Treatment method of papermaking black liquid

A technology for papermaking black liquor and a treatment method, applied in the papermaking field, can solve the problems of incapable of resource utilization and ineffective reduction of waste water treatment load, and achieve the effects of reducing waste water treatment load, increasing economic benefits, and reducing CODCr value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

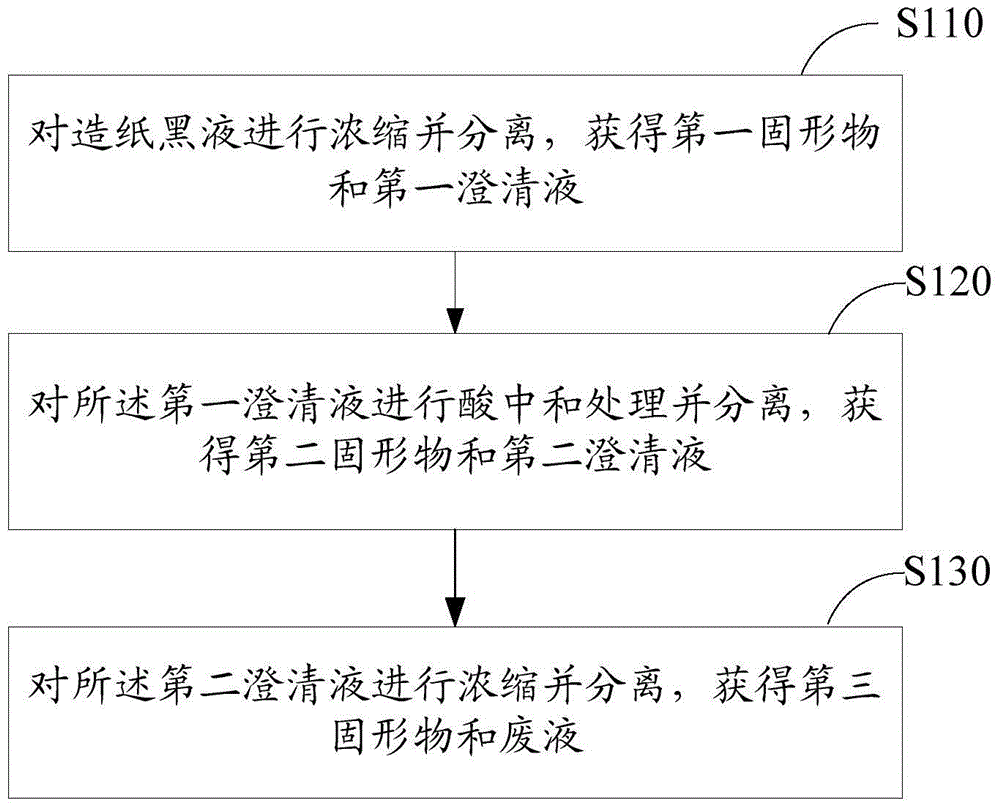

[0019] refer to figure 1 , figure 1 It is the first embodiment of the processing method of papermaking black liquor of the present invention, comprises the steps:

[0020] Step S110: concentrating and separating the papermaking black liquor to obtain a first solid and a first clarified liquid.

[0021] At present, the plant fiber raw materials used in papermaking mainly contain three parts: cellulose, lignin and hemicellulose (polysaccharides). The lignin accounting for 25%, the hemicellulose accounting for about 28%, and other organic extracts and inorganic substances are discarded along with the papermaking black liquor.

[0022] In this embodiment, firstly, the papermaking black liquor is concentrated to separate out the solid phase in the papermaking black liquor. In order to precipitate the solid phase of the papermaking black liquor, it can be concentrated by evaporation. Further, in order to fully separate out the solid phase of the papermaking black liquor, multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com