Bactericide composite containing streptomycin sulphate and application thereof

A bactericide composition, streptomycin sulfate technology, applied in the direction of bactericide, application, biocide, etc., can solve the problem of inability to effectively prevent the occurrence and development of resistant bacteria, poor control effect of resistant bacteria, and resistance of bacteria and other problems, to achieve the effect of strong resistance to rain erosion, good spreadability, and improved prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

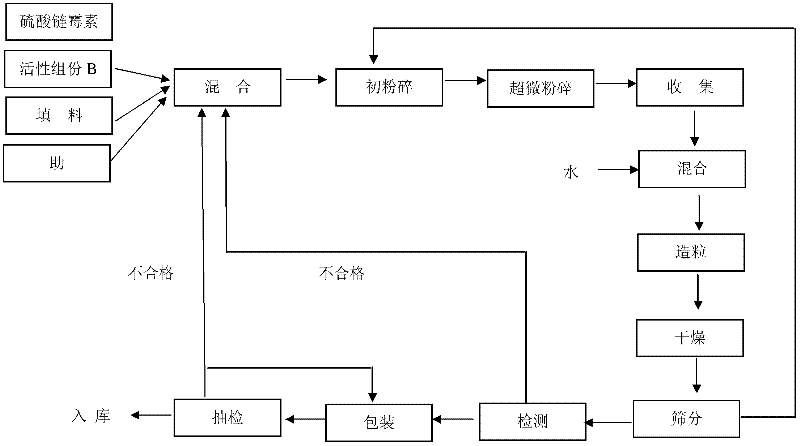

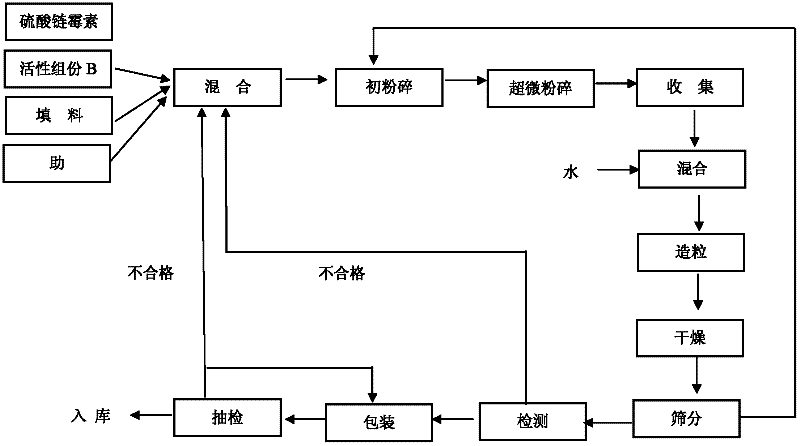

Method used

Image

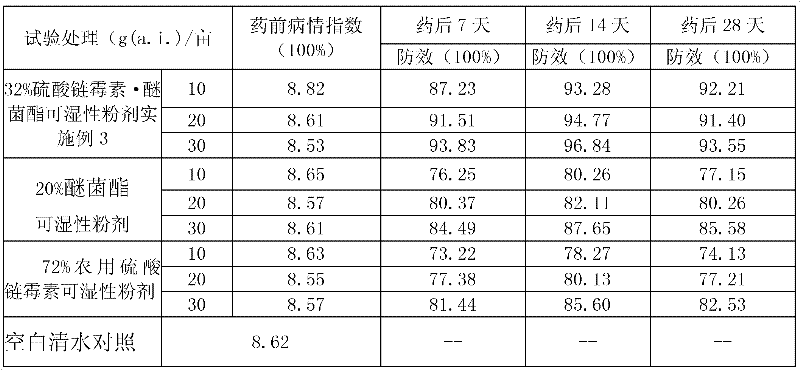

Examples

Embodiment 1

[0051] Example 2: Process the solid original drug streptomycin sulfate and pyraclostrobin to more than 325-800 mesh by means of jet crushing, then accurately weigh 25% streptomycin sulfate, 10% pyraclostrobin, and disperse 6% alkylnaphthalene formaldehyde condensate sulfonate as an agent, 4% alkylnaphthalene sulfonate as a wetting agent, 4% sodium sorbate as a stabilizer, 0.8% xanthan gum as a tackifier, and simethicone as an antifoaming agent Add 1% foaming agent and deionized water to 100% for initial mixing, shearing, stirring, and dispersing. After preparing a slurry, grind it for 1-2 hours in a horizontal sand mill to make the particle size below 5 microns, and A flowable 35% streptomycin sulfate pyraclostrobin liquid suspension preparation with a certain viscosity.

Embodiment 2

[0052] : Process the solid original drug streptomycin sulfate and kresoxim-methyl to above 325-800 mesh by means of jet crushing, then accurately weigh 22% thiazolyl copper, 10% kresoxim-methyl, dispersant polycarboxylate 6 %, wetting agent alkylphenol polyoxyethylene ether phosphate 5%, stabilizer epoxy soybean oil 5%, defoamer polyether modified silicone defoamer 1%, filler diatomaceous earth to 100% Mix and stir evenly without gravity to make 32% streptomycin sulfate kysstrobin wettable powder.

[0053] Embodiment 4:: use the method of airflow pulverization, process solid original drug streptomycin sulfate and enoxastrobin to more than 800-1000 mesh, then accurately weigh 15% streptomycin sulfate, 15% enoxastrobin, Dispersant Sodium Methylene Dimethyl Naphthalene Sulfonate 8%, Wetting Agent Sodium Dodecylbenzene Sulfonate 5%, Stabilizer Sodium Benzoate 5%, Disintegrant Bentonite 5%, Viscosifier Carboxymethyl Fiber Add 3% of cellulose, 1% of defoamer tributyl phosphate, fil...

Embodiment 4

[0054] Example 5: Process the solid original drug streptomycin sulfate and fenoxystrobin to more than 325-800 mesh by means of airflow pulverization, then accurately weigh 20% streptomycin sulfate, 5% phenoxystrobin, and disperse 6% alkylnaphthalene formaldehyde condensate sulfonate as an agent, 4% alkylnaphthalene sulfonate as a wetting agent, 4% sodium sorbate as a stabilizer, 0.8% xanthan gum as a tackifier, and simethicone as an antifoaming agent Add 1% foaming agent and deionized water to 100% for initial mixing, shearing, stirring, and dispersing. After preparing a slurry, grind it for 1-2 hours in a horizontal sand mill to make the particle size below 5 microns, and It is a flowable 25% streptomycin sulfate · fenoxystrobin liquid suspension preparation with a certain viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com