Optimizing process for alkali recovery of papermaking waste liquid

A technology for papermaking waste liquid and process, which is applied in the field of optimization process of papermaking waste liquid, can solve the problems such as difficulty in processing and recycling black liquor, and achieve the effect of eliminating heavy pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

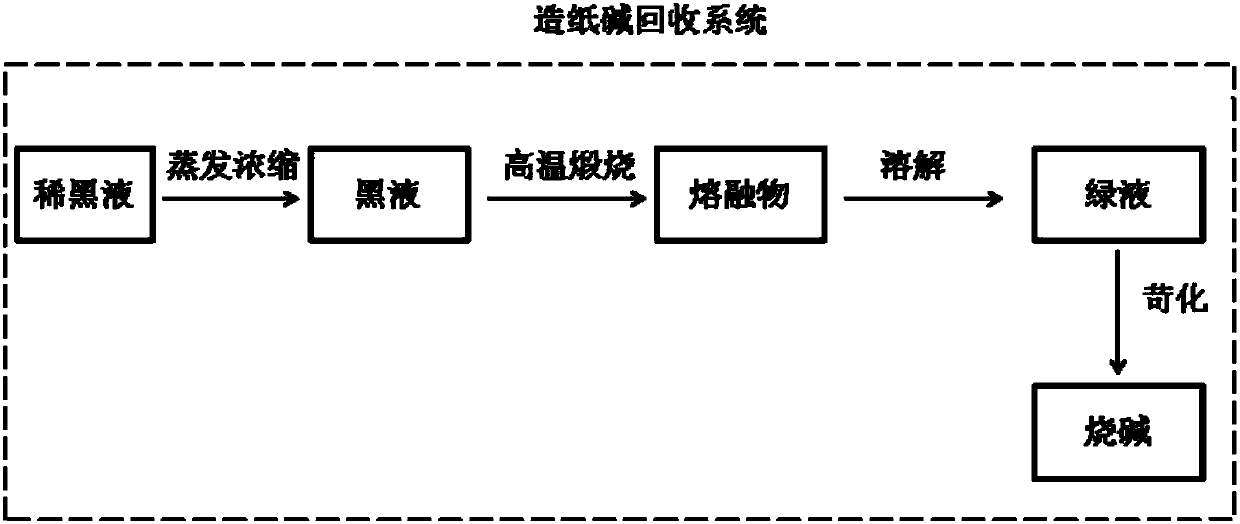

[0021] An optimized process for alkali recovery of papermaking waste liquor, including black liquor extraction, evaporation concentration, high-temperature calcination and causticization, the black liquor extraction section is to extract dilute black liquor from pulping cooking liquor, and then extract the extracted black liquor The dilute black liquor is sent to the evaporation workshop for evaporation and concentration, and the dilute black liquor is the raw material source in the alkali recovery process; the evaporation concentration section first uses the steam from the high-temperature calcination section to heat the black liquor from the extraction section, and the black liquor During the heating process, the concentration of water vaporized and escaped from the liquid is concentrated to 45%, and the evaporation and concentration section uses the waste heat of the flue gas to heat and concentrate to 50%; the high-temperature calcination section first further concentrates t...

Embodiment 2

[0030]An optimized process for alkali recovery of papermaking waste liquor, including black liquor extraction, evaporation concentration, high-temperature calcination and causticization, the black liquor extraction section is to extract dilute black liquor from pulping cooking liquor, and then extract the extracted black liquor The dilute black liquor is sent to the evaporation workshop for evaporation and concentration, and the dilute black liquor is the raw material source in the alkali recovery process; the evaporation concentration section first uses the steam from the high-temperature calcination section to heat the black liquor from the extraction section, and the black liquor During the heating process, the concentration of water evaporated and escaped from the liquid is concentrated to 46%, and the evaporation and concentration section uses the waste heat of the flue gas to heat and concentrate to 52%; the high-temperature calcination section first further concentrates t...

Embodiment 3

[0039] An optimized process for alkali recovery of papermaking waste liquor, including black liquor extraction, evaporation concentration, high-temperature calcination and causticization, the black liquor extraction section is to extract dilute black liquor from pulping cooking liquor, and then extract the extracted black liquor The dilute black liquor is sent to the evaporation workshop for evaporation and concentration, and the dilute black liquor is the raw material source in the alkali recovery process; the evaporation concentration section first uses the steam from the high-temperature calcination section to heat the black liquor from the extraction section, and the black liquor During the heating process, the concentration of water evaporated and escaped from the liquid is concentrated to 48%, and the evaporation and concentration section uses the waste heat of the flue gas to heat and concentrate to 55%; the high-temperature calcination section first further concentrates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com