Petroleum underground laser perforation well completion device

A kind of oil well and laser technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of low perforation efficiency, lower laser perforation operation efficiency, formation compaction effect, etc., and achieve improvement Operation efficiency and the effect of improving laser perforation operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

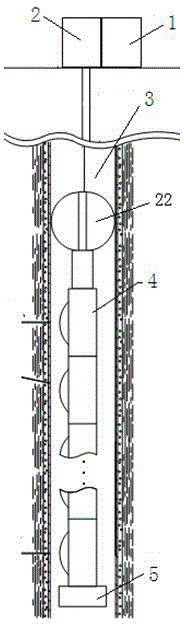

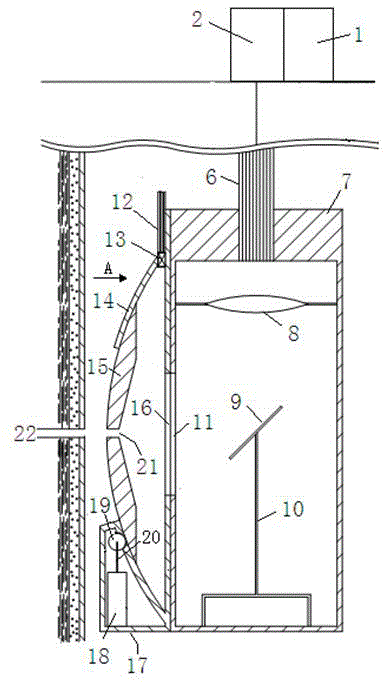

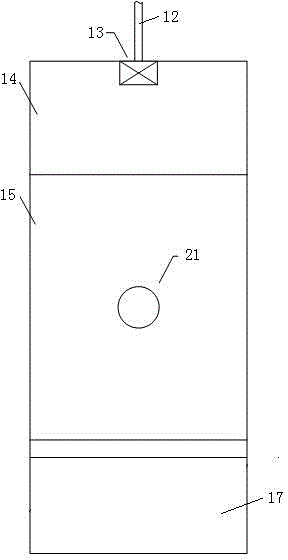

[0054] refer to Figure 1 to Figure 3 , the device in this embodiment includes a laser source 1, a high-pressure gas source 2 and a downhole laser perforator 3,

[0055] The laser source 1 and the high-pressure gas source 2 are located on the ground. On the one hand, it avoids the influence of the complex downhole environment on the instrument, and on the other hand, it eliminates the limitation of the size of the well pipe on the size and volume of the instrument. solid-state lasers.

[0056] The downhole laser perforator 3 includes a rotary controller 5 and four sets of laser perforation devices 4, wherein:

[0057] Four sets of laser perforating devices are connected in sequence along the longitudinal direction;

[0058] The rotation controller 5 is installed on the laser perforating device at the bottom of the downhole laser perforating device 3; in order to maintain the stability of the downhole laser perforating device 3 during operation, a laser perforating device 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com