Patents

Literature

149results about "Spent liquor concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for production of precipitated lignin from black liquor and precipitated lignin produced by the process

ActiveUS20130131326A1Increase productionImproved propertyLignin derivativesPulp by-products recoveryBlack liquorIncrease temperature

The present invention relates to a process tor the production of precipitated lignin from black liquor wherein the process comprises the steps of providing a black liquor stream treating the black liquor at an increased temperature and precipitating the lignin from the heat treated black liquor. The present invention further relates to precipitated lignin produced according to the process and use of the precipitated lignin produced.

Owner:STORA ENSO OYJ

Method of producing process steam from a black liquor

Method of producing a process steam from a first black liquor derived in connection with the production of paper pulp, wherein the first black liquor is treated to give a second black liquor of a higher concentration than the first black liquor as well as a liquid of low concentration, whereafter said process steam is produced from the low concentration liquid.

Owner:METABO PAPER SWEDEN

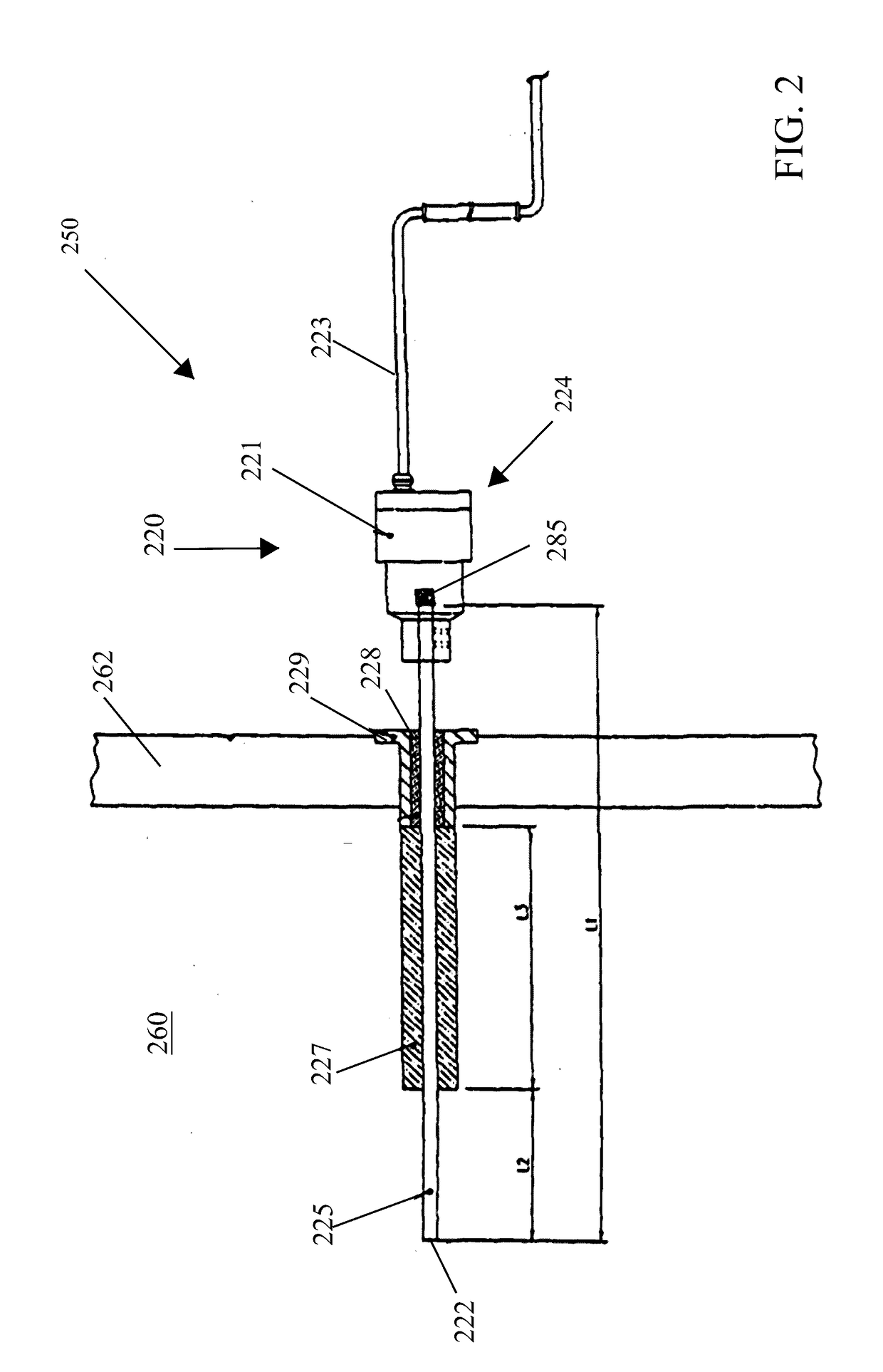

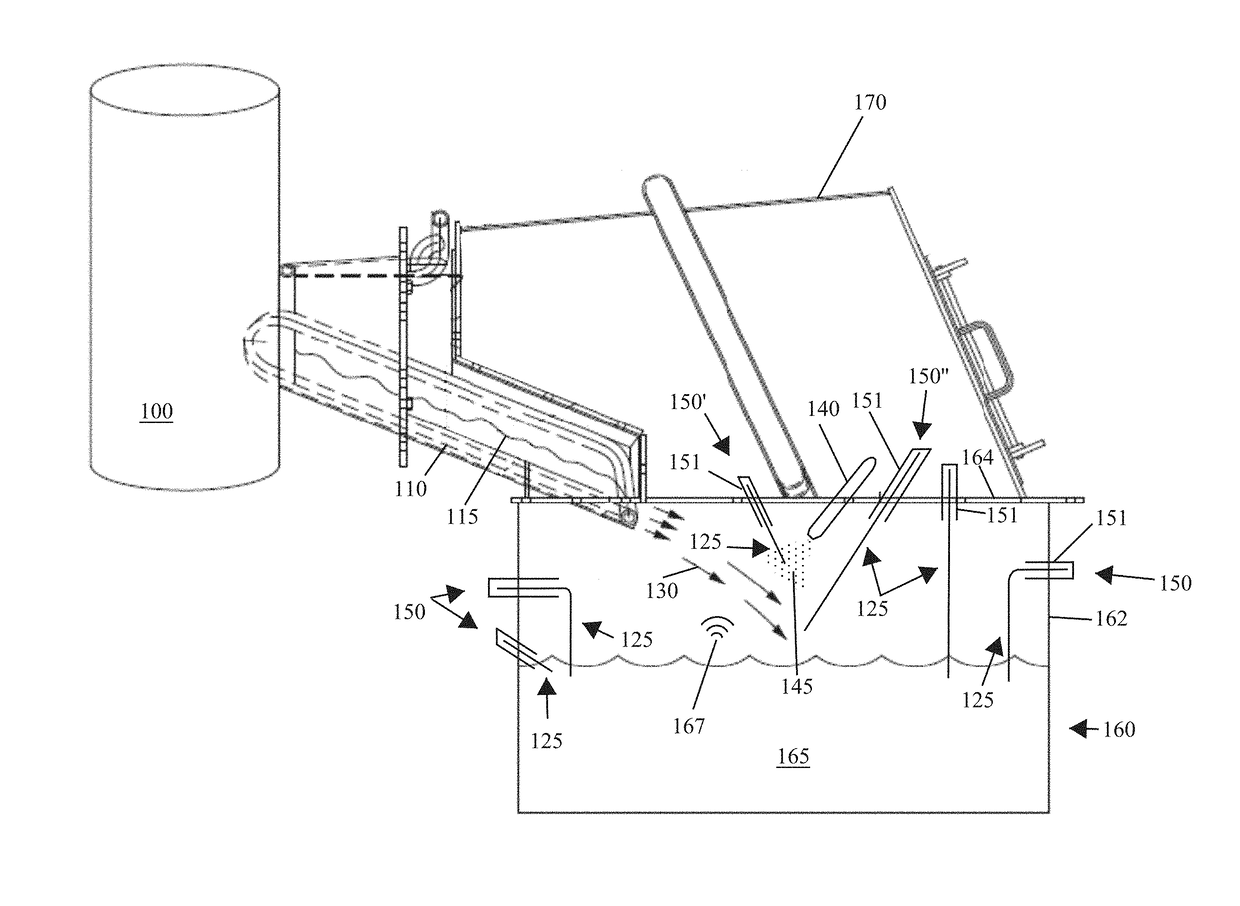

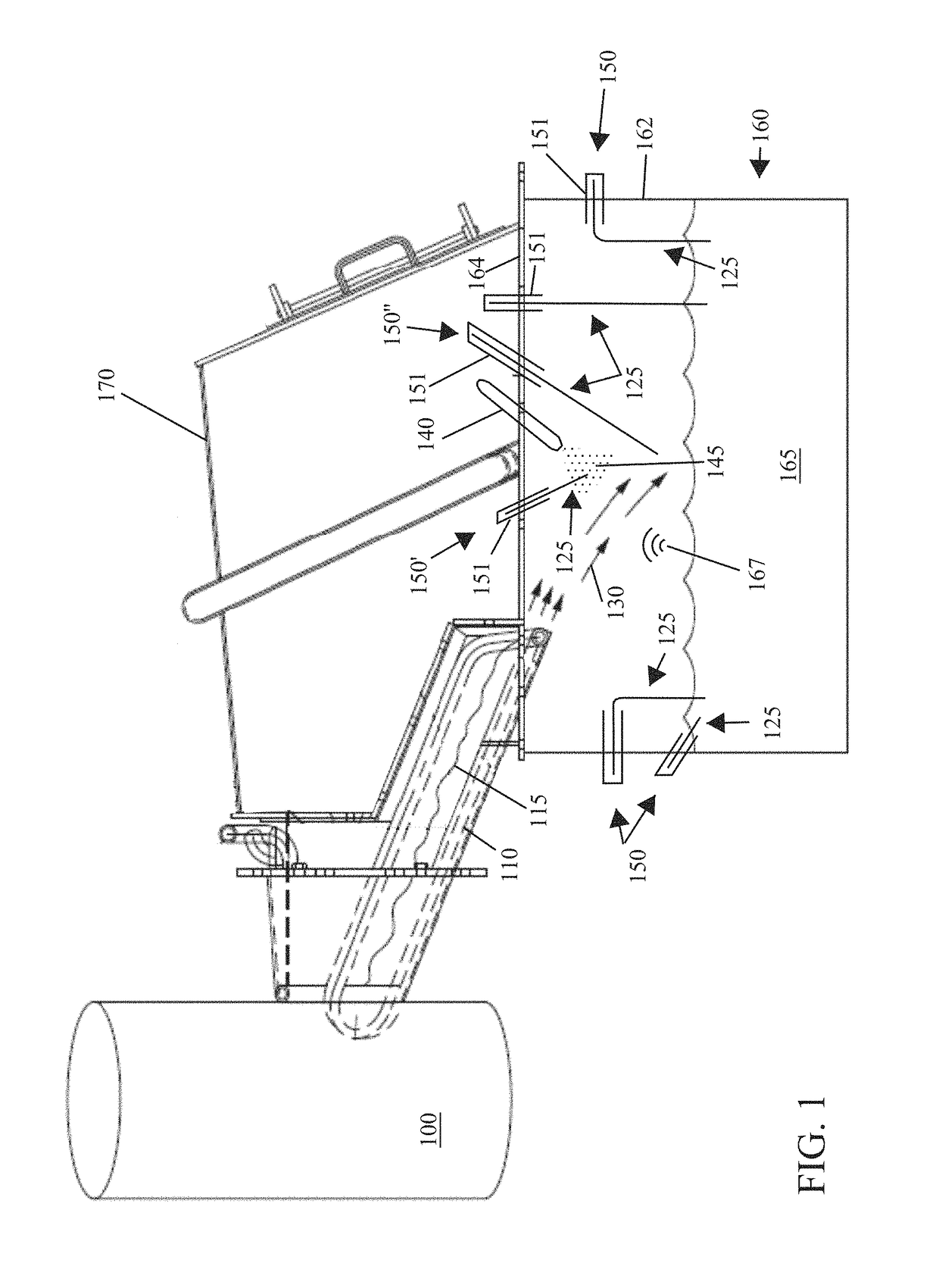

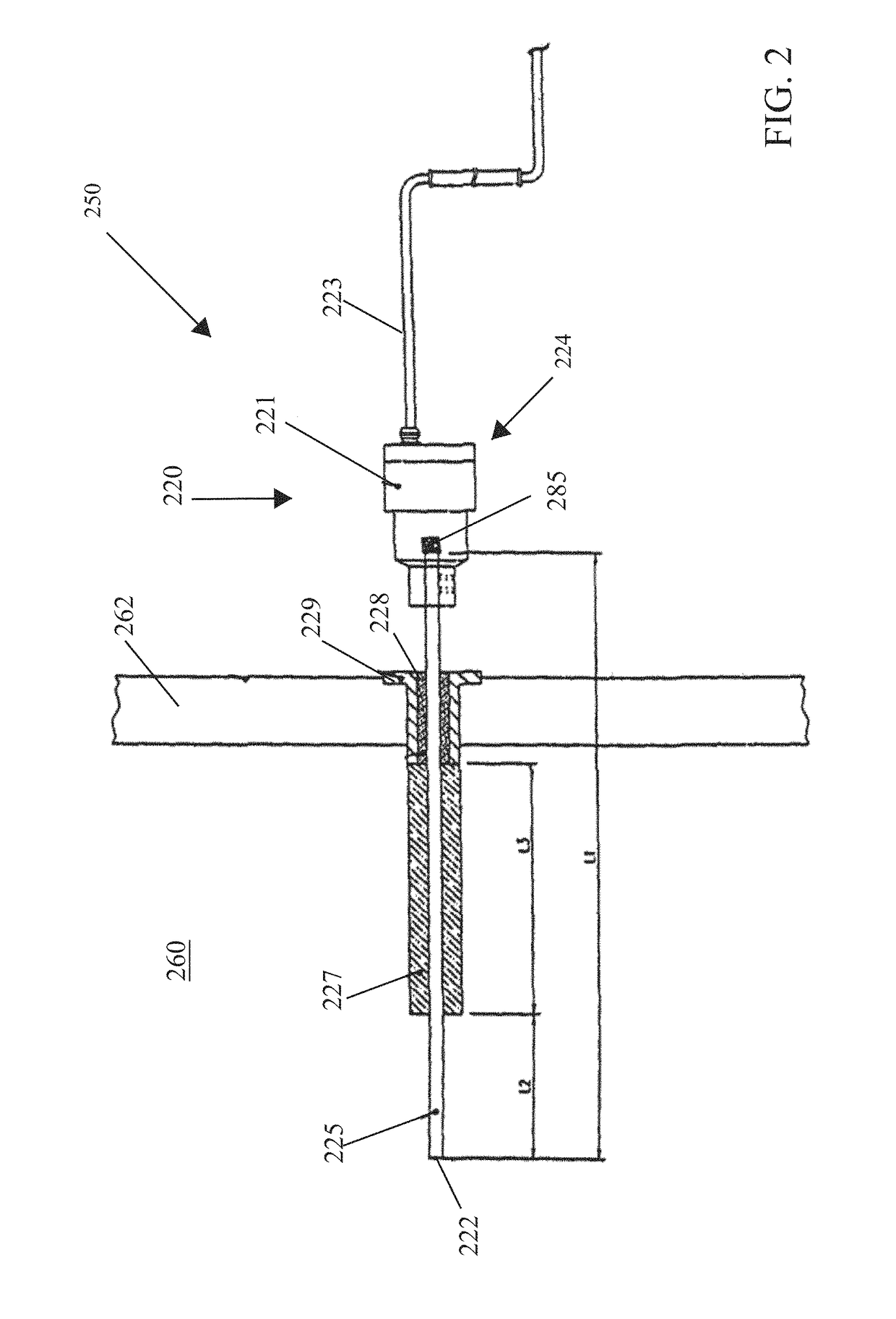

Acoustic emission system and method for predicting explosions in dissolving tank

ActiveUS20170131240A1Prevent and mitigate conditionAnalysing fluids using sonic/ultrasonic/infrasonic wavesPulp liquors combustionAcoustic emissionEngineering

The present disclosure describes a system for predicting explosions in a dissolving tank. The system includes acoustic emission sensors placed in or around the dissolving tank. By filtering the recorded frequencies to the range which is most sensitive for desired explosions “fingerprints,” it is possible to predict a smelt influx before the smelt influx occurs as well as program response actions to prevent compromising explosions.

Owner:ANDRITZ INC

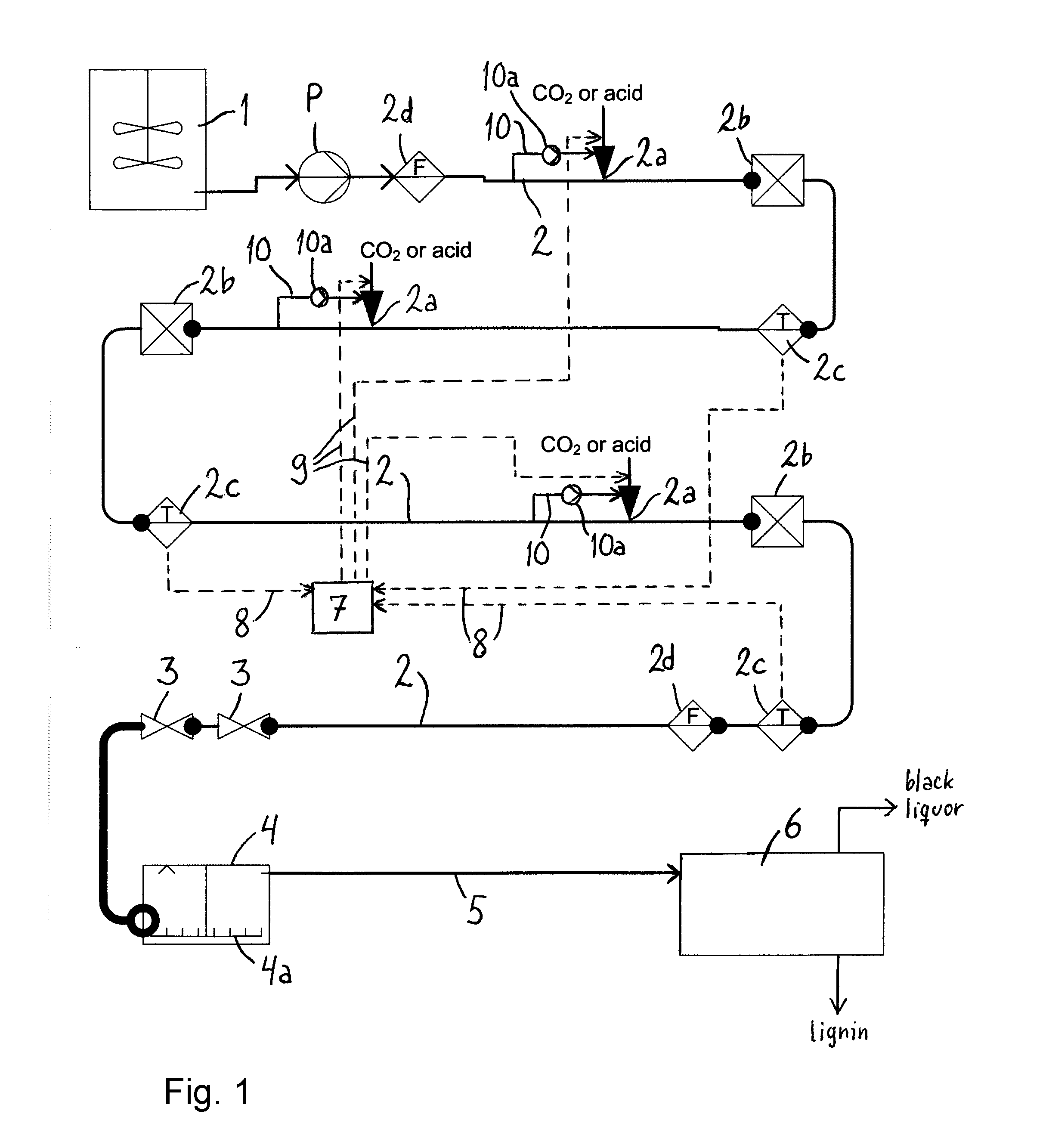

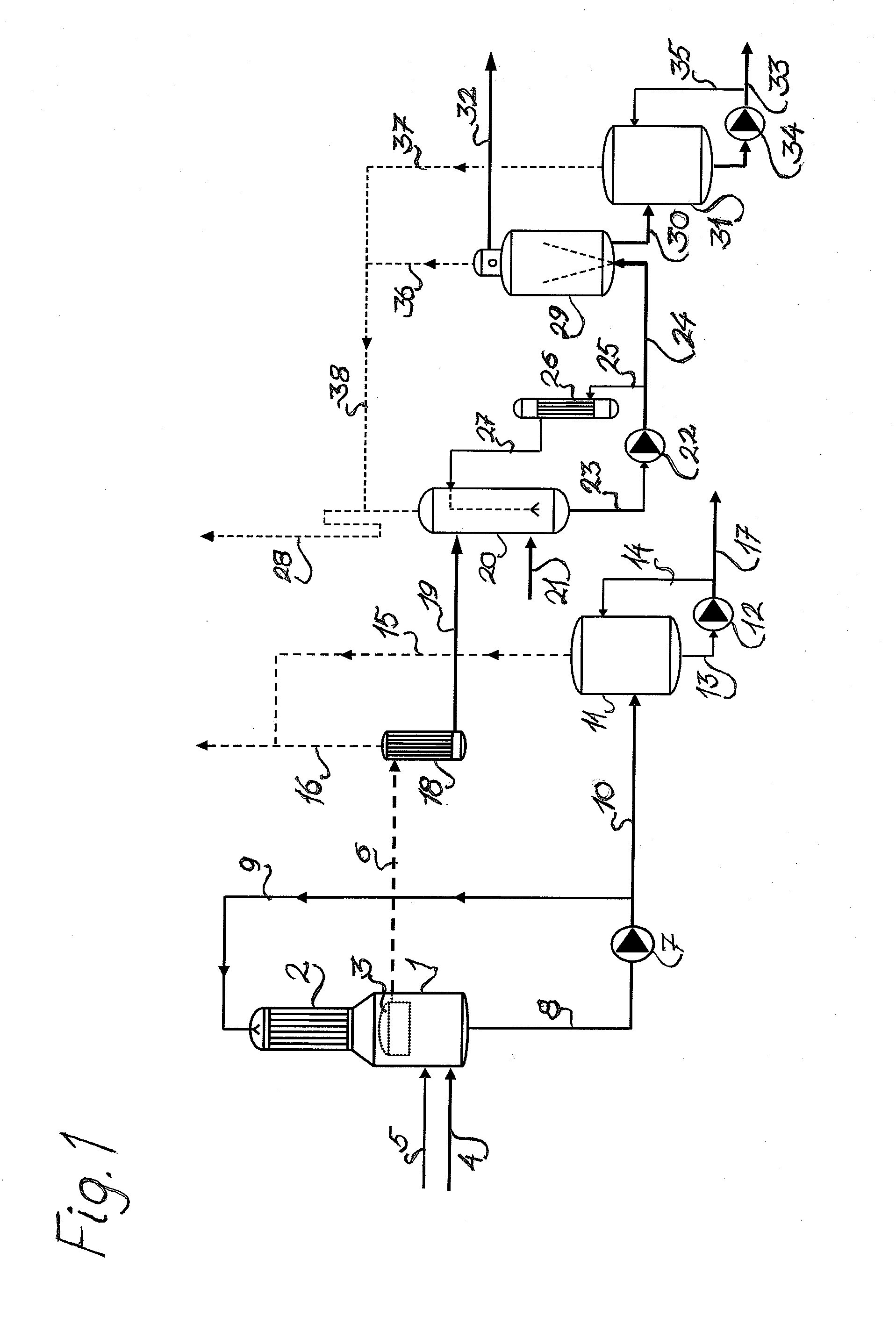

Continuous method for the precipitation of lignin from black liquor

ActiveUS20130203972A1Reduce dwell timeReduce operating costsPressurized chemical processLignin derivativesBlack liquorPrecipitation

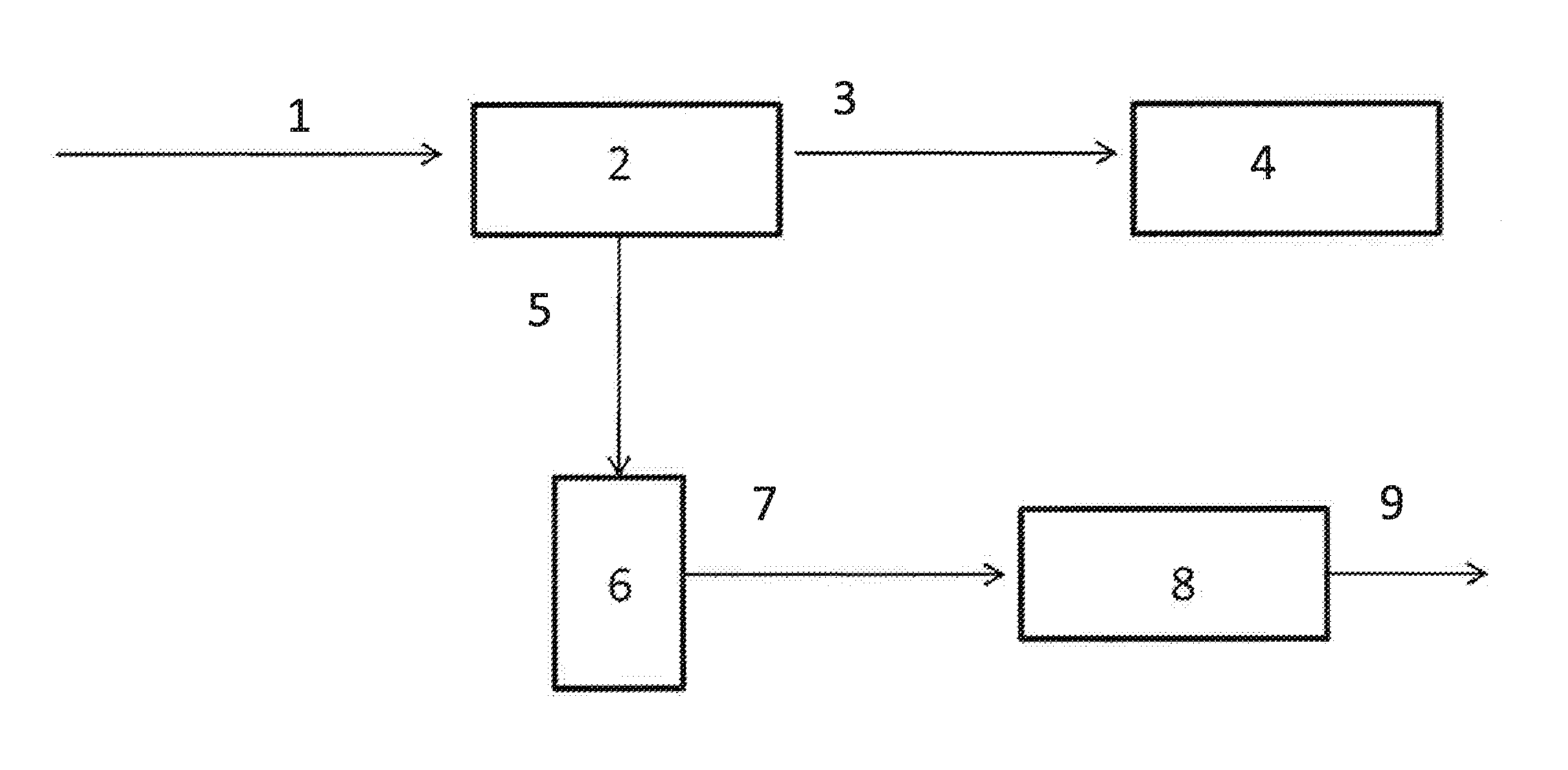

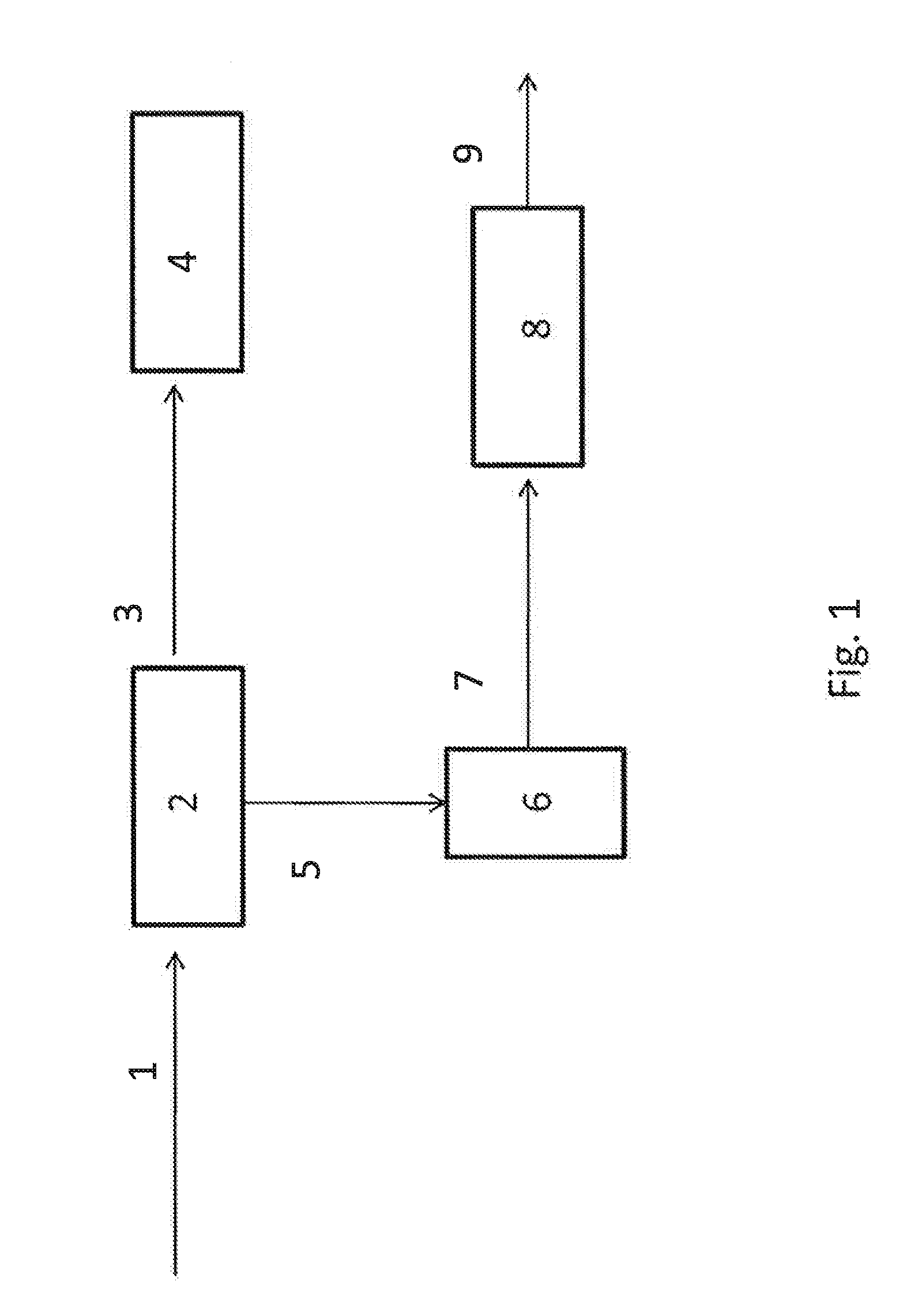

In a method for the continuous precipitation of lignin from black liquor black liquor is provided so as to flow as a pressurized flow in a reactor (2) with a dwell time of less than 300s,—an acidifying agent selected from the group of carbon dioxide, acid and their combinations is led to the flow at one or more feeding sites (2a) to lower the pH of black liquor,—the pH is allowed to decrease by the effect of the acidifying agent in the pressurized flow to the precipitation point of lignin, the pressure of the pressurized flow is abruptly released, and lignin particles are separated from black liquor.

Owner:UPM-KYMMENE OYJ

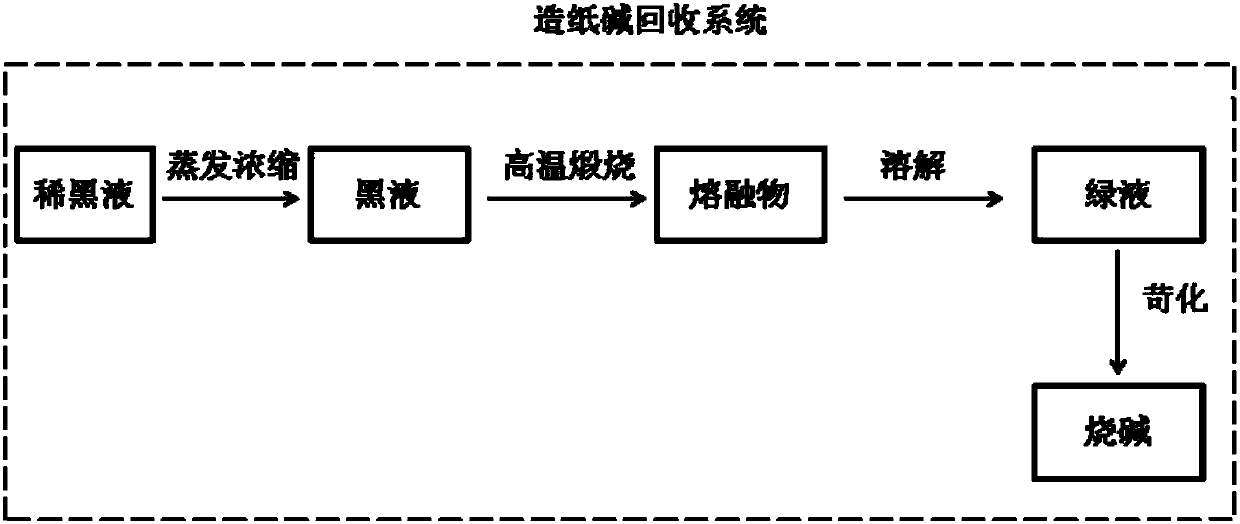

Process of recovering alkali from black liquor of papermaking

InactiveUS20050199358A1Equipment investmentReduce energy consumptionCalcium/strontium/barium carbonatesPulp liquors combustionBlack liquorPrecipitated calcium carbonate

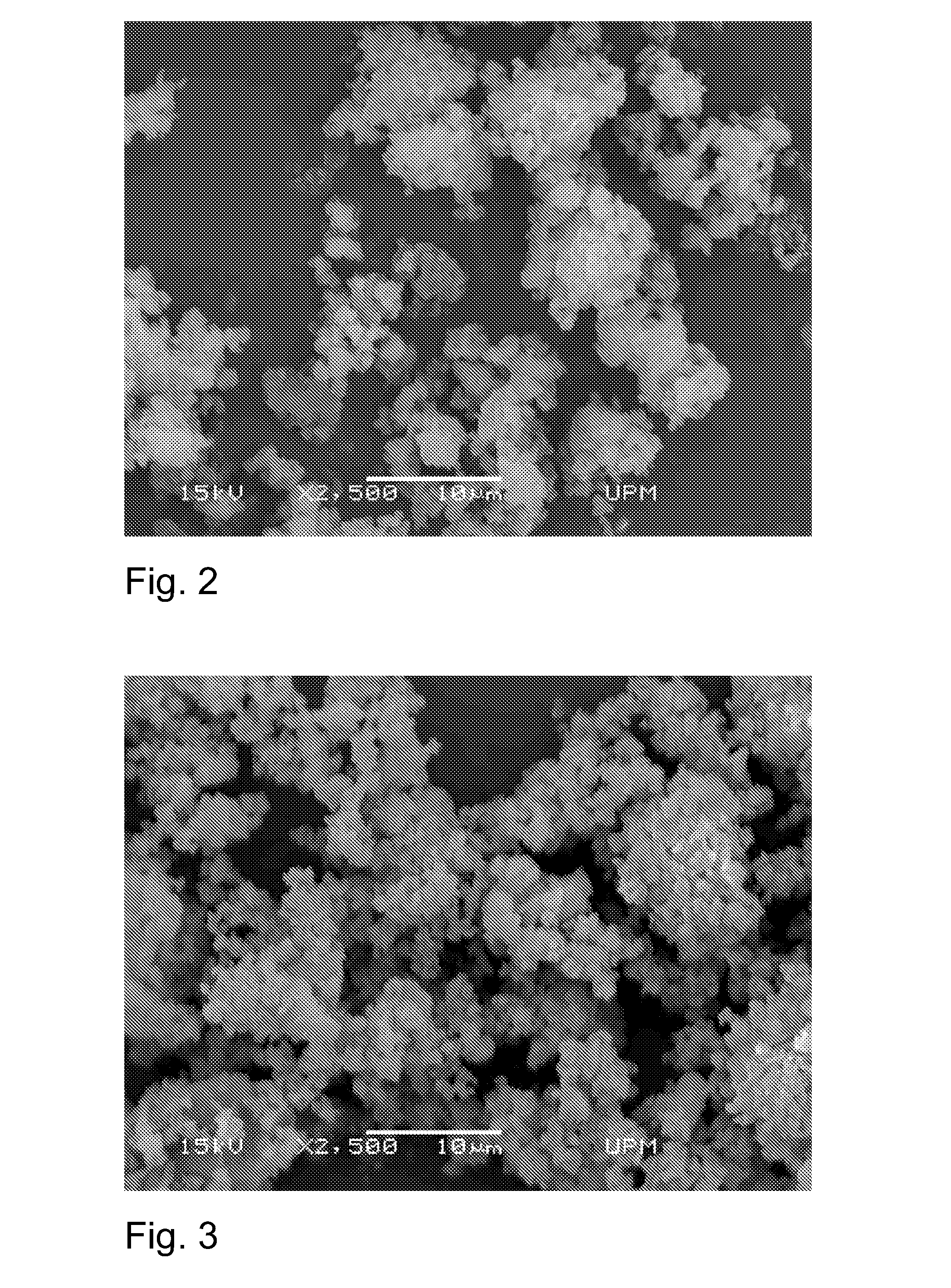

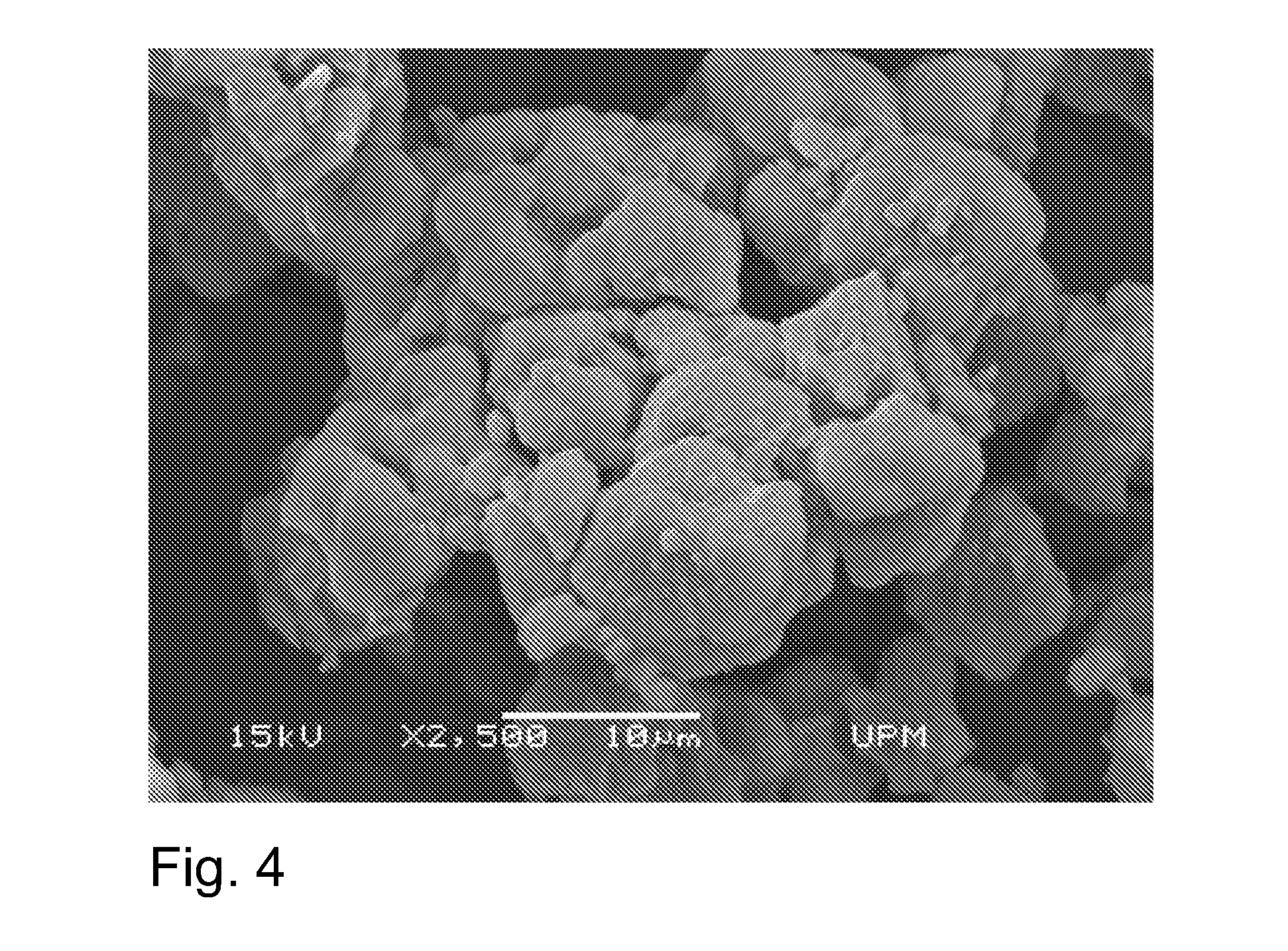

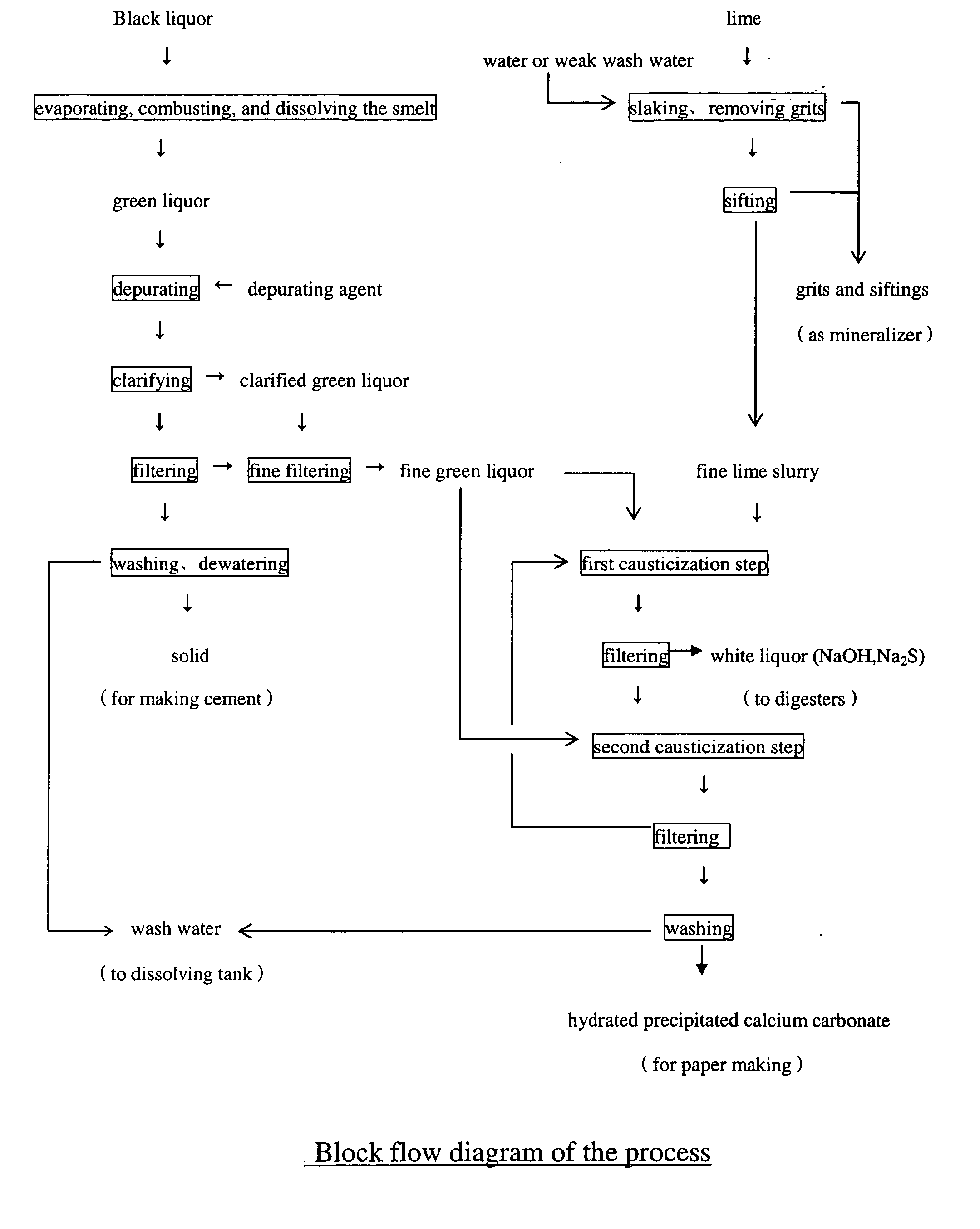

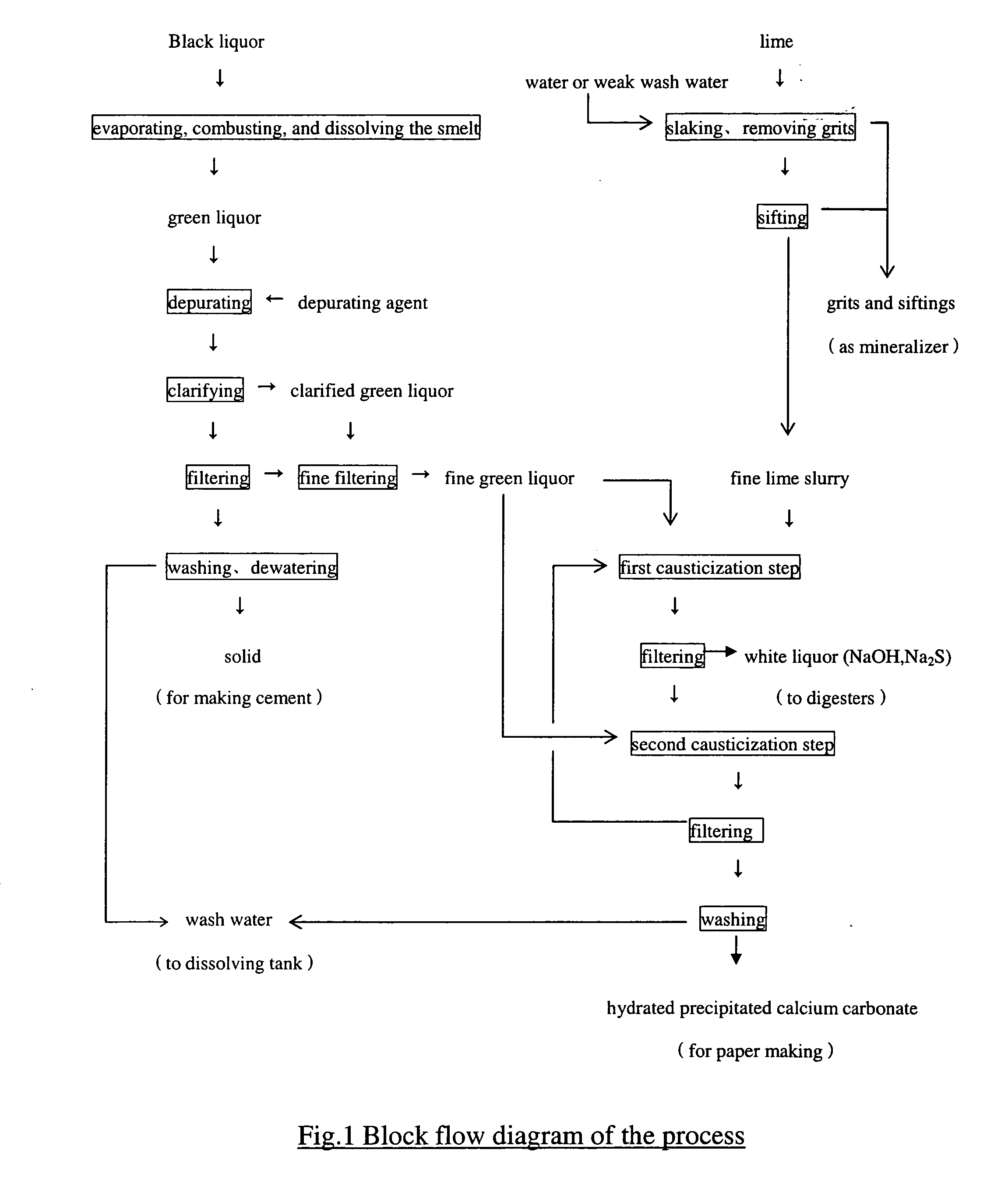

This invention provides an improved process for recovering chemicals from black liquor in alkaline pulping, which is achieved by introducing depuration treatments of green liquor and lime before causticization reaction and a two-step-causticization procedure in the causticization procedure of the conventional chemical recovery process. The process of this invention not only avoids the generation of the waste residue (lime mud) from the beginning and saves the recovery and treatment of lime mud, but also can directly produce a series of precipitated calcium carbonate products with various particle sizes by regulating process conditions while the alkali is recovered, said CaCO3 products including a CaCO3 suitable for making coated paper, wherein >=50% of the CaCO3 has a particle size below 2 mum; a CaCO3 suitable for making neutral sized paper, wherein >=90% of the CaCO3 have a particle size below 2 mum; a superfine CaCO3 having an average particle size <1 mum. The present invention can be used for treatment of pollution of black liquor in the alkaline pulping.

Owner:AI TIANZHAO +3

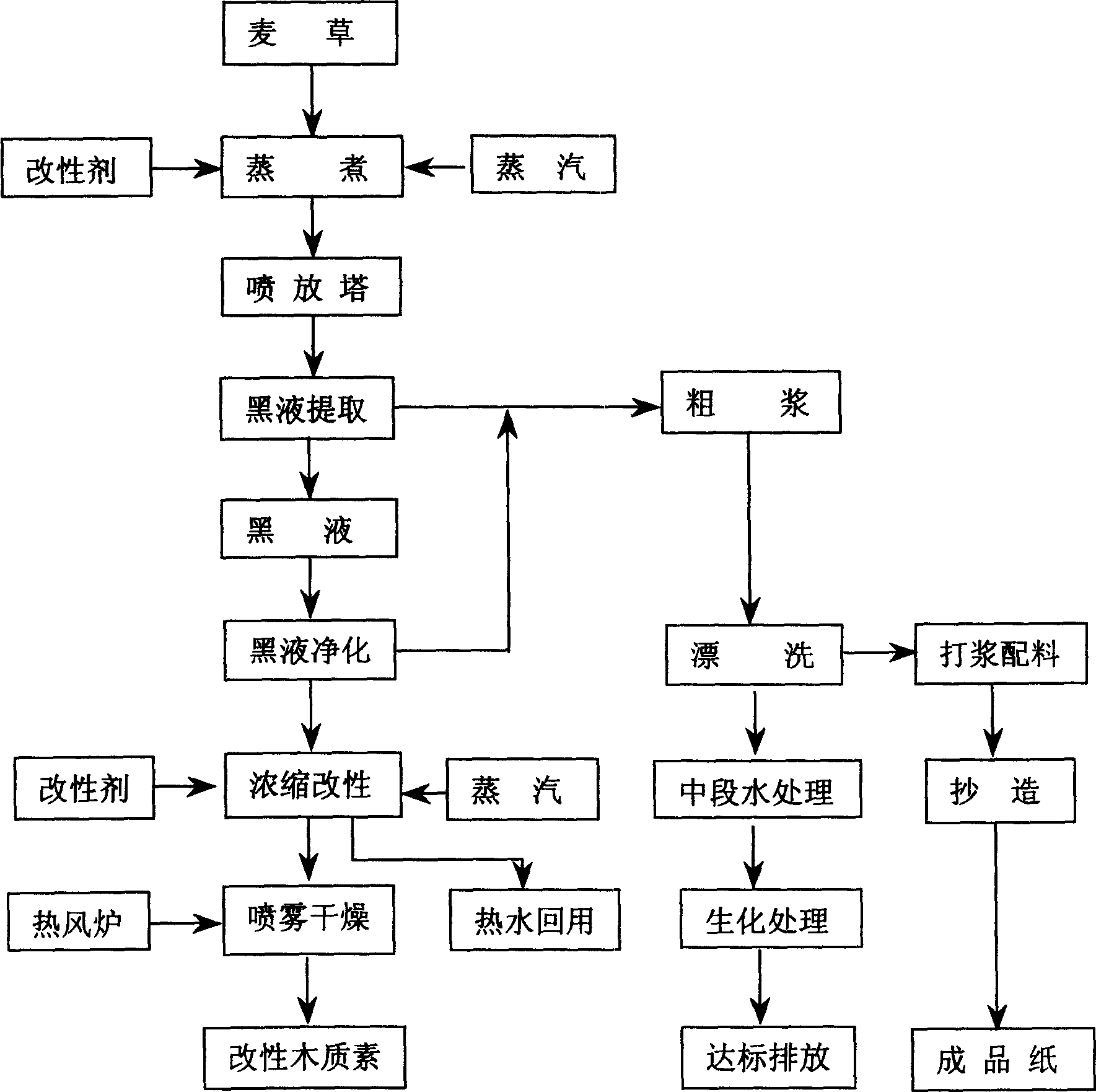

Cleaner production of paper by straw and lignin modification process

InactiveCN1603514ALow viscosityImprove performanceNon-fibrous pulp additionPaper/cardboardTextile fiberBlack liquor

The invention discloses the agricultural and subsidiary products straw stalk resources clean production paper and the modified lignin new craft. The craft the black liquor took the precious resources, in steams and its concentrates two stages separately to join the modifier, steams the medicinal preparation, the molecular weight and the performance regulation medicinal preparation, fully uses in the straw stalk the textile fiber, the lignin equicomponent, always will pollute the traditional straw pulp juice the load approximately 90% elimination in the technological process. The craft suits the size middle and small scale straw pulp paper mill use, becomes paper pulp which delivers rate high, the viscosity is low, Yi Xiyi floats, more importantly the by-product lignin after the modification, has performance and so on good disperser caking conformity, widely uses in the cement sur- medicinal preparation, the water coal tar chemical additive, the agricultural chemicals dispersing agent and so on.

Owner:孙海明

Solvent recovery method in cellulosic fiber preparation with ionic liquid as solvent

The invention discloses a method for reclaiming solvent in cellulose fiber preparation taking ionic liquid as the solvent, which comprises the following steps: filtering solution containing the ionic liquid to remove solid particle impurities; performing film condensation by a reverse osmosis membrane; and distilling the condensed solution containing the ionic liquid under reduced pressure to make the mass content of water in the solution containing the ionic liquid less than or equal to 2 percent, and obtaining the reclaimed ionic liquid. The method is suitable for reclaiming the solution containing the ionic liquid in wide concentration range, and has low energy consumption and easy implementation.

Owner:CHTC HELON

Acoustic emission system and method for predicting explosions in dissolving tank

ActiveUS10012616B2Prevent and mitigate conditionAnalysing fluids using sonic/ultrasonic/infrasonic wavesPulp liquors combustionAcoustic emissionEngineering

The present disclosure describes a system for predicting explosions in a dissolving tank. The system includes acoustic emission sensors placed in or around the dissolving tank. By filtering the recorded frequencies to the range which is most sensitive for desired explosions “fingerprints,” it is possible to predict a smelt influx before the smelt influx occurs as well as program response actions to prevent compromising explosions.

Owner:ANDRITZ INC

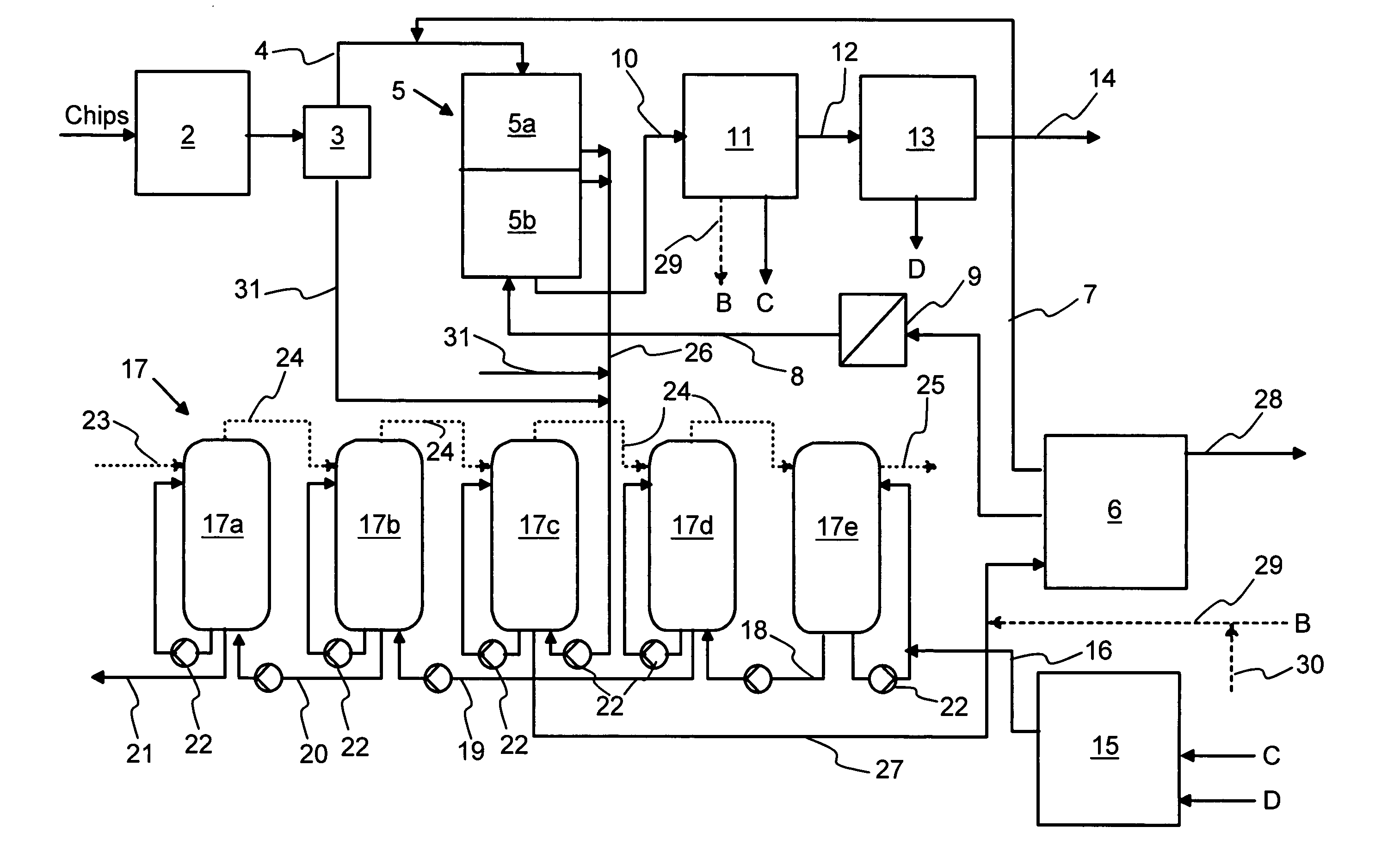

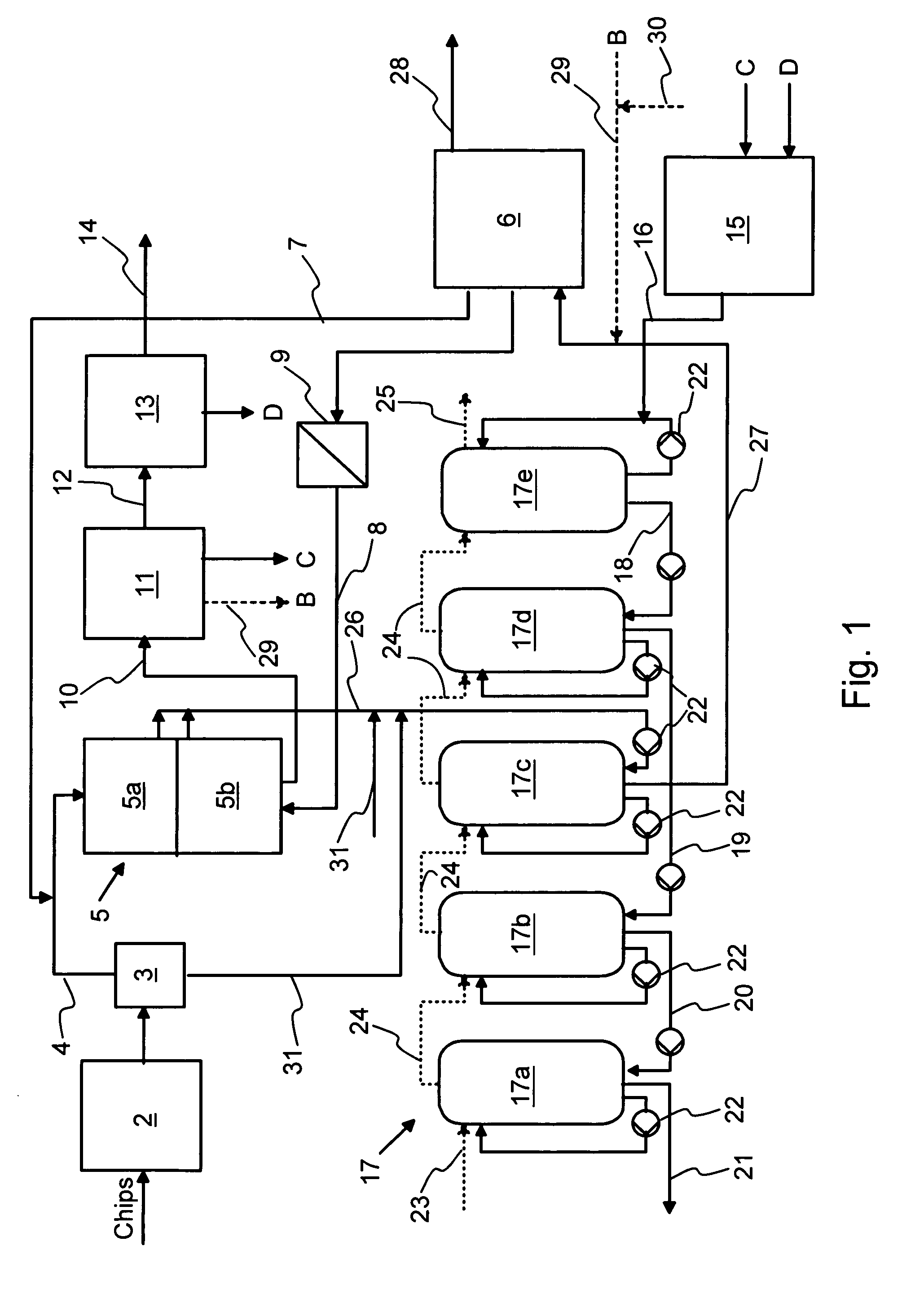

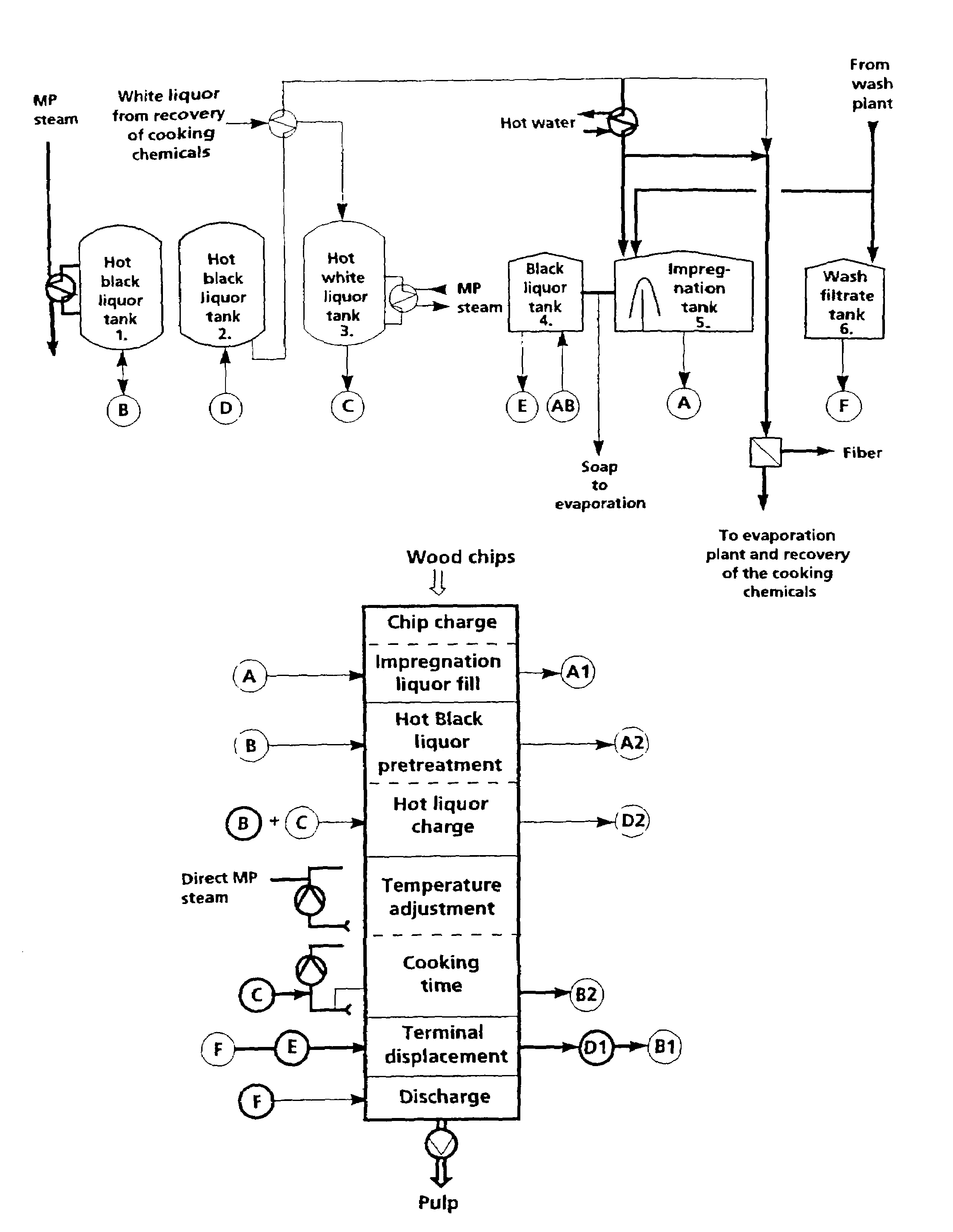

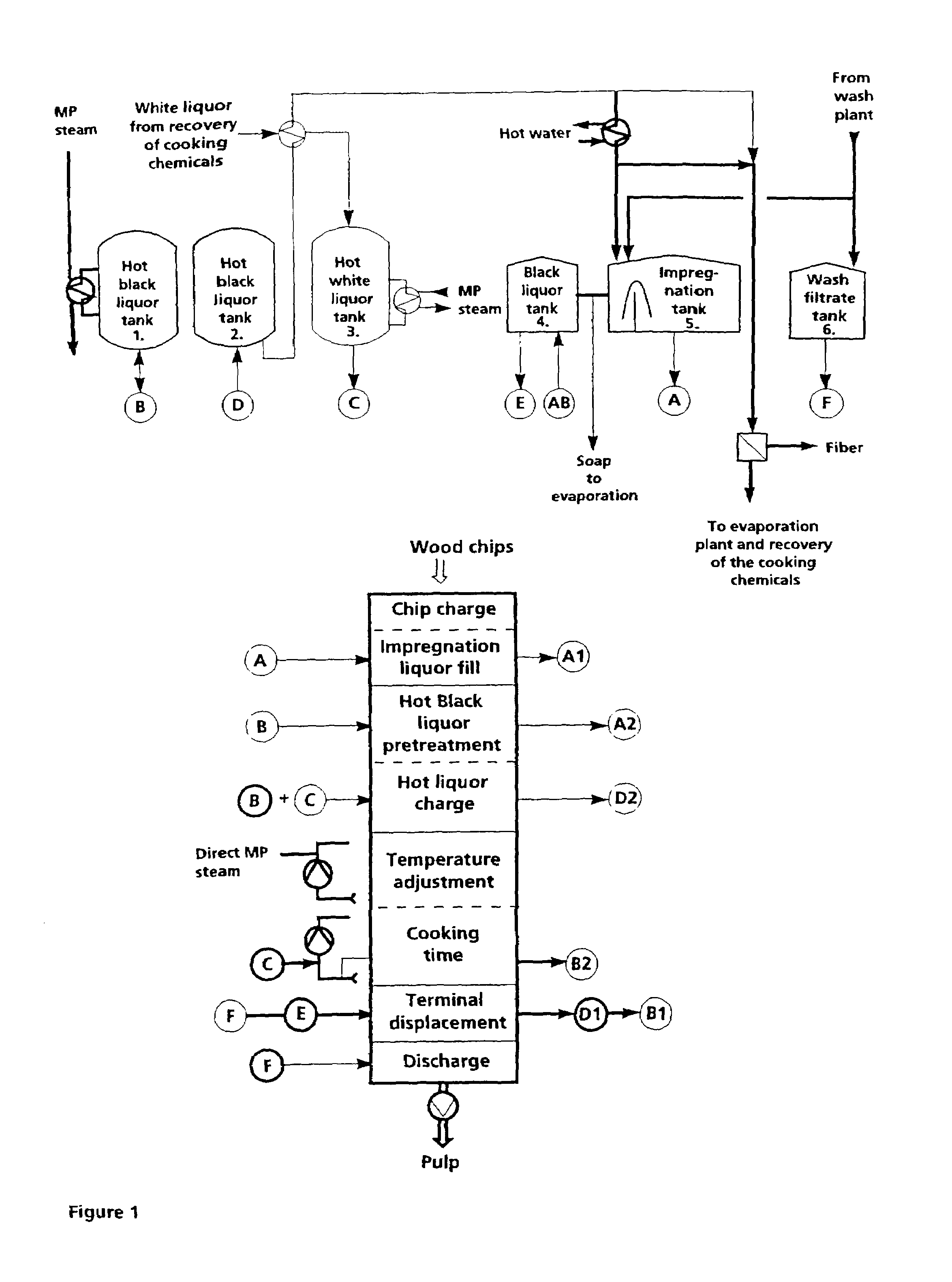

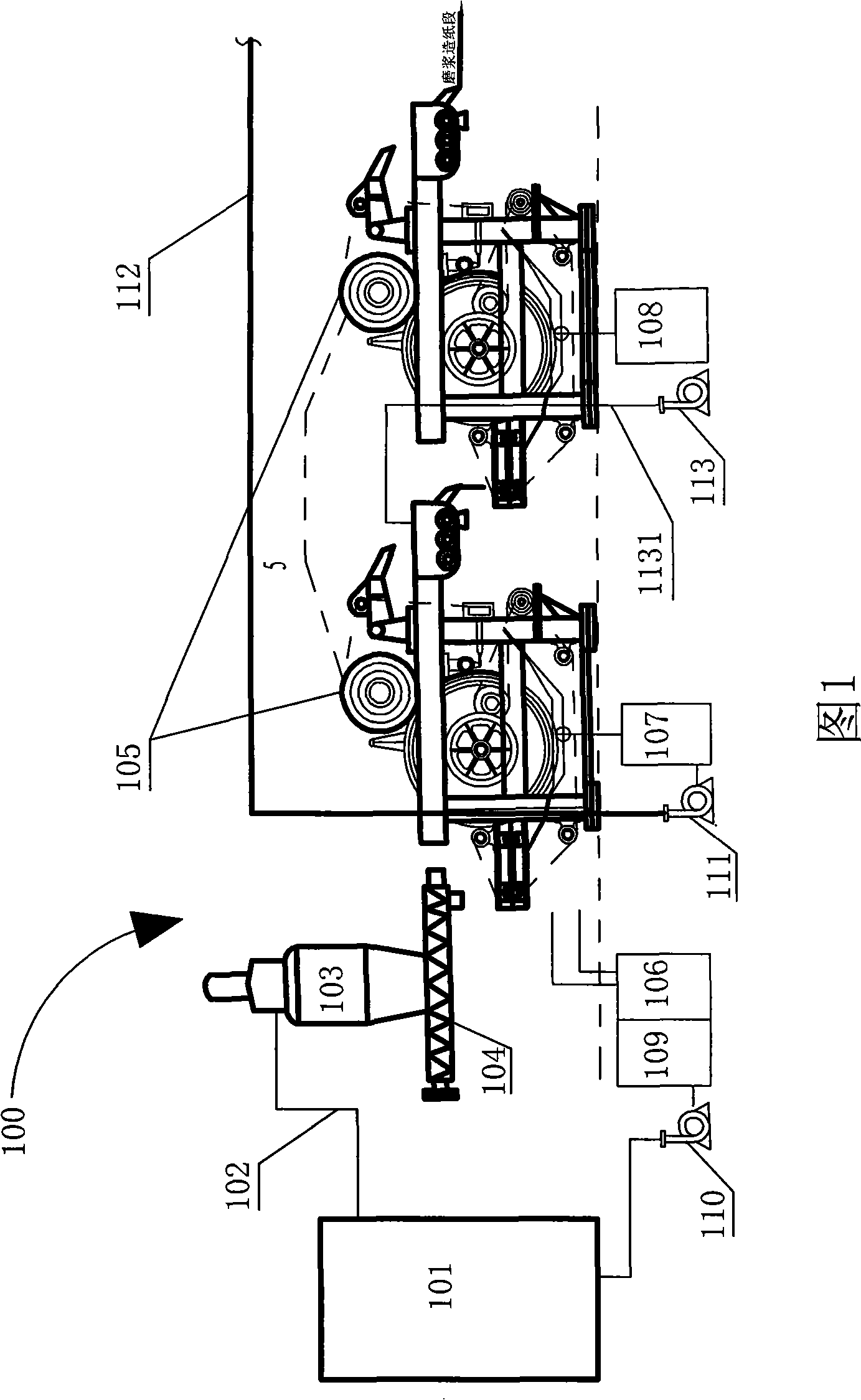

Method and a device for preparing cellulose pulp

InactiveUS20060070710A1Reduce the cooking temperatureImprove economyPulp liquors combustionPretreatment with alkaline reacting compoundsBlack liquorPulp mill

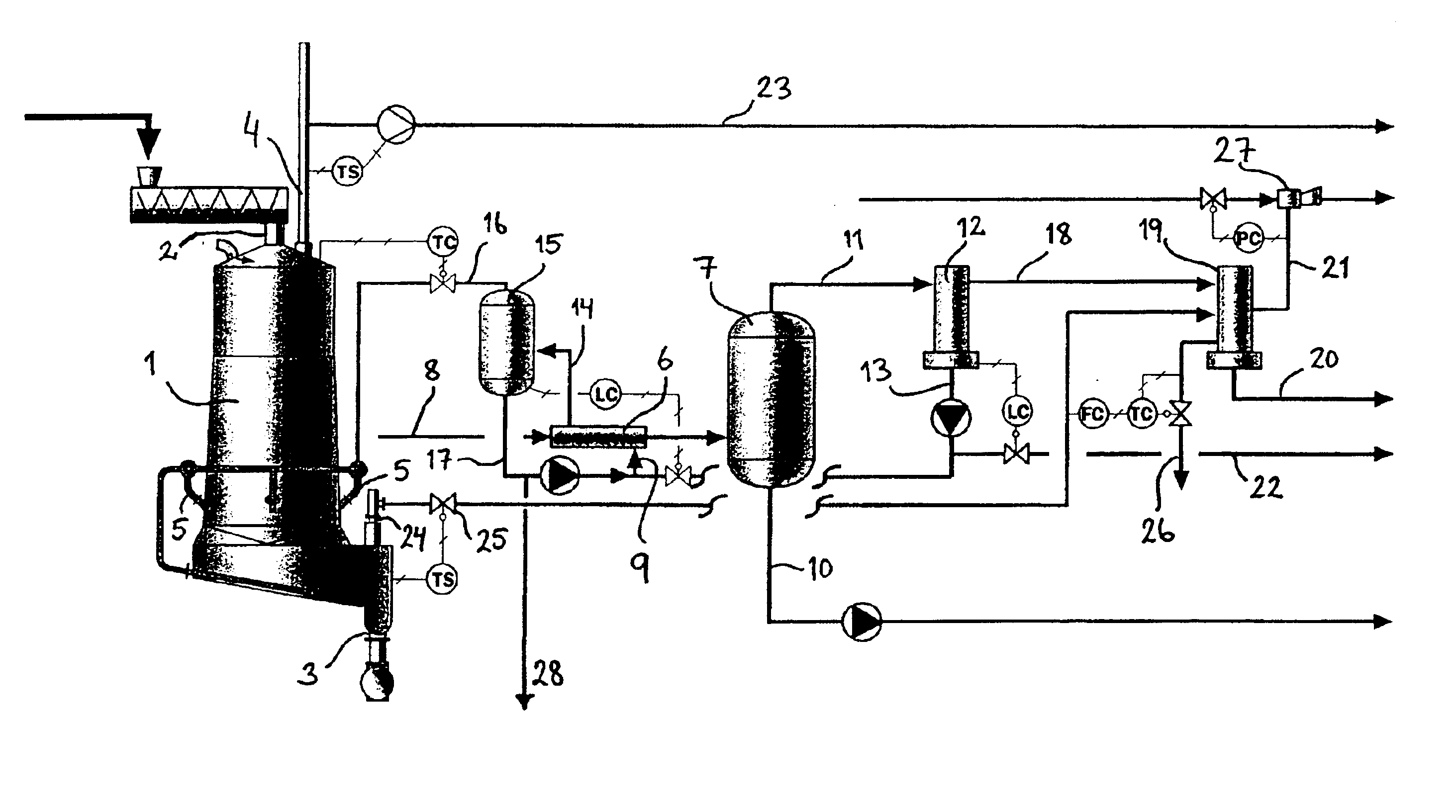

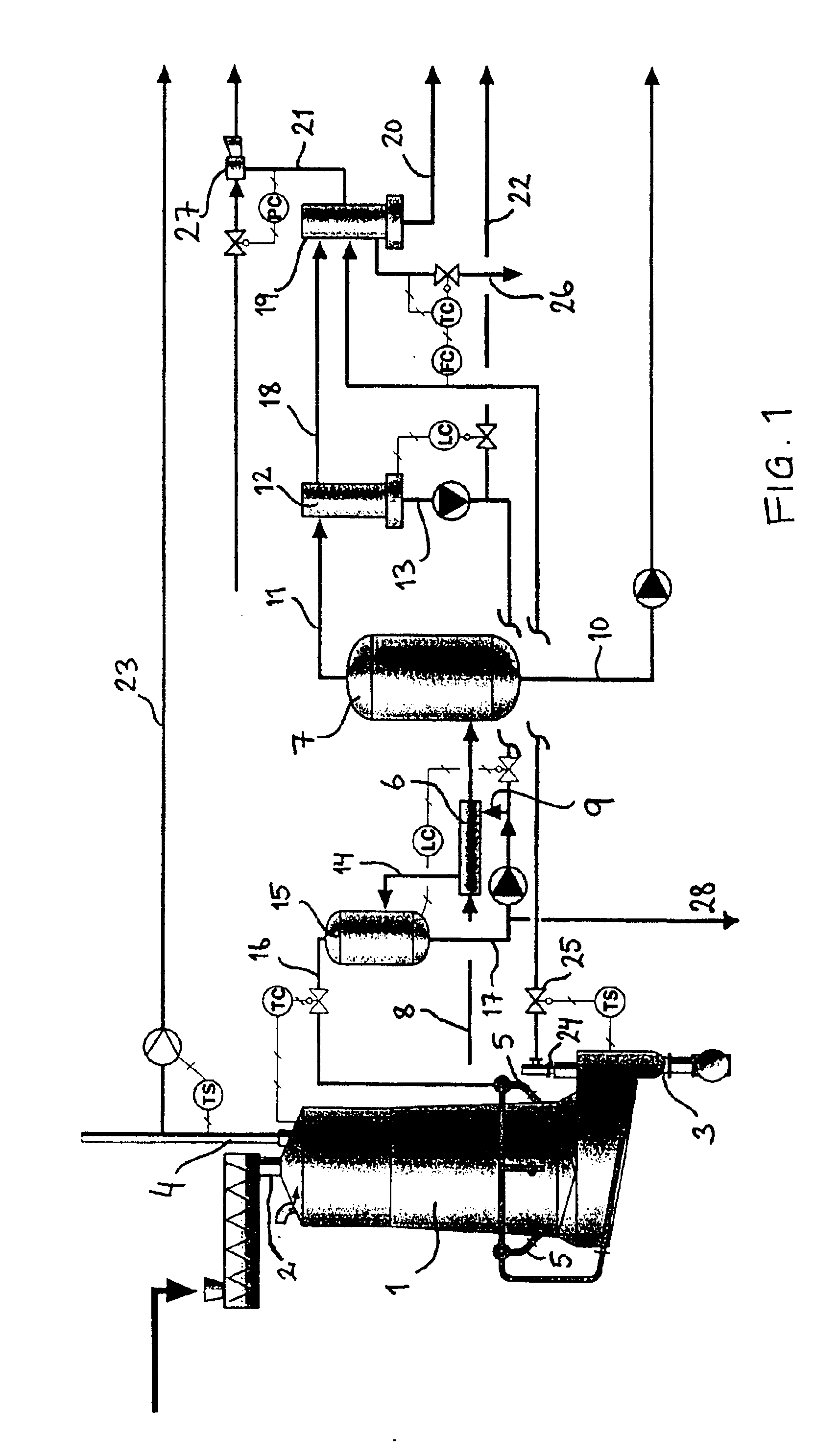

A method and an apparatus for preparing cellulose pulp, in which a lignin-containing raw material is impregnated with impregnation liquor and the impregnated raw material is cooked. The black liquor obtained by cooking is concentrated in an evaporation plant integrated in a chemical recovery plant. In the impregnation, the lignin-containing raw material is impregnated with a circulating alkaline impregnating liquor, which impregnating liquor is concentrated by evaporating water from it in at least one evaporator unit of the evaporation plant arranged in the chemical recovery plant of a pulp mill.

Owner:VALMET TECH INC

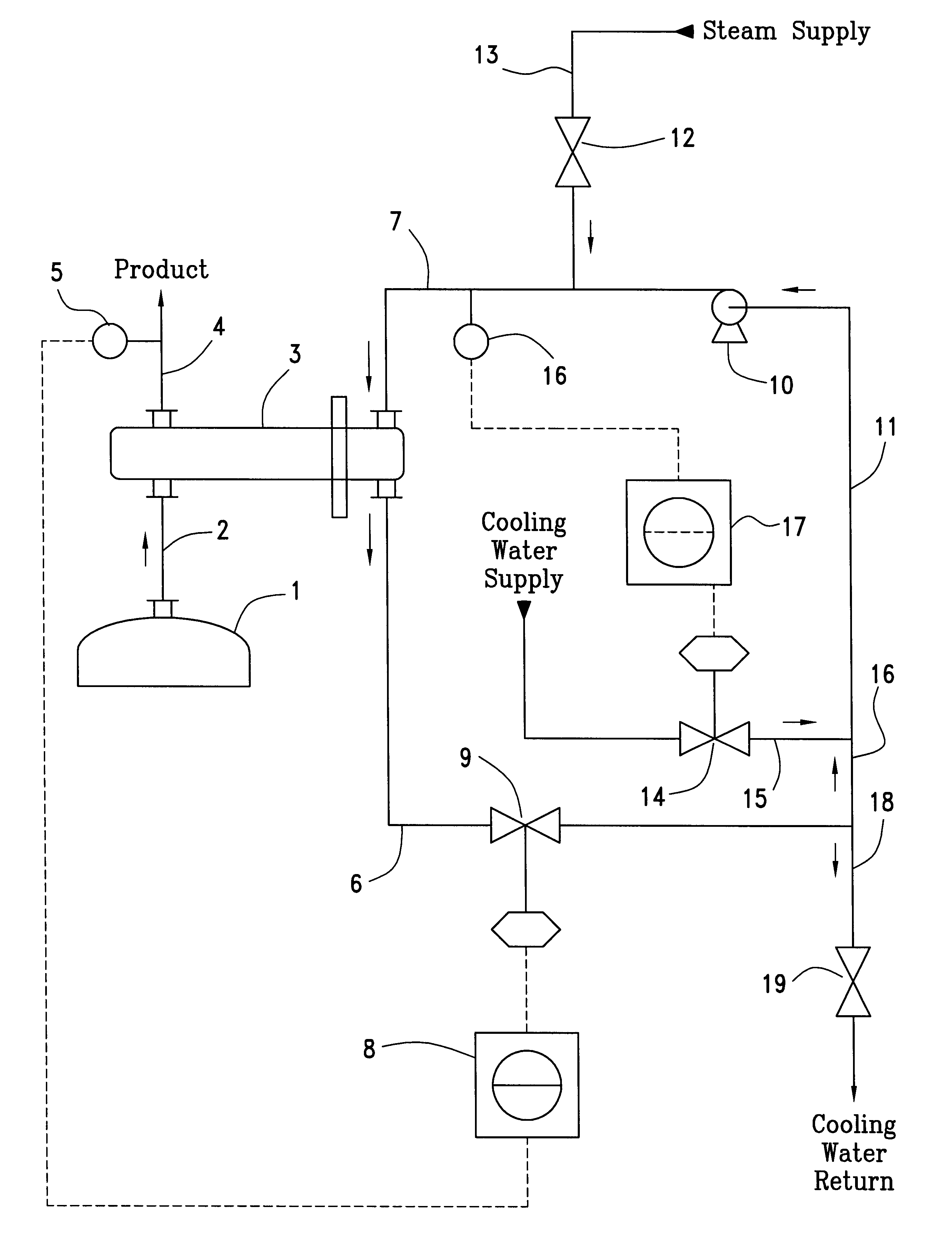

Method for extracting ammonium salt and methanol from a liquid obtained from foul condensates in a cellulose pulp mill

InactiveUS20100316553A1Avoid NOx emissionIncrease the number ofAmmonium nitratesNitrogen compoundsCellulose pulpAmmonia

Desirable chemicals are recovered from a raw material that is formed in substantial amounts during the production of cellulose pulp from renewable lingo-cellulose material. An ammonia / ammonium-containing methanol / water mixture is acidified with an acid that has the ability of forming ammonium salt with the ammonium. The mixture is circulated and passed through an apparatus that has an indirect heat exchanger combined with an storage volume fitted with a gas collection device.

Owner:METSO POWER AB +1

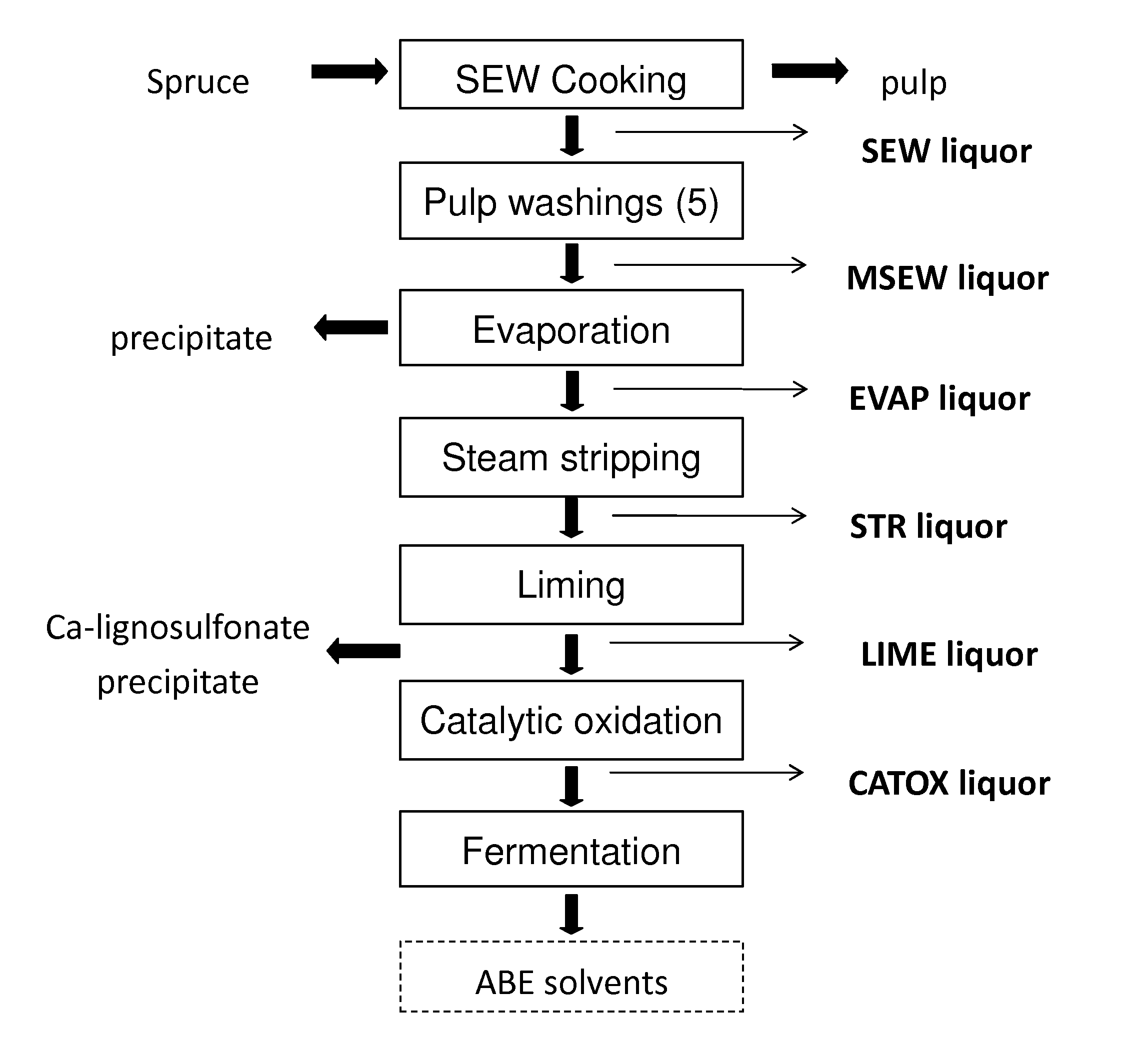

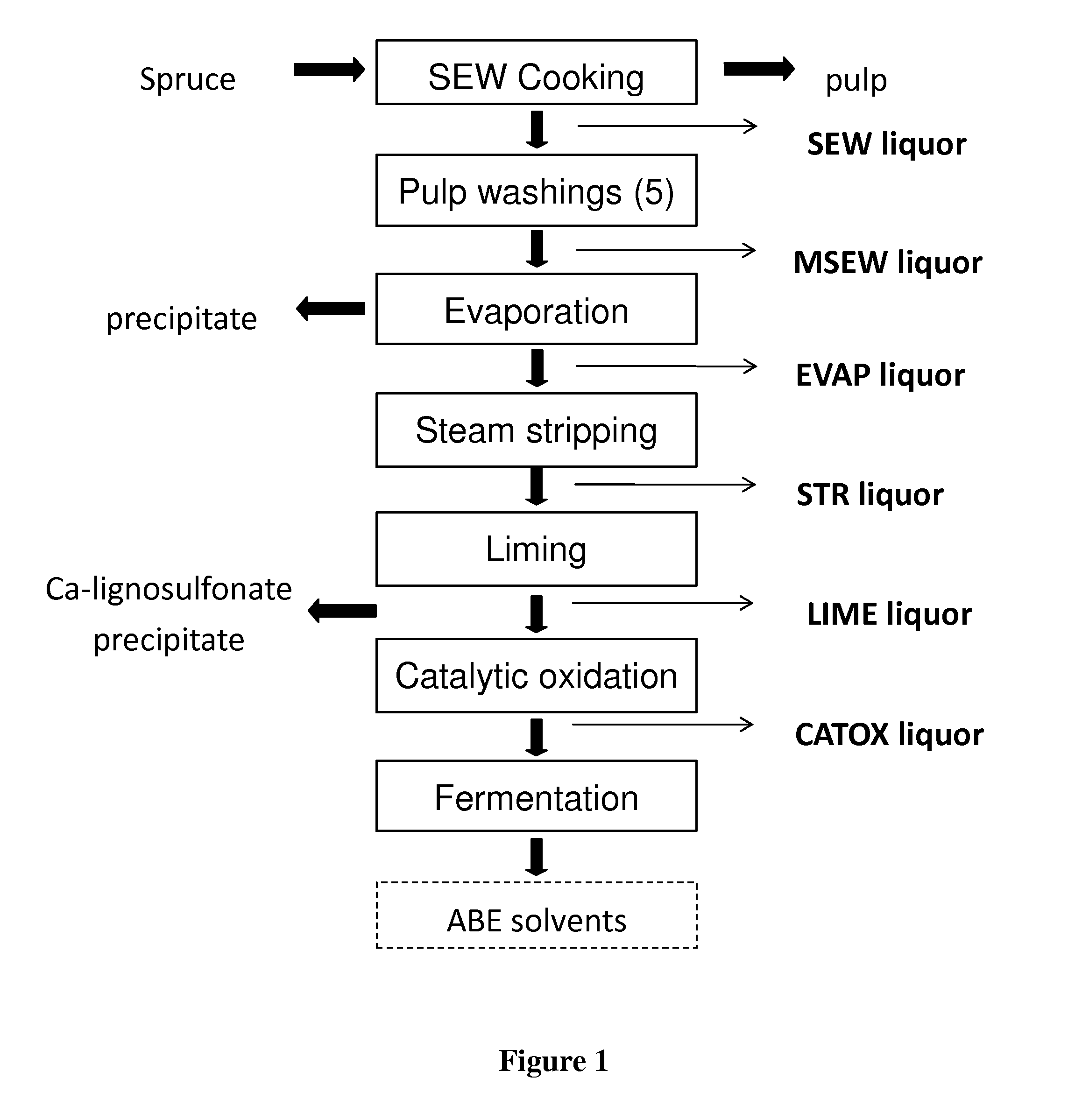

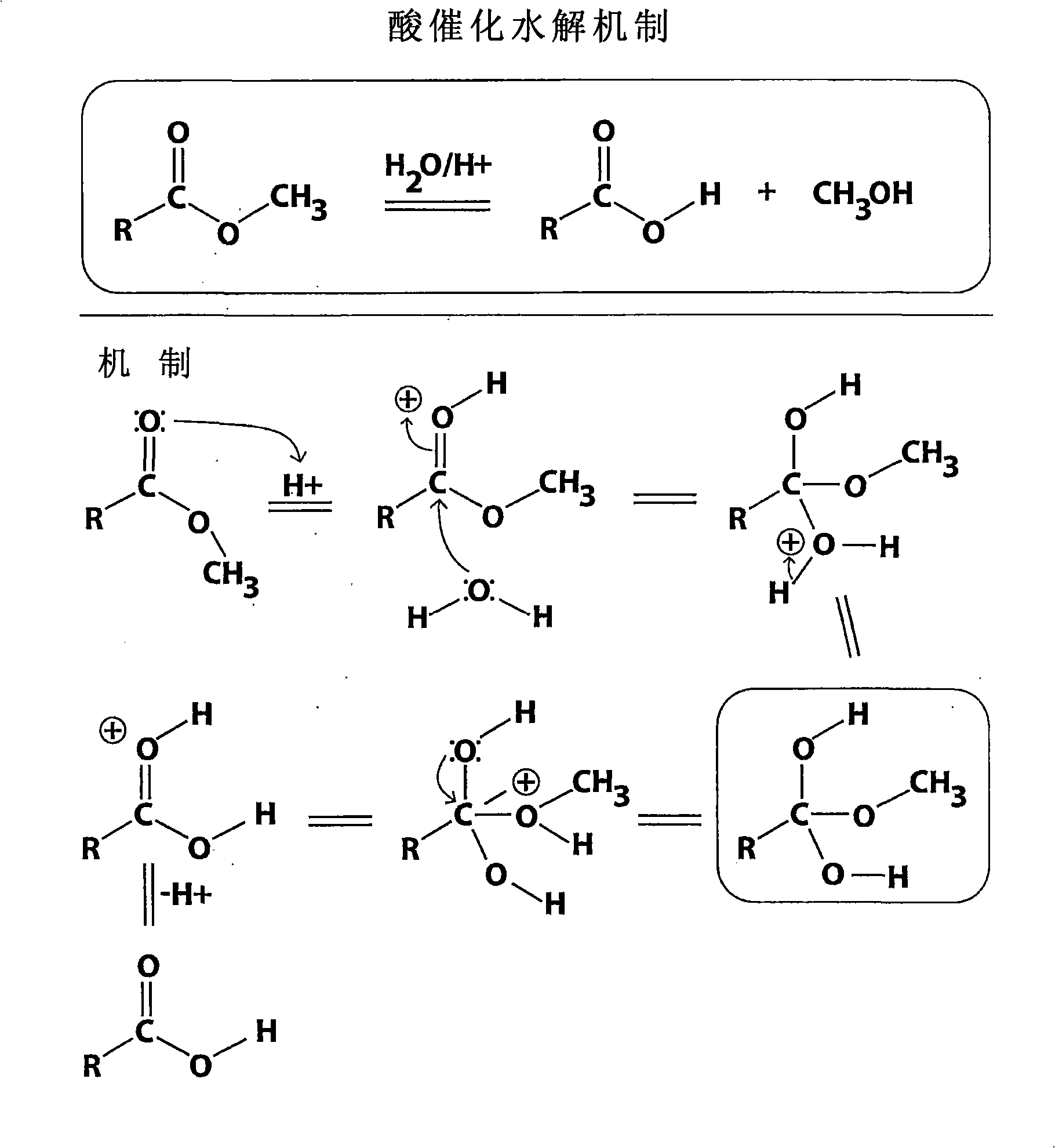

Conditioning of SO2-ethanol-water spent liquor for fermentation by clostridia

The present invention relates to producing chemicals and biofuels from wood material, e.g. mixed forest biomass. Specifically, the invention concerns a process for conditioning spent liquor produced by SO2-ethanol-water (SEW) fractionation of wood chips for fermentation to butanol, ethanol and acetone / isopropanol (so called ABE process) by Clostridia bacteria.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

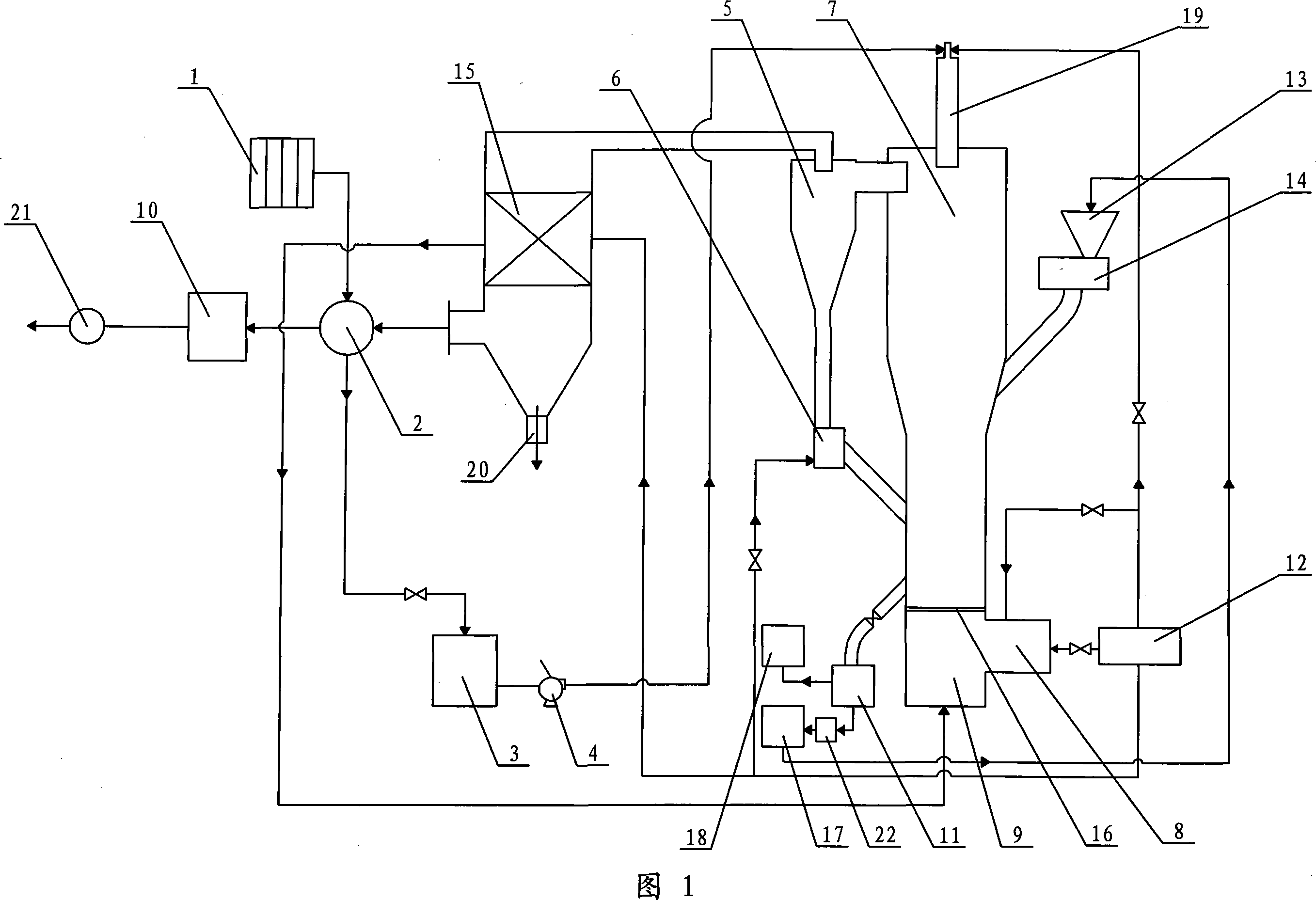

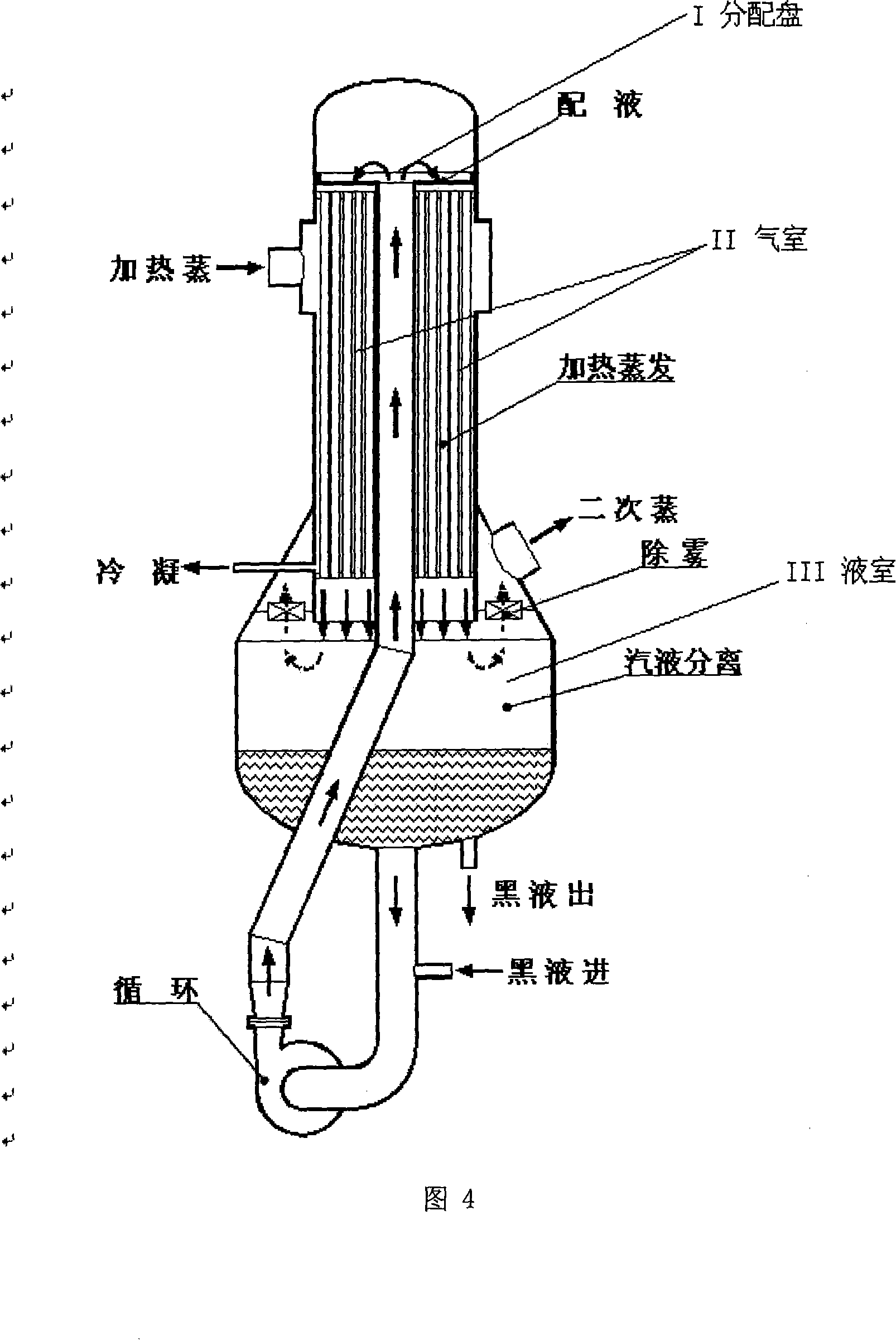

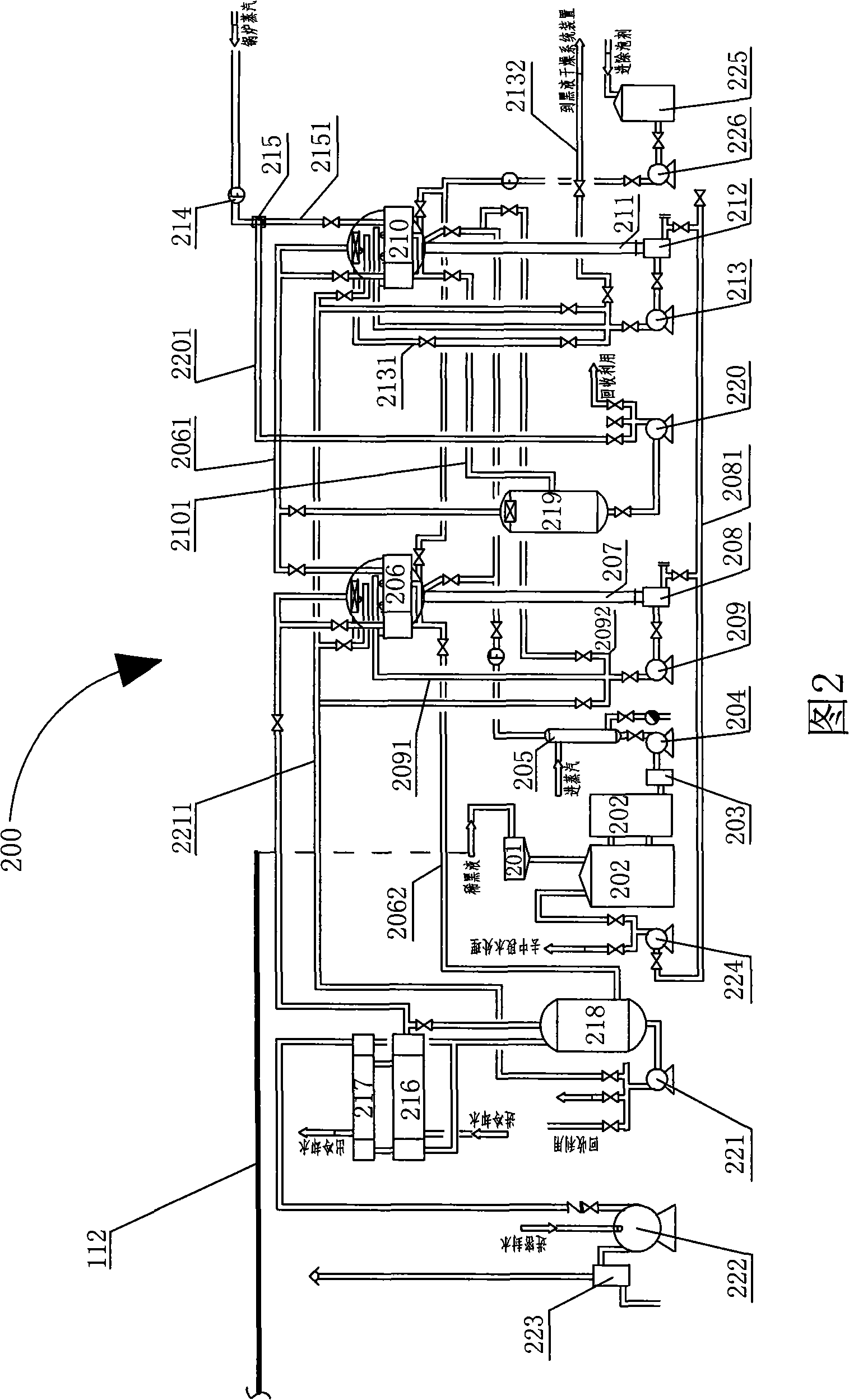

Paper-making black liquor fluidized bed alkali reclaiming device and method

InactiveCN101210396AAvoid pollutionLow running costSpent liquor concentrationAir preheaterFurnace temperature

A device and a method for recovering alkali from black liquid of papermaking by using fluidized bed relates to a fluidized bed alkali recovery device and a process thereof. The invention solves the problems of the prior art such as bed material sintering during burning black liquid of papermaking. The device comprises a fluidized bed alkali recovery furnace communicated with a cyclone with a bottom dipleg communicated with the fluidized bed alkali recovery furnace, and an air blower respectively communicated with a burner, the dipleg, a lance and an air preheater through pipes. The method comprises the following step of pumping the black liquid to the fluidized bed alkali recovery furnace through a multi-effect evaporator, a disk evaporator and a concentrated black liquid tank by a black liquid pump, burning the black liquid at a furnace temperature of 700 to 900 DEG C by using sodium-based zeolite as the bed material to produce an inorganic sodium salt, and precipitating and separating the inorganic sodium salt and the bed material in a dissolving tank. The invention solves the problems of pellet coagulation and sintering of bed material of the fluidized bed, and the bed material can be repeatedly used, thus effectively solving pollution of papermaking industry.

Owner:HARBIN INST OF TECH

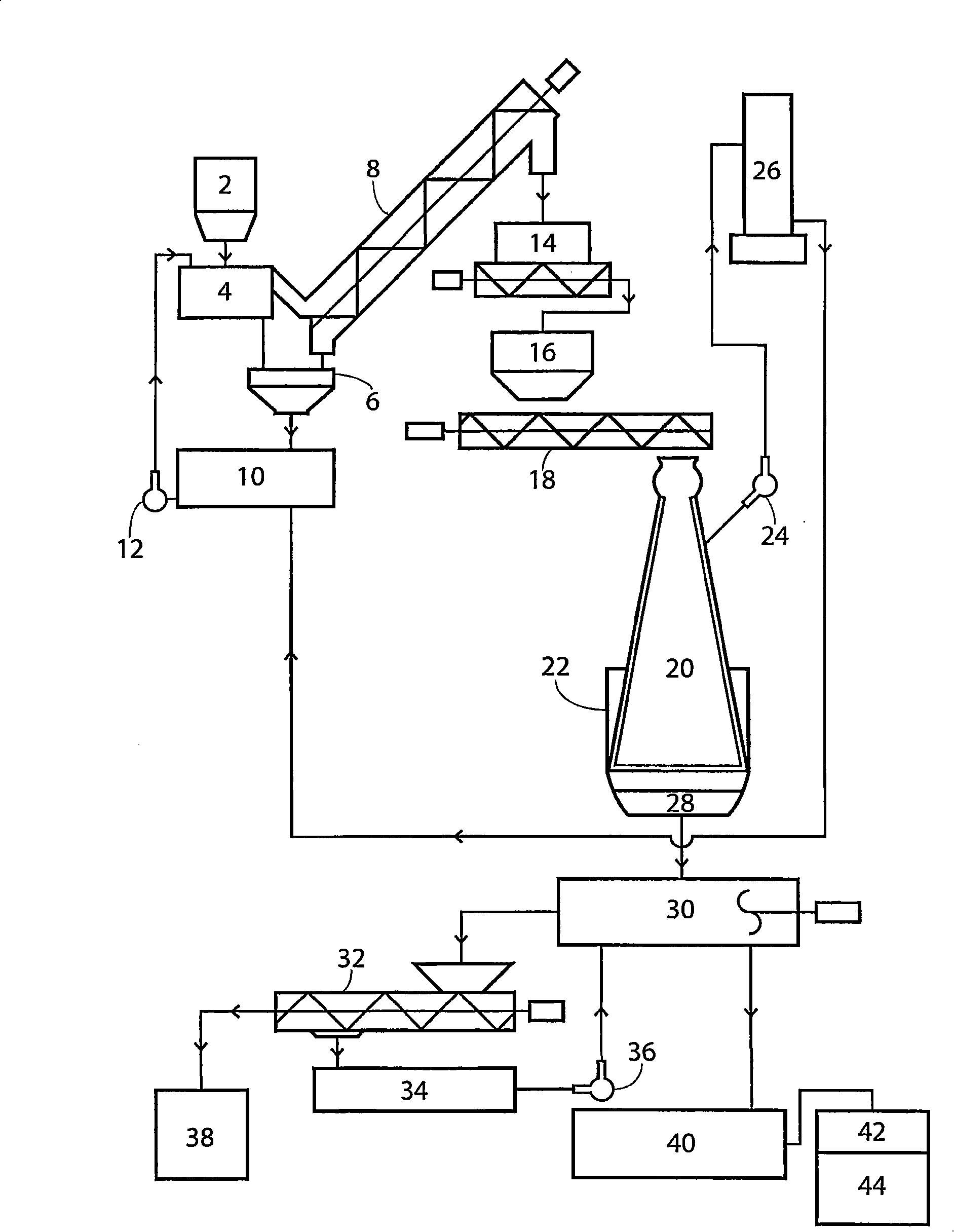

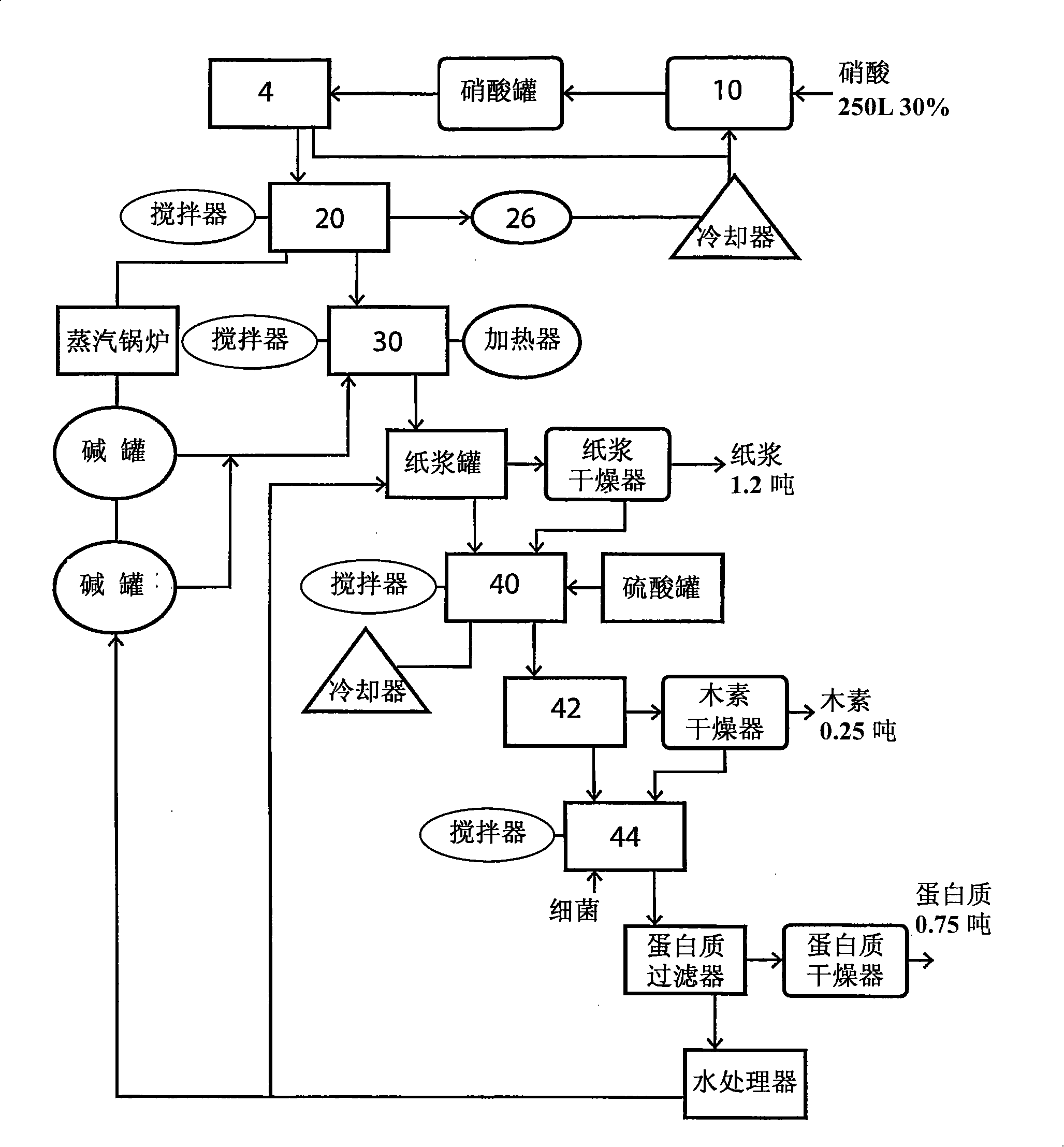

New catalystic reactor method for producing commercial grade pulp, native lignin and single cell protein

InactiveCN101326326ASolve the costAvoid lossPretreatment with acid reacting compoundsPulp de-wateringCelluloseVegetation

A continuous and batch system to produce cellulose, native lignin and unicellular protein from any form of vegetation in a closed process. The biomass is mixed in the impregnate solution of nitric acid and / or ammonium hydroxide and water. After a period of time at room temperature and atmospheric pressure the chemical solution is recycled. The biomass is moved to the reactor and heated. Evaporated impregnate is recovered via absorption tower and recycled back to chemical solution. The biomass is moved to an alkaline solution, then cooled to separate pulp from black liquor. The black liquor is pumped to a separation tank and is treated to precipitate lignin. The solution is filtered to separate sweet liquor and lignin. The lignin is dried and the sweet liquor is fermented to produce unicellular protein.

Owner:凯利·安东尼·O'弗林 +1

Tall oil refining improvement

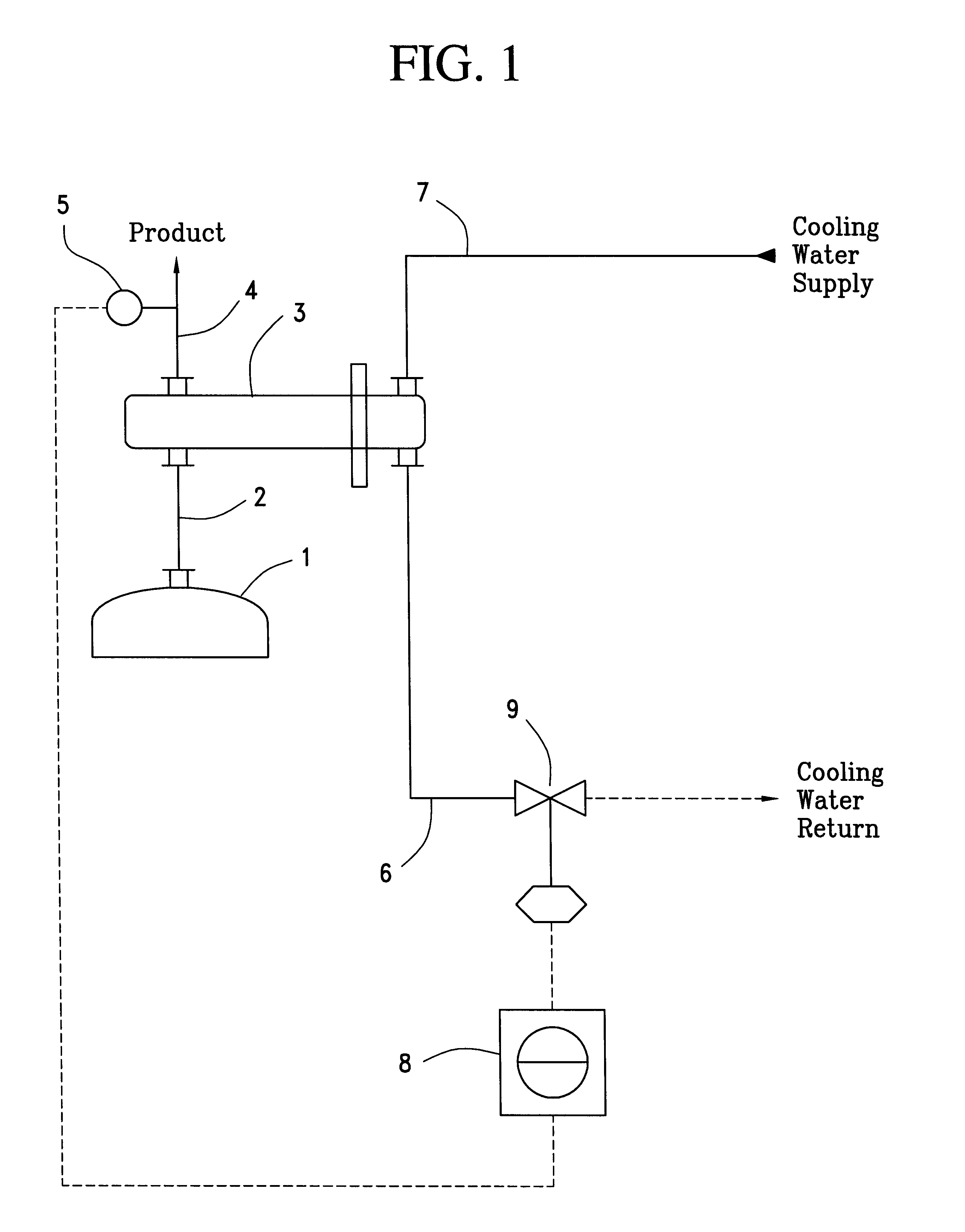

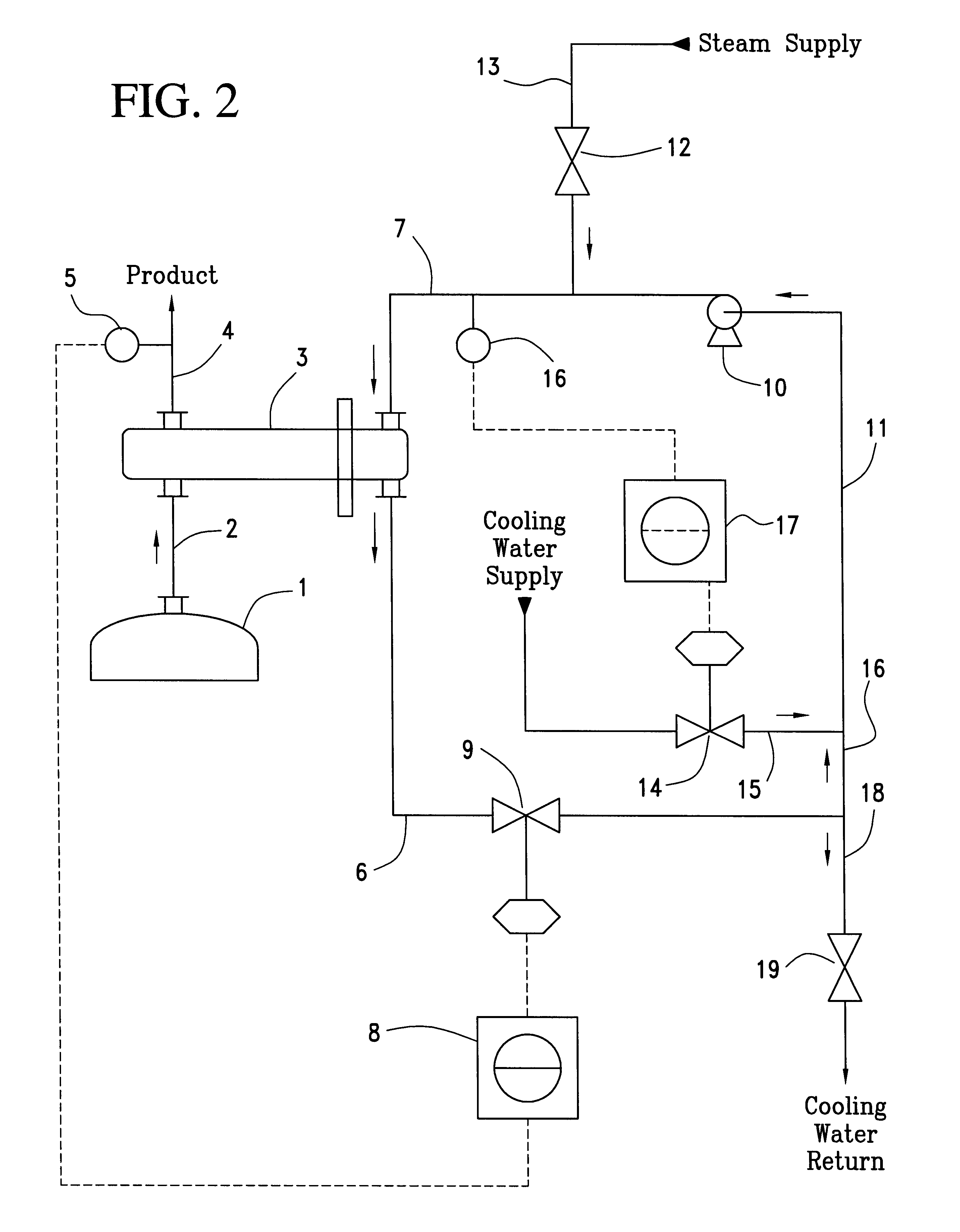

InactiveUS6409882B1Avoiding anthraquinone condensationIncrease pressure dropDistillation regulation/controlDigestersCooling towerWarm water

In a tall oil refining operating plant, a warm water loop is disclosed for cooling the tall oil heads fraction extracted from the crude tall oil, rather than the conventional use of cold water. This avoids condensation and the subsequent solidification of athraquinone pulping aid remaining in the crude tall oil; thus, avoiding fouling of the cooling towers. The temperature of the warm-water is controlled automatically by tempering the cold water entering the warm water "cooling" loop, while removing excessively warm water from said loop to the cooling tower system, as needed.

Owner:MEADWESTVACO CORP

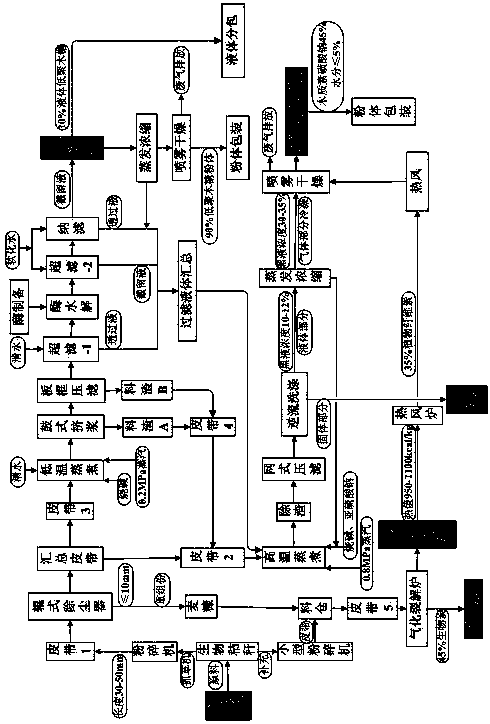

Five-coproduction process for comprehensively utilizing biological straw

PendingCN107586805AMaximize the use of scaleIncrease profitGaseous fuelsBiofuelsUltrafiltrationSlurry

The invention discloses a five-coproduction process for comprehensively utilizing biological straw, aiming at solving the technical problem of expanding the straw utilization scale. The process consists of three lines: the first line is used for producing xylooligosaccharide: smashing biological straw, introducing steam for boiling, passing through an ultrafiltration membrane-1 after filter pressing, passing through an ultrafiltration membrane-2 after enzymatic hydrolysis reaction, enabling penetrating fluid to be subjected to nanofiltration concentration so as to be concentrated by 3-5 timesto obtain the xylooligosaccharide; the second line is used for producing straw pulp and sodium lignosulfonate: smashing the biological straw, enabling the smashed biological straw and waste residue tobe subjected to pressurized high temperature boiling together, enabling obtained serous liquid to be subjected to filter pressing separation, and enabling solid matter obtained after separation to besubjected to adverse current cleaning to obtain wheat straw pulp; enabling black liquor and washing black water obtained after separation to evaporate and concentrate, then performing heat exchange via hot-blast air to obtain sodium lignosulphonate powder; and the third line produces biochar and combustible pyrolysis gas. On the premise of generating remarkable economical benefit, the five-coproduction process is friendly to environment and does not generate waste water so as to achieve zero discharging, solid waste does not exist, and the exhaust gas reaches the standard and is emitted.

Owner:临颍路得生物科技有限公司

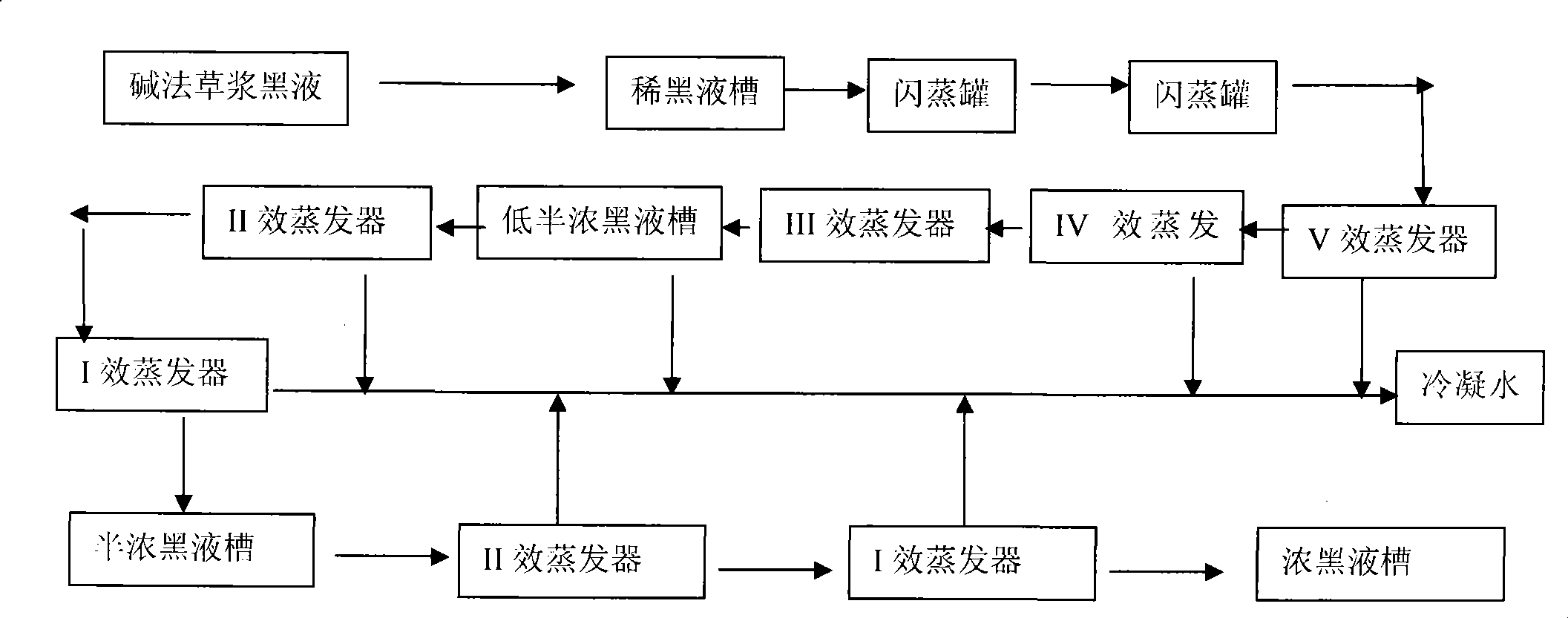

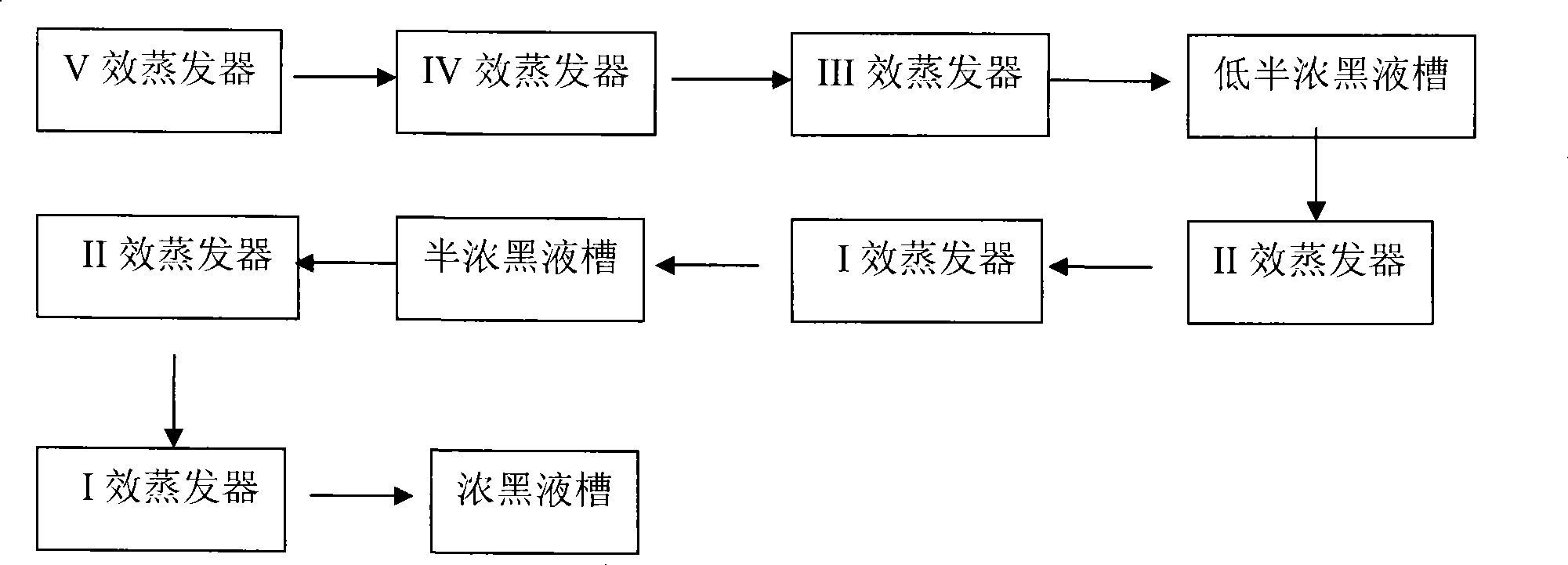

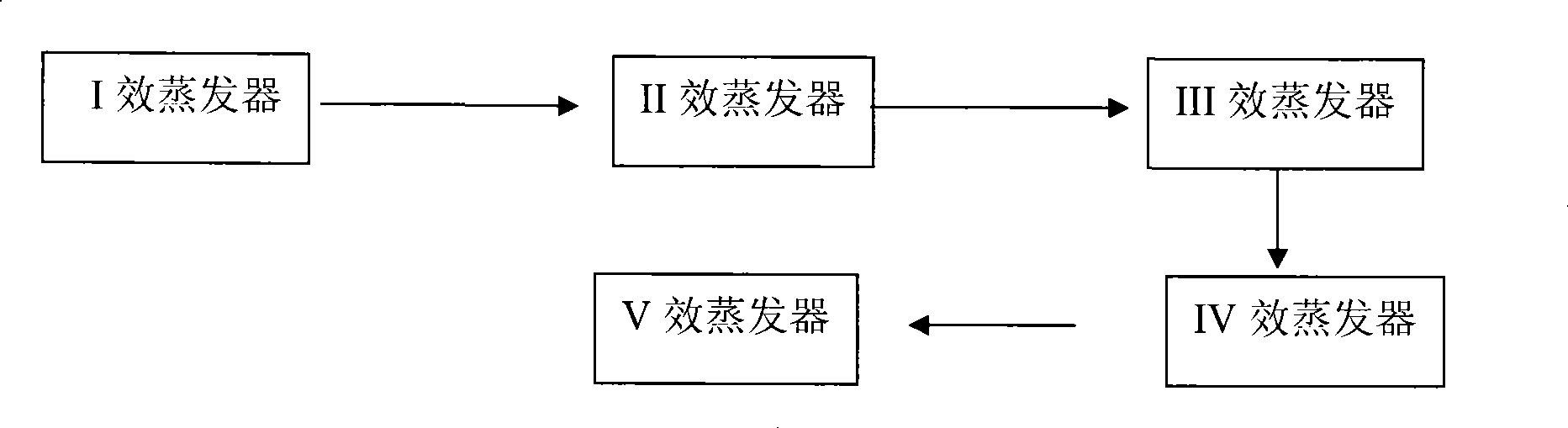

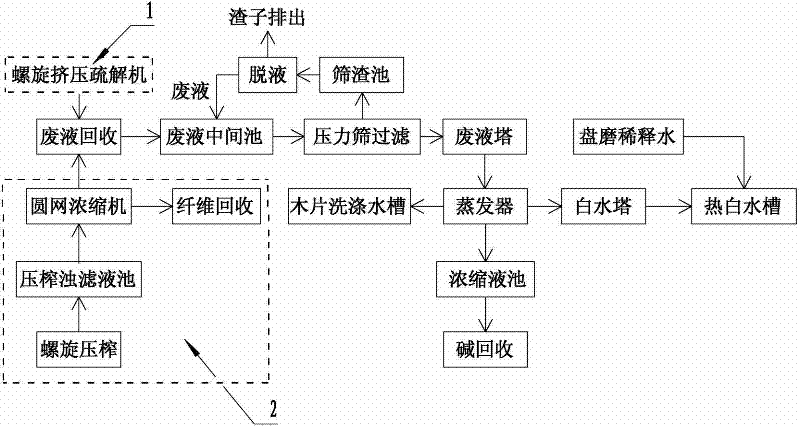

Straw pulp black liquor concentration process

ActiveCN101487197AReduce consumptionEasy to manageRegeneration of alkali lyeSpent liquor concentrationBlack liquorWater reducer

The invention relates to a process for concentrating straw pulp black liquor. When the production process is used for evaporating and concentrating the black liquor, the energy resource consumption is little, the efficiency is high, the produced solid in the concentrated black liquor mainly comprises alkali lignin which has wide application; and the alkali lignin can be used as raw materials of various products with extremely high economic value and for preparing excellent water reducing agent, and can be added by little crosslinking agent so as to prepare lignin sand solidification agent.

Owner:SHANDONG TRALIN PAPER

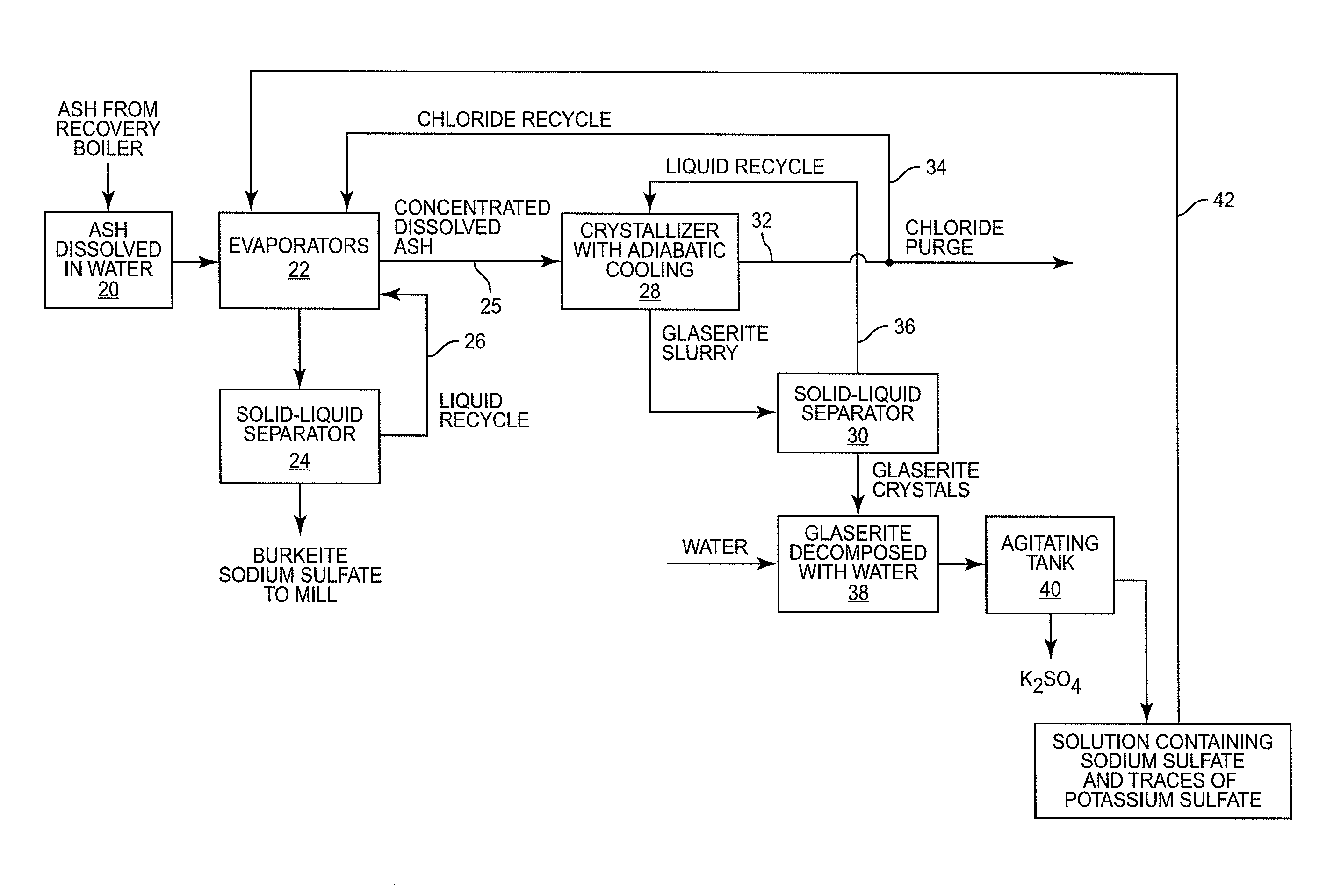

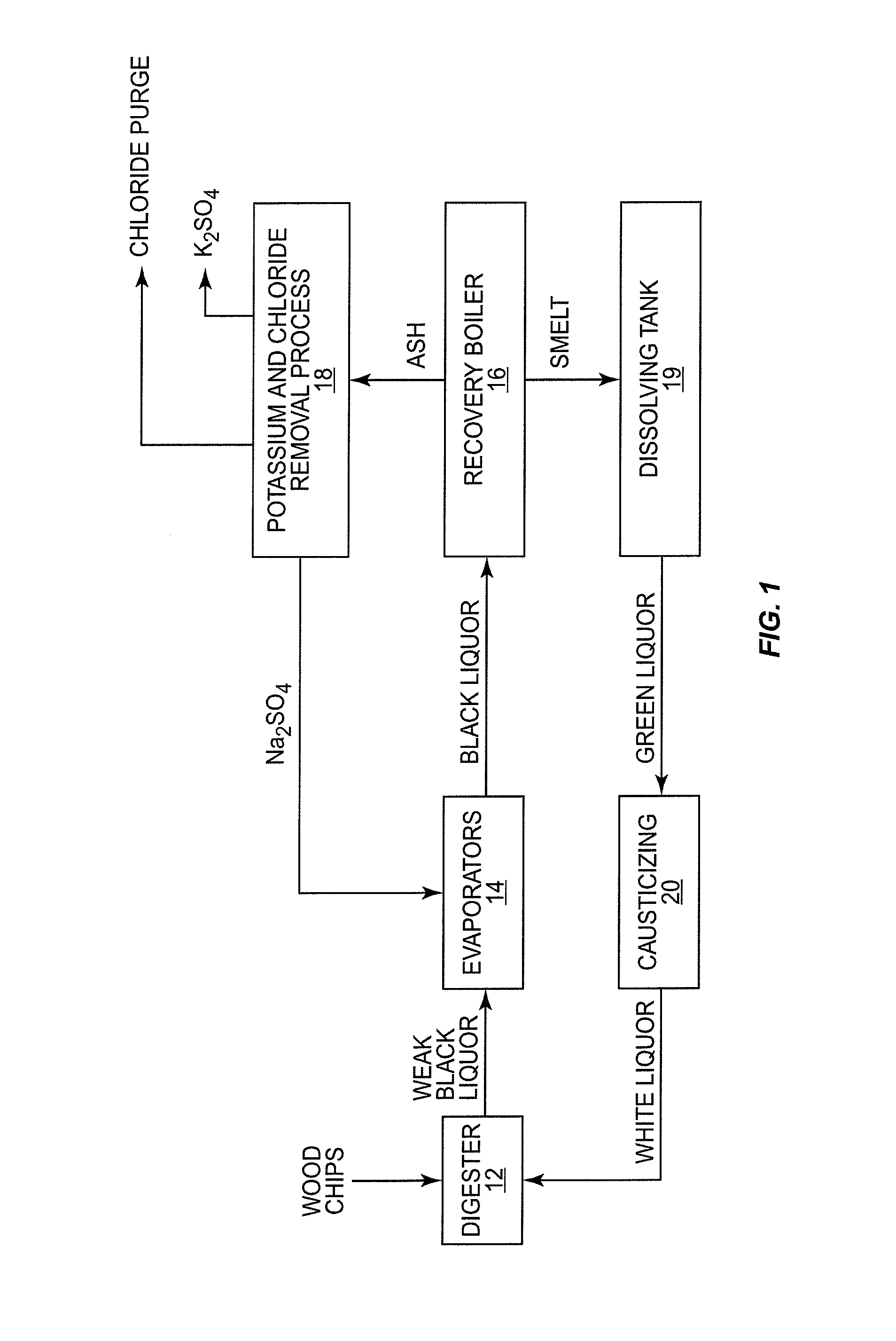

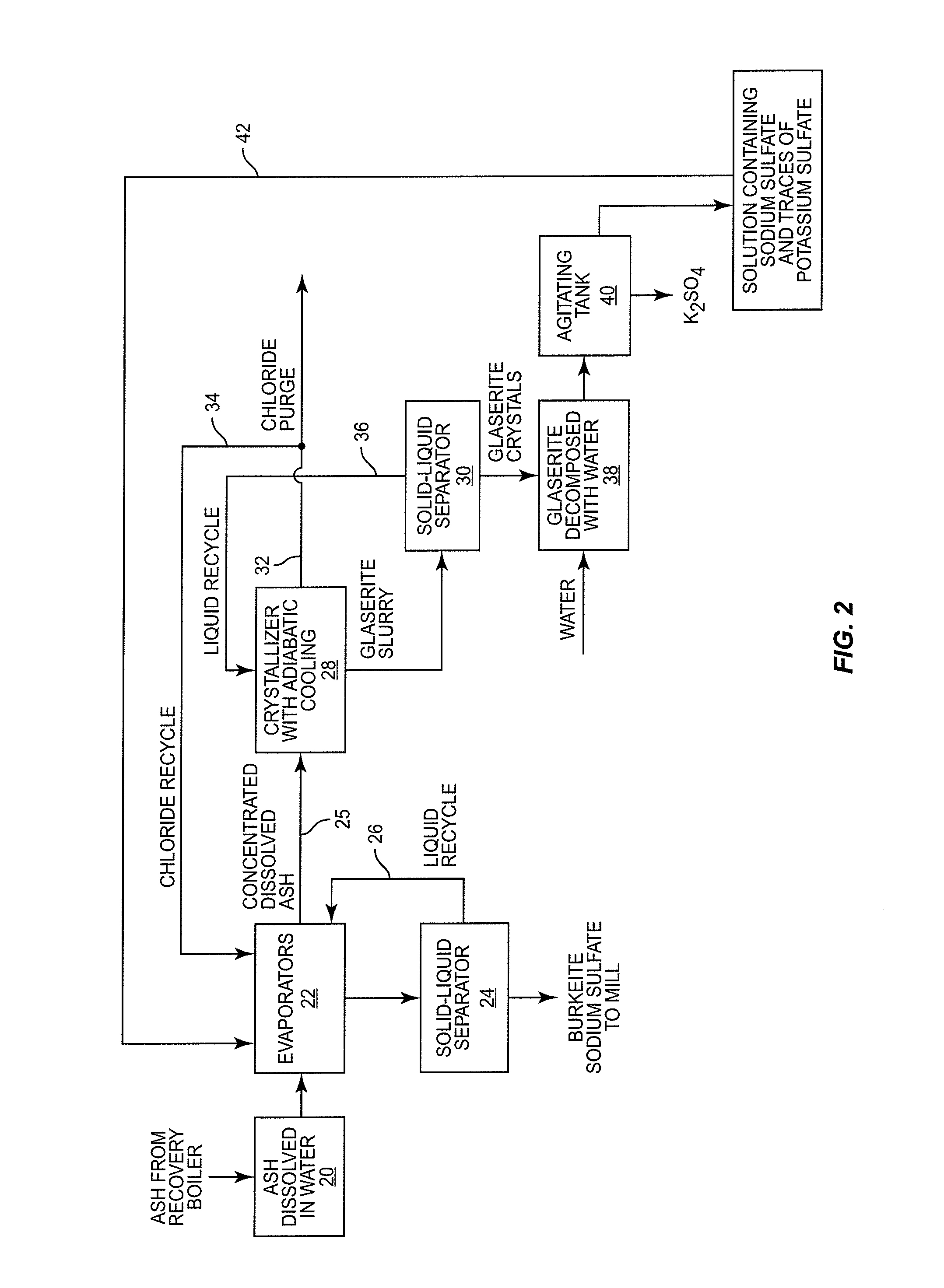

CRP Purge Treatment

ActiveUS20140027076A1Pulp liquors combustionFractionation/concentration of spent liquorsBlack liquorWhite liquor

In a digester, wood chips and white liquor are combined and cooked under pressure to pulp the wood. This produces black liquor which is concentrated and burned in a recovery boiler. The recovery boiler produces ash that contains sodium, sulphur, potassium and chloride. The ash is dissolved and subjected to a process that recovers sodium sulfate and burkeite. The concentration of potassium and chloride is reduced, in part at least, by subjecting the ash to adiabatic cooling in a crystallizer which produces glaserite and a purge stream rich in chloride. By leaching the glaserite, sodium sulfate is removed from the glaserite, leaving potassium sulfate. The recovered sodium sulfate and burkeite can be recycled and used as pulping chemicals. The removed potassium and chloride can be further treated or appropriately discarded.

Owner:VEOLIA WATER TECH INC

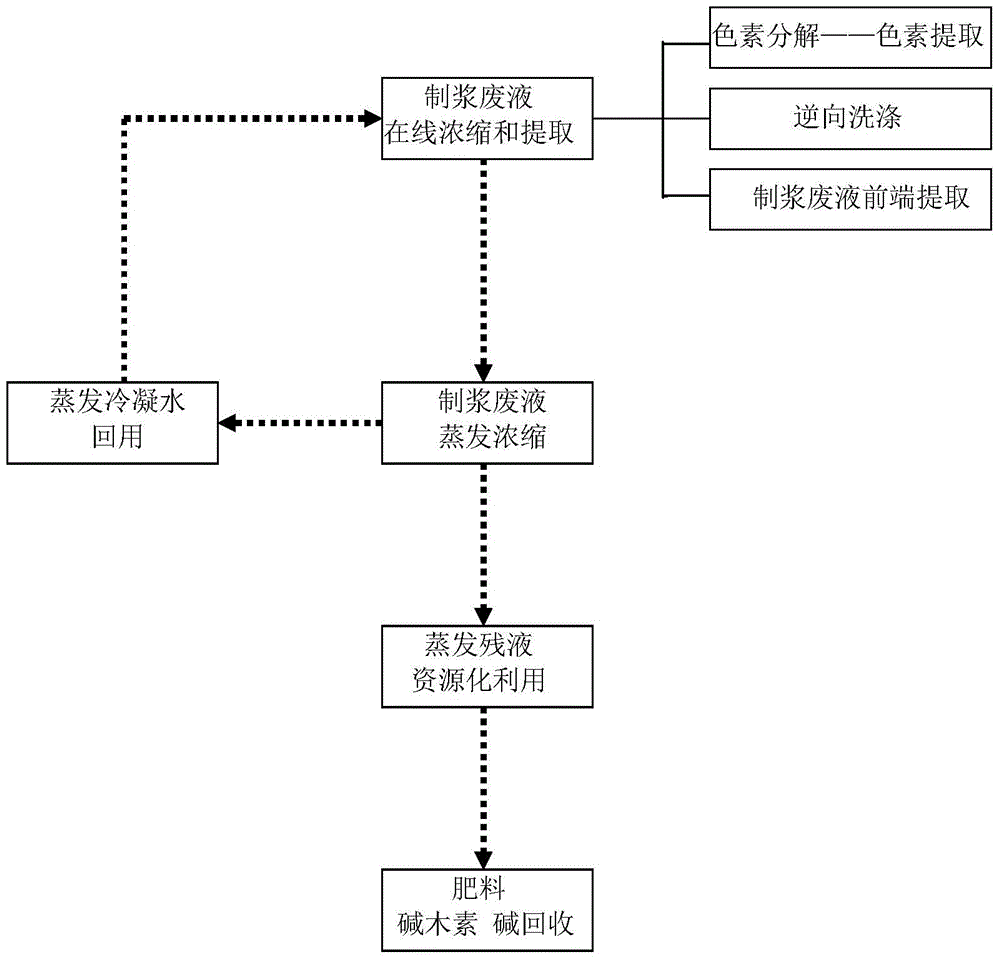

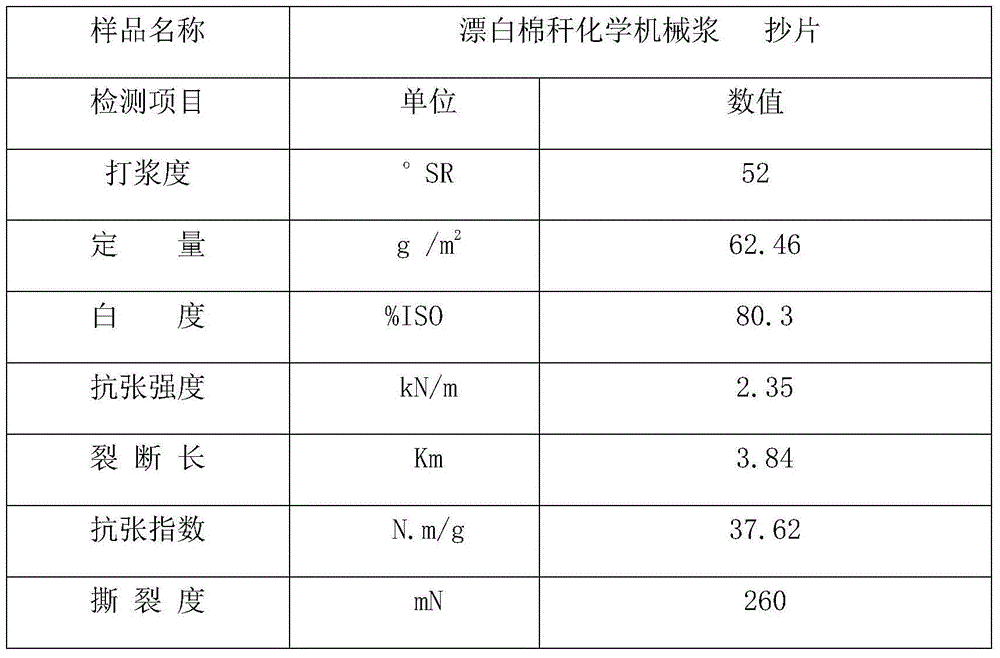

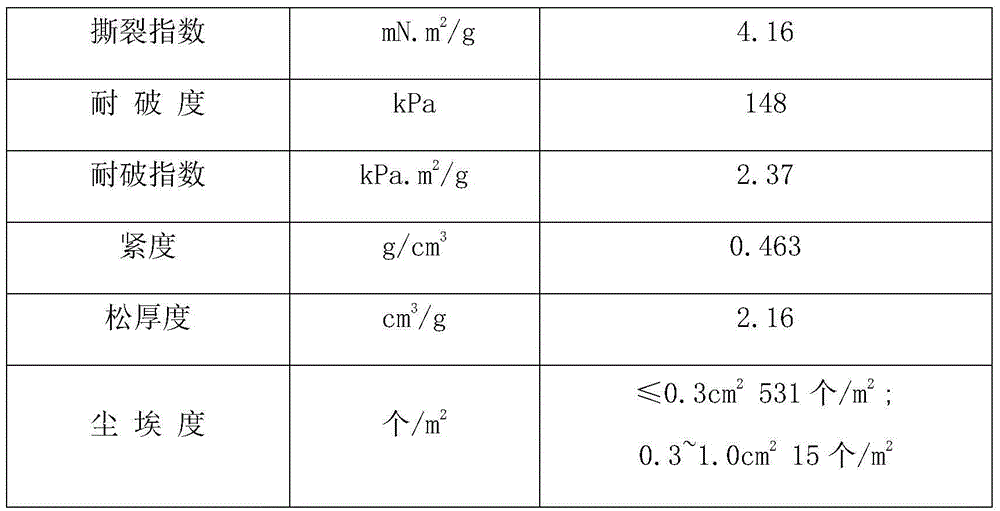

Zero discharge process of pulping waste liquid of all-cotton straw pulp

ActiveCN104928965AImprove bleaching efficiencyReduce pollution loadWashing/displacing pulp-treating liquorsPulp de-wateringHigh concentrationDecomposition

The invention discloses a zero discharge process of pulping waste liquid of all-cotton straw pulp. The process includes firstly performing front-end high concentration extraction of pulping waste liquid, then performing evaporation and concentration of the high concentration pulping waste liquid, recycling evaporation and condensation water, and recycling evaporation residue fluid, so as to realize the zero discharge of the pulping waste liquid finally. The front-end high concentration extraction of the pulping waste liquid includes cotton stalk raw material pigment decomposition, pigment extraction and reverse washing, and front-end extraction.

Owner:白博

Batch process for producing chemical pulp by removing and reintroducing calcium-containing spent liquor in the digester

InactiveUS6939439B1Increase investment costQuality improvementDigestersPulp bleachingLiquid wastePulp and paper industry

Methods for producing chemical pulp from lignocellulose-containing material in processes for kraft pulp production are disclosed including charging the lignocellulose-containing material to a digester, initially treating the lignocellulose-containing material with an impregnation liquor, and then treating the impregnated lignocellulose-containing material with hot liquor and displacing calcium-containing spent liquor from the digester during that treatment, heating and cooking the heated lignocellulose-containing material to produce cooked lignocellulose-containing material and cooking liquor and displacing the cooking liquor from the digester using at least a portion of the displaced calcium-containing spent liquor.

Owner:METSO PAPER PORI OY

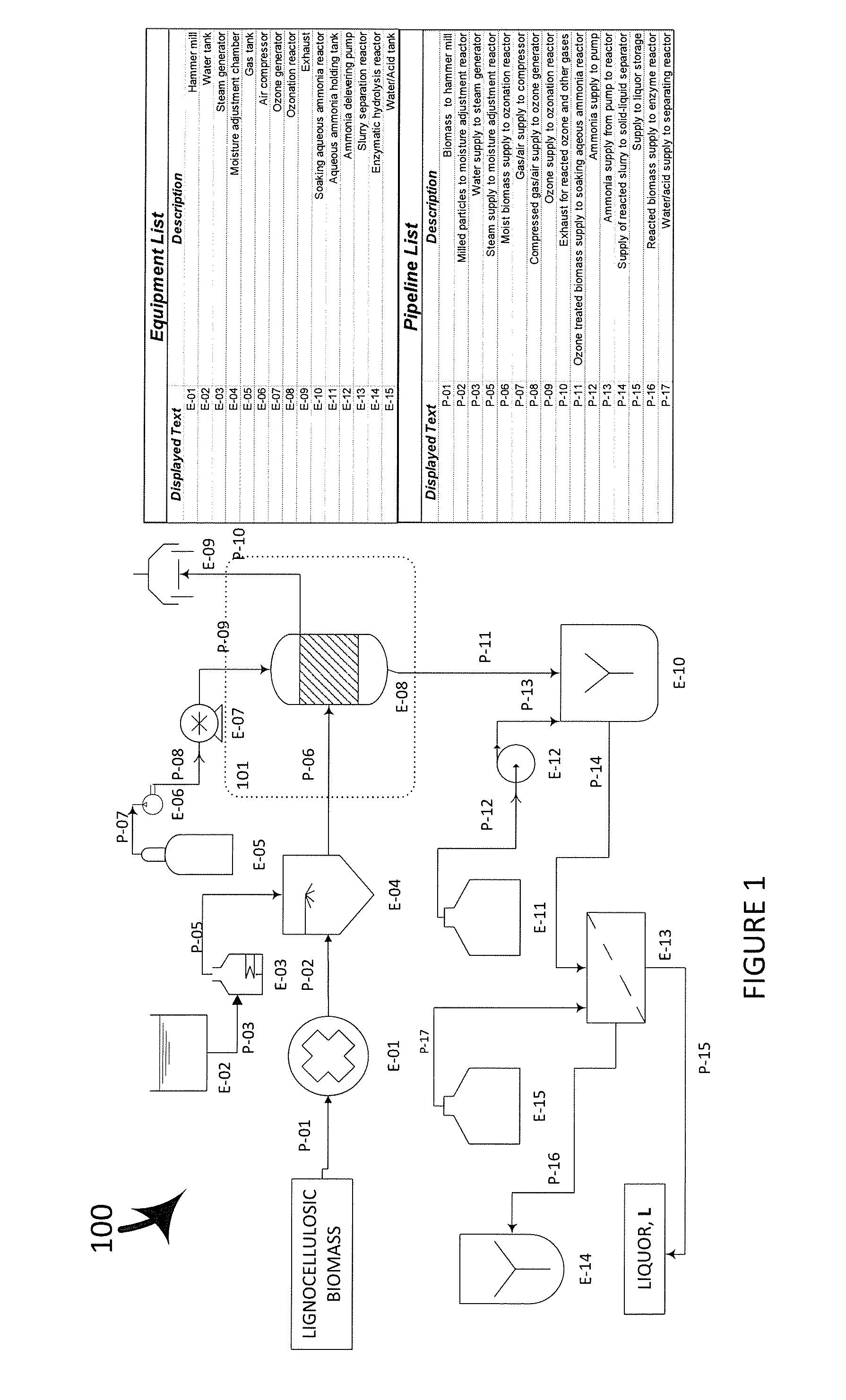

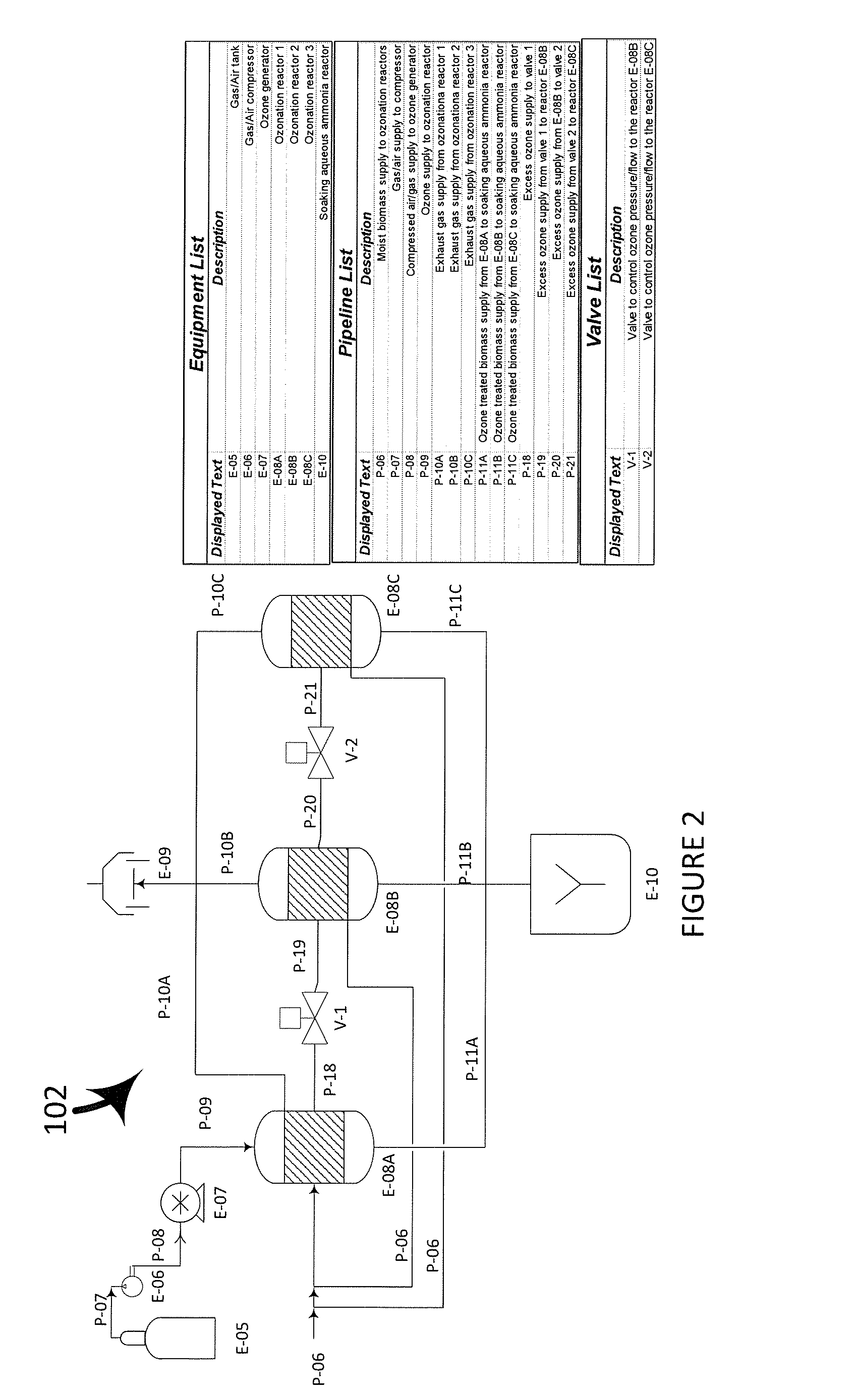

Advanced Methods for Sugar Production from Lignocellulosic Biomass and Fermenting Sugars to Microbial Lipids

InactiveUS20150184212A1Increase heightReduce crystallinityWashing/displacing pulp-treating liquorsBiofuelsCelluloseMicroorganism

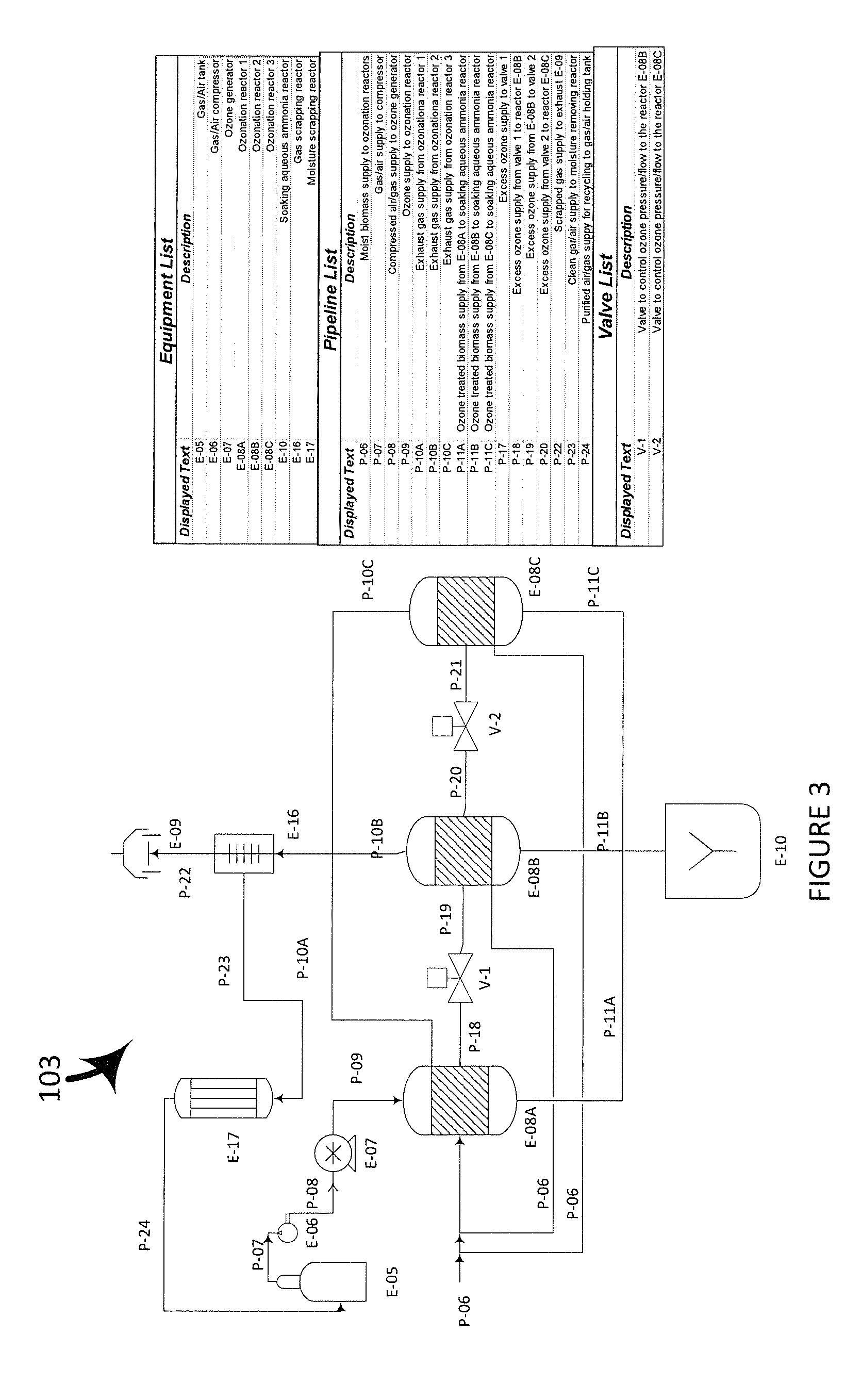

Methods for facilitating sugar release from lignocellulosic biomass and for utilizing the sugars for microbial lipid (e.g. biofuel) production are provided. The methods involve pretreating lignocellulosic biomass using various oxidizing agents (ozone, peroxone, etc.) at a temperature not higher than 50° C. and pressure no higher than 1.5 atm to render the biomass more accessible to enzymatic hydrolytic degradation into sugars and utilizing soluble sugars for fermenting oleaginous microorganism to produce microbial lipids.

Owner:WASHINGTON STATE UNIVERSITY

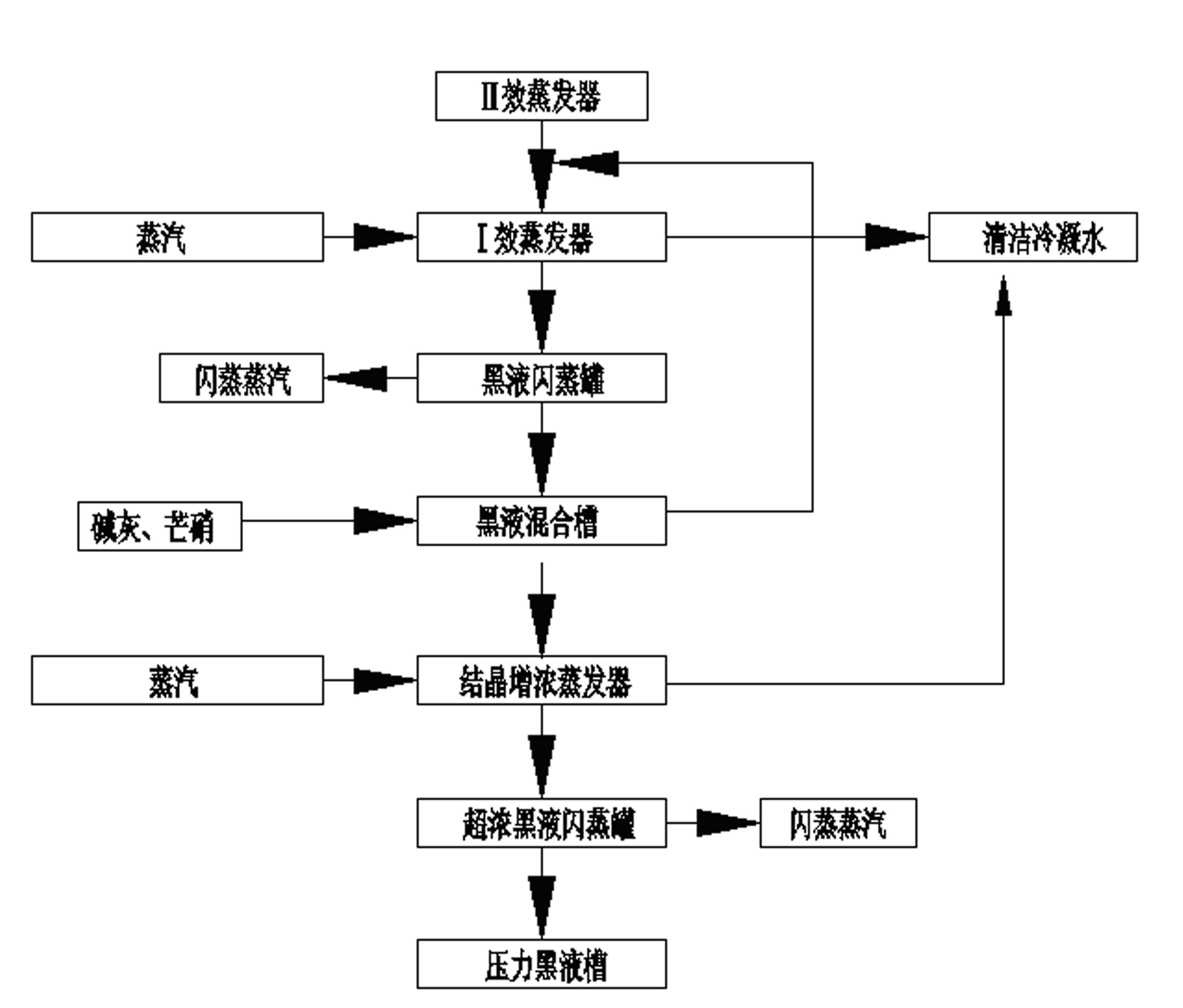

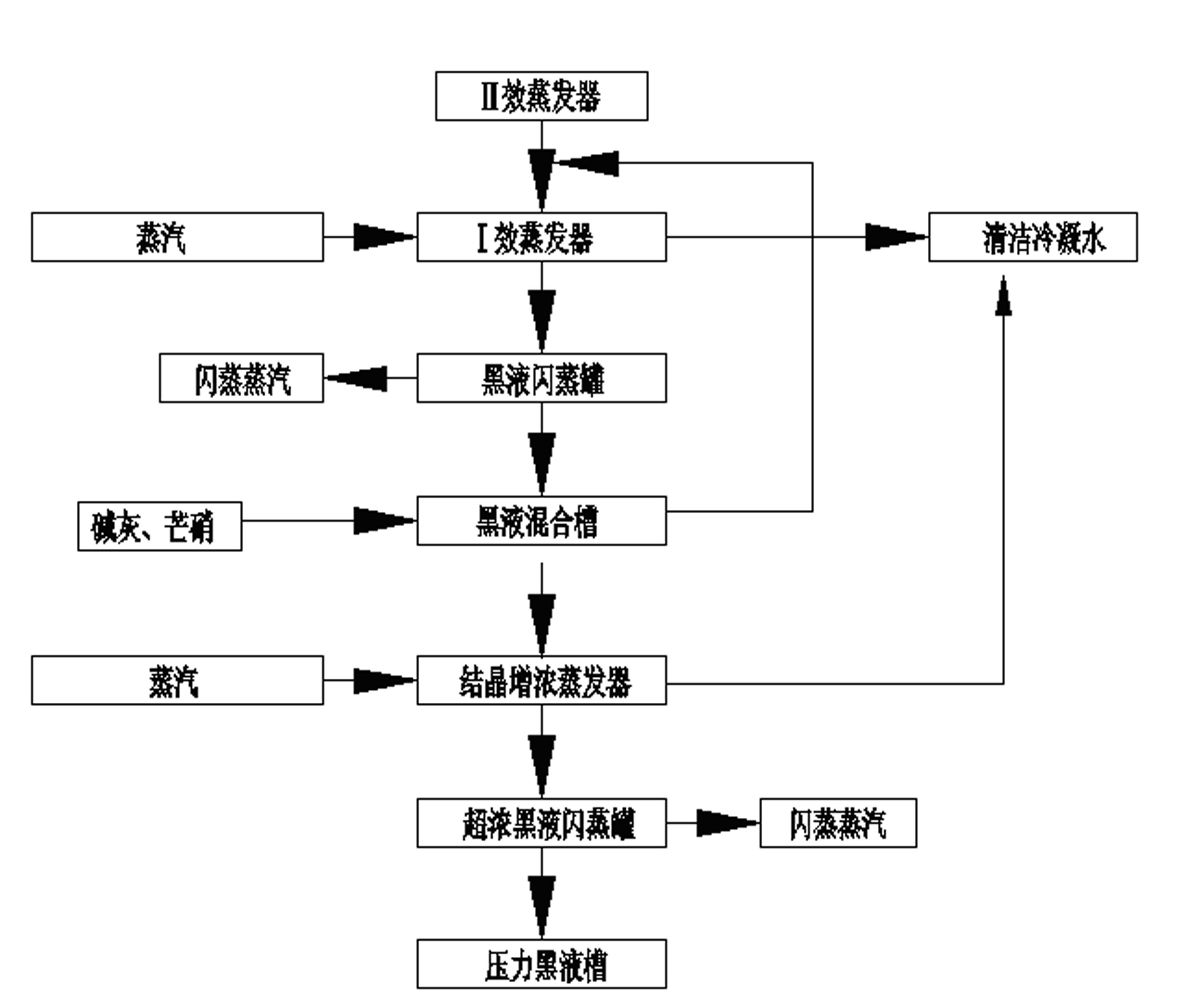

Paper making pulping black liquid crystallization and evaporation method

InactiveCN101831826AImprove recovery rateReduce cleaning and descaling timeSpent liquor concentrationHigh concentrationBlack liquor

The invention relates to a paper making pulping black liquid crystallization and evaporation method which comprises the following steps of: sending a black liquid from a first effect evaporator into a black liquid mixing tank, adding alkali ash and / or mirabilite, mixing with the black liquid to generate a mixed black liquid, and enabling the mixed black liquid to contain excess sulfate to become a sulfate supersaturated liquid; sending one part of the obtained mixed black liquid to a crystallization and densification evaporator for evaporation, and sending the evaporated black liquid to a pressure black liquid tank for storage; mixing one part of the black liquid with the black liquid from a second effect evaporator to sequentially enter three chambers of the first effect evaporator for evaporation, and sending into the black liquid mixing tank after evaporation. The invention can effectively avoid the scale formation of the black liquid in the evaporation process, obtains higher concentration of the black liquid, is beneficial to alkali reclamation and has lower energy consumption.

Owner:YUEYANG FOREST & PAPER CO LTD

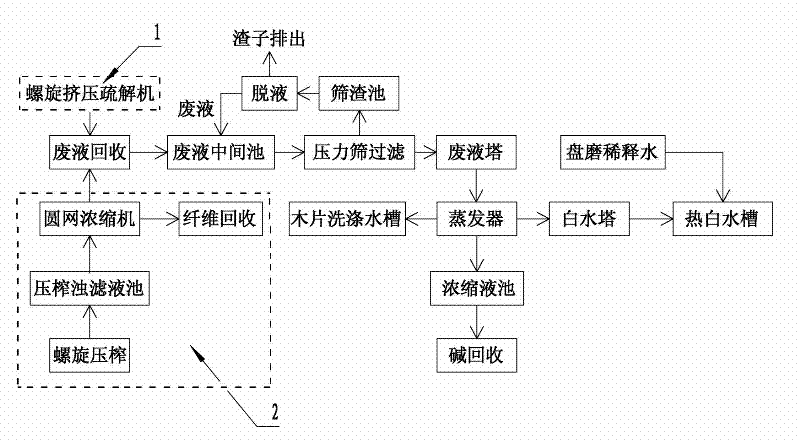

Evaporation pretreatment process method for alkaline peroxide mechanical pulp

InactiveCN102230293AHigh purityImprove utilization efficiencySpent liquor concentrationEvaporationPre treatment

The invention provides an evaporation pretreatment process method for alkaline peroxide mechanical pulp, which comprises a waste liquor recovery process and an alkali recovery process, wherein in the waste liquor recovery process, filter water in the production process of the alkaline peroxide mechanical pulp is collected to a waste liquor intermediate pond, and in the alkali recovery process, collected waste liquor in the waste liquor intermediate pond is subjected to alkali recovery treatment. Before the alkali recovery treatment, the method also comprises the following evaporation pretreatment steps of: (a) performing pressure filtering on waste liquor, namely filtering the waste liquor in the waste liquor intermediate pond by a pressure sieve, discharging dregs formed during filtering to a dreg sieving pond, and discharging the filtered waste liquor to a waste liquor tower to enter the step (b); and (b) performing evaporation grading treatment on the filtered waste liquor by an evaporator, wherein heavily-polluted concentrated solution is discharged to a concentrated solution pond for alkali recovery treatment, mildly-polluted concentrated solution is discharged to a wood chip washing water tank to clean wood chips, and after being mixed with disk mill dilution water in a white water tower, white water generated during evaporation is discharged to a hot white water tank and enters a pulping system of the alkaline peroxide mechanical pulp. The evaporation pretreatment process method has the advantages of high alkali recovery efficiency and environment friendliness.

Owner:SHANDONG TAIYANGZHIYE

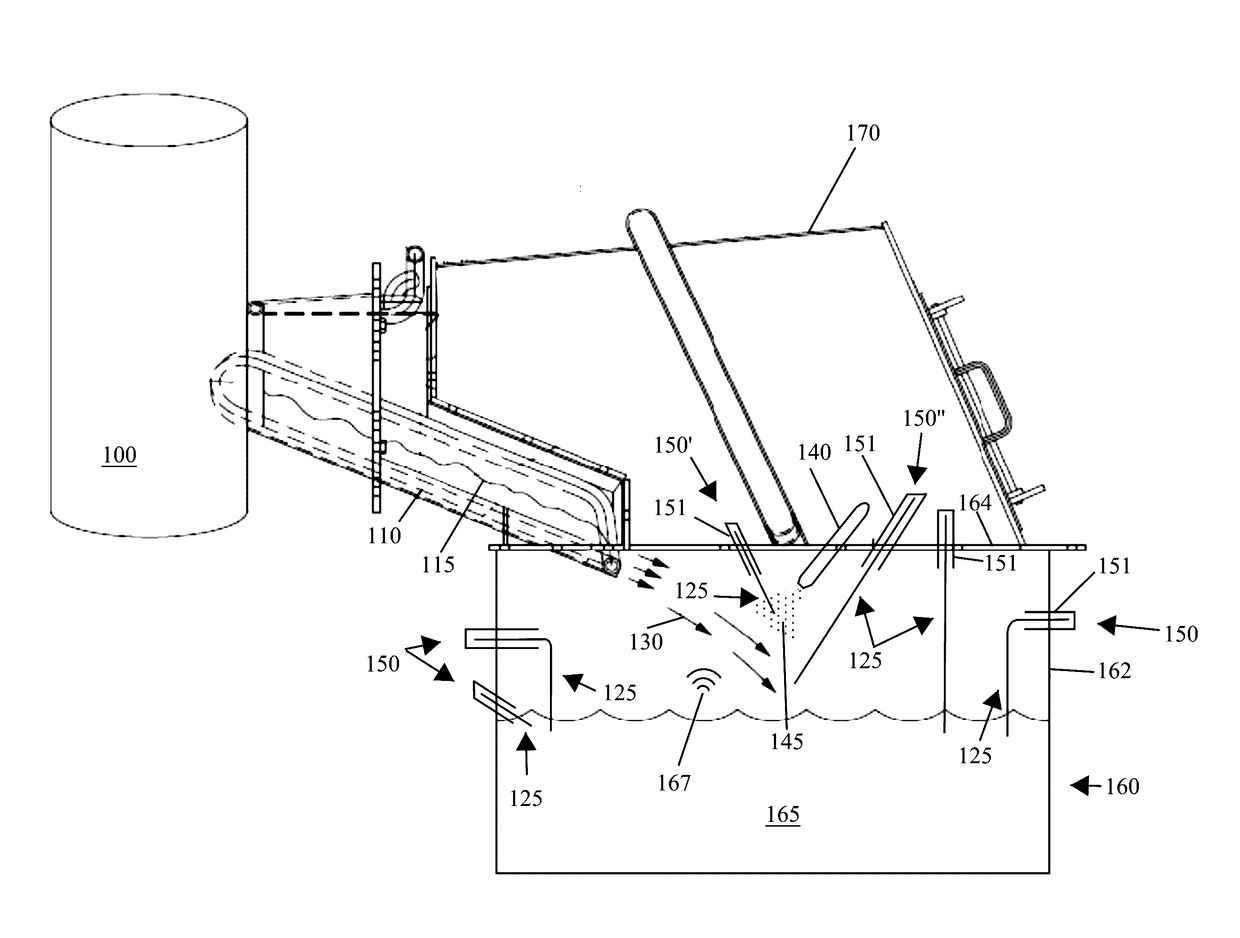

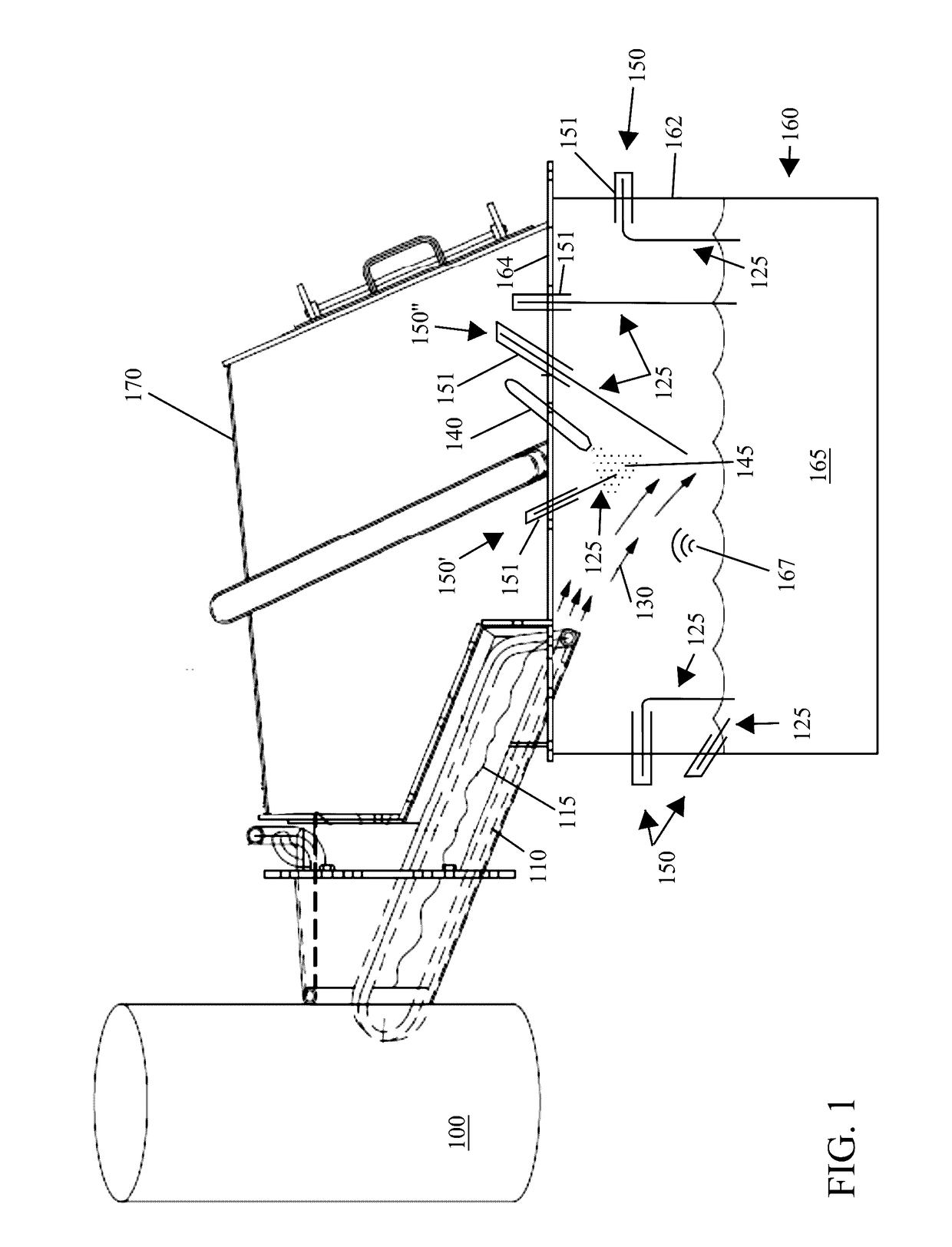

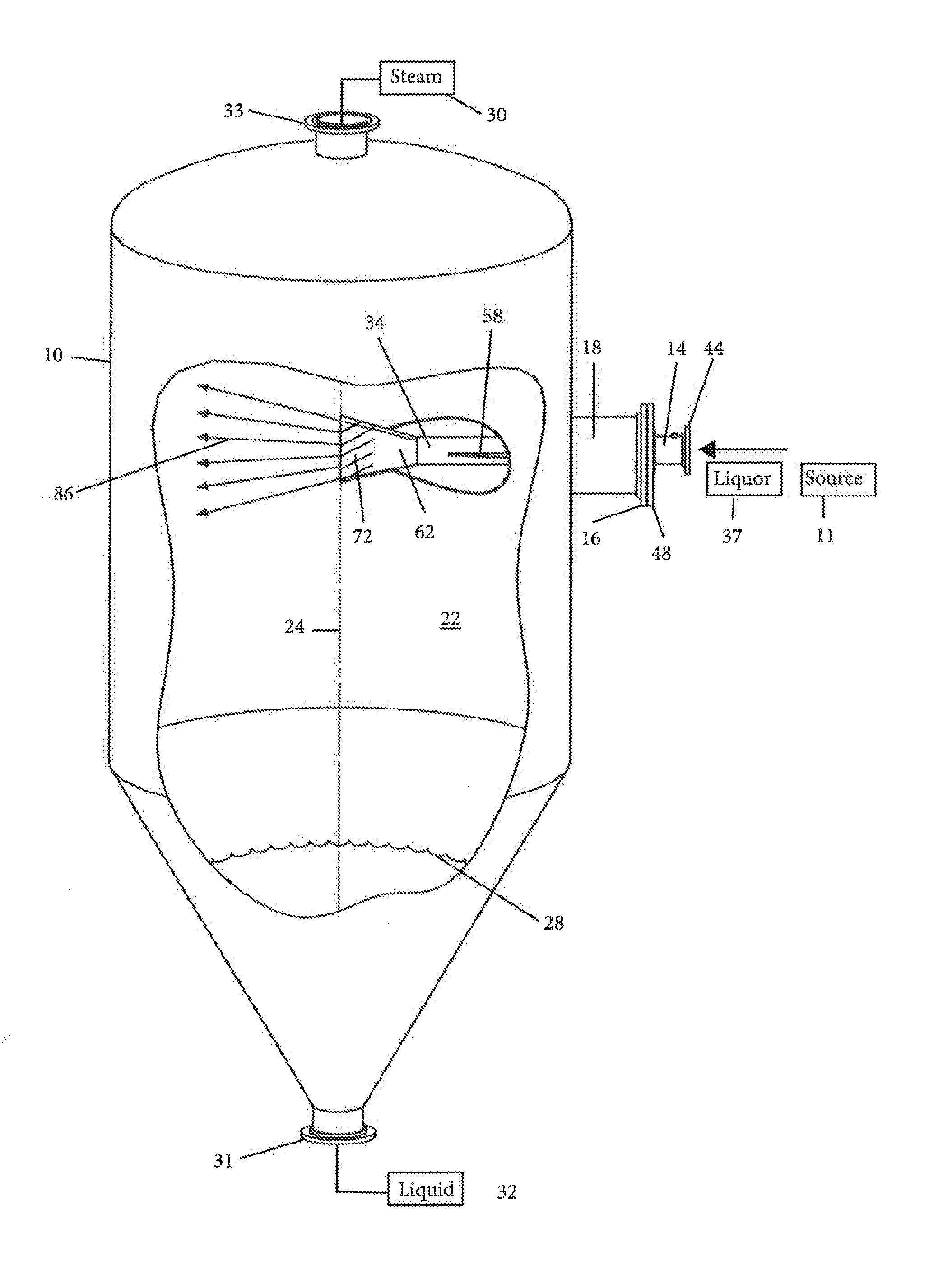

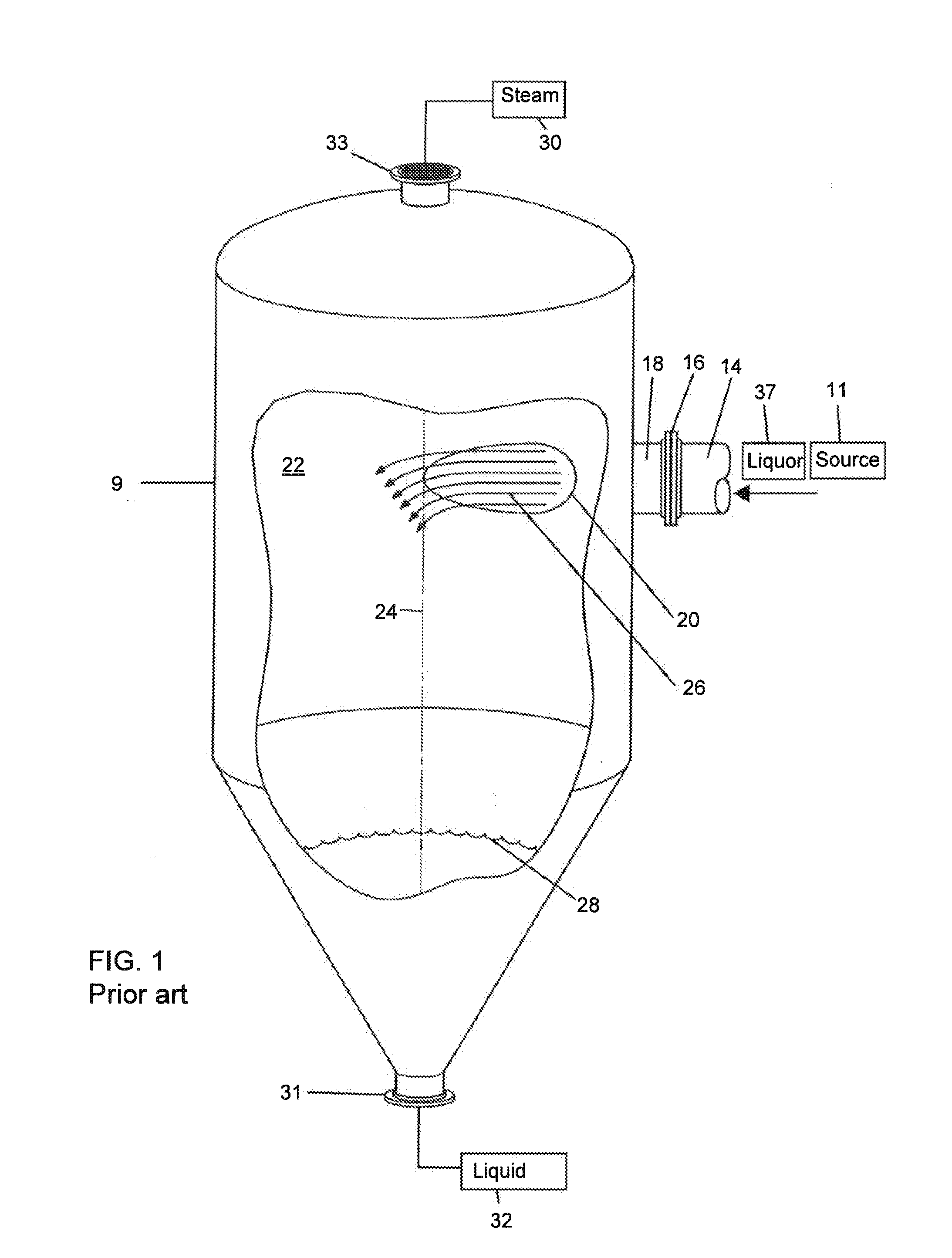

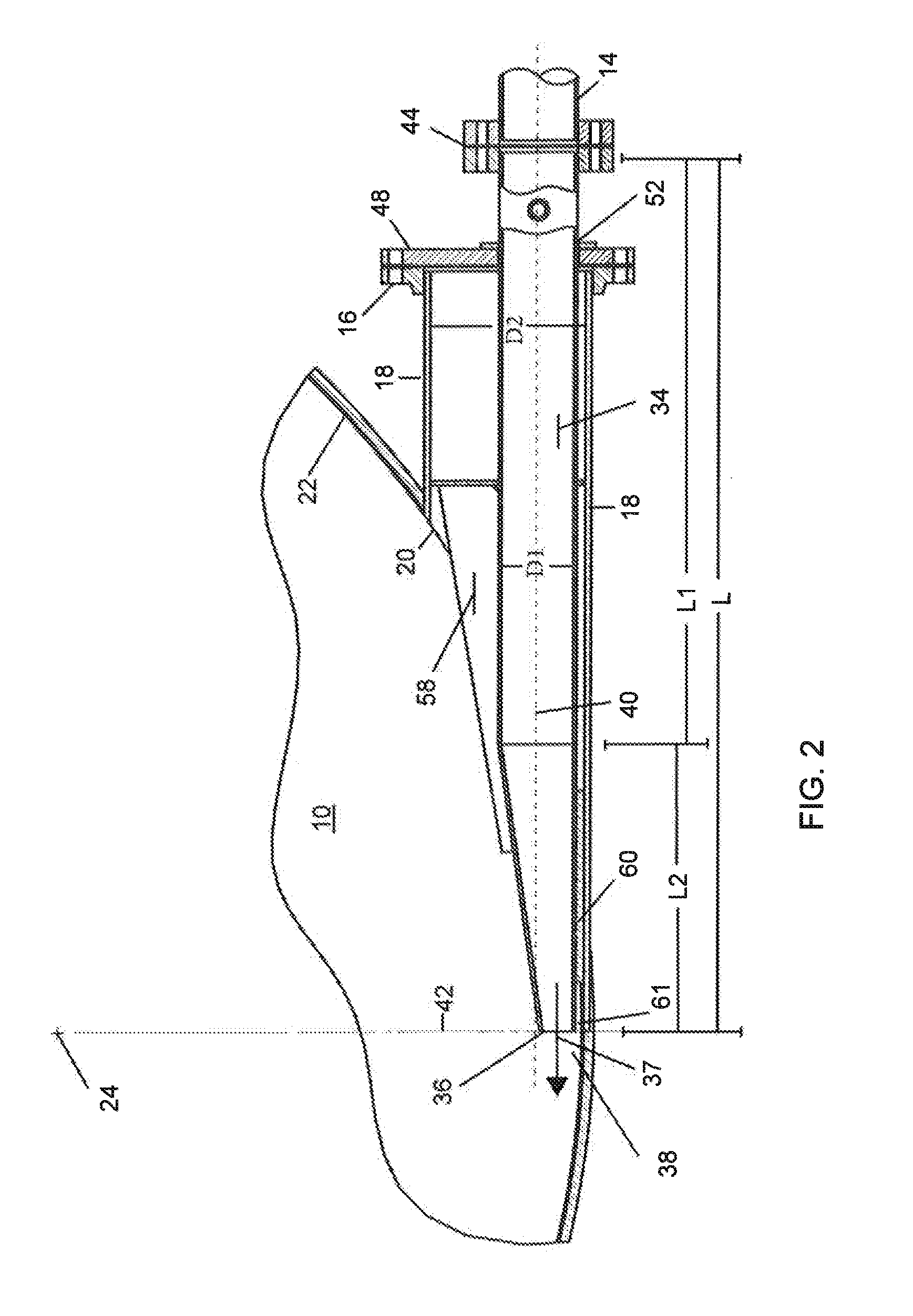

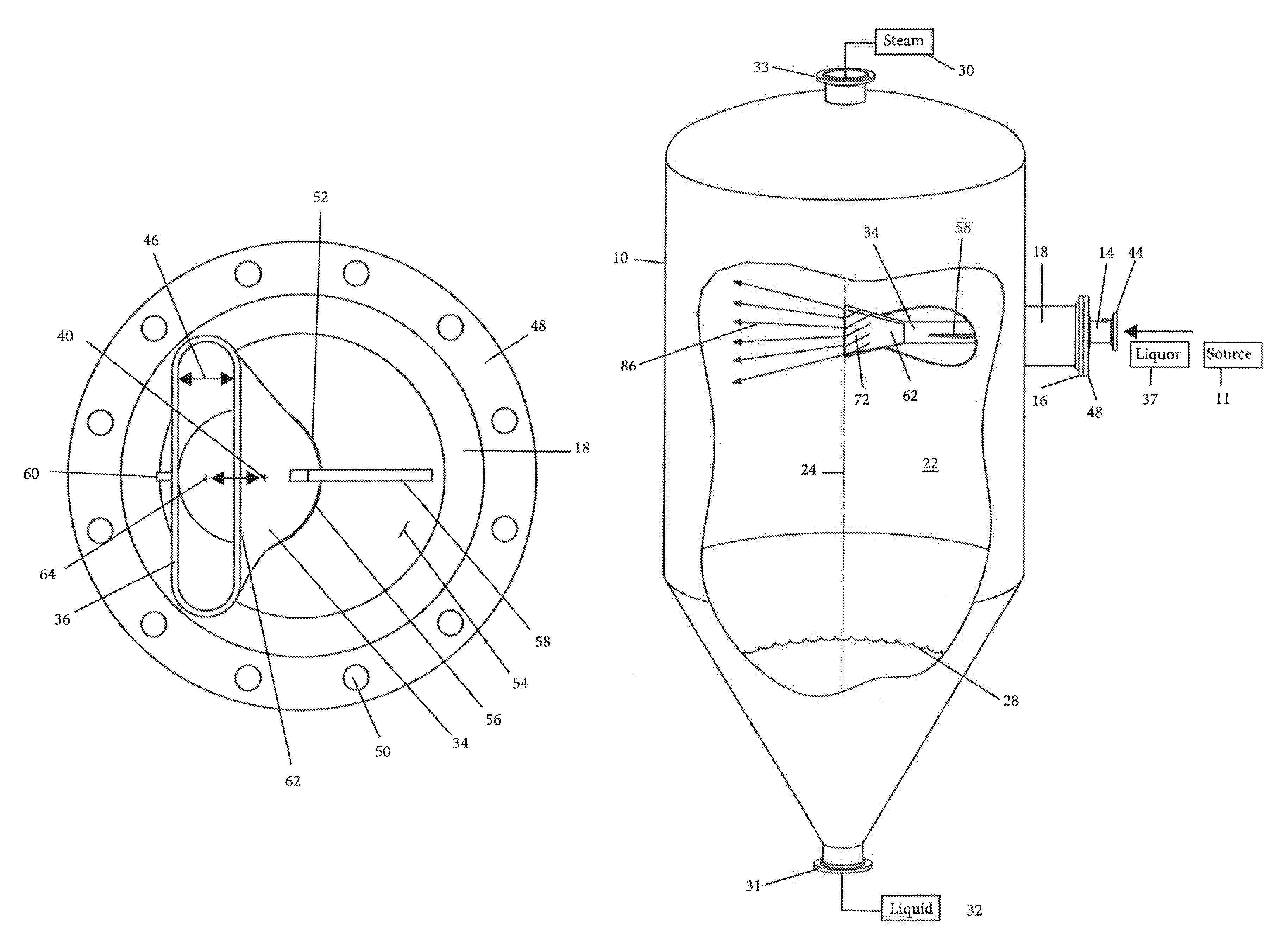

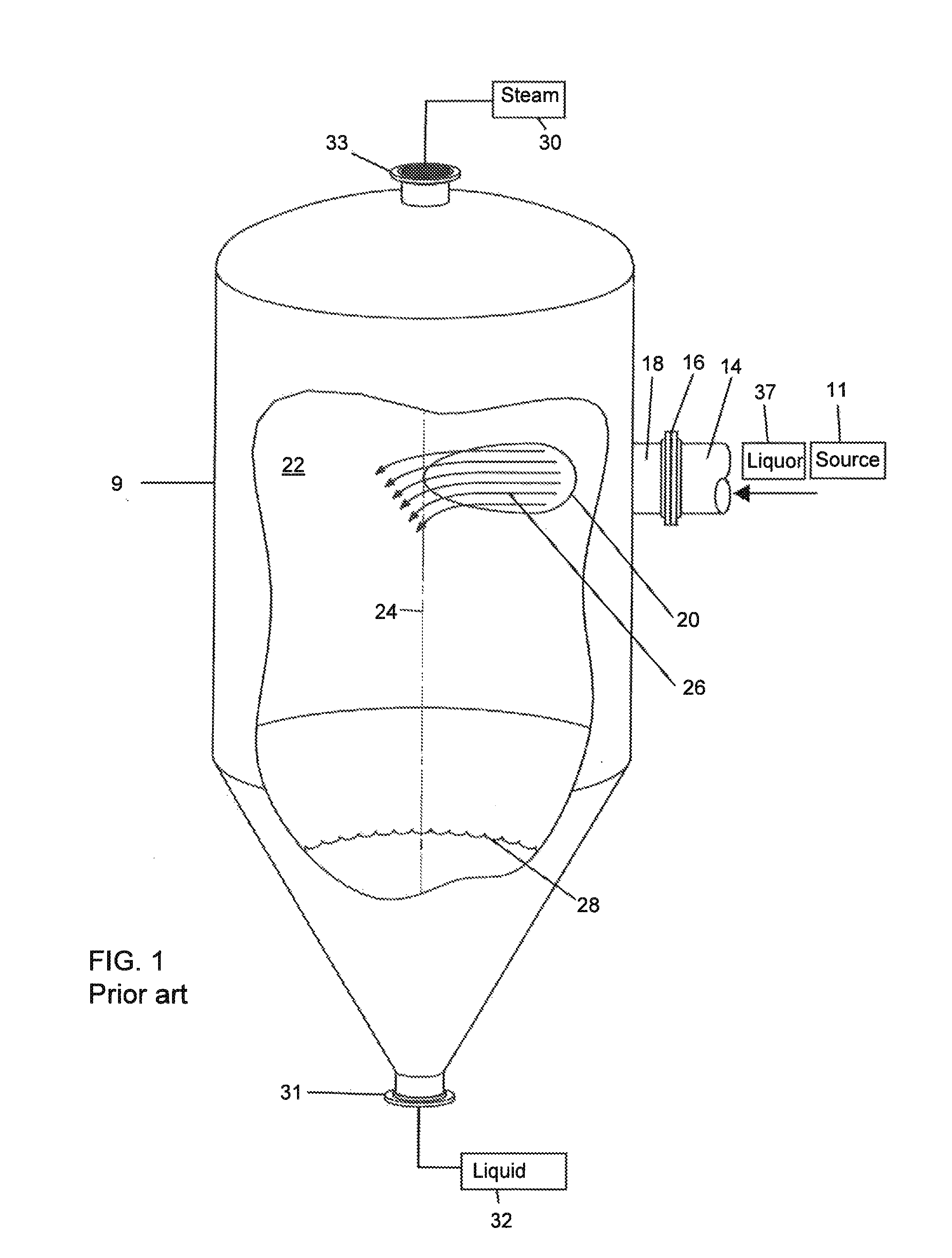

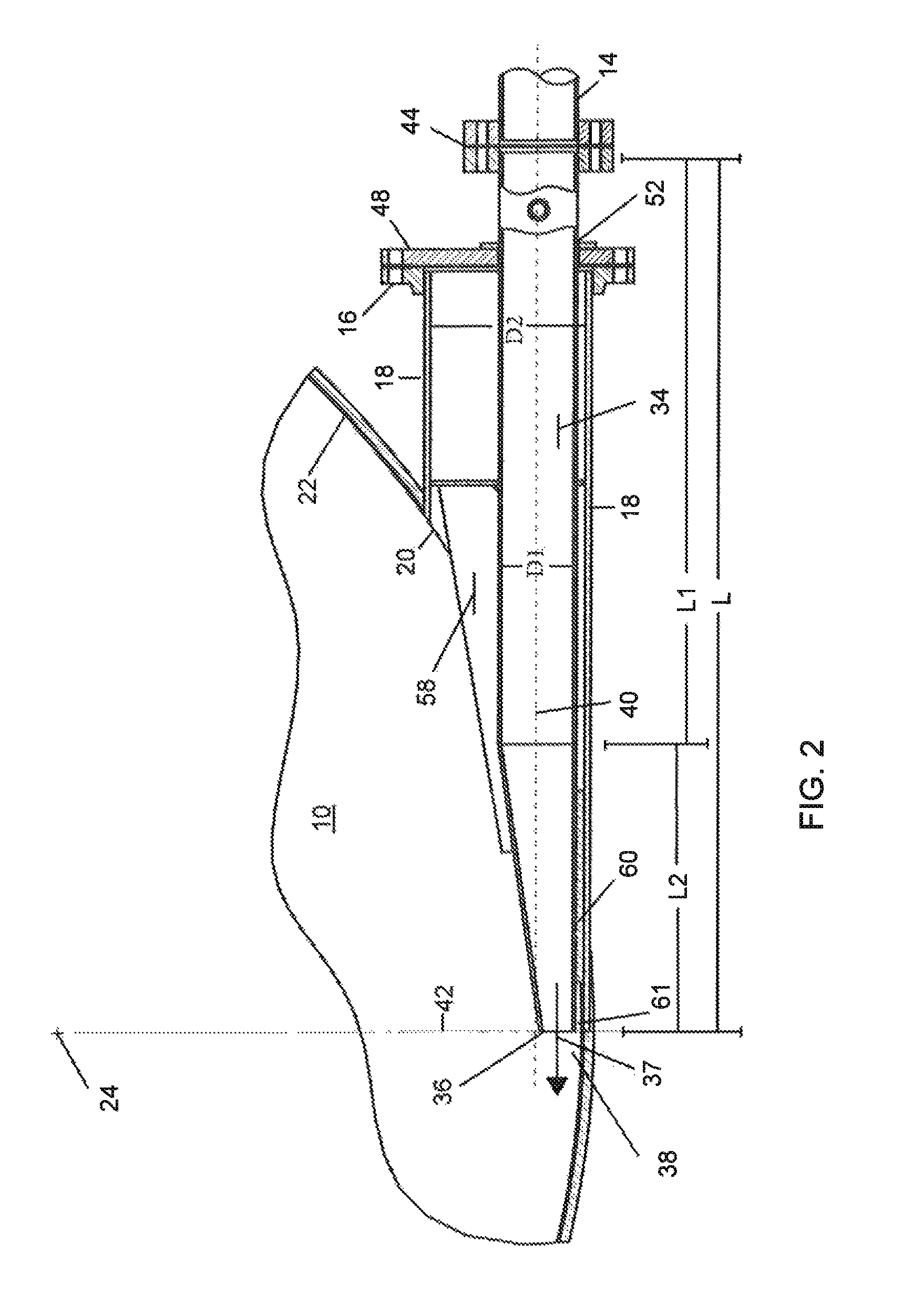

Flash tank with flared inlet insert and method for introducing flow into a flash tank

ActiveUS20140352900A1Speed up the flowMachine wet endFlash degasificationEngineeringMechanical engineering

A flash tank including: an interior chamber having a interior surface formed by a sidewall of the flash tank; a vapor exhaust port coupled to an upper portion of the chamber; a liquid discharge port coupled to a lower portion of the chamber; an insert inlet tube having an insert outlet and inserted into an inlet port of the chamber, wherein the insert inlet tube extends inward of the sidewall and the insert outlet has an elongated cross-sectional shape oriented substantially parallel to a center vertical axis of the flash tank and substantially perpendicular to a radial line of the flash tank, such that the insert outlet is substantially tangential to the sidewall.

Owner:ANDRITZ INC

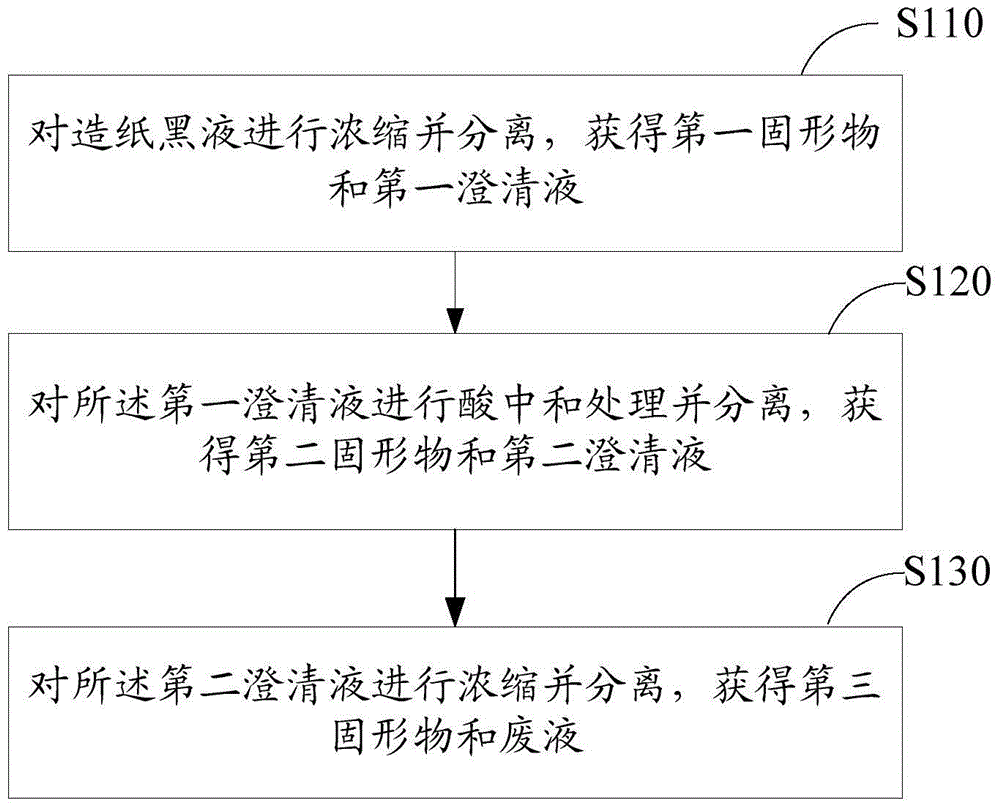

Treatment method of papermaking black liquid

ActiveCN104631182AReduce processing loadReduce COD

<sub>Cr</sub>

valueRegeneration of alkali lyeSpent liquor concentrationEconomic benefitsSolid matter

The invention discloses a treatment method of papermaking black liquid. The treatment method comprises the following steps: concentrating the papermaking black liquid, and separating to obtain a first solid matter and a first supernatant; neutralizing the first supernatant with an acid, and separating to obtain a second solid matter and a second supernatant; concentrating the second supernatant, and separating to obtain a third solid matter and a third supernatant. By adopting the treatment method disclosed by the invention, the CODCr of the waste liquid can be reduced, the wastewater treatment load can be reduced, different solid matters can be recycled respectively, and the economic benefit of enterprises can be increased.

Owner:GOLD EAST PAPER JIANGSU

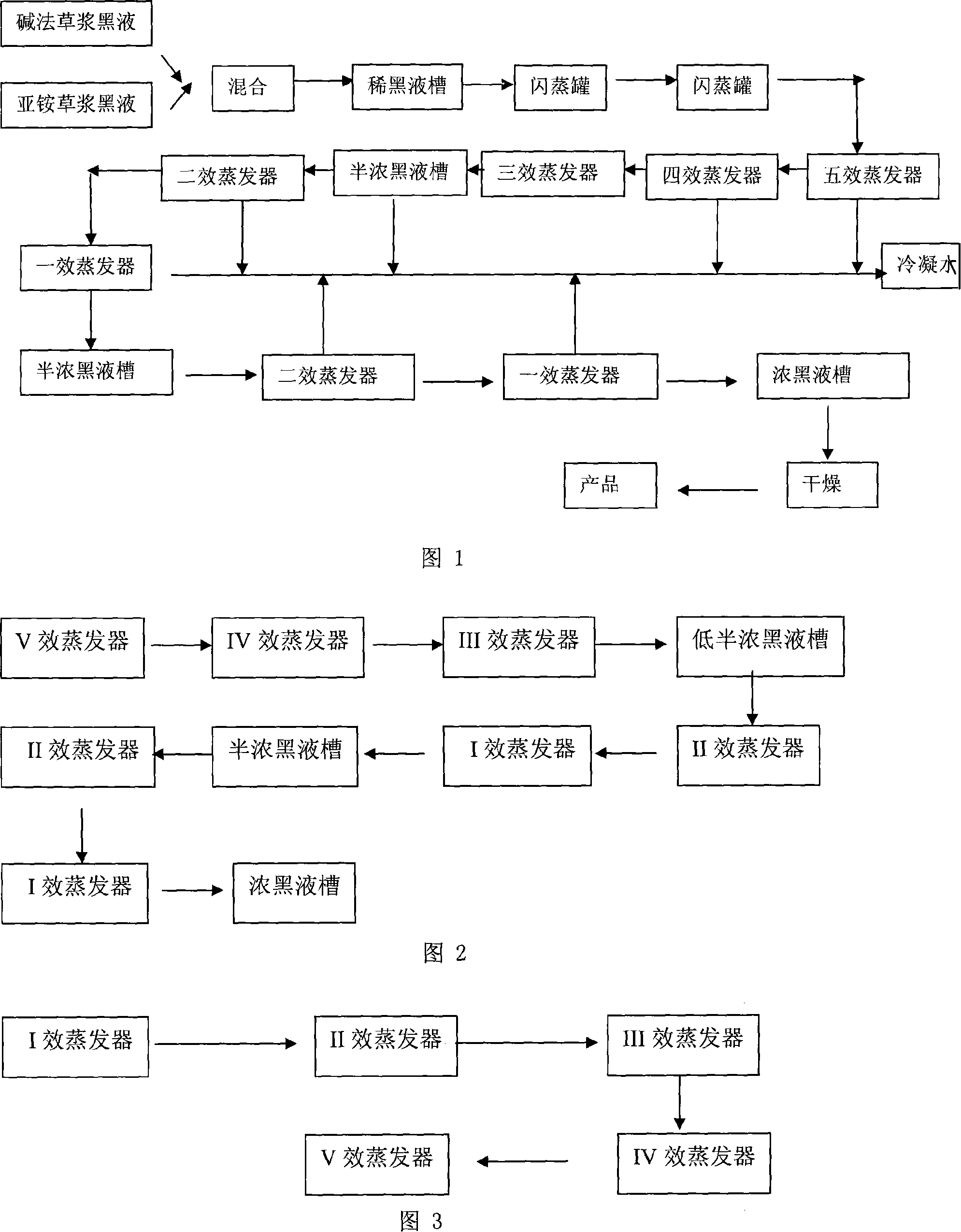

Alkali process and iminium process straw pulp black liquor hybrid dry matter and preparation method thereof

The invention relates to a mixture of dried grain of alkali and ammonium sulfite black straw liquor as well as relevant preparation method. The invention is mainly a product by mixing alkali method black straw liquor with ammonium sulfite black straw liquor before performing condensation and drying, as well as relevant products that are produced. Evaporating and condensing black liquor with the production technique needs less energy consumption, and main dried grains include sodium lignin and ammonium lignin sulfonate as well as fulvic acid like substances. Therefore, the invention has broad application and can be used as raw materials for many products with high economic value. Moreover, the invention can also be utilized in preparation of an excellent water reducer, or be added with some crosslinkers to prepare lignin sand-fixing solvent.

Owner:SHANDONG TRALIN PAPER

Process and device for abstracting lignose with zero discharge of paper making black liquor

InactiveCN101289820AIncrease conversion rateSolve the problem of black liquor pollutionDrying solid materials with heatStorage heatersFiberBlack liquor

The invention provides a method for extracting lignose with zero discharge of paper making black liquors and a device thereof. The method is mainly applicable to wood such as wheat straws, rice straws, sugar cane waste, cotton straws, eulaliopsis binata, reeds and bamboos; the wood after being selected is put in a spherical digester, a sauce pan or a continuous digester, sprayed in a spraying bin after the manganese value is obtained and sent to a twin screw squeezing pulp machine or other squeezing pulp equipment for squeezing by a screw discharging machine, and the high consistency black liquors are extracted by steam-boiling, and dilute liquors left in fibers are sent back to a boiler for recycling use; in the system adopting the low temperature condensation negative pressure principle, black liquors are automatically sucked in a reaction kettle for condensation reaction due to vacuum; after instant contact drying, grain-sized dry powder by products are generated. The method of the invention has the advantages of completely resolving the problem of back liquor pollution in the paper making industry because of clearing away the very root, improving the transfer ratio of resource reutilization and protecting the environment, along with low equipment cost, low cost and good economic benefits.

Owner:沁阳市泰昌环保造纸设备工程有限公司

Plate-type down-film evaporator descaling method

InactiveCN101254504AEfficient and complete removalImprove evaporation efficiencyFlush cleaningCleaning using liquidsFiberPulp and paper industry

A descaling method for plate-type falling-film evaporators is provided, which belongs to the technology field of pulp and paper industry. The method includes the following steps: immersing a heat exchange plate of a plate-type falling-film evaporator in a white liquor containing 70-90 g / L of NaOH, boiling under such conditions that the temperature is 110-130 DEG C and the pressure is 0.1-0.15 MPa until the fiber scale is loose; and purging the fibrous scale from the surface of the heat exchange plate by using a high-pressure water gun at a pressure of 400-500 Kg / cm<2>. The method can remove fiber scale efficiently and completely. Compared with the prior art, the method lengthens the descaling period from one month to three months, shorten the descaling time by a half, removes the scale completely, increases the efficiency of the plate-type falling-film evaporator and improves the production capacity of the equipment.

Owner:MCC PAPER YINHE

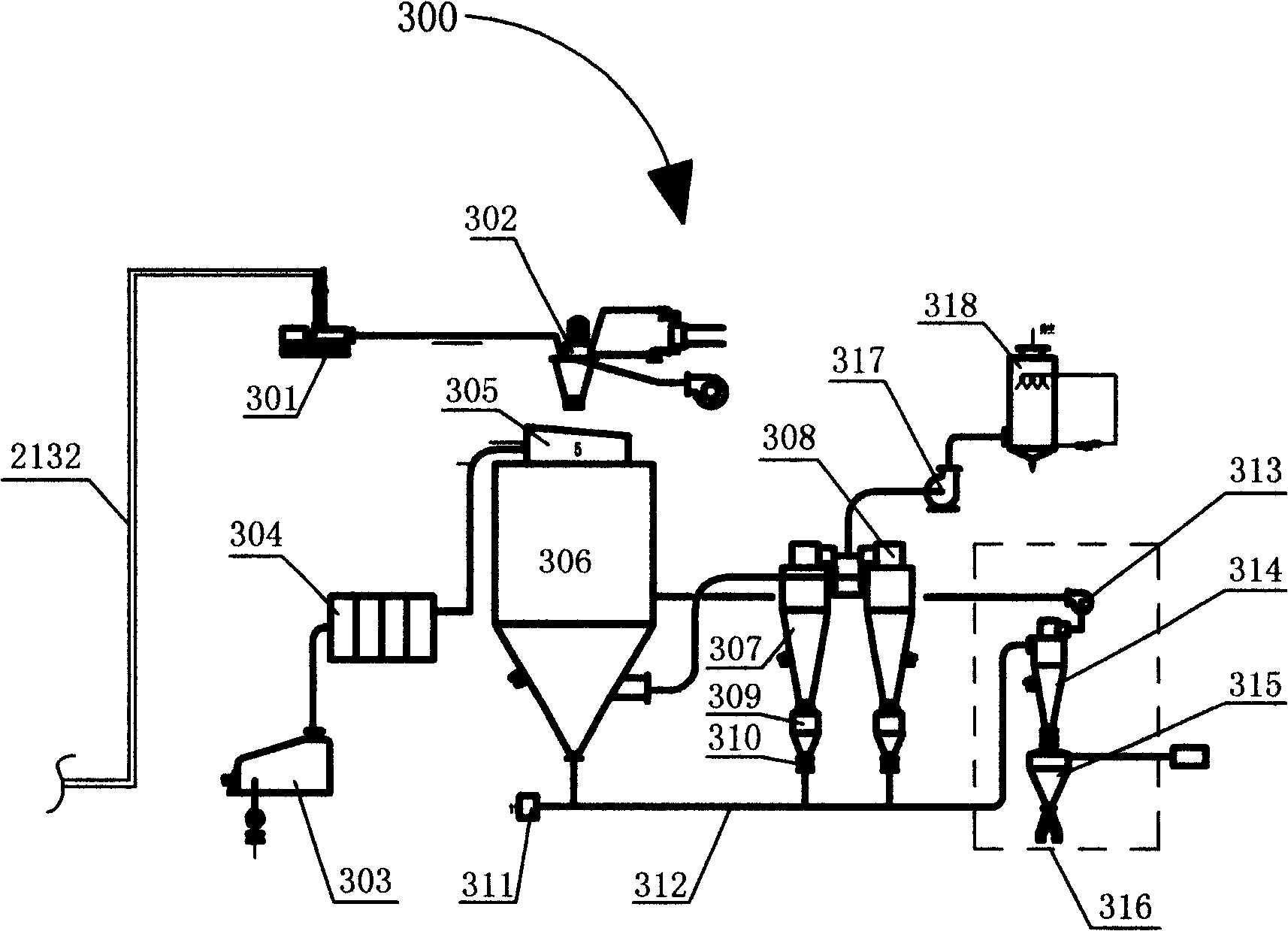

Optimizing process for alkali recovery of papermaking waste liquid

The invention discloses an optimizing process for alkali recovery of papermaking waste liquid, the optimizing process comprises black liquor extraction, evaporation concentration, high-temperature calcining and causticization, the black liquor extraction section is used for extracting dilute black liquor from pulping cooked liquor, the evaporation concentration section is used for heating the black liquor of the black liquor extraction section by virtue of steam from the high-temperature calcining section; the high-temperature calcining working section is used for first concentrating the blackliquor with the concentration of 50% obtained by the evaporation concentration section further to the concentration of 65%, the obtained black liquor is sent to an alkali furnace for high-temperaturecalcining, a melt is formed by the calcined black liquor, and the melt is dissolved into water obtain green liquor; and the causticization section is used for reacting the green liquor with limestoneto obtain a sodium hydroxide solution. According to the optimizing process, the process is simple and feasible, the recycling efficiency of the black liquor is high, and the quality is guaranteed.

Owner:INT CENT FOR BAMBOO & RATTAN

Flash tank with flared inlet insert and method for introducing flow into a flash tank

ActiveUS9127403B2Speed up the flowFlash degasificationRegeneration of alkali lyeMechanical engineeringVertical axis

A flash tank including: an interior chamber having a interior surface formed by a sidewall of the flash tank; a vapor exhaust port coupled to an upper portion of the chamber; a liquid discharge port coupled to a lower portion of the chamber; an insert inlet tube having an insert outlet and inserted into an inlet port of the chamber, wherein the insert inlet tube extends inward of the sidewall and the insert outlet has an elongated cross-sectional shape oriented substantially parallel to a center vertical axis of the flash tank and substantially perpendicular to a radial line of the flash tank, such that the insert outlet is substantially tangential to the sidewall.

Owner:ANDRITZ INC

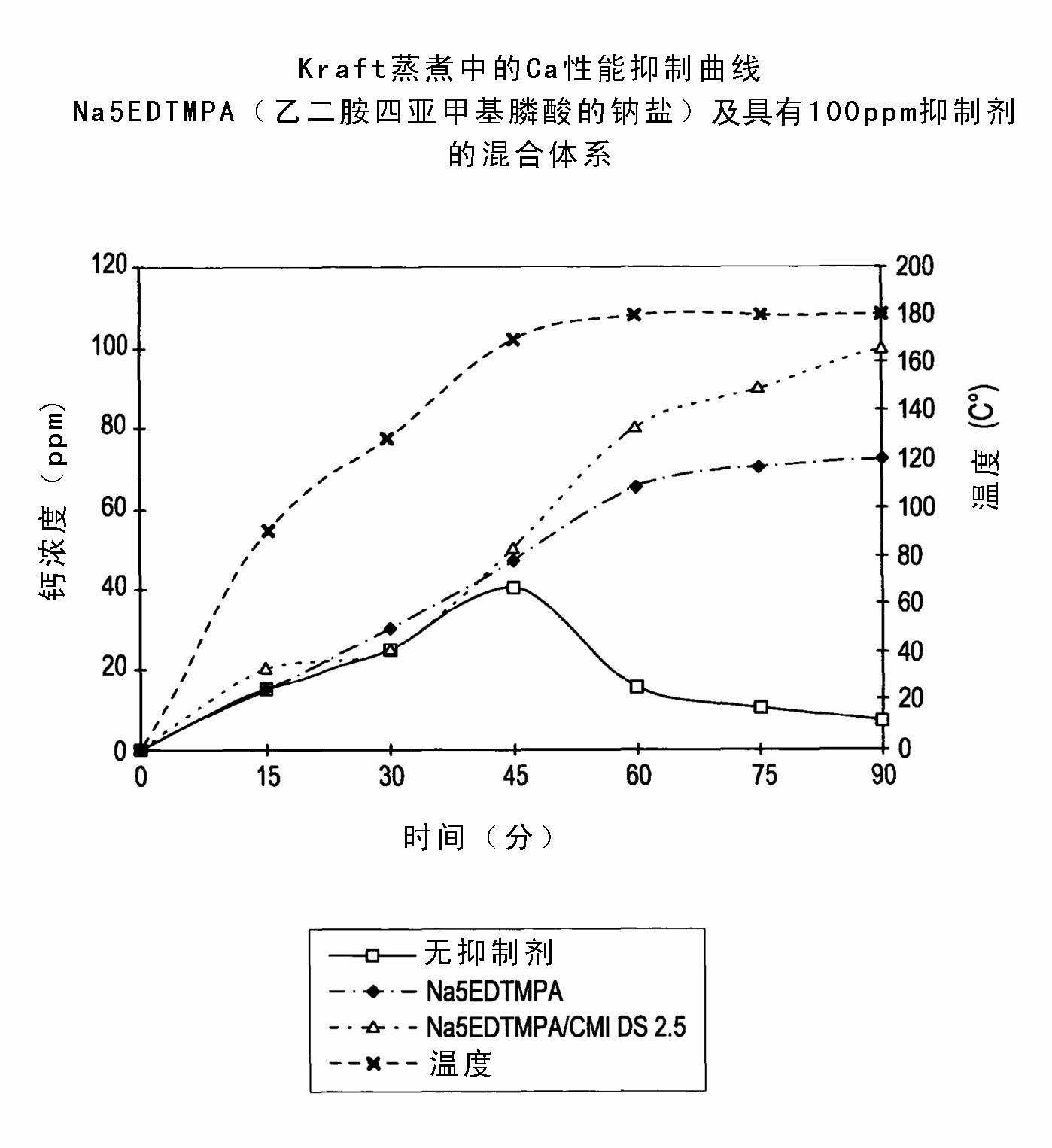

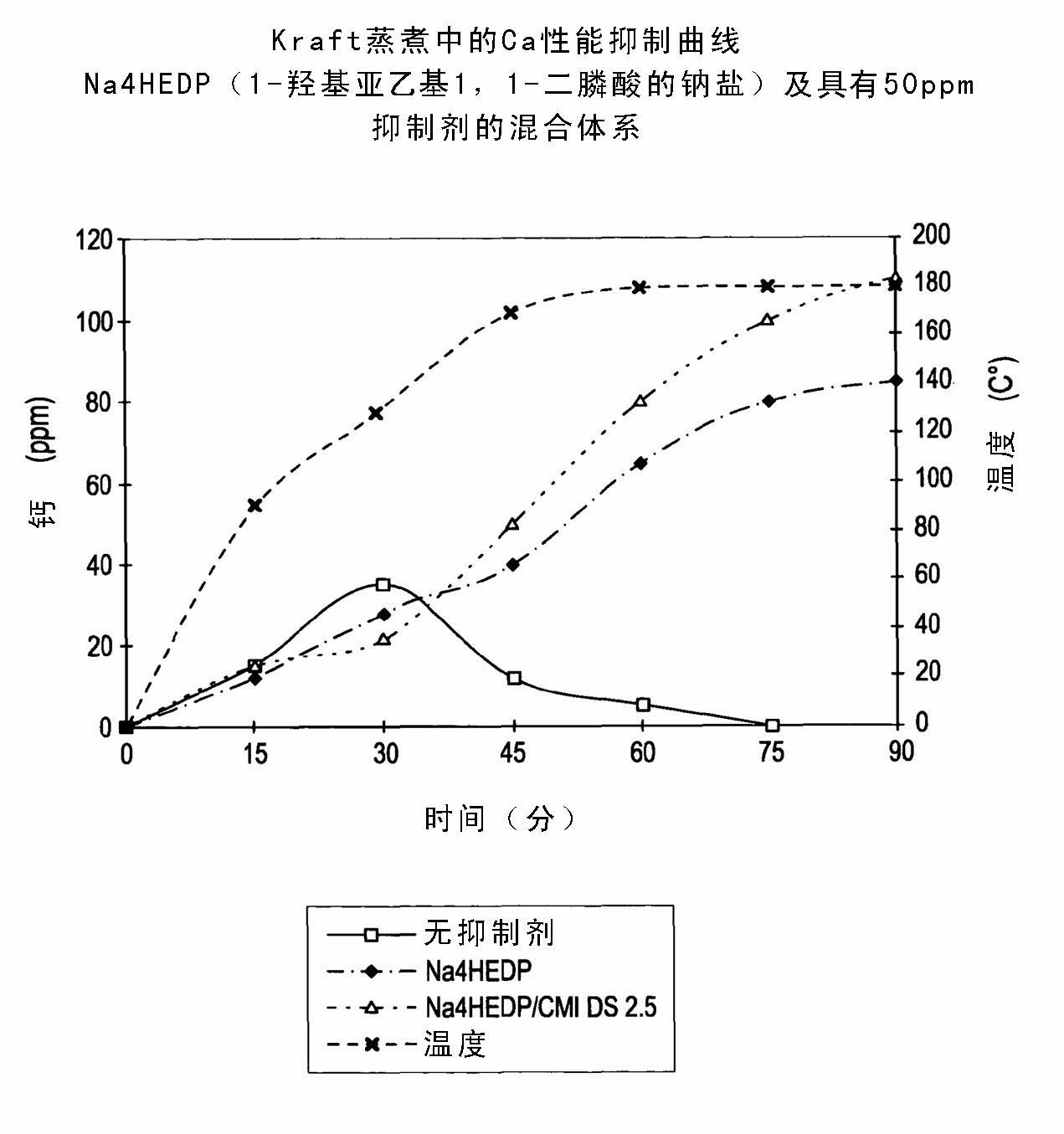

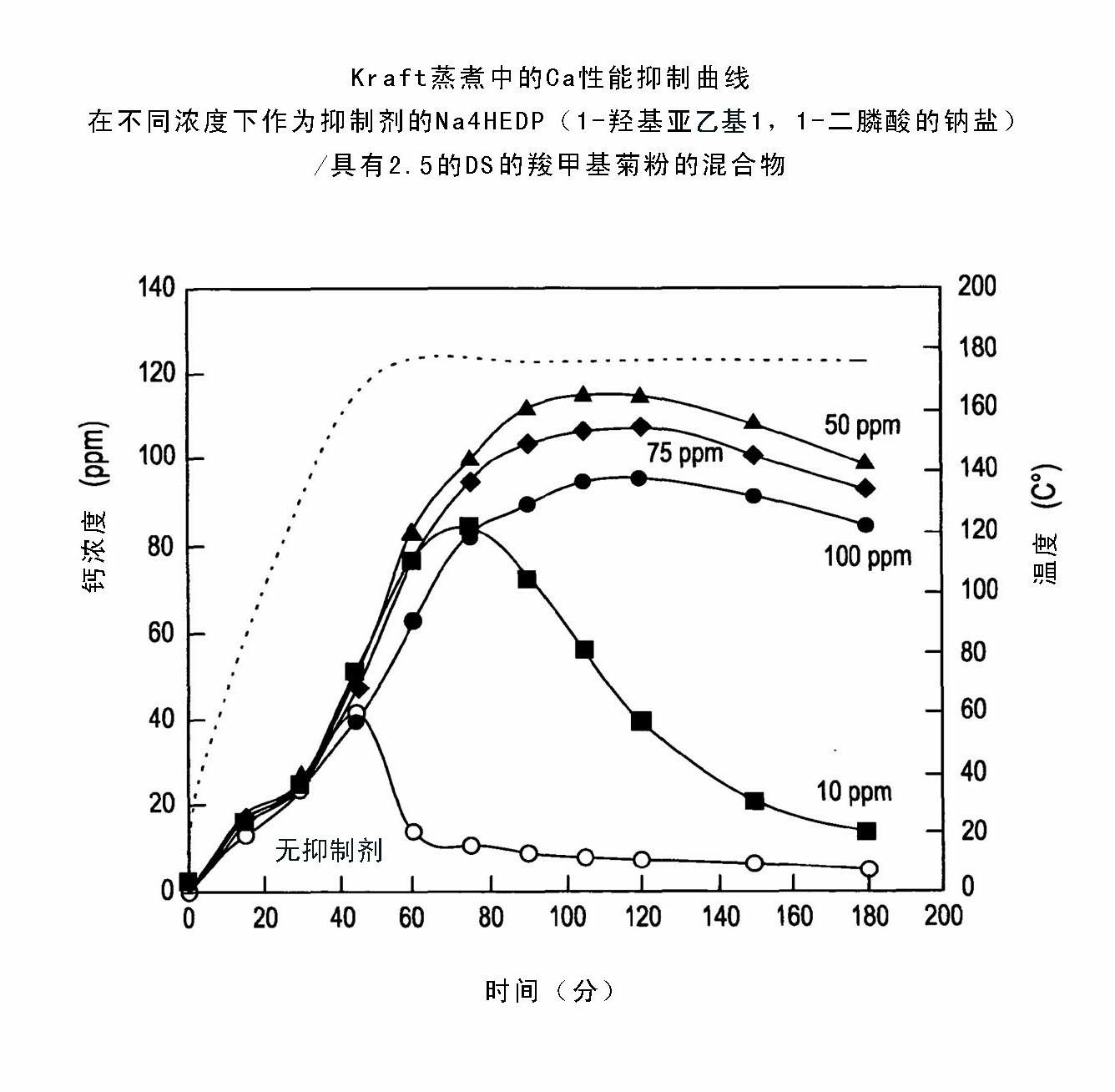

Composition for inhibiting calcium salt scale formation

ActiveCN102428040APulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpCalcium EDTAMetal

A method for inhibiting the formation, deposition and adherence of calcium salt scale to metallic and other surfaces in the equipment, vessels and / or piping of a chemical pulp process facility comprising adding an effective scale inhibiting amount of a composition to the alkaline aqueous mixture in the digester of said chemical pulping process. Said composition consists of at least one phosphonate component (I) and at least one component (II) consisting of at least one carboxylated fructan compound.

Owner:伊塔尔麦奇化学股份公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com