Alkali process and iminium process straw pulp black liquor hybrid dry matter and preparation method thereof

A technology of straw pulp black liquor and ammonium method, applied in the direction of concentrated waste liquid, etc., can solve the problems of equipment corrosion, black liquor drop, low evaporation efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

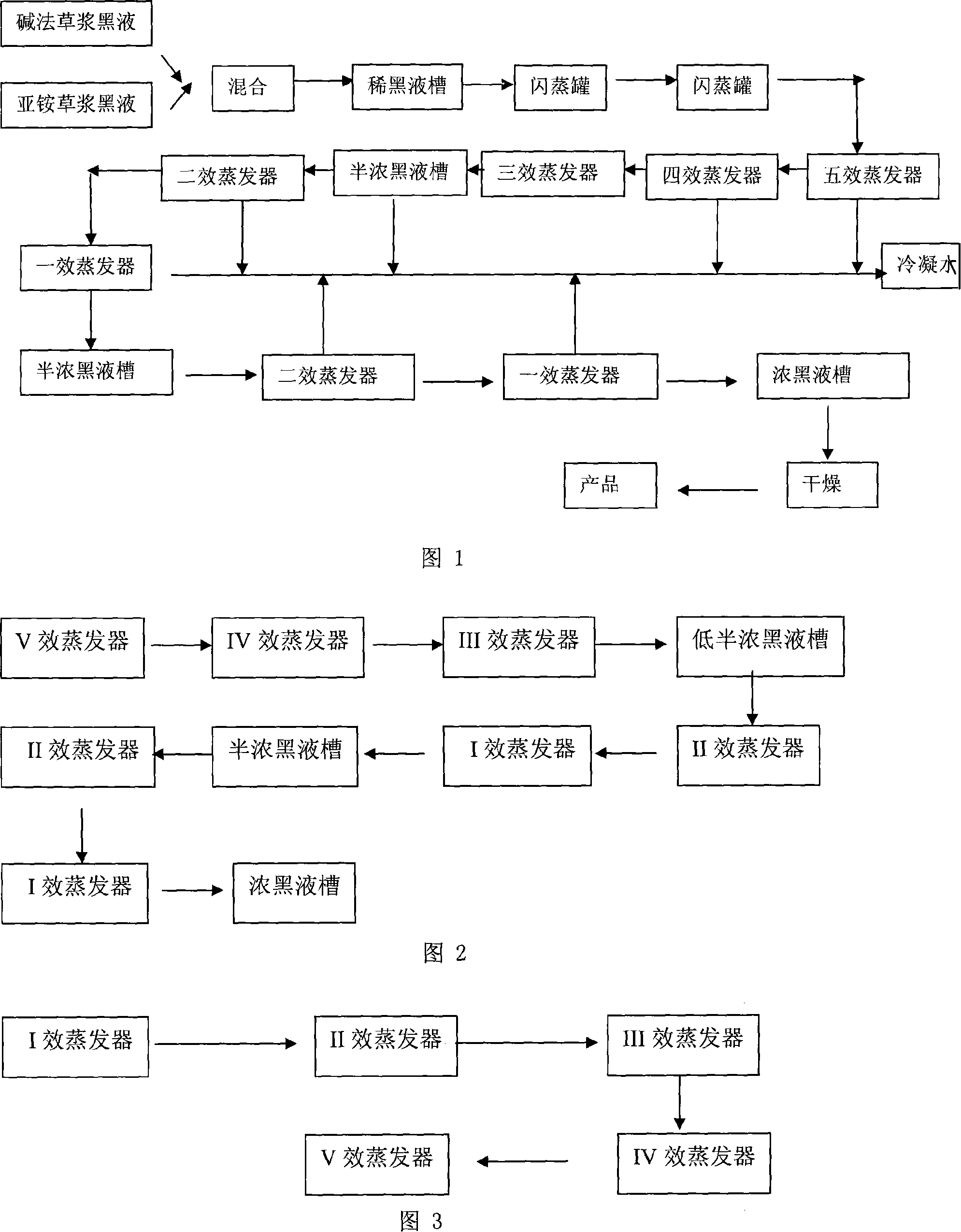

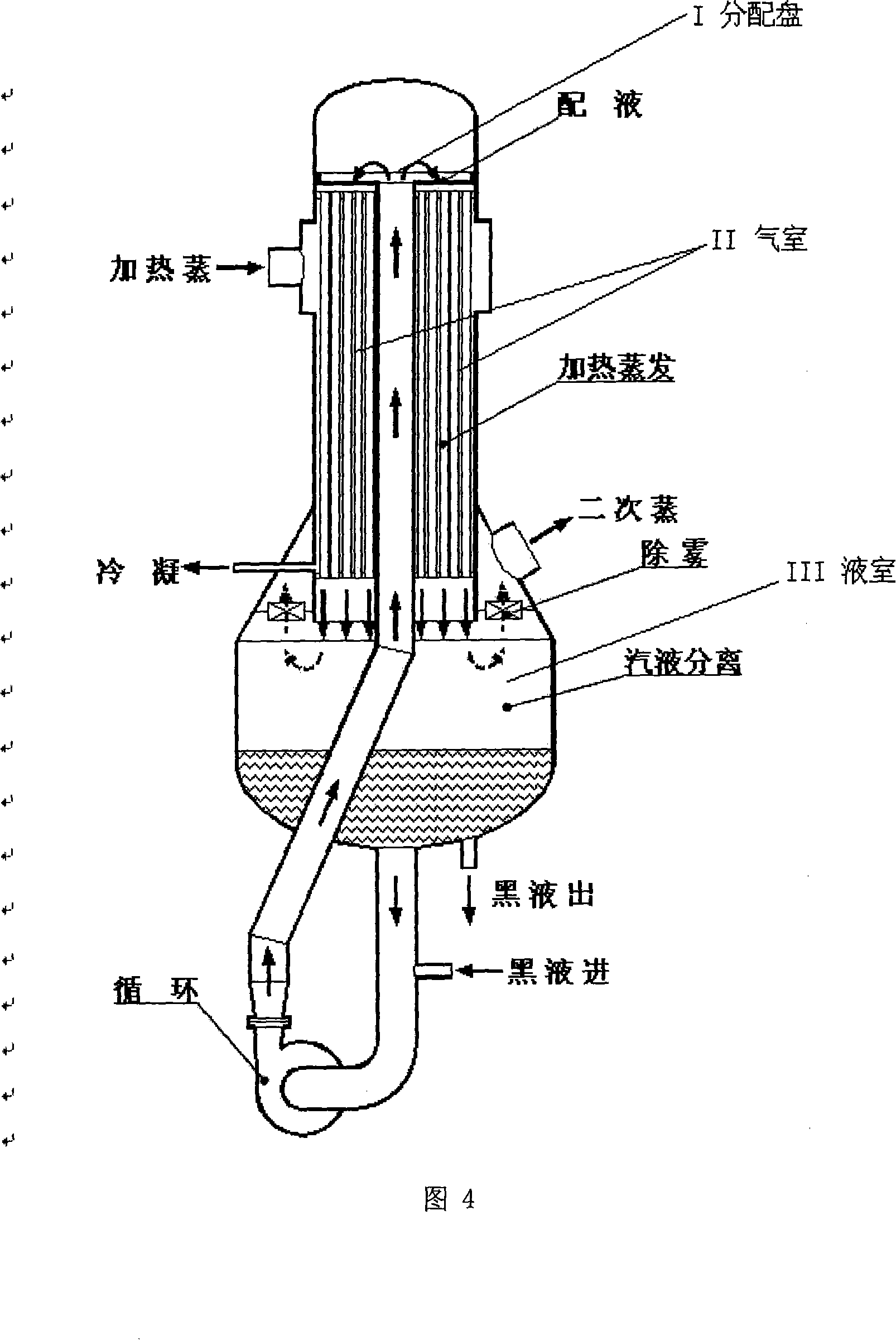

Method used

Image

Examples

Embodiment 1

[0090] (1) mixed

[0091] Mix the straw pulp black liquor of the ammonium method and the straw pulp black liquor of the alkaline method according to the volume ratio of 1:100 to obtain the mixed straw pulp black liquor; wherein the black liquor of the straw pulp of the imonium method has a Baume degree of 2 and a solid content of 4% , pH=7; described soda straw pulp black liquor, Baume degree 2, solid content=4%, pH=9; Alkali method and ammonium method mixed straw pulp black liquor after mixing, Baume degree 2, Solid content = 4%, pH = 8.7.

[0092] (2) Evaporation and concentration

[0093] The mixed straw pulp black liquor is directly evaporated and concentrated until the water weight percentage is less than or equal to 20%, so as to obtain a mixed dry product of the alkali method and the ammonium method grass pulp black liquor.

[0094] The alkali lignin content of the mixed dried straw pulp black liquor obtained by the alkali method and the imonium method is 90%, the amm...

Embodiment 2

[0096] (1) mixed

[0097] The ammonium method straw pulp black liquor and the alkali method straw pulp black liquor are mixed according to the volume ratio of 100:1 to obtain the mixed straw pulp black liquor; wherein the cellulose content of the ammonium method straw pulp black liquor is 200mg / L, Baume degree 9. Solid content = 15%, pH 10; the cellulose content of the alkaline straw pulp black liquor is 200 mg / L, Baume degree 9, solid content = 15%, pH = 13; the mixed alkaline method and immonium method Mixed grass pulp black liquor, Baume degree 9, solid content = 15%, pH = 9.3;

[0098] (2) Evaporation and concentration

[0099] The mixed straw pulp black liquor is directly evaporated and concentrated until the water weight percentage is less than or equal to 20%, so as to obtain a mixed dry product of the alkali method and the ammonium method grass pulp black liquor.

[0100] The content of alkali lignin, 60% of ammonium ligninsulfonate, 35% of fulvic acid and 3% of mois...

Embodiment 3

[0102] (1) mixed

[0103] The ammonium method straw pulp black liquor and the alkali method straw pulp black liquor are mixed according to the volume ratio of 70:30 to obtain the mixed straw pulp black liquor; wherein the cellulose content of the ammonium method straw pulp black liquor is 100 mg / L, Baume degree 7. Solid content = 10%, pH8; the cellulose content of the alkaline straw pulp black liquor is 100 mg / L, Baume degree 7, solid content = 10%, pH = 10; the mixed alkaline method and immonium method Mixed grass pulp black liquor, Baume degree 7, solid content = 10%, pH = 9.1;

[0104] (2) Evaporation and concentration

[0105] The mixed straw pulp black liquor is directly evaporated and concentrated until the water weight percentage is less than or equal to 20%, so as to obtain a mixed dry product of the alkali method and the ammonium method grass pulp black liquor.

[0106] The content of alkali lignin, 48.7% of ammonium lignin sulfonate, 18.4% of fulvic acid and 20% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com