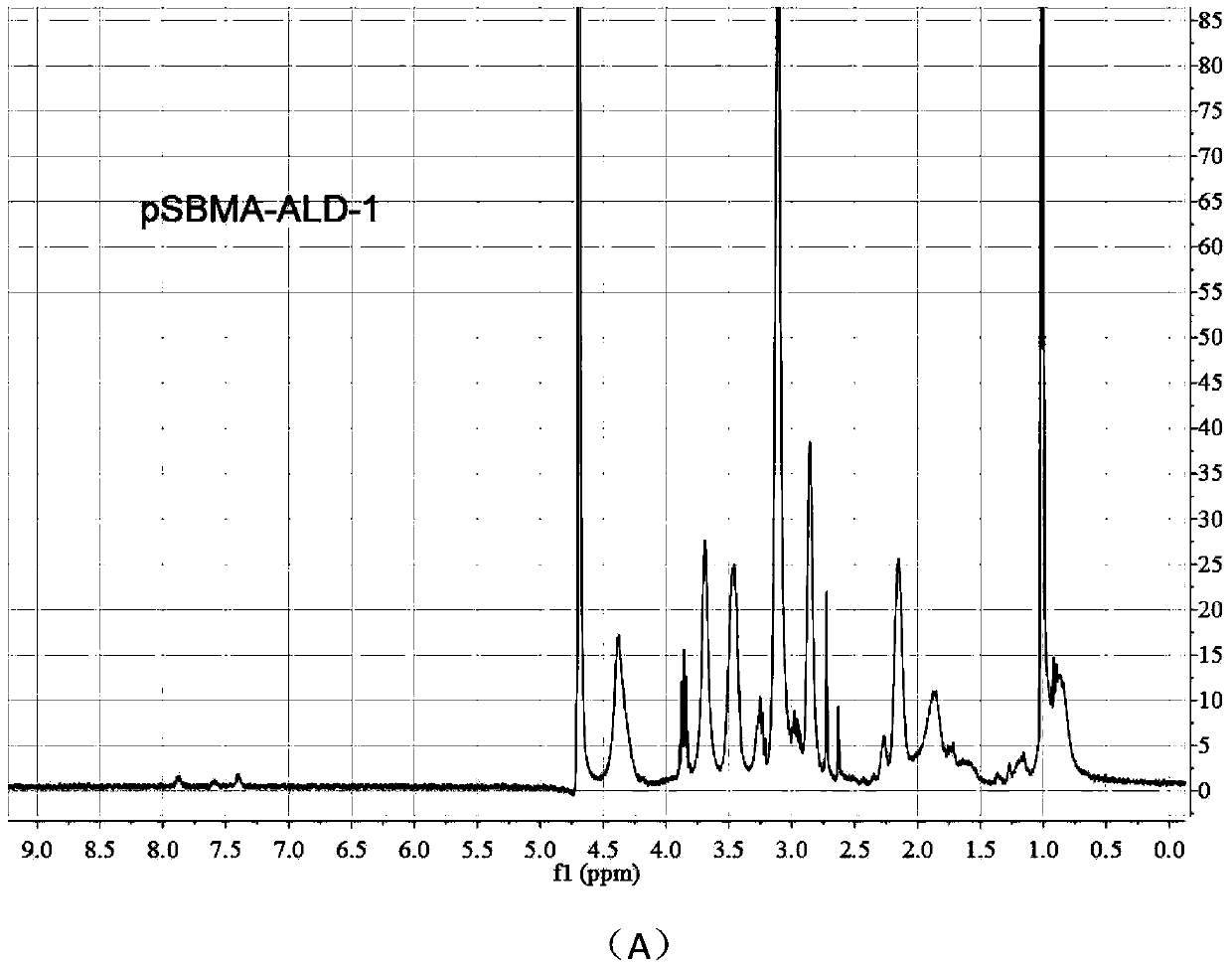

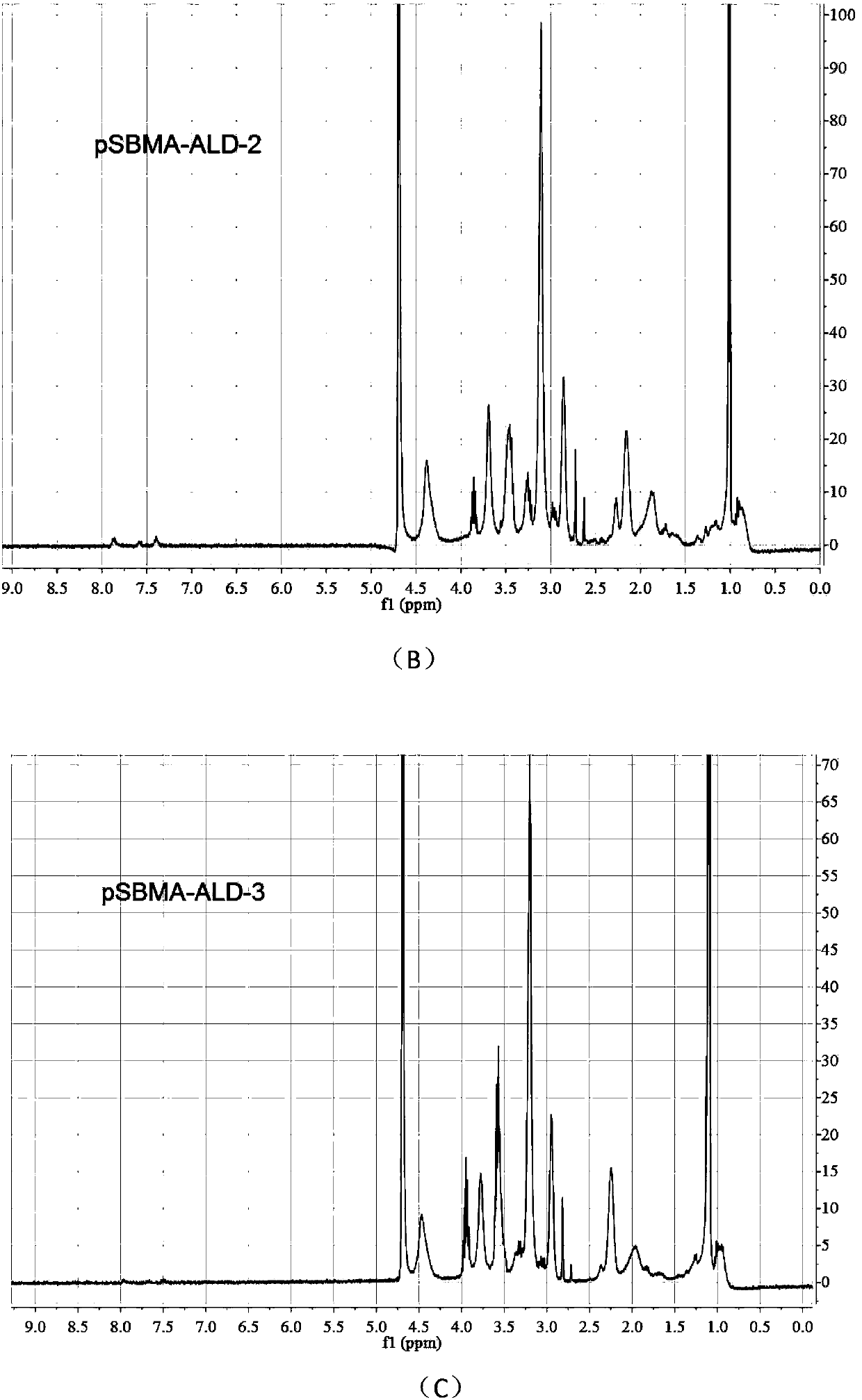

New zwitter-ionic polymer containing multiple phosphonic acid end groups, preparation method and application thereof

The invention discloses new zwitter-ionic polymer containing multiple phosphonic acid end groups, a preparation method and an application thereof. The new zwitter-ionic polymer has the structure shown in a formula (I). In the formula (I), n is more than or equal to 10 and less than or equal to 37. The new zwitter-ionic polymer can be used for grafting modification of the metal-oxide surface, so that the modified surface has excellent hydrophilicity, protein adsorbability and bacterium adhesion resistance; and the new zwitter-ionic polymer is especially applicable to fast modification of the surface of the biomedical material containing the metal-oxide surface so as to improve the biocompatibility, bacterium adhesion resistance and surface lubricity of the material.

Owner:ZHEJIANG UNIV

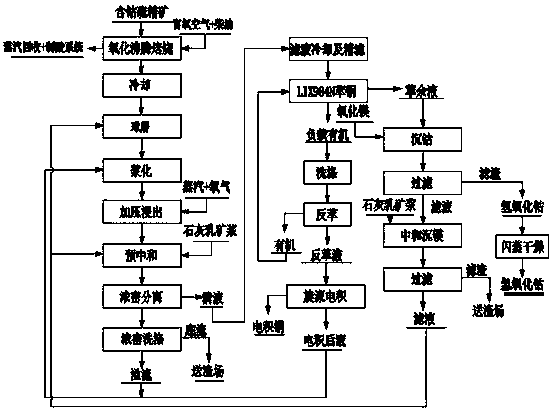

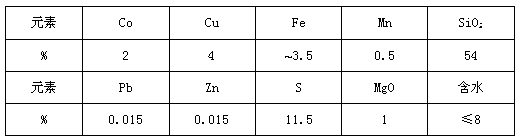

Comprehensive recovery processing method for cobalt-sulfur concentrates

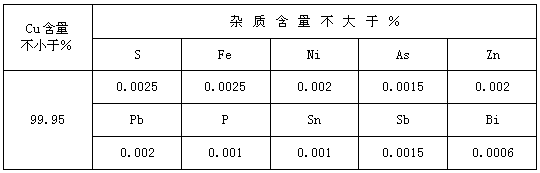

ActiveCN109234522AHigh direct yield of copperPrevent precipitationPhotography auxillary processesProcess efficiency improvementChemistryMagnesium

The invention belongs to the technical field of nonferrous metallurgy and particularly relates to a comprehensive recovery processing method for cobalt-sulfur concentrates. The comprehensive recoveryprocessing method comprises the following steps: carrying out oxidizing boiling roasting on the cobalt-sulfur concentrates so as to obtain roasted sand and SO2 flue gas, carrying out purification anddust removal on the SO2 flue gas, introducing the SO2 flue gas into a flue gas acid-making system, and carrying out acid making; after the roasted sand is cooled, carrying out ball milling so as to obtain fine particles, carrying out pulpifying and presoaking on the fine particles, carrying out continuous and selective leaching by virtue of a continuous pressurizing system, pre-neutralizing lime milk ore pulp so as to obtain supernate and a filter residue, treating the supernate, introducing the supernate into a copper extraction system, and carrying out extraction, so as to obtain cathode copper, an electrodeposited liquid and raffinate; and washing the filter residue to obtain a washing liquid, carrying out pulpifying and presoaking on the roasted sand by virtue of the electrodeposited liquid and the washing liquid which are taken as a pulpifying liquid, introducing raffinate into a cobalt precipitation process and a magnesium precipitation process, carrying out cobalt precipitationand magnesium precipitation so as to obtain cobalt and magnesium solids, and transporting the cobalt and magnesium solids to a residue field, and carrying out stockpiling. According to the method, cobalt and copper in ores can be effectively recycled once, the recovery rates of cobalt and copper are high, low grade cobalt and sulfur concentrates can be effectively treated, and the maximal utilization of resources is realized.

Owner:浙江科菲科技股份有限公司

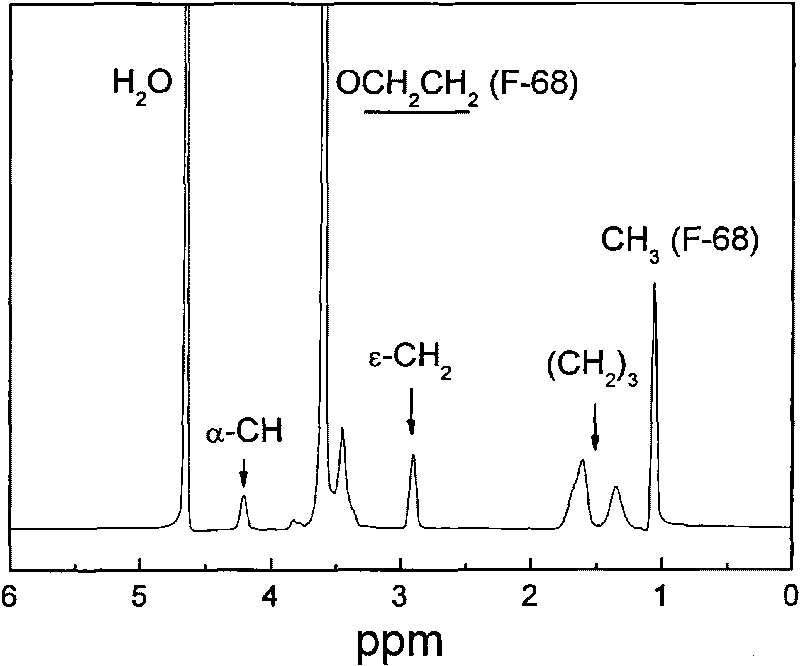

Supramolecular hydrogel gene vector material, and preparation method and application thereof

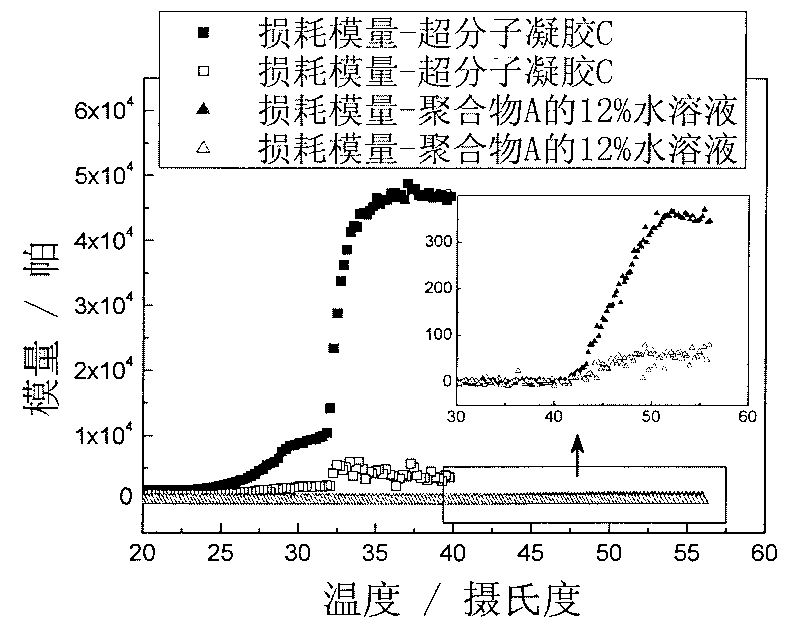

InactiveCN101716346AEasy to prepareMild conditionsGenetic material ingredientsImmunological disordersEnd-groupGene vector

The invention discloses a supramolecular structural hydrogel gene vector material and a preparation method and application thereof. The method comprises the following operation steps: synthesizing a multi-block copolymer with cation chain segments through modification of a terminal group of triblock copolymer of a polyethylene glycol-polypropylene glycol-polyethylene glycol which is modified by polylysine; then, mixing the copolymer with DNA solution to obtain DNA compound micelle; further, mixing and then stirring the micelle solution and solution of alpha-cyclodextrin; and keeping mixed solution at the room temperature to obtain hydrogel. The hydrogel can be used for preparing an injectable gene vector. The method has the advantages that the method has simple operation, can adjust the strength of the hydrogel and the gelatination time, can mold at the room temperature and does not relate to chemical crosslinking reaction and the use of organic solvent; and the obtained hydrogel has the advantages of temperature sensitivity, good bio-compatibility, obvious transfection effect and the like; and the method is hopeful to be widely applied in the field of a biomedical engineering material.

Owner:SUN YAT SEN UNIV

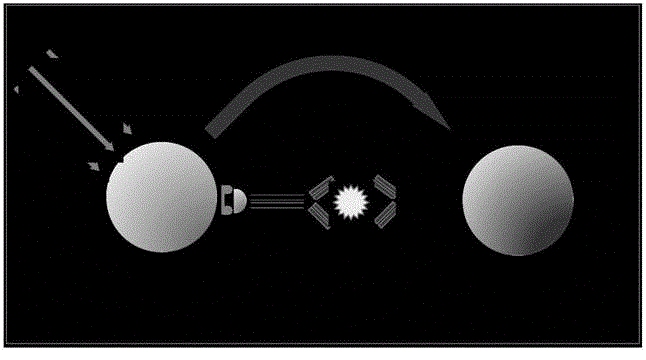

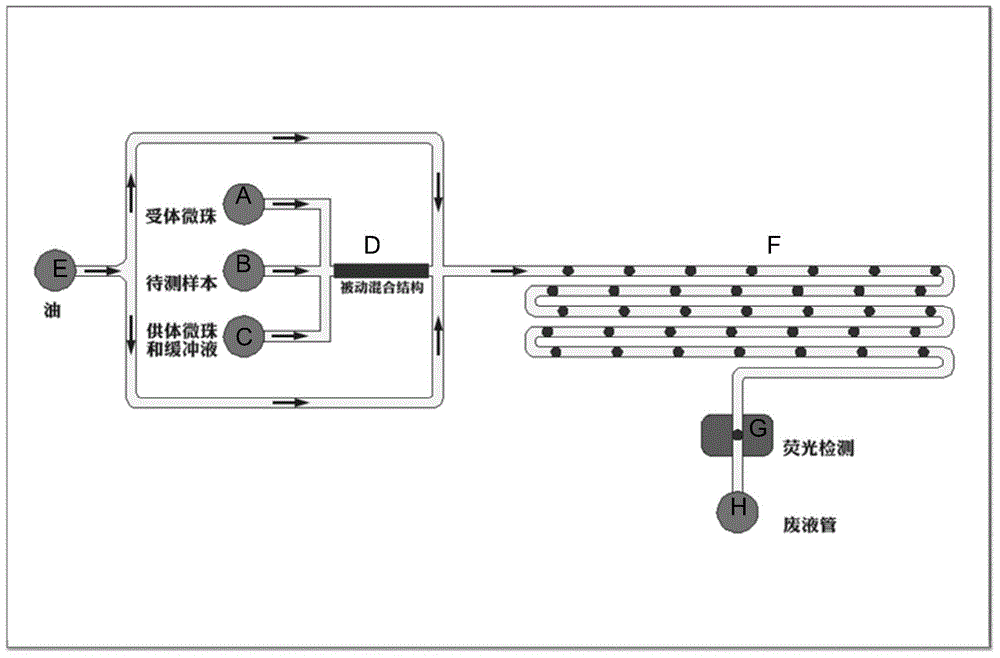

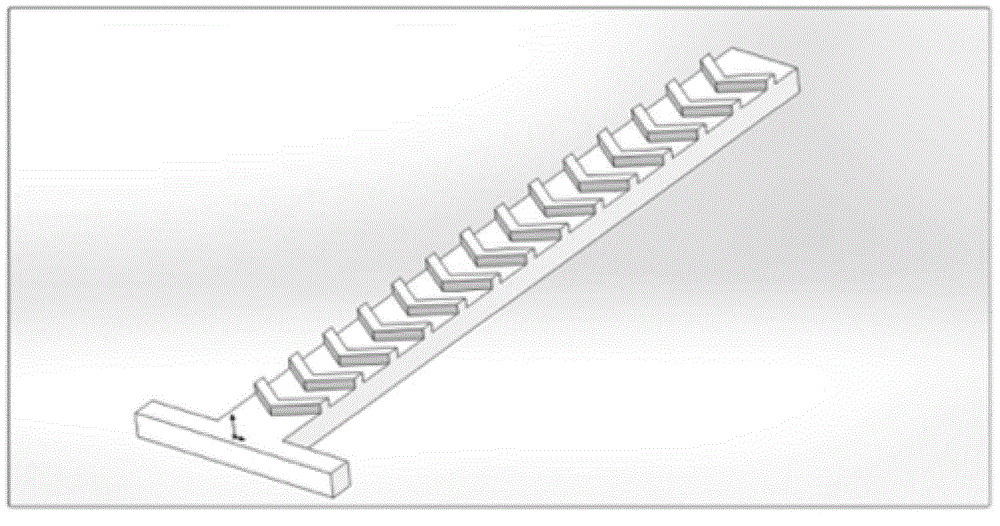

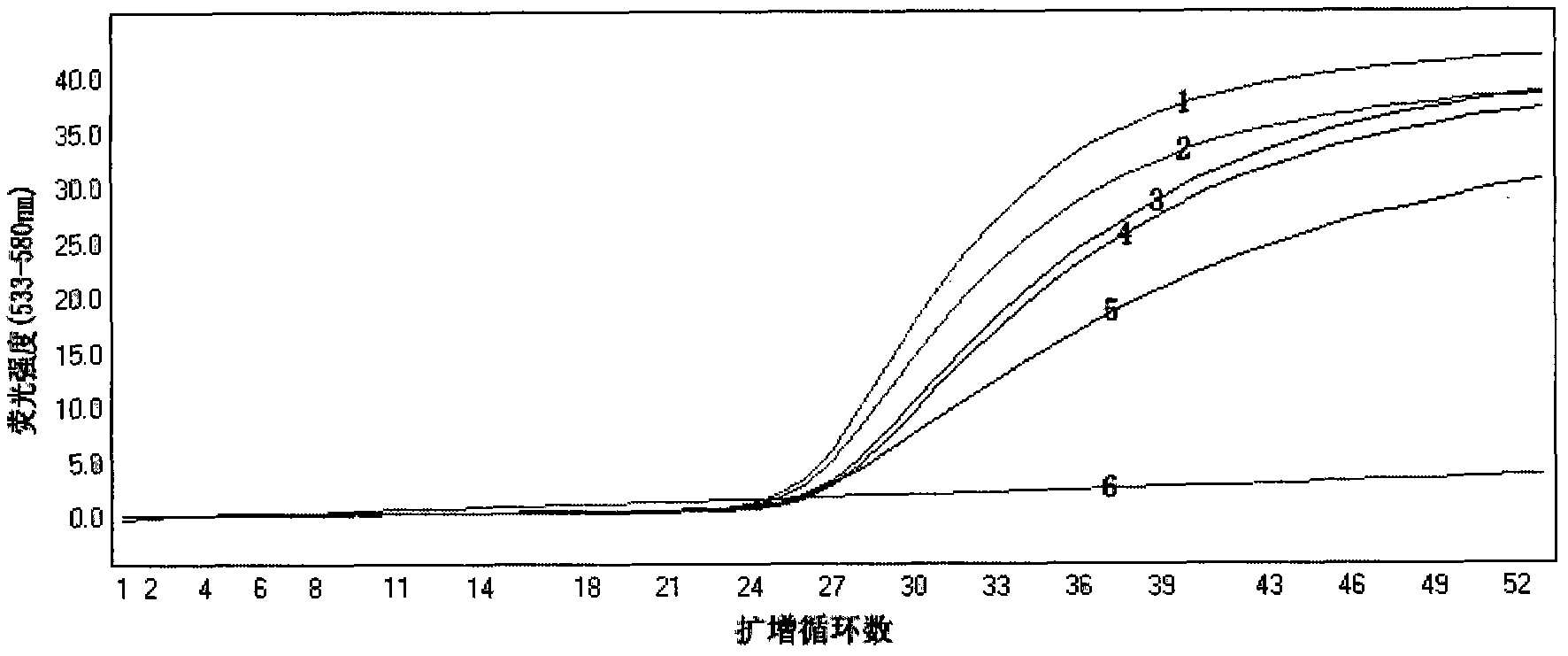

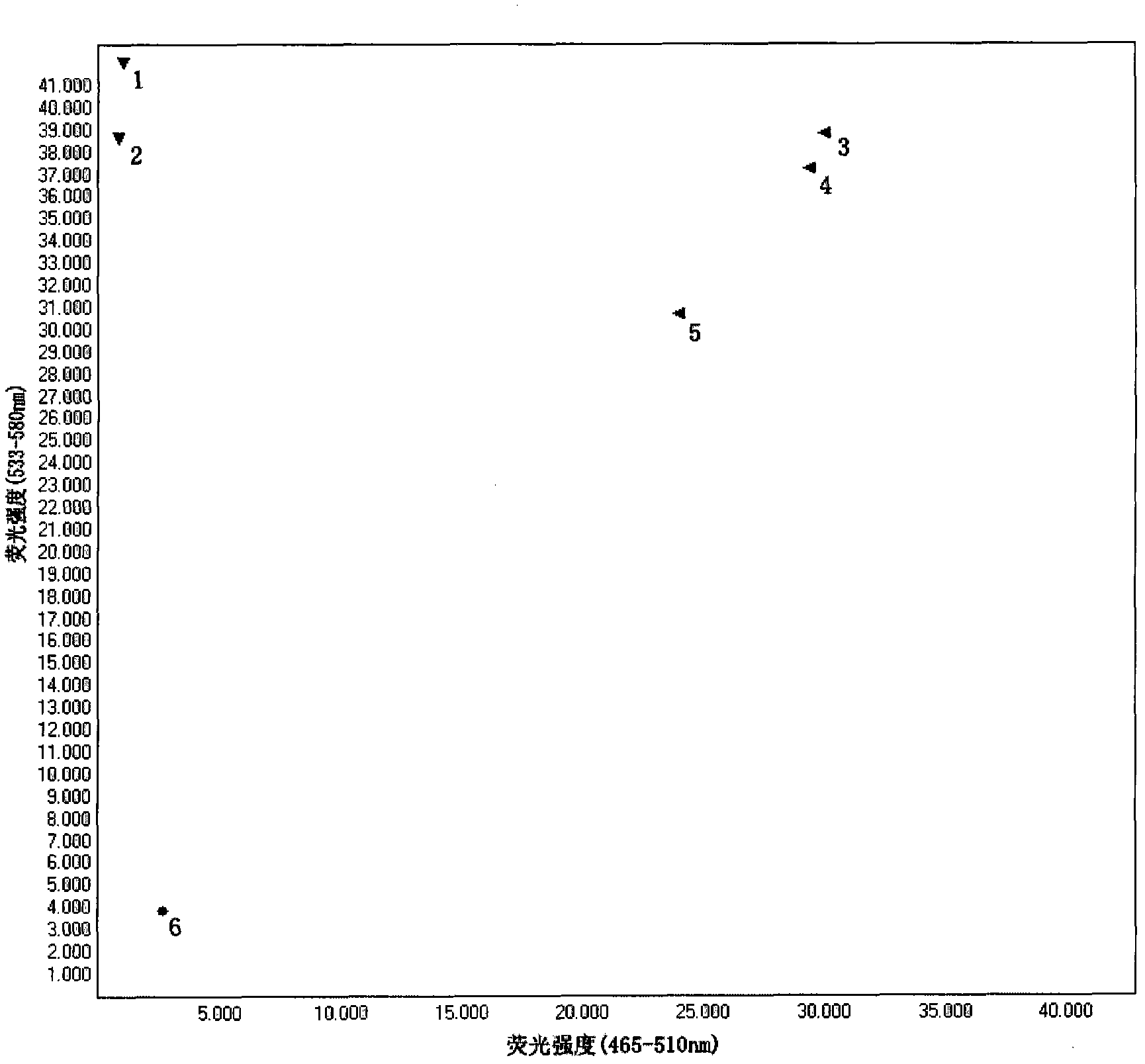

Biological macromolecule detection method based on nano homogeneous time-resolved fluoroimmunoassay and droplet-based micro-fluidic technology

InactiveCN106324236AReduce volumeLow concentration requirementBiological testingFluorescenceEngineering

The invention belongs to the field of micro-fluidic chips, and relates to a biological macromolecule detection method. An alpha-LISA technology and a droplet-based microfluidics technology are combined and optimized to prepare a micro-fluidic chip liquid. A novel biological macromolecule detection method with a high sensitivity is provided. A three-phase mixing technology is adopted. A passive mixing structure is used to fully and evenly mix the reaction liquid. A cross focusing technology is used to form droplets. The generated droplets have the advantage of smaller volume, and thus the reactions become faster. Moreover, the requirements on the samples are lower, the reactions are specific, sensitive, fast, and full; the washing does not need to be carried out after reactions; complicated complexes such as complete proteins, enzyme complex, bacteriophage, and the like, can be detected; the technical bottleneck of conventional commercial liquid chips at present can be broken through; the provided method can be applied to fast clinical biological macromolecule detection; the detection sensitivity and specificity are both improved, and the required sample amount is reduced.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

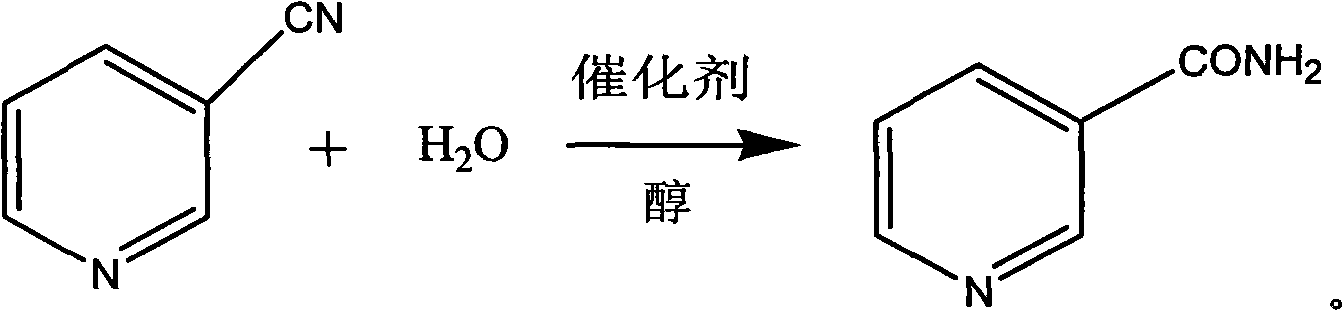

Method for preparing nicotinamide

The invention discloses a method for preparing nicotinamide, which comprises the following steps: dissolving 3-cyanopyridine in alcohol; adding water and a catalyst to perform a hydrolysis reaction; and performing posttreatment on the reaction product to obtain the nicotinamide. The method avoids introducing auxiliary reagents, is highly economic, ensures mild reaction conditions, easy product separation, high product purity and high yield, generates little waste gas, liquid and solid, and is favorable for industrial production.

Owner:浙江新赛科药业有限公司

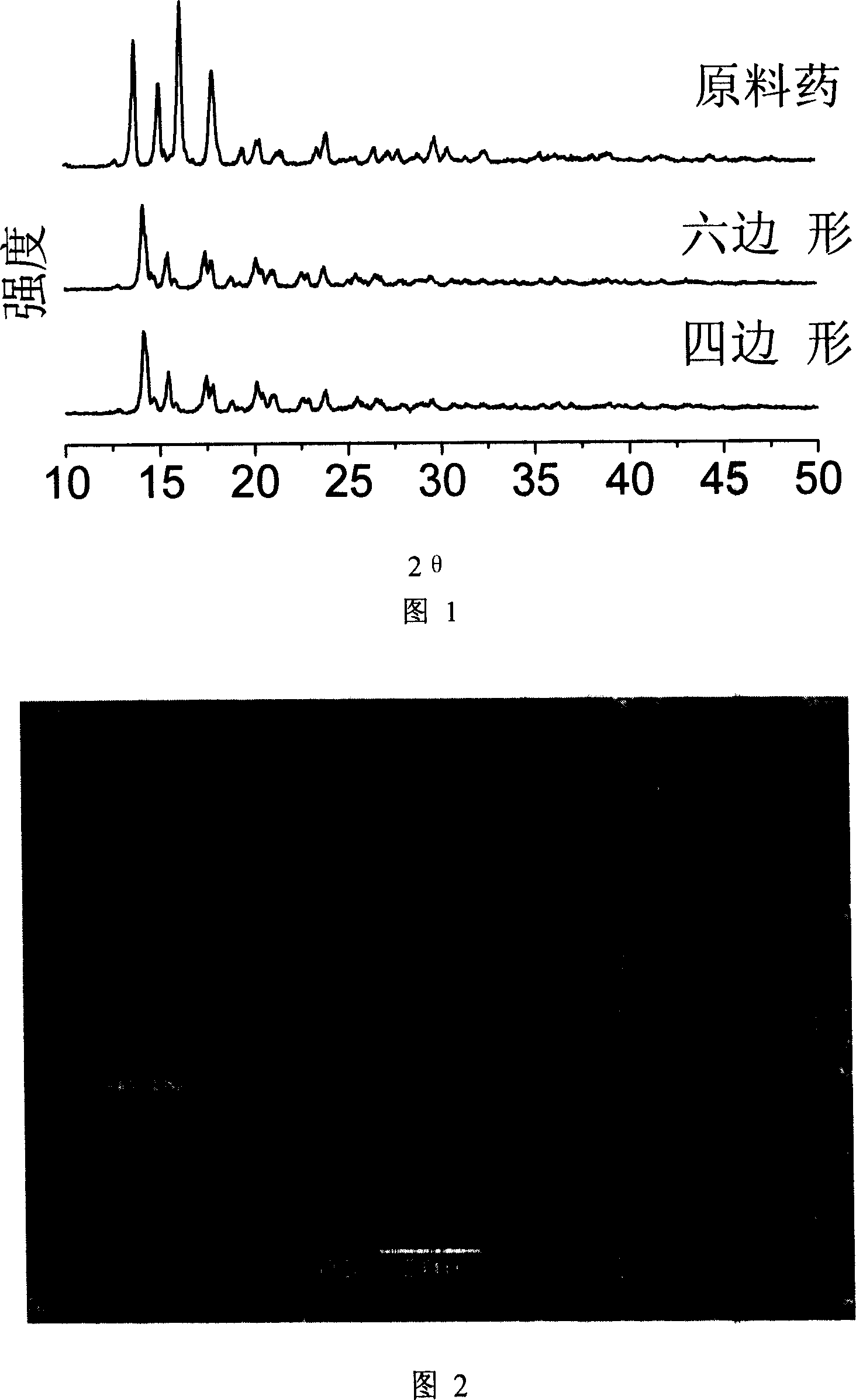

Preparation of superfine prednisolone powder

InactiveCN101015558AHigh yieldTo overcome the solubility difference is not large enoughOrganic active ingredientsPowder deliveryPrednisoloneInstability

This invention relates to a method for preparing superfine prednisolone powder, and belongs to the field of micronization. Open question at present: particle diameter of prednisolone is small but can not obtain dry powder, or the dry powder has wide size distribution, bad redispersibility, and instability in water. The invention is to realize the preparation of prednisolone granule with controllable particle diameter, narrow particle size distribution, and superfine or nano-graded quadrilate and hexagon through inverse solvent recrystallization.the prednisolone of the invention has the advantages of controllable particle diameter, narrow particle size distribution, good redispersibility, stable micropowder, and good dissolving effect; and has prodigious dominance in the development of drug effect and new medicament form.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for recovering tellurium through cyclone electrolysis of solution containing tellurium

InactiveCN105862059AShorten the electrolysis cycleAvoid Concentration RequirementsElectrolysis componentsCycloneHigh current density

The invention discloses a method for recovering tellurium by swirl electrolysis of a tellurium-containing solution, which comprises the following steps: adding concentrated sulfuric acid into the tellurium-containing solution until the pH value of the tellurium-containing solution is 5.7-6.5, controlling the temperature of the tellurium-containing solution to be higher than React at 90°C for 2 to 4 hours, filter; leach the filter residue obtained after filtration with sodium hydroxide solution; perform swirl electrolysis on the leaching solution obtained after leaching, and take out the cathode after swirl electrolysis; The solution is boiled, washed, and dried to obtain high-purity tellurium. The invention adopts swirl electrolysis to recover tellurium in the tellurium-containing solution, which avoids the influence of unfavorable factors on electrowinning such as the decrease of current efficiency and the increase of concentration polarization caused by the slow flow of the solution in the traditional electrolysis process, and shortens the electrolysis cycle of tellurium , which reduces the concentration requirements of impurity elements in the electrolyte, and has many advantages such as high selectivity, high current density, and high product purity.

Owner:CENT SOUTH UNIV

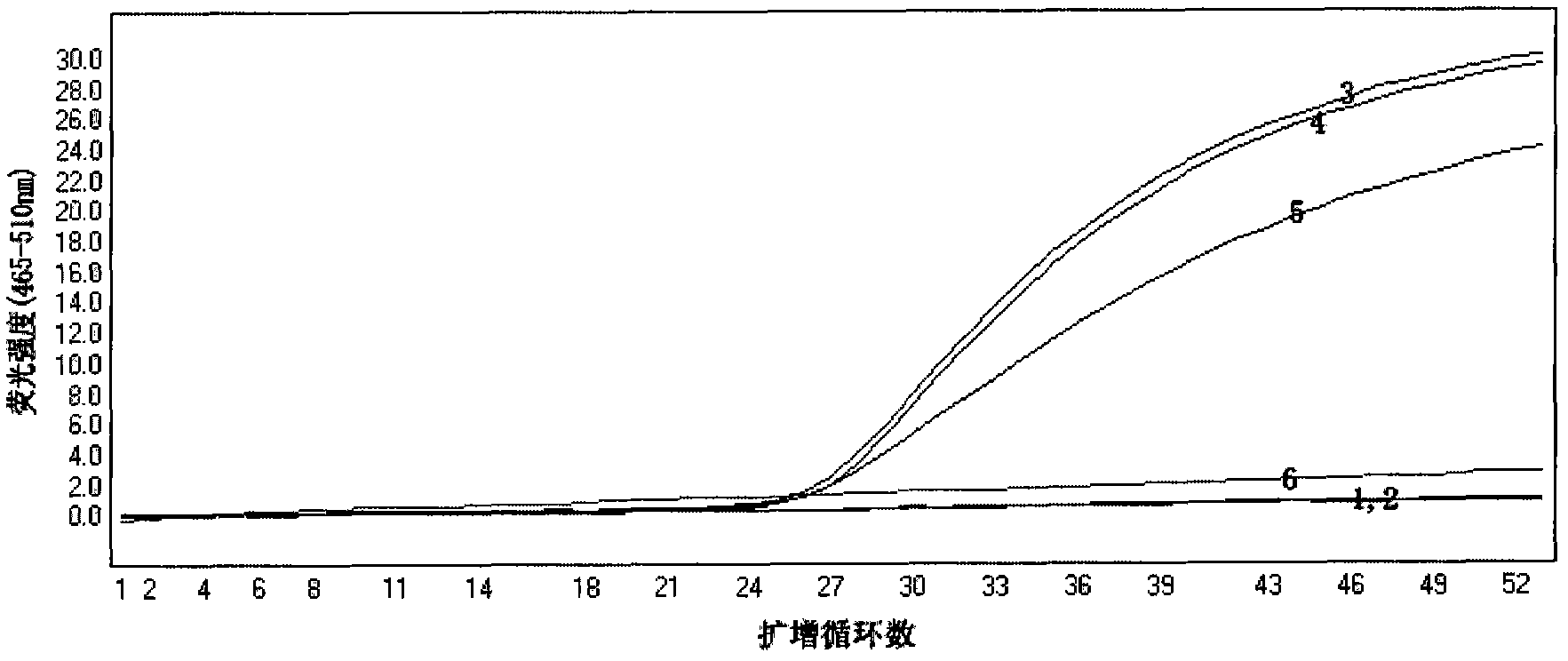

Primers and probes for detecting cow SLC35A3 gene V180F mutation

InactiveCN102002526AStrong specificitySensitive detectionMicrobiological testing/measurementFluorescence/phosphorescenceVertebral malformationFluorescence

The invention provides primers and specific TaqMan MGB probes for accurately and efficiently detecting SLC35A3 gene V180F mutation bits. When the primers and the probes are used, and the real-time fluorescence quantitative PCR (Polymerase Chain Reaction) technology is utilized, the gene type of the cow SLC35A3 gene V180F mutation bits to be detected can be fast and sensitively detected, so that the cow CVM (Complex Vertebral Malformation) hereditary defect carriers can be accurately sieved. Compared with the traditional detection technology, the primers and the probes have various advantages including high detection speed, high sensitivity and high automation degree, in addition, the types can be judged through one PCR, the whole reaction process is carried out in a sealed tube, and the cross contamination is reduced.

Owner:CHINA AGRI UNIV

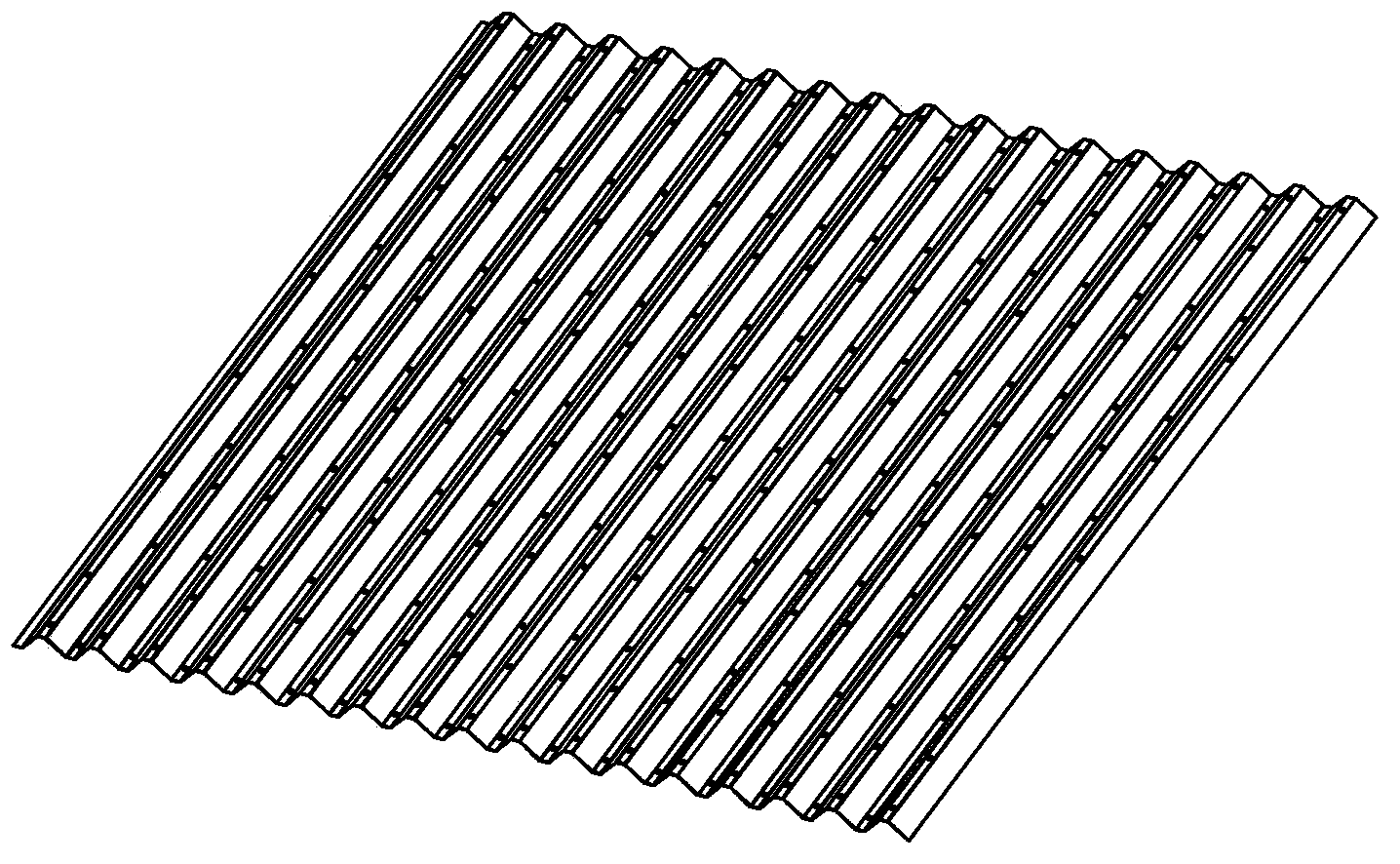

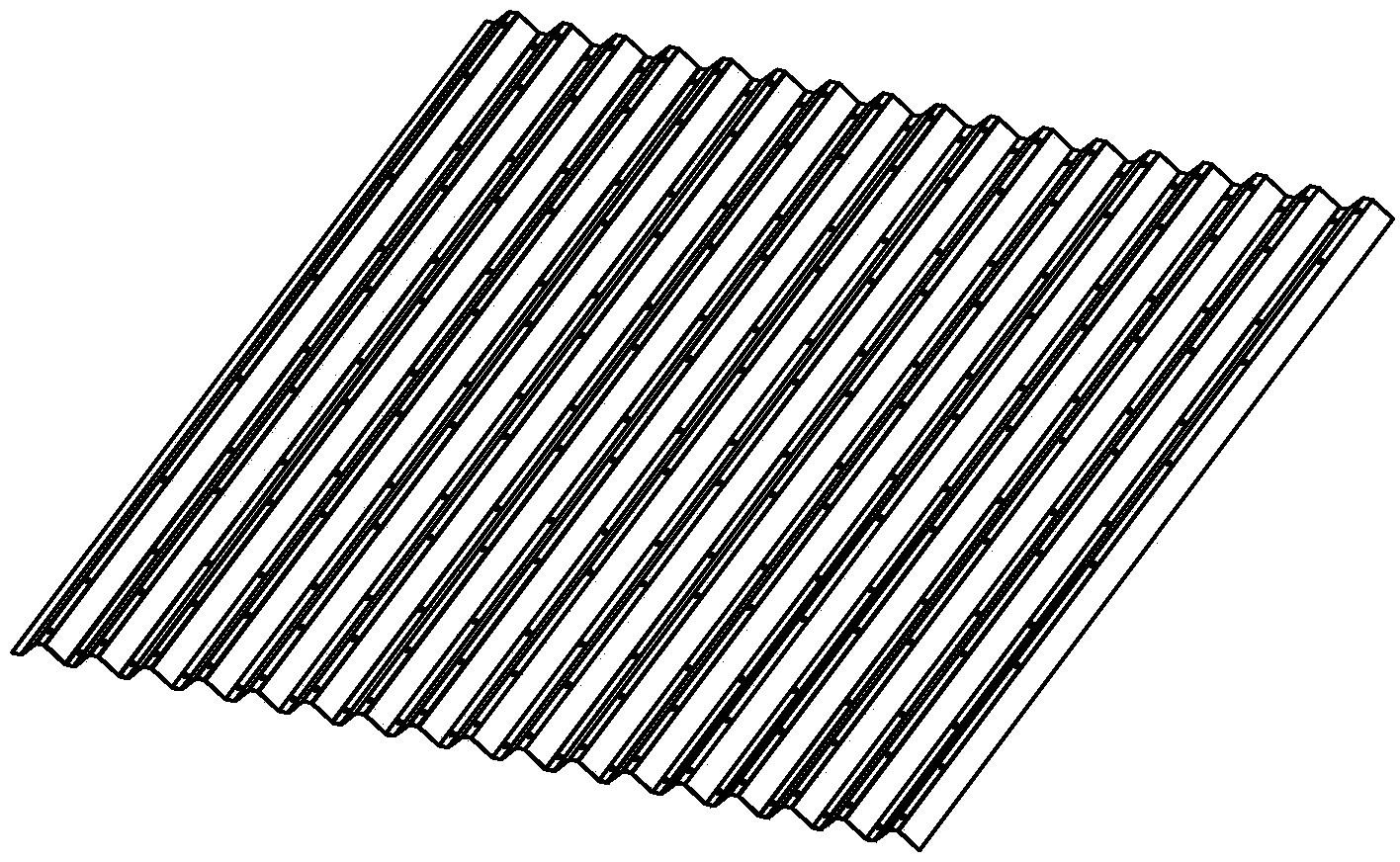

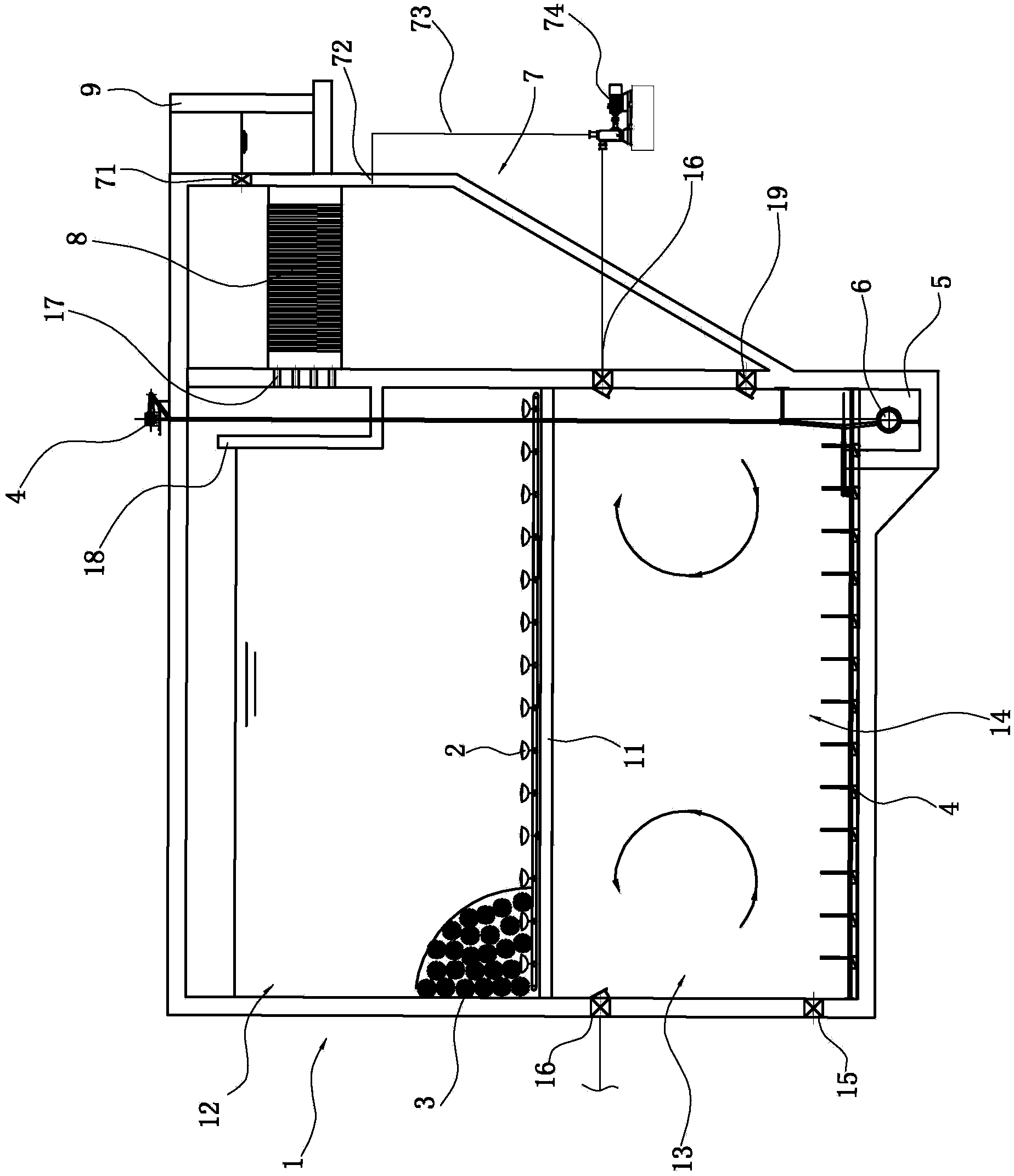

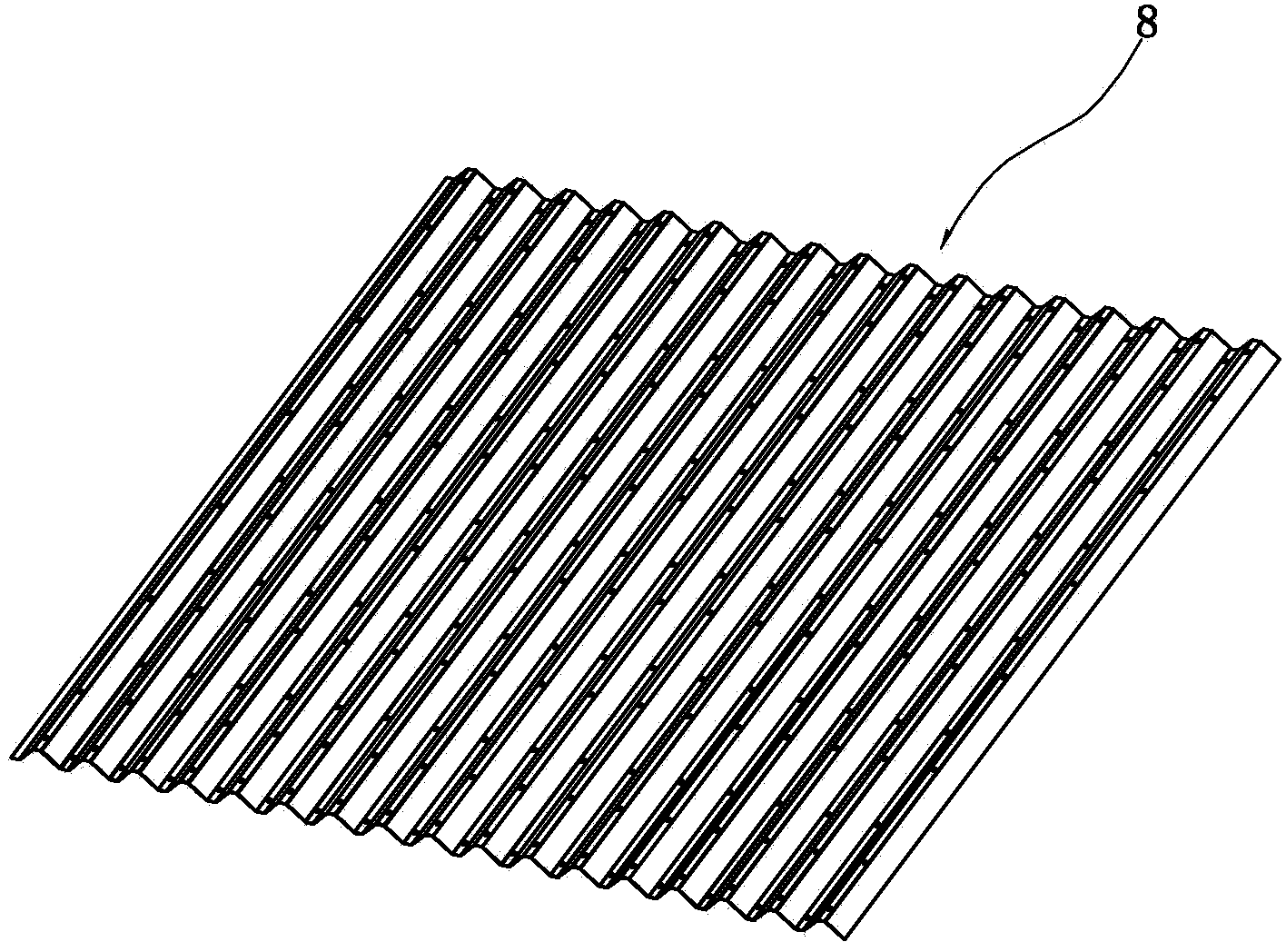

Horizontal flow precipitation separation device

InactiveCN103405946AAvoid disturbing effectPrevent resuspensionSedimentation settling tanksSludgeWater flow

The invention relates to a horizontal flow precipitation separation device. The horizontal flow precipitation separation device is characterized by comprising multiple corrugated plates arranged in a precipitation pond, wherein each corrugated plate is vertically arranged relative to a horizontal plane, the adjacent corrugated plates are symmetrically arranged and are spaced, and the smallest interval of the adjacent corrugated plates serves as a sludge discharging channel. Compared with the prior art, the horizontal flow precipitation separation device preserves the advantages that a flow direction and a precipitate sludge discharging direction are mutually vertical without interfering with each other, the disturbance between the horizontal flow and a precipitate is avoided, the submerged sludge is prevented from suspending again, meanwhile, a sludge discharging manner is optimized, the vertical sludge discharging channel is adopted, when stream horizontally flows through a stream channel, suspended solids are collided with a frame of the stream channel to rapidly precipitate, and slide downwards along the frame to enter the sludge discharging channel so as to directly precipitate to the bottom of the precipitation pond, and a wobble plate does not need to bear load, so that a problem of load-bearing of the wobble plate caused by large precipitate quantity is solved.

Owner:ZHEJIANG DEAN TECH

Particulate matter detection device and detection method

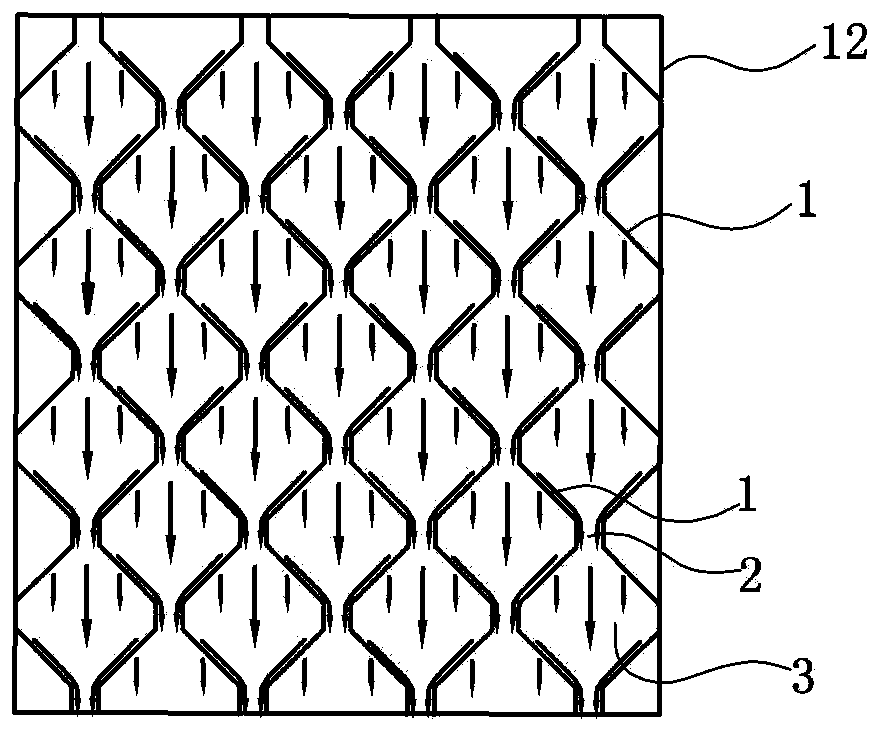

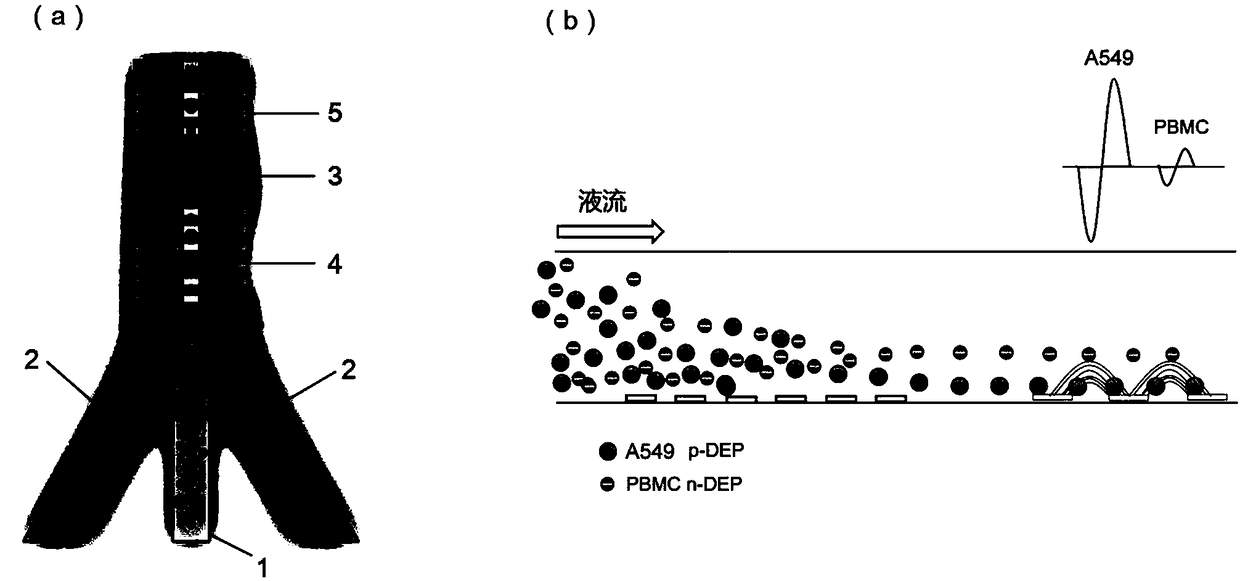

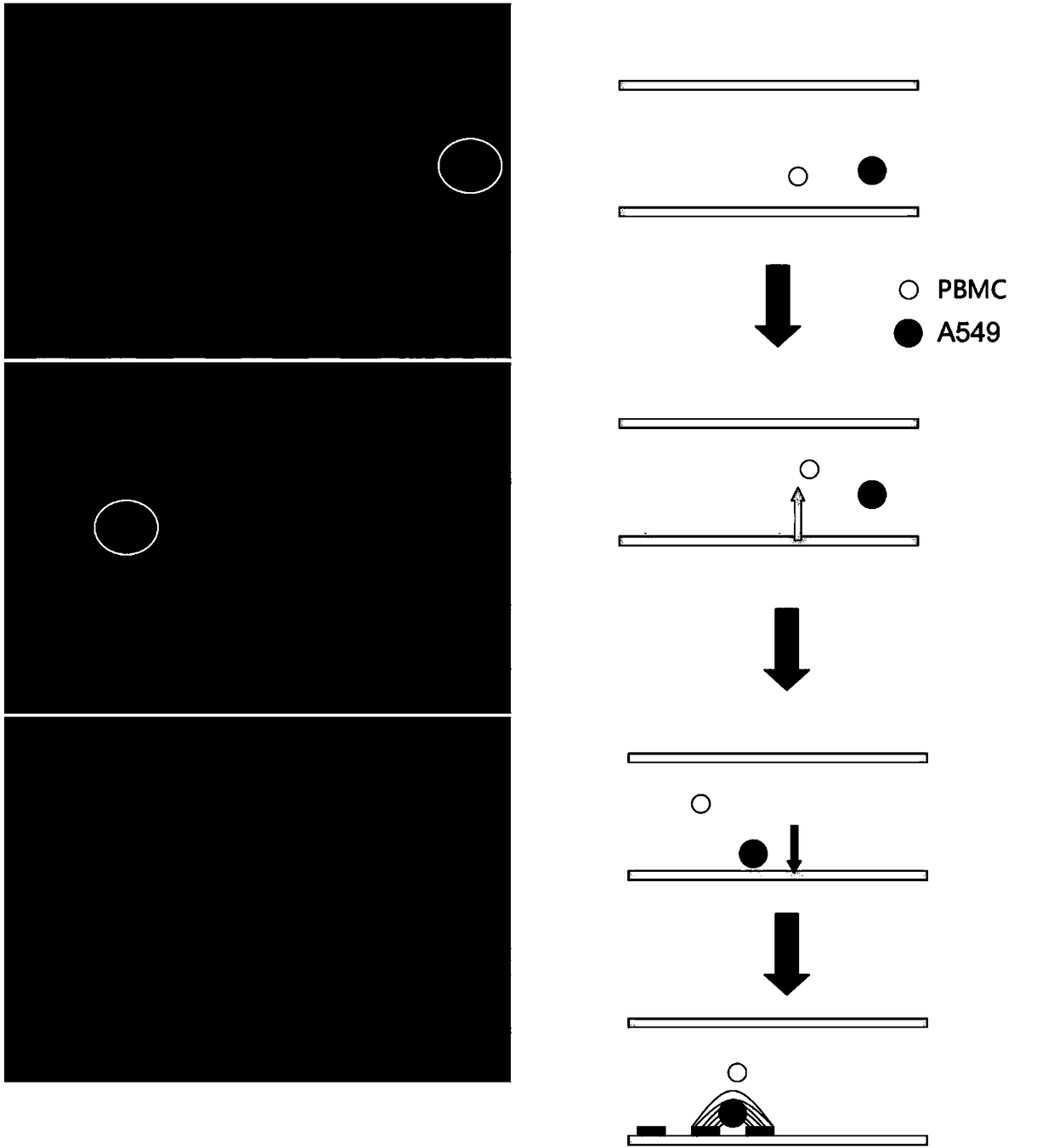

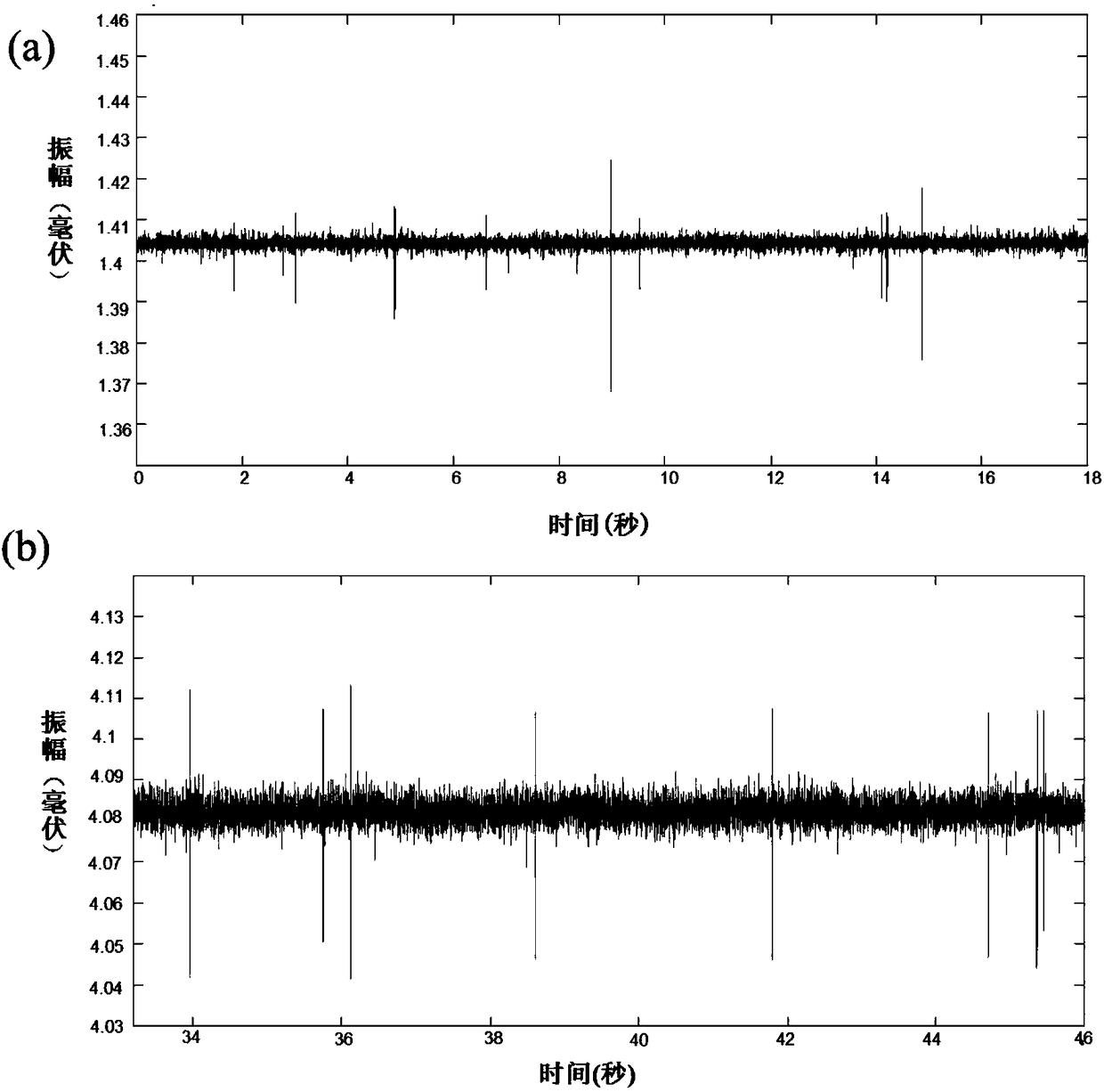

ActiveCN108387488ALow concentration requirementImprove signal-to-noise ratioDielectrophoresisLaboratory glasswaresParticulatesDielectrophoresis

The invention relates to a particulate matter detection device and a detection method, in particular relates to a detection device and a detection method based on a dielectrophoresis and electrical impedance measurement technology, and more in particular relates to an electrical impedance detection device utilizing a microfluidic chip and application of the electrical impedance detection device todetection of target particles.

Owner:上海欣戈赛生物科技有限公司

Method for recycling waste water containing ammonium chloride

InactiveCN103043823ALow concentration requirementSimple processOrganic compound preparationMultistage water/sewage treatmentAir compressionSulfate

The invention provides a method for recycling waste water containing ammonium chloride. The method includes the steps of adding ferrous sulfate flocs into waste water containing ammonium chloride after aminolysis, and subjecting the mixture to sedimentation for removing impurities; then adding sodium hydroxide to replace ammonia, stripping ammonia through warming and air compression bubbling, recycling ammonia water, adding acids to surplus waste water containing ammonium chloride to adjust the pH value, and filtering the mixture; and using a filter solution to be partial base water in a chlorination production process of 6-chloro-2,4-dinitro-anilin. According to the method for recycling waste water containing the ammonium chloride, the treatment process is simple and reasonable, the energy is saved, the recycling rate is high, and production environment improvement and environmental protection are facilitated.

Owner:ZHEJIANG RUNTU

Detection method of yak FOXO1 gene single nucleotide polymorphism and kit thereof

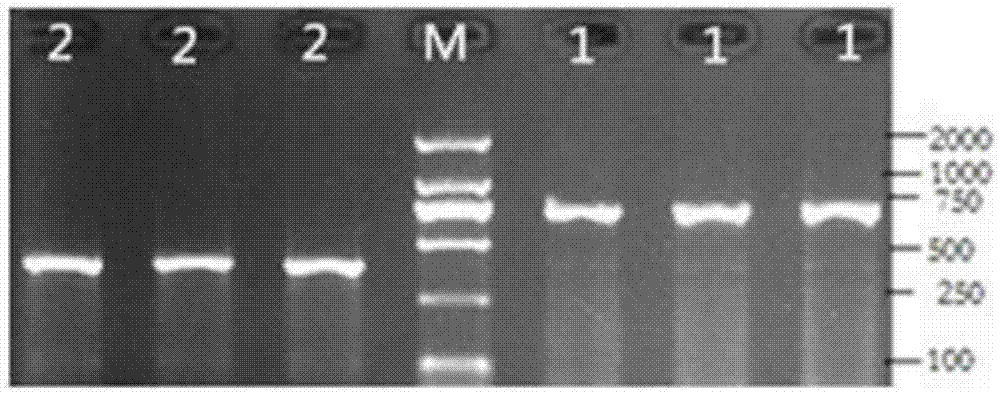

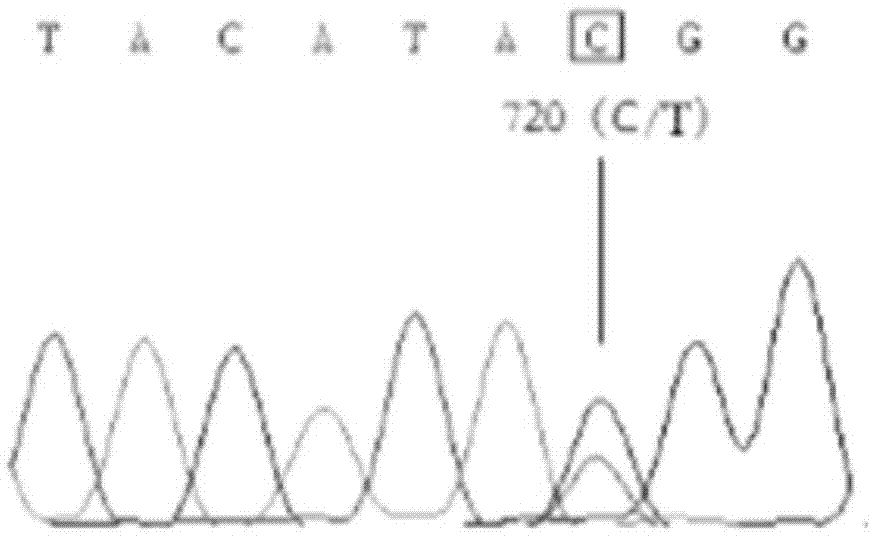

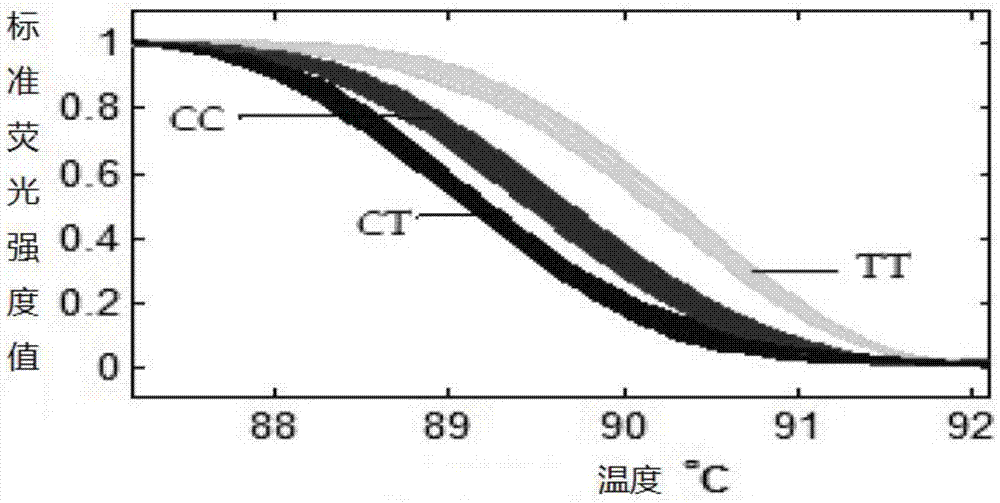

ActiveCN105441567APrecise positioningSensitive positioningMicrobiological testing/measurementNucleotideA-DNA

The invention relates to the technical field of gene polymorphism detection, in particular to a detection method of yak FOXO1 gene single nucleotide polymorphism and a kit thereof. The detection method comprises the following steps: 1) preparing a yak FOXO1 gene amplification product; 2) synthesizing a high and low temperature interior label; 3) preparing an HRM-PCR (High Resolution Melt-Polymerase Chain Reaction) amplification product; 4) collecting a fluorescence signal. Compared with an HRM method used for detecting polymorphic sites in the prior art, a gene probe designed by the detection method is more accurate and flexible in positioning, is accurate in parting, does not need PCR post-processing, has high working efficiency and good repeatability and is low in sample quality and quantity requirements, especially, the concentration requirement of a DNA template can be lowered to 0.1ng / mu L, and time and labor are saved when a sample size is large. Meanwhile, the detection kit has the advantages of high sensitiveness, high detection speed and good stability.

Owner:GANSU AGRI UNIV

Optical hydrogen ion air clarifying device

InactiveCN101285608AEfficient purificationImprove purification effectLighting and heating apparatusDeodrantsEngineeringAir purifier

The invention discloses a photohydroionization air purifier, which comprises a ventilated encloser and an electric cabinet. The encloser is provided with a photon wave generating tube and a nanometer catalytic coating inside. The photon wave generating tube is connected with the electric cabinet. The air purifier can be arranged in an air duct of a central air-conditioning, through the process of photohydroionization, to kill various bacteria and viruses in the air rapidly and effectively to remove various peculiar smell and odor in the air, and to oxidize and decompose chemical toxic and harmful gas in the air. In particular, the encloser is provided with a grid plate with a catalytic coating, which can maximize the effect of air purification. The air purifier can fully and efficiently purify the air, and the purification process does not produce chemical residual substance and avoids secondary pollution.

Owner:SHANGHAI MASTECK ENVIRONMENTAL

Extracting norfibroase from snake venom and preparation process for liquid drugs injection of norfibroase

ActiveCN1597945AHigh purityEasy to operateHydrolasesPeptide/protein ingredientsDrug injectionMonoclonal antibody

The invention discloses a method of extracting defibrase from snake poison and preparing defibrase injection preparation, and the process of extracting defibrase includes the steps: preparing monoclonal antibody; preparing crude defibrase; preparing antibody affinity chromatography column; preparing defibrase; and the process of preparing the defibrase injection preparation includes the steps: taking and adding purified defibrase to a proper amount of injection water for dissolving so as to obtain a solution, adding 5-20g NaCl stabilizer to every 1000ml solution, making split charging and obtaining the defibrase injection preparation.

Owner:BEIJING SAISHENG PHARMA

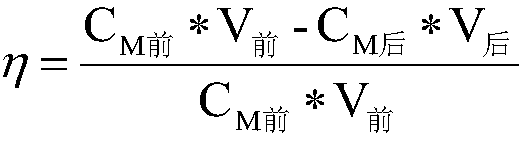

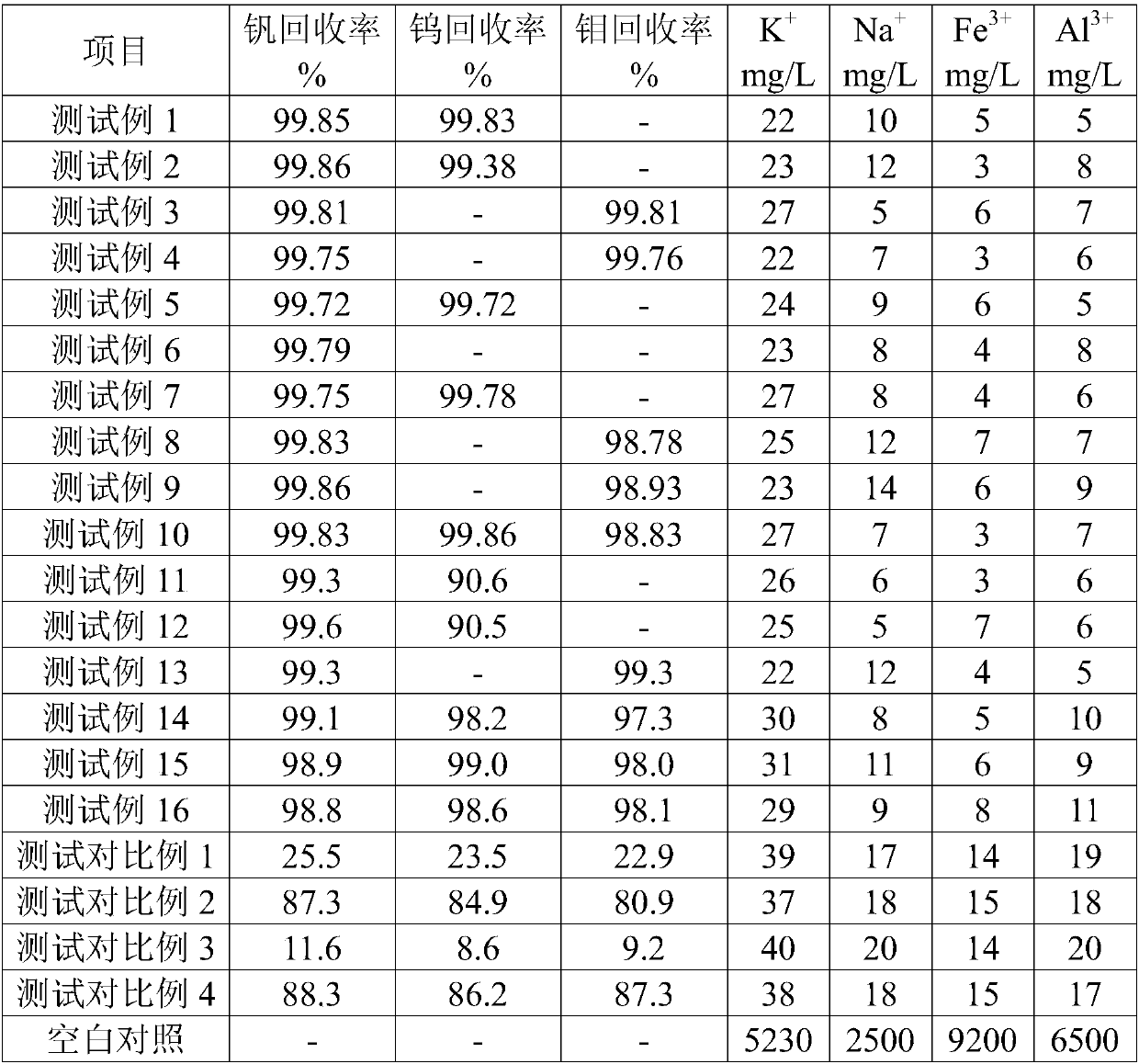

Extraction agent composition, application thereof and method for recycling active component in solution

InactiveCN110218881AHigh recovery rateImprove adaptabilityProcess efficiency improvementKeroseneActive component

The invention relates to the technical field of denitrification catalyst recycling, and discloses an extraction agent composition, application thereof and a method for recycling an active component inthe solution. The extraction agent composition comprises alkylamine, a neutral phosphine extraction agent, high alcohols and sulfonated kerosene. The method for recycling the active component in thesolution comprises the steps that the solution with pH being 2 to 7 is in contact with the extraction agent, and the active component is extracted to obtain extraction liquid; the extraction liquid makes contact with ammonium hydroxide to carry out reverse extraction on the active component, and a reverse extraction liquid containing the active component is obtained; and the active component is selected from one of vanadium, tungsten and molybdenum. The beneficial effects that impurities and the active component are separated at a time, and adaptability is high; the recycling rate of the active component is high; the concentration requirement for the active component in the solution is low, and the wider application range is achieved; and the extraction agent composition obtained after reverse extraction can be recycled, one-time investment is achieved, cost is low, and needed equipment and process are very simple are achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

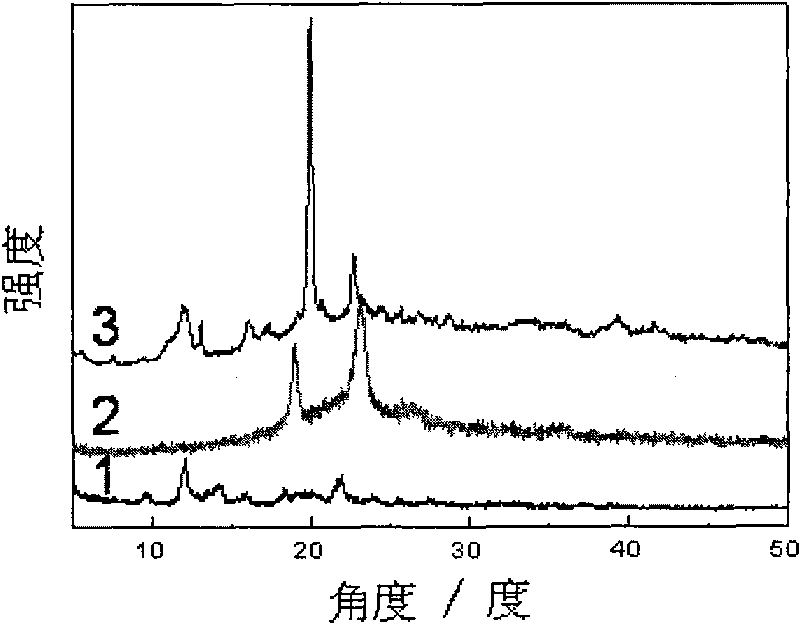

Method for preparing cellulose nanocrystals

InactiveCN102877342AEffective separation and crackingEvenly dispersedPulping with acid salts/anhydridesContinuous pulping processAqueous solutionUltrasonic generator

The invention discloses a method for preparing cellulose nanocrystals. The method comprises the following steps of: (1) putting refined cotton linter into water of which the mass is 10 to 20 times that of the refined cotton linter, and performing ultrasonic stirring in an ultrasonic generator for 4 to 8 hours; (2) continuously adding a 0.5mol / L sulfuric acid aqueous solution of which the mass is 5 to 8 times that of the refined cotton linter and a 0.5mol / L hydrochloric acid aqueous solution of which the mass is 2 to 6 times that of the refined cotton linter into the ultrasonic generator, and performing ultrasonic stirring at the temperature of between 30 and 60 DEG C for 8 to 12 hours; and (3) washing a solid product obtained in the step (2) by using water until the pH value is 6 to 7. The method is simple in process and low in cost; and the prepared cellulose nanocrystals are uniform in granularity and high in performance.

Owner:WUXI KAILI PHARMA

Horizontal water flow vertical mud discharging sedimentation and separation device

ActiveCN103657165AAvoid disturbing effectPrevent resuspensionSedimentation settling tanksSludgeWater flow

Owner:ZHEJIANG DEAN TECH

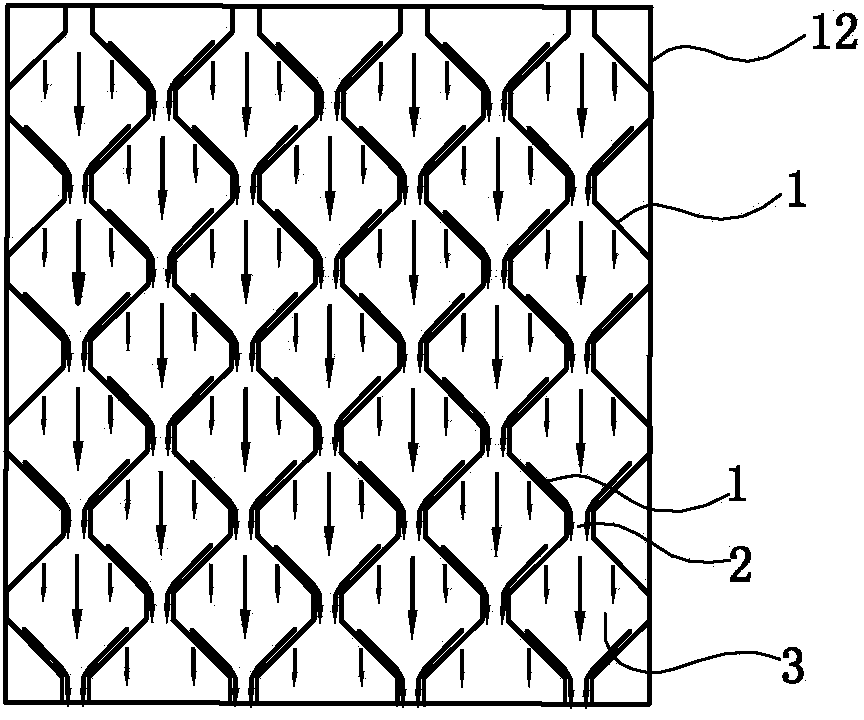

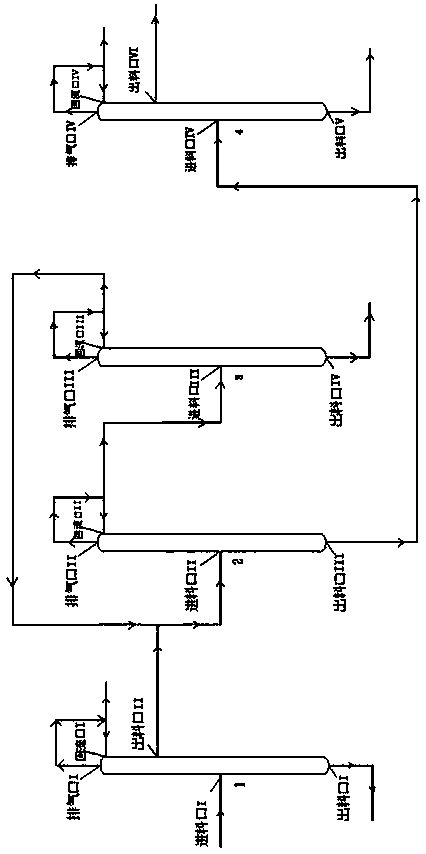

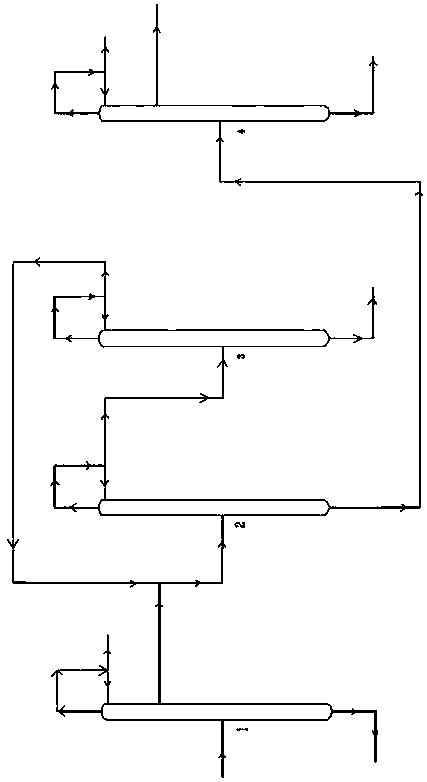

Method and equipment for producing acetal through catalytic distillation

InactiveCN103058837ALow concentration requirementReduce energy consumptionOrganic chemistryOrganic compound preparationVapor liquidWater discharge

The invention relates to a method and equipment for producing acetal through catalytic distillation. Through the application of a catalytic rectifying tower and an ethanol recycle tower, the method comprises the following specific steps of: (1) feeding a raw material, namely ethanol into a lower feeding hole of the catalytic rectifying tower after passing through a metering pump and a preheater, feeding a raw material, namely an acetaldehyde solution into an upper feeding hole of the catalytic rectifying tower after passing through the metering pump, wherein aldolization happens between the raw material acetaldehyde and ethanol at the middle part of the catalytic rectifying tower, and carrying out vapor-liquid mass transferring; (2) condensing mixed vapor of acetal and ethanol obtained at the top of the catalytic rectifying tower through a condenser, wherein a part of the condensed mixed vapor flows back to the top of the catalytic rectifying tower through a reflux pump, and collecting the remaining mixed vapor out as product; and (3) pumping waste water discharged out at the bottom of the catalytic rectifying tower into the middle part of the ethanol recovery tower to carry out distillation and separation, and condensing azeotrope steam of ethanol and water obtained at the top of the tower through the condenser, wherein a part of the condensed azeotrope steam flows back to the top of the ethanol recovery tower by depending on gravity, and the remaining condensed azeotrope steam flows back to the ethanol inlet of the catalytic rectifying tower for cyclic utilization. The device has the advantages of being high in yield, small in circulating amount, low in energy consumption and the like.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Device and method for producing high-concentration dimethyl carbonate

PendingCN111072481AObvious benefitsProcess environmental protectionCarbonic/haloformic acid esters purification/separationMethanol fuelAzeotrope

The invention discloses a device and a method for producing high-concentration dimethyl carbonate. Low-concentration dimethyl carbonate is separated in a light component removal column, a part of light components is refluxed and the other part of light component and heavy components are fed into a methanol fuel tank; a mixture of dimethyl carbonate and methanol is extracted from the side line andis fed into a pressurized column; through separation in the pressurized column, high-concentration dimethyl carbonate is obtained at the column bottom and conveyed to a refining column for further purification; a methanol azeotrope containing 15-18% of dimethyl carbonate is distilled off from the column top, a part of the azeotrope is refluxed, and the other part of the methanol azeotrope is sentto an atmospheric-pressure column; through separation in the atmospheric-pressure column, an azeotrope containing dimethyl carbonate and methanol and having a concentration of 30% is distilled off from the column top, a part of the azeotrope is refluxed, and the other part of the azeotrope is sent to the pressurized column; methanol is discharged from a column bottom and conveyed into the methanolfuel tank; the high-concentration dimethyl carbonate is separated in the refining column, a part of light components is refluxed, the other part of light component and heavy components are fed into the methanol fuel tank, and high-purity dimethyl carbonate with the content of 99.9% or above is extracted from the side line to serve as a product.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Novel sewage treatment device

ActiveCN103803705ARealize self-refluxReduce outputTreatment with aerobic and anaerobic processesSludgeSewage treatment

The invention relates to a novel sewage treatment device. The novel sewage treatment device comprises a reaction tank, wherein the reaction tank is separated into an aerobic zone, an anaerobic oxygen-poor zone and an anaerobic zone; the side wall is provided with a water inlet hole and a mud scraper is arranged at the bottom; a mud bucket is arranged below the reaction tank; the mud bucket is internally provided with a pushing device; a separation plate is provided with an aeration device and is accumulated with an AO reactor; a water passing hole and a water passing weir are arranged on the upper part of the reaction tank; a sludge reflowing hole and a liquid supernatant reflowing hole which is connected with a liquid supernatant pumping-out hole of a sedimentation basin are formed in the side wall of the reaction tank; the sedimentation basin and the reaction tank share one side wall; the sludge reflowing hole on the lower part of the sedimentation basin is communicated with the bottom of the sedimentation basin; the sedimentation basin is internally provided with a horizontal flow sediment separation device; a clean water outlet hole is formed in the side wall of the sludge sedimentation basin; the clean water outlet hole is formed above the horizontal flow sediment separation device; a water outlet weir is arranged on the outer side wall of the sedimentation basin. According to the novel sewage treatment device, the plane occupied area is greatly reduced; organic carbon in raw water can be sufficiently utilized to be used as a carbon source needed by a denitrification process of the oxygen-poor zone can be sufficiently utilized so that the adding amount of the additionally-arranged carbon source is reduced and the whole performance of a sewage treatment system is strengthened.

Owner:ZHEJIANG DEAN TECH

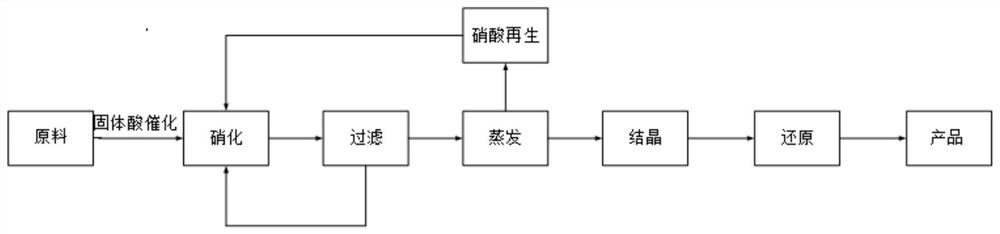

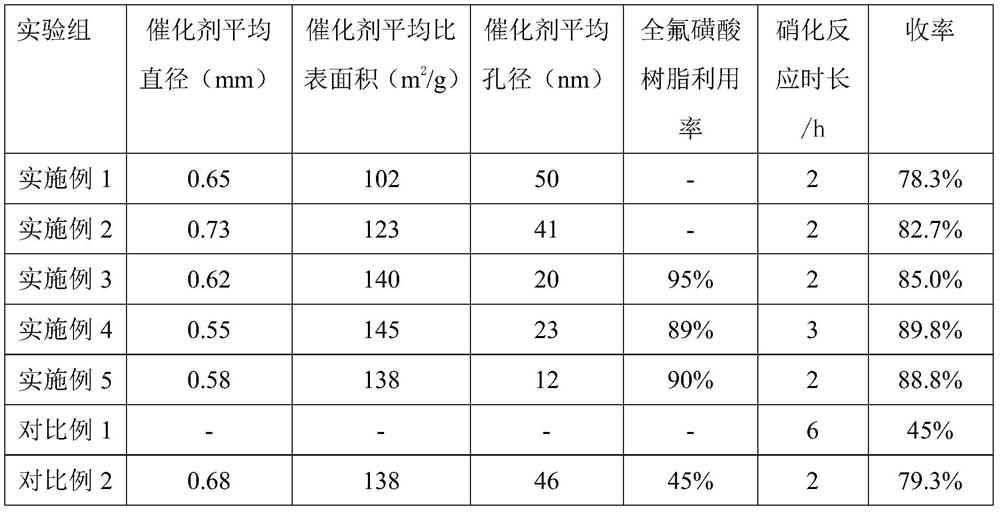

Preparation method of diamino diphenyl ether

ActiveCN112876367AImprove convenienceThe preparation process is environmentally friendlyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDiphenyl etherEther

The invention provides a preparation method of diaminodiphenyl ether. The method comprises the following steps: under the catalysis of solid acid, mixing aromatic ether and nitric acid for nitration reaction; carrying out hot filtration on the nitration reaction product, recovering the filtrate, and carrying out post-treatment on the filtrate; and reducing the filtrate subjected to post-treatment to obtain the diamino diphenyl ether. According to the invention, the requirement of nitration reaction on the concentration of nitric acid is greatly reduced, the yield of the diamino diphenyl ether is increased, and the preparation process is environmentally friendly, efficient and low in cost.

Owner:泰兴中科艾德膜材料科技有限公司 +1

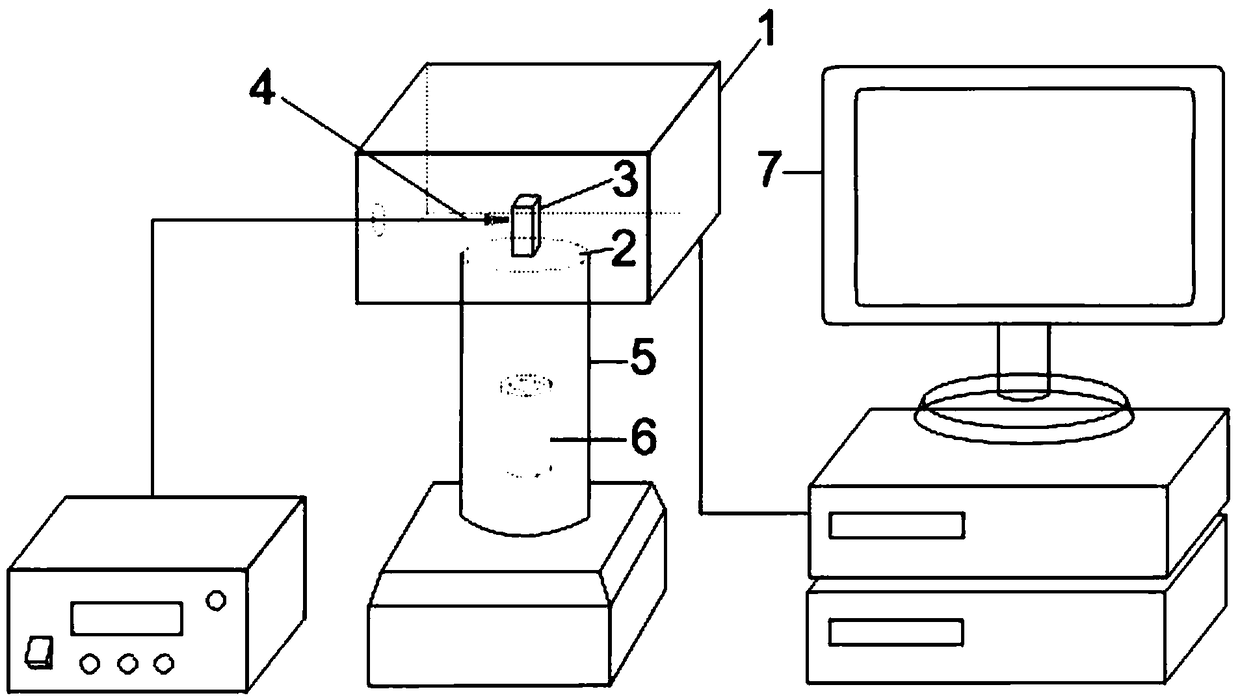

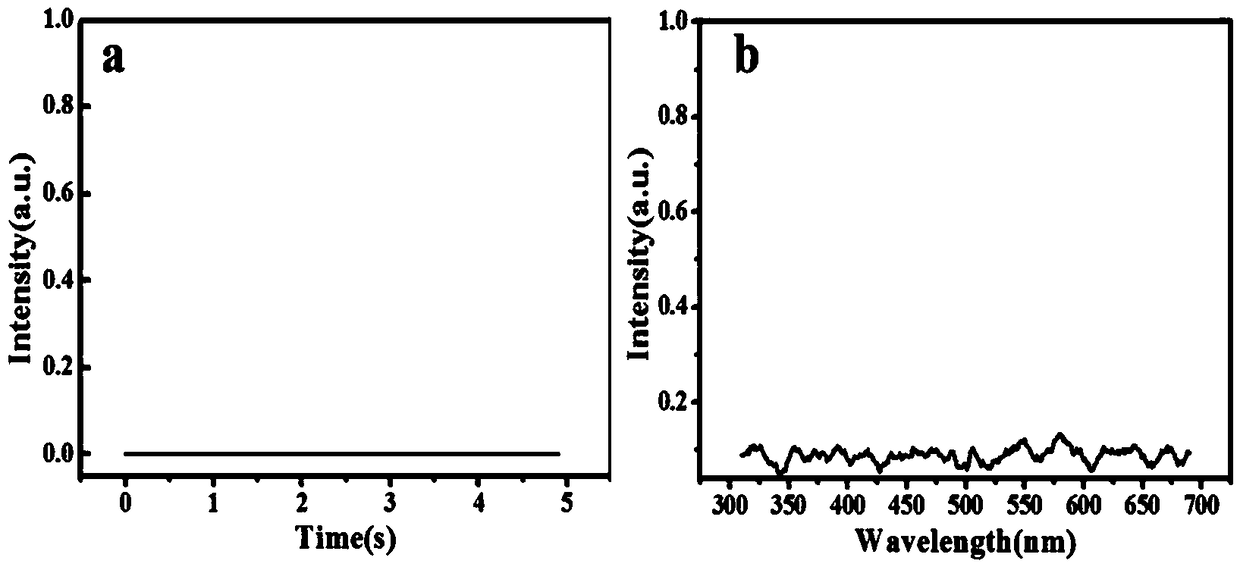

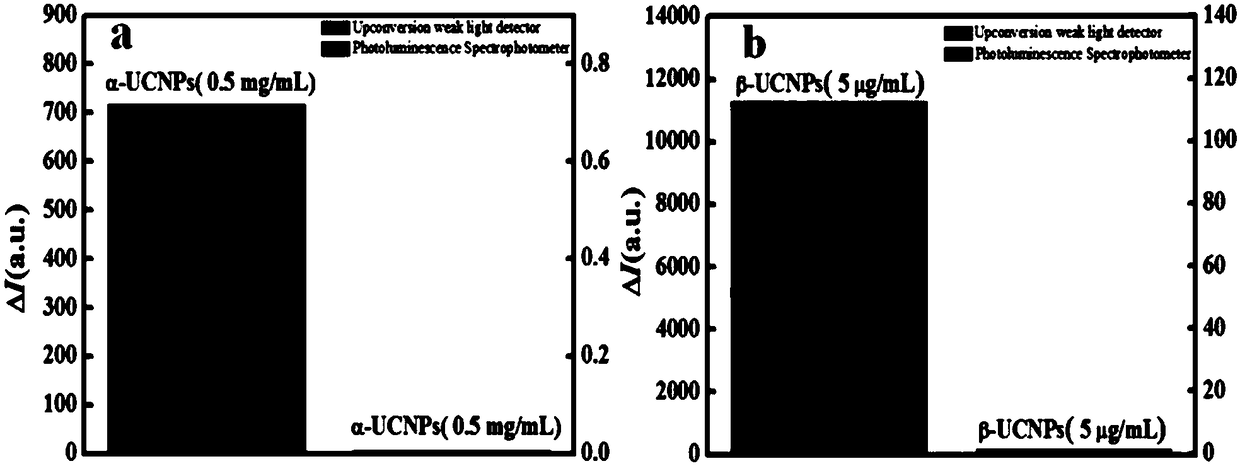

Construction of up-conversion weak light detector and application thereof in detecting glutathione

InactiveCN108982440ALow concentration requirementEasy to detectFluorescence/phosphorescenceLow demandRare earth

The invention discloses a construction of an up-conversion weak light detector and an application thereof in detecting glutathione and relates to the construction of an up-conversion weak light detection instrument. The detection instrument has the main advantages of (1) excellent detection performance and capability of detecting alpha-phase UCNPs with simple synthetic method and weak luminescenceduring the process of detecting UCNPs, and (2) low demand on UCNPs concentration and capability of detecting UCNPs in an approximately homogeneous system. In addition, the invention develops a biosensor taking a rare earth doped up-conversion nanometer material as a fluorescence probe and the application thereof in detecting GSH. The fluorescence response value of the sensor and the GSH concentration within the scope of 0.5-100uM have an excellent linear relation; the detection limit is 0.24uM; thus, the up-conversion weak light detector is expected to become a novel detection method for up-conversion luminescence and can be applied to more fields.

Owner:FUJIAN MEDICAL UNIV

Lactide continuous melt crystallization purification system and method

ActiveCN113893573AReduce labor intensityReduce energy consumptionOrganic chemistrySolution crystallizationPolymer scienceMixed feeding

The invention discloses a lactide continuous melt crystallization purification system and method. The system comprises a mixed feeding system, a crude lactide crystallization section, a crystal sweating purification section and a mother liquor crystallization recovery section. The mixed feeding system is connected with the crude lactide crystallization section through a pumping pipeline. A crystal mush outlet is formed in the bottom of the crude lactide crystallization section and is connected with the crystal sweating purification section, and the top of the crude lactide crystallization section is provided with a mother liquor outlet connected with the mother liquor crystallization recovery section. A product outlet and a backflow liquid inlet are formed in the bottom of the crystal sweating purification section, and a mother liquor outlet is formed in the top of the crystal sweating purification section and is connected with the crude lactide crystallization section. A crystal slurry outlet is formed in the bottom of the mother liquor crystallization recovery section and connected with a solid-liquid separation system, and a solid phase outlet is connected with a mixed feeding system. A circulating branch is arranged at a liquid phase outlet and returns to the mother liquor crystallization recovery section. By adopting the system and the method disclosed by the invention, efficient separation and purification of the crude lactide can be realized, and the system has the advantages of high product purity, low system energy consumption, high yield, continuous and stable operation and the like.

Owner:天津乐科节能科技有限公司 +1

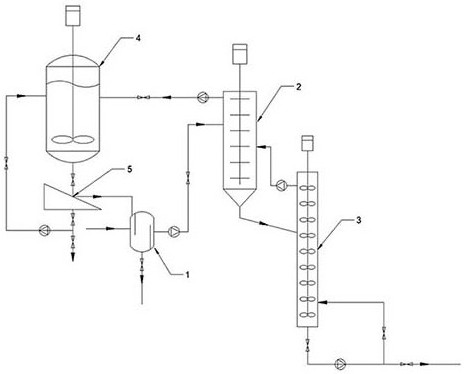

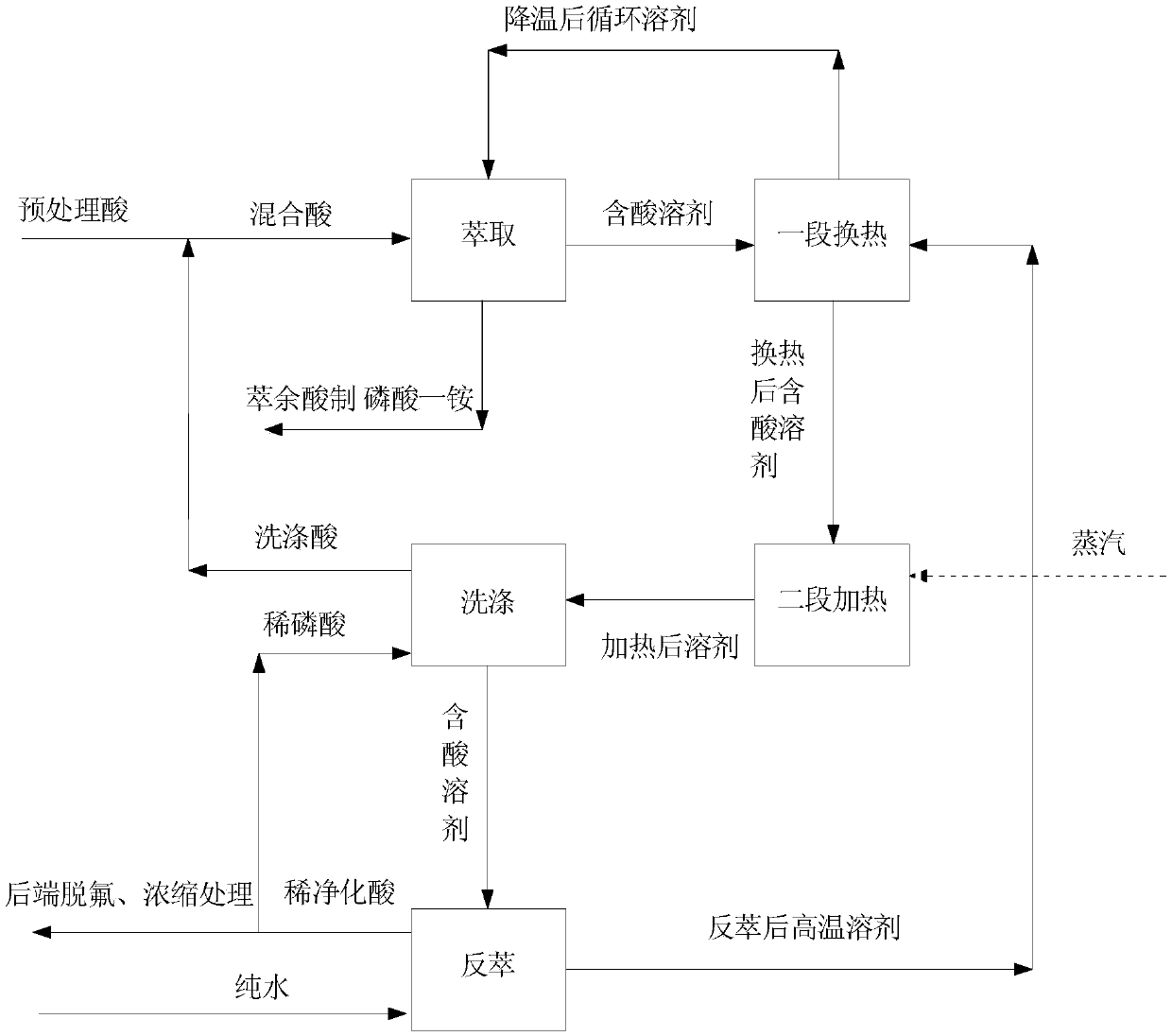

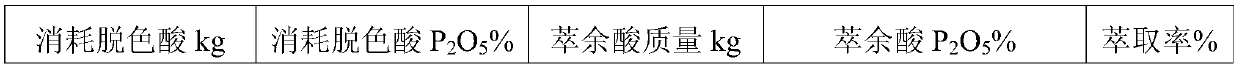

Method for purifying wet-process phosphoric acid by using centrifugal extractor

InactiveCN109650362ALow concentration requirementNo energy consumptionLiquid solutions solvent extractionPhosphorus compoundsPhosphoric acidPhase ratio

The invention discloses a method for purifying wet-process phosphoric acid by using a centrifugal extractor in the technical field of chemical production. The method mainly includes several phases ofpretreatment, extraction, washing, back extraction, desulphurization and condensation; and the main improving point is the extraction, washing and back extraction phases which adopt a centrifugal extractor. The centrifugal extractor can be used as extraction equipment which has low requirement for the phosphoric acid concentration of raw materials, only 30-40% is needed for the content of P2O5, requirements can be met by only performing simple treatment of ordinary semi-aqueous wet-process phosphoric acid without extra energy consumption, but the requirements in the prior art for the phosphoric acid concentration have to be controlled at 40-58%; extra control on the temperature of an extraction section is not needed, normal temperature reaction can be performed, the extraction rate of morethan 75% can be achieved when a phase ratio is 4 : 1, and compared with a rotating disc column, 6-8 : 1 has to be achieved; and through the centrifugal extractor, two phases can be fully mixed undera high-speed condition, so that high extraction efficiency and good split-phase effects can be realized, equivalent phase ratio with the rotating disc column can be achieved, and rapid split-phase andno entrainment can be realized.

Owner:CHANHEN ECO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com