Method and a device for preparing cellulose pulp

a technology of cellulose pulp and cellulose pulp, which is applied in the direction of continuous pulping process, pulping with inorganic bases, pulp liquor regeneration, etc., can solve the problem of insufficient separation of fibers, affecting the thickness of chips, and affecting the distance and rate of penetration of chemicals into the central parts of chips, so as to improve the yield of the cooking stage following the impregnation stage, the effect of increasing the efficiency of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In this description, the term impregnation liquor refers to the alkaline solution used in the impregnation stage, consisting primarily of white liquor. The effective agents in white liquor are sodium hydroxide (NaOH) and sodium sulfide (Na2S). The term line refers to any tube, duct or channel suitable for conveying a liquid, a gas, or a suspension.

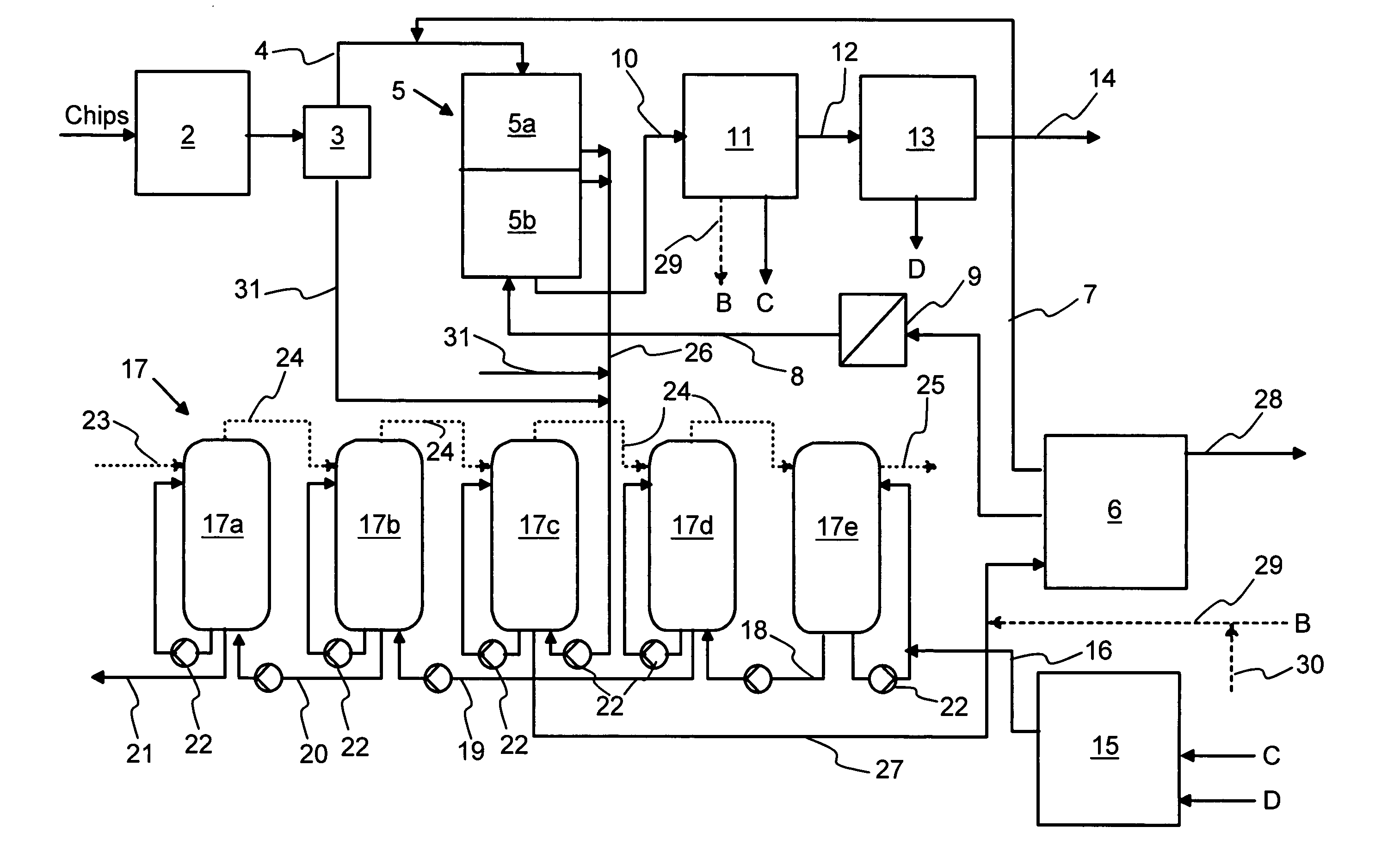

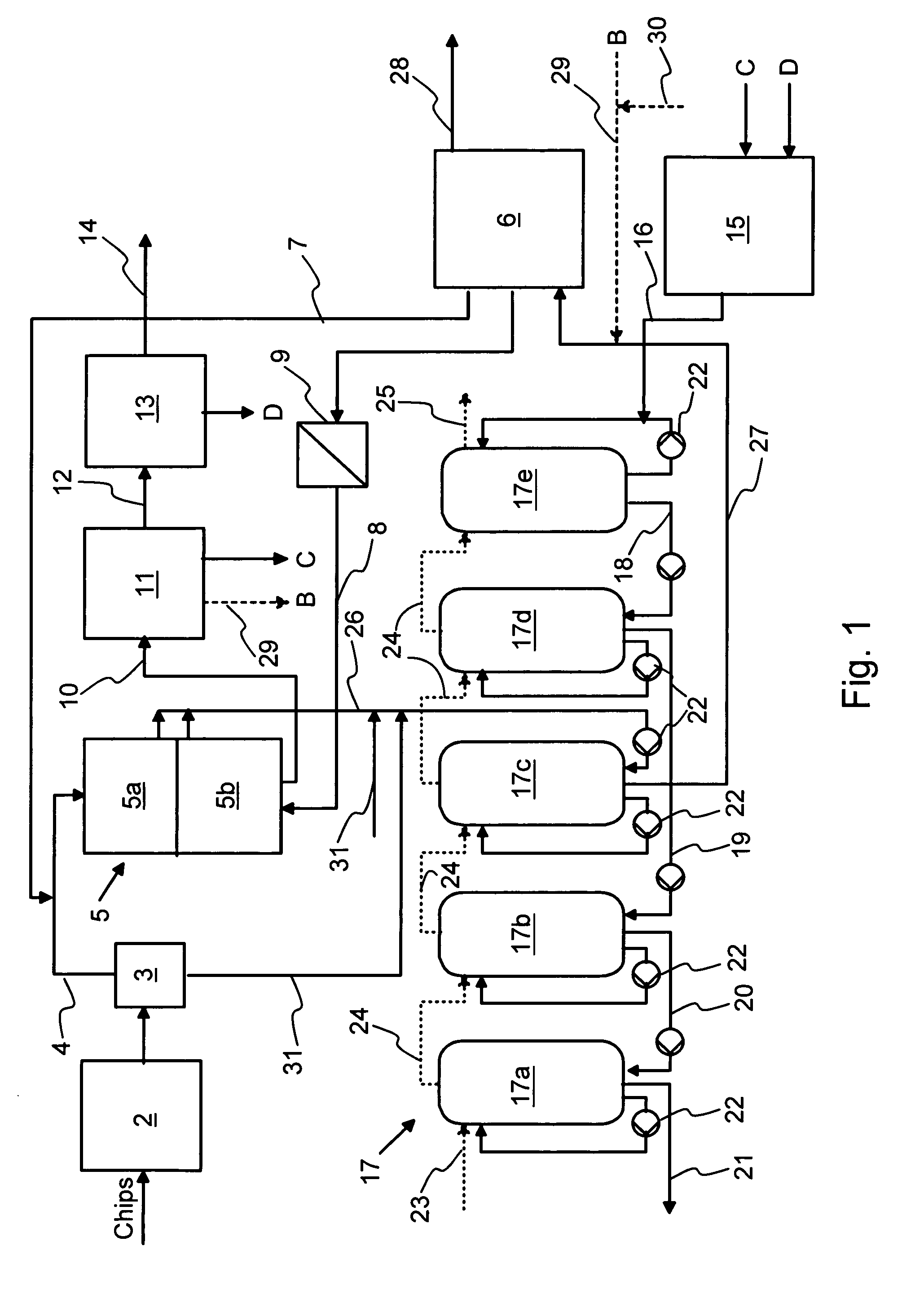

[0027]FIG. 1 is a schematic view showing a device for cellulose pulping according to the invention. The chips used as raw material for cellulose pulp are first subjected to a gas removal stage. In the gas removal stage, the chips are treated in a gas removal unit 2 with a hot gaseous medium, such as steam, to remove gases from within and between the chips. After the gas removal, the chips are transferred by a transfer device 3 via a line 4 to the impregnation stage. Impregnation liquor from an impregnation liquor tank 6 is also supplied via a line 7 into the line 4.

[0028] In the embodiment of FIG. 1, the impregnation stage is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com