Method for producing fulvic acids fertilizer by using alkaline process black liquor

A technology of alkaline pulping and fulvic acid, applied in the direction of organic fertilizer, sewage/sludge fertilizer, application, etc., can solve the problems of small application range of fertilizer, low content of fulvic acid, high production cost, etc., and achieve economic benefits Considerable, no secondary pollution, low one-time investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

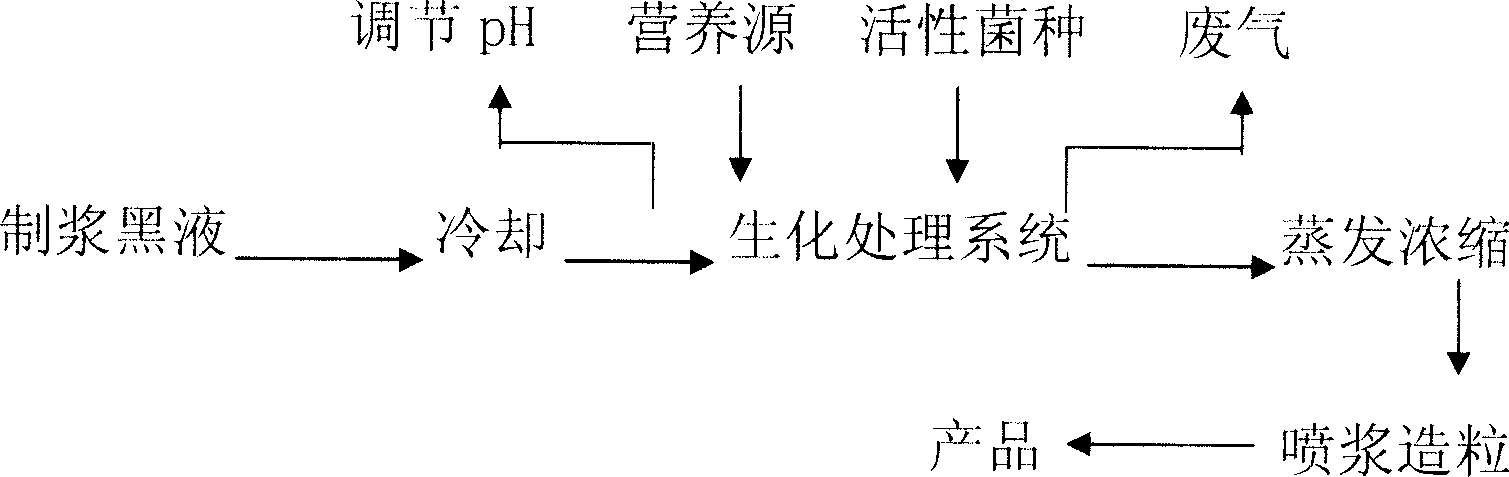

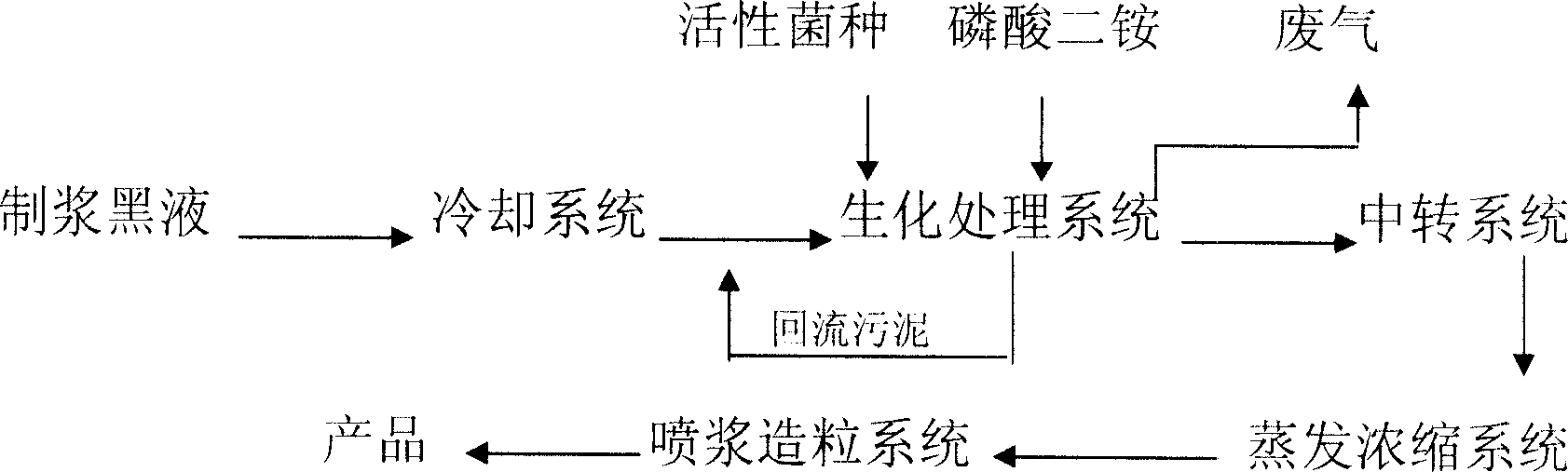

Method used

Image

Examples

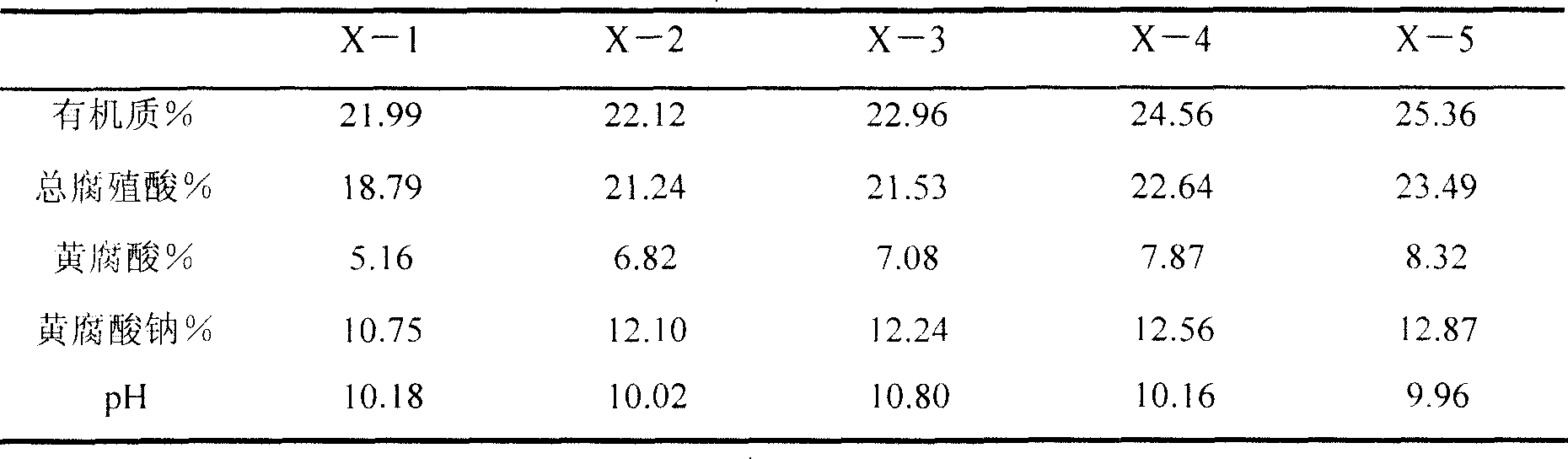

Embodiment 1

[0064] Put the potato dextrose agar medium inoculated with Bacillus licheniformis AS.1.518 into the fermenter for fermentation, the temperature is controlled at 28°C, the ratio of aeration volume to liquid volume is 0.5, the stirring speed is 150 rpm, and the fermentation time is 24 hours , to obtain the strain liquid, which contains 1.5 billion strains per milliliter.

[0065] Cool the black liquor from wheatgrass soda pulping to 40°C in a cooling pool whose length, width and height are 5m, 5m, and 3m respectively, and mix the returned sludge and fresh black liquor at a weight ratio of 8:1. The pH of the liquid is 9.6, and 0.1‰ of diammonium phosphate is added at the same time, and it is passed into the UASB-100 reactor manufactured by Jinan Lufa Environmental Protection Technology Co., Ltd., and the black liquor volume 1 / 35 of Bacillus licheniformis AS.1.518 is added to the UASB reactor When the pH of the system drops to 8.0, the black liquor that has completed the biochemic...

Embodiment 2

[0067] Put the potato comprehensive medium inoculated with Bacillus licheniformis AS1.932, AS.1.518 and Bacillus cereus CFCC1007 into the fermenter for fermentation, the temperature is controlled at 31°C, the ratio of aeration rate to liquid volume is 1.0, and the stirring speed is 250 rev / min, the fermentation time is 36 hours, and the strain liquid is obtained, which contains 2.5 billion strains per milliliter.

[0068] Cool the soda pulping black liquor to 38°C in a cooling pool with a length, width, and height of 5m, 5m, and 3m respectively, and mix the return sludge and fresh black liquor at a weight ratio of 10:1. After mixing, The pH of the black liquor is 10.0, and 15‰ of urea is added at the same time, and it is passed into the UASB-100UASB reactor manufactured by Jinan Lufa Environmental Protection Technology Co., Ltd., and the black liquor volume 1 / 40 of Bacillus licheniformis AS1.932, For the seed solution of AS.1.518 and Bacillus cereus CFCC1007, when the pH of th...

Embodiment 3

[0070] The potato yeast extract medium inoculated with Bacillus licheniformis IFFI10020 and Bacillus pumilus AS1.594 was put into a fermenter for fermentation, the temperature was controlled at 30°C, the ratio of ventilation rate to liquid volume was 0.8, and the stirring speed was 200 rpm. The fermentation time is 32 hours, and the strain liquid is obtained, which contains 2.25 billion strains per milliliter.

[0071] After cooling the cotton stalk alkaline pulping black liquor to 39°C in a cooling pool with a length, width, and height of 5m, 5m, and 3m respectively, mix the return sludge and fresh black liquor at a weight ratio of 5:1, and mix The pH of the final black liquor is 9.0, and 10‰ of phosphate rock powder is added at the same time, and passed into the UASB-100UASB generator manufactured by Jinan Lufa Environmental Protection Technology Co., Ltd., and the black liquor volume 1 / 38 of Bacillus licheniformis IFFI10020 is added to the UASB reactor and the strain soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com