Method for Separating Non-Wood Lignocellulosic Biomass Lignin with Composite Solvent

A technology of lignin and extraction method, applied in continuous pulping process, pulping with inorganic alkali, etc., can solve the problems of lignin molecular structure degradation, crude lignin yield not higher than 65%, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

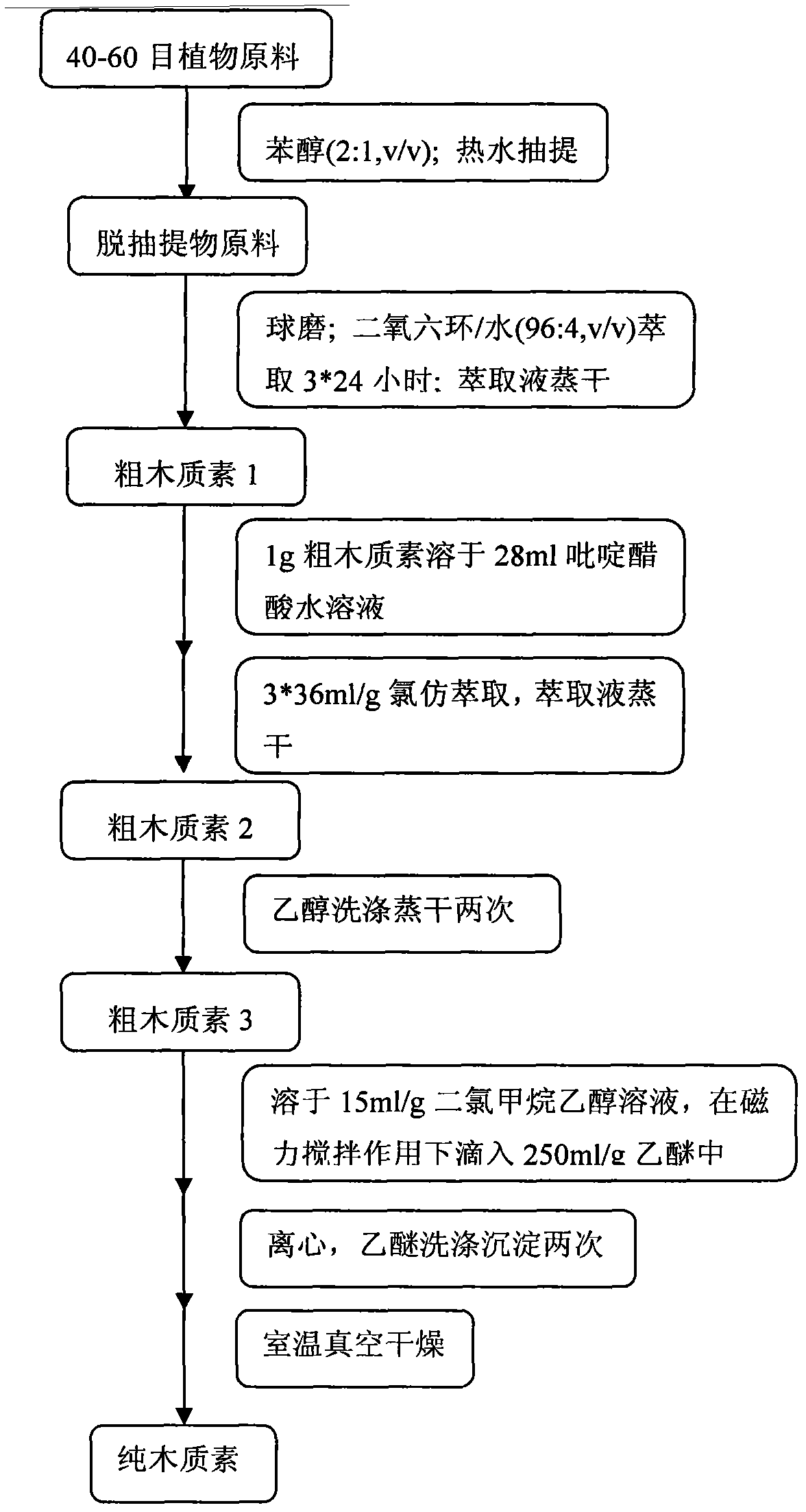

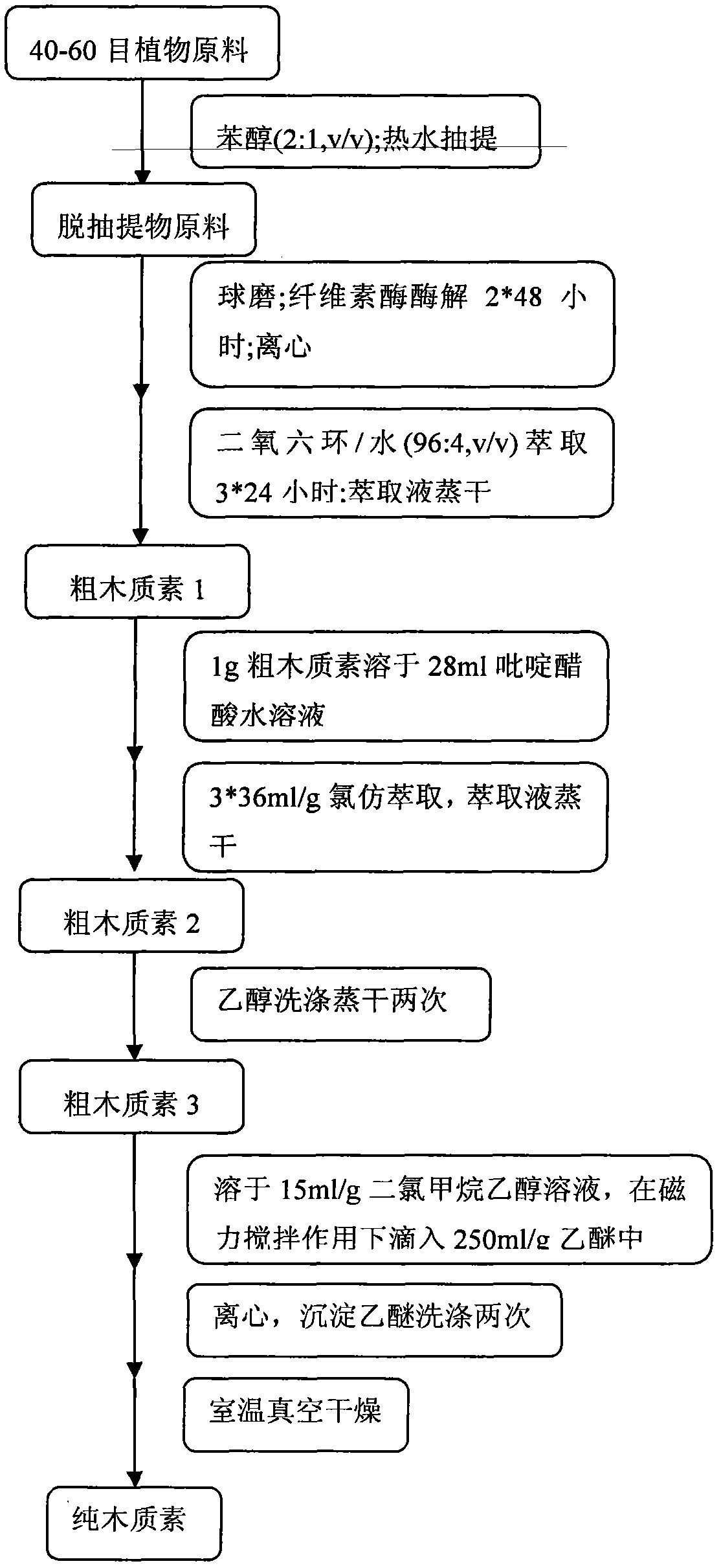

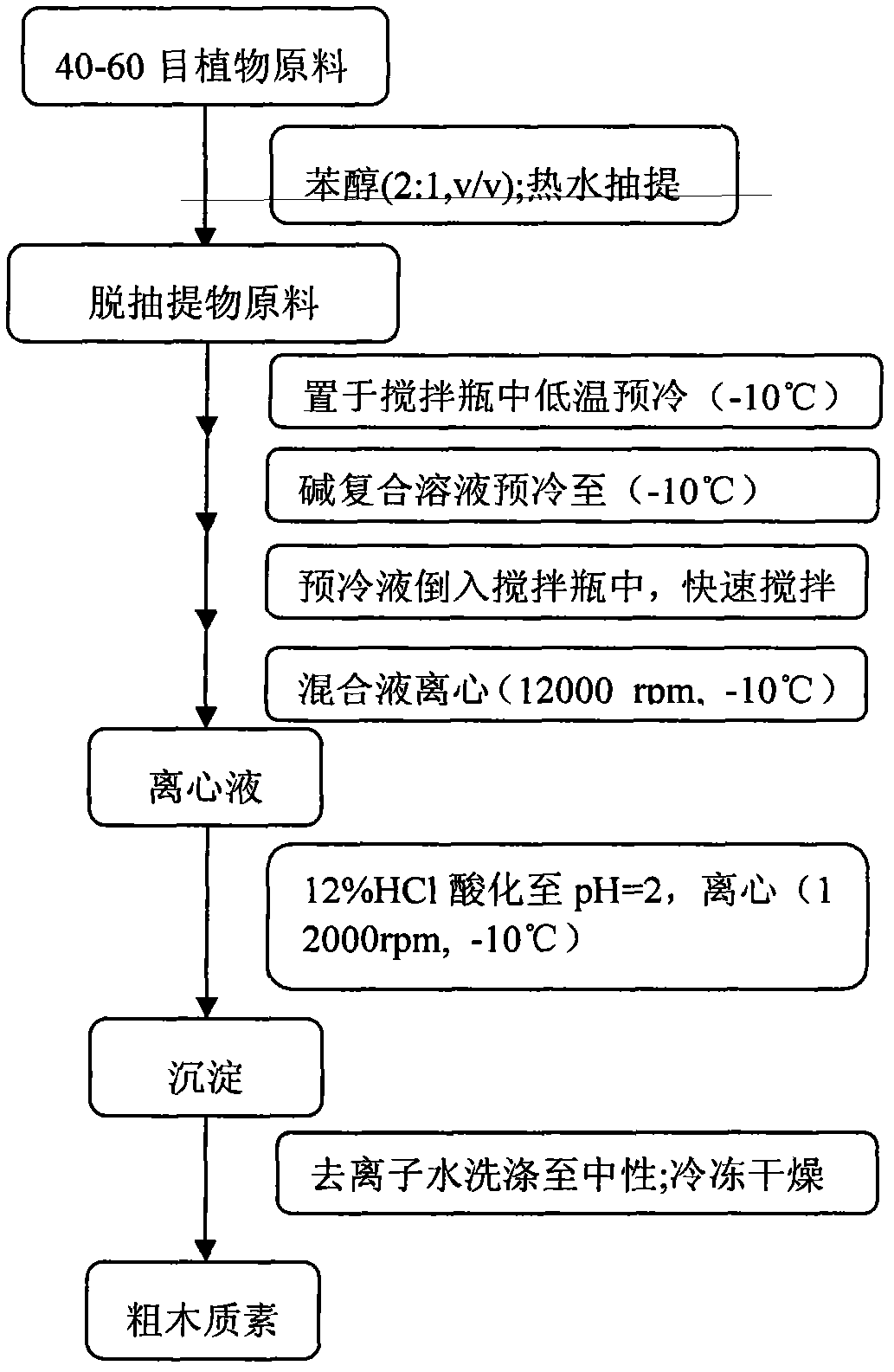

[0019] Separation process:

[0020] Below through specific embodiment and in conjunction with appendix image 3 Explain the separation process: remove the leaves, ears, sheaths and nodes of wheat grass, grind 40-60 mesh grass powder through a plant grinder, and then extract with benzene alcohol (benzene and ethanol, the volume ratio is 2:1) and hot water extraction , air-dried for later use. Weigh 6g of absolute dry grass powder into a 500ml polyethylene bottle, stir, and pre-cool at -10°C for 3 hours, weigh 10g, 8g, 6.5g and 69.5g of sodium hydroxide, urea, thiourea and deionized water g mixed and poured into a 500ml polyethylene bottle, mixed and pre-cooled at -10°C for 3 hours.

[0021] After pre-cooling, quickly pour the alkali compound solution into a stirring bottle containing grass powder, stir at 8000rpm for 3 minutes, then transfer to a 500ml centrifuge bottle, and centrifuge at 12000rpm for 10 minutes at -10°C. The centrate and residue were collected separately....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com