Automatic spinning device of perforating bullet cumulative cover and forming method

A technology of condensing cover and perforating charges, which is applied in the fields of earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of the impact of energy-concentrating cover product quality and manufacturing cost, so as to improve the suppression production efficiency and simplify the production. Production process, the effect of simplifying the pressing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

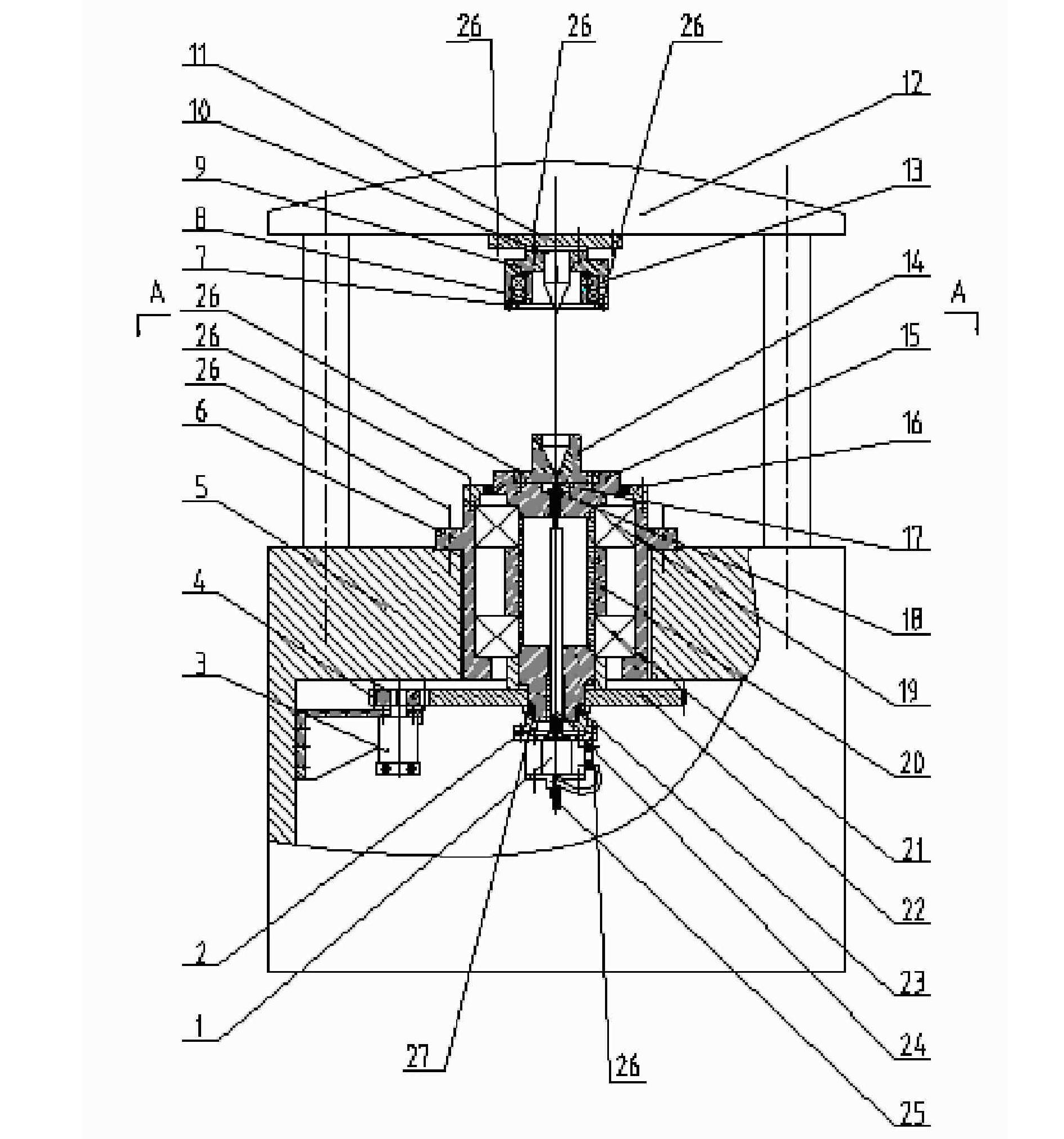

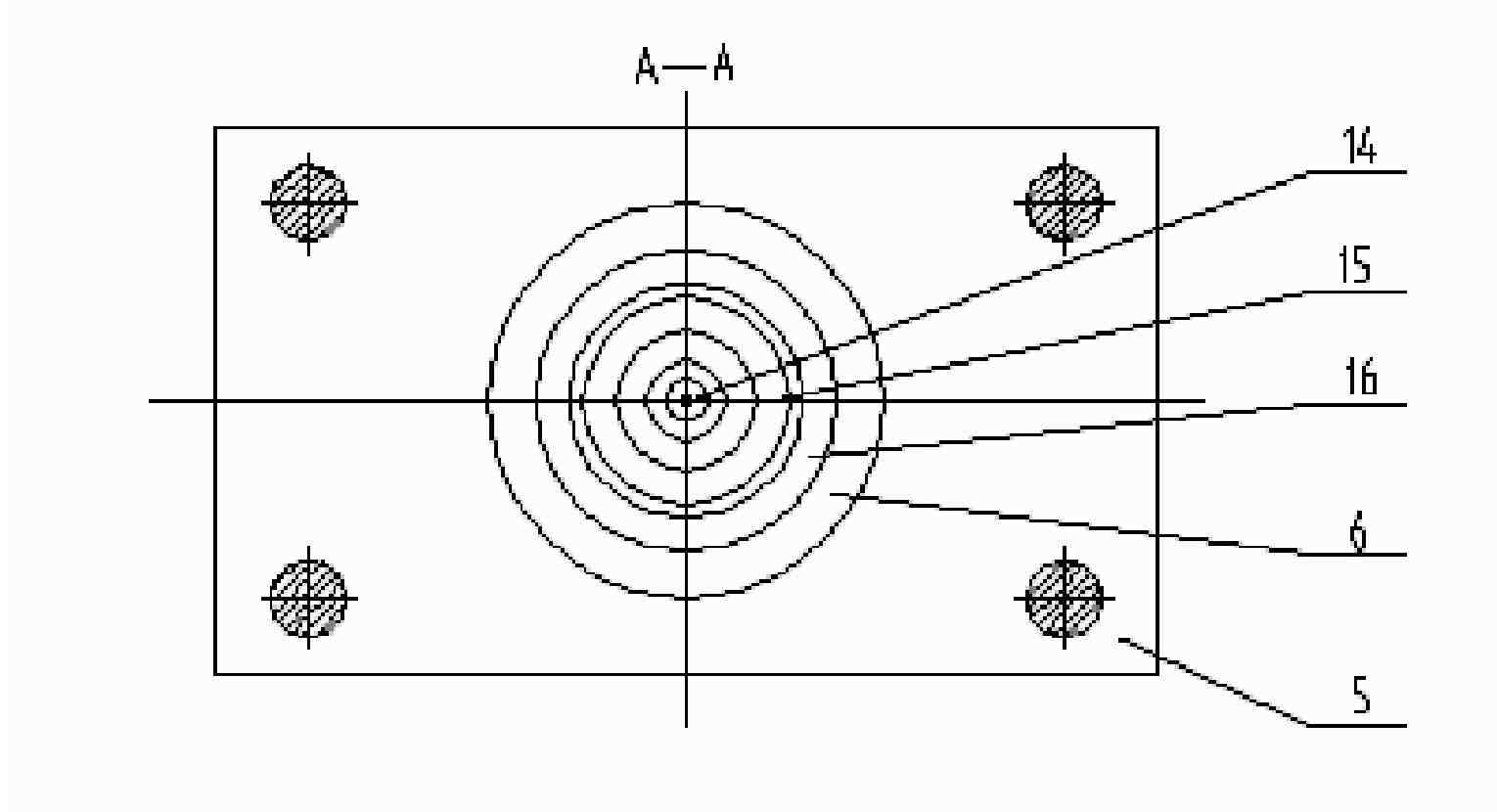

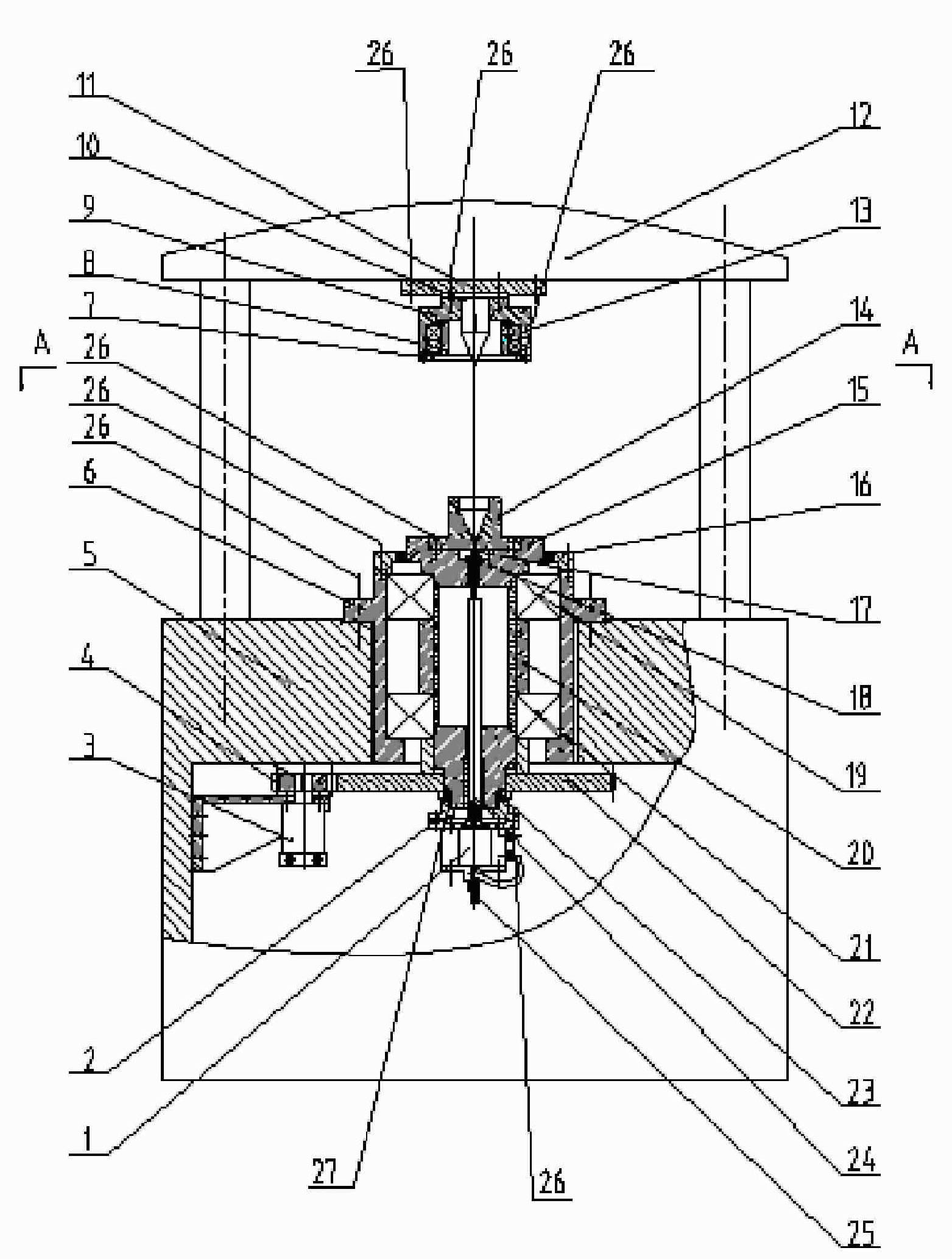

[0017] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0018] After starting the equipment; firstly, the metal powder is loaded on the feeding manipulator; the upper pallet 12 drives the punch 10 to move downward at a speed of 30-60mm / min; when the guide sleeve 13 of the punch part contacts the die 14; the hydraulic motor 3 Start to work; through the transmission of the pinion 4 and the bull gear 22; the torque is transmitted to the rotating main shaft 15; the main shaft 15 drives the die 14 to rotate at a speed of 500-600rpm; the guide sleeve 13 contacts the outer wall of the die 14; at the same time, the deep groove ball The bearing 8 starts to rotate; at this moment, the upper supporting plate 12 drives the punch 10 to advance at a speed of 10-30mm / min. The die 14 at a rotational speed of 500-600rpm causes the metal powder to generate centrifugal force; as the punch 10 advances downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com