Plateau continental facies shale gas testing and flowback equipment, gas testing method and flowback method

A shale gas and plateau technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of plateau continental shale gas gas testing and flowback, etc., and achieve perforation Test continuous cropping process, test direct, avoid contamination of shale reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

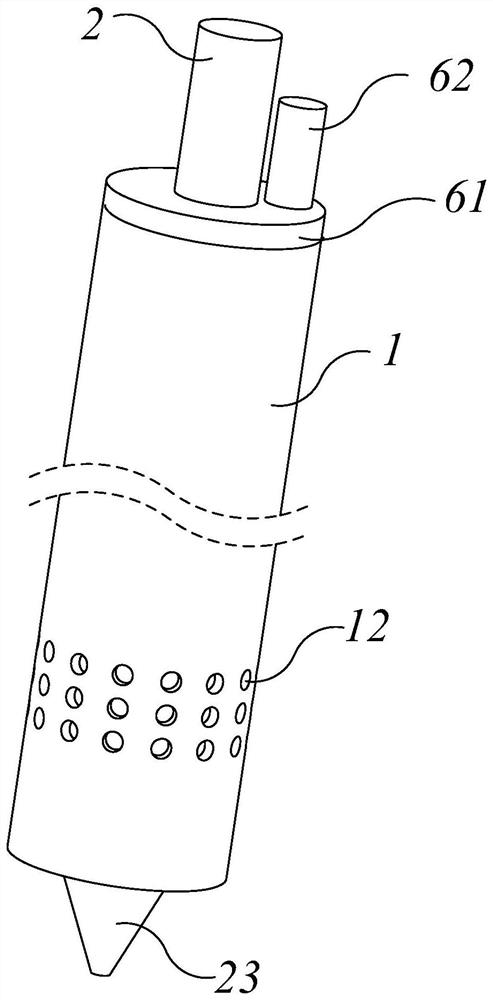

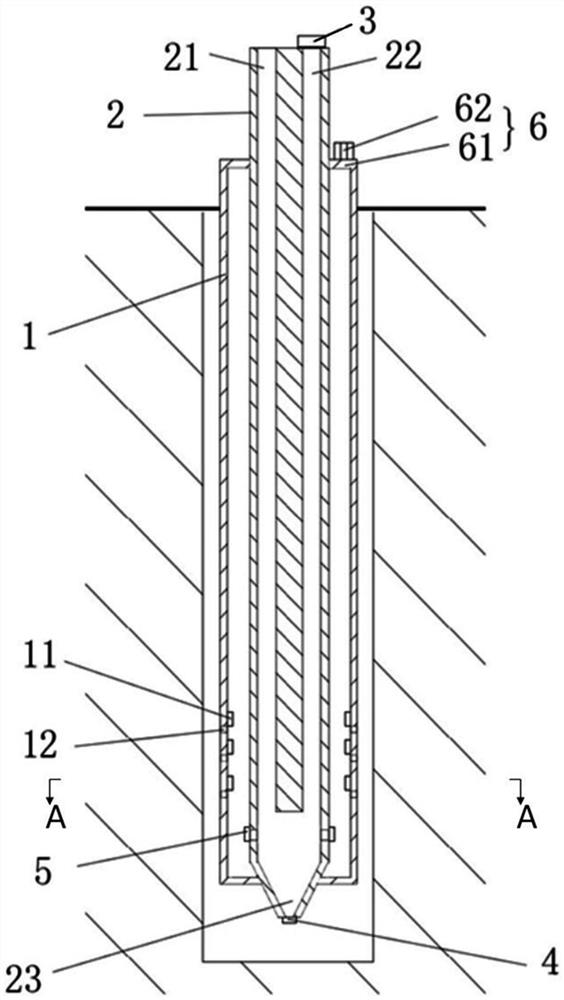

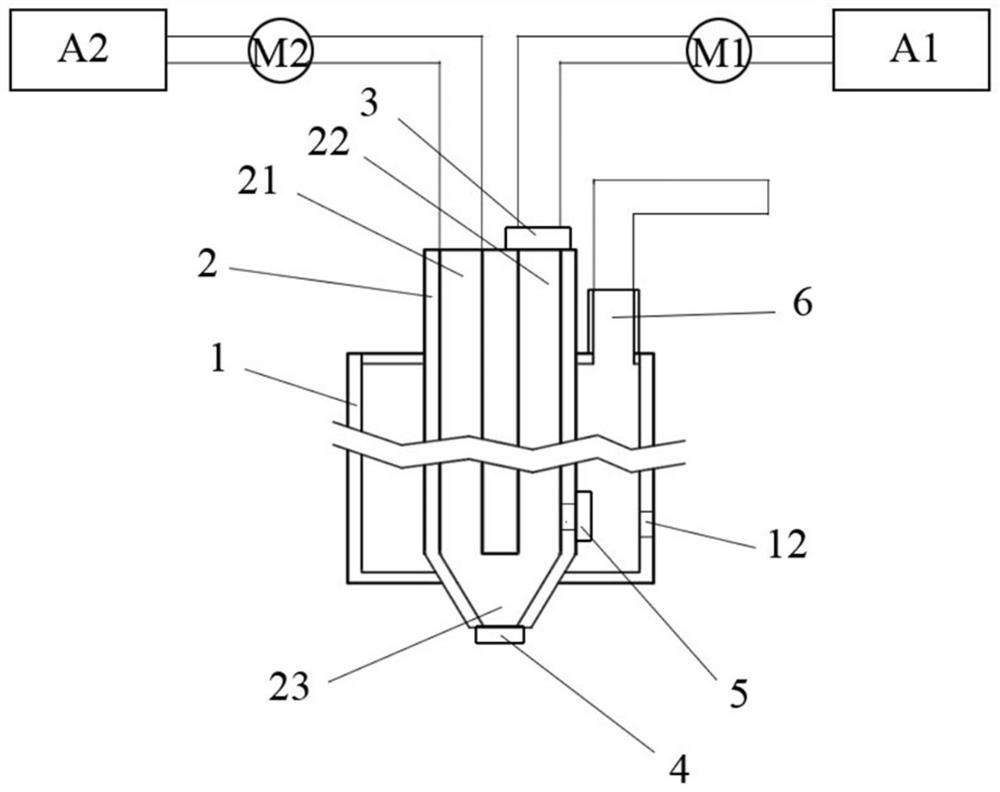

[0042] figure 1 It is a schematic structural diagram of the plateau continental shale gas gas testing and flowback equipment in the embodiment of this application. figure 2 It is a schematic diagram of the internal structure of the plateau continental shale gas gas testing and flowback equipment in the embodiment of this application.

[0043] refer to figure 1 and figure 2 , the embodiment of the present application provides a plateau continental shale gas gas testing and flowback equipment, including: a pipeline, arranged along the direction of wellbore extension, the pipeline includes a U-shaped inner pipe 2 and an outer pipe sleeved outside the inner pipe 2 The U-shape of the pipe 1 and the inner pipe 2 opens upward along the extending direction of the well, and an annular space is formed between the outer wall of the inner pipe 2 and the inner wall of the outer pipe 1; one end of the U-shaped inner pipe 2 is the first liquid inlet port 21, The other end is the second li...

Embodiment 2

[0063] The embodiment of the present application provides a gas testing method for plateau continental shale gas using the plateau continental shale gas gas testing and flowback equipment in Example 1 of the present application.

[0064] Figure 6 It is a flow chart of the gas testing method for plateau continental shale gas in the embodiment of this application.

[0065] refer to Figure 6 , the gas testing method of plateau continental shale gas in the embodiment of the present application includes:

[0066] S1.1, equipment construction

[0067] The wellbore is excavated in advance, and the pipelines of plateau continental shale gas gas testing and flowback equipment are installed in the wellbore, and the fracturing fluid source A2 is connected at the same time.

[0068] S1.2. Adjust the valve

[0069] Close the first valve 3, open the second valve 4, and close the third valve 5. At this time, the first liquid inlet end 21 of the inner tube 2, the inner tube 2, the jet ...

Embodiment 3

[0080] The flowback of fracturing fluid is an important process that determines the success or failure of fracturing. A scientific process can make the fluid loss of fracturing fluid as small as possible, thereby reducing the damage to the reservoir and improving the stimulation effect. Unreasonable selection of flowback time will cause backflow of proppant, or the fracture of the formation near the gas well, so that the proppant in the fracture is not enough to form a suitable flow conductivity, which will lead to poor fracturing effect. If the drainage flow is not well controlled, insufficient flow will cause the fracturing fluid to stay for a long time, causing more damage to the formation.

[0081] The embodiment of the present application provides a flowback method of plateau continental shale gas, using the plateau continental shale gas gas testing and flowback equipment in Example 1 of the present application.

[0082] Figure 7 It is a flow chart of the flowback metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com