Complete self-backflow well type anabroeic-anoxic-oxic (AAO) sewage treatment method

A sewage treatment method and sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve practical application limitations, poor stability, and inability to denitrify synchronously Phosphorus removal and polymer organic waste water treatment, etc., to achieve the effect of small footprint, simple structure, and high-efficiency water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The raw sewage water used in this example is artificially prepared to simulate high-concentration wastewater, and NaHCO 3 The pH value of the configured wastewater is controlled between 7.5 and 8.5, the temperature is controlled at 25°C, the influent TOC (total organic carbon) is 1000 mg / L, TN (total nitrogen) is 40 mg / L, TP ( total phosphorus) is 6 mg / L.

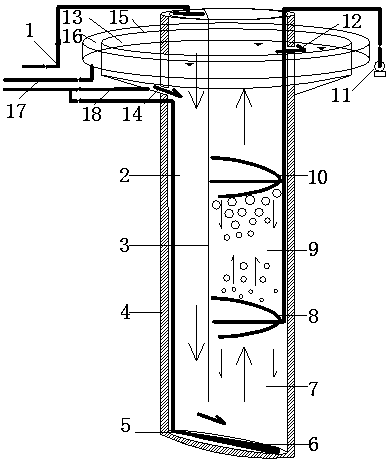

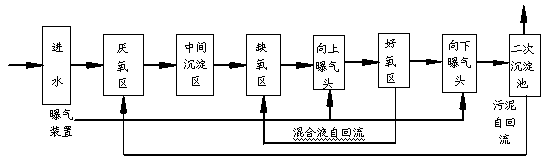

[0021] (1) A complete self-reflux well type AAO sewage treatment device is set, including a well body and a secondary sedimentation tank 13; The plate 3 is divided into two sides with a space ratio of 1:4, the side with a space ratio of 1 is the anaerobic zone 2, the top of the anaerobic zone 2 is provided with a water inlet pipe 1, and the bottom of the shaft is an intermediate sedimentation zone 5, and the intermediate sedimentation zone 5 is equipped with Gravity mud discharge pipe 6; a reciprocal aeration system is installed on the side with a space ratio of 4. The reciprocal aeration system includes an upward a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com