Method for separating non-wood lignocellulosic biomass lignin with composite solvents

A technology of lignin and extraction method, applied in continuous pulping process, pulping with inorganic alkali, etc., can solve the problems of crude lignin yield not higher than 65%, degradation of lignin molecular structure, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

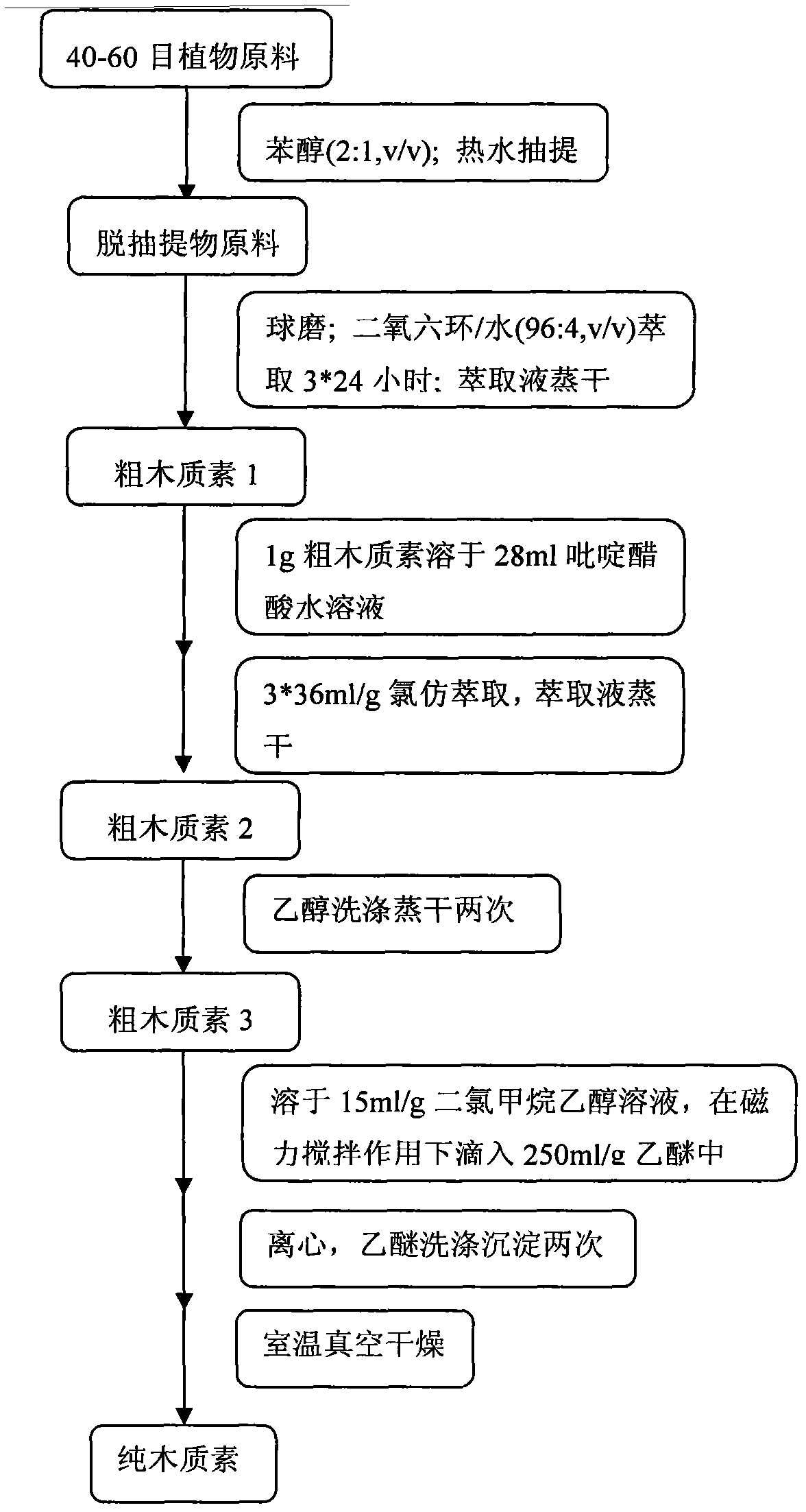

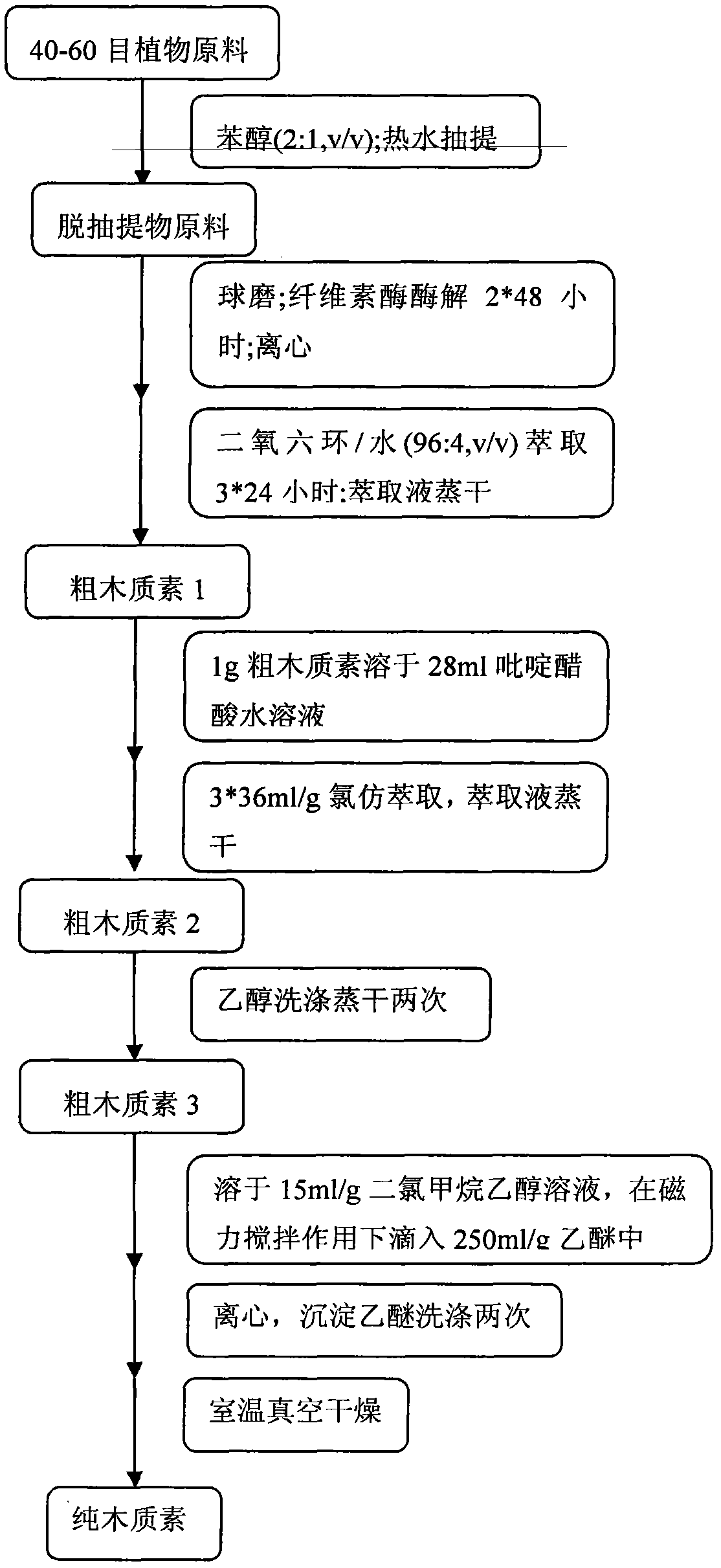

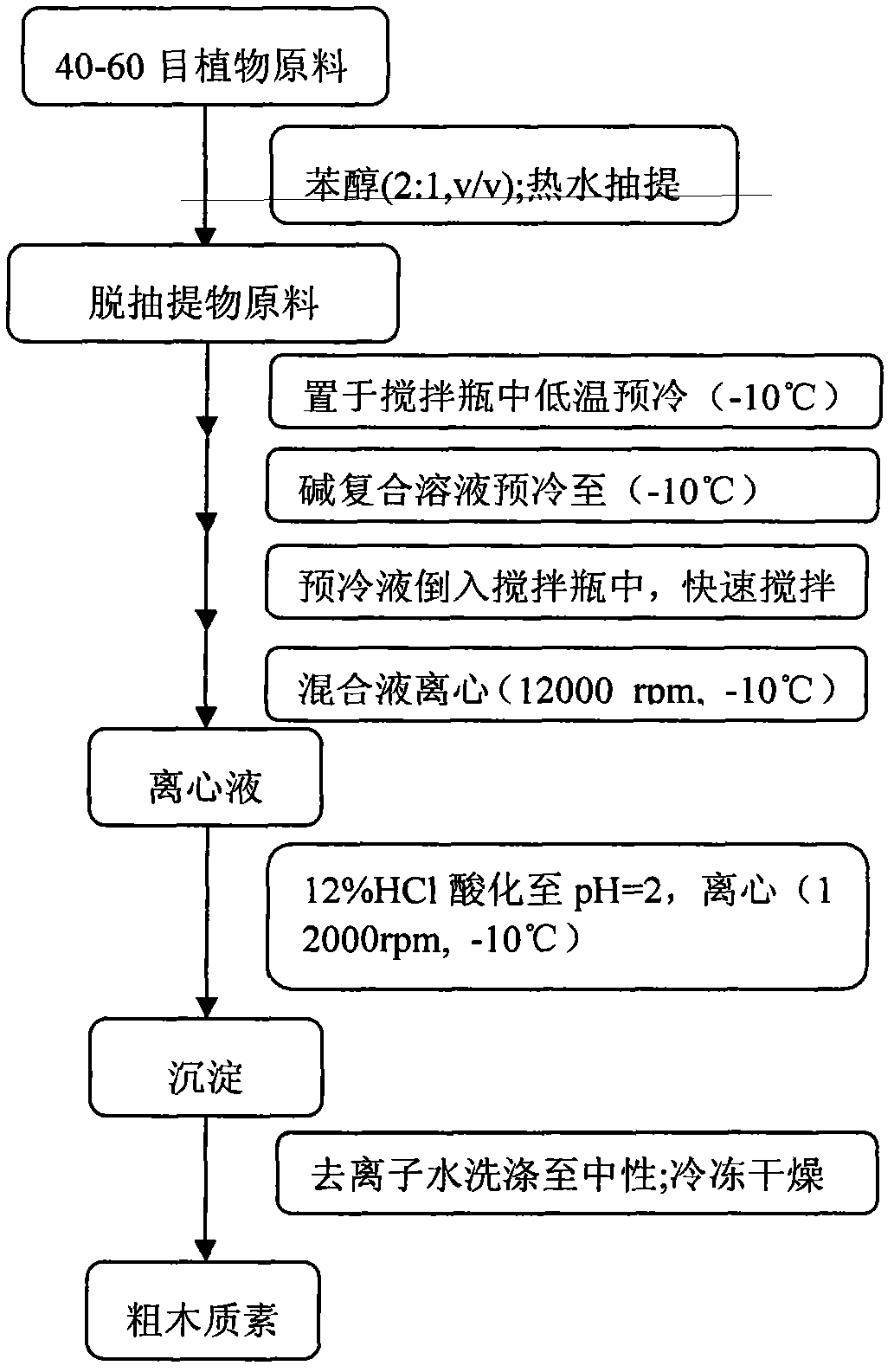

[0019] Separation process:

[0020] Below through specific embodiment and in conjunction with appendix image 3 Explain the separation process: remove the leaves, ears, sheaths and nodes of wheat grass, grind 40-60 mesh grass powder through a plant grinder, and then extract with benzene alcohol (benzene and ethanol, the volume ratio is 2:1) and hot water extraction , air-dried for later use. Weigh 6g of absolute dry grass powder into a 500ml polyethylene bottle, stir, and pre-cool at -10°C for 3 hours, weigh 10g, 8g, 6.5g and 69.5g of sodium hydroxide, urea, thiourea and deionized water g mixed and poured into a 500ml polyethylene bottle, mixed and pre-cooled at -10°C for 3 hours.

[0021] After pre-cooling, quickly pour the alkali compound solution into a stirring bottle containing grass powder, stir at 8000rpm for 3 minutes, then transfer to a 500ml centrifuge bottle, and centrifuge at 12000rpm for 10 minutes at -10°C. The centrate and residue were collected separately....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com