Laser perforation device in oil well

An oil well and laser technology, applied in installation, optics, optical components, etc., can solve the problems that optical components and gas nozzles cannot control the pitch angle of laser beam and high-pressure airflow, and the angle of perforation cannot be flexibly adjusted, so as to improve laser shooting Hole operation efficiency, effect of increasing perforation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

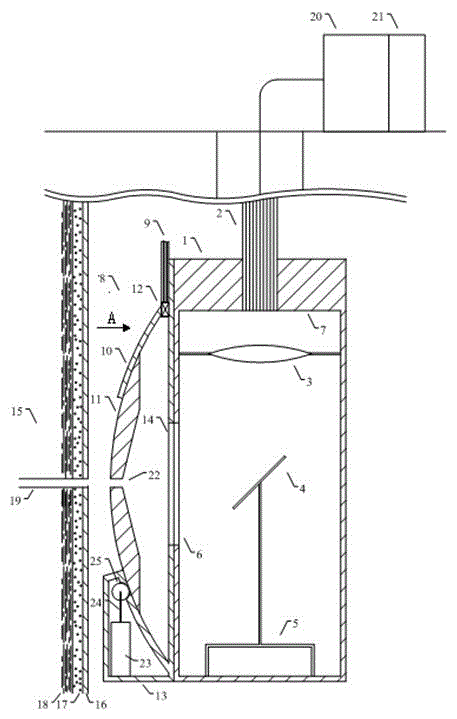

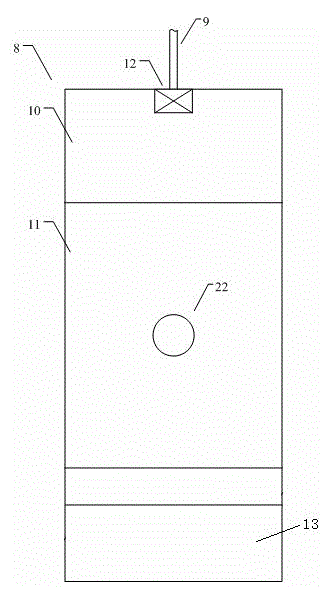

[0044] refer to figure 1 with figure 2 , the device structure of this embodiment includes a laser source 20, a laser control unit 1, and a gas cleaning unit 8;

[0045] The laser source 20 used is a high-power all-solid-state laser, which is placed on the ground together with the high-pressure gas source 21 in the gas cleaning unit. The size of the well pipe limits the size and volume of the laser source, and at the same time it is more convenient to control the instrument. The high-energy laser generated by the laser source 20 is transmitted to the laser control unit 1 through the optical fiber 2;

[0046] Laser control unit 1 comprises shell 7, optical fiber 2 and the focusing lens 3 that is installed in shell 7, reflector 4 and reflector rotation control frame 5, and this reflector rotation control frame 5 is installed at the bottom of shell 7, and reflector rotation control frame A motor and a transmission device are installed in the 5, the motor is connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com