Patents

Literature

152results about "Continuous pulping process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

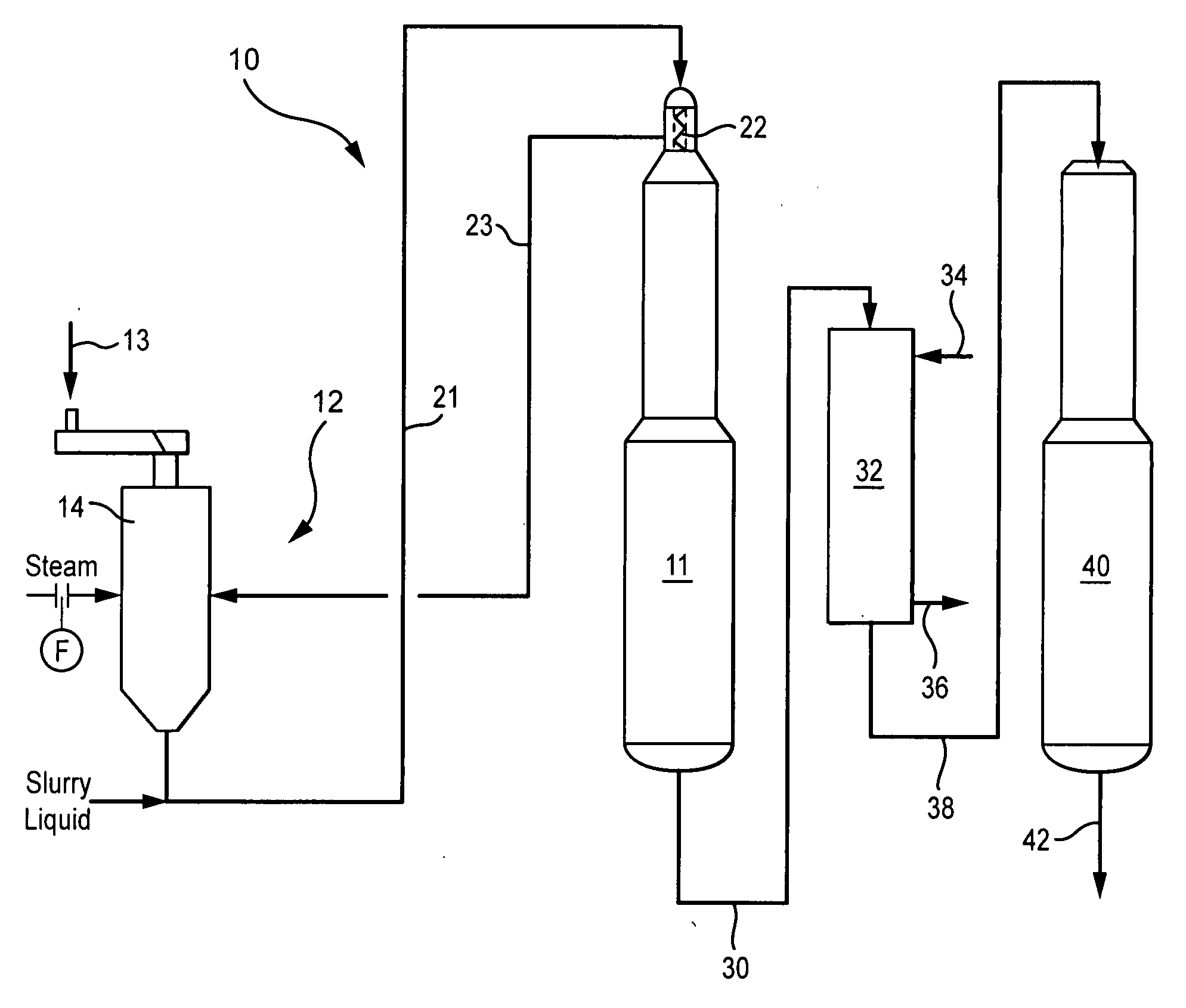

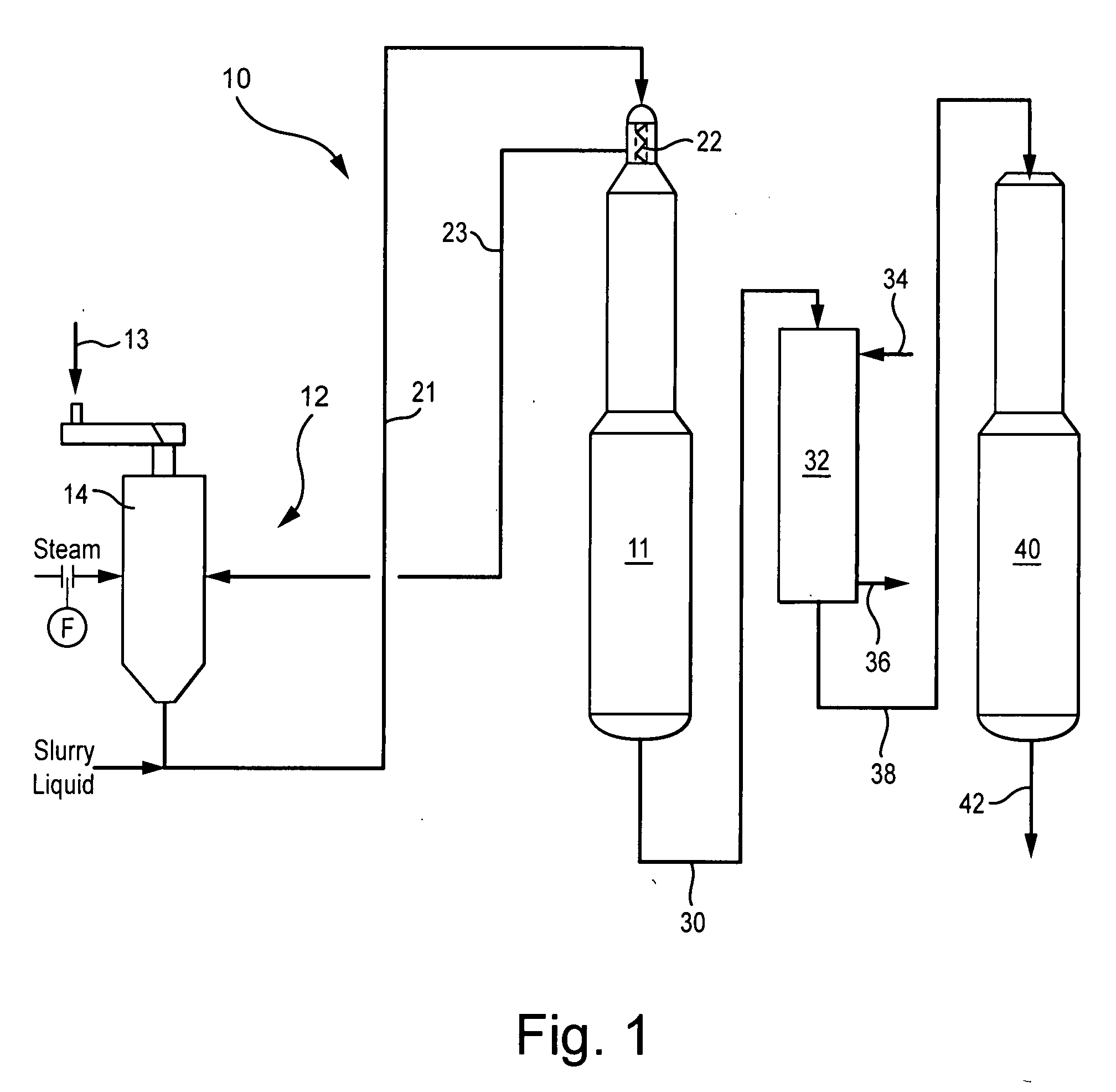

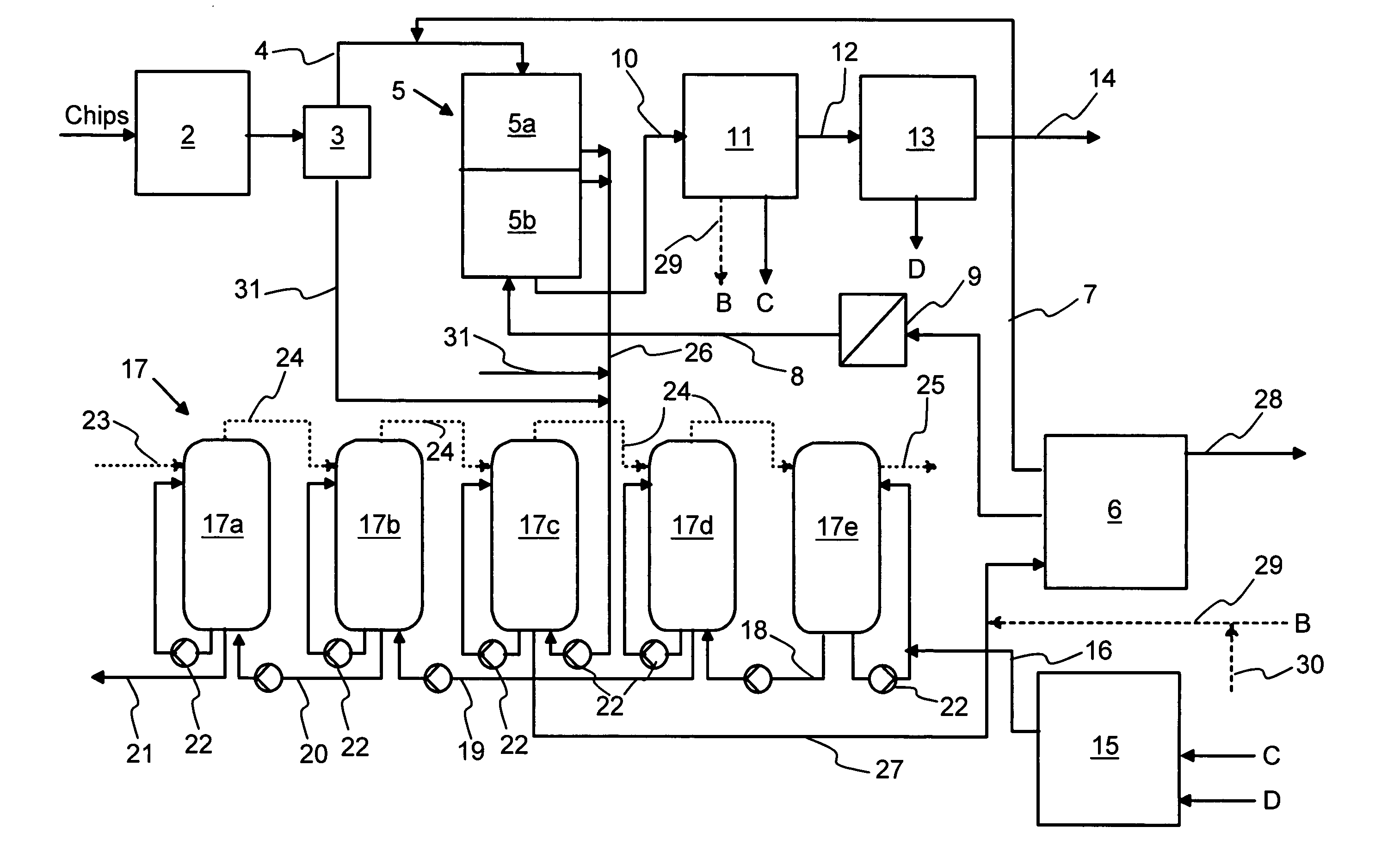

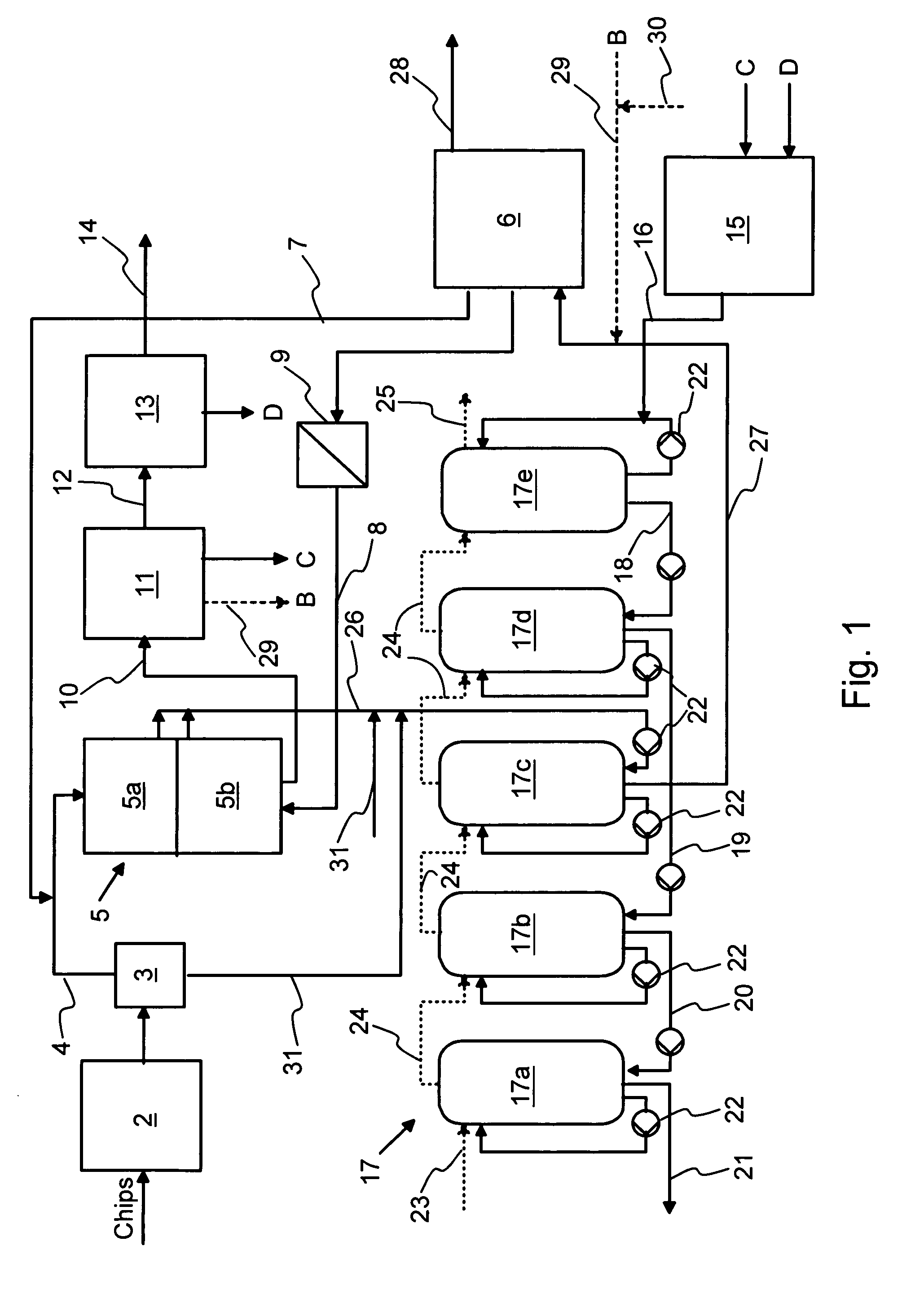

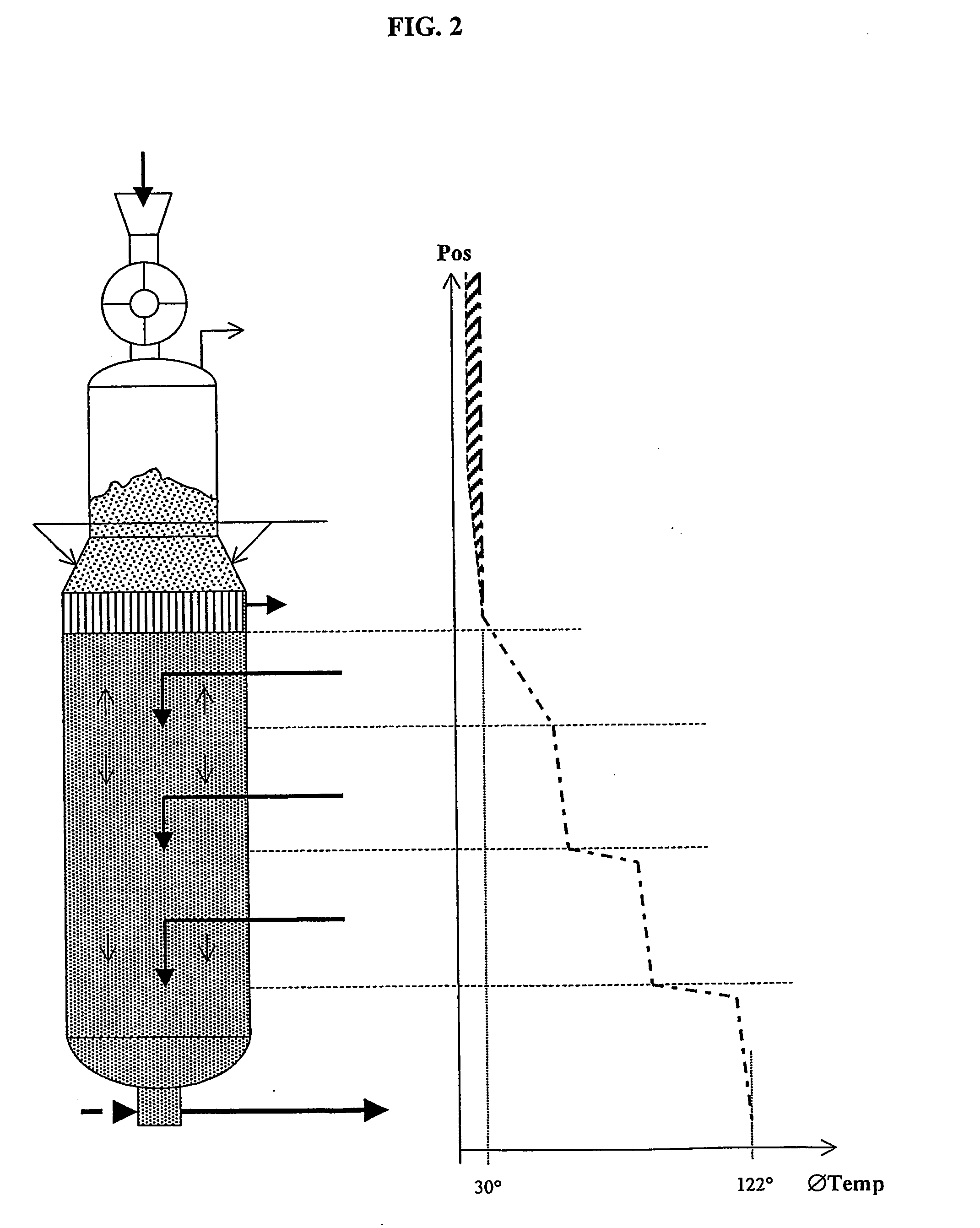

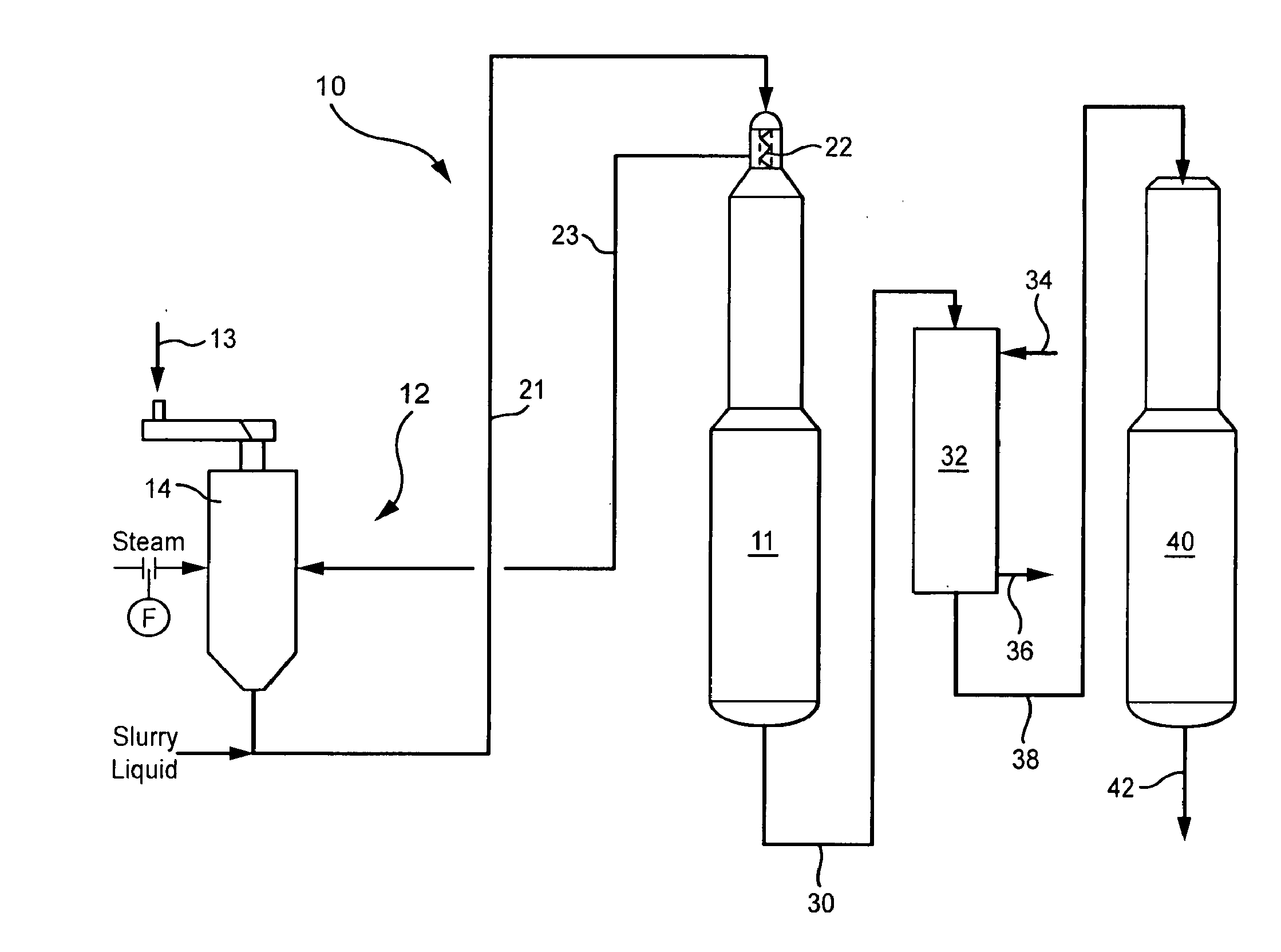

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

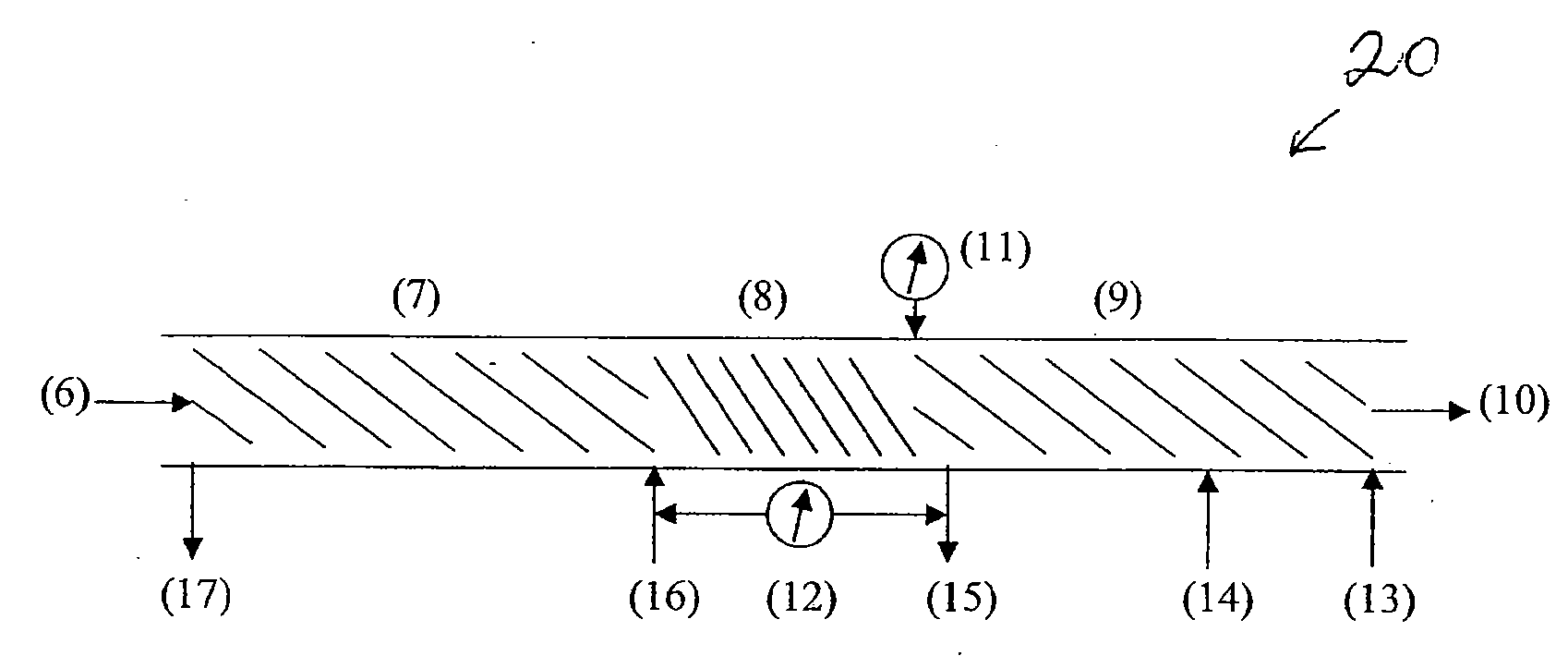

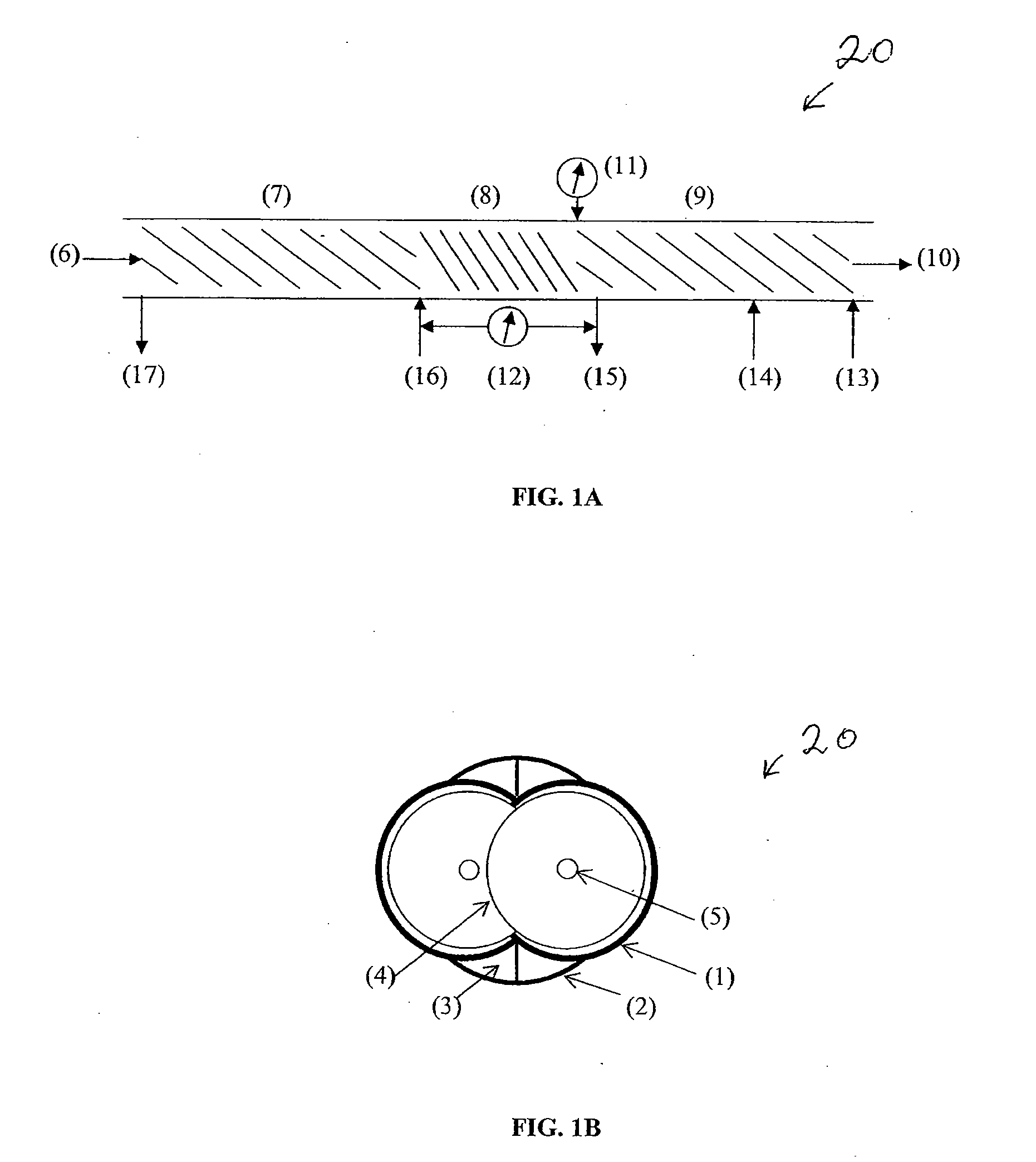

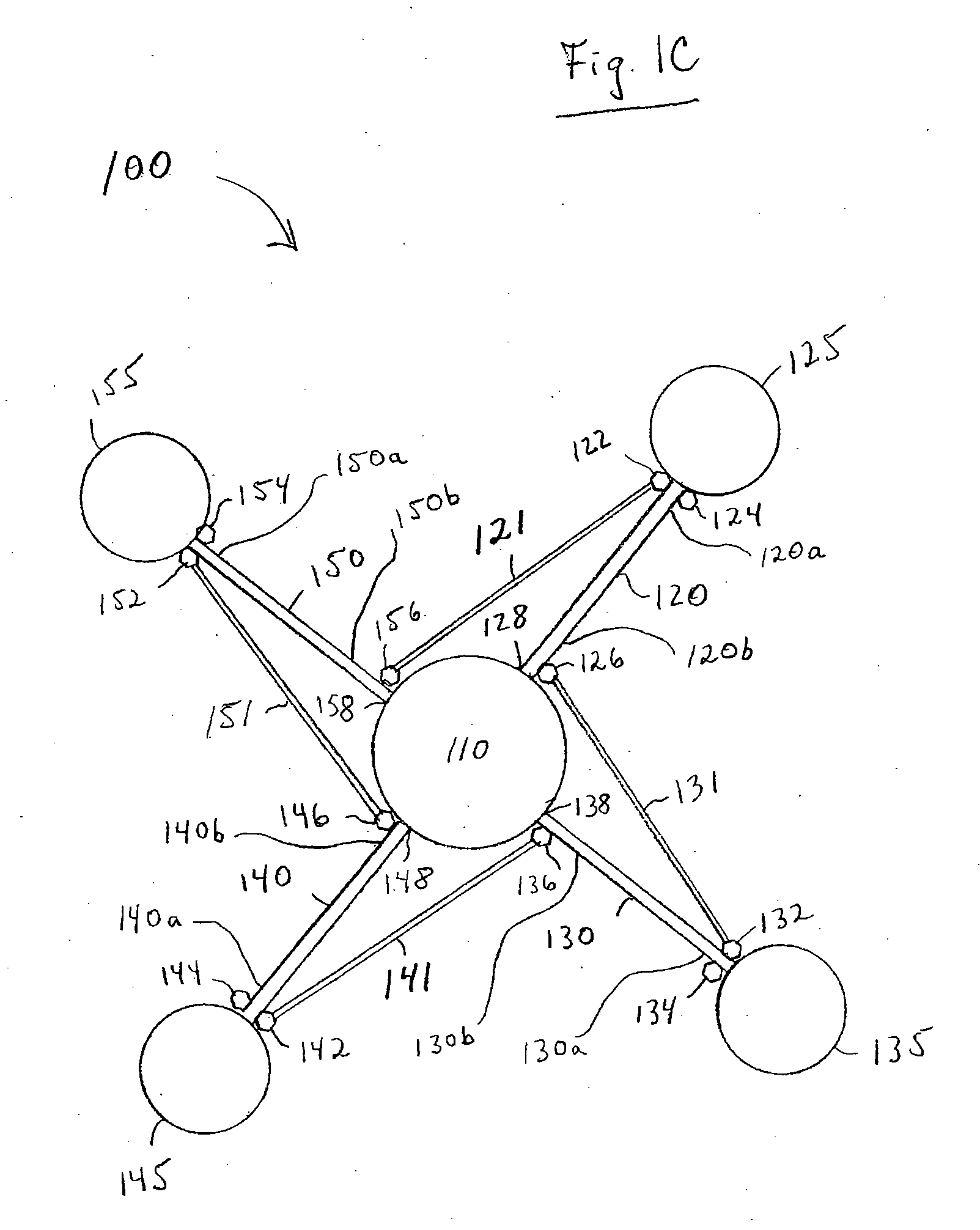

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

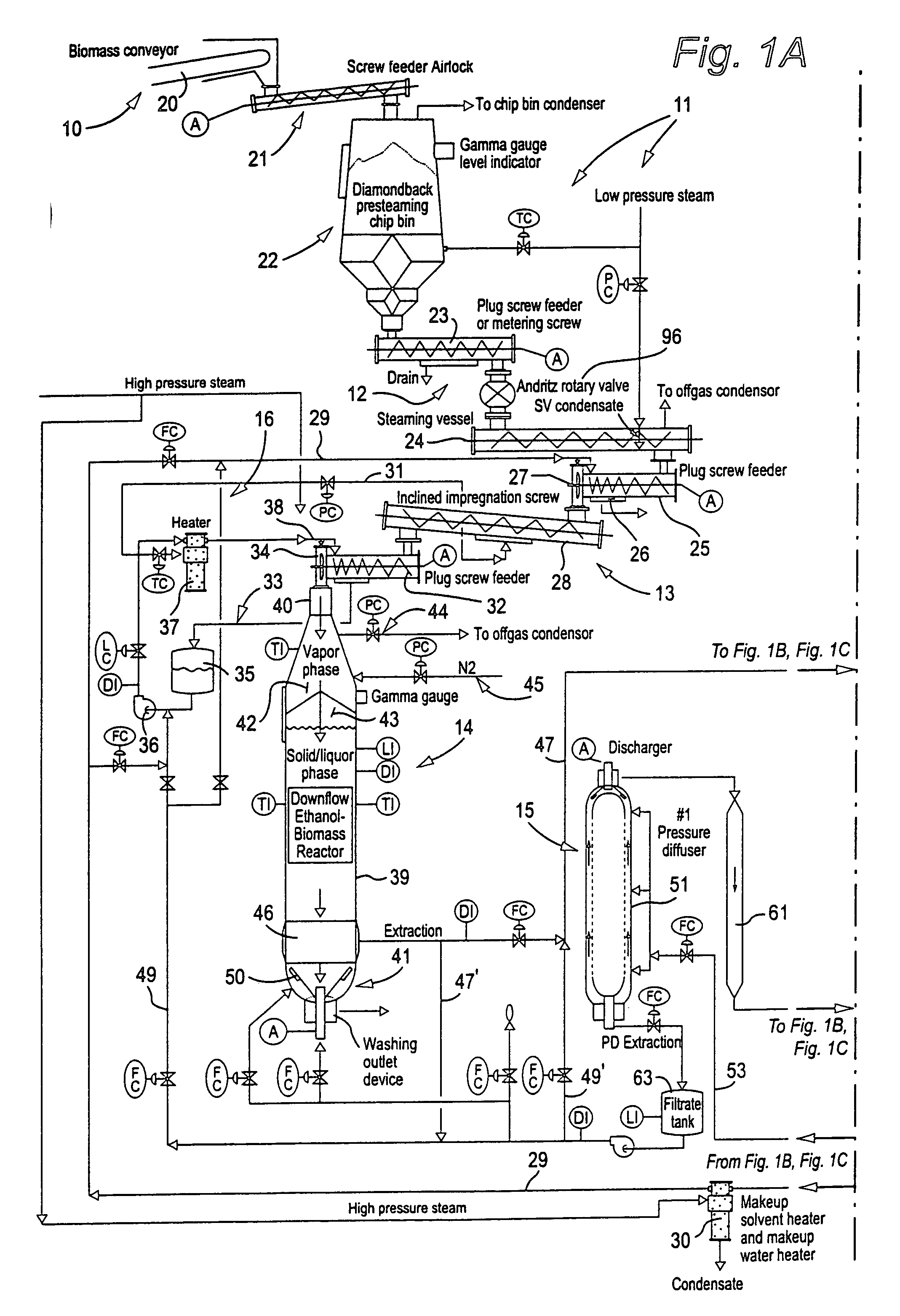

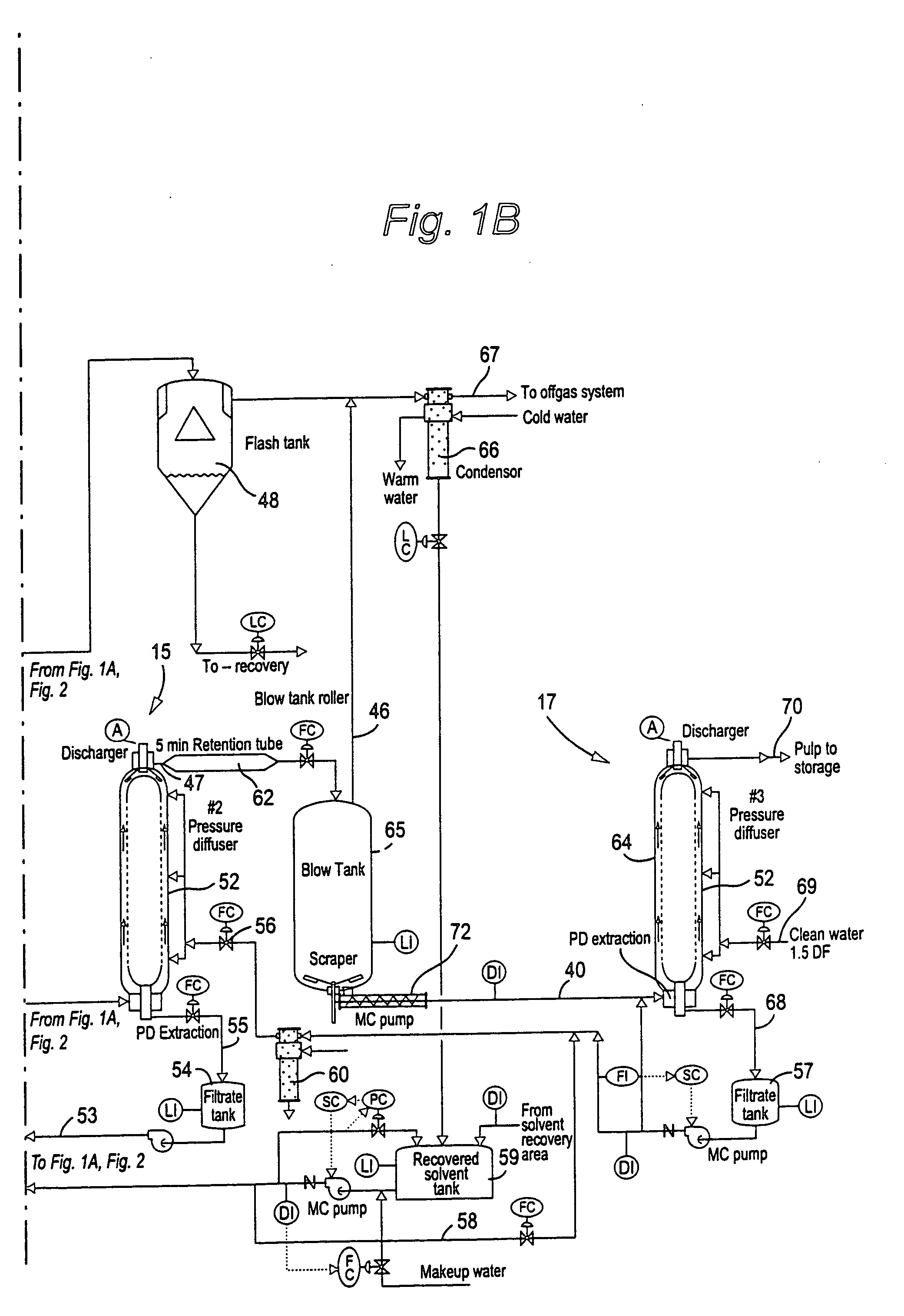

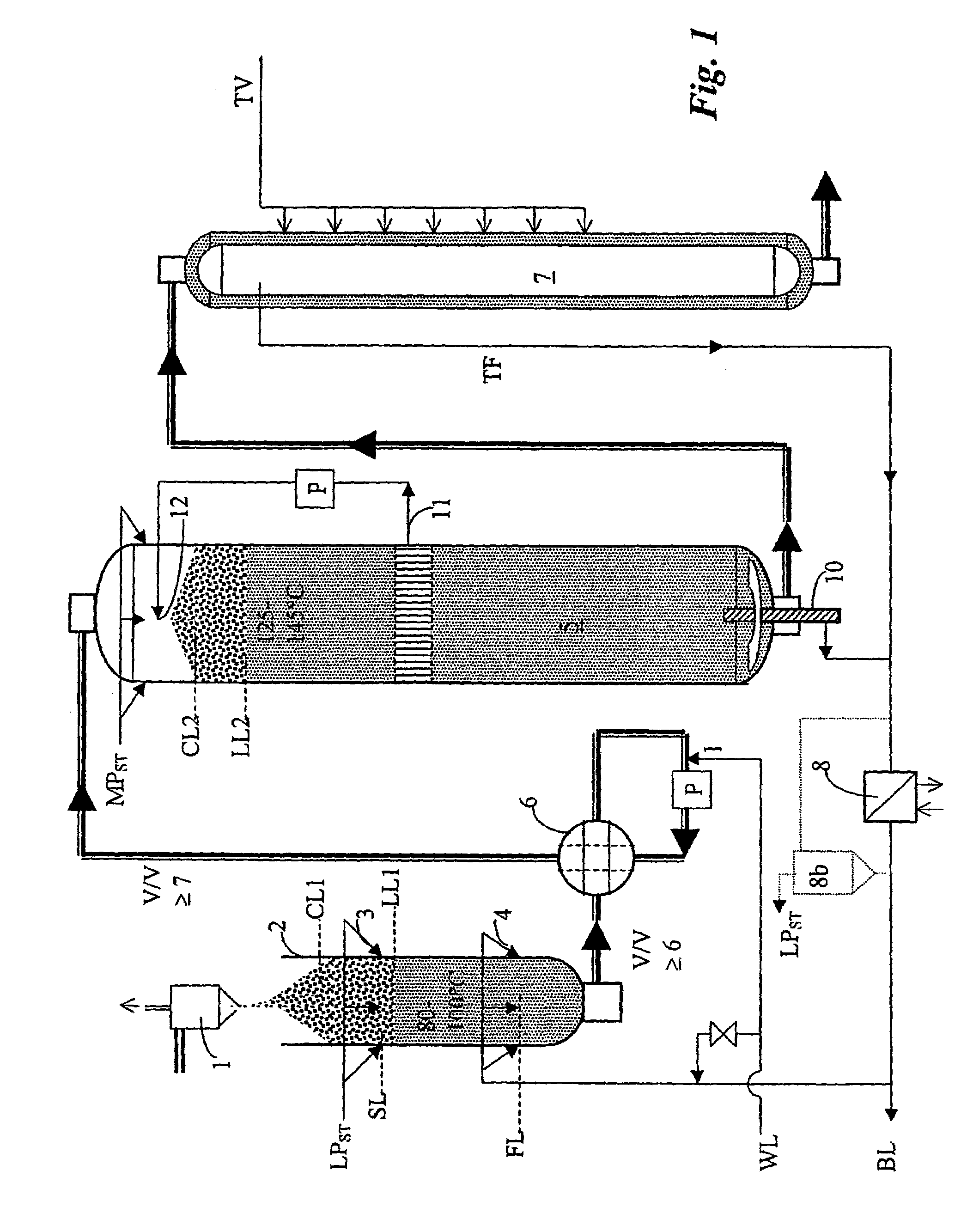

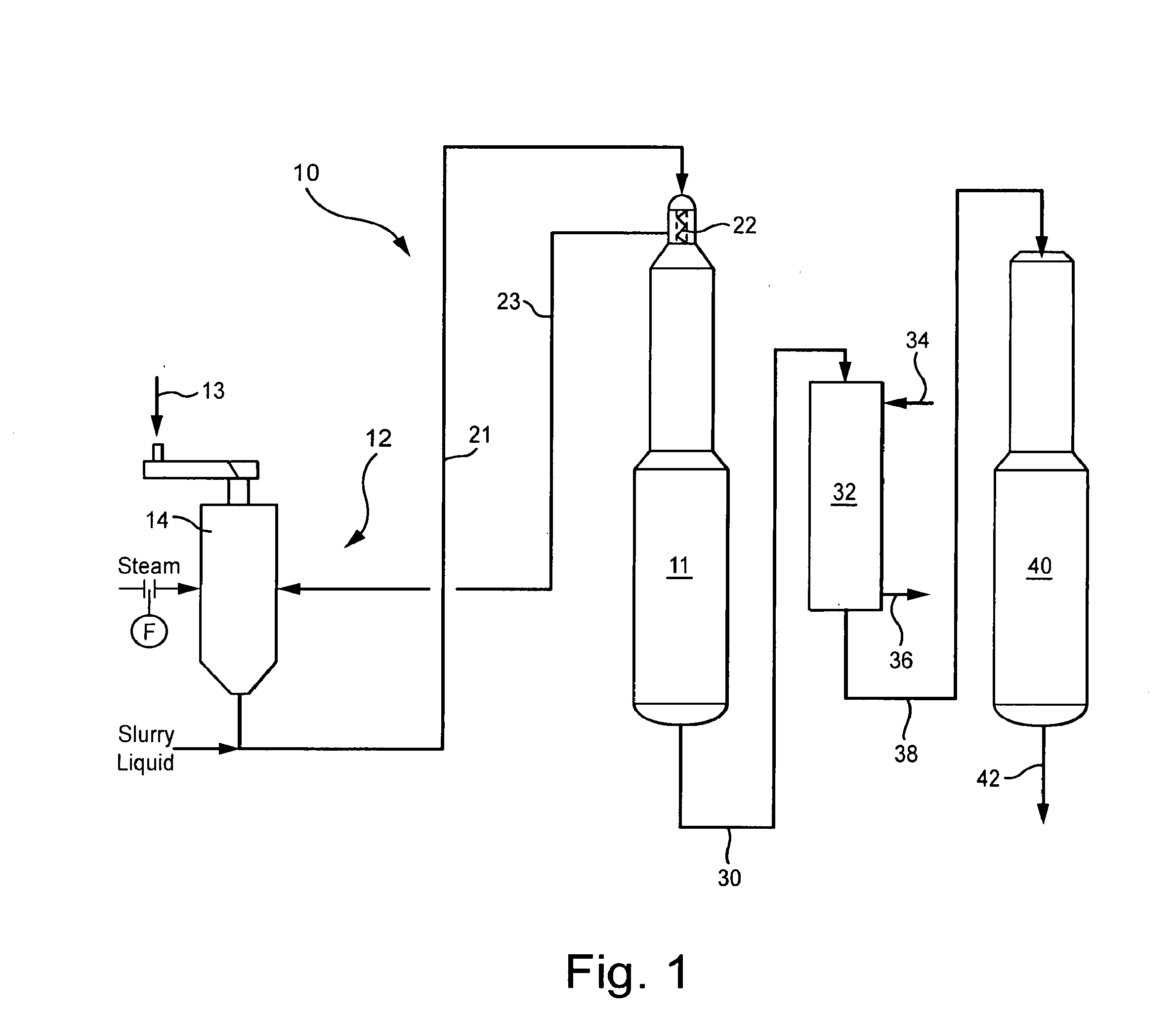

Solvent pulping of biomass

InactiveUS20040060673A1Pretreatment with water/steamWashing/displacing pulp-treating liquorsCellulose fiberChemistry

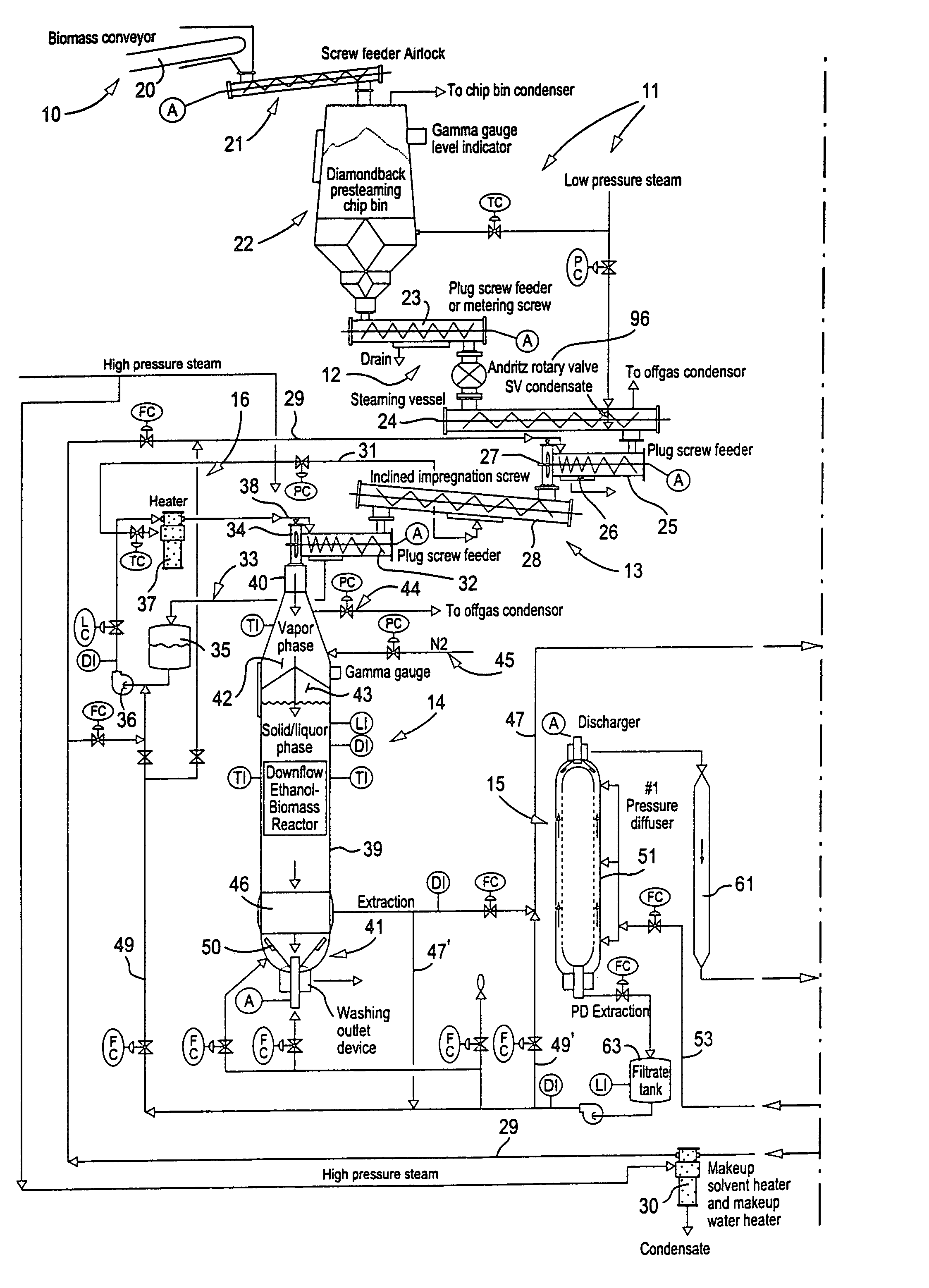

An apparatus and process for solvent pulping of cellulose-containing biomass utilizes at least one steaming vessel, a plug screw feeder or compression screw device, at least one super-atmospheric impregnation vessel, a solvent delignification reactor capable of operating at a pressure of 350 psig or more, and a solvent containing line for introducing solvent-containing liquor at the plug screw feeder outlet or compression screw device outlet. The process and system can also include at least one series connected pressure diffuser and optionally a retention tube downstream of each pressure diffuser to provide sufficient retention time to substantially preclude re-deposition of lignin on the cellulose fibers of the biomass, a blow tank connected to the last of the pressure diffusers and retention tubes, and vessels for multistage alcohol washing. The method steams the biomass and impregnates it with solvent to produce an aqueous slurry of biomass and solvent, delignifies the particulate biomass in the slurry, removes solvent while continuing delignification of the biomass in the slurry and while substantially precluding re-deposition of lignin on the cellulose of the biomass, reduces the pressure of the slurry; and then washes the slurry.

Owner:ANDRITZ INC

Method for loading fibers contained in a pulp suspension

InactiveUS20080210391A1Easy to usePulp properties modificationWashing/displacing pulp-treating liquorsFiberCalcium hydroxide

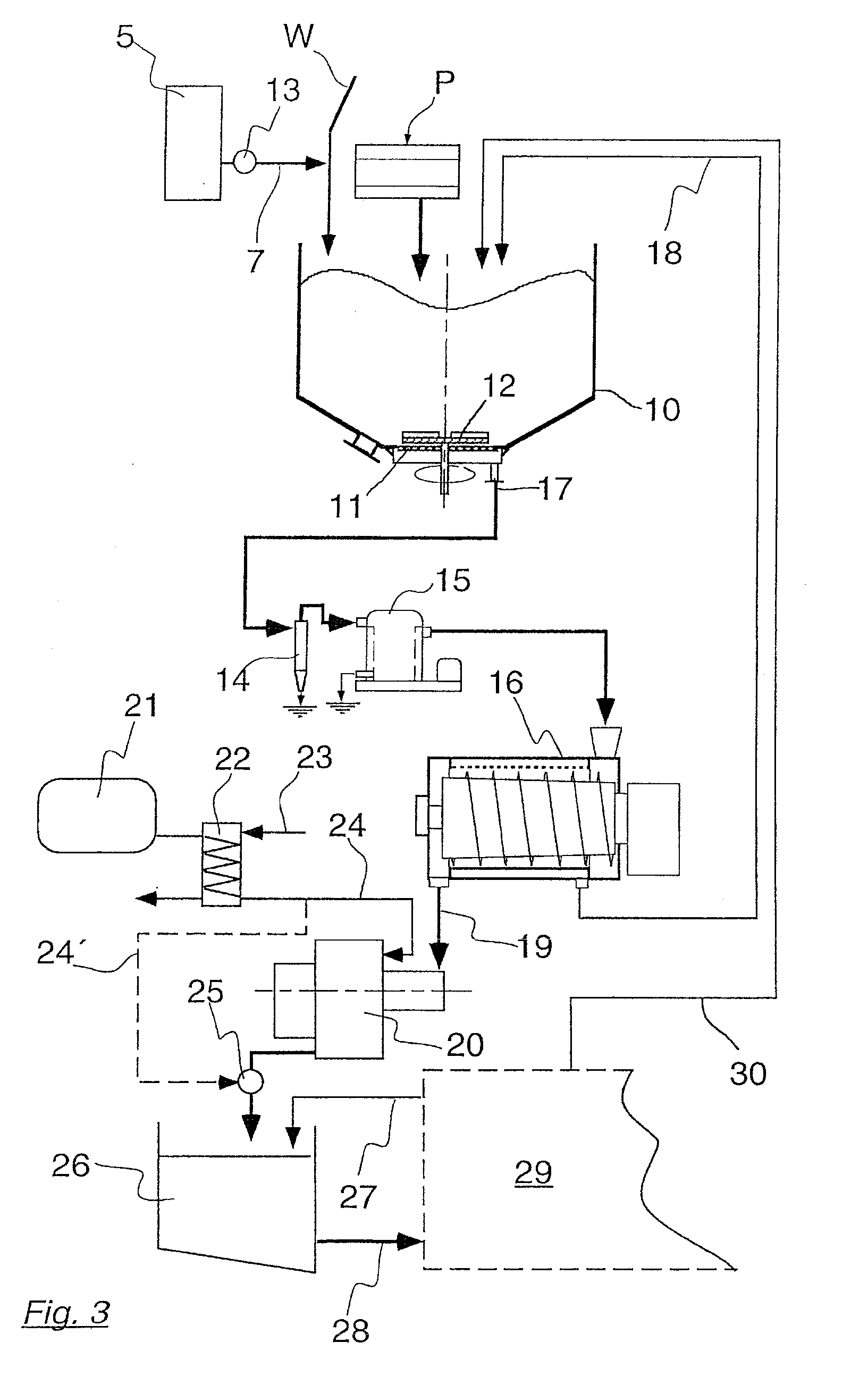

The present invention serves for loading a pulp suspension (S) with calcium carbonate. Liquid calcium hydroxide as milk of lime (7) is added during or before the pulp operation (1) carried out to form the pulp. By introducing gaseous carbon dioxide (8) into the pulp suspension thus treated, a chemical reaction is triggered therein, in which the finely divided calcium carbonate is precipitated. The present invention is particularly economic and effective due to the early addition of calcium oxide or calcium hydroxide.

Owner:VOITH PATENT GMBH

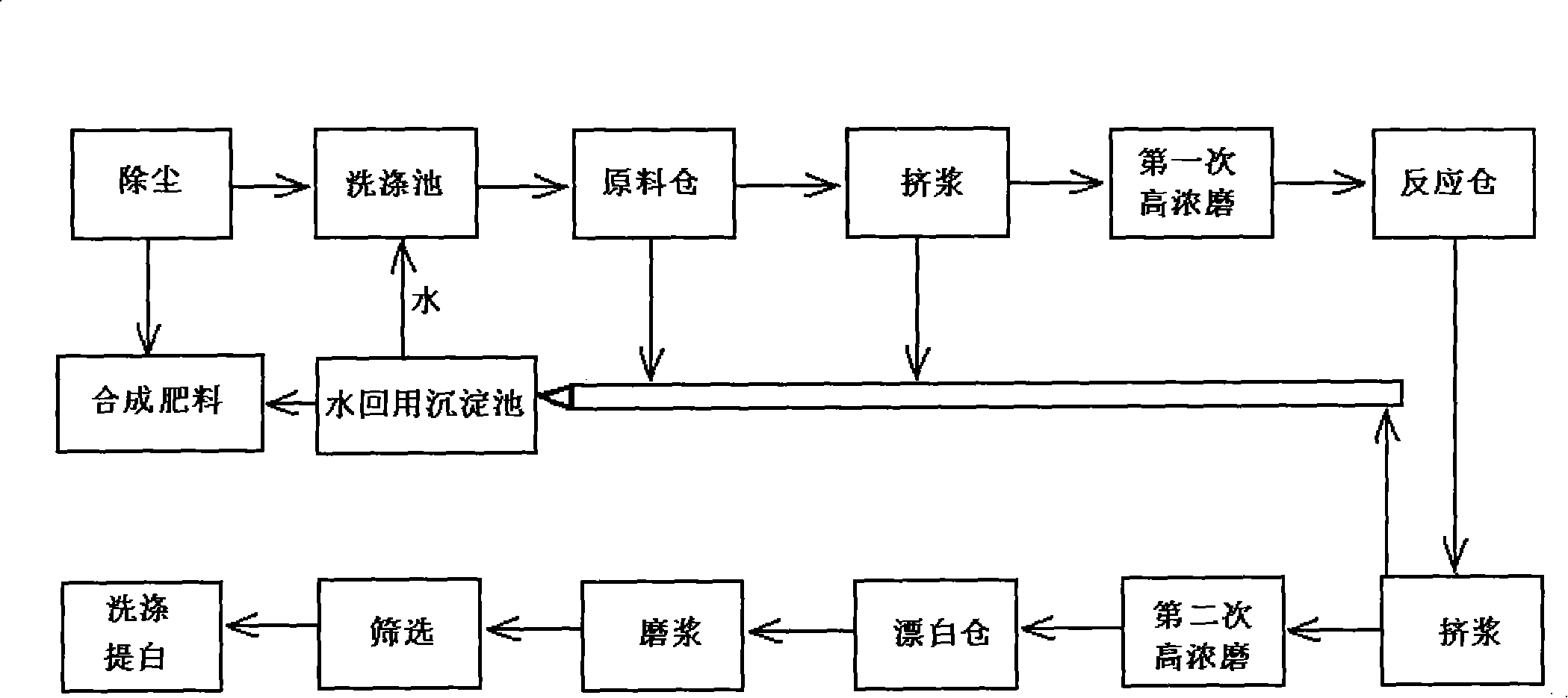

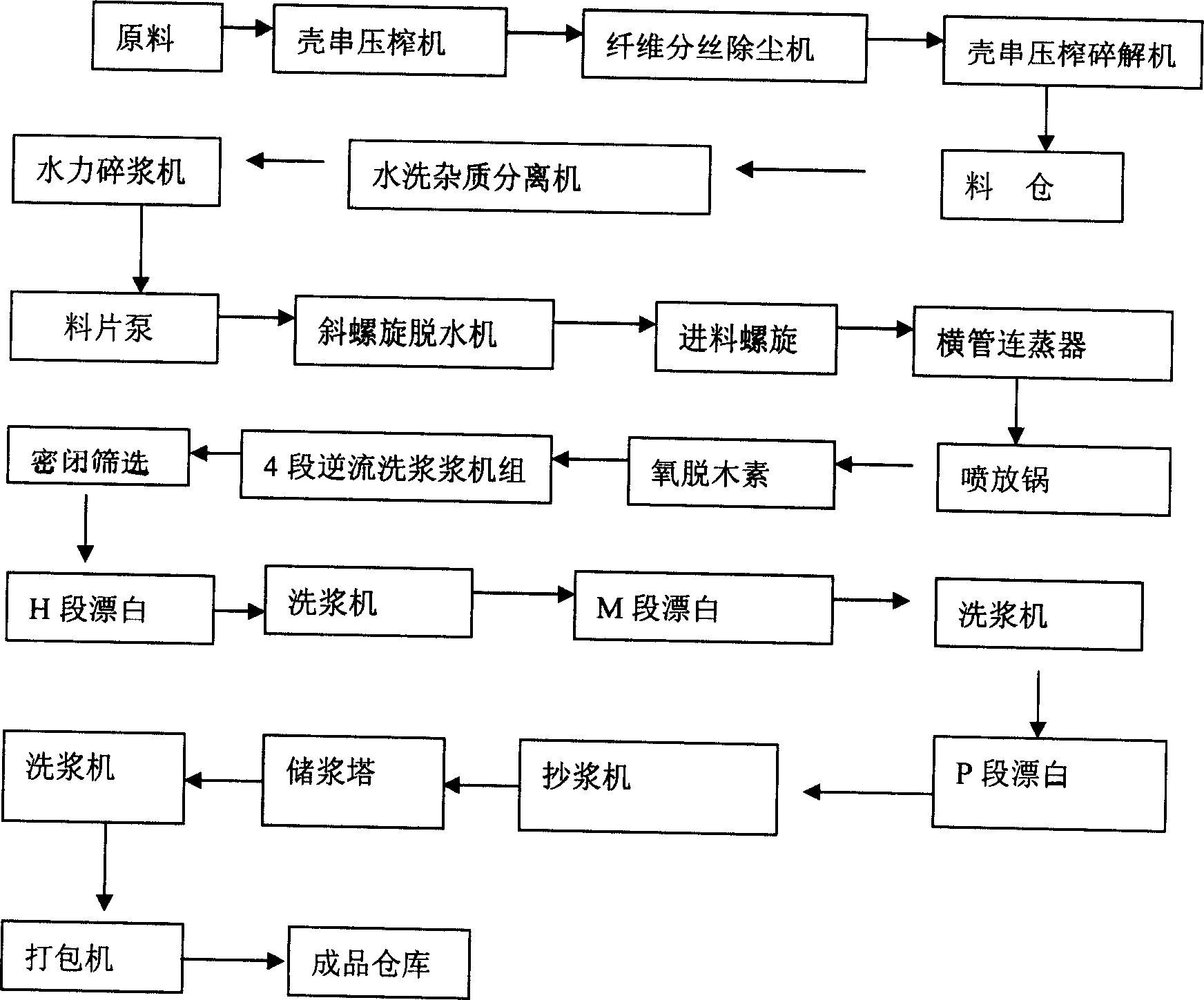

Clean pulping process

InactiveCN101200862ASimple pulping processReduce manufacturing costPulp de-wateringPulp bleachingFiberPulp and paper industry

The present invention relates to a pulping technology, in particular to a clean pulping technique with straw or broad leaves as raw materials. In the technical scheme, the clean pulping technology mainly includes twelve steps: (1) straw cutting or fragmenting and dedusting; (2) a fly cutter material-washing pool; (3) a raw material bin; (4) a press master; (5) the first-stage high-consistency grinding; (6) a reaction bin; (7) a press master; (8) the second-stage high-consistency grinding; (9) a high-consistency bleaching and temperature-keeping bin; (10) pulping; (11) filtering; (12) washing and whiteness enhancement. The technology uses straw or broad leaves as raw materials to realize the pollution-free fiber pulping technique, and applicable to large and medium paper-making enterprises, the whole pulping technique has the advantages of simplicity, low production cost, high yield rate of white pulp, good pulp quality, obvious reduction of energy consumption, etc.

Owner:SHANDONG HUALIN ENVIRONMENTAL PROTECTION TECH +1

Bamboo fiber processing process

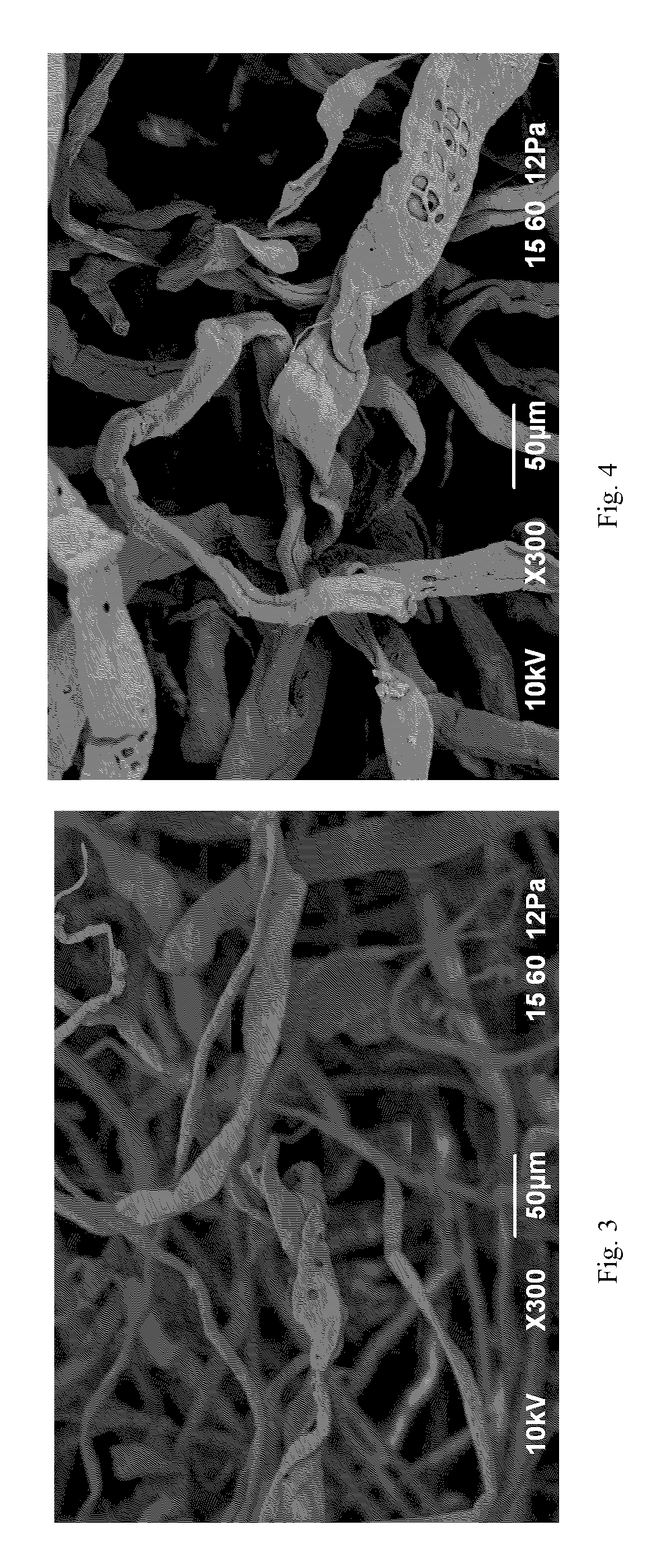

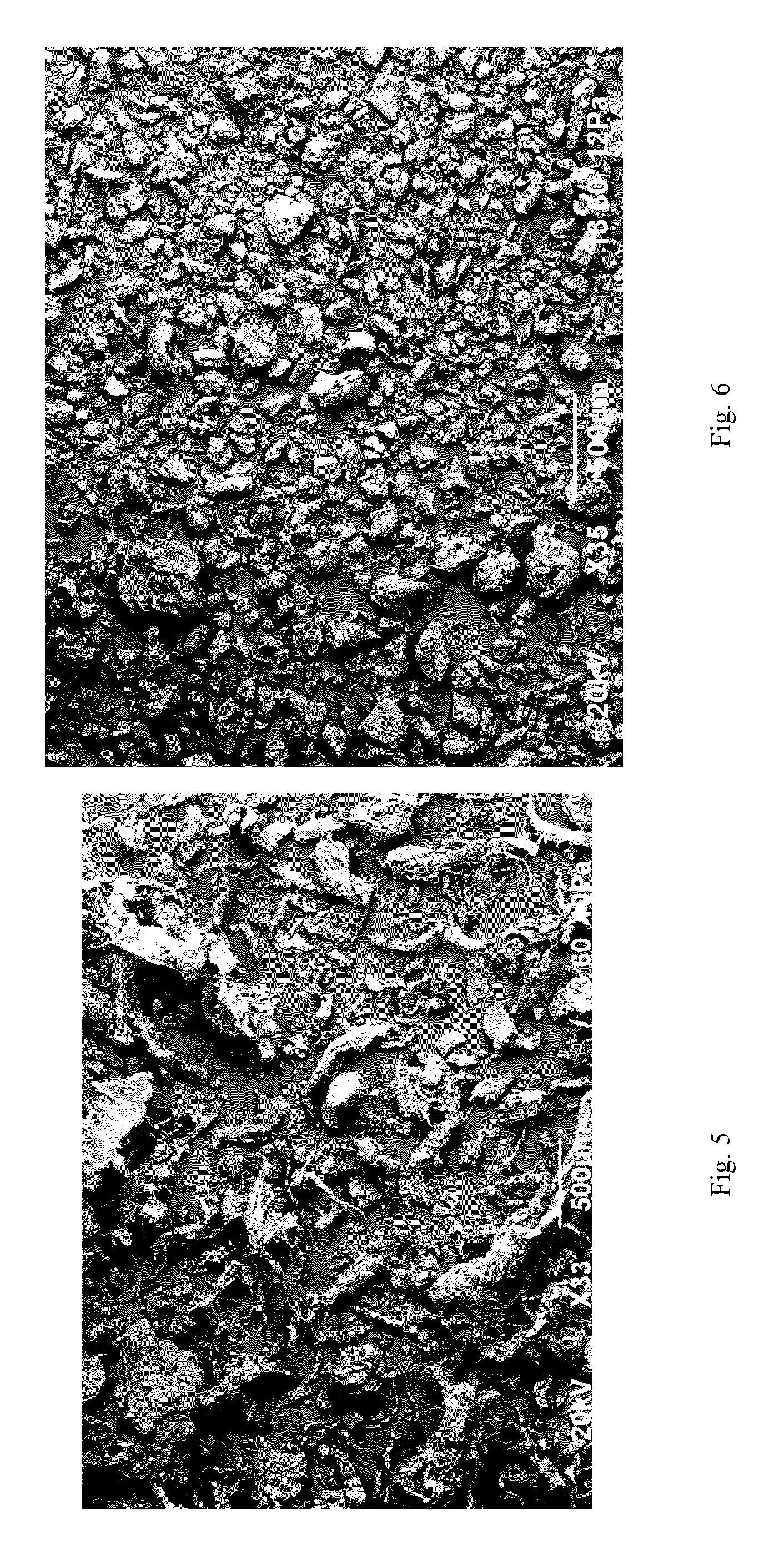

InactiveCN1587504AApplicable to the needs of comprehensive utilizationImprove mechanical propertiesPretreatment with alkaline reacting compoundsContinuous pulping processPre treatmentFiber orientation

The present invention relates to the technological scheme of treating bamboo fiber. The treating process of bamboo fiber includes the following steps: pre-treating via cutting bamboo, scraping out green skin and rolling; soaking the pre-treated bamboo in pre-treatment pond with Ca(OH)2 solution of 5-10 wt% concentration for 10-30 days to obtain coarse bamboo fiber; and flushing in the flushing pond to eliminate impurity and obtain pure bamboo fiber. The present invention features that additive mixture comprising NaOH, Na2CO3 and NaHCO3 is added into pre-treatment pond. The present invention has the advantages of less investment, low cost, fast effect, cheap processing solution of Ca(OH)2 and small amount of additive, short processing period and raised mechanical performance of bamboo fiber.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

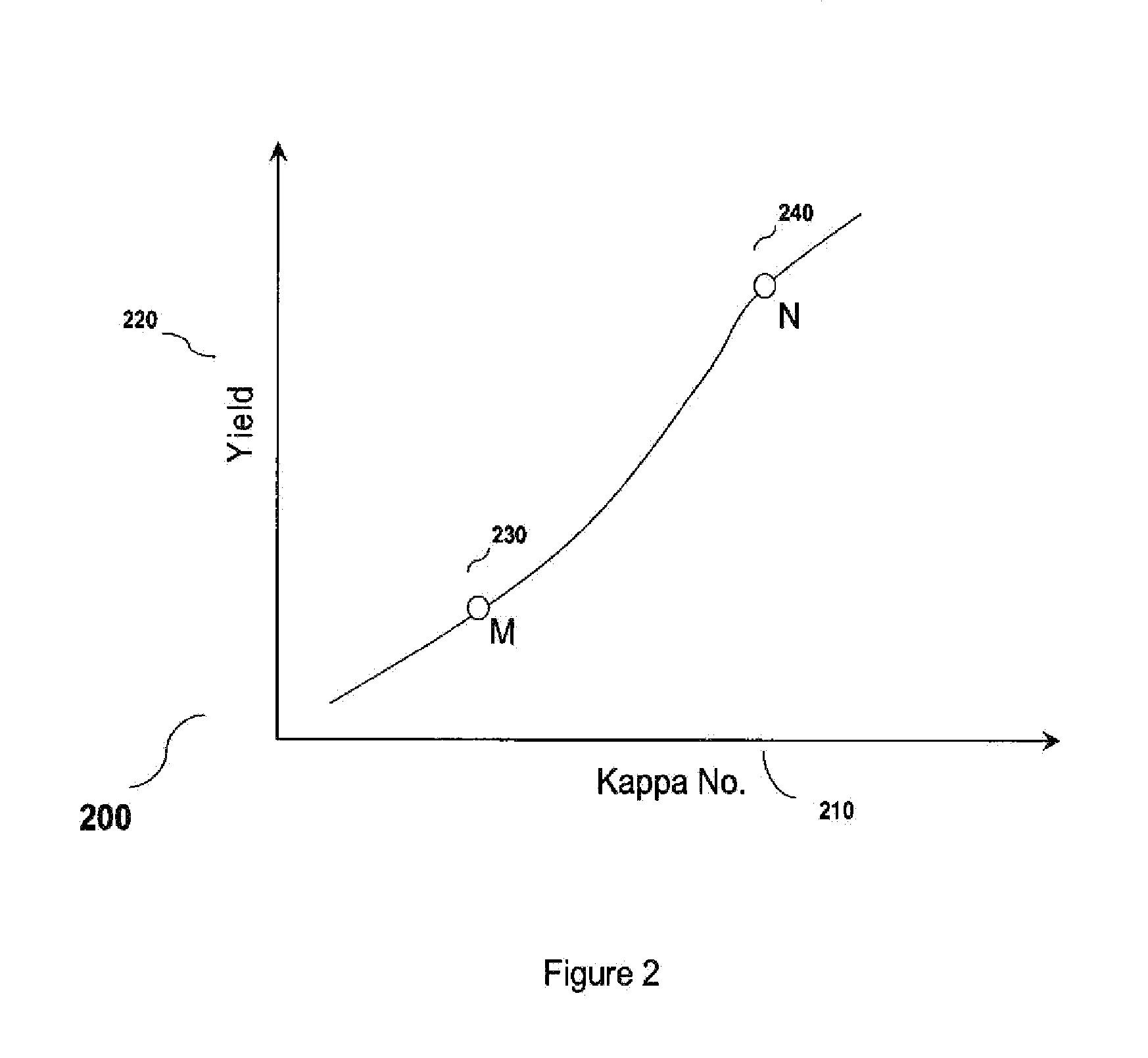

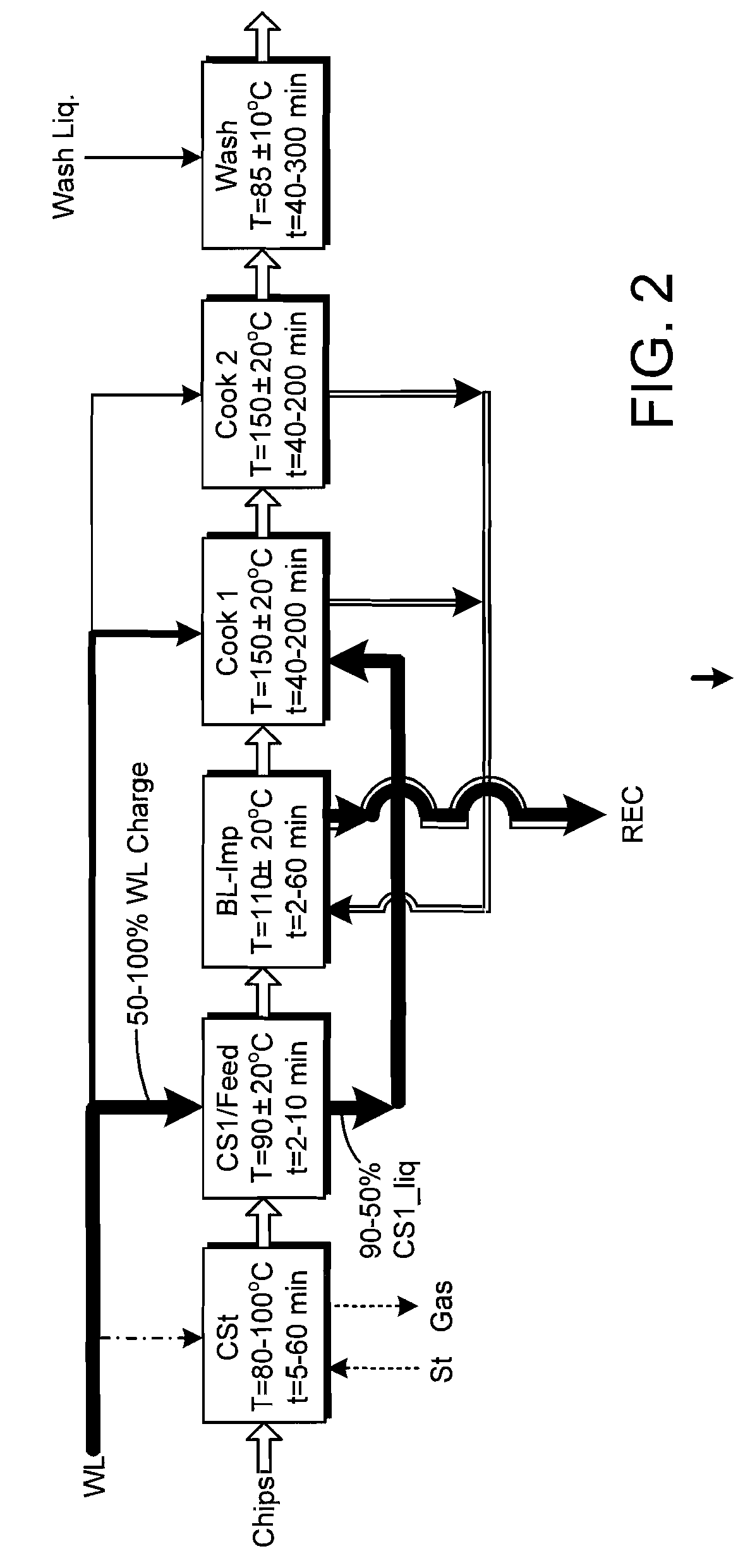

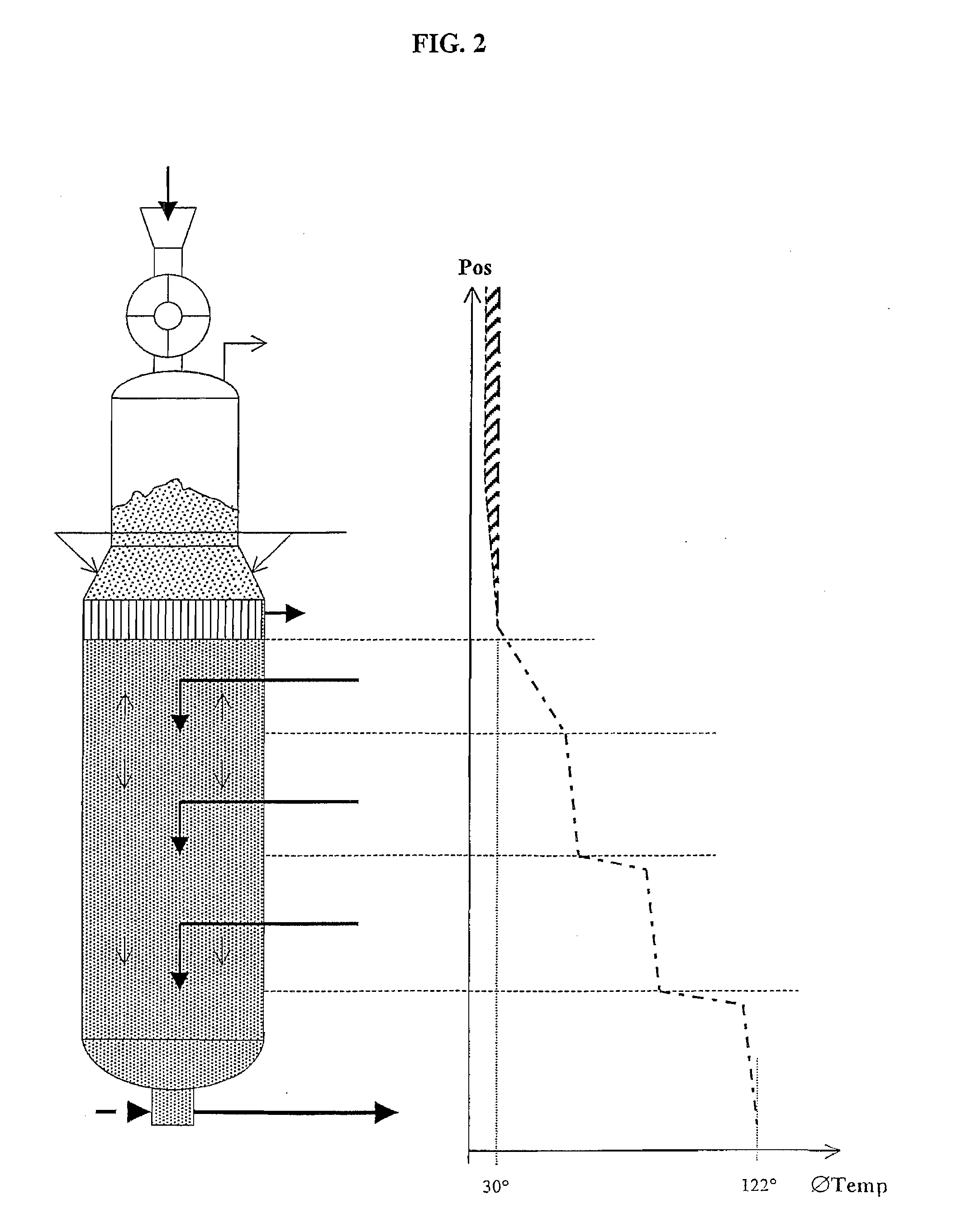

System and a method for optimization of continuous digestion process

A method is disclosed for optimization of continuous digestion process. Exemplary embodiments can control a delignification process in a continuous pulp digester in an optimal way for different pulp grades taking into account process disturbances and model uncertainties. This can be achieved by customizing a generic mathematical model for a continuous digestion process which runs through a software application on a dedicated electronic device. The model can be updated periodically based on on-line information, and used with a plant optimization component involving multiobjective optimization to evaluate optimal set points for the controllers. A system is also disclosed for optimizing control of a continuous pulp digester.

Owner:ABB (SCHWEIZ) AG

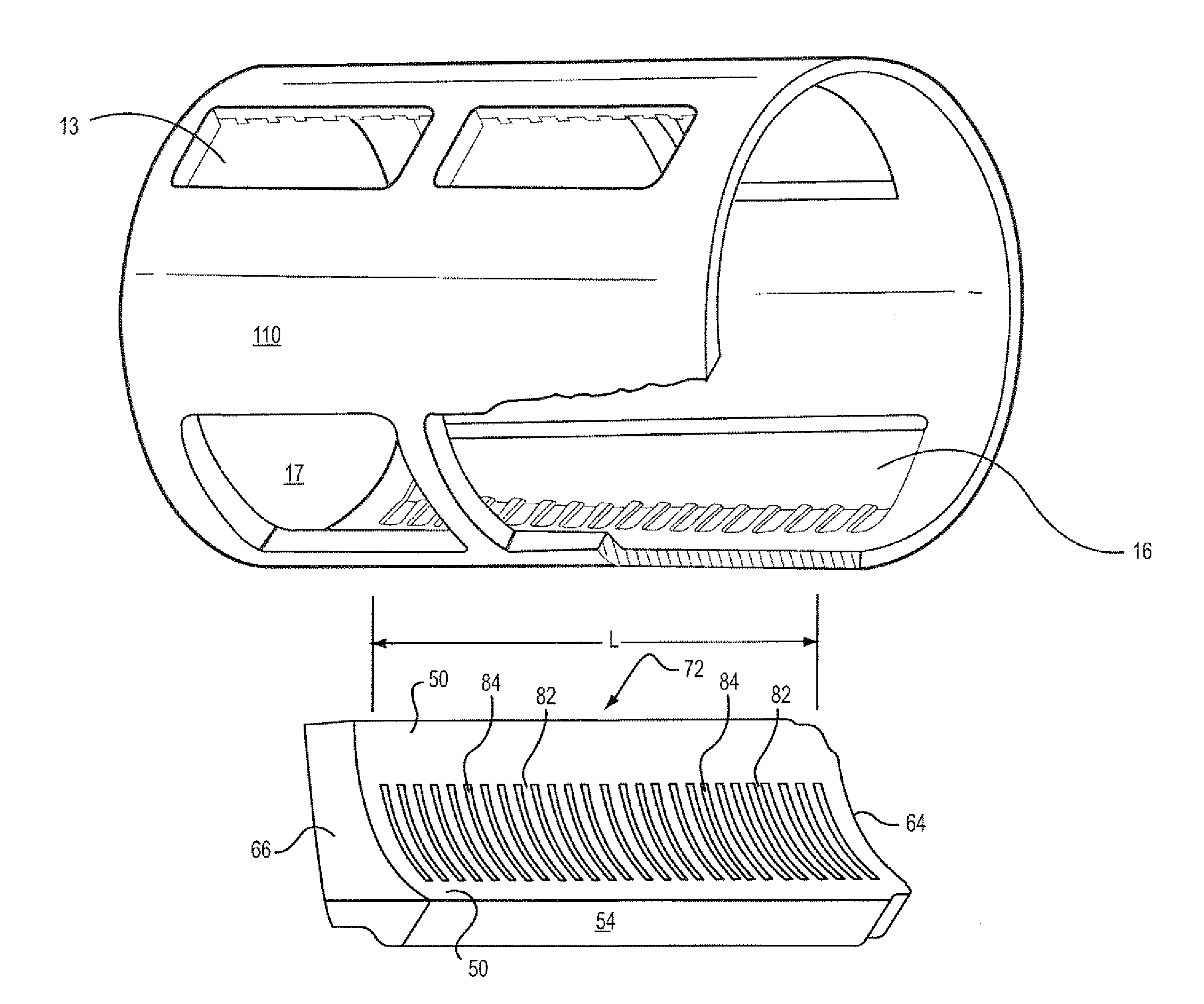

Unobstructed low pressure outlet and screen grid for a high pressure feeder

ActiveUS20100266351A1Easily flow through and outHigh trafficDigestersBulk conveyorsCellulose fiberEngineering

A rotary high pressure feeder for processing cellulosic fibrous material including: a rotor rotatable about an axis and comprising at least one pocket comprising a conduit extending through the rotor in a direction perpendicular to the axis and having end openings at opposite ends of the pocket, wherein each of said end openings of each pocket functions as both an inlet and outlet depending upon an angular position of the rotor within a housing; the housing encloses said rotor and said housing includes a low pressure inlet port and a low pressure outlet port aligned vertically, and a high pressure inlet port and a high pressure outlet port aligned horizontally, wherein the ports are arranged on the housing for registry with the end openings of at least one pocket, and a screen grid seated in or adjacent to the low pressure outlet port, wherein the screen grid includes an array of screen slots and bars forming a uniform pattern of slots and bars extending without interruption across an entirety of the low pressure outlet port.

Owner:ANDRITZ INC

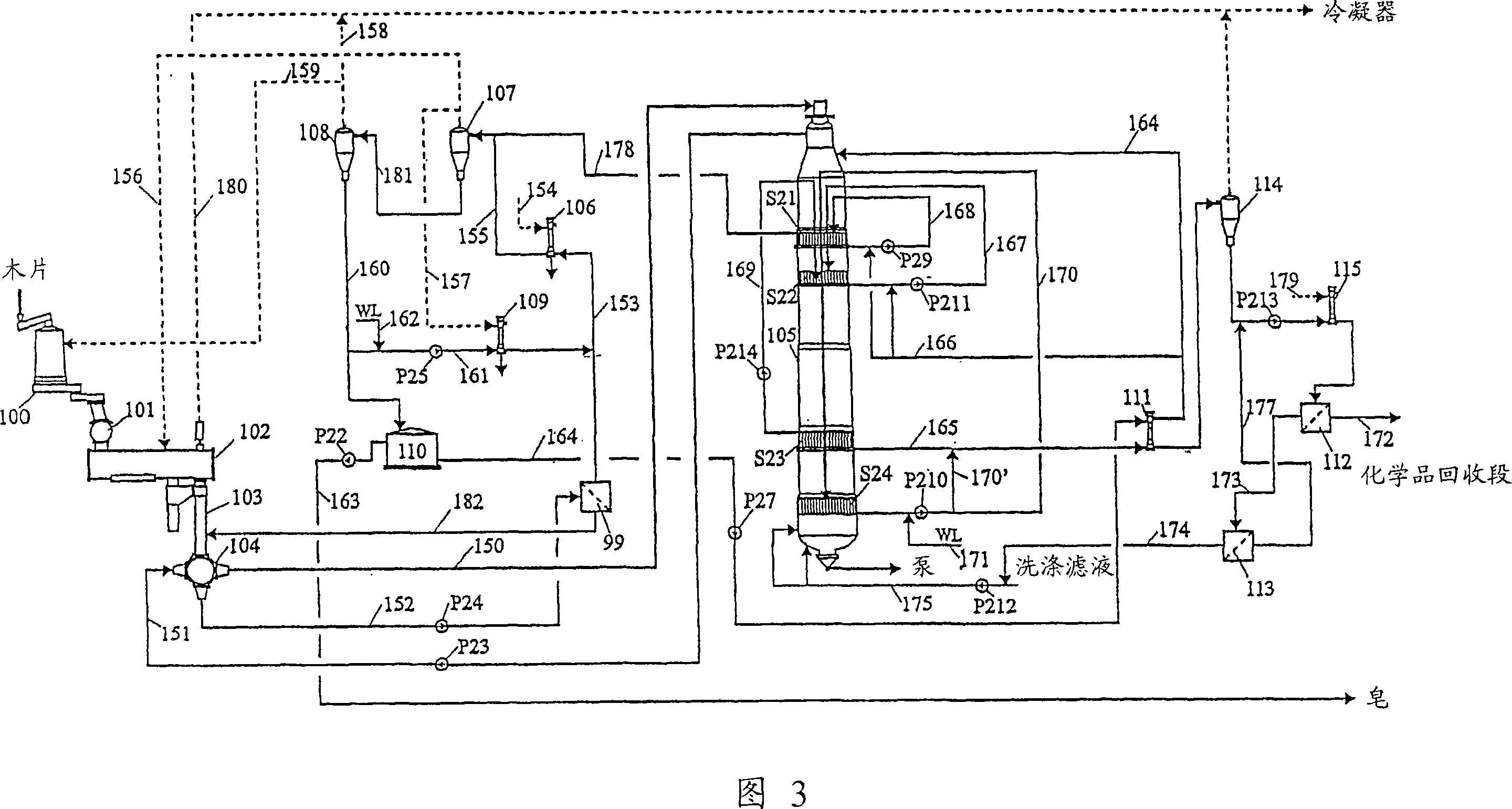

Alkaline process and system for producing pulp

InactiveCN101068977APretreatment with water/steamPretreatment with alkaline reacting compoundsCelluloseBlack liquor

A process and an apparatus for producing pulp from lignocellulosic material by an alkaline cooking process, in which process preheated chips are treated in an impregnation stage with impregnation liquor, which is taken from the impregnation stage, and concentrated to obtain both a high inorganic and organic dry solid content. The temperature is higher than in the heating of the chips and in the removal of air, and sufficient to enable the finishing of the reactions in the impregnation stage before the cooking stage. The majority of the alkali is added to the impregnation stage. In the cooking stage alkali is added to enable the delignification to be performed to a desired degree, and at the end of the cook black liquor is added to regulate the liquid-to-wood ratio. The process can be applied both to a continuous cook and to a batch cook.

Owner:METSO PAPER INC

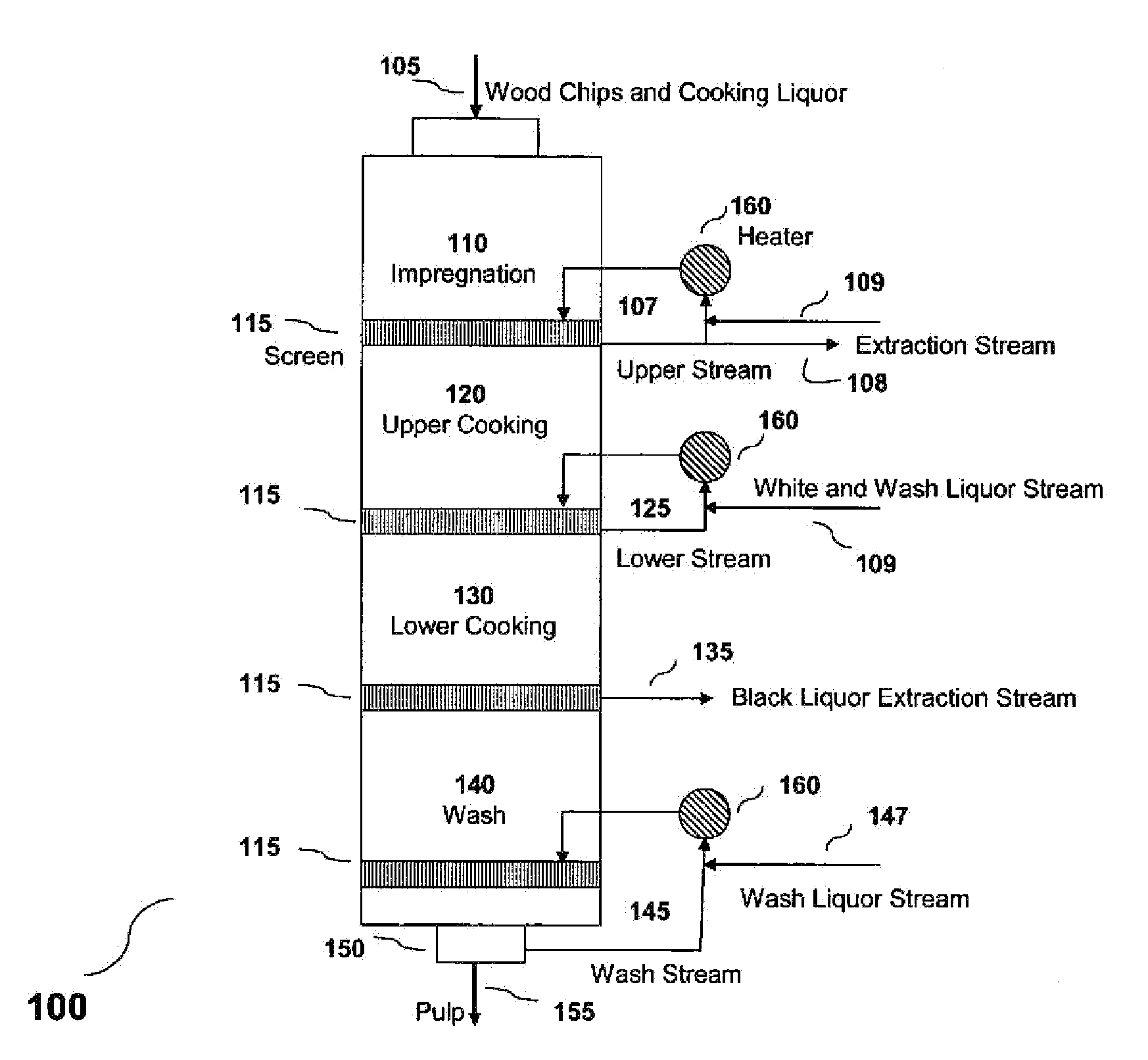

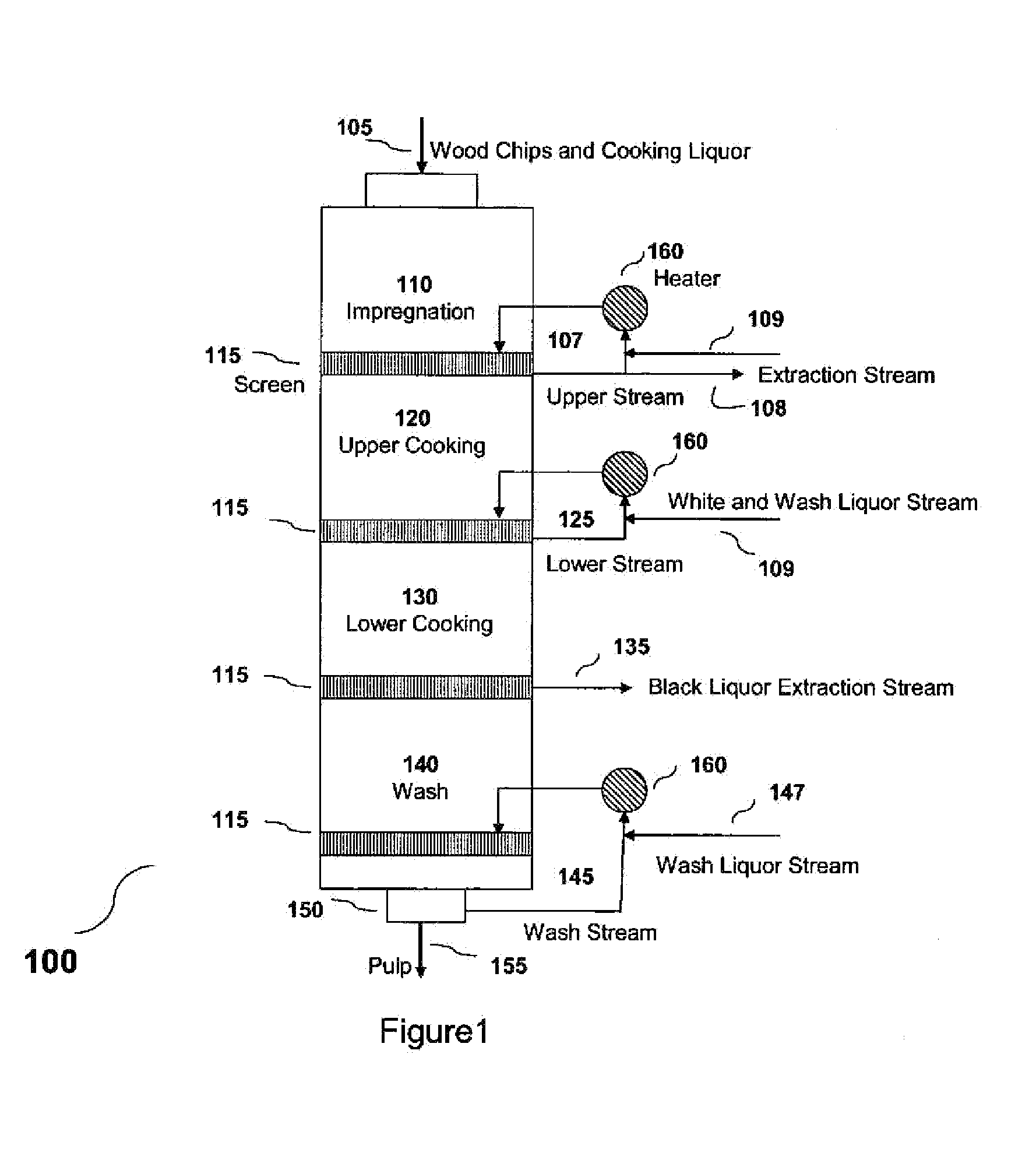

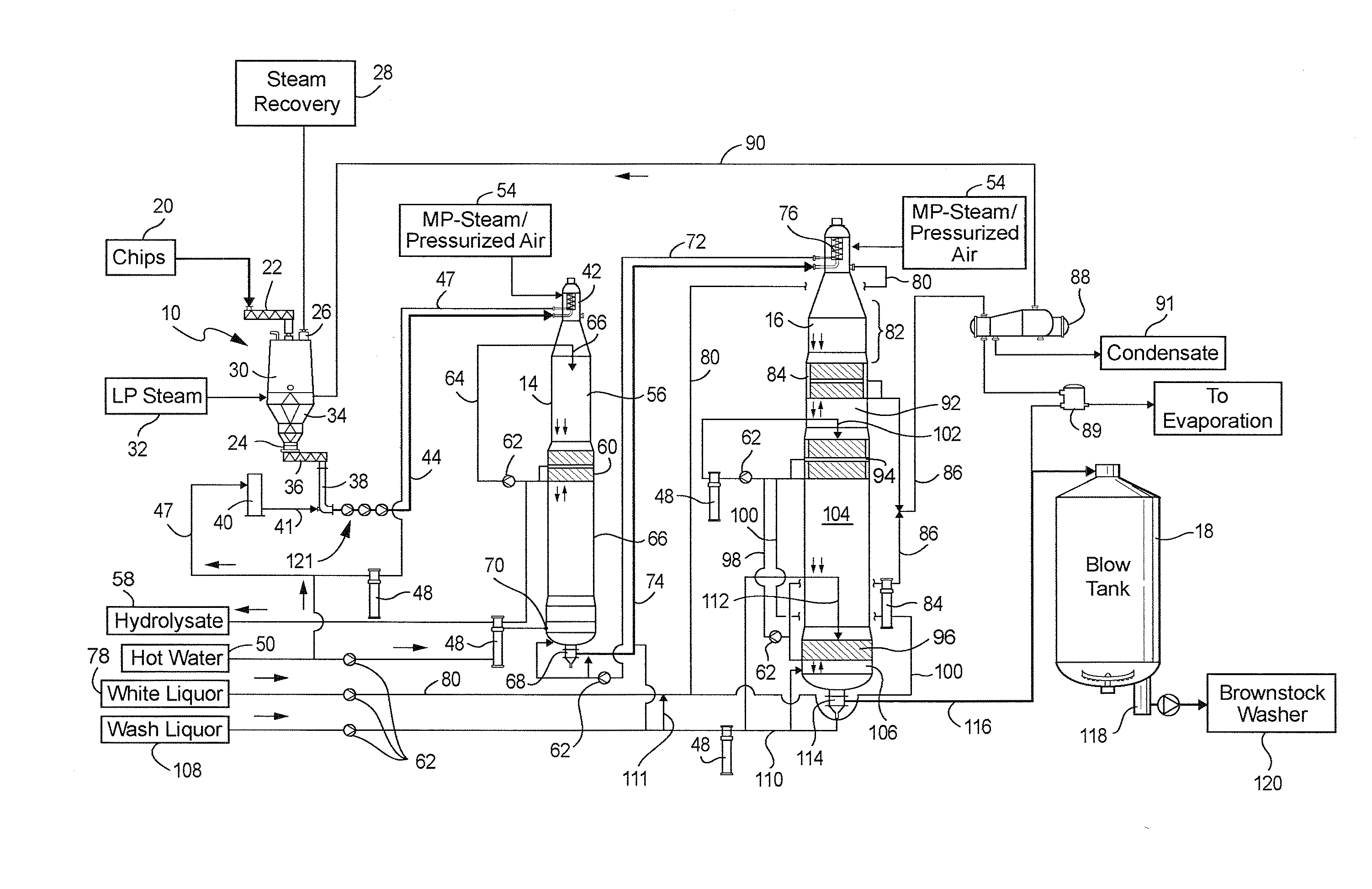

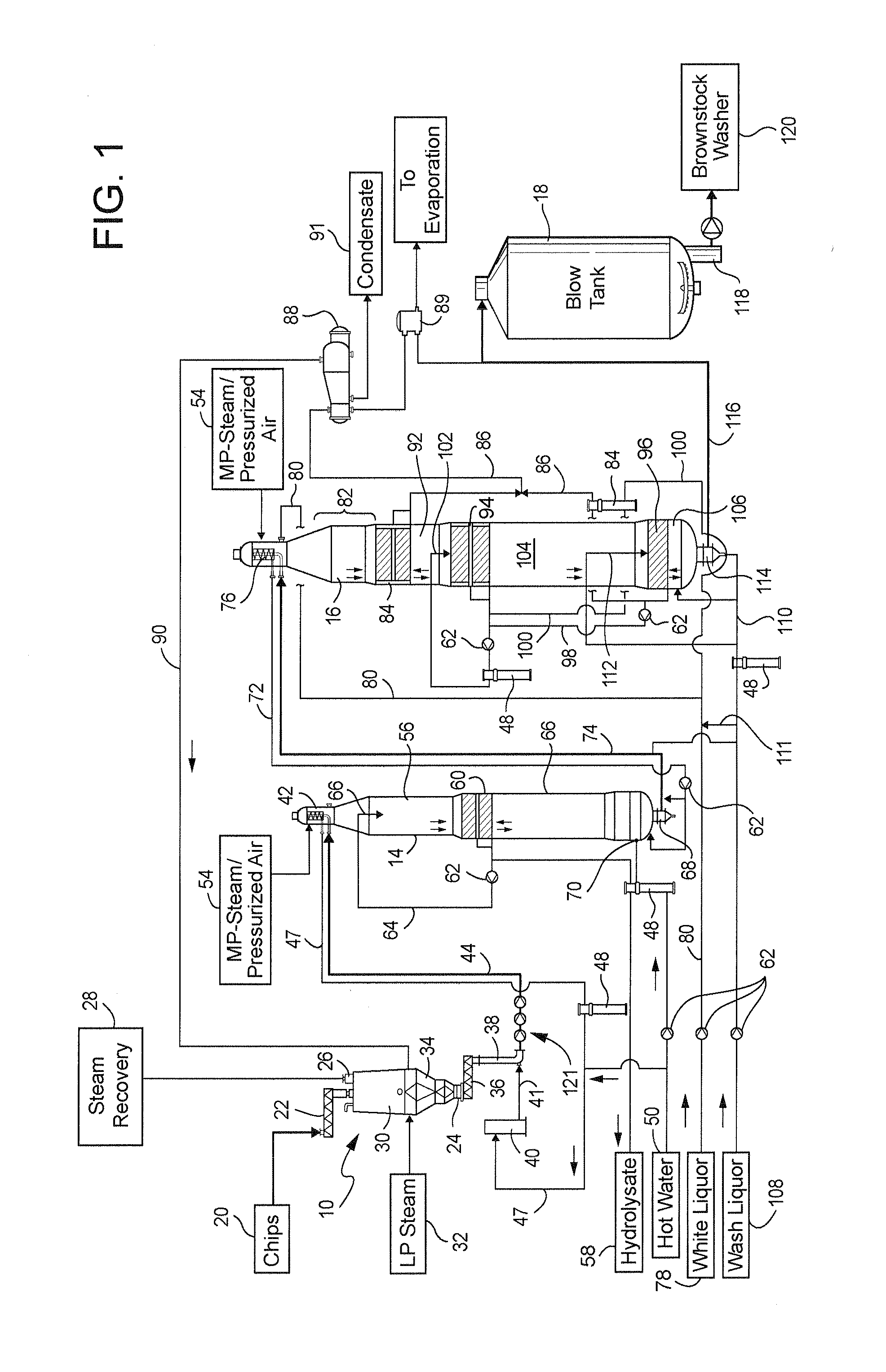

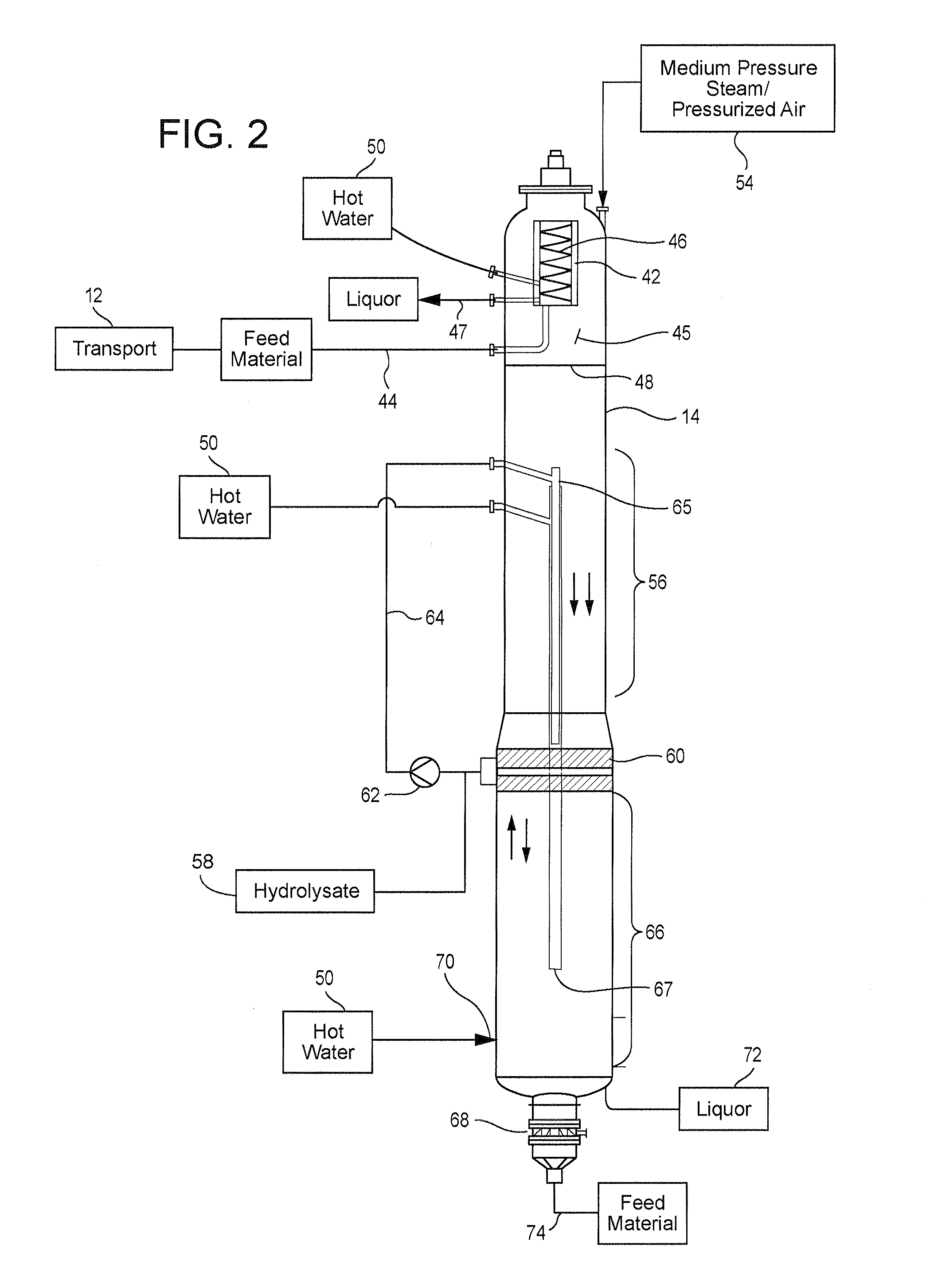

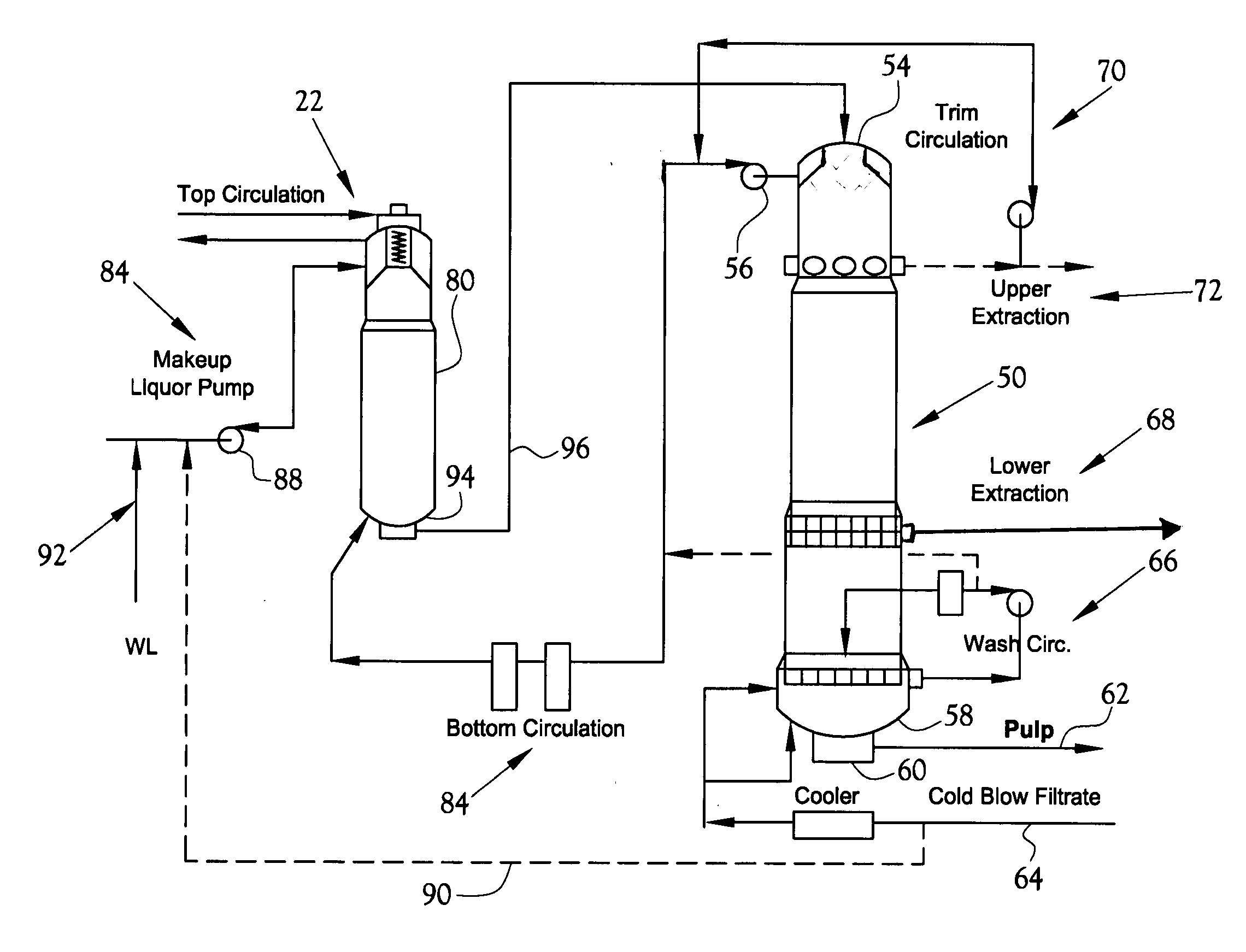

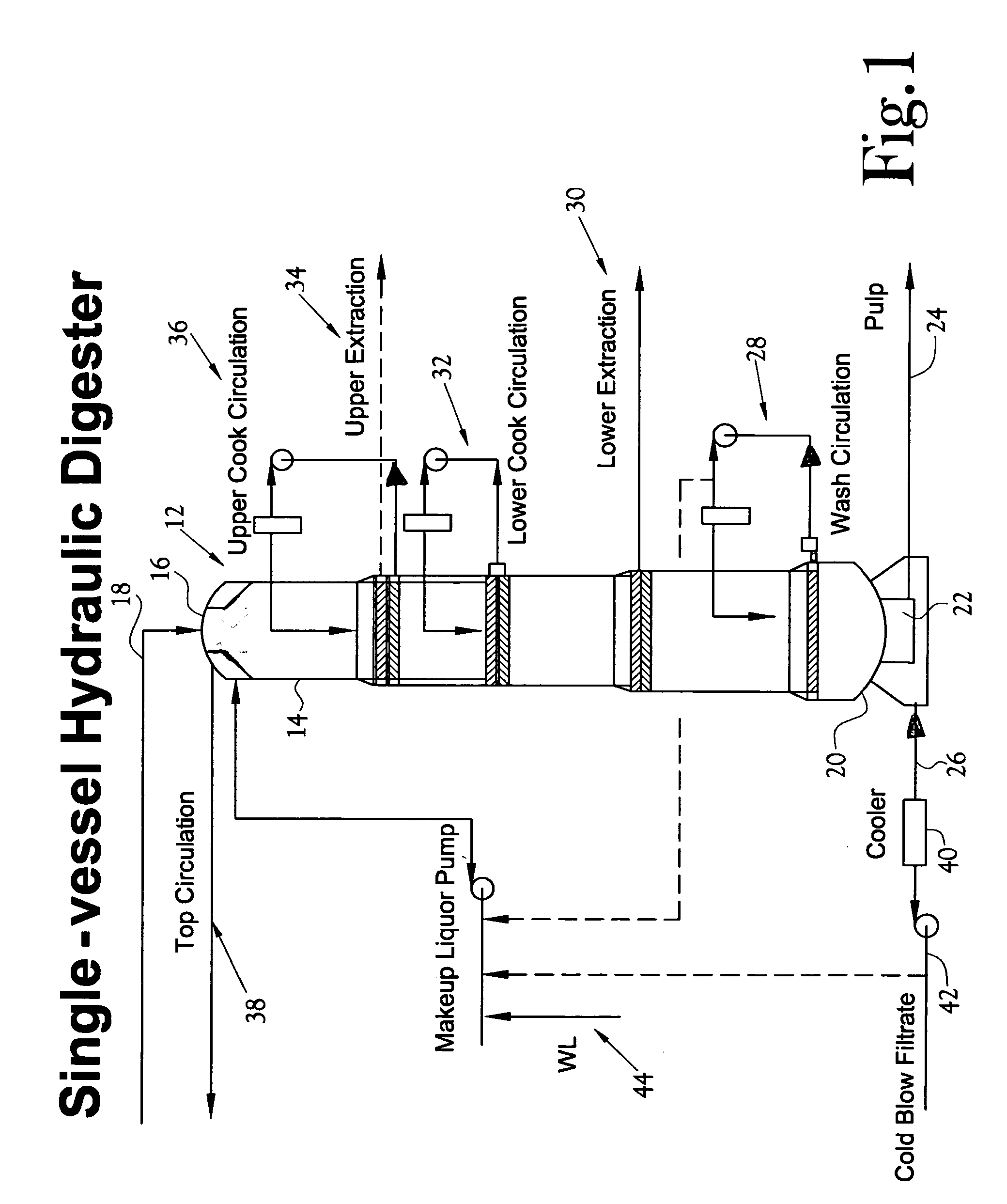

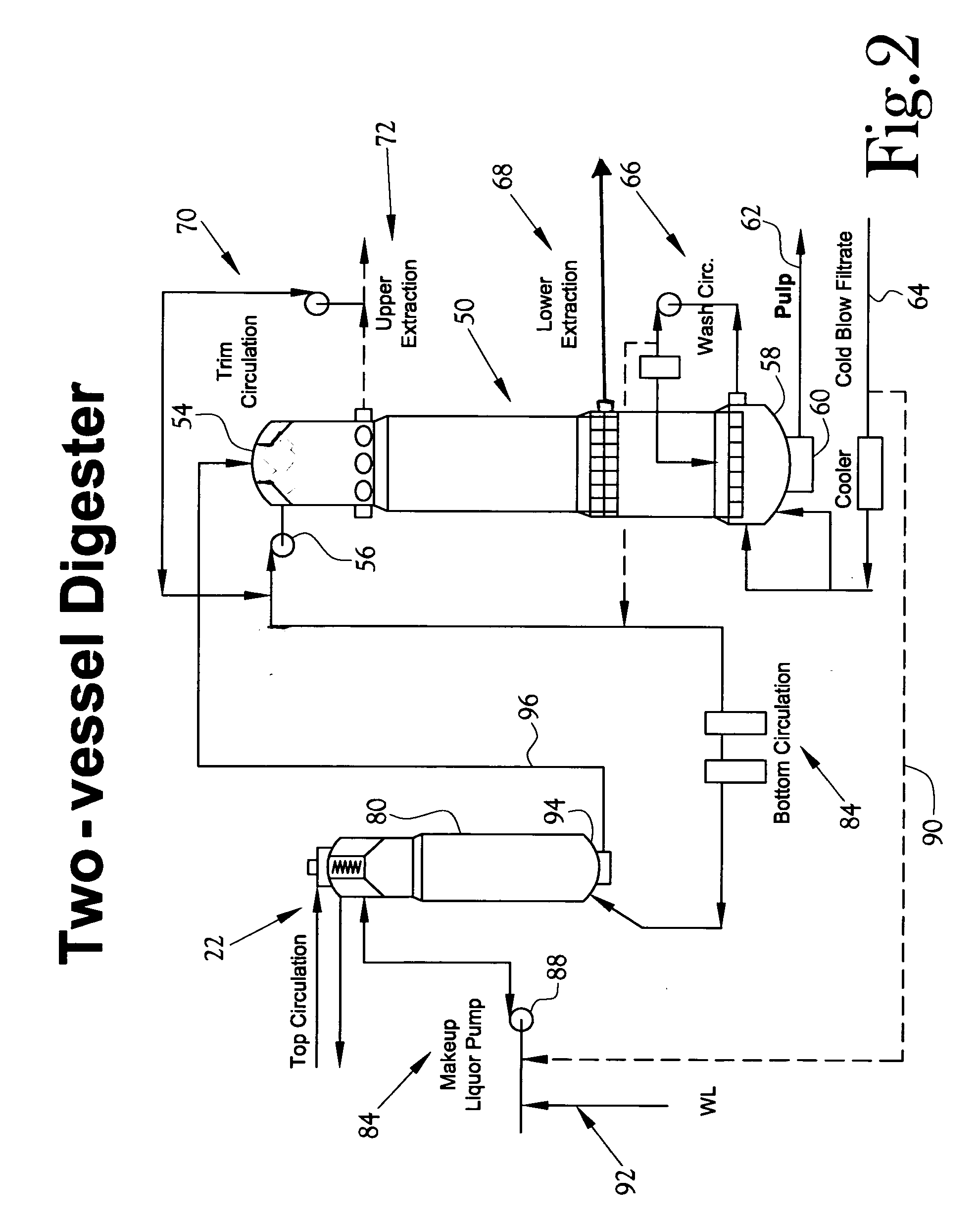

Method and apparatus to produce pulp using pre-hydrolysis and kraft cooking

ActiveUS20120211183A1Reduce buildEasy to controlWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsHydrolysateSulfate

A pulp cooking system including: a cellulosic material feed system, a pre-hydrolysis reactor vessel and a Kraft cooking reactor vessel. The feed material system includes a steaming chip bin and a high pressure transfer device. The pre-hydrolysis reactor vessel maintains the feed material in a mildly acidic condition and allows hydrolysate to be extracted through screens below a hydrolysis zone in the vessel. A wash zone is below the screens and allows wash liquid to flow through the feed material in a cross-current direction. The wash liquid and hydrolysate removed from the feed material is extracted through the screens. The feed material is maintained in a mildly acidic condition through the pre-hydrolysis reactor vessel until the material enters the Kraft cooking vessel where the feed material is treated with alkaline cooking liquors.

Owner:ANDRITZ INC

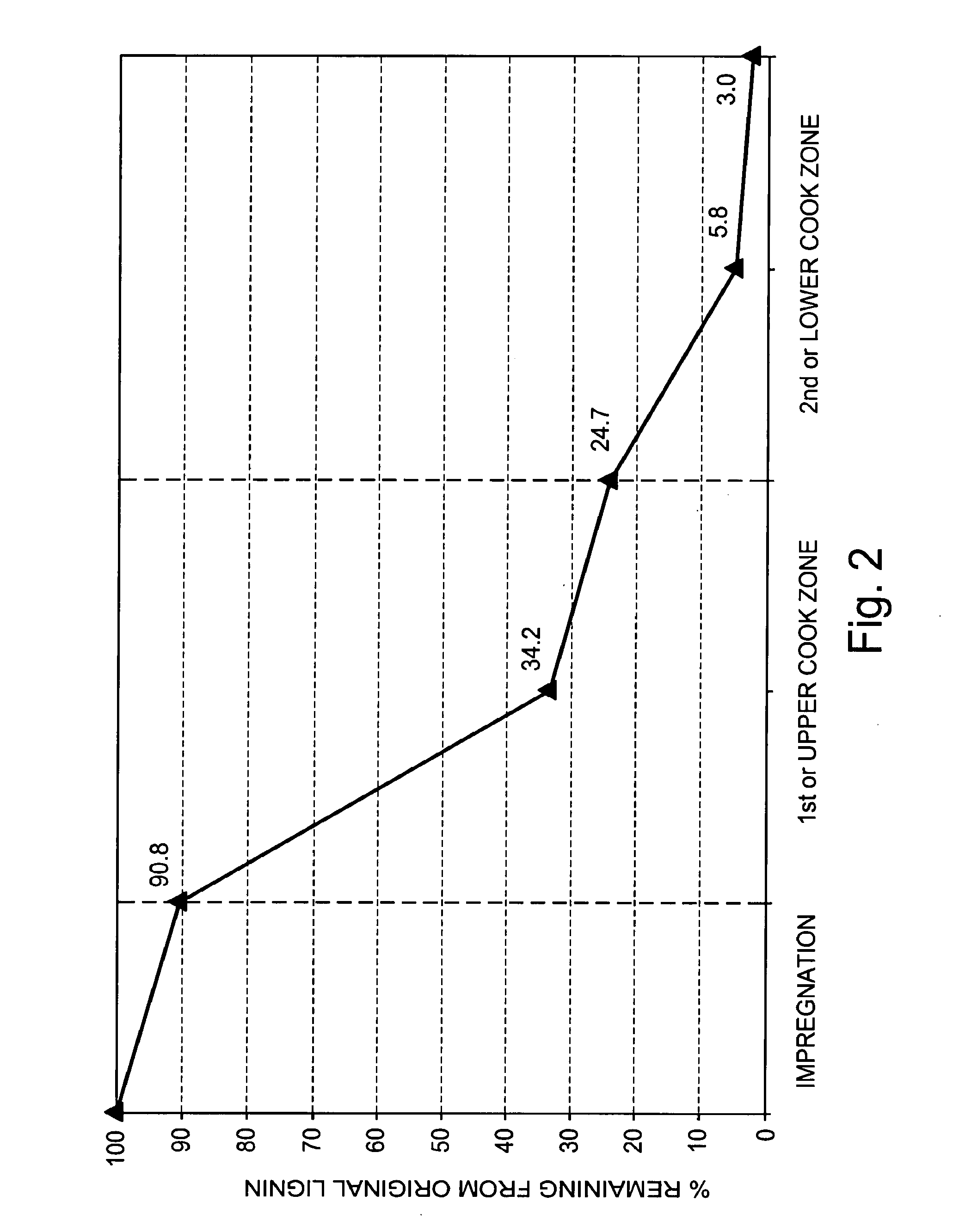

Hardwood alkaline pulping processes and systems

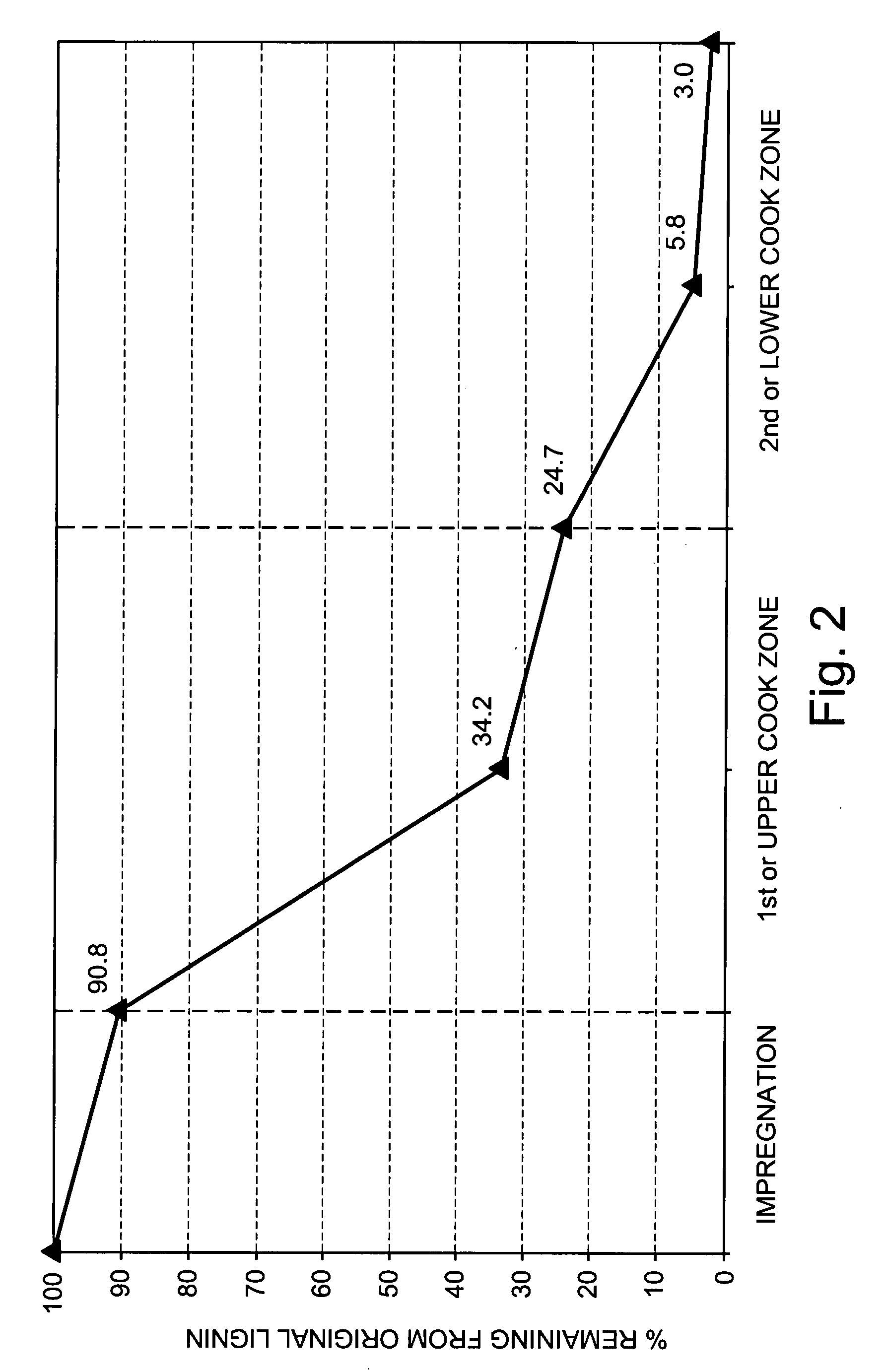

InactiveUS20070240837A1Reduce rejectionReduce percentagePretreatment with alkaline reacting compoundsPretreatment with acid reacting compoundsKappa numberWaste product

Hardwood pulp rejects at a given Kappa number can be reduced by subjecting the hardwood pulp to specified cooking conditions at the end of cooking. In this regard, it has been discovered that s-lignin reacts faster than g-lignin and that there exists a higher proportion of g-lignin at the end of a hardwood cook as compared to the g-lignin present at the beginning of the cook. Thus, when cooking hardwoods, relatively harsher cooking conditions (e.g., higher cooking temperatures) at the end of the cooking have been discovered to decrease the g-lignin content which in turn decreases the percentage of pulp rejects at a given Kappa number. In preferred embodiments, methods and systems are provided for continuously producing chemical cellulose pulp from a slurry of comminuted hardwood material by subjecting the slurry of comminuted hardwood material to a first cooking stage under conditions sufficient to reduce syringyl lignin (s-lignin) content in the hardwood material as compared to guaiacyl lignin (g-lignin) content therein, and thereafter subjecting the slurry of comminuted hardwood material to a second cooking stage under conditions sufficient to reduce the g-lignin content remaining therein after the first cooking stage.

Owner:ANDRITZ INC

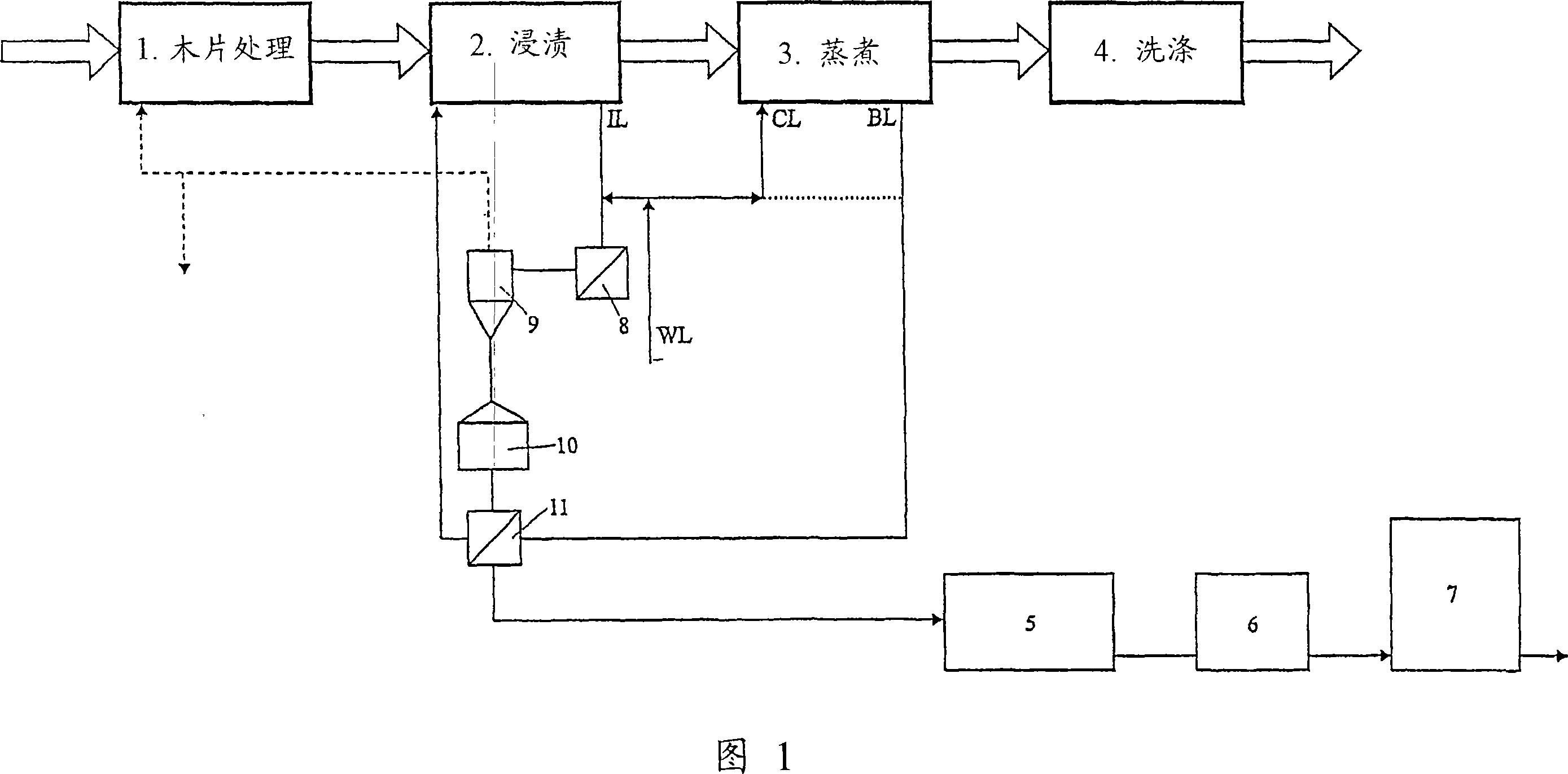

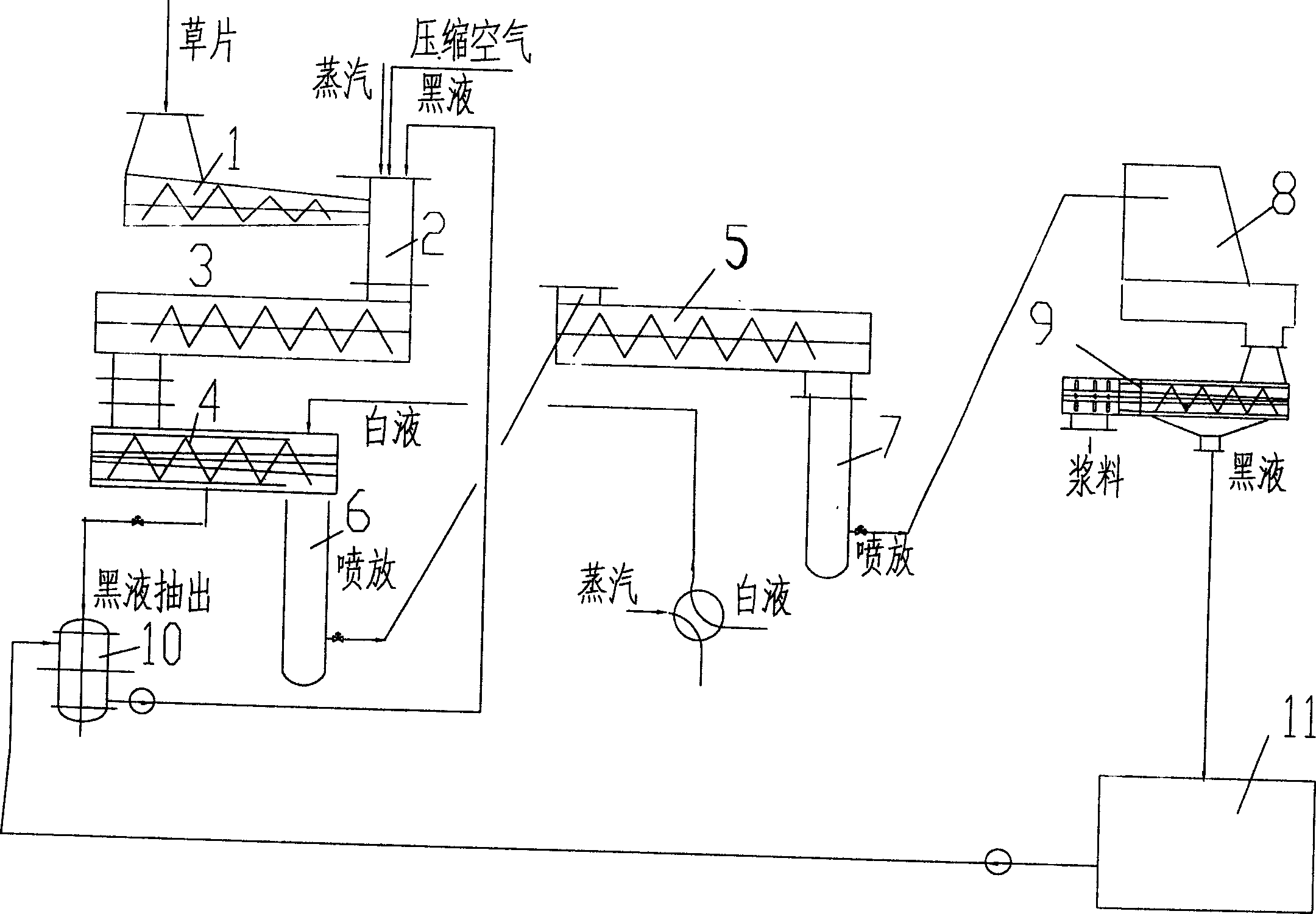

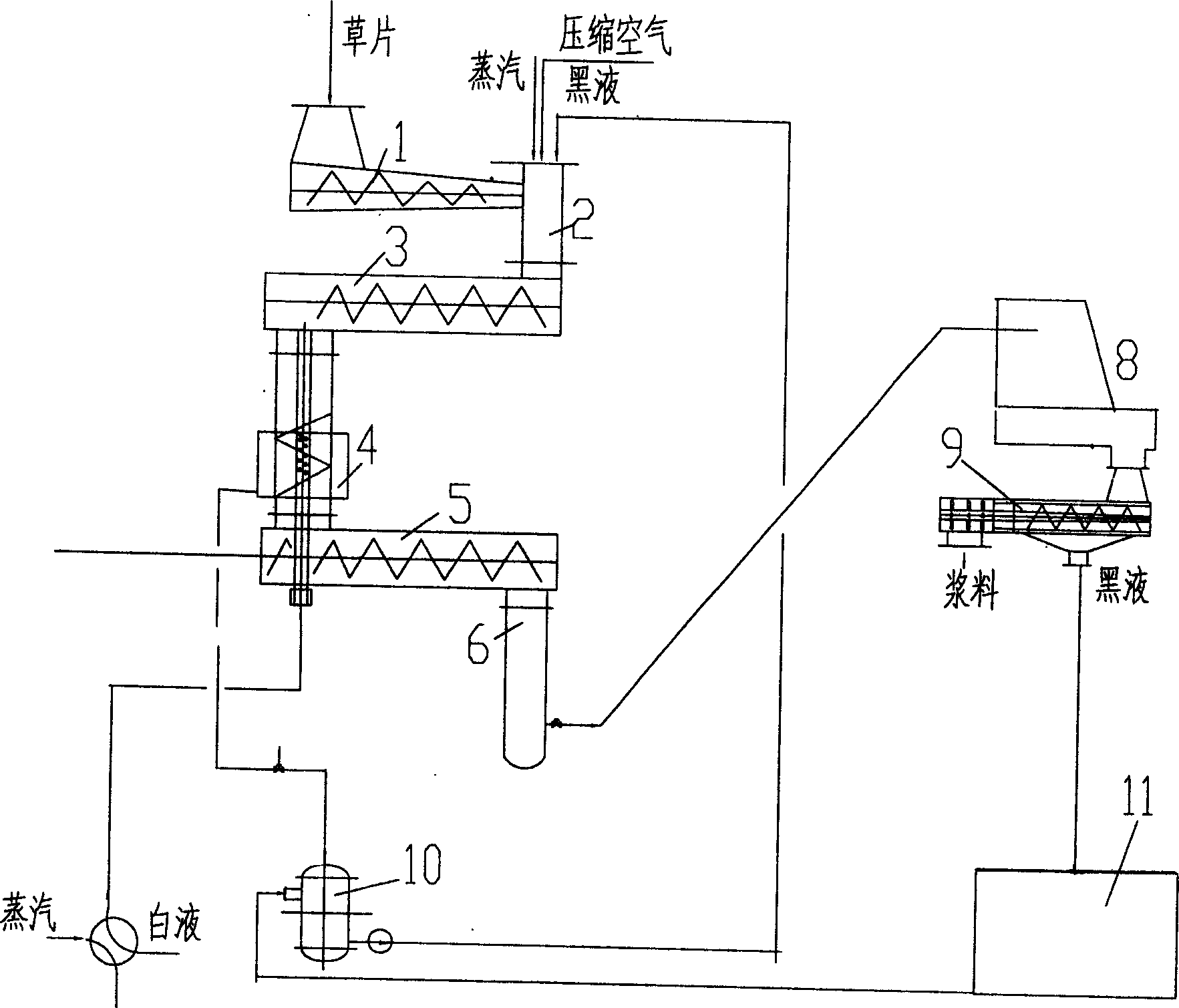

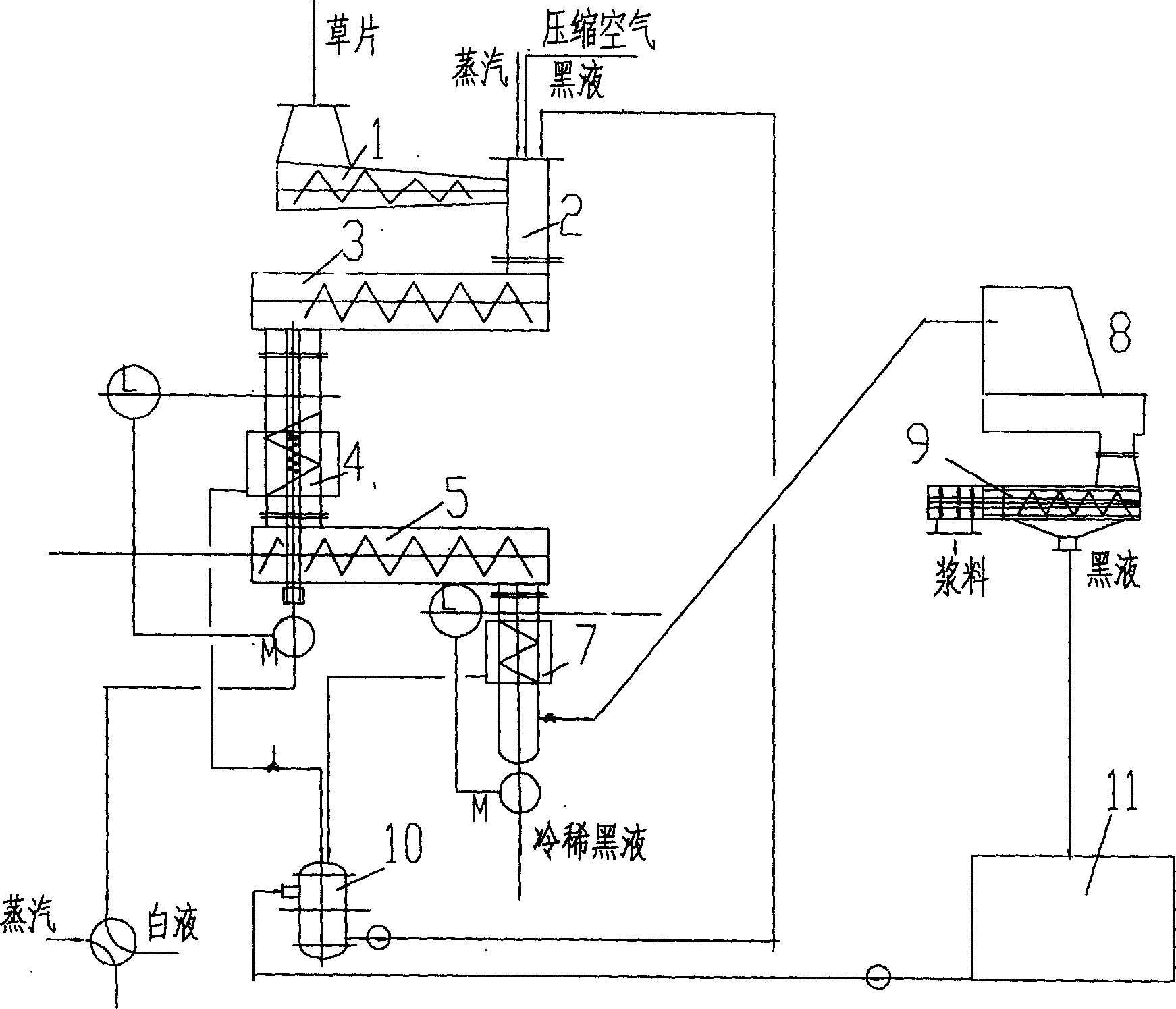

Non-wood fibre displacement, continuous boiling method and apparatus therefor

InactiveCN1566521AQuality improvementHigh hardnessContinuous pulping processNon-woody plant/crop pulpBlack liquorWood fibre

The invention provides a displacement and continuous cooking method for non-wood fiber and device thereof. The method combines the displacement cooking technology with the transverse tube continuous cooking technology, can improve the pulp quality, hardness and bleaching property, and the black liquor can be recycled. Especially, the method has low energy consumption, protects the environment.

Owner:王广维

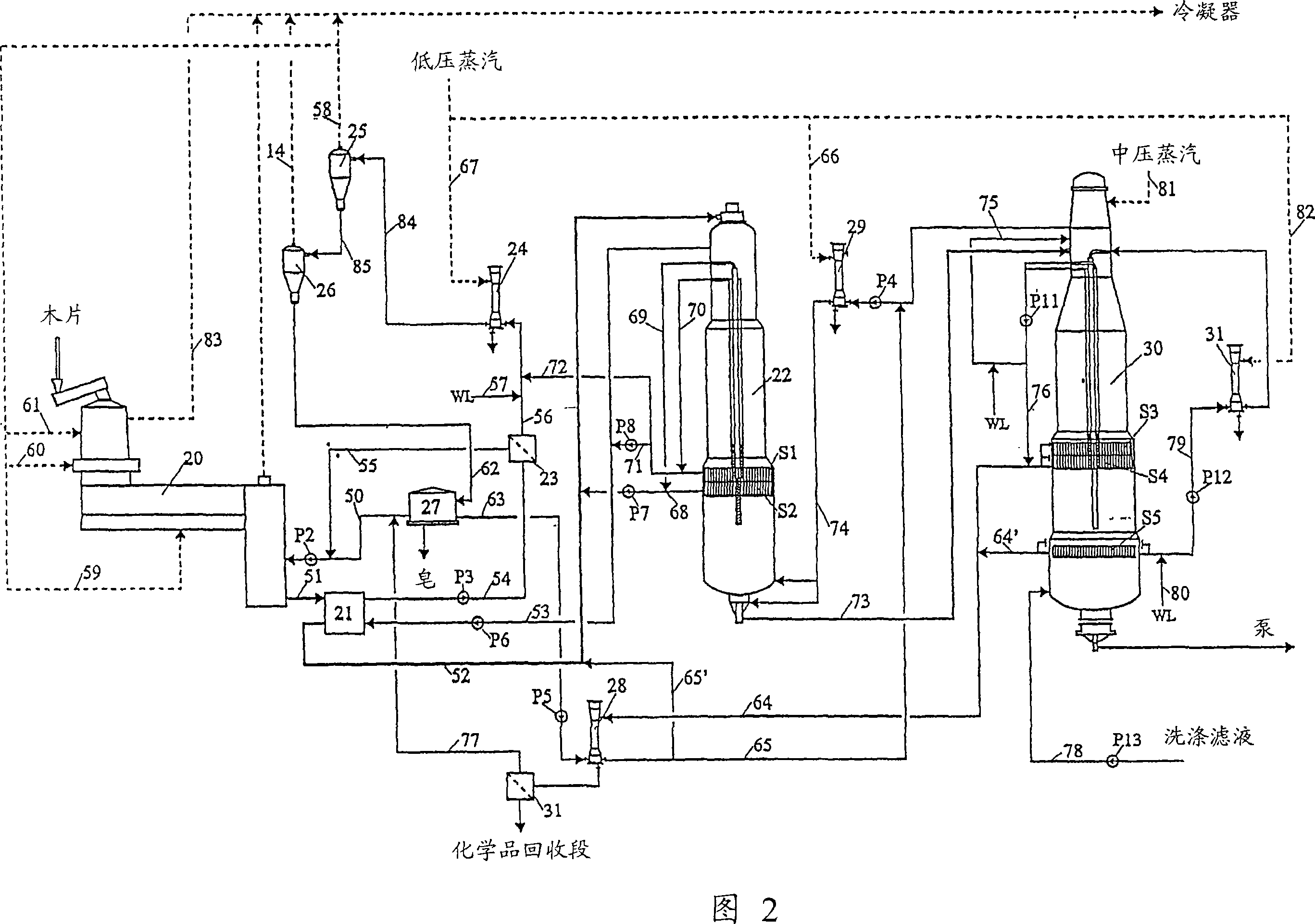

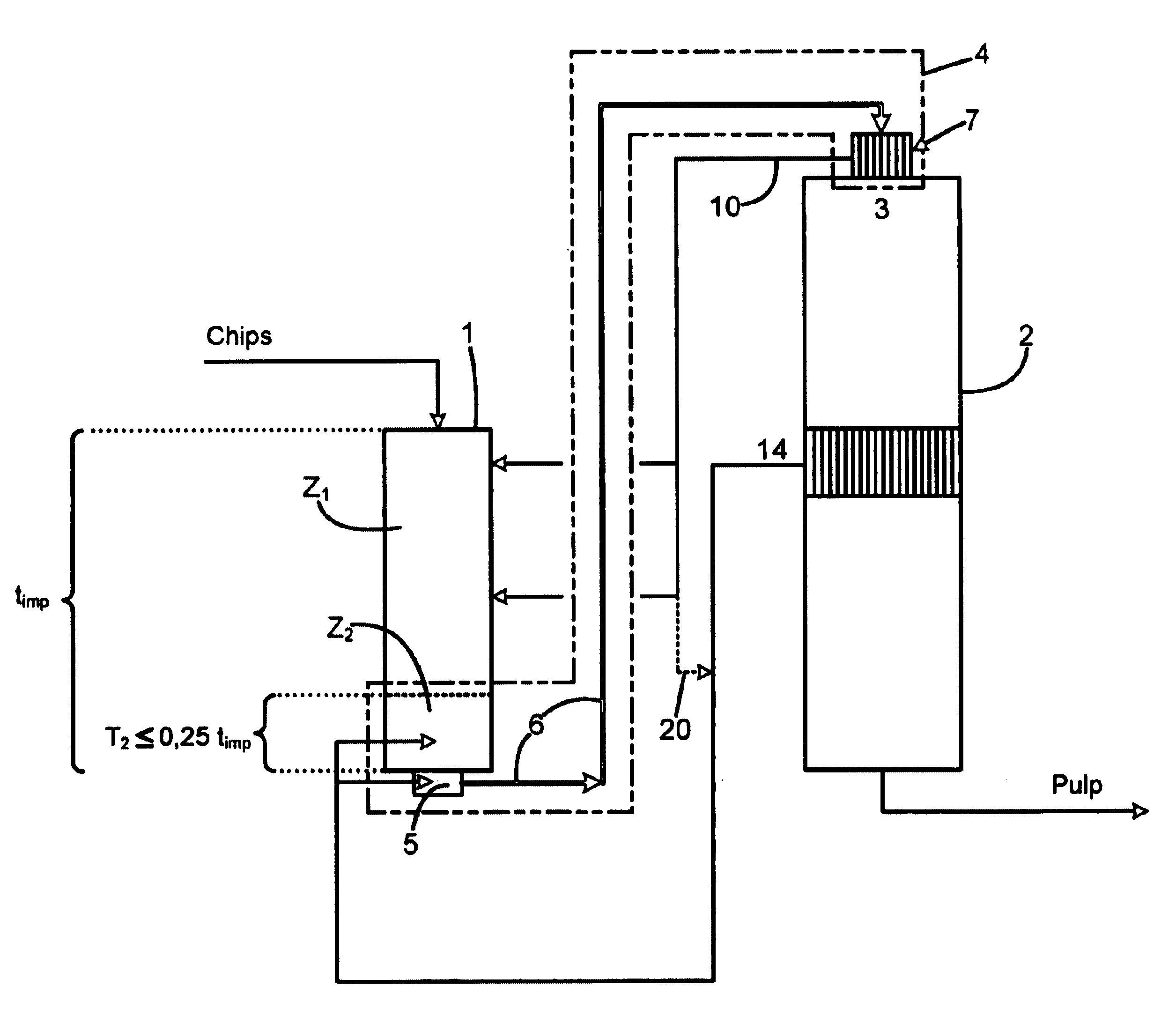

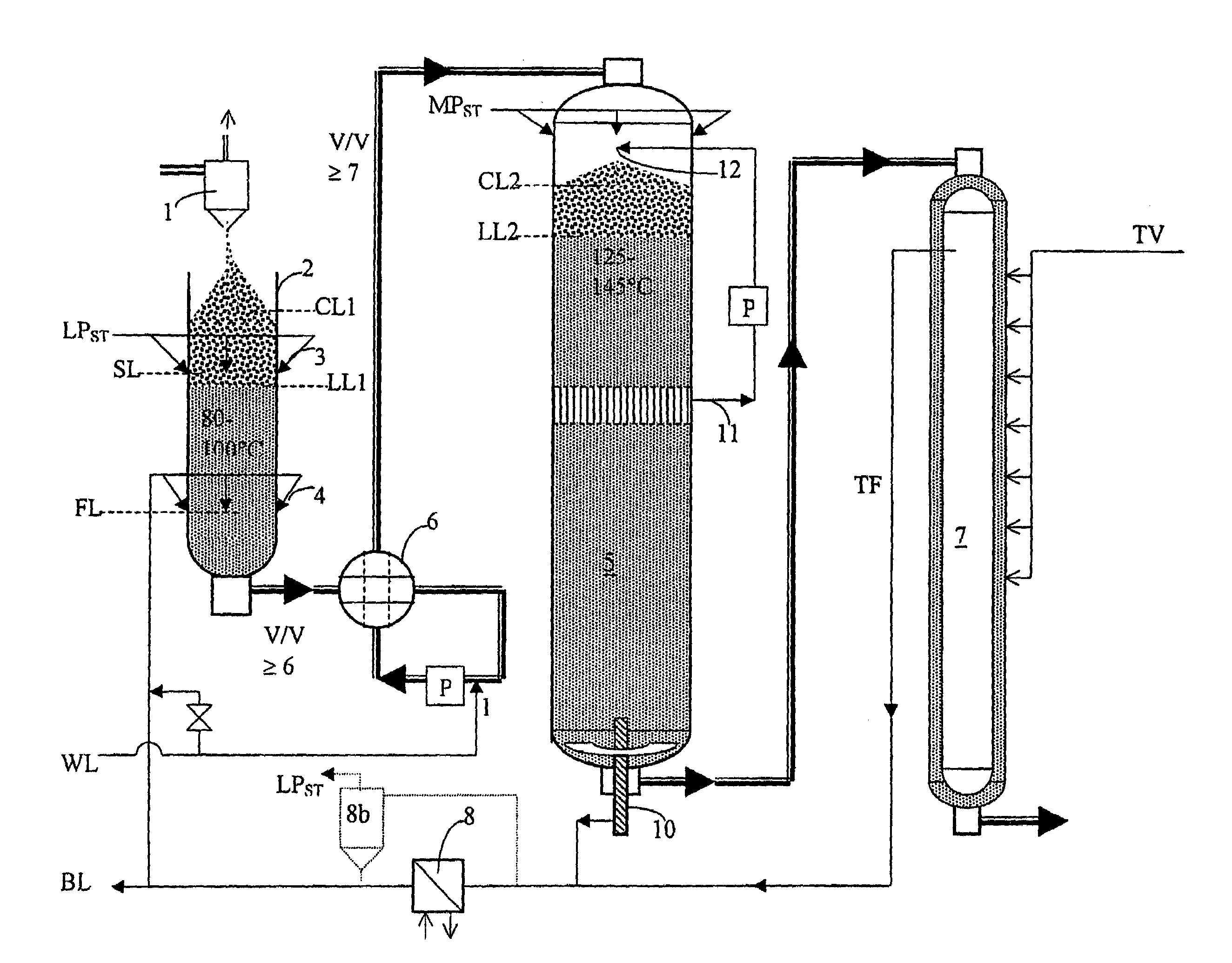

Method for continuous cooking of chemical pulp to improve heat economy

ActiveUS7112256B2Reduces and eliminates requirementImprove thermal economyDigestersPulp bleachingCelluloseBlack liquor

A method for the continuous cooking of chemical pulp with the aim of achieving improved heat economy in a digester system having a vessel (1) for impregnation and a vessel (2) for cooking the impregnated cellulose chips. A part of the black liquor (14) withdrawn from the digester (2) is added at the beginning of a transfer system (4) to increase the temperature of the chips mixture in the transfer system (4). A fraction of the transport fluid (10) from the transfer system (4) that is continuously withdrawn from the impregnated chips fed into the top of the digester is returned to the impregnation vessel (1) at essentially the maintained transfer temperature.

Owner:METABO PAPER SWEDEN

Methods for removing hemicellulose

A method for treating a cellulosic material comprising extracting the cellulosic material with an extractant to selectively extract hemicellulose therein and separating the extracted hemicellulose to form a cellulosic product comprising less hemicellulose than the cellulosic material. The extractant comprises an amine oxide and a non-solvent. The cellulosic product retains the cellulosic fiber morphology.

Owner:CELANESE INT CORP

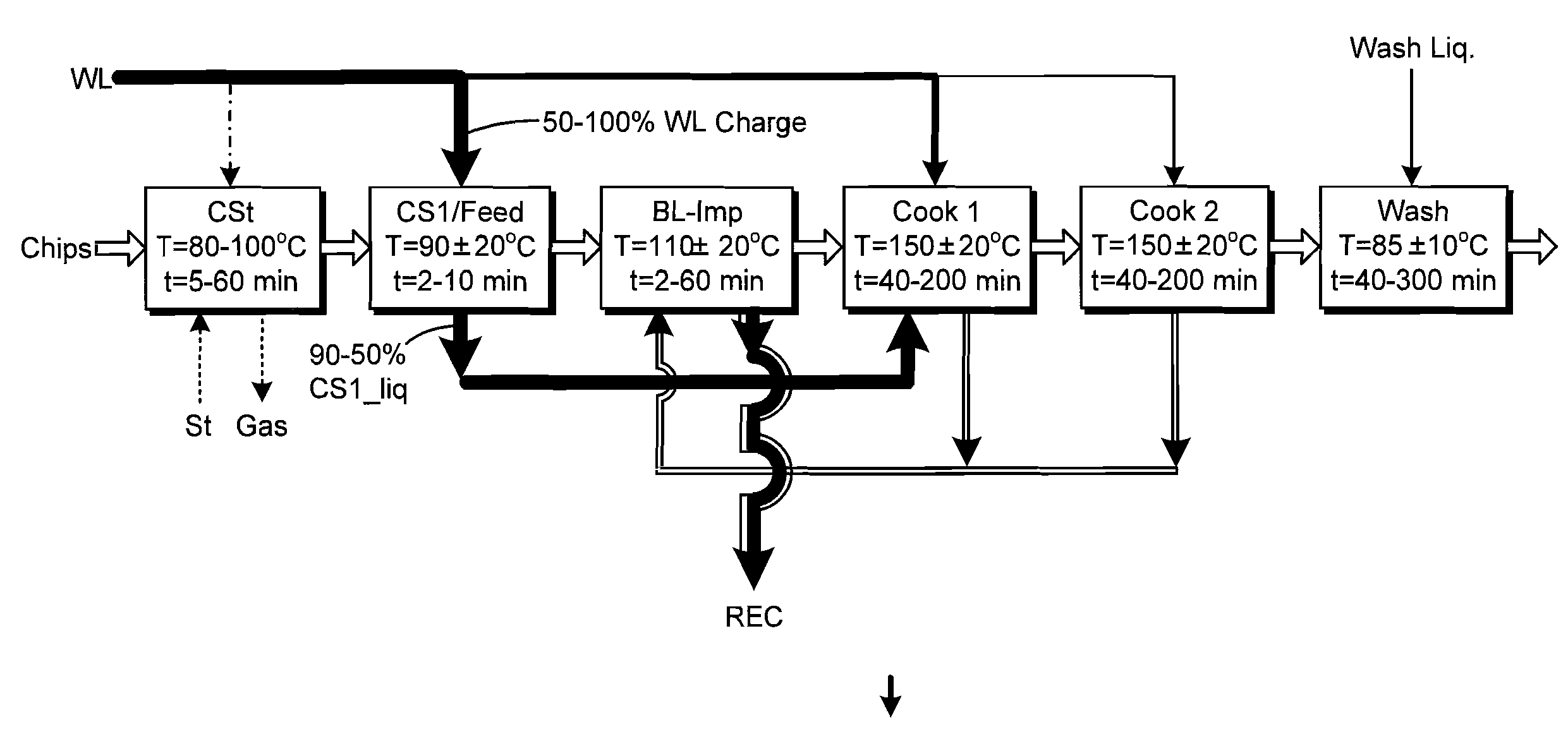

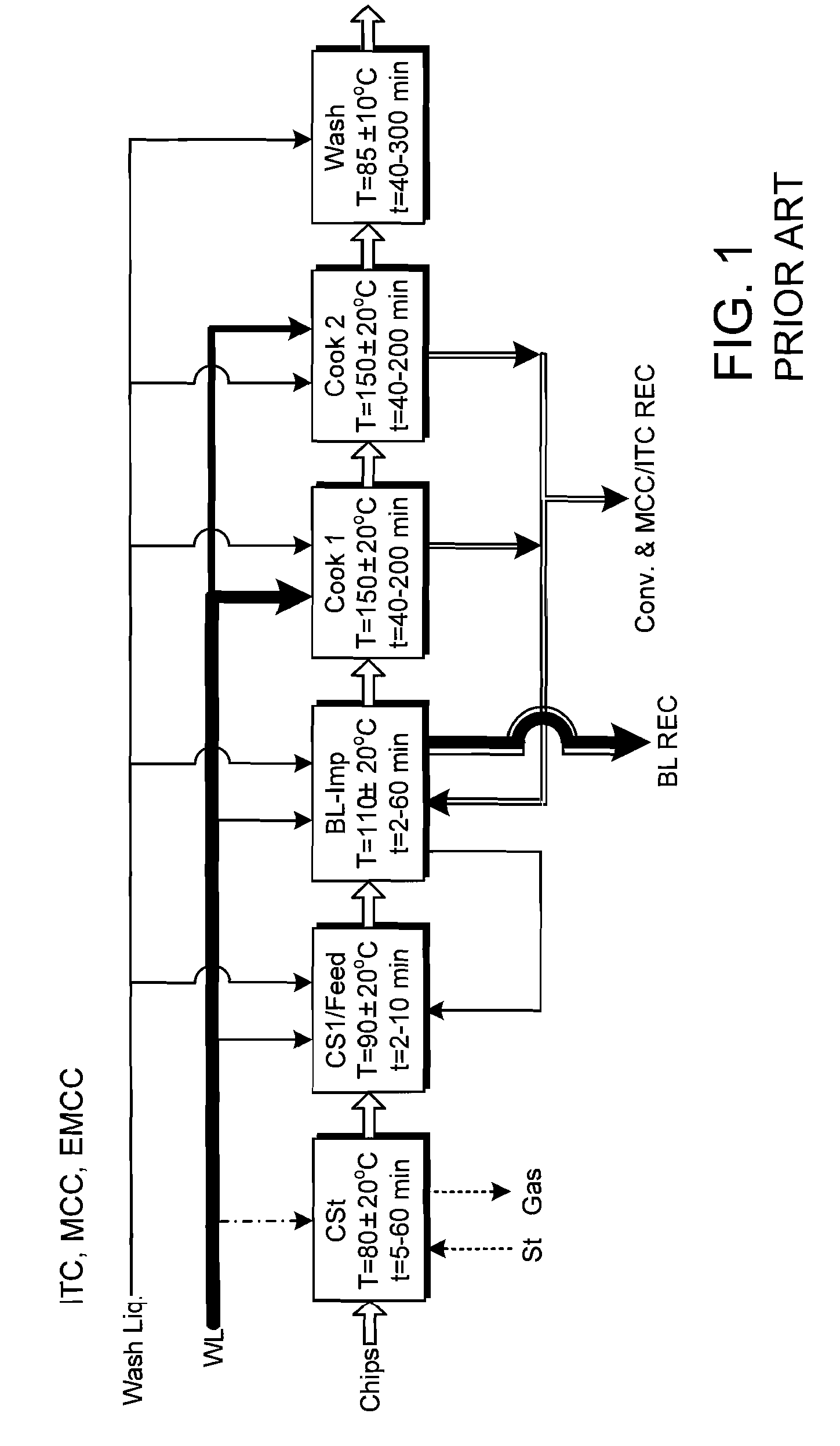

Pretreatment of chips with white liquor prior to a treatment with black liquor

The method is for the manufacture of cooked cellulose pulp in which the starting material, preferably chips, undergoes a successive increase in temperature towards cooking temperature. This is done while the chips are first treated in a pre-treatment zone in which the main part, greater than 50%, of fresh white liquor necessary for the cooking stage is added, after which this alkali-rich treatment fluid is withdrawn and replaced to a major extent by black liquor. The alkali-rich treatment fluid that has been withdrawn after the pre-treatment stage is then added to the cooking stage, which is why the addition of fresh white liquor to the cooking stage is reduced to an equivalent amount. Maximal yield-enhancing effect is obtained using poly-sulphide-rich white liquor during the pre-treatment at a temperature in the interval 60±40° C. and retention time in the interval 2-60 minutes, preferably 2-10 minutes.

Owner:METABO PAPER SWEDEN

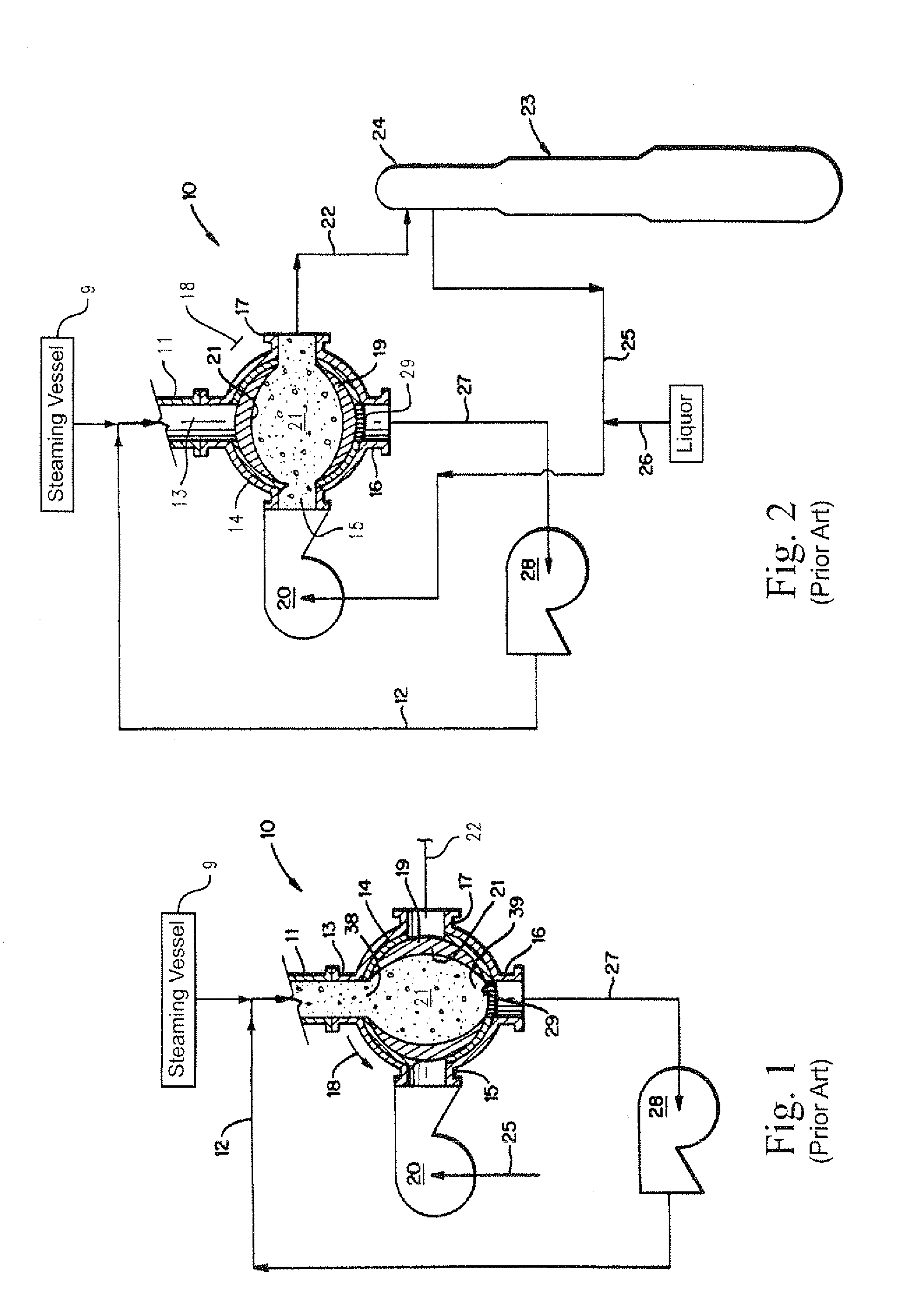

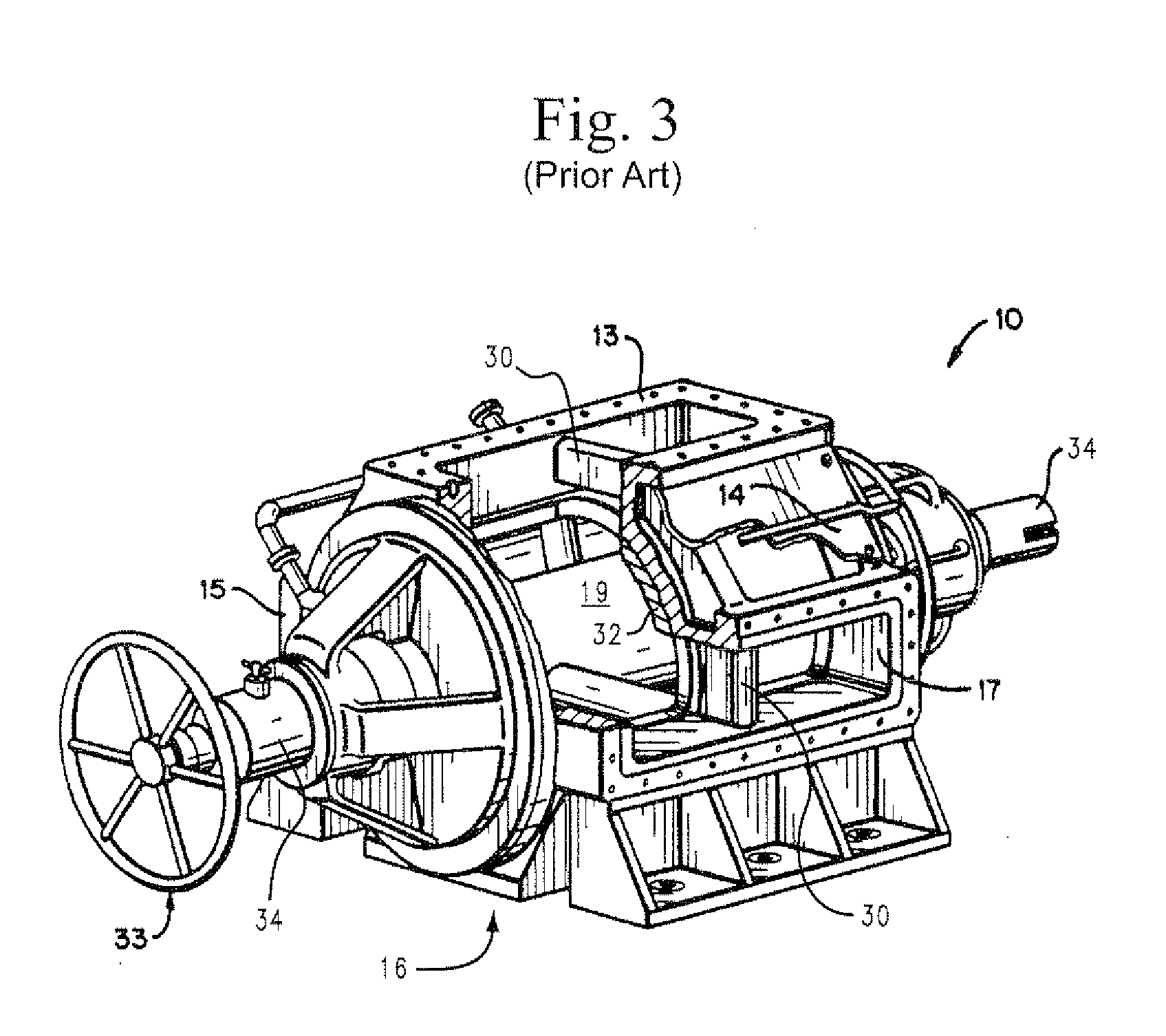

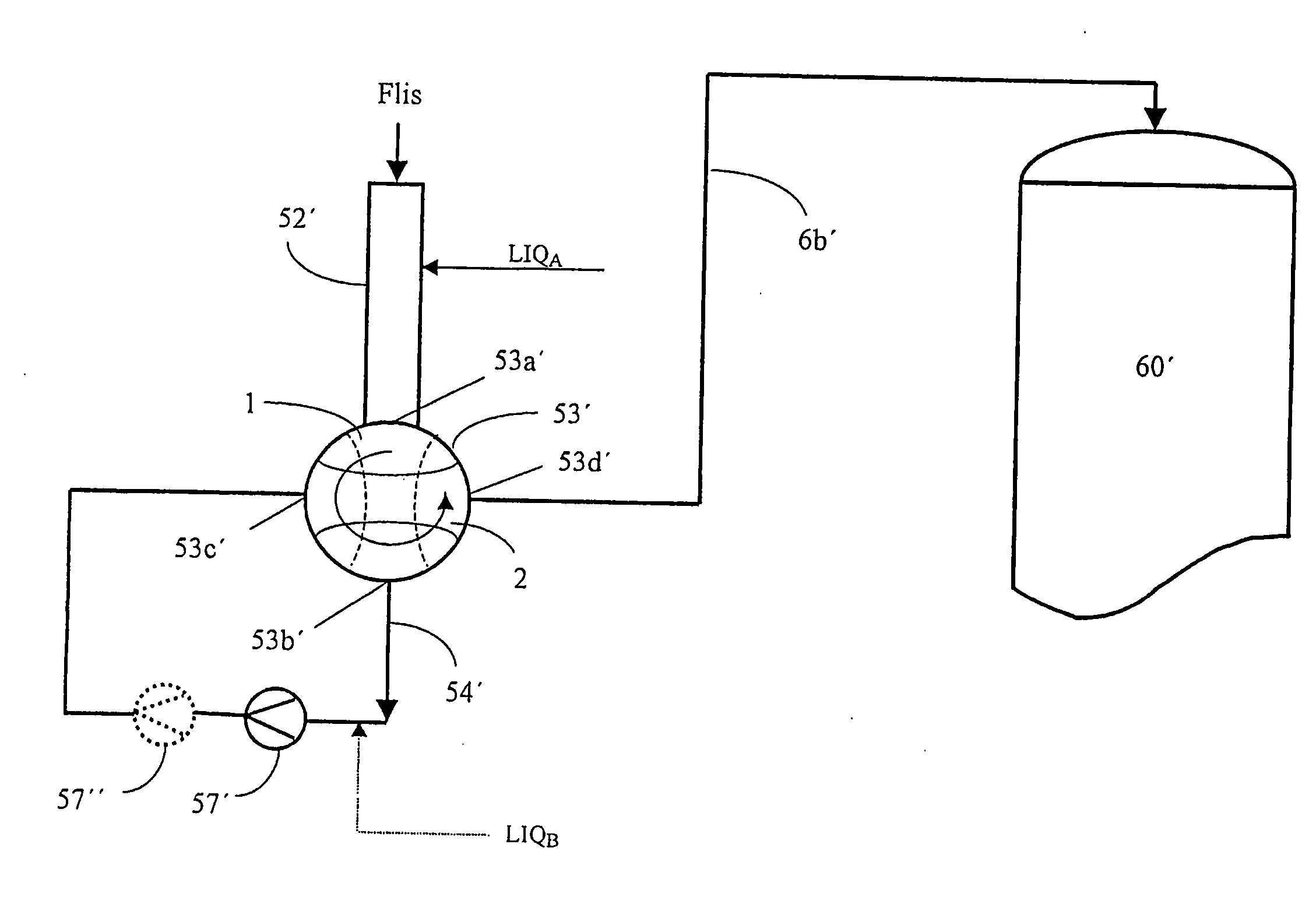

Method for the feed of cellulose chips during the continuous cooking of cellulose

The method is for feeding a chips-slurry from a low-pressure to a high-pressure system during the continuous cooking of chemical cellulose pulp. The feed takes place through a sluice feeder 53′ between these systems. The sluice feeder is provided with a rotor with through-pockets 1, 2 that are alternately connected with the low- or the high-pressure system. A recirculation line 54′, that has a high-pressure pump 57′, extends from the first outlet 53b′ of the sluice feeder to the second inlet 53c′ of the sluice feeder for transporting the fluid that has been expelled from the pockets of the sluice feeder when these are located in their first position. The fluid expels the chips mixture from the pockets of the sluice feeder in their second position and is essentially exclusively constituted by the fluid that has been expelled from the pockets in their first position.

Owner:METABO PAPER SWEDEN

Method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste

ActiveCN102704300AIncrease profitImprove overall utilizationWashing/displacing pulp-treating liquorsContinuous pulping processFiberWaste material

The invention discloses a method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste, which includes procedures of material treatment, impregnation, defibrination, washing and concentration. Impurities in the filter stick waste are eliminated, and the filter stick waste is cut off into particles of 1-150 mm; the particles are impregnated by 4-10 times of water for 5-30 minutes under 70-100 degree C; inorganic base with weight being 0.5%-6% of dry weight of the particles is added into the impregnation liquid, so that the chemical concentration of the impregnation liquid is 0.25g-3g / L; the pulp liquid is concentrated to 10%-30%, and then pan-grinding defibrination is performed; and finally, the pulp liquid is washed and concentrated to 20-30%, so that the paper pulp used for wet process papermaking cigarette filter stick filter material can be obtained. The method disclosed by the invention has low treatment requirement for the impurities in the raw material, dispenses with molding paper stripping procedure, uses no toxic solvent, has high paper pulp yield, is excellent in fiber evenness, has centralized length distribution and uniform pulp, has no paper fragments and fiber beams, has excellent dispersion property, and is very suitable for making the filter stick core paper.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

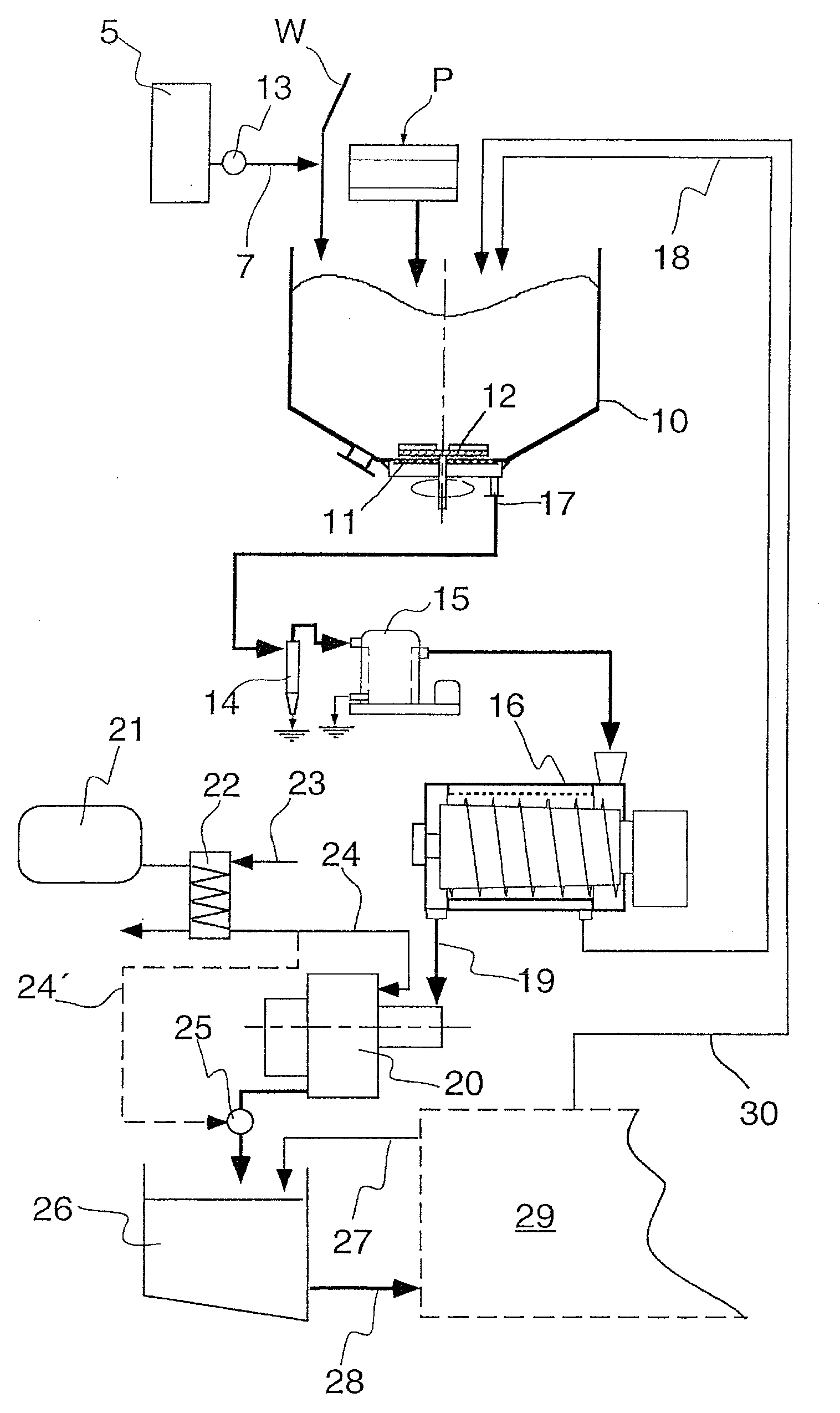

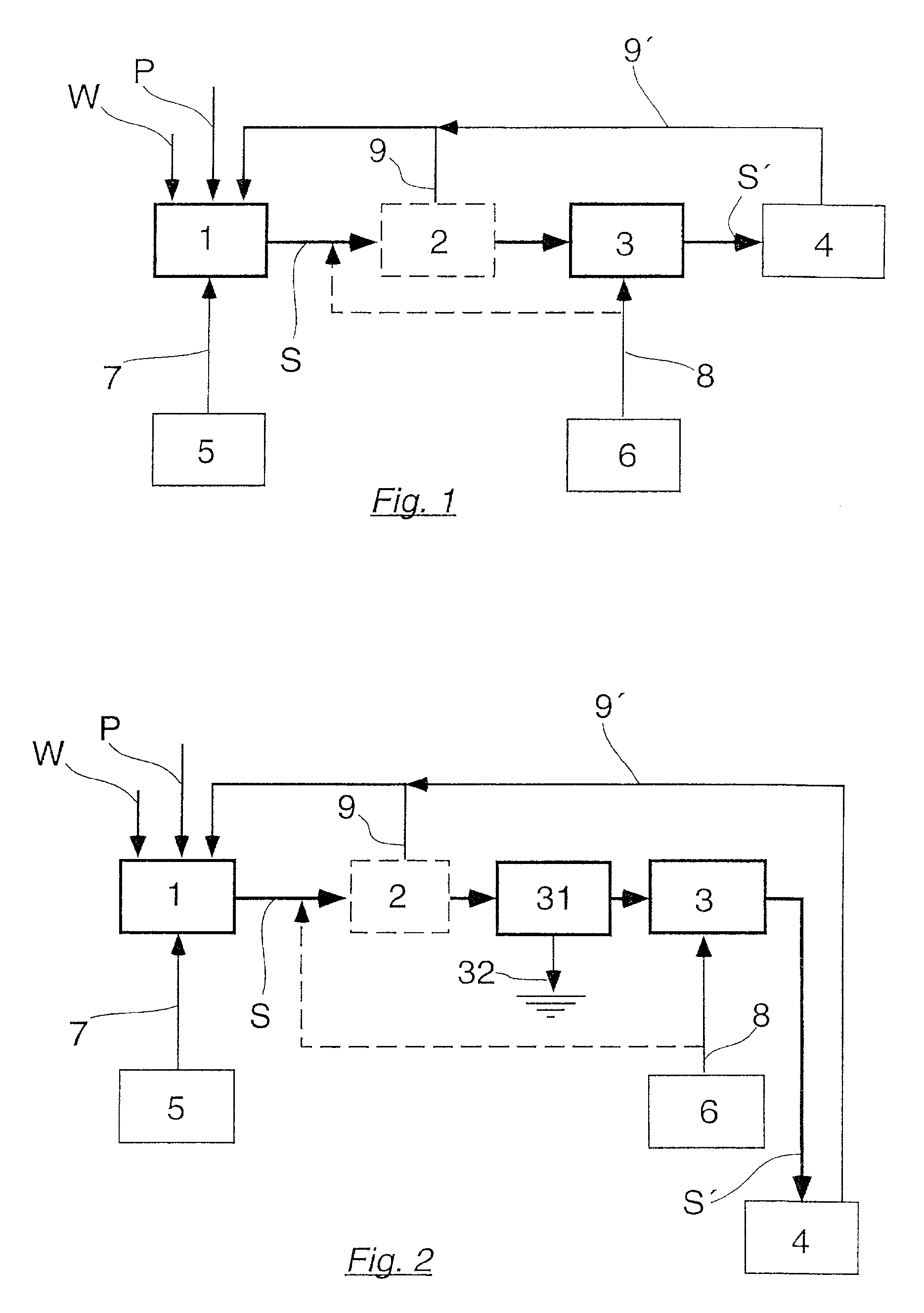

Method and a device for preparing cellulose pulp

InactiveUS20060070710A1Reduce the cooking temperatureImprove economyPulp liquors combustionPretreatment with alkaline reacting compoundsBlack liquorPulp mill

A method and an apparatus for preparing cellulose pulp, in which a lignin-containing raw material is impregnated with impregnation liquor and the impregnated raw material is cooked. The black liquor obtained by cooking is concentrated in an evaporation plant integrated in a chemical recovery plant. In the impregnation, the lignin-containing raw material is impregnated with a circulating alkaline impregnating liquor, which impregnating liquor is concentrated by evaporating water from it in at least one evaporator unit of the evaporation plant arranged in the chemical recovery plant of a pulp mill.

Owner:VALMET TECH INC

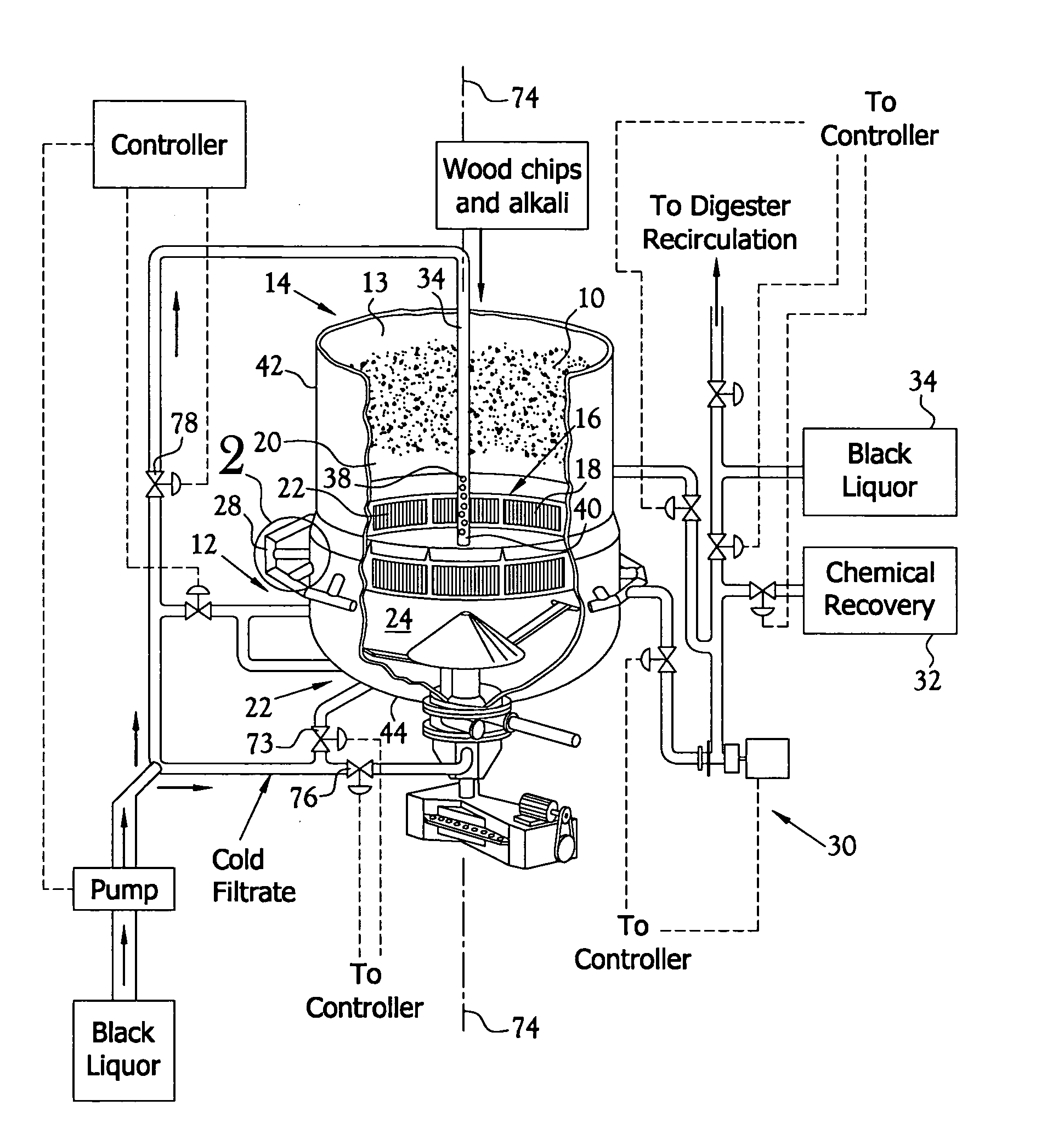

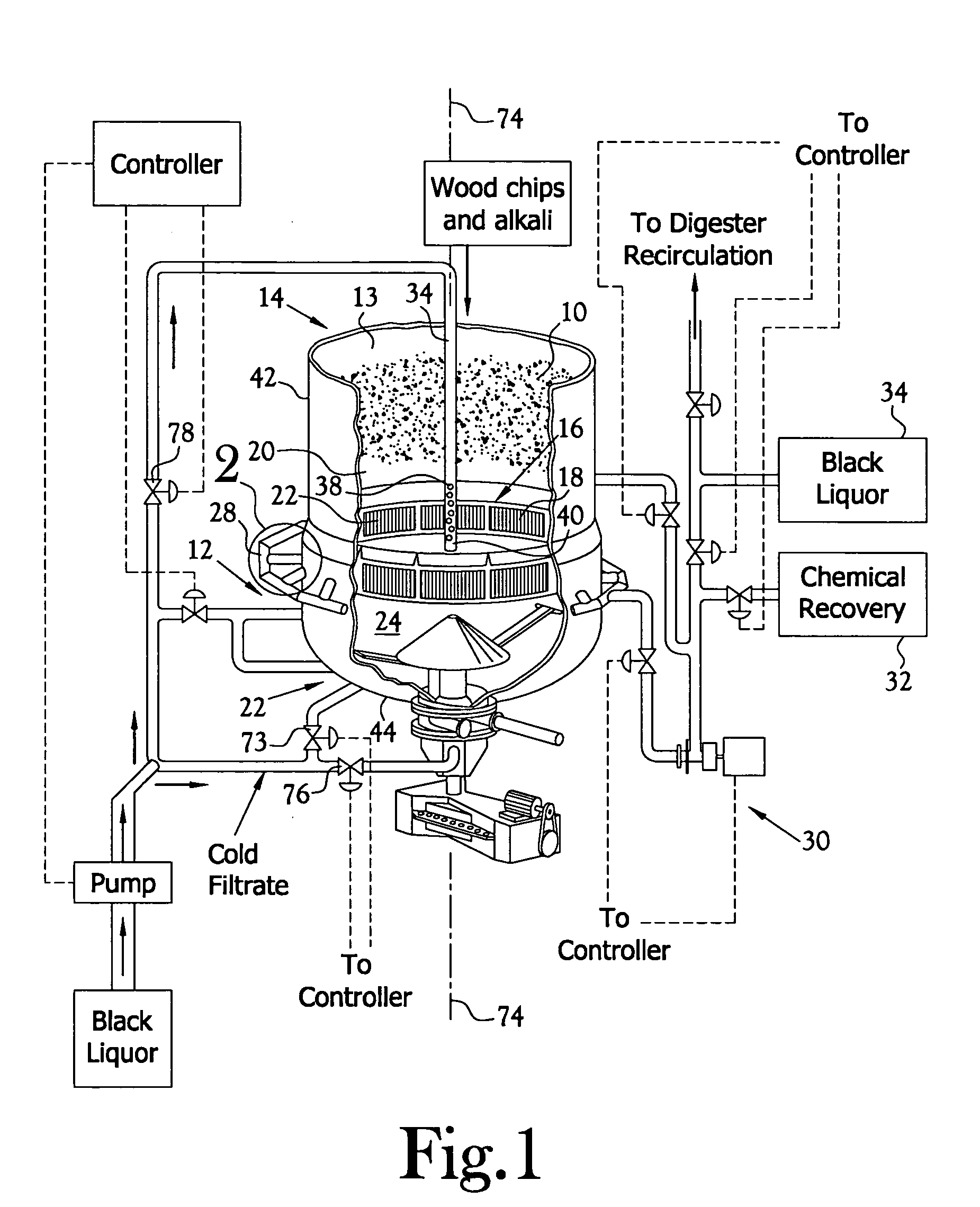

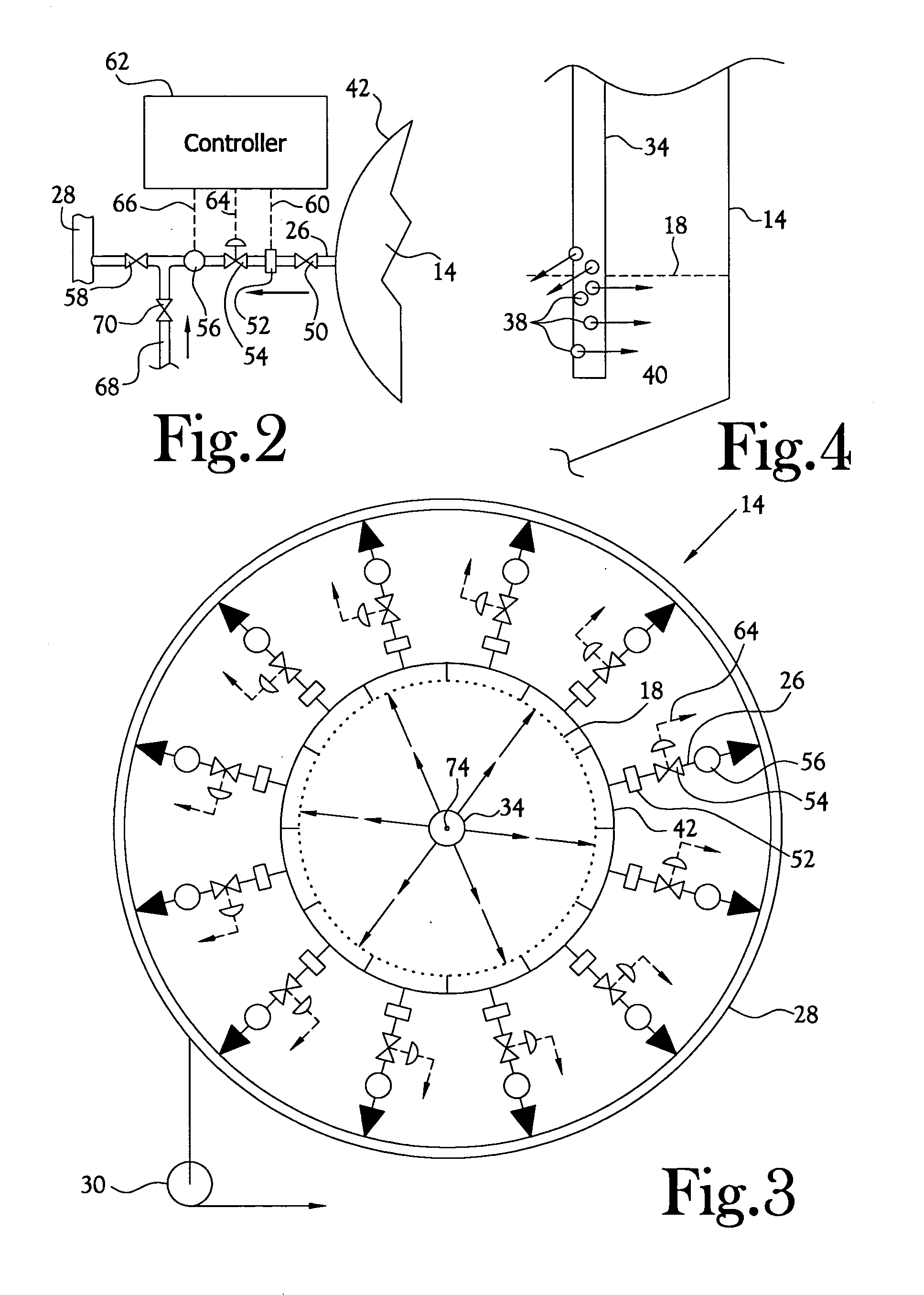

Digester wash extraction by individual screen flow control

ActiveUS20050274467A1Avoid cloggingMaximize efficiencyFats/resins/pitch/waxes removal in pulpDigestersWood fibreEngineering

This invention is directed to a method for cooking wood chips in a digester for the separation of wood fibers from their bonded state, the digester having a vertical centerline, a substantially circular cross-section, and a wash zone adjacent the bottom end thereof and a plurality of individual wash screens disposed about the inner wall of the digester for the withdrawal of liquor from the wash zone. In the first step of the method, substantially equal volumes of liquor are dynamically withdrawn from the wash zone through individual ones of the wash screens, while monitoring of the flow rate of liquor exiting the digester through individual ones of the wash screens. The monitored flow rate is used to increase or decrease the flow rate from screens to a value substantially equal to the flow rate of liquor from the digester through each of the screens. As a result, the total volume of liquor exiting the digester through the screens is divided into equal volumes flowing from the wash zone of the digester through each of the wash screens. The equal volumes were extracted substantially simultaneously in a flow direction substantially radially of the digester about substantially the entire circumference of the digester and within a plane disposed substantially perpendicular to the vertical axis of the digester.

Owner:INT PAPER CO

Method for the continuous cooking of wood raw material for cellulose pulp

The invention concerns a simplified method for the continuous cooking of wood raw material in the form of sawdust for the production of cellulose pulp, The method does not require any thickening stages and can be carried out with a minimum of process equipment. The complete process can be established with a steaming vessel, a cooking vessel and a subsequent pressure diffuser while the sawdust is mixed with the cooking fluid to form a slurry. The slurry has a consistency that throughout the process does not exceed 20%. The maximum consistency is preferably held at a maximum consistency of about 15-17%.

Owner:METABO PAPER SWEDEN

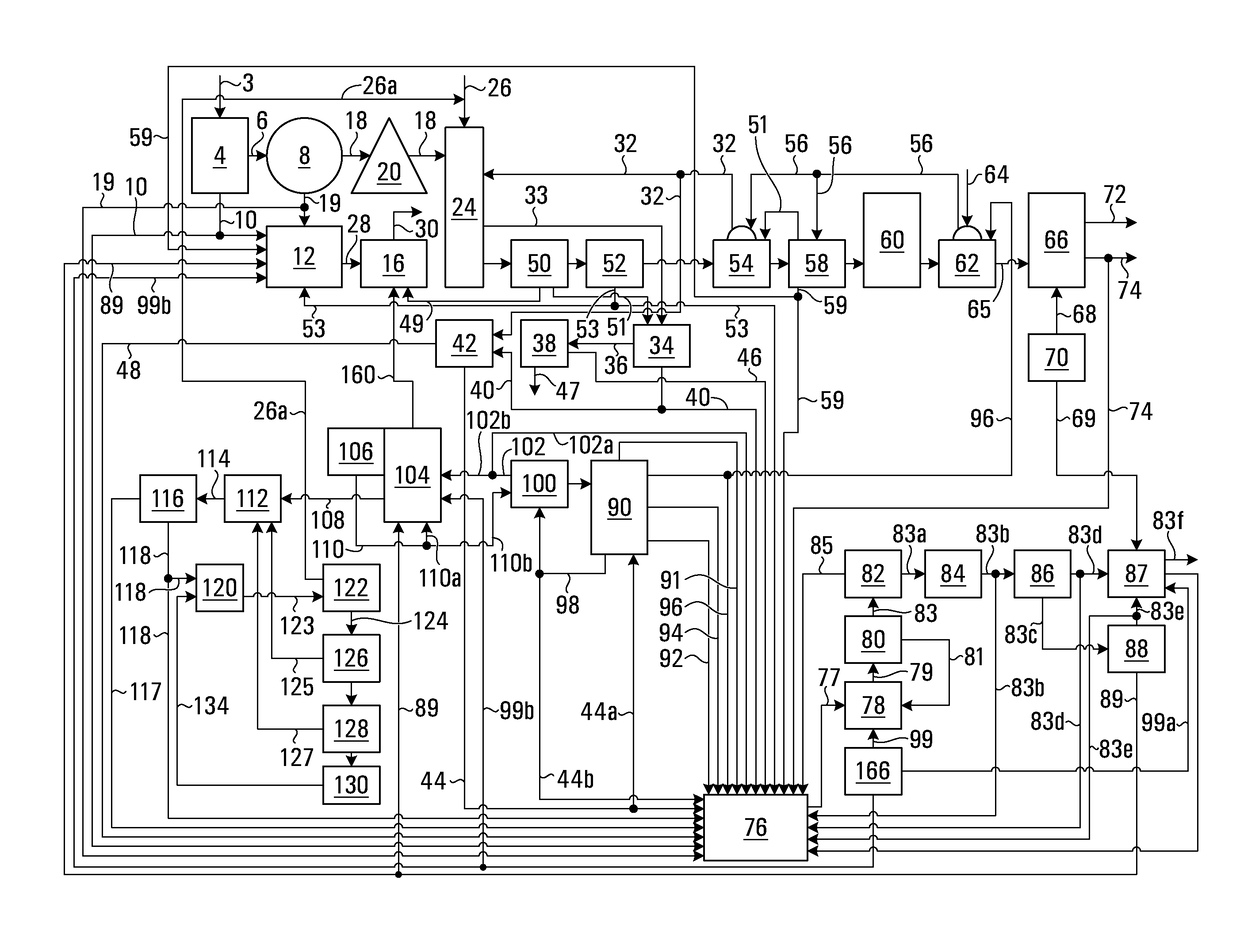

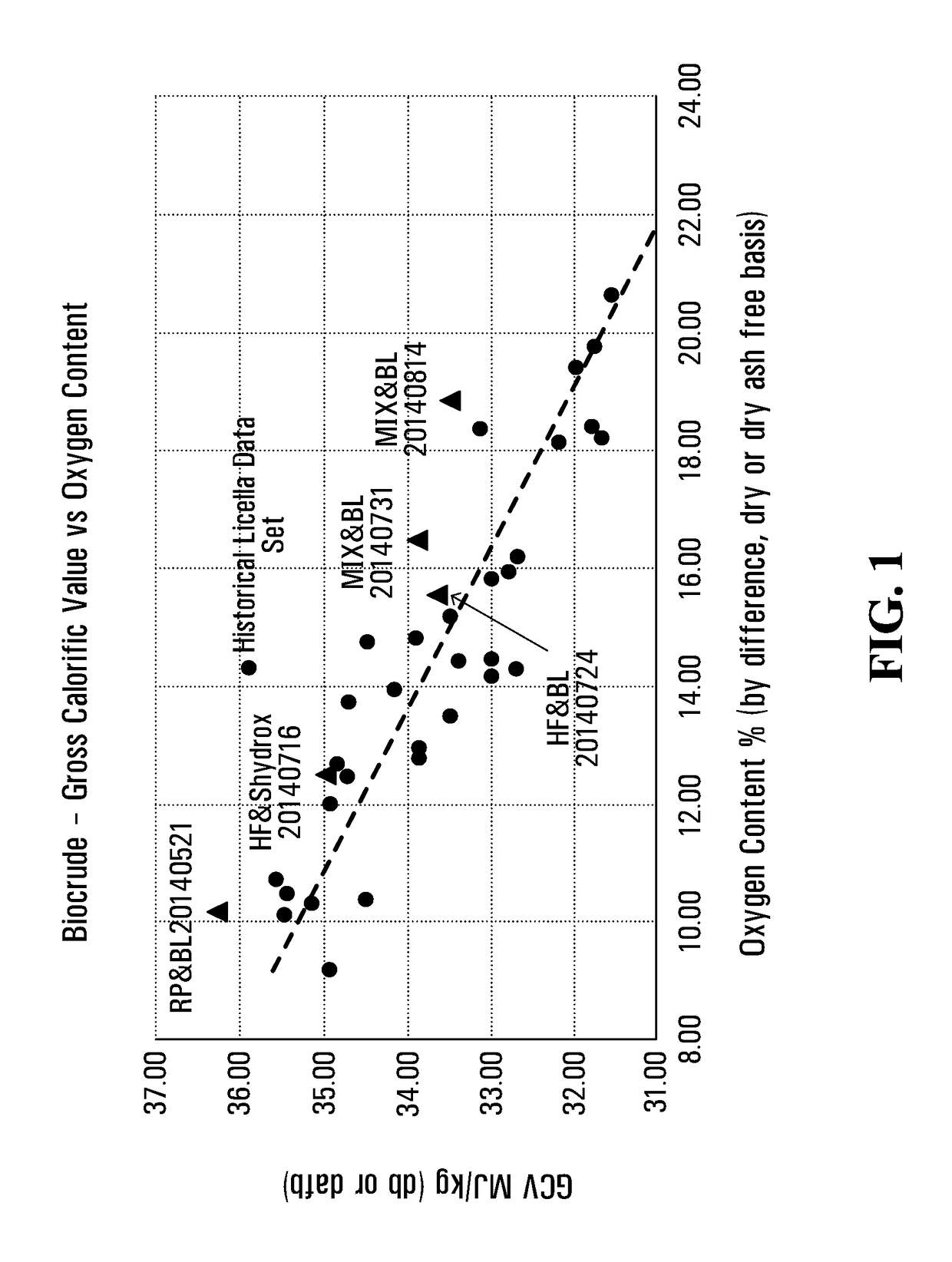

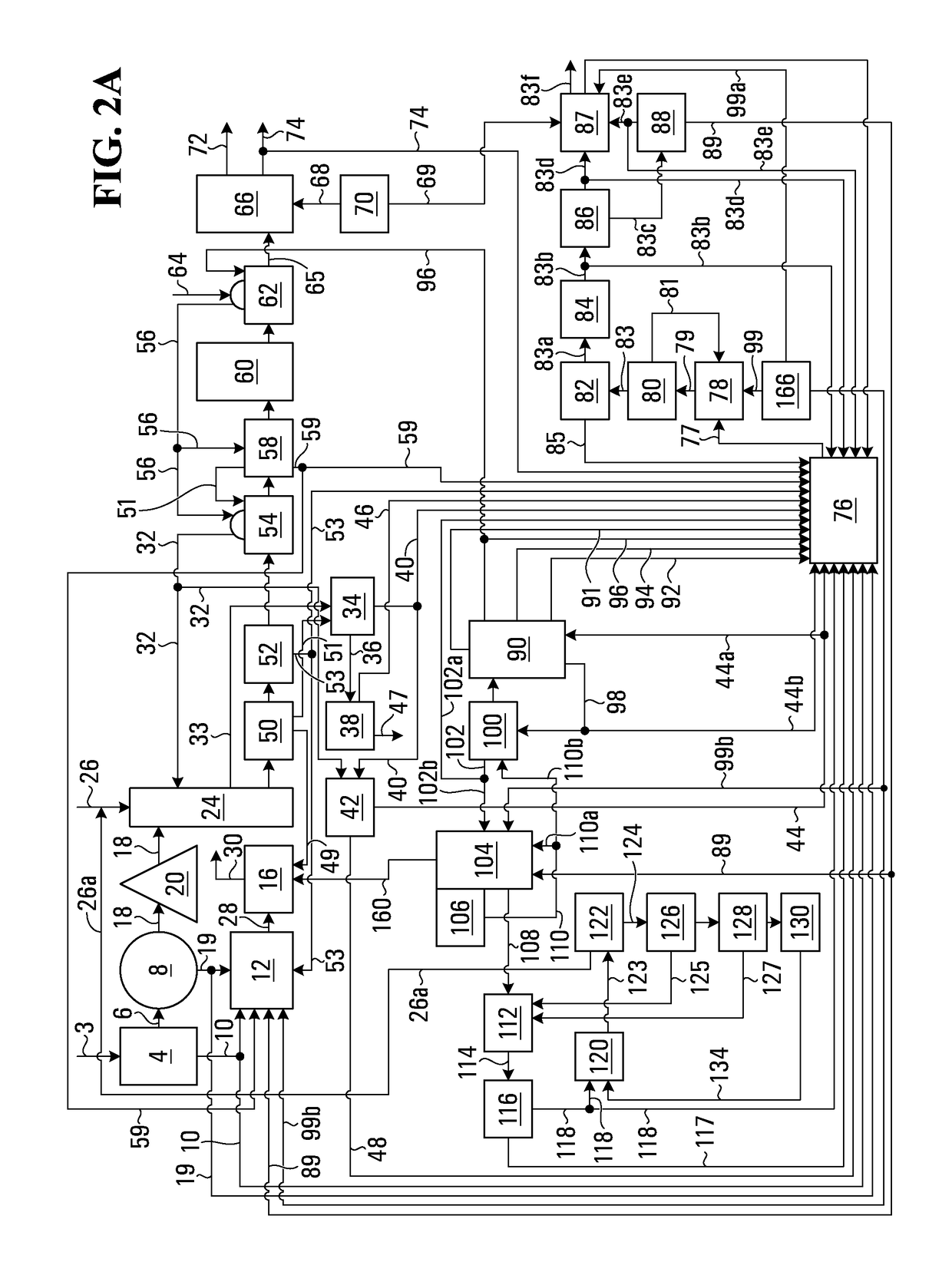

Integrated kraft pulp mill and thermochemical conversion system

ActiveUS20170226695A1Increase productionReduce problem sizeDirect heating destructive distillationBiofuelsCelluloseBioproducts

This disclosure pertains to the use of black liquors from kraft pulp mills as a source of catalysts for the thermochemical conversion of organic matter feedstocks to bio oils. More particularly, some embodiments pertain to integrated kraft pulp mill and thermochemical conversion systems, which include: a Kraft pulp mill comprising a digester for digesting a lignocellulosic material with white liquor to produce pulp and black liquors; a thermochemical conversion subsystem comprising: at least one mixing tank for combining pulping liquors received from the pulp mill with an organic matter feedstock and water to produce a reaction mixture; a reactor vessel for treating the reaction mixture received from the mixing tank at a reaction temperature and pressure suitable for conversion of all or a portion of the organic matter in the reaction mixture into a product mixture comprising a bioproduct and an aqueous stream containing both organic and inorganic compounds; and a depressurizer for depressurizing product mixture received from the reactor vessel; and one or more conveyors for conveying the pulping liquors from the pulp mill to the mixing tank.

Owner:CANFOR PULP +1

Mulberry bark slurry used for calligraphy and painting paper and production method thereof

InactiveCN104343032AHigh yieldHigh whitenessPretreatment with water/steamPulping with inorganic basesLiquid ratioLower grade

The invention provides a mulberry bark slurry used for calligraphy and painting paper and a production method thereof, the method comprises the following steps: a)peeling and removing the impurities of mulberry bark, immersing by clear water for 4-12 hours; b)scouring and bleaching mulberry bark, wherein alkali temperature is 80-85 DEG C, by metering with NaOH, the alkali concentration accounts for 5-25% of absolute dry weight of the mulberry bark, hydrogen peroxide amount accounts for 0.5-5% of absolute dry weight of mulberry bark, anthraquinone amount accounts for 0.05-1% of absolute dry weight of mulberry bark, boiling osmotic agent amount accounts for 0.5-1% of absolute dry weight of mulberry bark, Na2SiO3 amount accounts for 1-10% of absolute dry weight of mulberry bark, MgSO4 amount accounts for 0.05-0.5% of absolute dry weight of mulberry bark, liquid ratio is 1: 3-20; c)performing pulp washing, wherein pH value of slurry is 7.0-8.0; d)cutting off; and e)performing pulp refining by a double disc refiner, wherein the refiner gap is 0.05-1.5mm, the slurry concentration is controlled at 20-30%, and forming small pulp pellets. The method has the advantages of simple process and easy operation, pulping is carried out without chlorine by combination of scouring and bleaching at low temperature, scouring and bleaching effects can be increased by adding a boiling auxiliary agent, a boiling osmotic agent and a bleaching stabilizing agent, the produced mulberry bark slurry has the advantages of high yield and good whiteness, and can be used for producing calligraphy and painting paper with high, middle and low grades.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Method for pulping and paper-making

InactiveCN1715556ALow costWide variety of sourcesPulp liquor regenerationWashing/displacing pulp-treating liquorsBlack liquorEngineering

The pulping and paper-making method adopts the material includes dried leaf, stem peel and fruit leftover of coconut, palm, areca, banana and pineapple. The production process includes material analysis, preparing material, pulping, recovering black liquor, making pulp sheet and making paper. The present invention utilizes the waste, is economic, environment friendly, wide in application range and reasonable in technological process.

Owner:俞祖勋

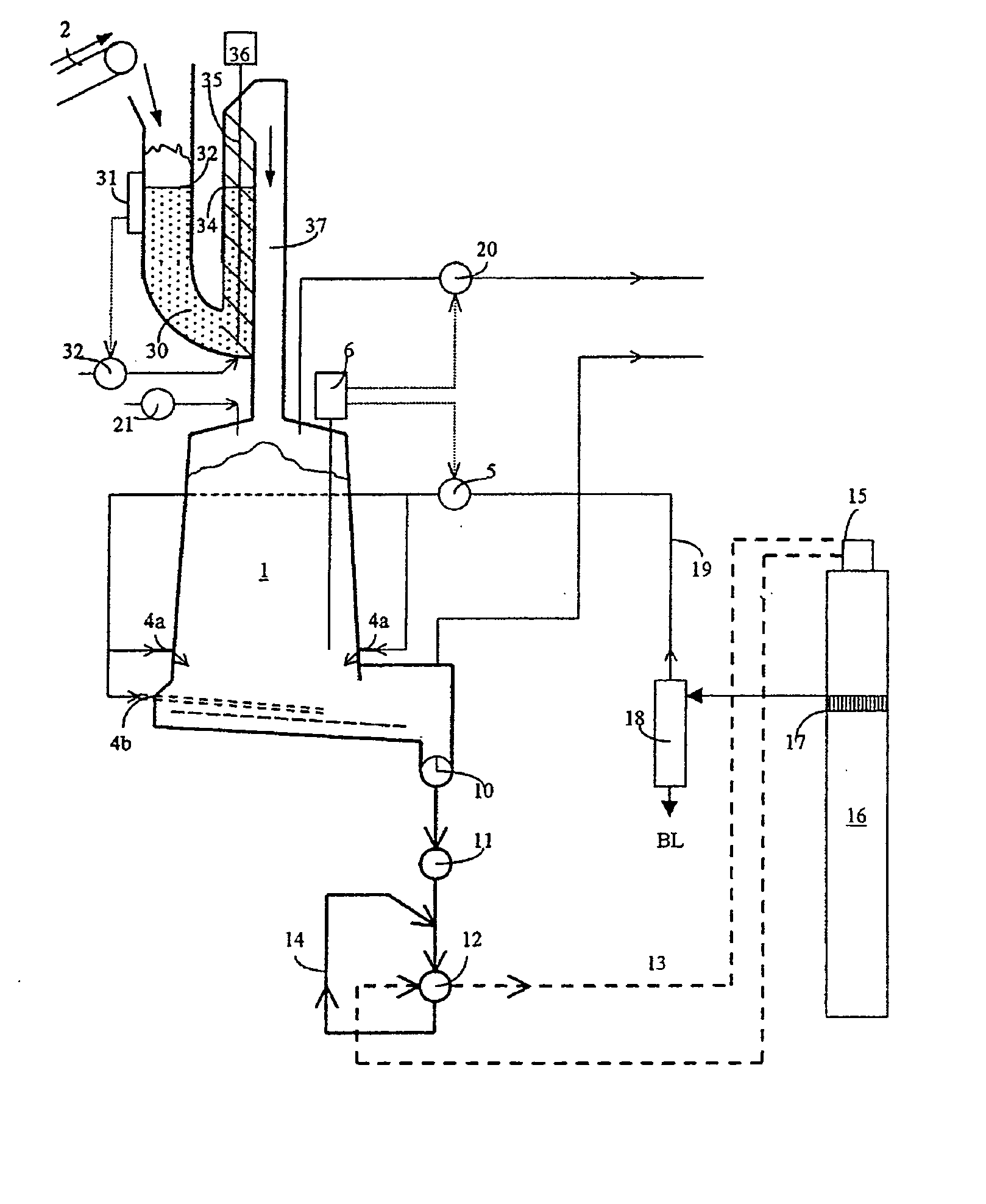

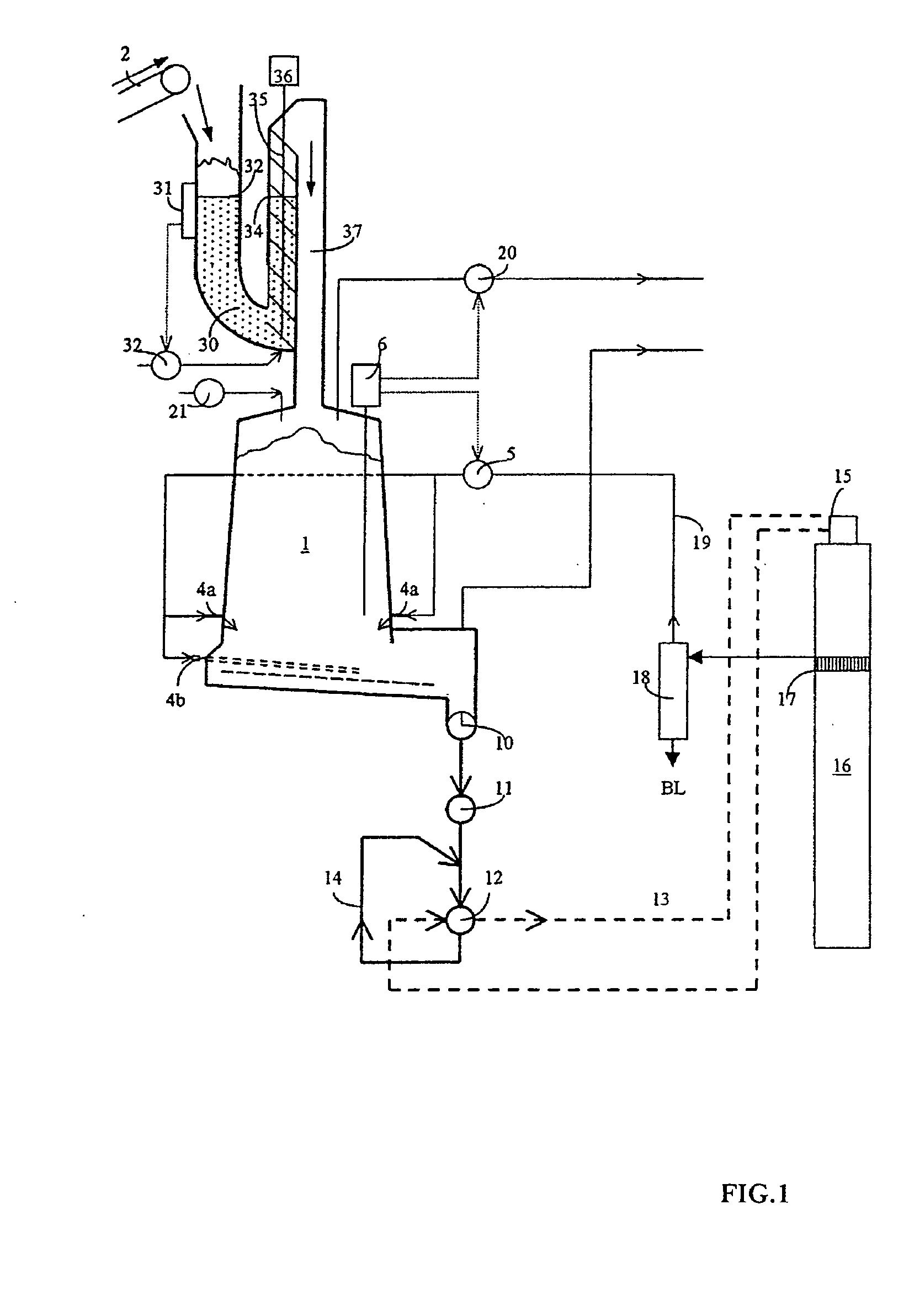

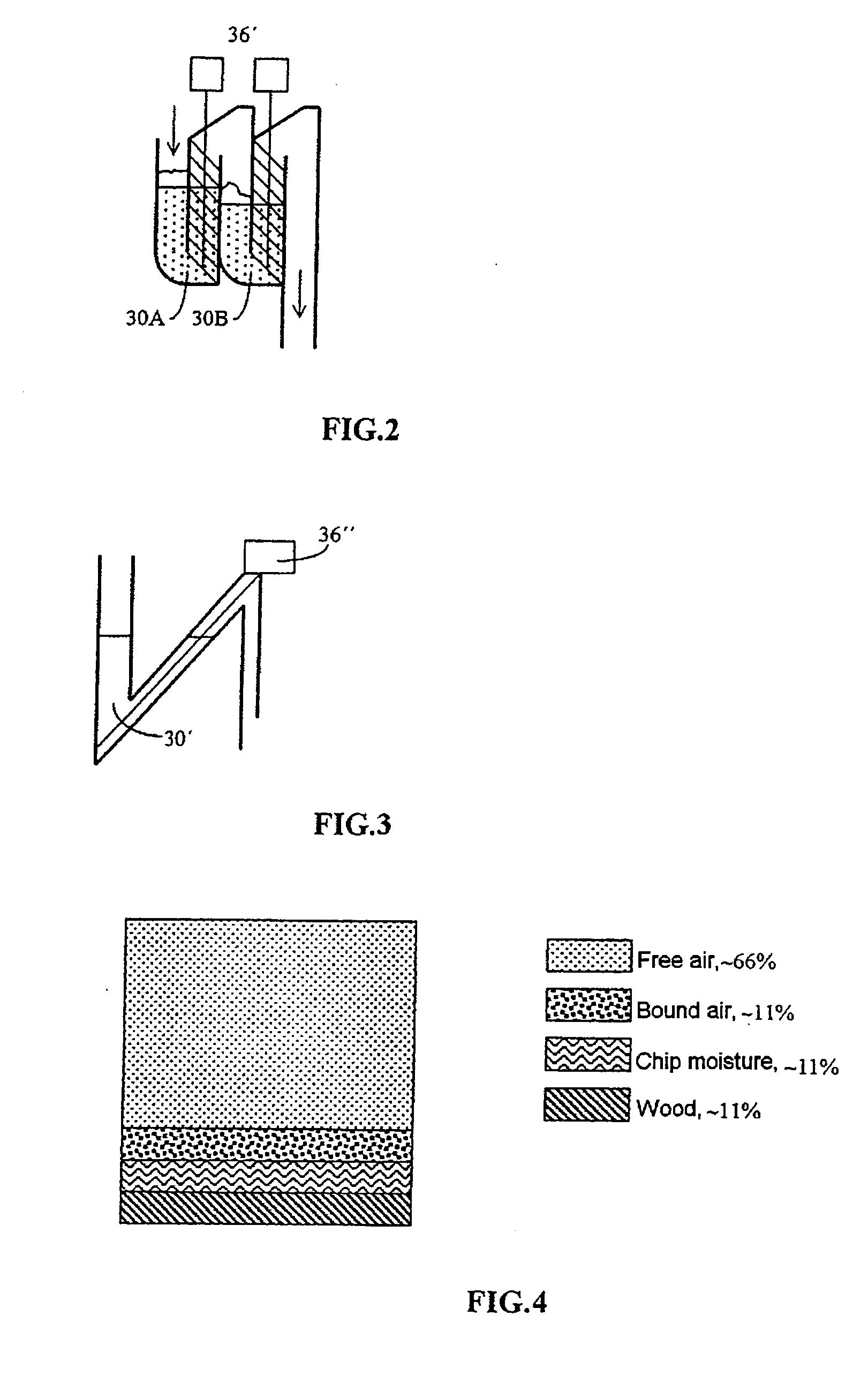

Feeding arrangement for feeding of chips to chip bins

InactiveUS20050061464A1Quantity minimizationLower the volumePretreatment with water/steamDigestersCellulose pulpWaste management

The invention relates to a feed arrangement for feeding chips to chip bins (1) in the production of cellulose pulp in continuous digesters (16), in which the chip bin is constituted by a treatment vessel having a top and a bottom, in which the chips are fed into the top (13) of the treatment vessel and fed out via the bottom of the treatment vessel using suitable lock members (10, 11). Distribution devices (4a, 4b) for the addition of steam are disposed in the treatment vessel so as to heat the chips to a level above 80° C., preferably around 100° C., when the chips are fed out via the bottom of the treatment vessel. By virtue of the fact that the chips are fed into the treatment vessel via at least one liquid lock (30) and the treatment vessel is otherwise sealed off, the quantity of driven-off gases from the chip bin is reduced to a minimum, at the same time as an effective utilization of available energy is obtained.

Owner:METABO PAPER SWEDEN

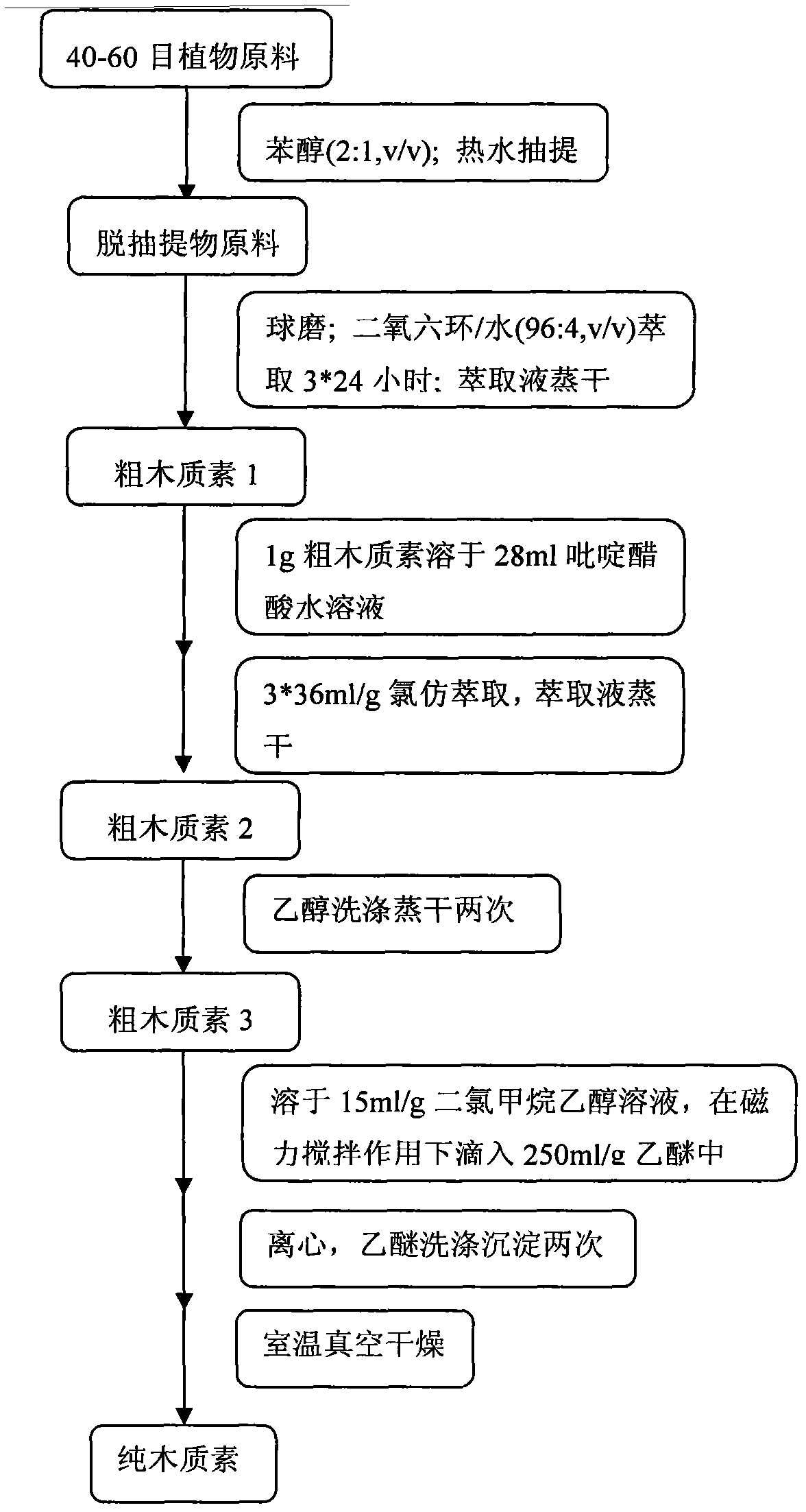

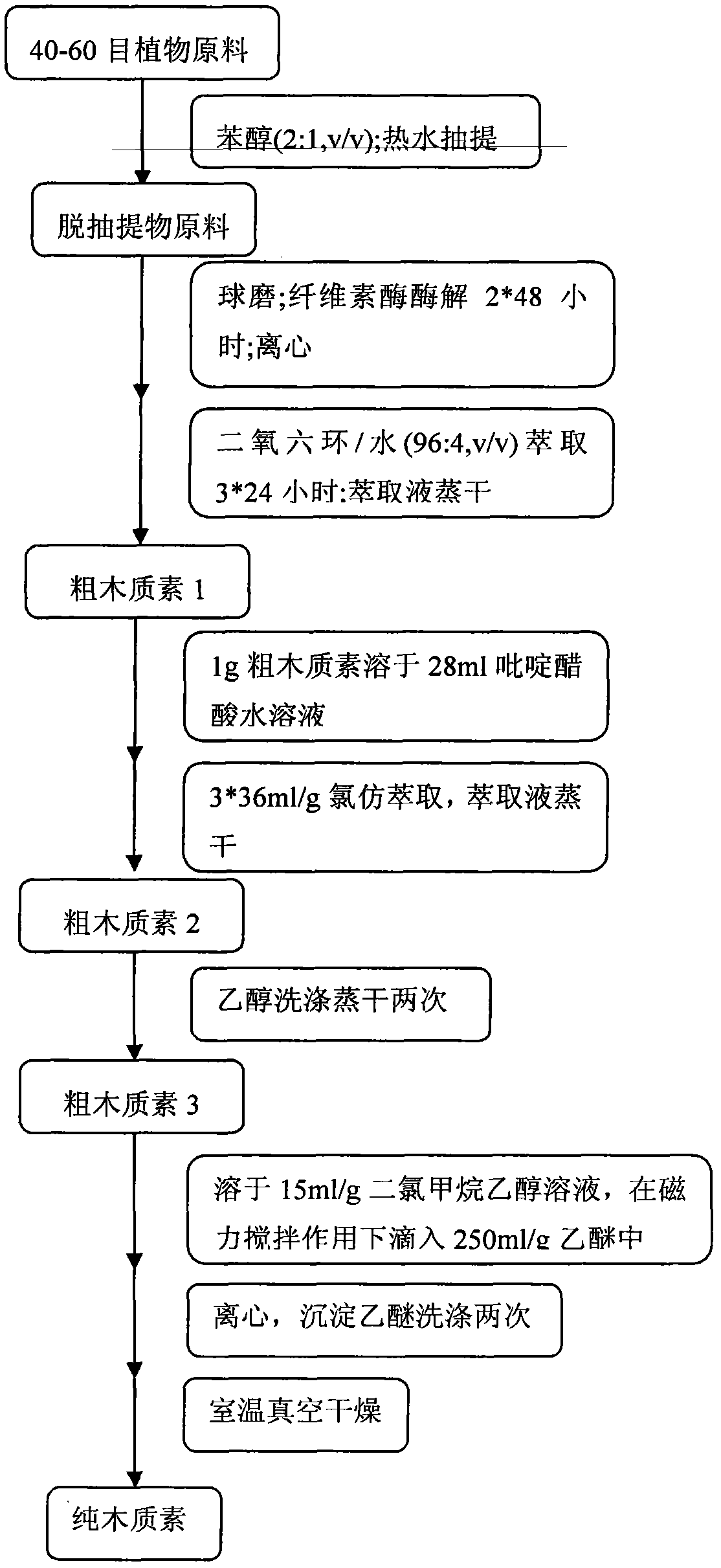

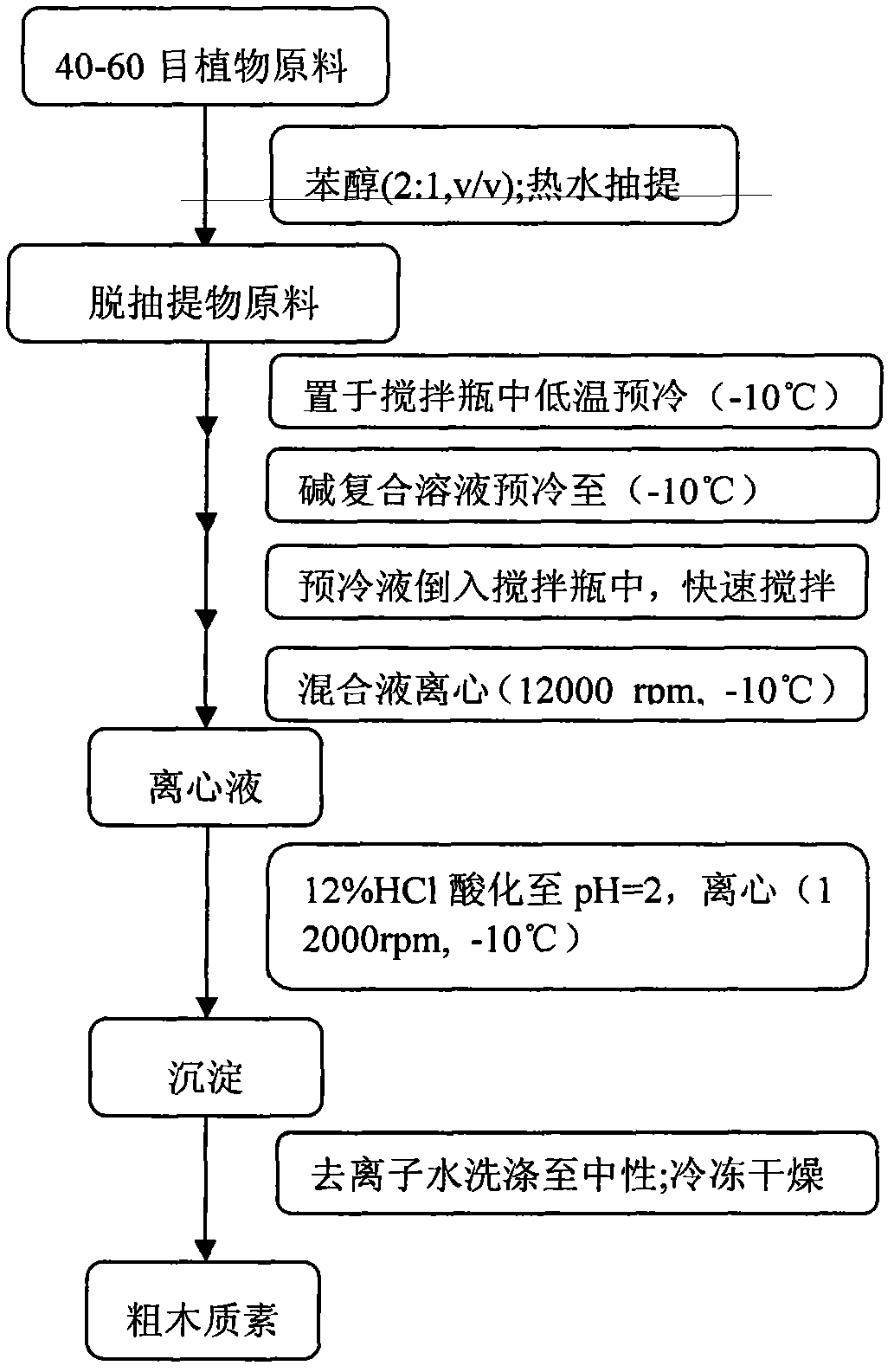

Method for separating non-wood lignocellulosic biomass lignin with composite solvents

InactiveCN102704297AProtect chemical structurePreserve the ester bondPulping with inorganic basesContinuous pulping processChemical structureFiber

The invention relates to a method for separating non-wood lignocellulosic biomass lignin from pulp lignin with composite solvents. The method comprises the steps of extraction, separation and purification. The method utilizes sodium hydroxide / urea / thiourea / aqueous solution systems to separate much wheat straw lignin successfully at low temperature, the receiving rate of crude lignin reaches 60%, the receiving rate of pure lignin reaches 30%, and the purity of the isolated lignin can reach 99%. The time span of separating processes is very short and only needs 16 minutes, thereby protecting the chemical structure of the lignin effectively, and keeping ester linkages between lignin molecules in a relatively intact mode.

Owner:NANJING FORESTRY UNIV

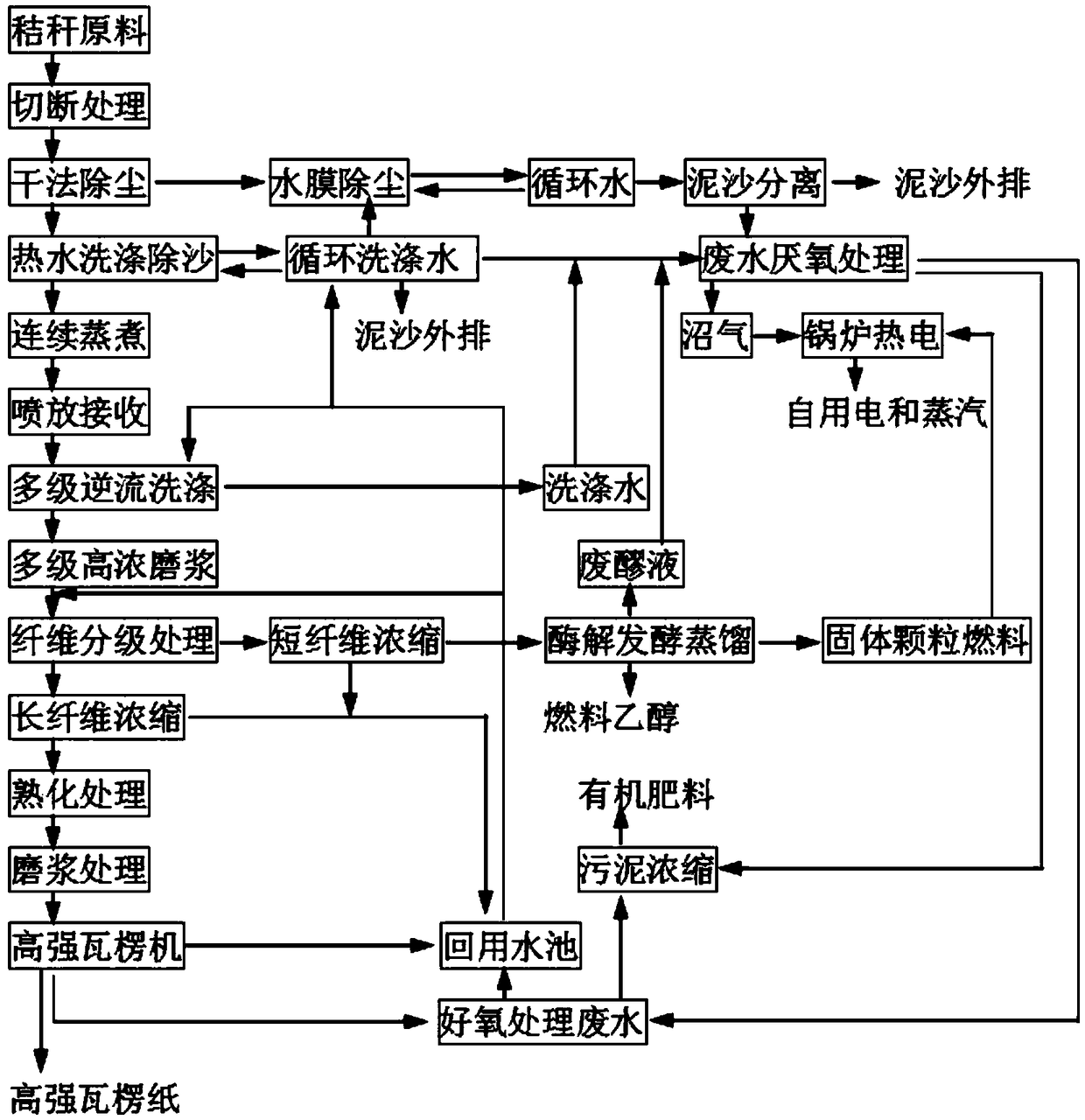

Comprehensive straw utilization method

InactiveCN109056400AImprove COD valueImprove water filtration performanceBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationFiber

The invention relates to a comprehensive straw utilization method, which belongs to the technical field of comprehensive biomass material utilization. The method mainly comprises the following key steps: straw cutting, dry dedusting, hot-water washing for sand removal, continuous cooking, discharge and reception, multi-stage countercurrent washing, multi-stage high-concentration pulping, fiber grading, long fiber concentration, long fiber curing, long fiber pulping, production of corrugated paper from long fibers, short fiber concentration, production of fuel ethanol and solid pellet fuel by enzymolysis, fermentation and distillation of short fibers and the like. The method has the advantages that the high-value comprehensive utilization of each component of straw material is realized, chemicals are not added, a water system is closed and circulated, and no wastewater is discharged; the tiny fiber component has a large specific surface area and high enzymolysis efficiency; the corrugated paper produced from the long fiber component has high strength and good quality; and applying the tiny fiber component to an enzymolysis system not only increases the enzymolysis of the material, but also greatly reduces the cost of saccharide enzymolysis, thus promoting the development of the comprehensive biomass utilization technology.

Owner:刘同林 +3

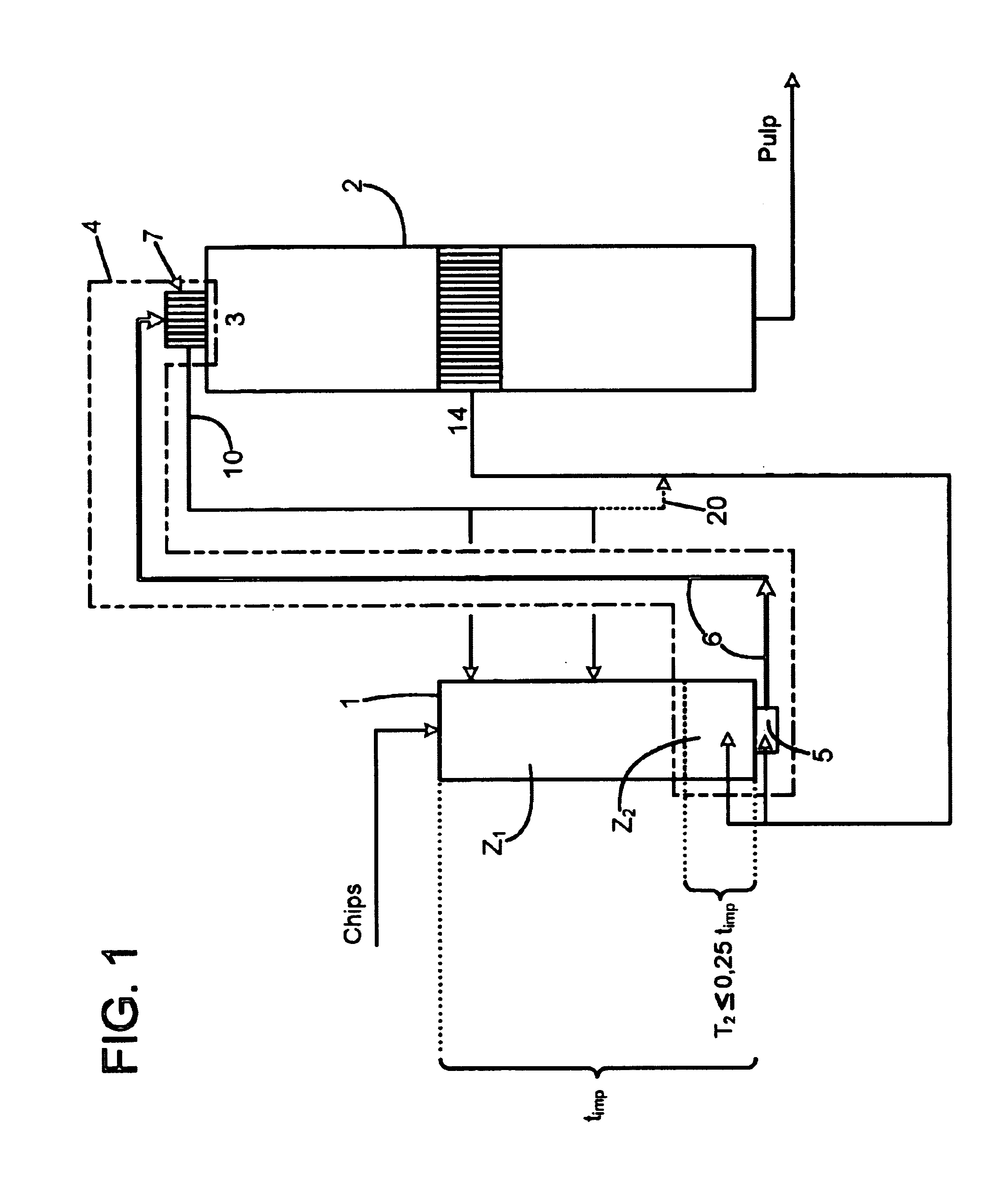

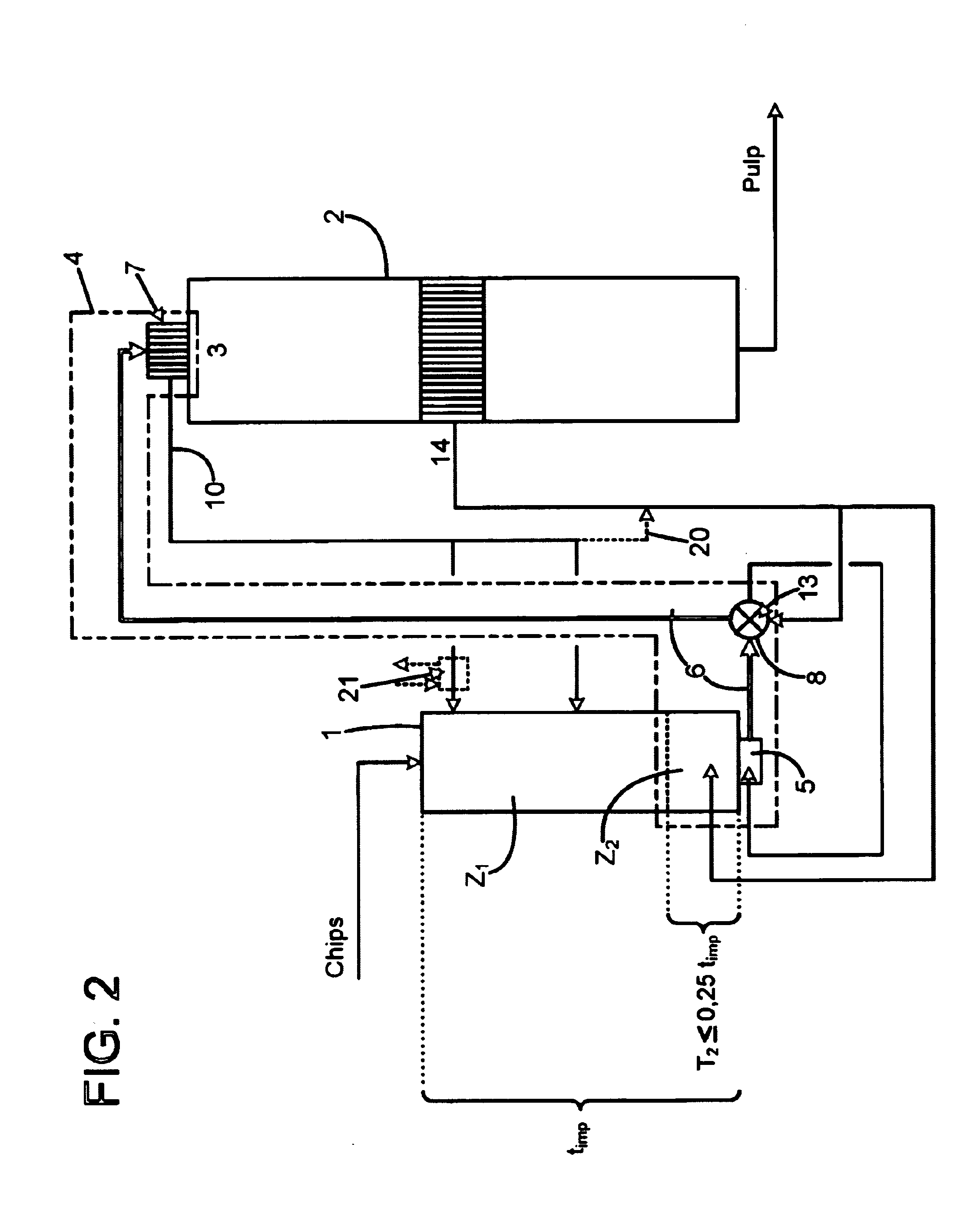

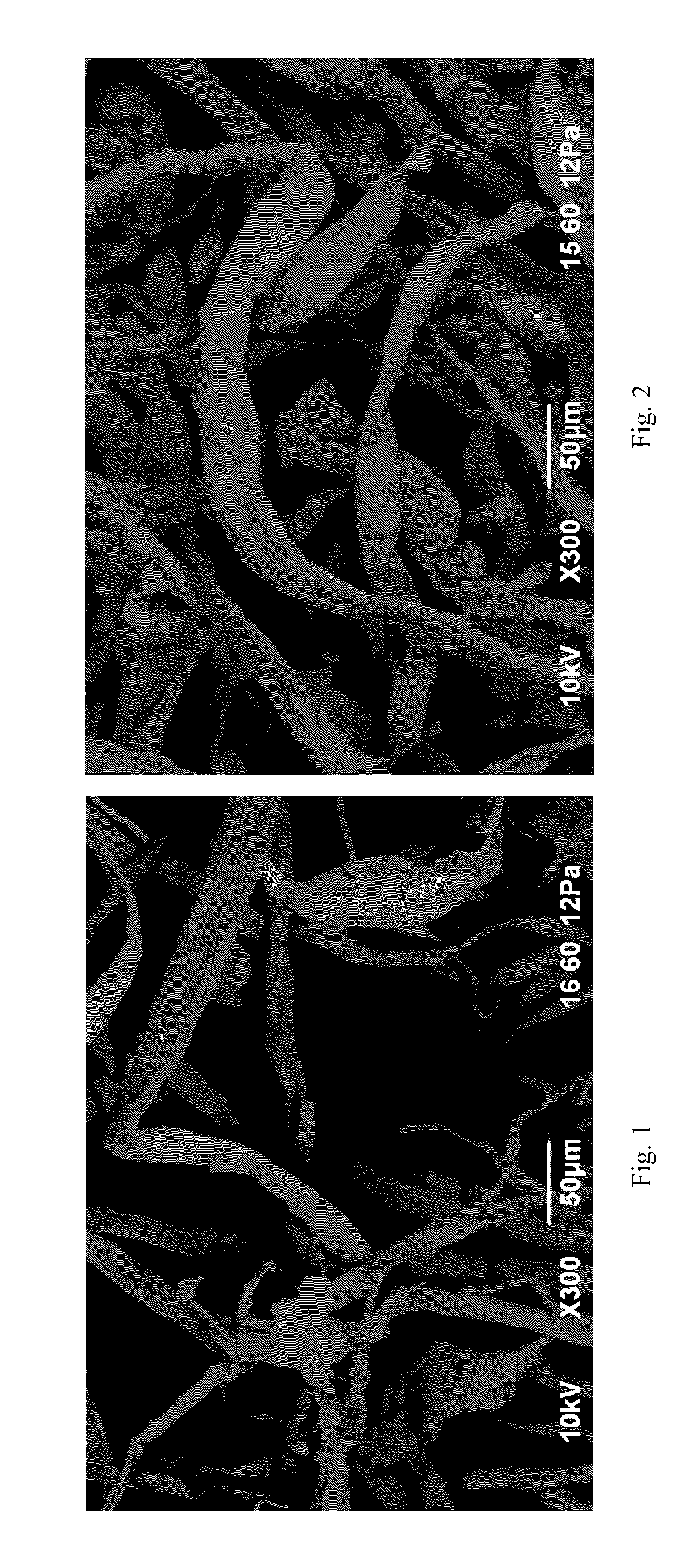

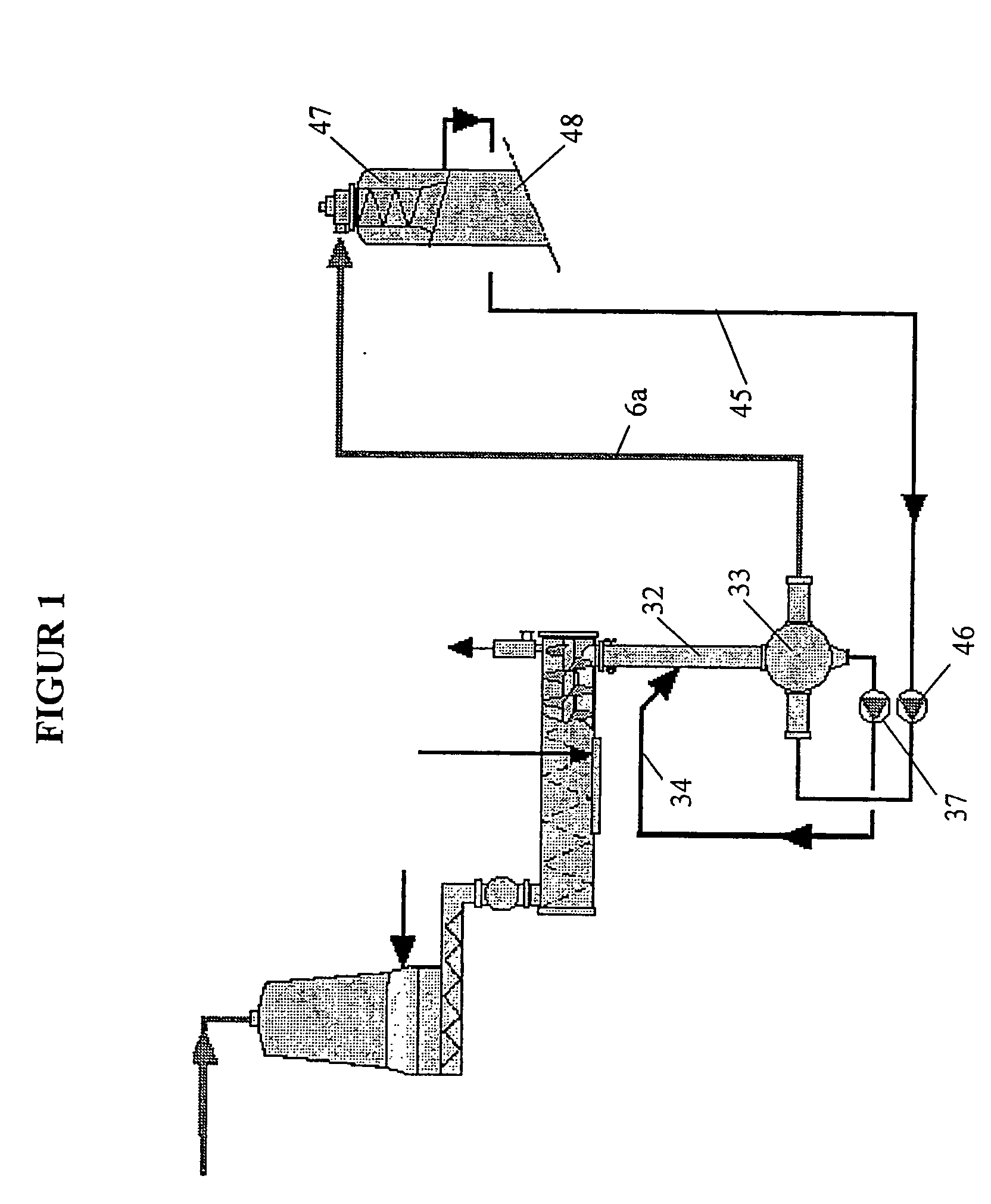

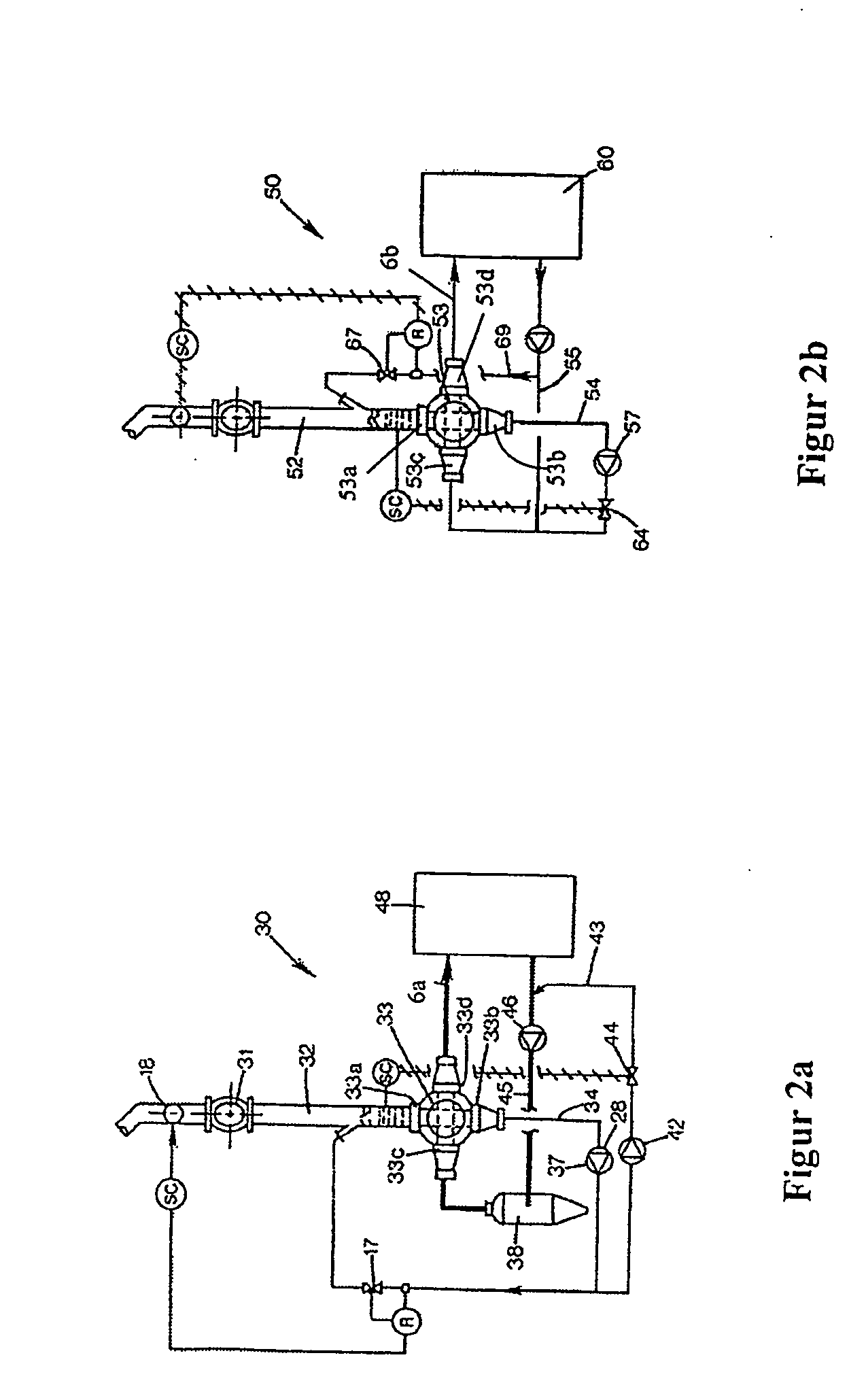

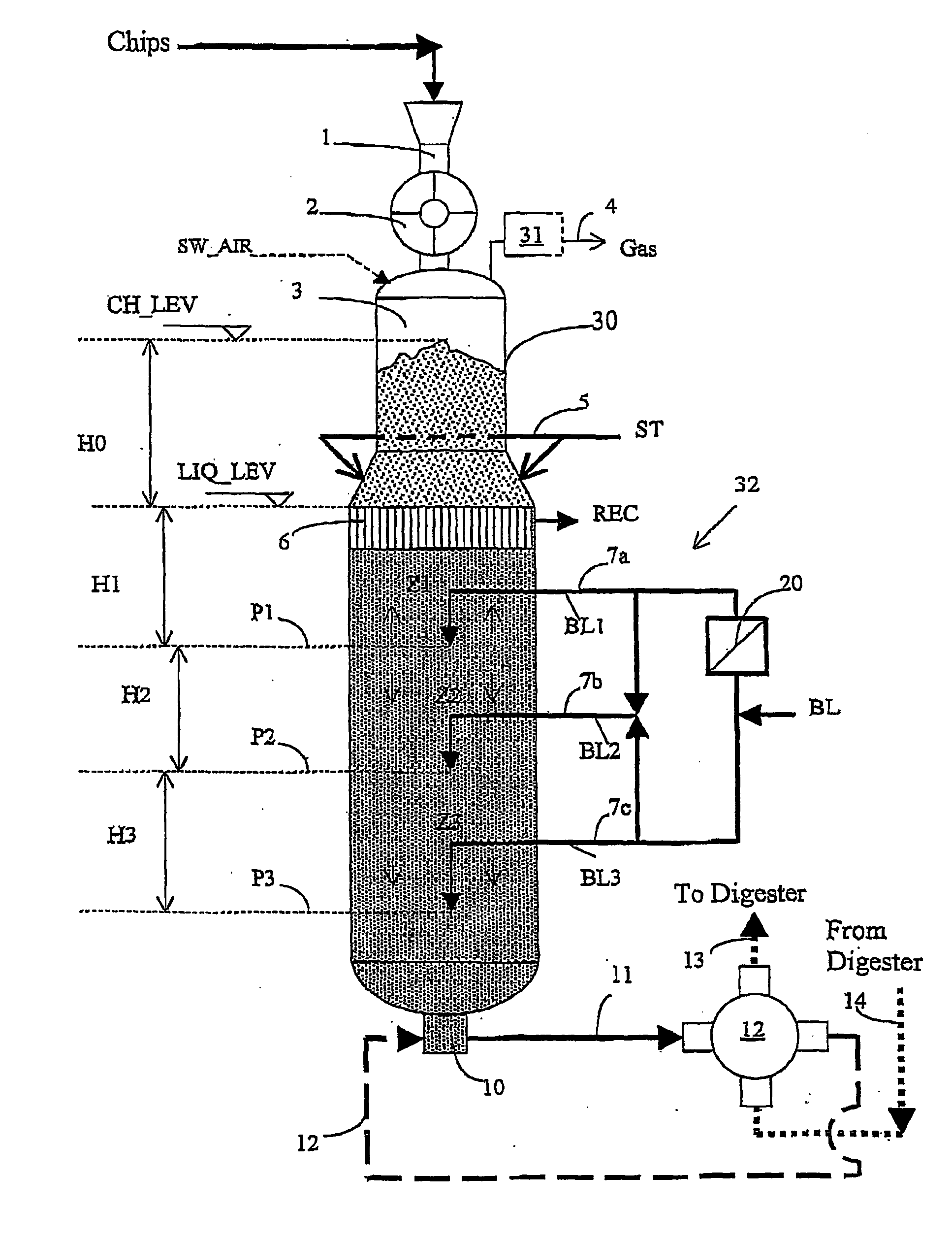

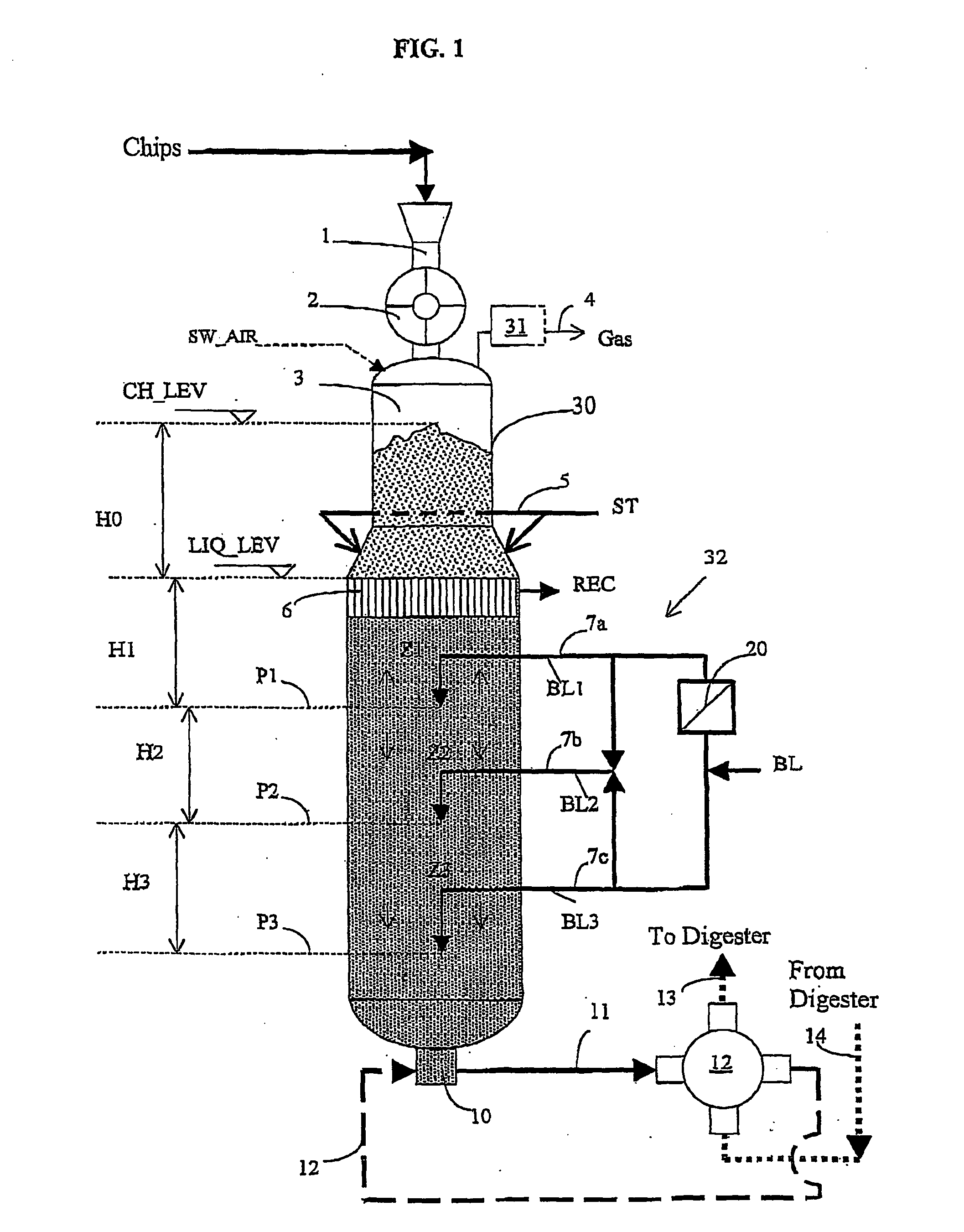

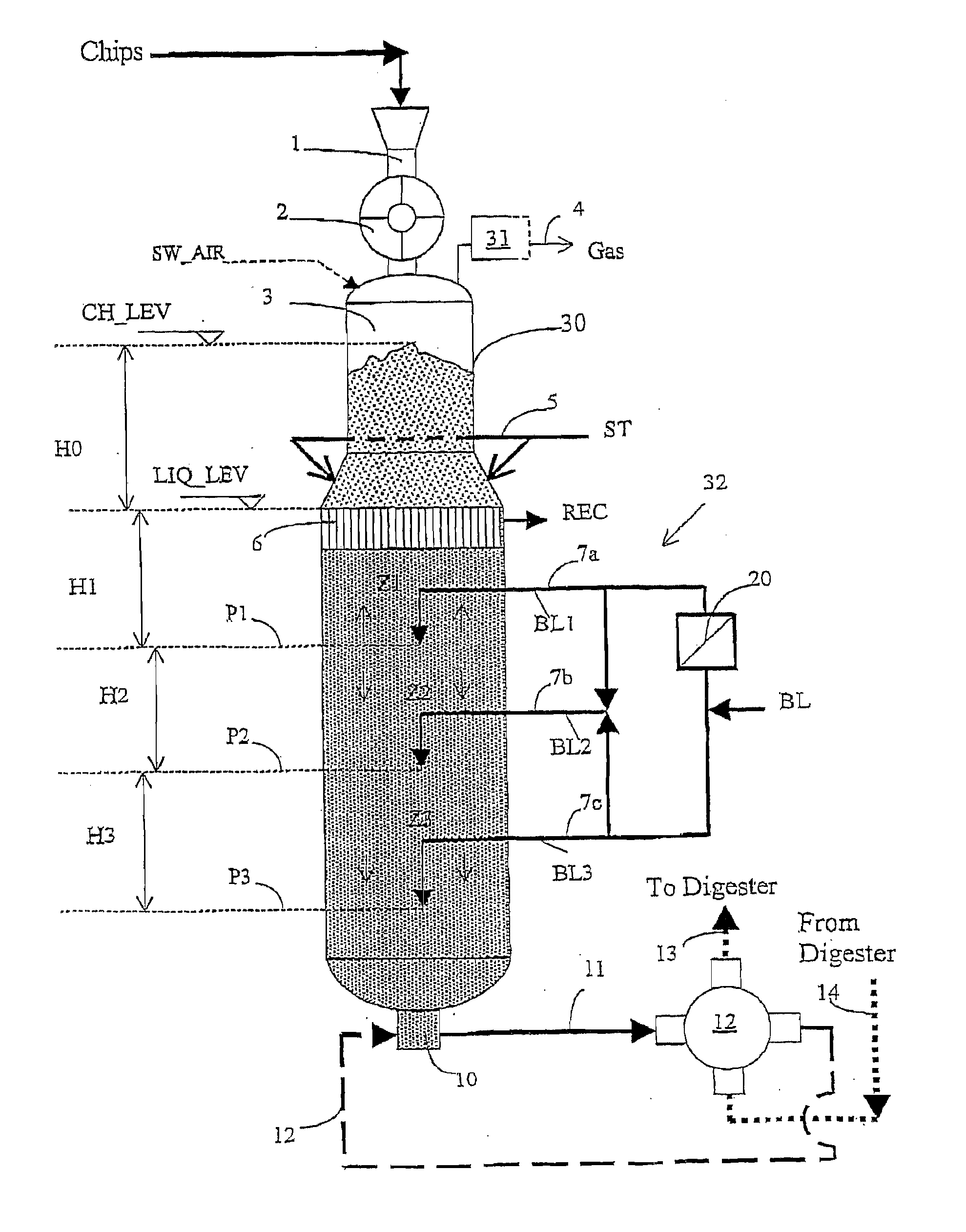

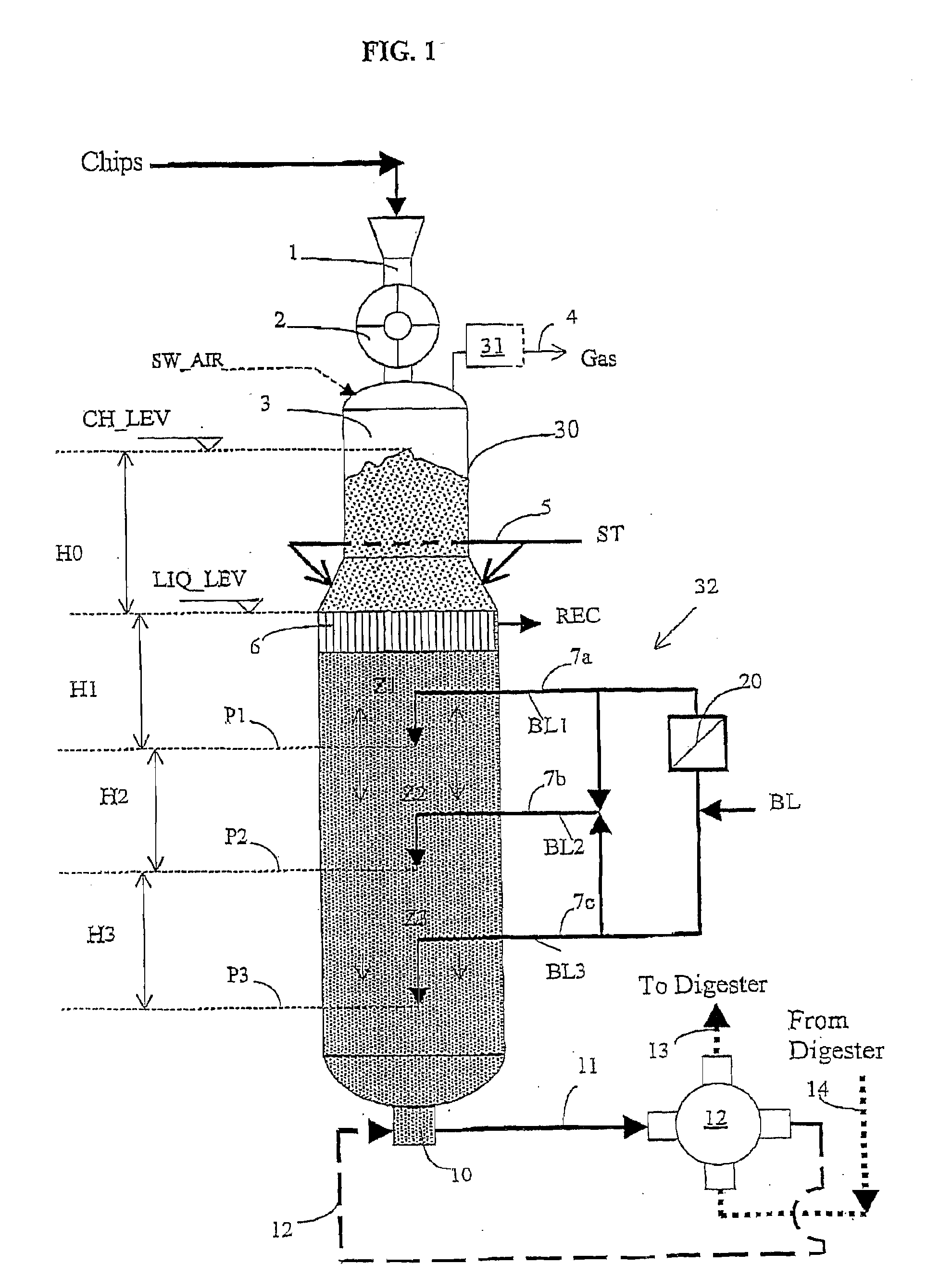

Method and arrangement for impregnating chips

InactiveUS20050061458A1Reduce the temperatureReduce the amount requiredPretreatment with water/steamPretreatment with alkaline reacting compoundsCounter flowEngineering

The method and an arrangement are for improved impregnation of chips in association with the manufacture of chemical cellulose pulp. Un-steamed chips are fed into an impregnation vessel (30) in which a fluid level (LIQ_LEV) is established under the highest level (CH_LEV) of the chips. An improved impregnation arrangement for the chips is obtained by the addition of impregnation fluids (BL1 / BL2 / BL3) with increasing temperatures at different heights (P1, P2, P3), and by the establishment of a counter-flow zone (Z1) in the uppermost part of the impregnation vessel. The requirement for steaming may in this way be dramatically reduced while at the same time the amount of expelled waste gases may be minimized. A major part of the volatile compounds present in the wood are bound to the impregnation fluid (REC) that is withdrawn.

Owner:METABO PAPER SWEDEN

Hardwood alkaline pulping processes and systems

InactiveUS20120305209A1Reduce rejectionPretreatment with alkaline reacting compoundsDigestersPulp and paper industrySlurry

Systems are provided for continuously producing chemical cellulose pulp from a slurry of comminuted hardwood material by subjecting the slurry of comminuted hardwood material to a first cooking stage under conditions sufficient to reduce syringyl lignin (s-lignin) content in the hardwood material as compared to guaiacyl lignin (g-lignin) content therein, and thereafter subjecting the slurry of comminuted hardwood material to a second cooking stage under conditions sufficient to reduce the g-lignin content remaining therein after the first cooking stage.

Owner:ANDRITZ INC

Method and arrangement for impregnating chips

InactiveUS20070187053A1Reduce the temperatureReduce the amount requiredPretreatment with alkaline reacting compoundsDigestersCounter flowEngineering

The method and an arrangement are for improved impregnation of chips in association with the manufacture of chemical cellulose pulp. Un-steamed chips are fed into an impregnation vessel (30) in which a fluid level (LIQ_LEV) is established under the highest level (CH_LEV) of the chips. An improved impregnation arrangement for the chips is obtained by the addition of impregnation fluids (BL1 / BL2 / BL3) with increasing temperatures at different heights (P1, P2, P3), and by the establishment of a counter-flow zone (Z1) in the uppermost part of the impregnation vessel. The requirement for steaming may in this way be dramatically reduced while at the same time the amount of expelled waste gases may be minimized. A major part of the volatile compounds present in the wood are bound to the impregnation fluid (REC) that is withdrawn.

Owner:METABO PAPER SWEDEN

Method for preparing cellulose nanocrystals

InactiveCN102877342AEffective separation and crackingEvenly dispersedPulping with acid salts/anhydridesContinuous pulping processAqueous solutionUltrasonic generator

The invention discloses a method for preparing cellulose nanocrystals. The method comprises the following steps of: (1) putting refined cotton linter into water of which the mass is 10 to 20 times that of the refined cotton linter, and performing ultrasonic stirring in an ultrasonic generator for 4 to 8 hours; (2) continuously adding a 0.5mol / L sulfuric acid aqueous solution of which the mass is 5 to 8 times that of the refined cotton linter and a 0.5mol / L hydrochloric acid aqueous solution of which the mass is 2 to 6 times that of the refined cotton linter into the ultrasonic generator, and performing ultrasonic stirring at the temperature of between 30 and 60 DEG C for 8 to 12 hours; and (3) washing a solid product obtained in the step (2) by using water until the pH value is 6 to 7. The method is simple in process and low in cost; and the prepared cellulose nanocrystals are uniform in granularity and high in performance.

Owner:WUXI KAILI PHARMA

Methods to decrease scaling in digester systems

ActiveUS20050284592A1Reduced calcium carbonate scalingReduction in pulping energy requirementPulp liquor regenerationDigestersCalcium concentrationChemistry

One aspect of this invention relates to a method and digester for reducing the deposition of calcium-based scale in a wood chip digester including extraction from the digester of first and second quantities of cooking liquor having respective first and second calcium concentrations, treating the extracted cooking liquors to produce a cooking liquor having a calcium concentration less that the calcium concentration of the either of the first and second extracted cooking liquors, and, reintroducing the treated cooking liquor to the digester. Another aspect of this invention relates to a method and digester in which through put through the digester is increased by the continuous addition of process liquor into the digester preferably at an upper region of the digester.

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com