Sleeve type composite positioning and shooting angle-fixed perforating device

A technology of fixed shooting angle and fixed orientation, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems such as the difficulty in realizing compound perforation, improve formation permeability, increase perforation depth, reduce The effect of burst pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but should not be construed as limiting the present invention:

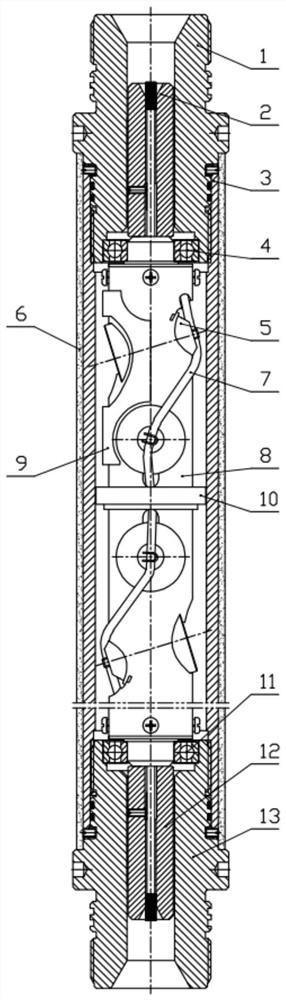

[0012] figure 1 It is a structural schematic diagram of the present invention. As shown in the figure, a sleeve-type composite perforating device with fixed orientation and fixed shooting angle includes a perforating gun body 3, a fixed shooting angle bullet holder 8, an intermediate joint one 1, and an intermediate joint two 13 , the two ends of the perforating gun body 3 are respectively connected to the intermediate joint one 1 and the intermediate joint two 13, the perforating gun body 3 is equipped with a fixed-shot angle bullet frame 8, and the fixed-fire angle bullet frame 8 is equipped with a perforating charge 5, Every firing hole bullet 5 communicates by detonating cord 7 . The outside of the perforating gun body 3 is covered with a sleeve cartridge 6 , and the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com