Novel sewage treatment device

A sewage treatment device and a new technology, applied in the field of new sewage treatment devices, can solve the problems of restricting the promotion and application of denitrification process, complex operation management, high infrastructure costs, etc., to ensure the sludge residence time, ensure the sludge concentration, solve the The effect of sludge clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

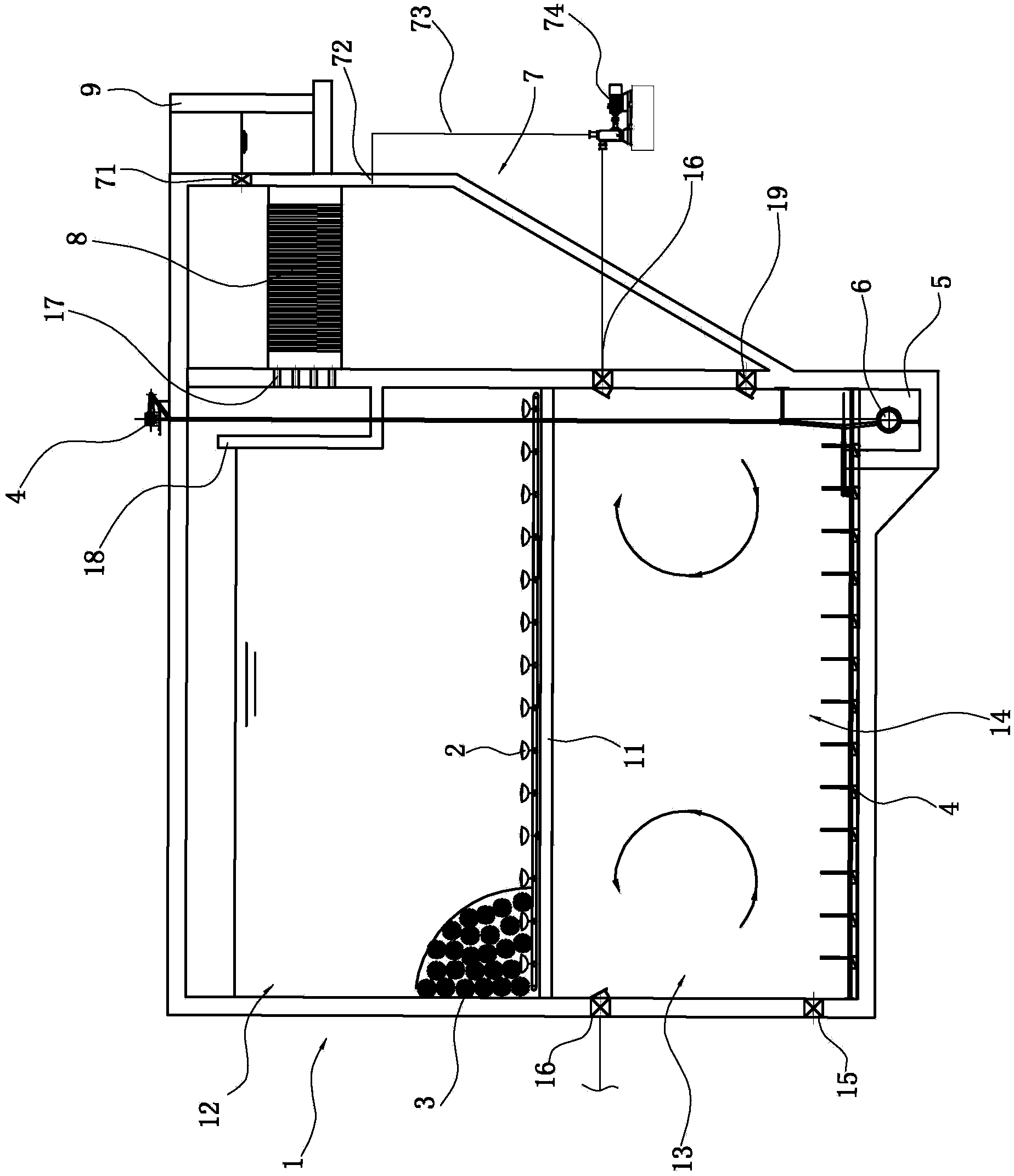

[0045] like Figure 1 to Figure 17 As shown, the new sewage treatment device includes:

[0046] Reaction tank 1, a place for biochemical treatment of sewage, which is provided with a transverse partition 11 to separate the inner cavity of the reaction tank into an aerobic zone 12 located above, an anaerobic anoxic zone 13 located in the upper part of the lower part, and a Lower lower anaerobic zone 14.

[0047] The structural design corresponding to the anaerobic section:

[0048] The side wall of the reaction tank is provided with a water inlet hole 15 for sewage to enter the reaction tank at a position close to the bottom of the reaction tank. There is a pushing device 6 for pushing the sludge to the outside of the mud hopper. The pushing device in this embodiment adopts a screw conveyor 6, and the screw conveyor sends the sludge out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com