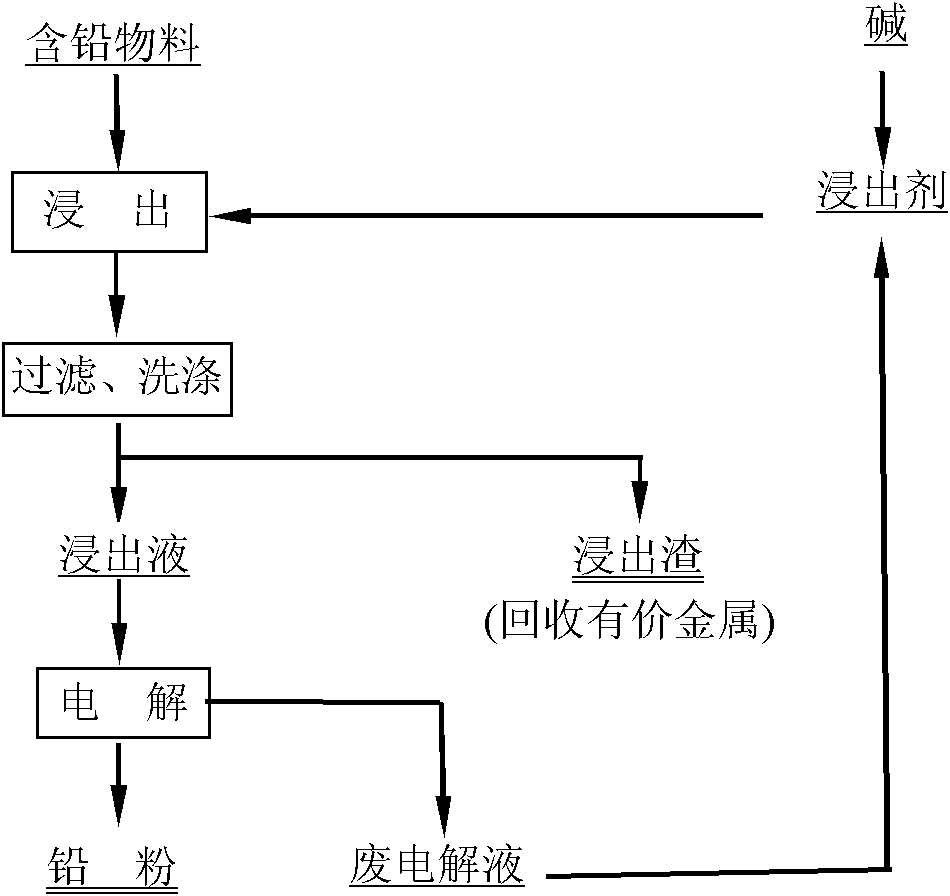

Method for recovering lead from lead-containing material by matching leaching-electrowinning method

A material and leaching technology, applied in the direction of process efficiency improvement, photographic technology, instruments, etc., can solve environmental and human health hazards and other problems, and achieve the effects of easy operation, reduced environmental pollution, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Zinc oxide soot, a by-product of lead smelting in a factory, material composition (%): Zn 52.43, Pb 12.44, Cu 0.04, In 0.0199, S 3.2, Cl 0.06, F 0.084, As 0.32, Sb 0.047.

[0039] Disodium edetate 0.15mol / L, NaOH 0.2mol / L solution, weigh suboxide soot according to the solid-to-liquid ratio of 200g / L, add it into the reactor, control the reaction temperature at 90°C, stir and leaching for 2.0h , the lead in the secondary zinc oxide soot enters the leachate in the form of Pb(EDTA) complex, the slag contains 1.06% of Pb, and the pH value of the leachate is 10. During the leaching process, the leaching rate of lead was 93.65%, and the leaching rate of zinc was only 4.24%.

[0040] The leaching solution contains 22.04g / L of lead, and stainless steel is used as the cathode, coated with PbO 2 The titanium plate is the anode, at 20-30°C, the current density is 100A / m 2 Electrowinning was carried out at 1.7-2.2V for 10 hours, the waste liquid contained 1.8g / L of lead, and the c...

Embodiment 2

[0042] A zinc sulfate factory produces acid leaching lead slag, material composition (%): Zn 3.89, Pb18.16, In 0.025, SO 4 2- 14.2, Fe0.56, Cu0.05, Sb1.47, Bi0.85, Ca1.20.

[0043] CaEDTA 0.3mol / L, the solution of CaO 1.0mol / L, according to the solid-liquid ratio is 150g / L to take lead-containing slag, add in the ball mill reactor together, control reaction temperature to be normal temperature, the ratio of ball and slurry is 1kg: 10L, ball milling reaction time 0.5h, make PbSO 4 The lead in the slag enters the leaching solution in the form of PbEDTA complex, SO 4 2- CaSO 4 The form of slag remains in the slag, the leaching slag contains 0.64% Pb, and the leaching rate of lead during the leaching process is 96.65%.

[0044] The leachate contains 27.08g / L of lead, stainless steel is used as the cathode, and PbO is coated 2 The titanium plate is the anode, at 40°C, the current density is 400A / m 2 Electrowinning was carried out at 2.0-2.5V for 12 hours, the waste liquid c...

Embodiment 3

[0046] A wet zinc plant produces high acid leaching slag, the material composition (%) is: Zn 8.21, Pb 7.76, Ag 0.162, Ge 0.015, Fe13.76, SO 4 2- 4.2, SiO 2 25.34.

[0047] CaEDTA 0.4mol / L, the solution of CaO 0.5mol / L, according to the solid-liquid ratio is 300g / L to take lead-containing slag, add in the ball mill reactor together, control reaction temperature to be normal temperature, the ratio of ball and slurry is 1kg: 30L, ball milling reaction time 1.0h, make PbSO 4 The lead in the slag enters the leaching solution in the form of PbEDTA complex, SO 4 2- CaSO 4 The form of slag remains in the slag, the leaching slag contains 0.48% of Pb, the leaching rate of lead is 93.52%, and the leaching rate of silver is 85%.

[0048] The leaching solution contains 21.24g / L of lead, stainless steel is used as the cathode, and IrO is coated 2 The titanium plate is the anode, at 45°C, the current density is 200A / m 2 Electrowinning was carried out at 1.7-2.2V for 24 hours, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com