Hardwood alkaline pulping processes and systems

a technology of alkaline pulping and hardwoods, applied in the field of chemical treatments, can solve the problems of decreasing the percentage of pulp rejects at a given kappa number, and conventionally not being able to practice, and achieve the effect of reducing the percentage of pulp rejects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

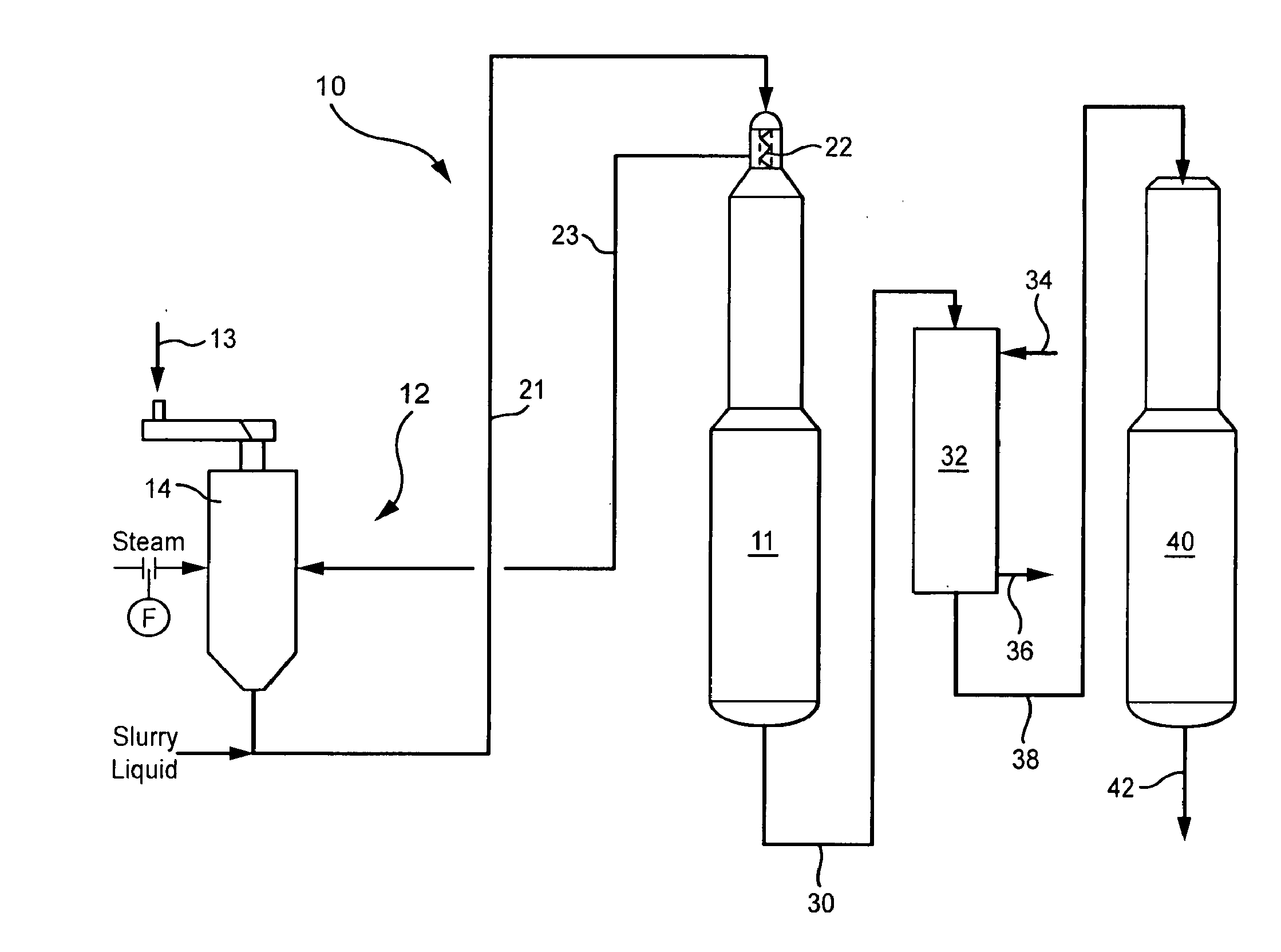

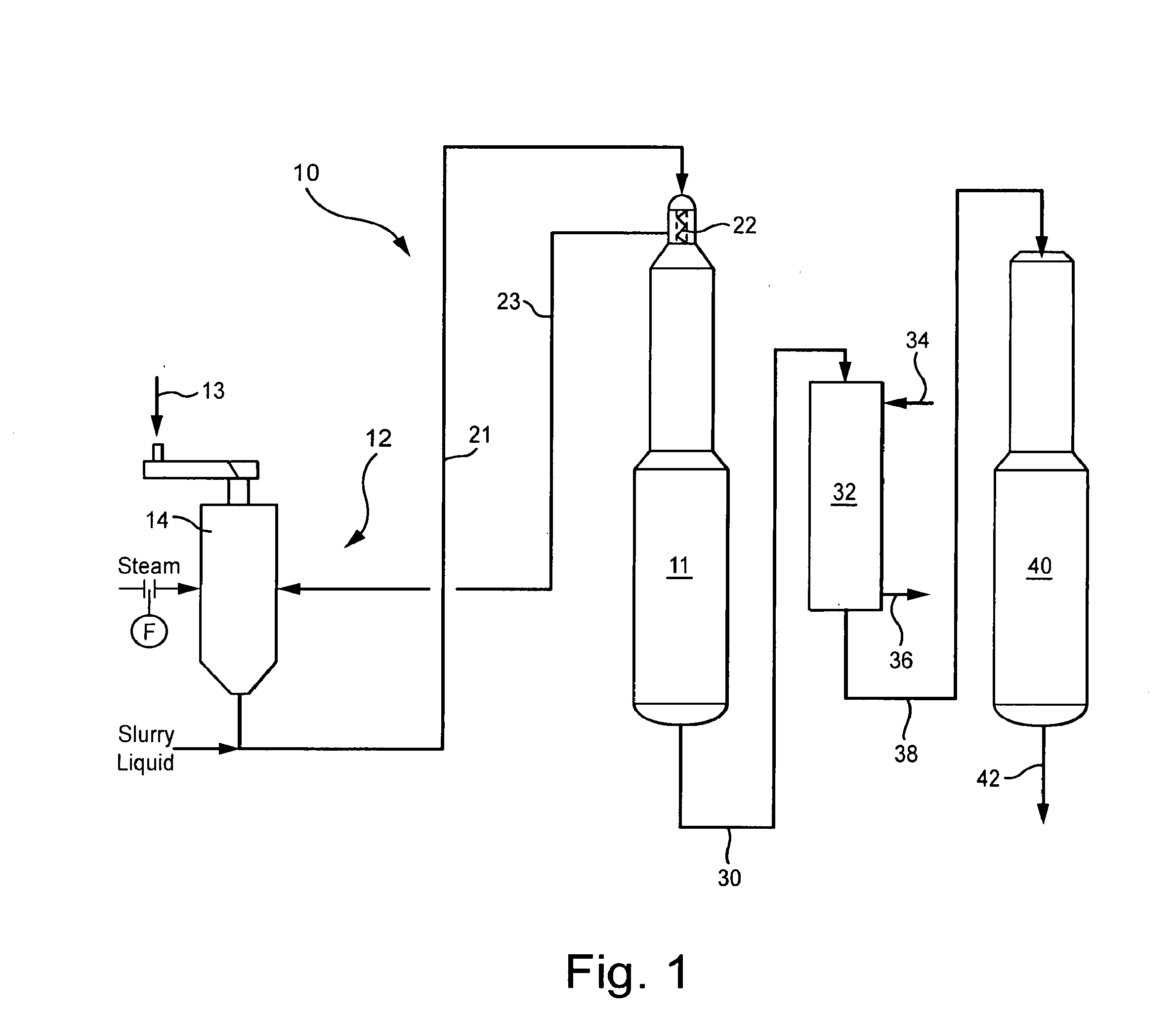

Method used

Image

Examples

example 1

[0031]A hardwood cooking cycle was performed using a total EA (effective alkaline as NaOH) charge of 18% introduced during the impregnation, first cook and second cook stages. The following conditions were used during each of the stages:

[0032]Impregnation:

[0033]60% of the total EA or 10.8% EA charged

[0034]Impregnation temperature of 110° C.

[0035]Time to impregnation temperature=15 minutes

[0036]Time at impregnation temperature=30 minutes

[0037]1st Cook Stage:

[0038]25% of the total EA or 4.5% EA added at beginning of cook

[0039]Cook temperature=140° C.

[0040]Time to heat to cook temperature=15 minutes

[0041]Time at cook temperature=60 minutes

[0042]2nd Cook Stage:

[0043]15% of total EA or 2.7% EA added at beginning of cook

[0044]Cook temperature=158° C.

[0045]Time at cook temperature=76 minutes

[0046]From this set of cooking conditions, the high temperature in the second stage of the cook gave lower Kappa number and at least 30% lower reject rate than the set of cooking conditions using 140° C...

example 2

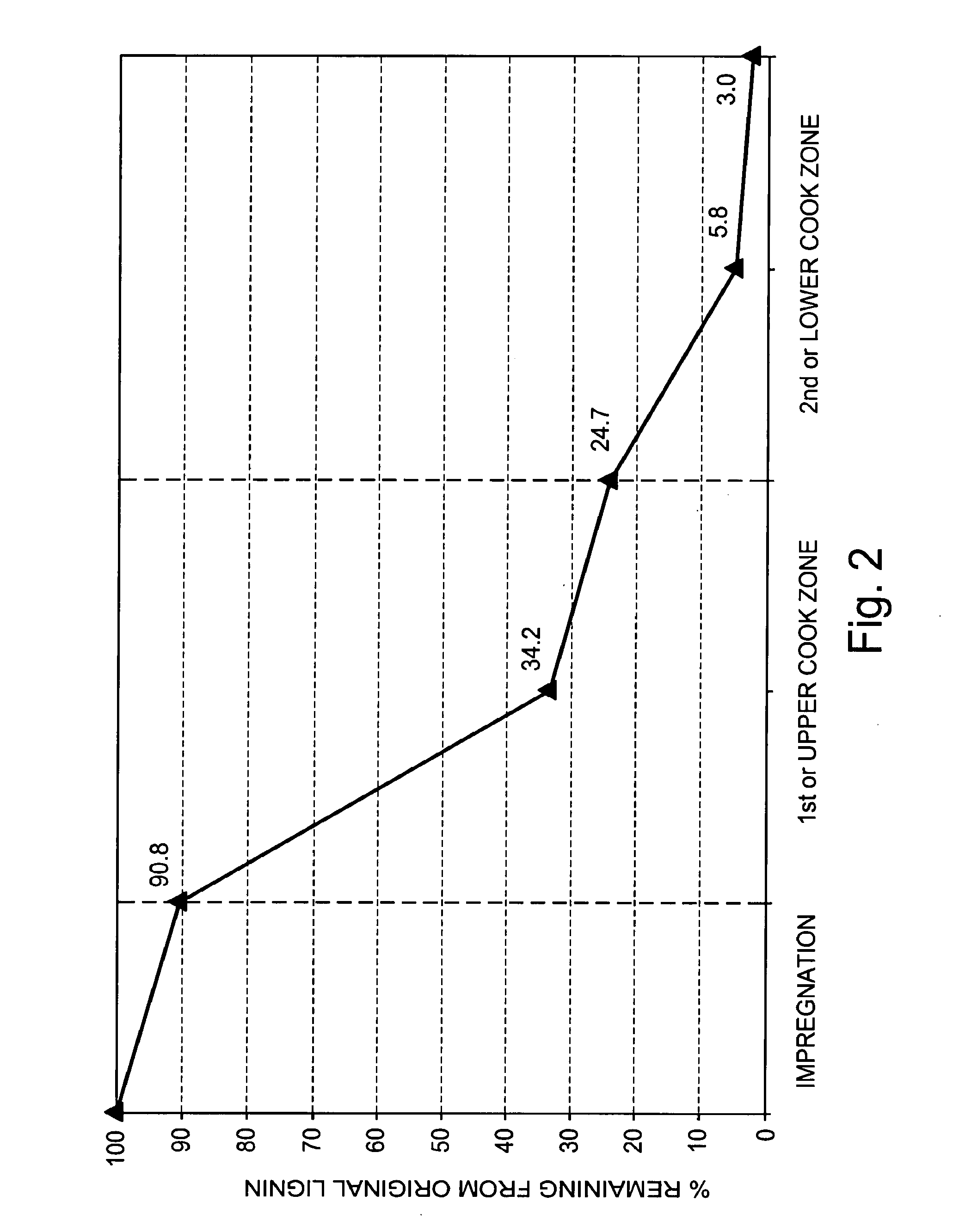

[0047]A hardwood cooking cycle was performed using a total EA (effective alkaline as NaOH) charge of 17.5% introduced during the impregnation, first (or upper) cook and second (or lower) cook sequences. The following conditions were used during each of the cook sequences:

[0048]Impregnation:

[0049]50% of the total EA or 8.75% EA charged

[0050]Impregnation temperature of 110° C.

[0051]Time to impregnation temperature=15 minutes

[0052]Time at impregnation temperature=30 minutes

[0053]1st (Upper) Cook:

[0054]30% of the total EA or 5.25% EA added at beginning of cook

[0055]Cook temperature=155° C.

[0056]Time to heat to cook temperature=15 minutes

[0057]Time at cook temperature=60 minutes

[0058]2nd (Lower) Cook:

[0059]20% of total EA or 3.5% EA added at beginning of cook

[0060]Cook temperature=156° C.

[0061]Time at cook temperature=120 minutes

[0062]A sample of the cellulosic material (wood chips) was taken after impregnation was complete and tested for s-lignin and g-lignin in the laboratory using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com