Patents

Literature

178 results about "Chemical recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for economically viable and environmentally friendly central processing of home laundry

InactiveUS20060123563A1Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesEnvironmental effectWash water

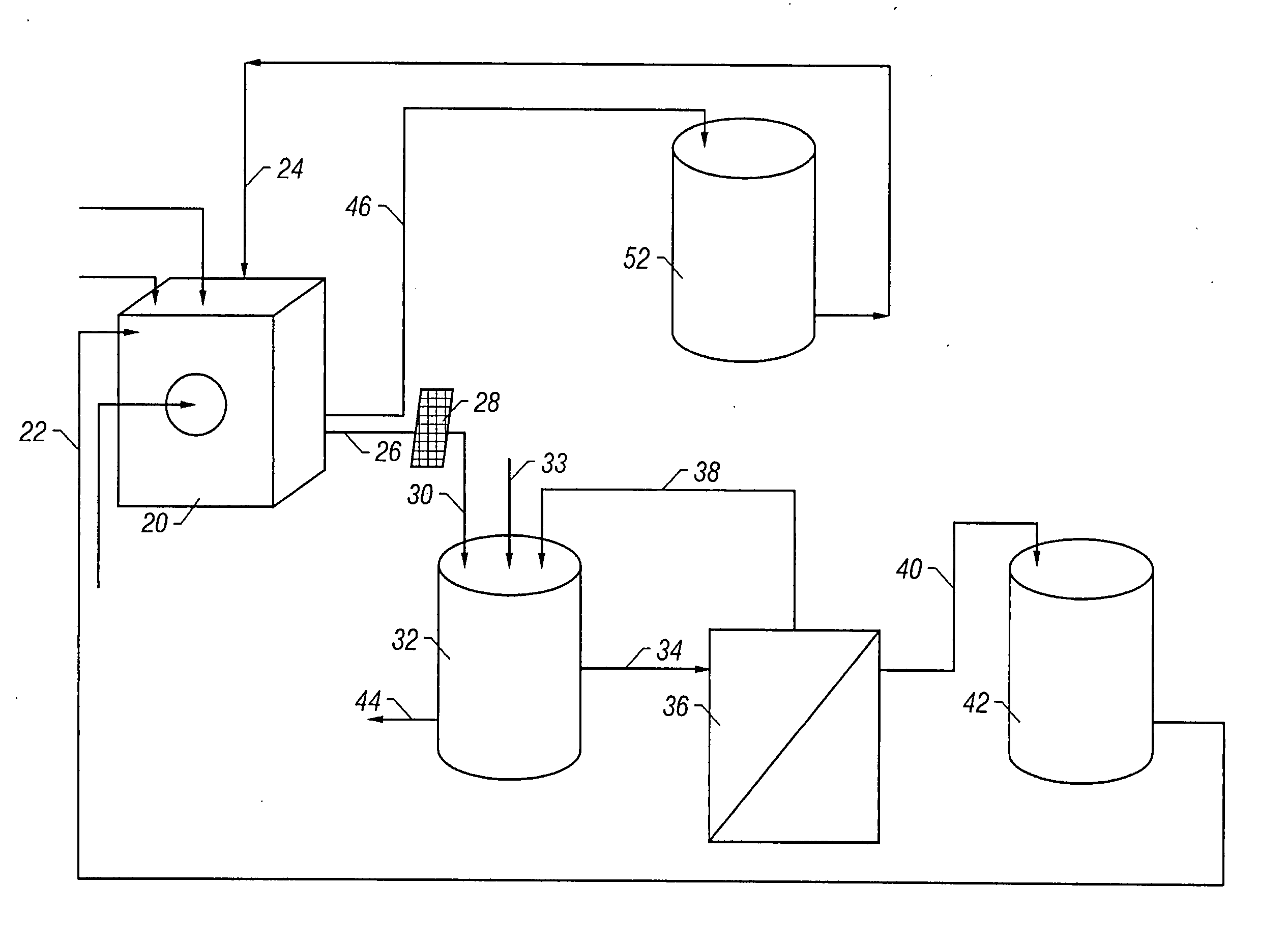

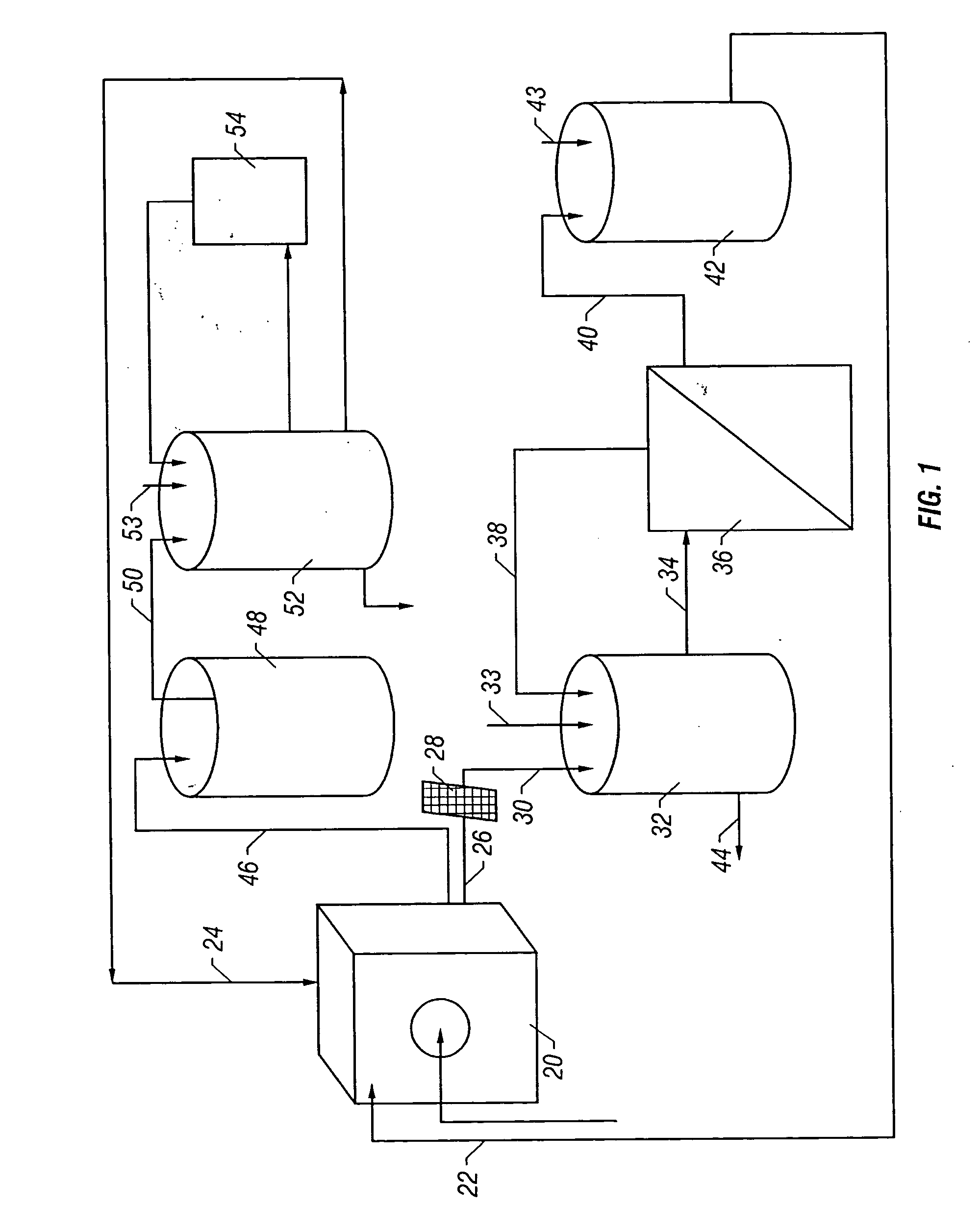

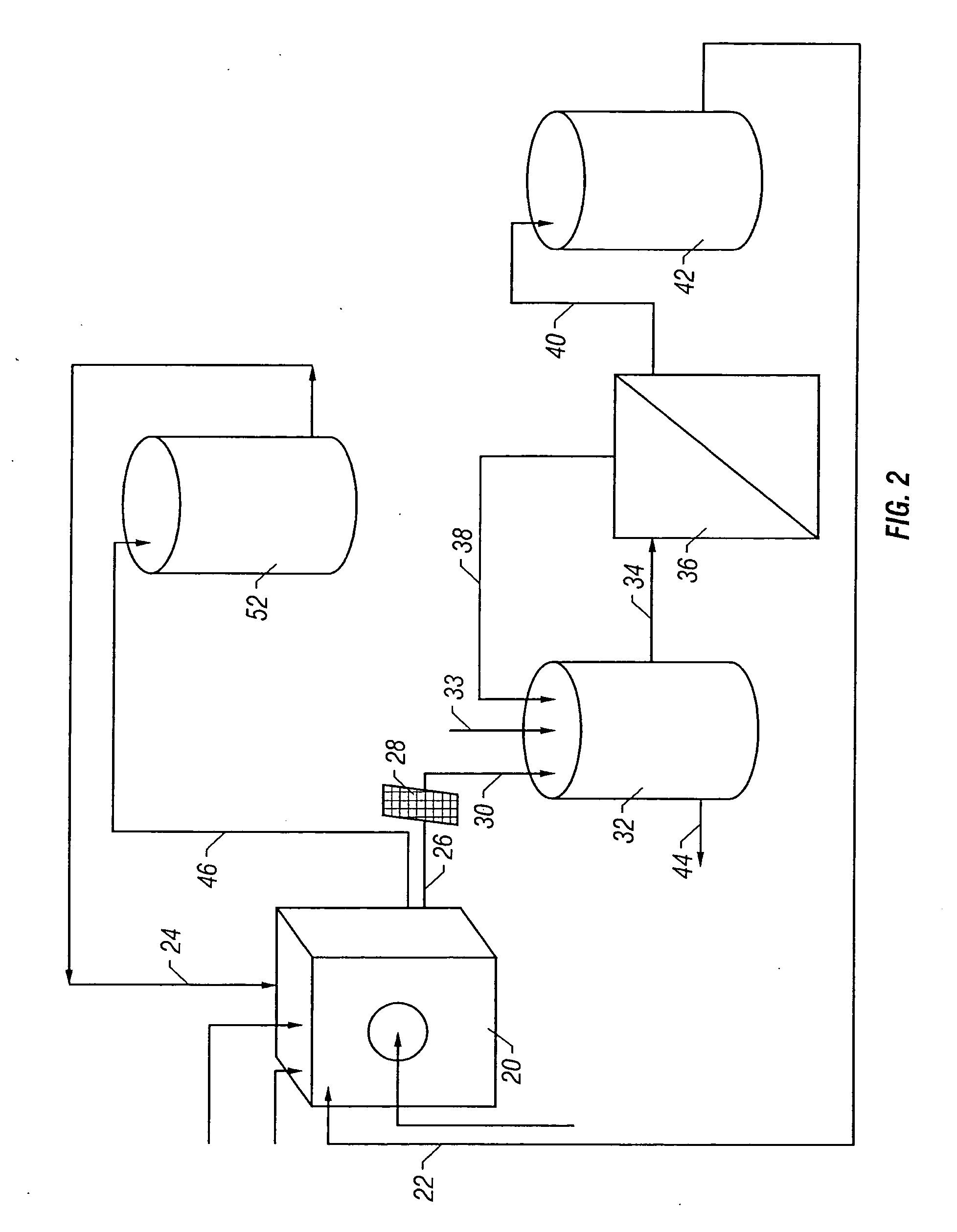

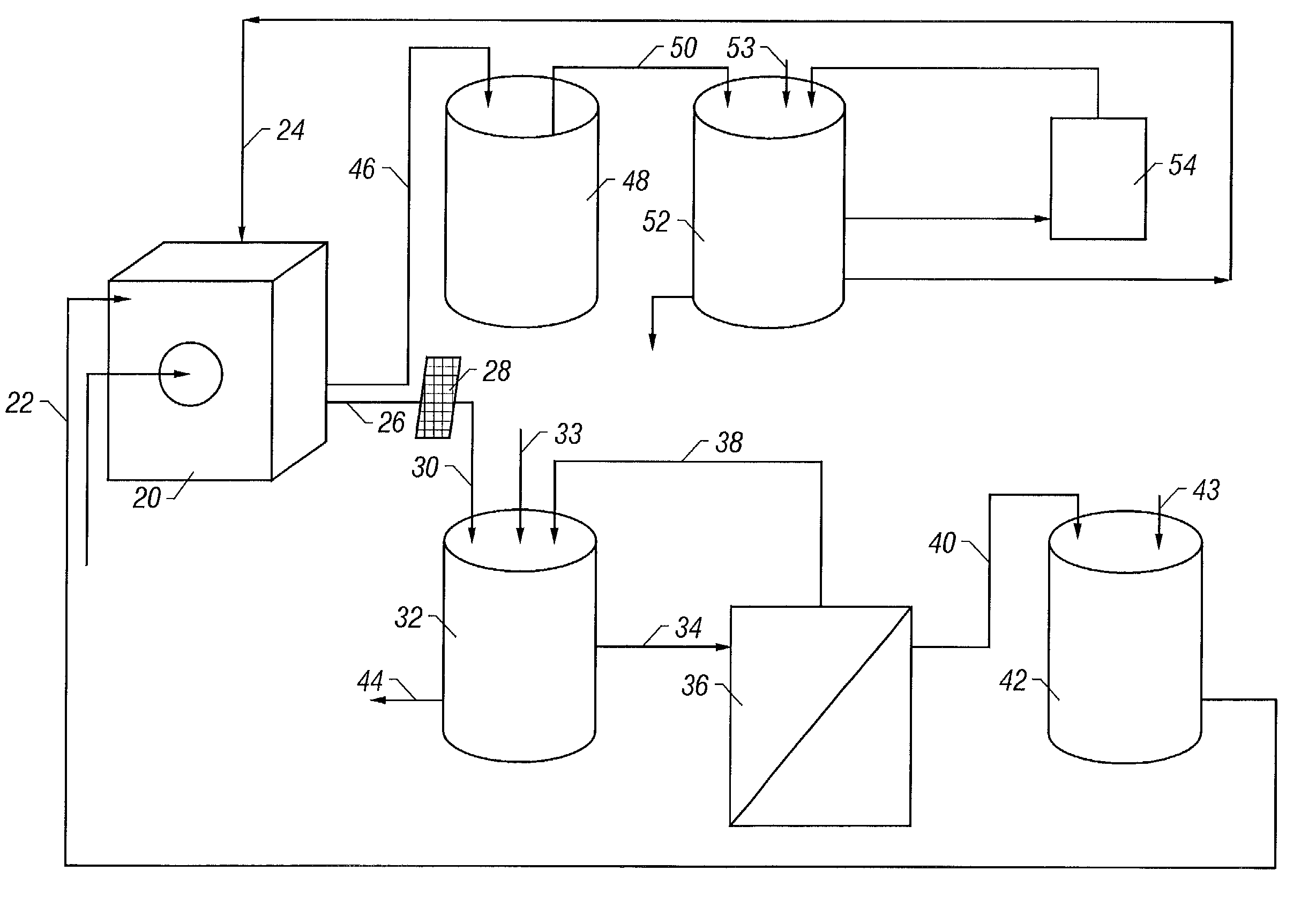

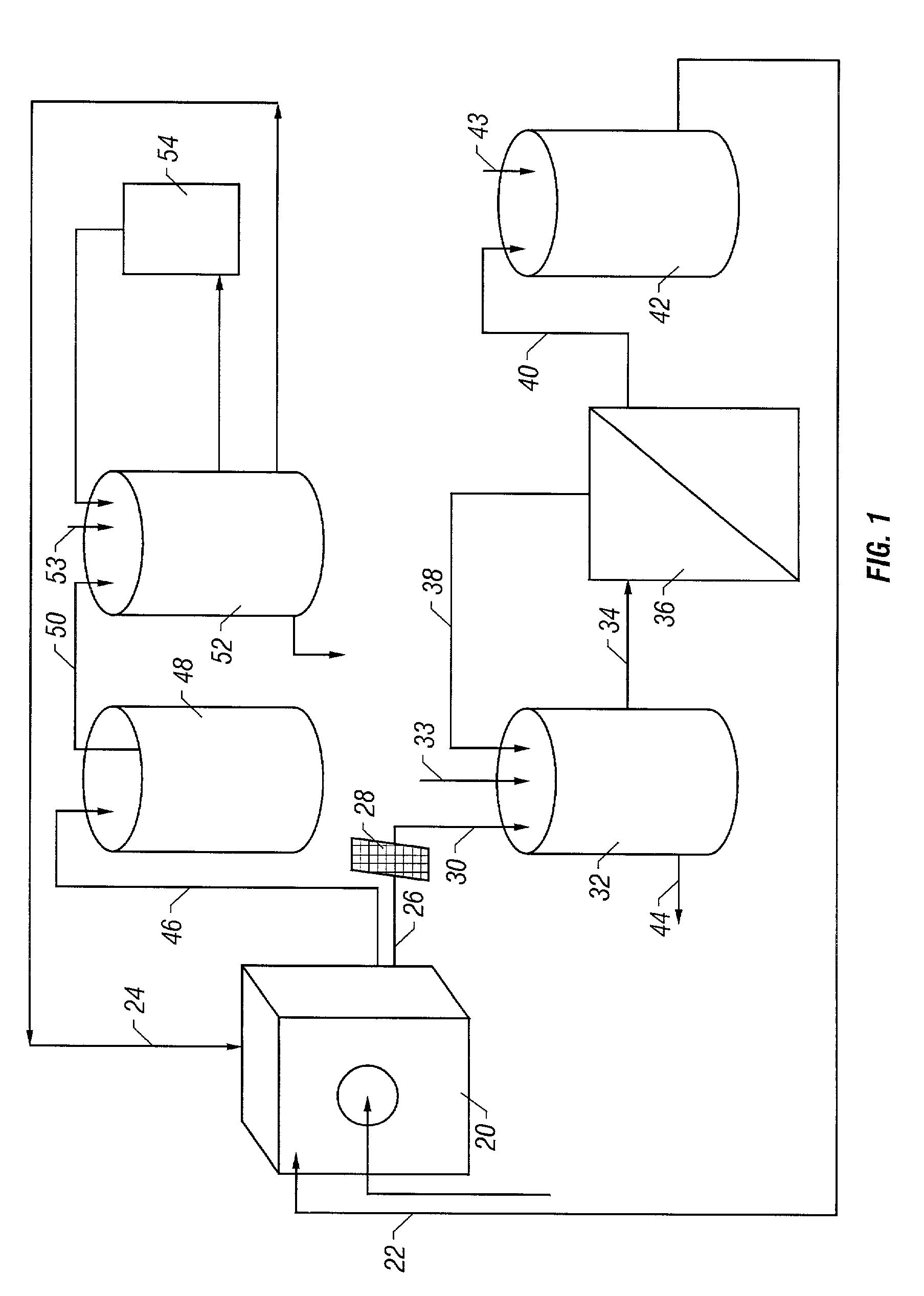

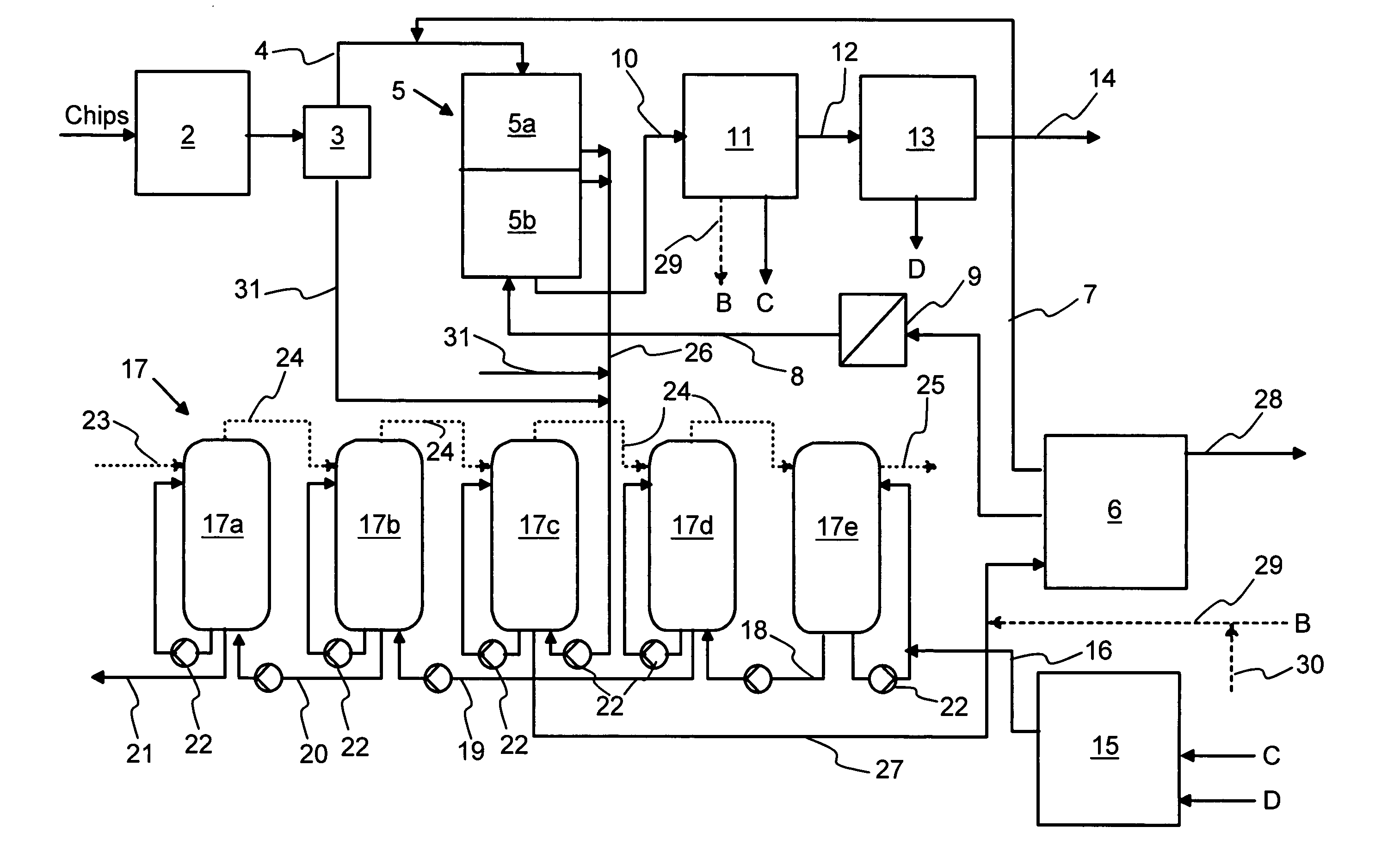

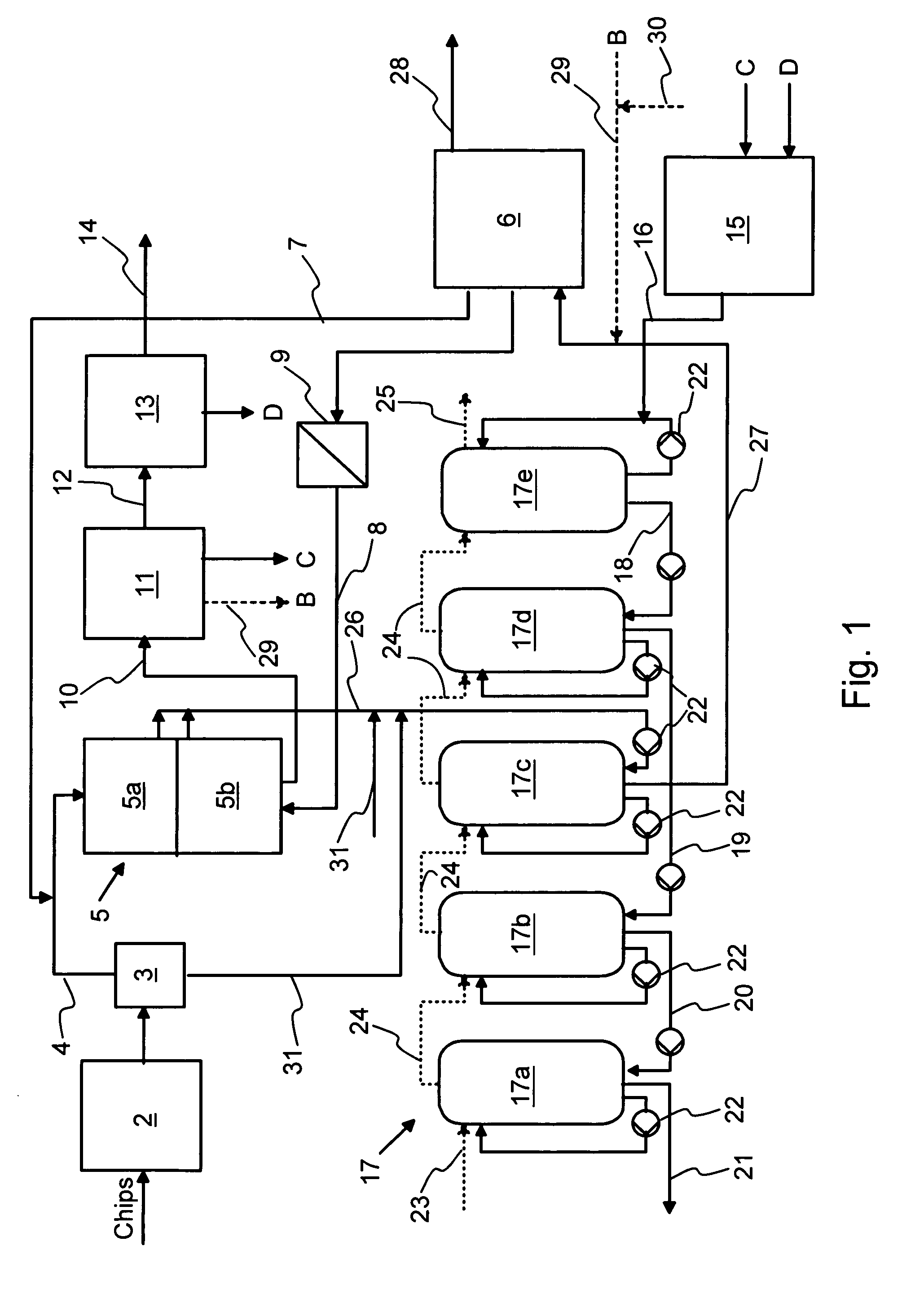

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:RANEY KIRK HERBERT +5

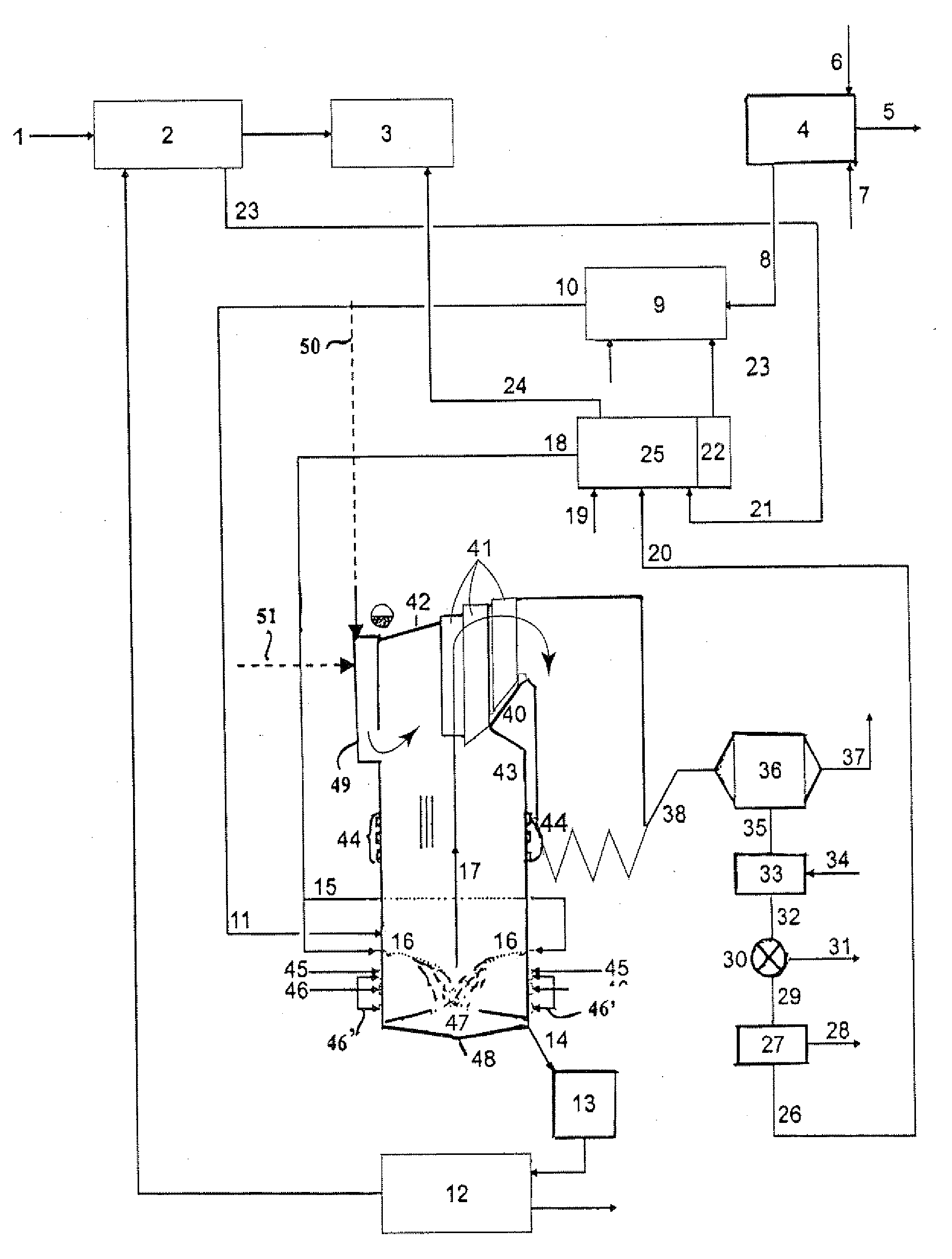

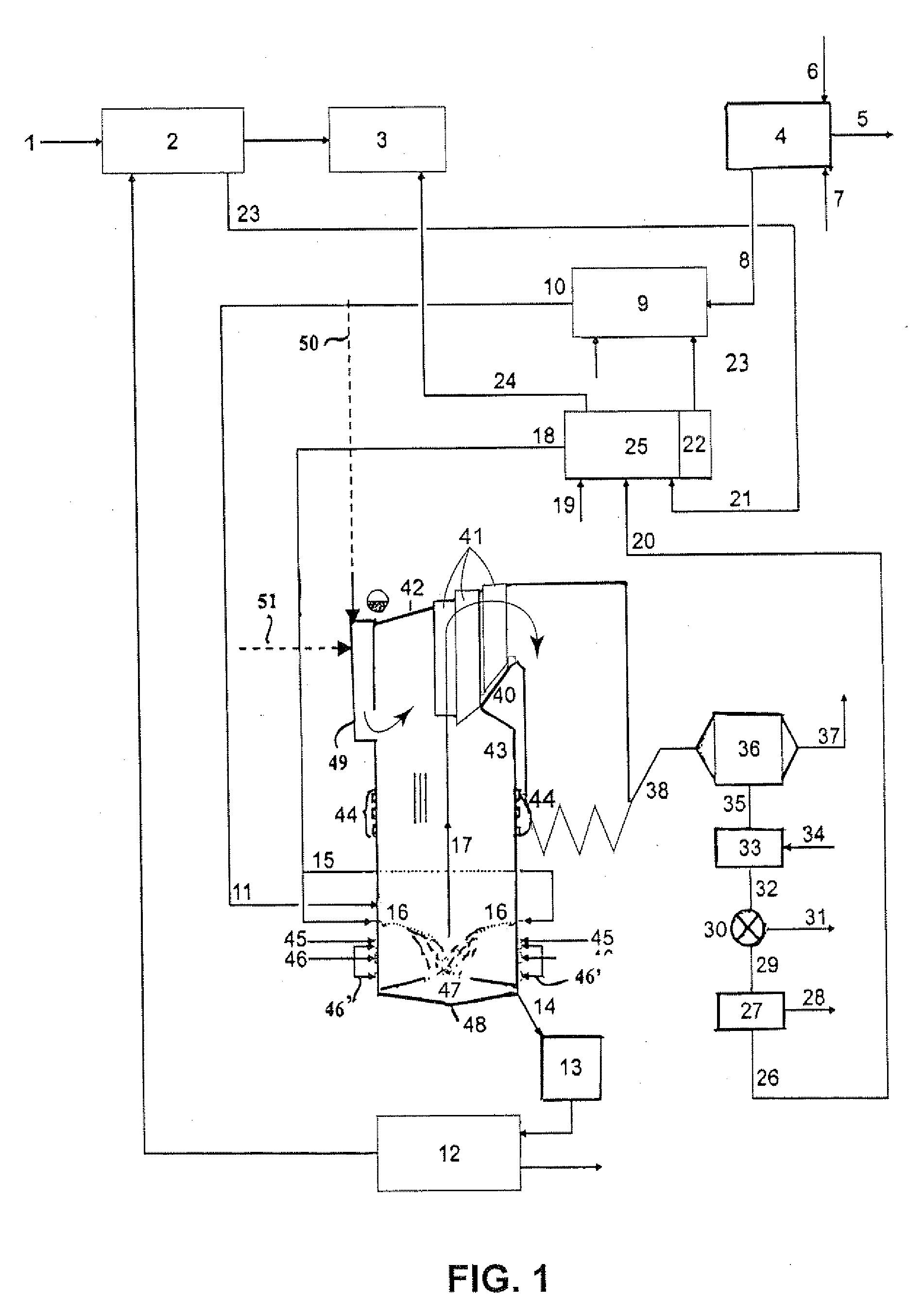

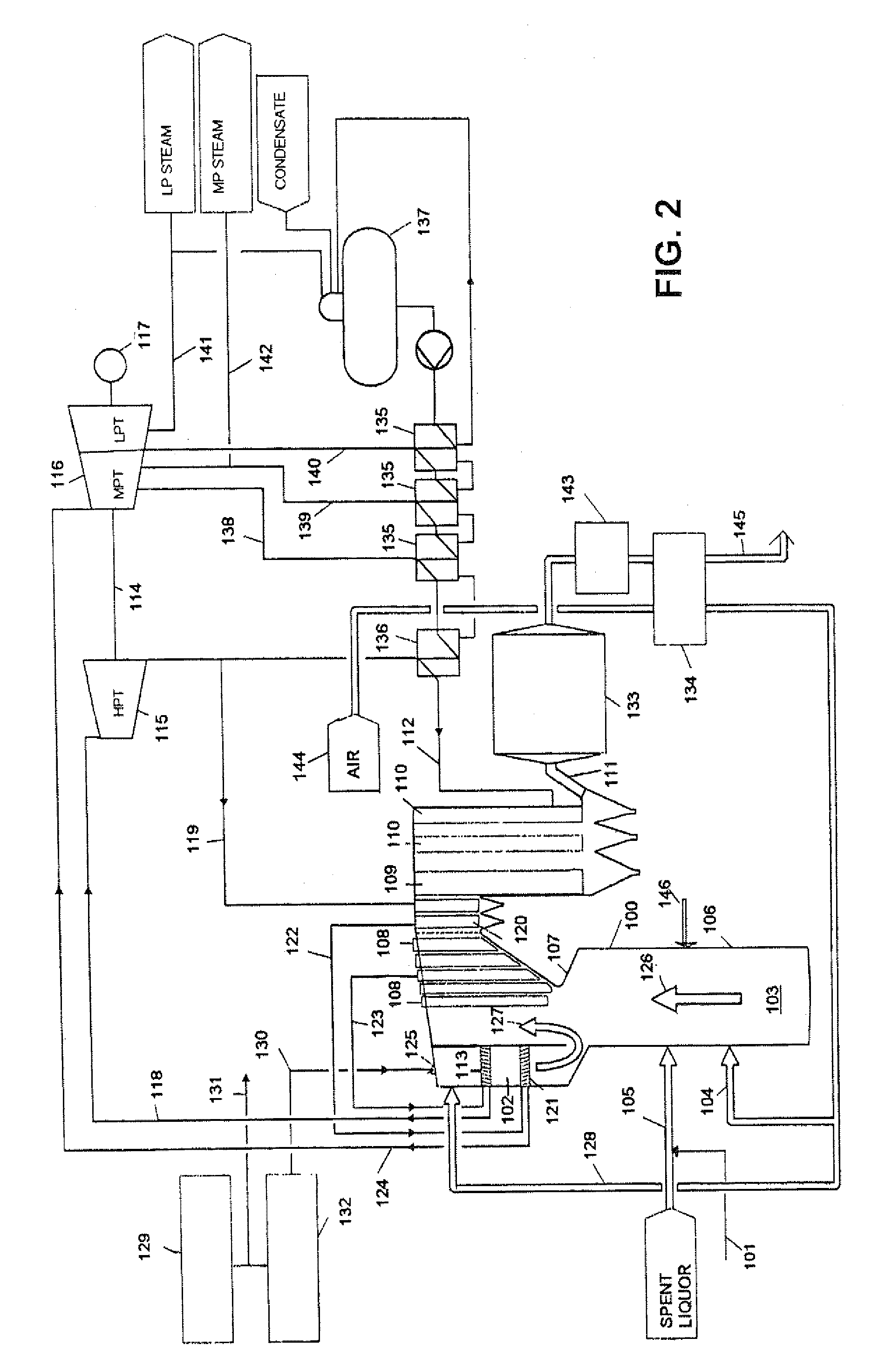

Method and apparatus for optimizing the combustion air system in a recovery boiler

InactiveUS6279495B1Improve boiler efficiencyAvoid costly modificationPulp liquors combustionSolid fuel combustionParticulatesChemical recovery

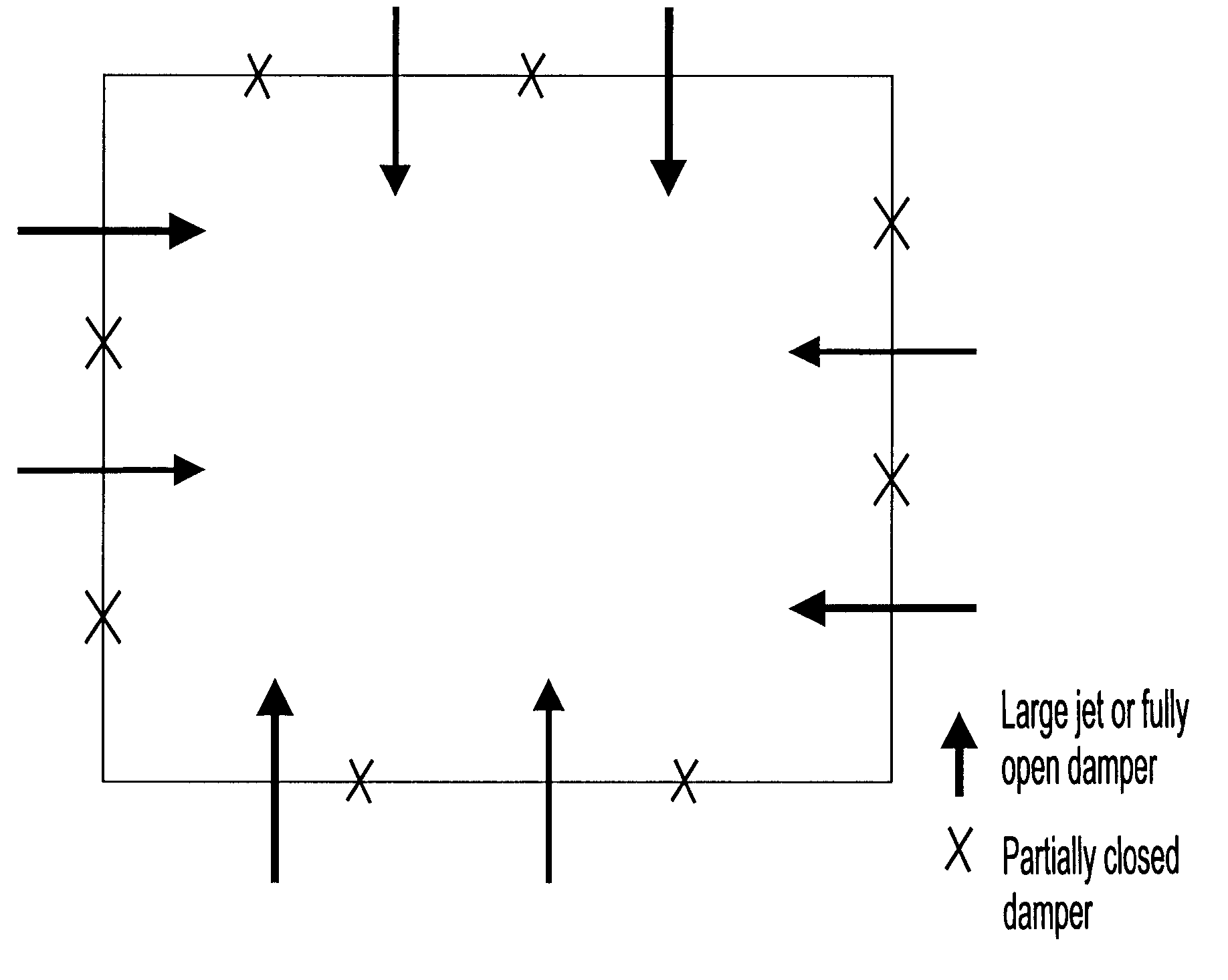

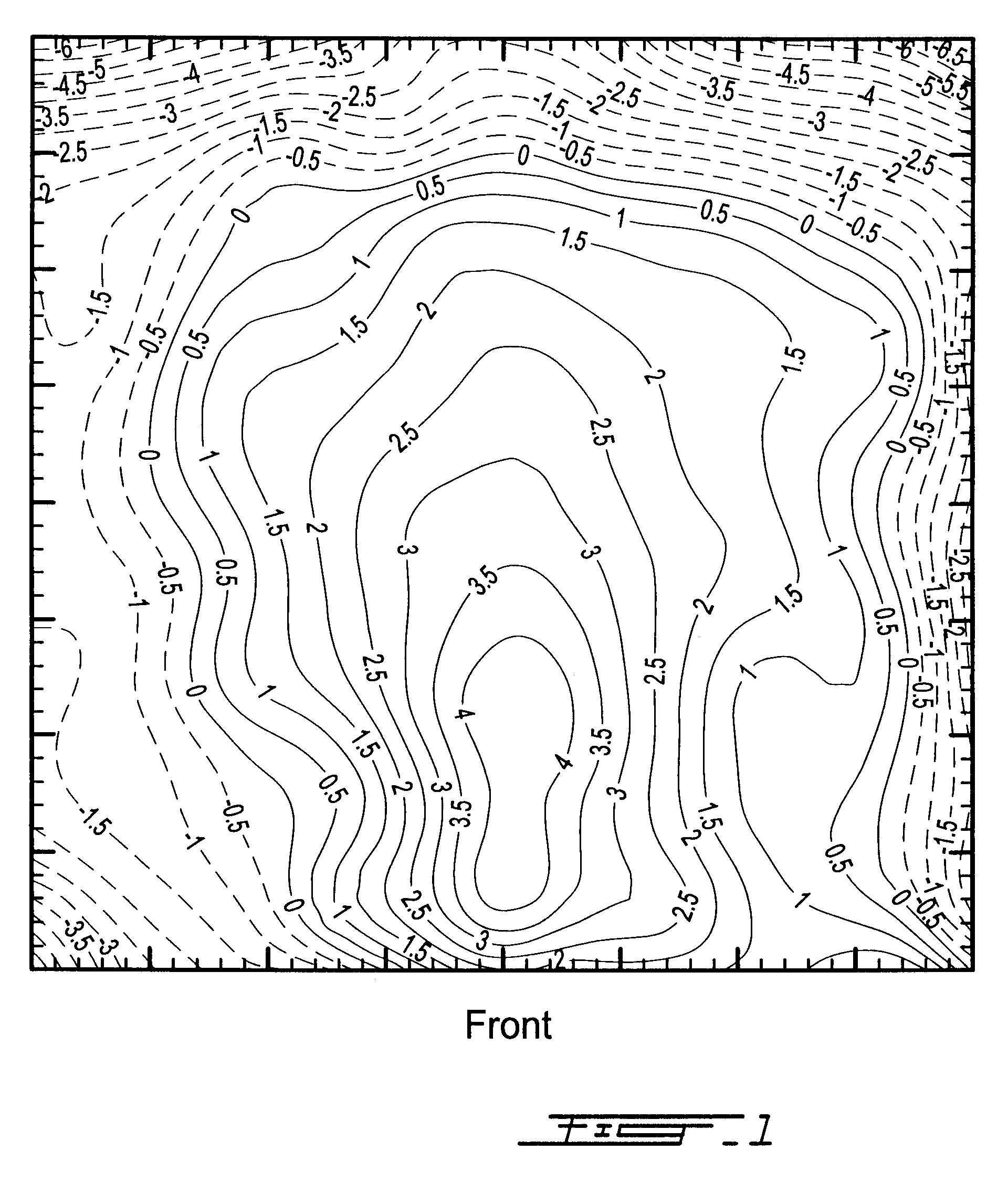

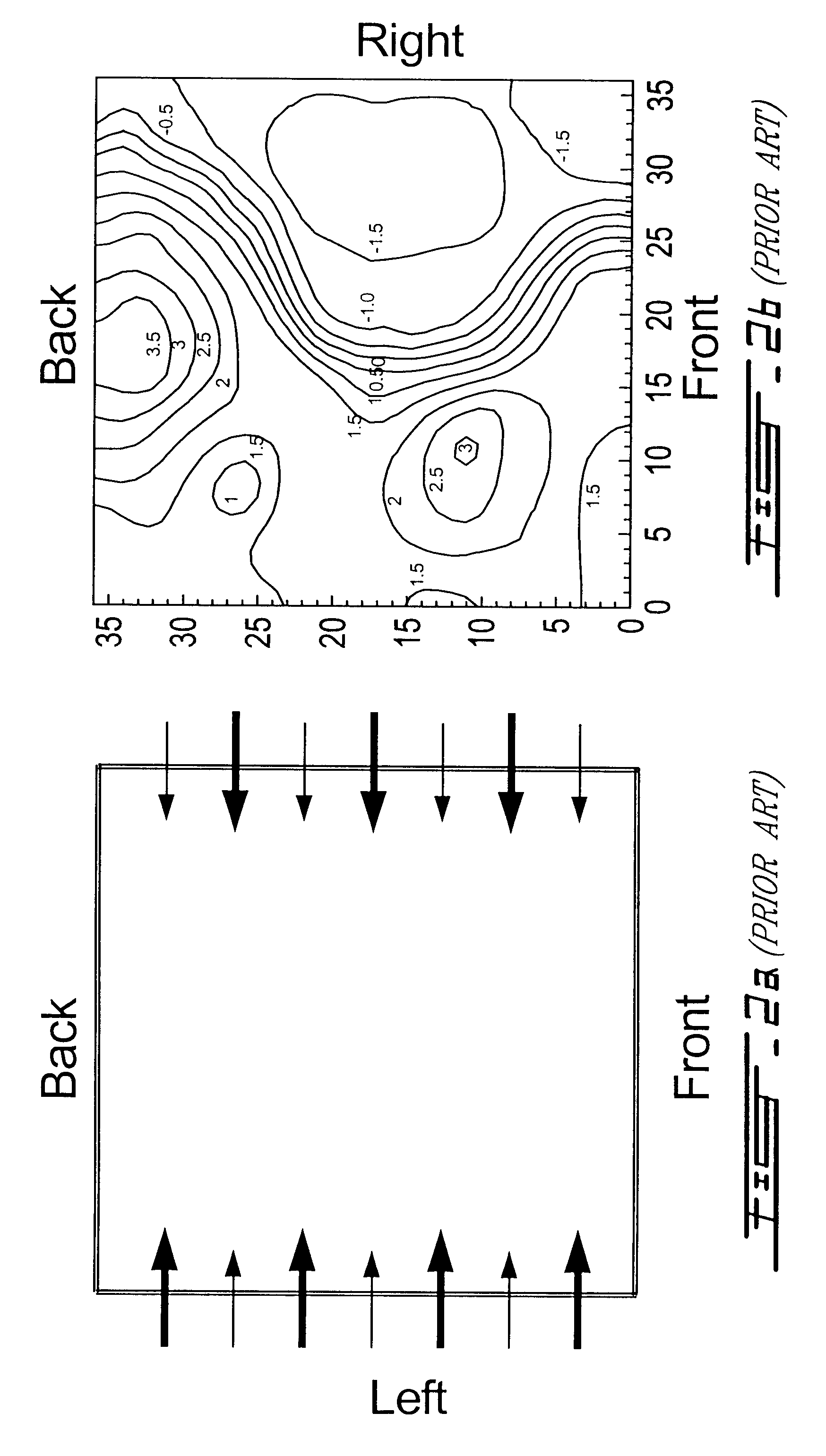

A method and an apparatus for optimizing the combustion air system in a power boiler or chemical recovery boiler by improving fluid flow and gas mixing are disclosed, whereby one can increase boiler capacity and combustion uniformity and reduce particulate and gaseous emissions. The method involves interlacing of the secondary and, where applicable, the tertiary air supply through opposing air ports on all four walls of the boiler, and is implemented by alternately opening wide or partially closing a port damper on one side, while partially closing or opening wide a port damper on the opposite side, such that a 70-100% open damper on one side opposes a partially closed (10-40% open) damper on the other and vice versa in an alternating fashion, along opposing walls. In a preferred embodiment, the optimization is further enhanced by balancing primary air flow, achieved by adjusting port dampers and windbox pressures so that the primary air flow is evenly distributed between opposite walls, between all four walls of the boiler and between individual airports on each wall. Windbox pressure and other key measurements of boiler operation ensure proper balancing and an adequate interlacing of air flows at the primary, secondary and tertiary elevations, respectively.

Owner:FPINNOVATIONS INC

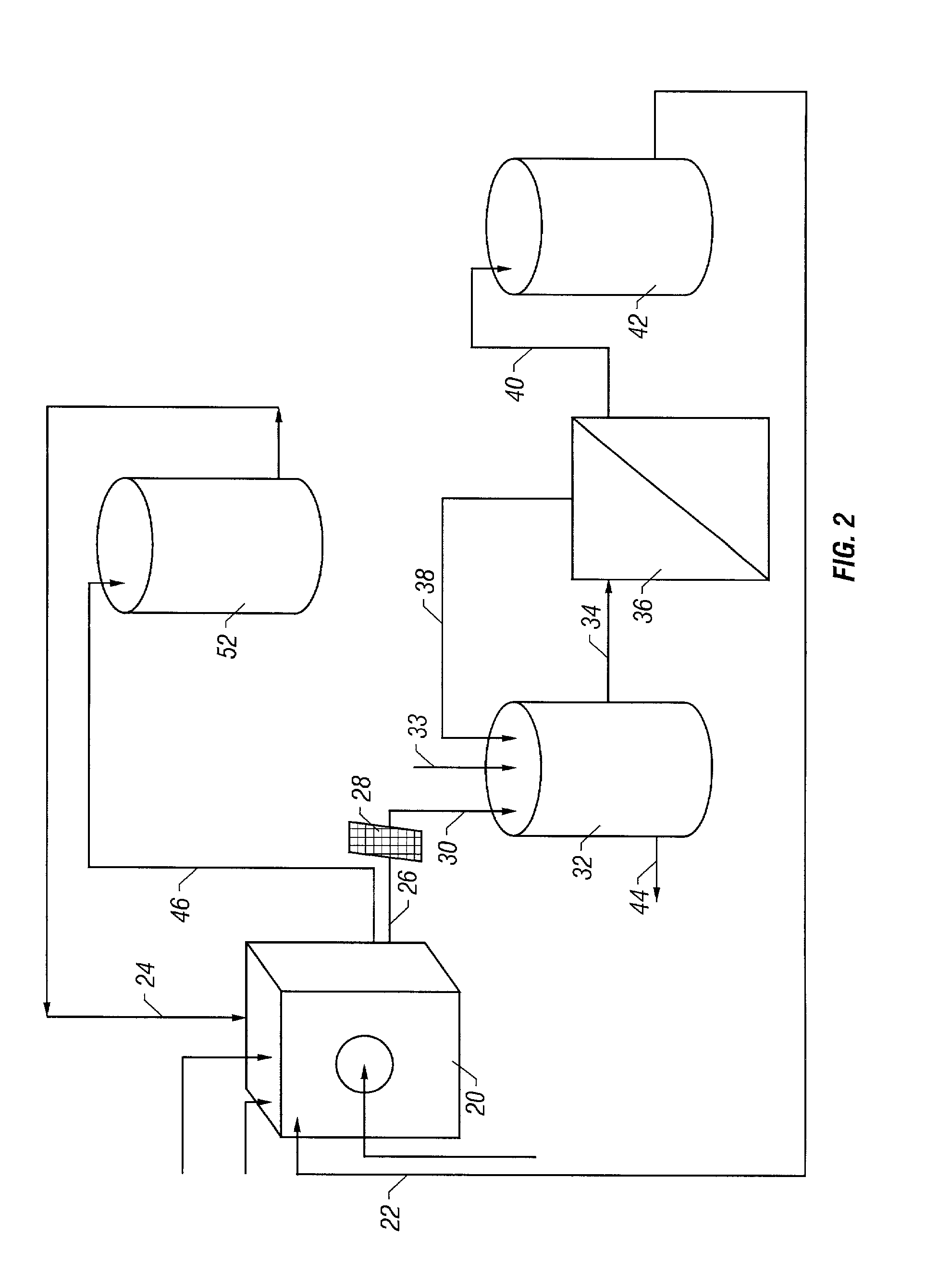

System and method for economically viable and environmentally friendly central processing of home laundry

InactiveUS7000437B2Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesWash waterChemical recovery

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:SHELL OIL CO

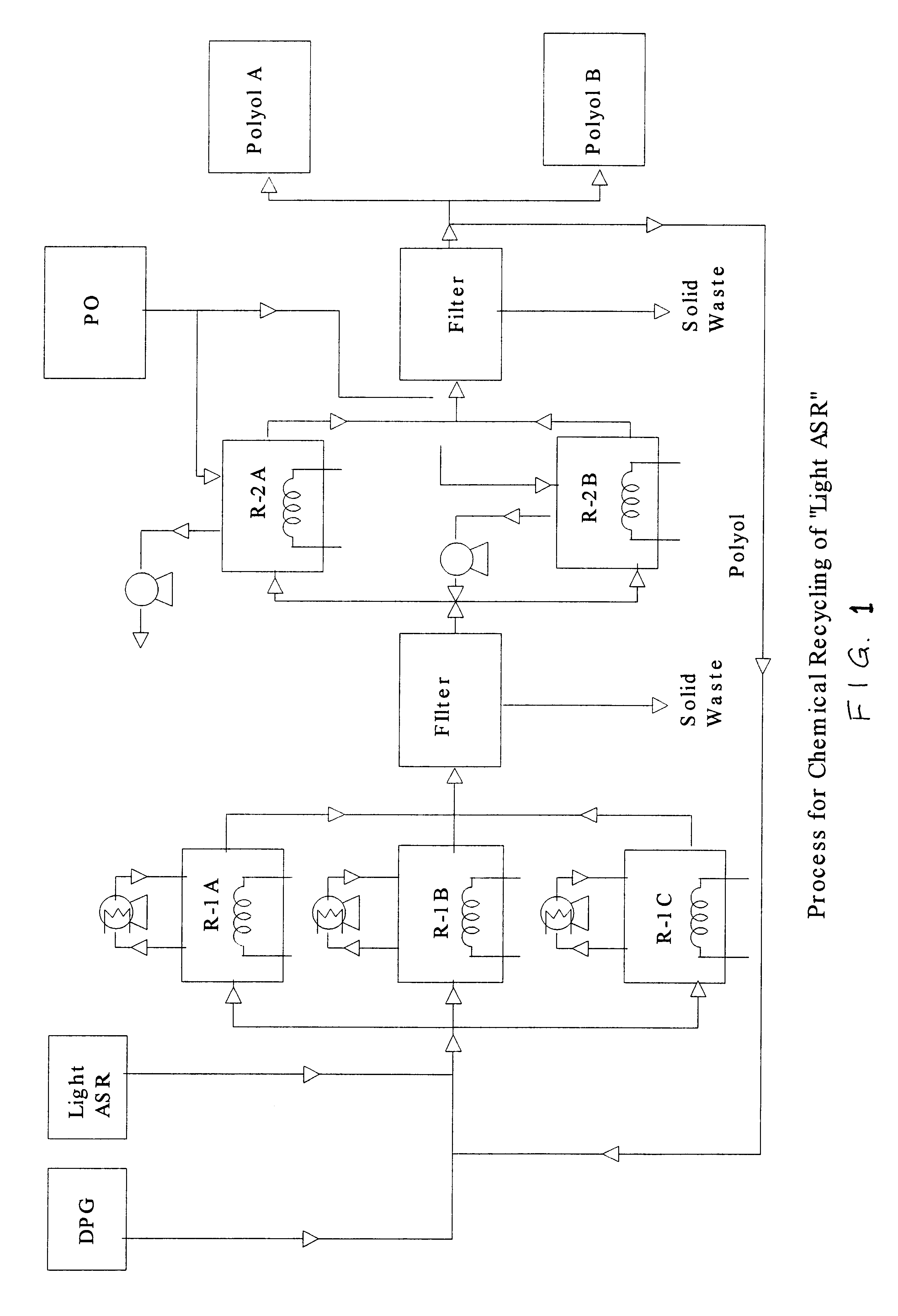

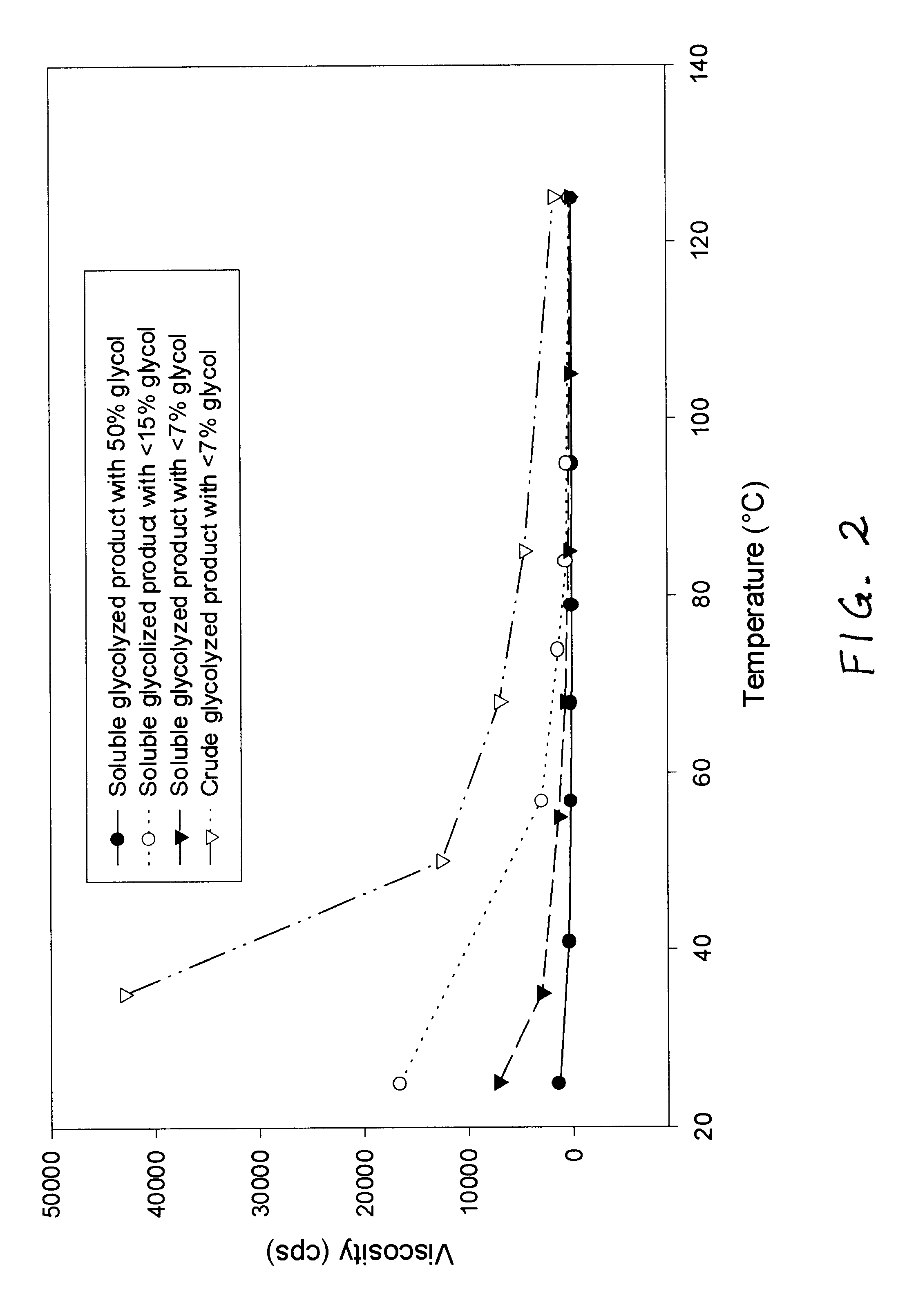

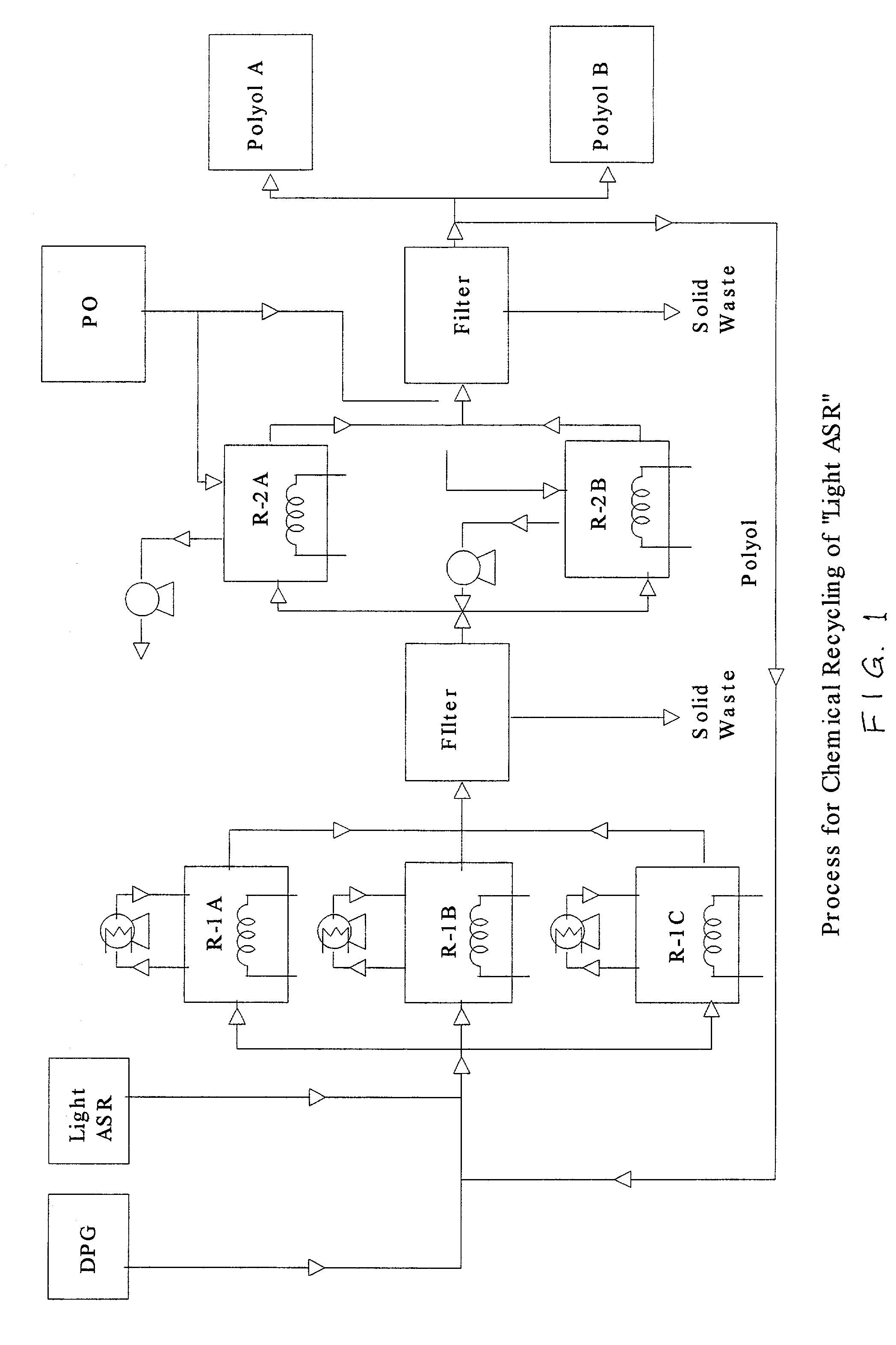

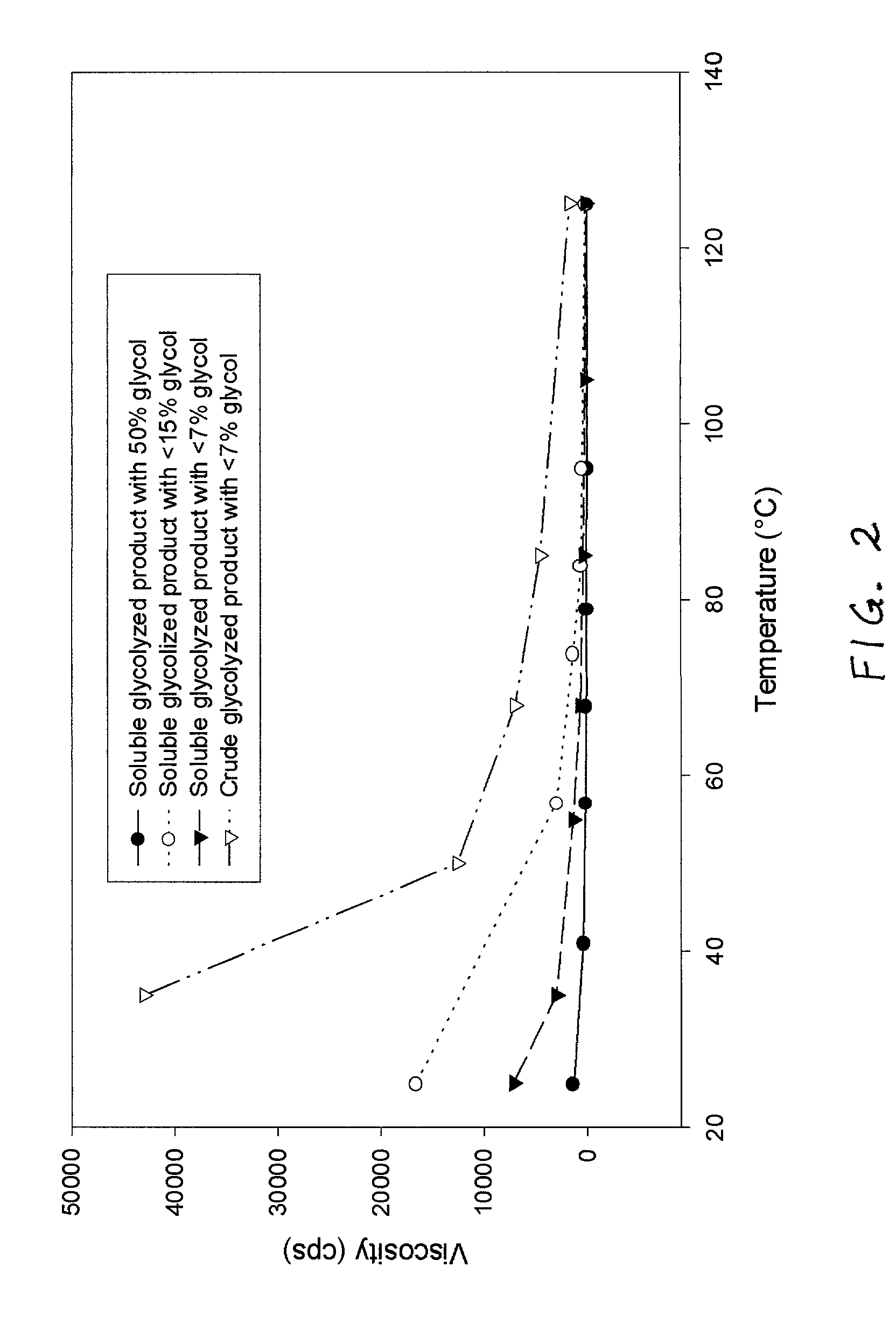

Process for chemical recycling of polyurethane-containing scrap

A process of chemically recycling polyurethane-containing scrap. Polyurethane-containing scrap is subjected to a chemolysis reaction to produce chemolysis polyol products. The chemolysis polyol products are used as initiators in a reaction with alkylene oxide to produce oxyalkylated polyols for preparing polyurethanes.

Owner:TROY POLYMERS

Chemical Process For Recycling Polyethylene Terephtalate (Pet) Waste

InactiveUS20070219339A1Improve efficiencyPreparation from carboxylic acid saltsPlastic recyclingPolyethylene terephtalateCompanion animal

The present invention relates to a process for chemical recycling of PET waste that comprises, among other stages, a saponification reaction stage, wherein PET waste particles are reacted with stoichiometric or excessive amounts of a strong base metal in an alcoholic reaction media, the reaction being brought to the boiling temperature of the alcoholic reaction media, preferably at atmospheric pressure, thereby obtaining as reaction products a salt of terephthalic acid with the base metal and ethylene glycol, the latter being incorporated to the alcoholic reaction media. From this reaction it is possible to afford ethylene glycol, terephthalic acid and salts thereof, which are products with a high commercial value.

Owner:UNIV IBEROAMERICANA A C

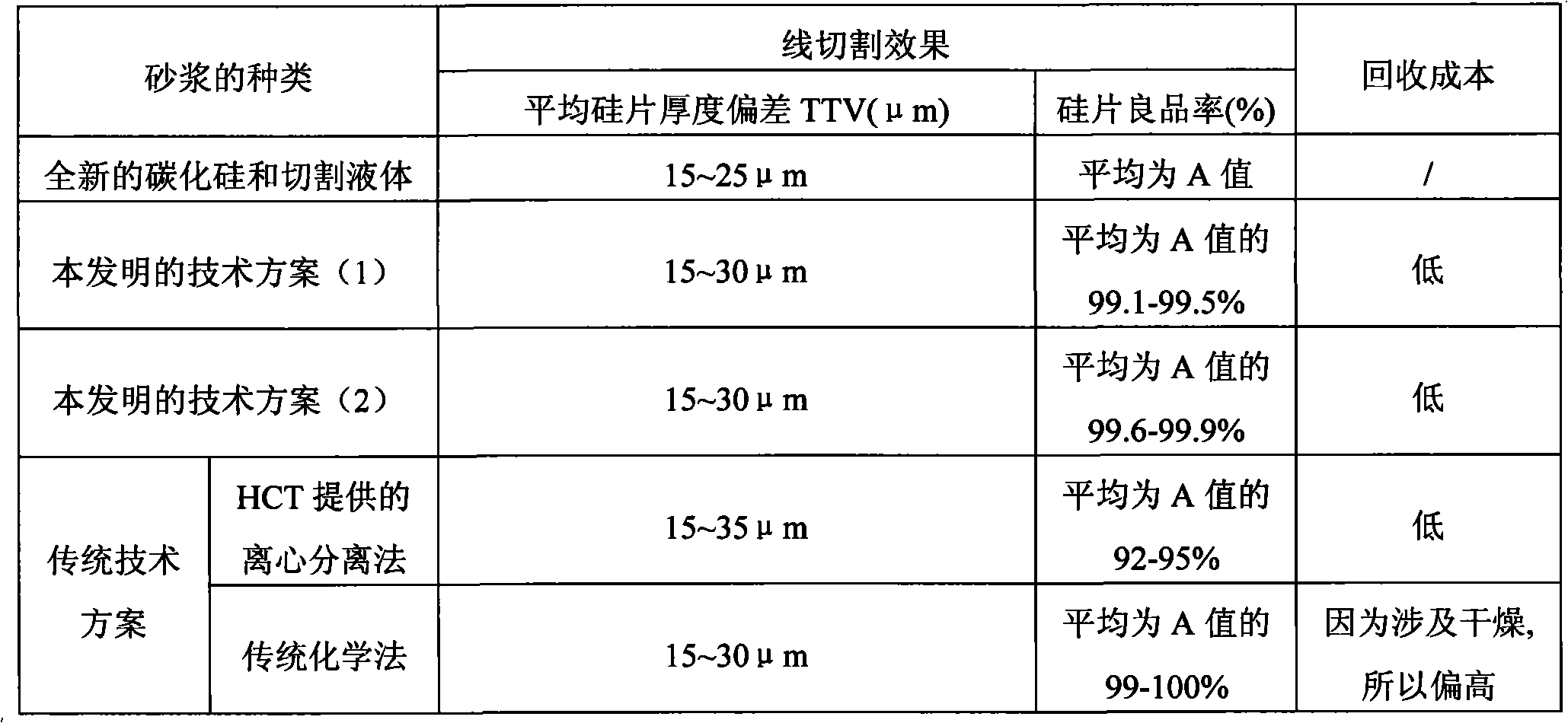

Chemical recovery method for mortar in wire cutting technology

InactiveCN101623898ASave energyAvoid Slight DowntrendsWorking accessoriesFine working devicesChemical treatmentRecovery method

The invention relates to a recovery method for mortar in a wire cutting technology, in particular to a chemical recovery method for the mortar in the wire cutting technology. The chemical recovery method comprises the following operation steps: firstly, solid-liquid separation is carried out on the mixed mortar containing cutting liquid A, silicon powders, metal filings and silicon carbide abrasives after wire cutting to obtain a liquid part B and a solid part C; secondly, the silicon powders and the metal filings in the solid part C are removed by adopting a chemical treatment method to obtain a solid part D which is rich in the silicon carbide abrasives; and thirdly, the solid part D which is rich in the silicon carbide abrasives is directly and uniformly stirred with cutting liquid E to obtain mixed materials G, and the mixed materials G are used for wire cutting again. The invention removes metal impurities and the silicon powders, can be used for secondary cutting without drying the silicon carbide abrasives, and enables the silicon carbide abrasives and water soluble cutting liquid to be repeatedly and reasonably utilized. The use effect of recovered mortar is nearly same with the use effect of new mortar, therefore, the cost of chemical recovery of the mortar is greatly lowered.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

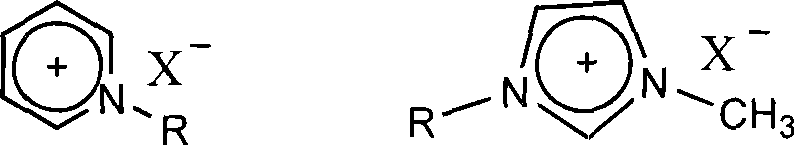

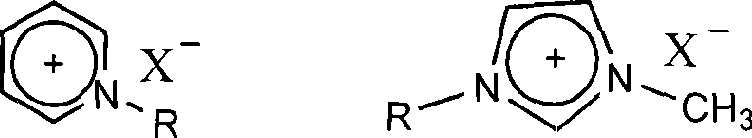

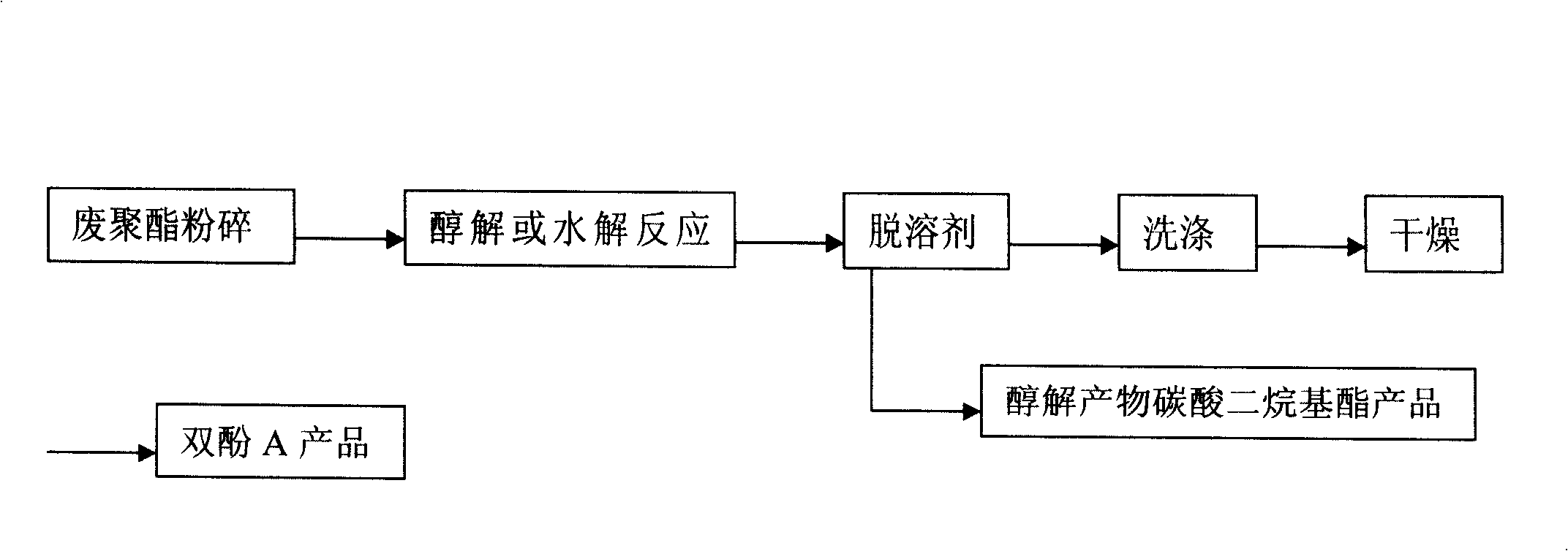

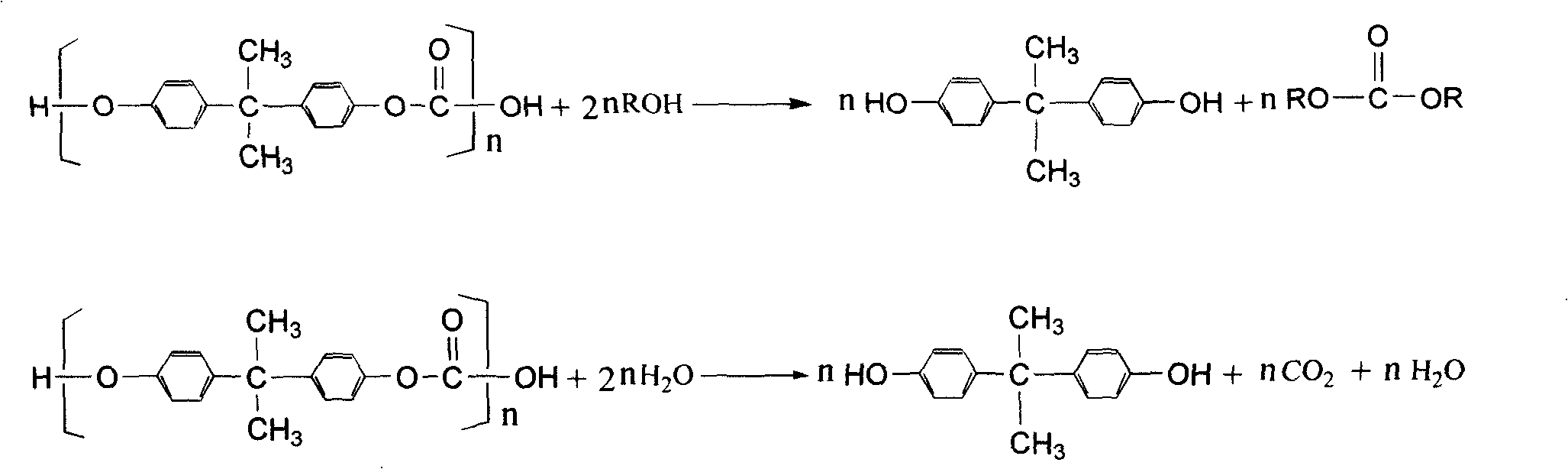

Chemical recovery method for waste polycarbonate material in ionic liquid surrounding

InactiveCN101429100ARelaxed reaction conditionsReduce the discharge of three wastesOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityHigh concentration

The invention relates to a novel method for generating bisphenol A and dialkyl carbonate by chemical degradation of waste polycarbonate (PC) to realize chemical recycling of the bisphenol A and the dialkyl carbonate. The method is characterized in that reusable ionic liquid such as chloridized 1-allyl-3-methylimidazole and bromized 1-butyl-3-methylimidazole is taken as a reaction medium and catalyst, and subjected to hydrolysis reaction or alcoholysis reaction at a temperature of between 60 and 170 DEG C; after reaction is over, bisphenol A products are obtained after extraction, distillation and other operations (as for alcoholysis reaction, the dialkyl carbonate is obtained simultaneously); reclaimed ionic liquid is directly reused without any treatment; and the yield of the bisphenol A is more than 93 percent. Compared with the prior art, the method has the characteristics that: firstly, the method overcomes the defects in the prior art that high-concentration inorganic strong acid / strong alkali is applied and can not be recycled; and secondly, due to adoption of the ionic liquid which has certain solubility on the PC as the reaction medium and the catalyst, the method relieves the reaction conditions on one hand and can realize reutilization of the ionic liquid on the other hand, and obviously solves the problems of equipment corrosion and environmental pollution.

Owner:QINGDAO UNIV OF SCI & TECH

Shaped cellulose manufacturing process combined with a pulp mill recovery system

ActiveUS20120000621A1Low capital intensityImprove the environmentNon-fibrous pulp additionPulp liquors combustionFiberUnit operation

Provided is a process for manufacturing shaped cellulose materials from lignocellulose where a dissolving grade pulp is manufactured and dissolved in an aqueous alkaline or acidic solvent system forming a solution suitable for shaping new cellulose structures including fibers, films and cellulose derivatives. At least a part of the spent cellulose dissolving or cellulose shaping chemicals are recovered in one or more unit operations in a pulp mill chemical recovery cycle.

Owner:TREETOTEXTILE AB

Chemical recycling of pla by alcoholysis

ActiveUS20120029228A1Simple processImprove impactPreparation from carboxylic acid halideOrganic compound preparationSolventPolymer

Owner:FUTERRO SA

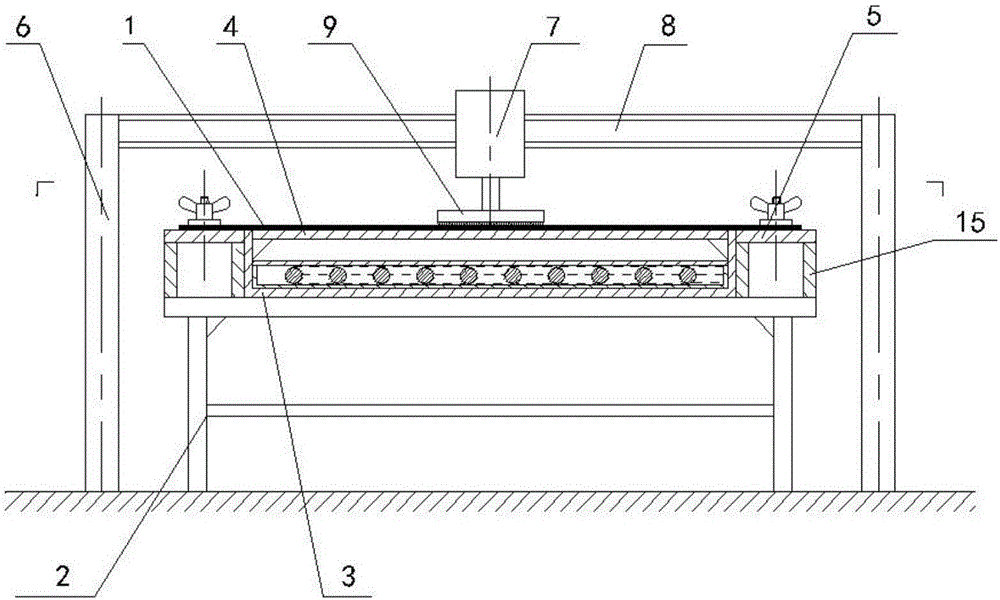

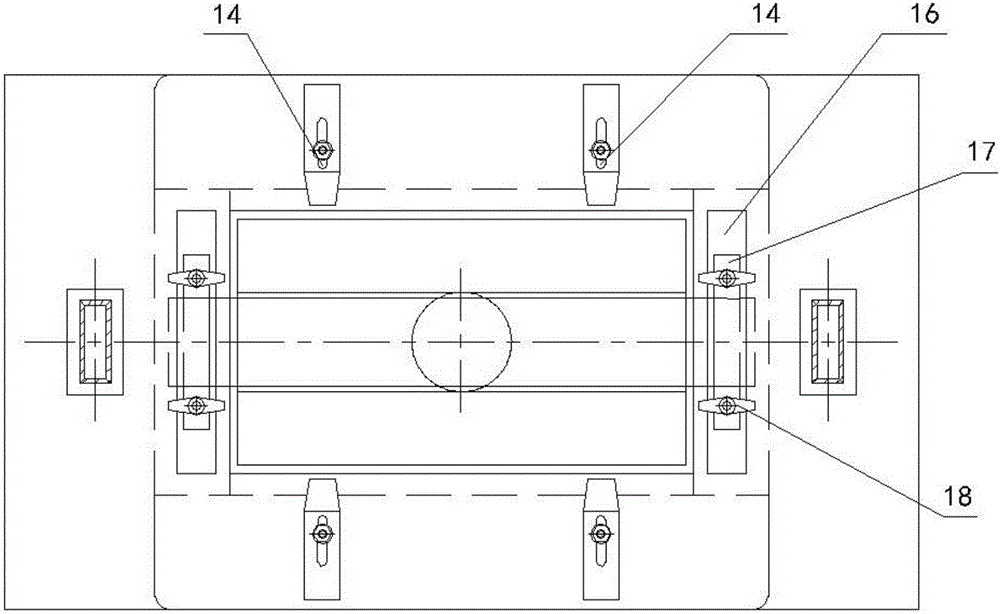

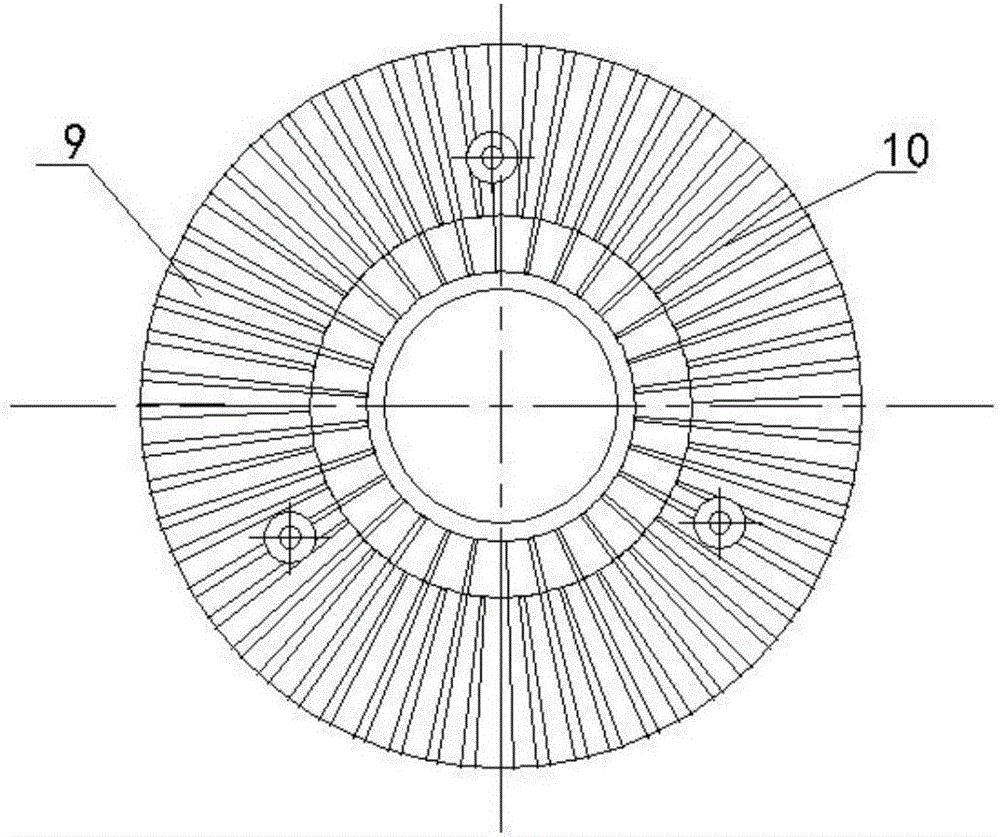

Recovery technology and separation device of waste lithium iron phosphate battery anode cathode material

ActiveCN106450560ARealize repair and reuseEffectively achieve complete separationWaste accumulators reclaimingBattery recyclingRecovery methodLithium iron phosphate

The invention discloses a recovery technology and a separation device of a waste lithium iron phosphate battery cathode material. The recovery technology is characterized by firstly separating a lithium iron phosphate material from an aluminum foil by adopting a physical method of heating treatment and mechanical force separation, and then obtaining a novel lithium iron phosphate material by adopting the technologies of fine smashing, dissolving and impurity removing, and roasting, repairing and lithium supplementing; separating and obtaining a lithium iron phosphate recovery material by the separation device through a grinding mode of a millstone. The safe and industrial recovery method and the separation device are provided for recycling of the waste lithium iron phosphate battery cathode material, the material recovery rate can be increased, the cost is reduced, a chemical recovery technology is simplified, the resources are saved, and environment pollution is reduced.

Owner:HEFEI UNIV OF TECH

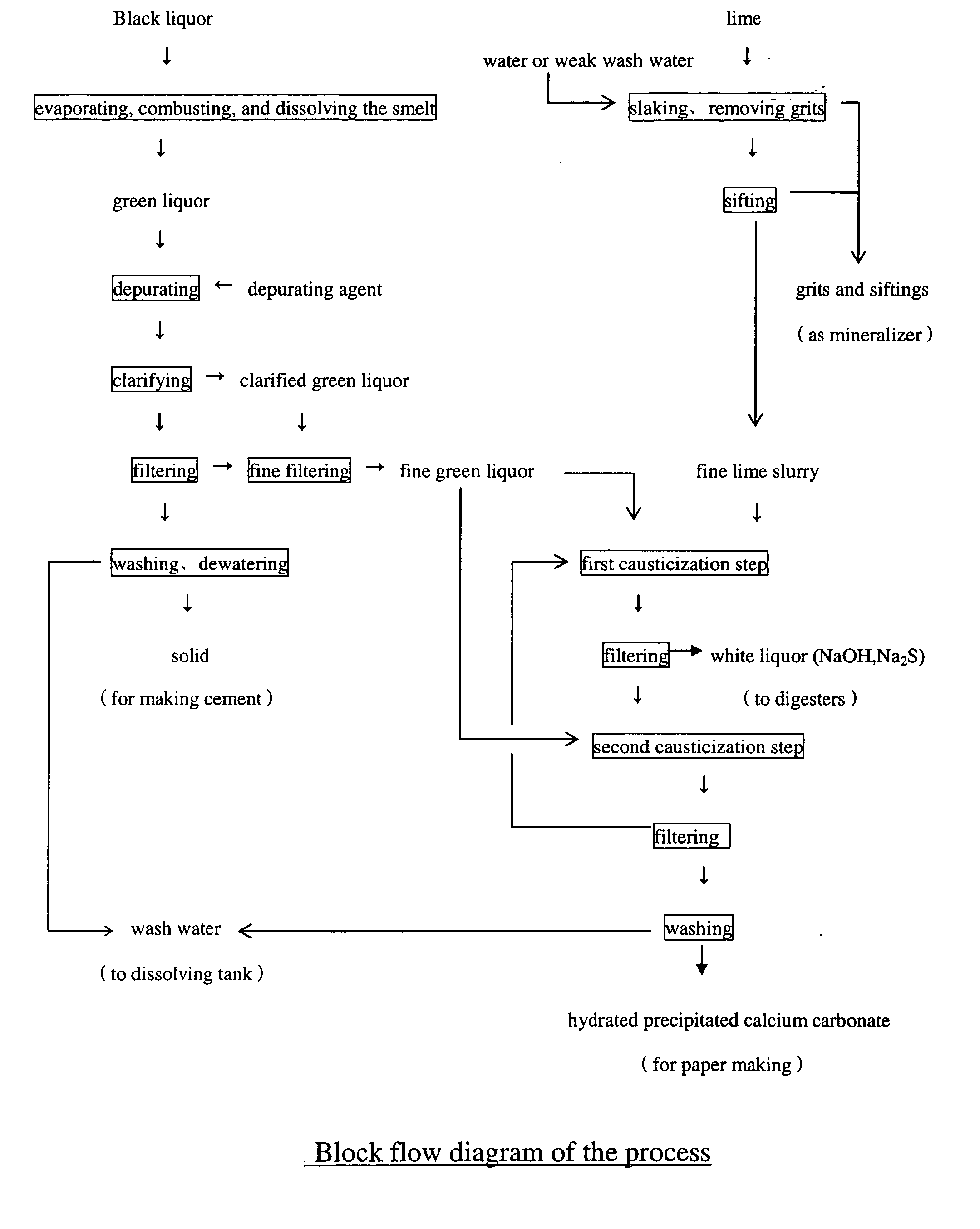

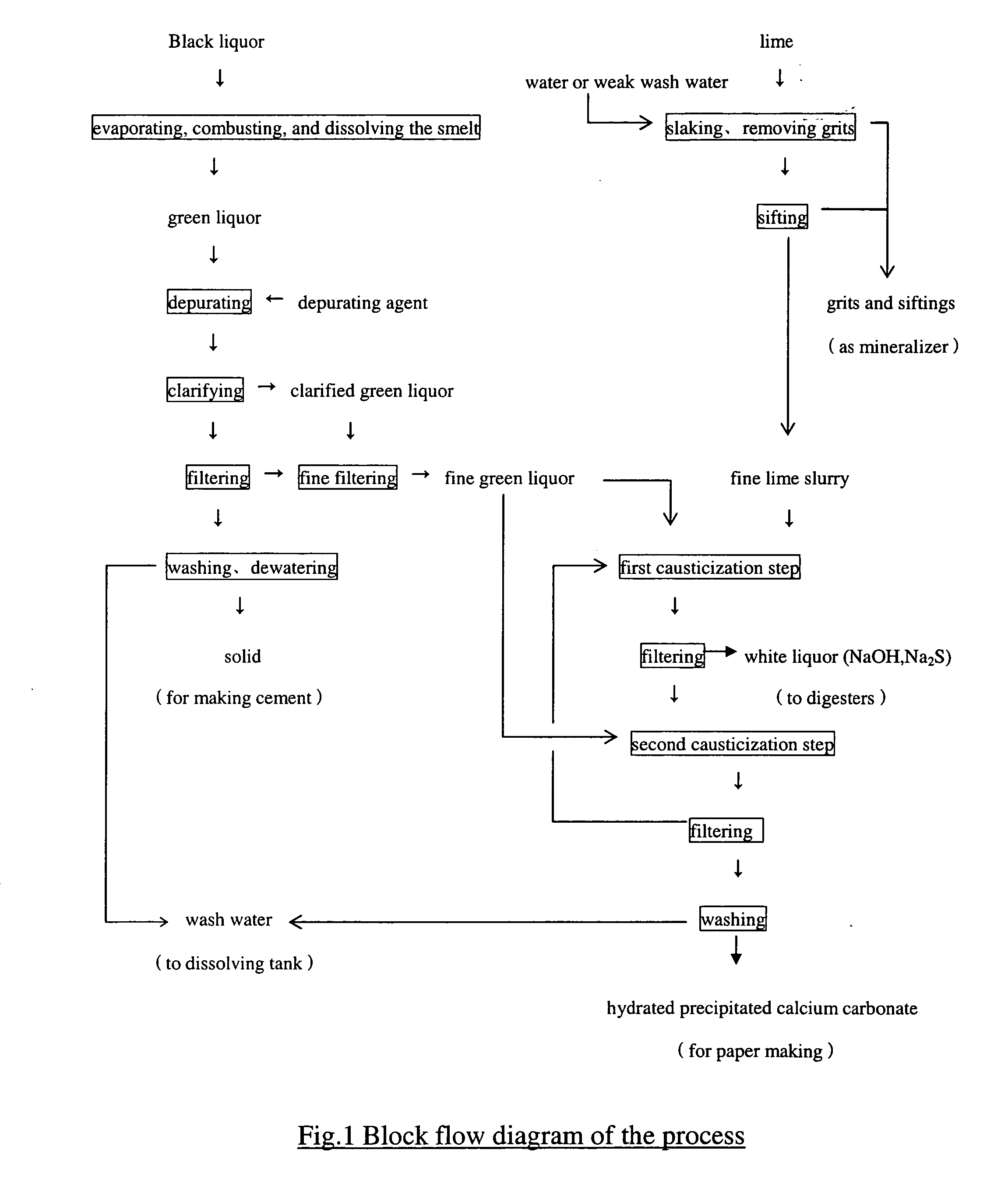

Process of recovering alkali from black liquor of papermaking

InactiveUS20050199358A1Equipment investmentReduce energy consumptionCalcium/strontium/barium carbonatesPulp liquors combustionBlack liquorPrecipitated calcium carbonate

This invention provides an improved process for recovering chemicals from black liquor in alkaline pulping, which is achieved by introducing depuration treatments of green liquor and lime before causticization reaction and a two-step-causticization procedure in the causticization procedure of the conventional chemical recovery process. The process of this invention not only avoids the generation of the waste residue (lime mud) from the beginning and saves the recovery and treatment of lime mud, but also can directly produce a series of precipitated calcium carbonate products with various particle sizes by regulating process conditions while the alkali is recovered, said CaCO3 products including a CaCO3 suitable for making coated paper, wherein >=50% of the CaCO3 has a particle size below 2 mum; a CaCO3 suitable for making neutral sized paper, wherein >=90% of the CaCO3 have a particle size below 2 mum; a superfine CaCO3 having an average particle size <1 mum. The present invention can be used for treatment of pollution of black liquor in the alkaline pulping.

Owner:AI TIANZHAO +3

Chemical recovery method for waste polycarbonate material

InactiveCN101407450AMild reaction conditionsQuick responseOrganic compound preparationChemical recyclingDeterioration rateMethyl carbonate

The invention relates to a new method for generating bisphenol A and dimethyl carbonate by solvent waste polycarbonate and chemical degradation waste polycarbonate material under a moderate condition to realize recycling of waste polycarbonate material. The method is characterized in that tetrahydrofuran, drewamine, N-methyl-pyrrolidone, 1, 2-dichloroethane, N, N-dimethyl formamide, diethylamine, ethylene dimine or composite material thereof which are easy to be recycled are used as reaction media, and with the presence of catalysts of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, lithium hydroxide or composite material thereof, and the like, an alcoholysis reaction is carried out under a normal pressure or a high pressure and at reaction temperature of 20 DEG C-80 DEG C; and a hydrolysis reaction is carried out at reaction temperature of 50 DEG C-160 DEG C. After the reactions, product bisphenol A is obtained (alkyl dimethyl easter product is also obtained in the alcoholysis reaction) after operation processes of solvent removing, washing, drying, and the like are carried out to the reaction liquid. The deterioration rate is over 98 percent. Compared with the traditional methods, the new method for generating bisphenol A and dimethyl carbonate by solvent waste polycarbonate and chemical degradation waste polycarbonate material under a moderate condition to realize recycling of waste polycarbonate material is characterized in that: (1) the reaction conditions are moderate; the reaction speed is high; and the operation is easy and simple; and (2) the problems of long reaction time period and strict requirements for equipment condition existing in the background technology, and the like, are overcome.

Owner:QINGDAO UNIV OF SCI & TECH

Recovery process and system for a pulp mill

InactiveUS20080289782A1Efficient productionImprove reusePulp liquors combustionFlue gasChemical recovery

A method for burning chlorine-containing liquors in a chemical recovery boiler at a pulp mill, wherein the recovery boiler includes spent liquor sprayers for feeding spent liquor and a number of combustion air levels including: increasing a combustion temperature in the recovery boiler in a burning zone where a chlorine-containing liquor or a chlorine-containing effluent is burned; while burning the liquor or effluent, volatilizing the chlorine in the liquor or effluent to produce chloride-containing salts in flue gases in the boiler, and removing the chloride-containing salts from the flue gases.

Owner:ANDRIZ OY

Process for chemical recycling of polyurethane-containing scrap

A process of chemically recycling polyurethane-containing scrap. Polyurethane-containing scrap is subjected to a chemolysis reaction to produce chemolysis polyol products. The chemolysis polyol products are used as initiators in a reaction with alkylene oxide to produce oxyalkylated polyols for preparing polyurethanes.

Owner:TROY POLYMERS

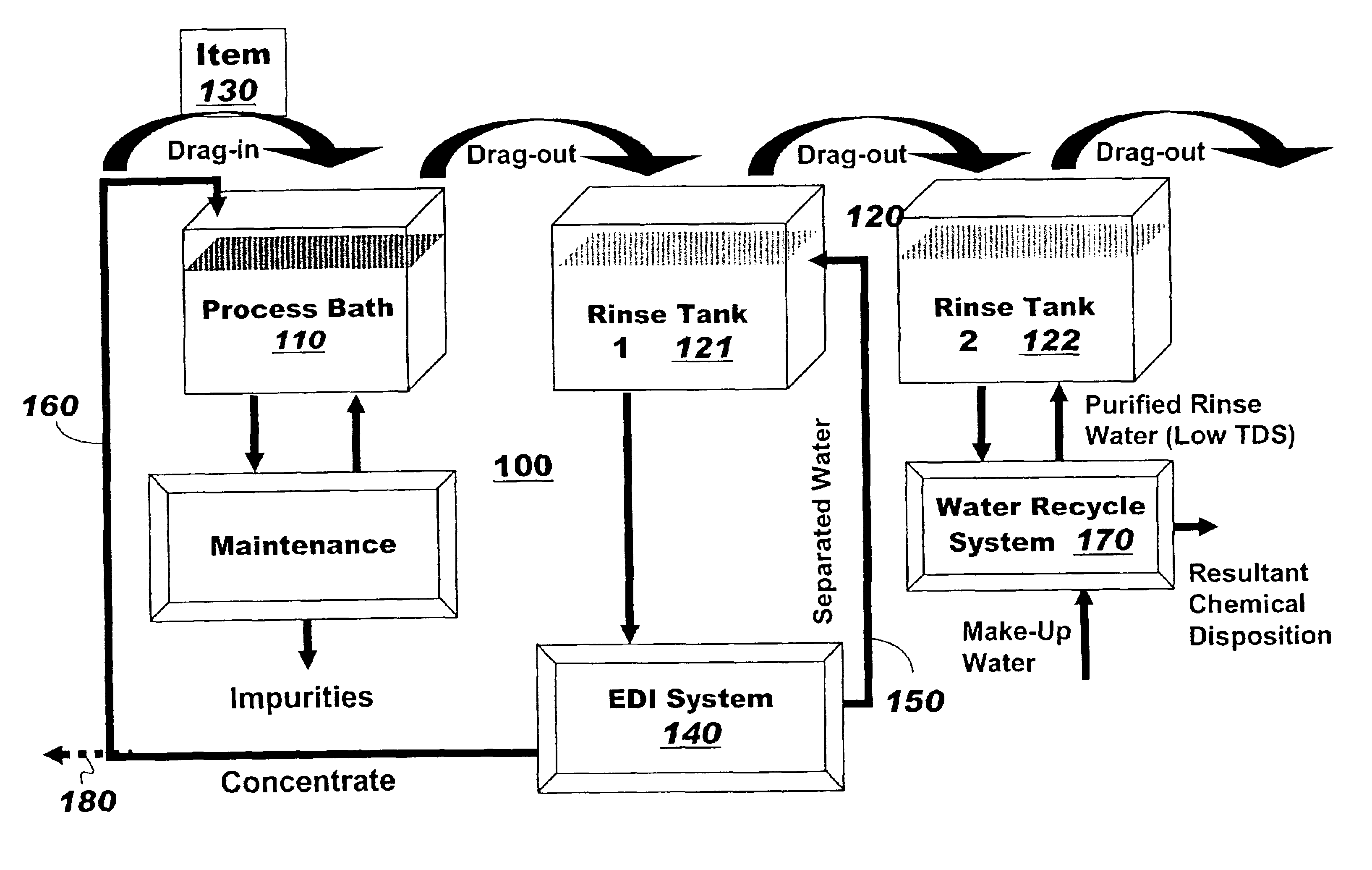

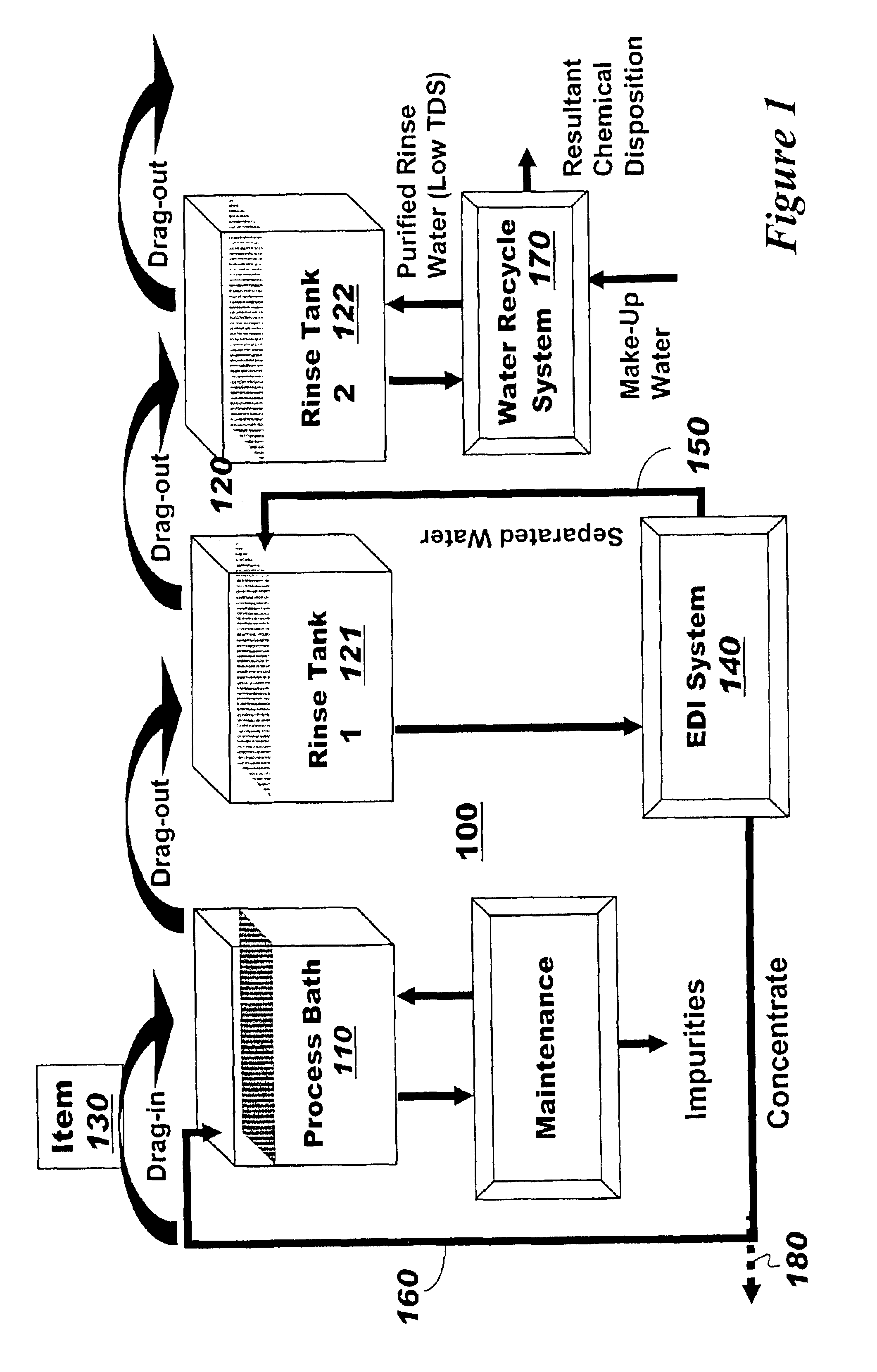

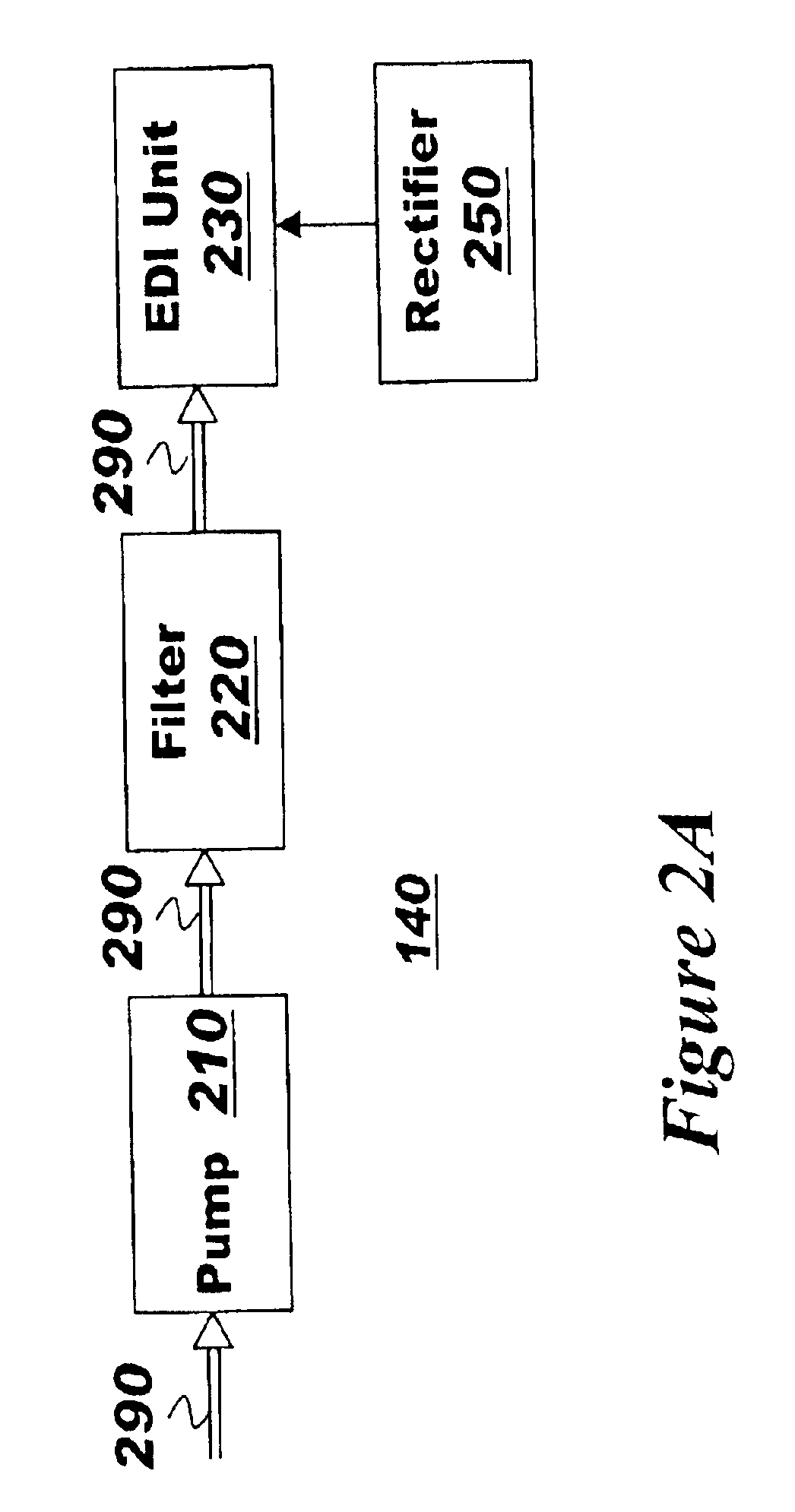

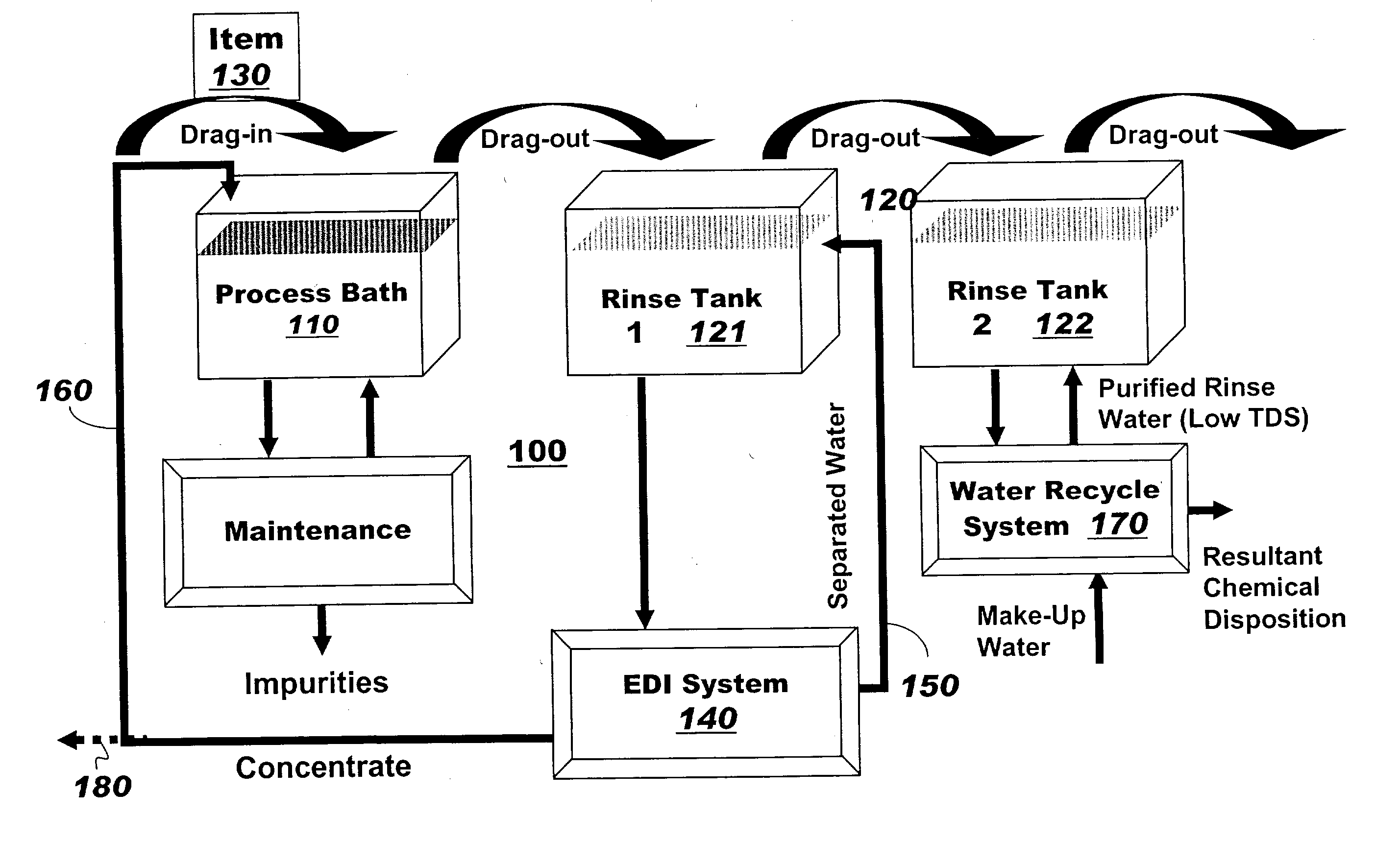

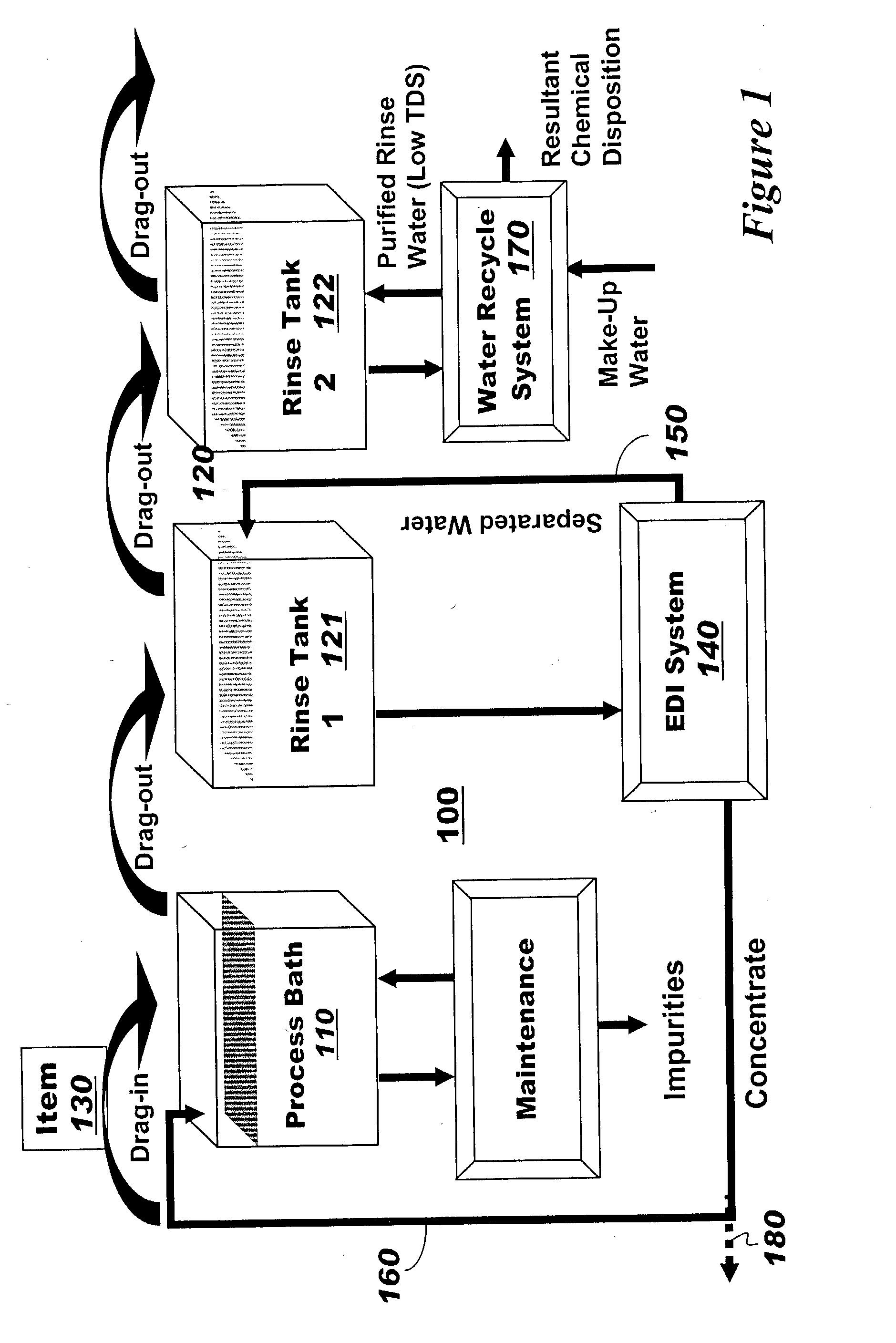

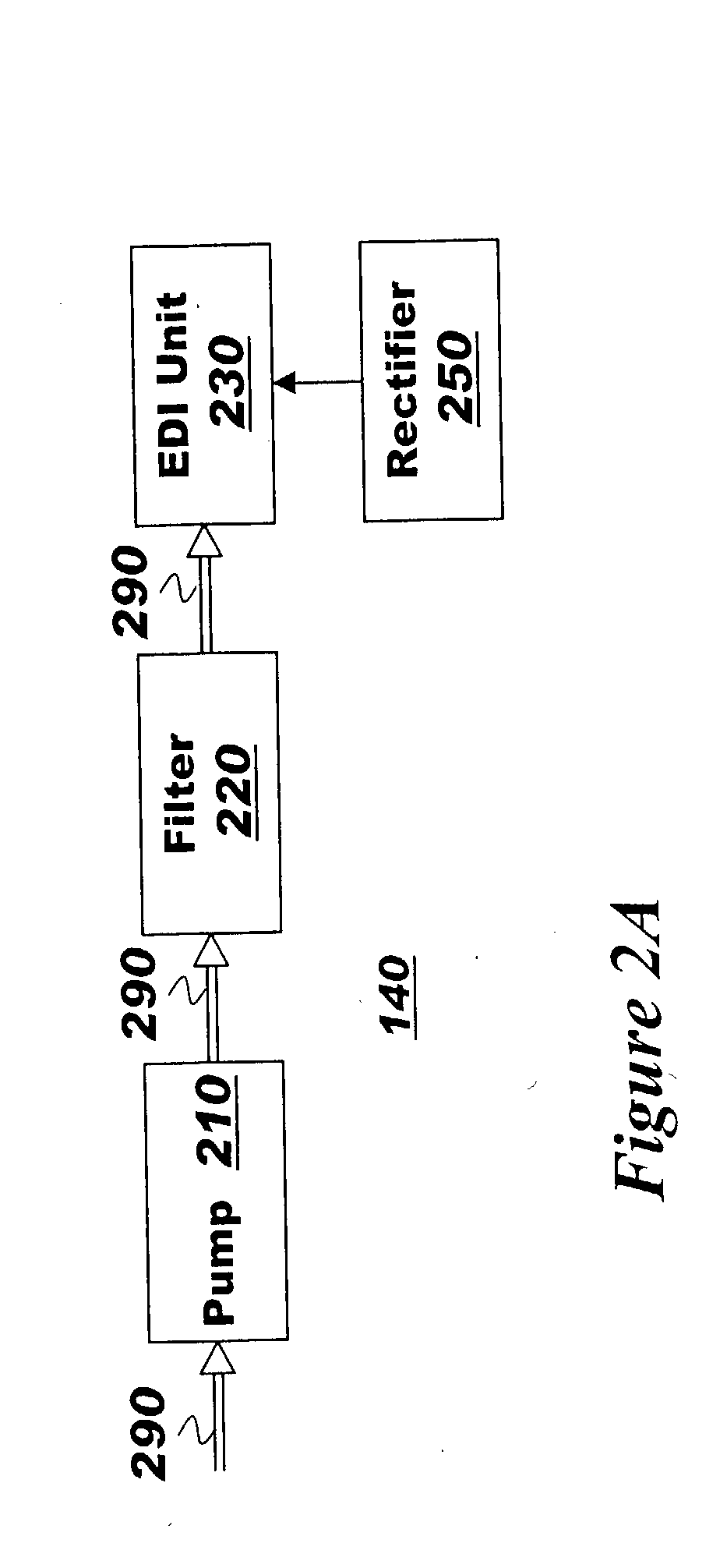

Advanced electrodeionization for fluid recycling

InactiveUS6905608B2Electrostatic separatorsLiquid separation by electricityElectricityChemical recovery

In one embodiment, a system comprises a filter and at least one electrodeionization (EDI) unit for chemical recovery. The filter is adapted to receive a fluid and to remove a selected chemical element or contaminant from the fluid. The EDI unit is coupled to the filter and adapted to recover a chemical element from the fluid and to separate the recovered chemical element from the fluid.

Owner:EXERGY TECH

Method for catalytically degrading waste polyester material by using zinc catalyst

PendingCN113173856ASimple structureFew synthetic stepsOrganic compound preparationOrganic chemistry methodsPolyesterTrans esterification

The invention discloses a method for catalytically degrading a waste polyester material by using a zinc catalyst, belongs to the technical field of polyester degradation, and aims to solve the problems that an existing polyester waste chemical recovery catalyst is low in catalytic efficiency and low in material universality. According to the method disclosed by the invention, a zinc catalyst with a simple structure is adopted, and various polyester materials are depolymerized into small organic molecules through an ester exchange reaction catalyzed by the zinc catalyst under the participation of an alcohol compound, so that the recycling of the waste polyester is realized; and the method disclosed by the invention has good universality, and has a good depolymerization effect on polyester materials with various different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Advanced electrodeionization for fluid recycling

InactiveUS20050040115A1Electrostatic separatorsLiquid separation by electricityElectricityChemical recovery

In one embodiment, a system comprises a filter and at least one electrodeionization (EDI) unit for chemical recovery. The filter is adapted to receive a fluid and to remove a selected chemical element or contaminant from the fluid. The EDI unit is coupled to the filter and adapted to recover a chemical element from the fluid and to separate the recovered chemical element from the fluid.

Owner:EXERGY TECH

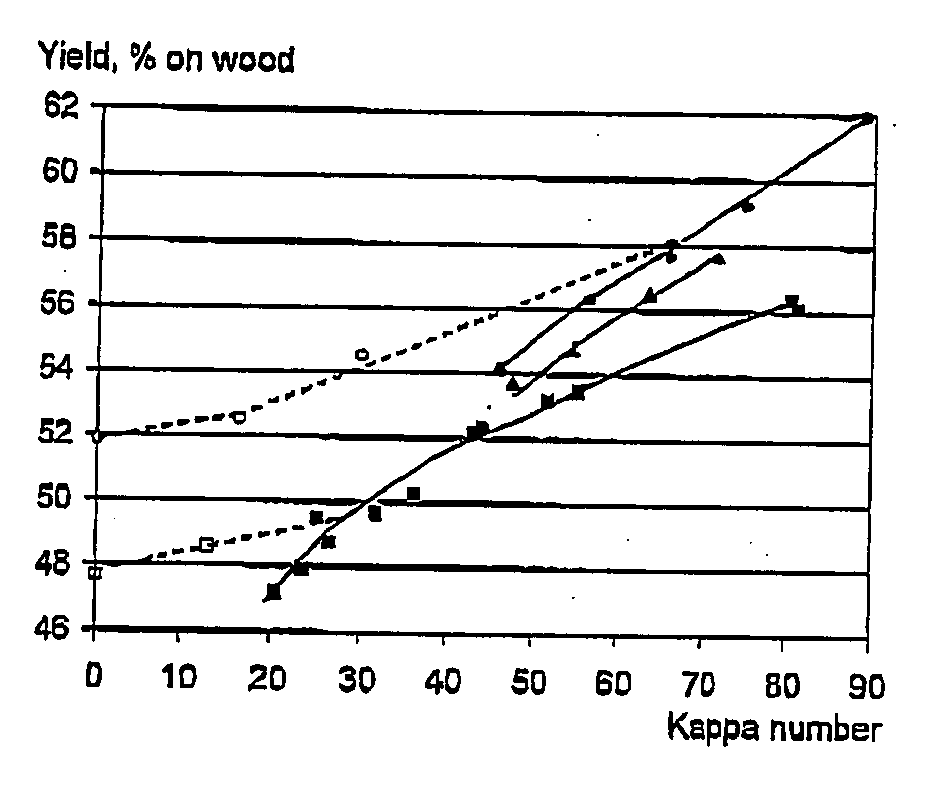

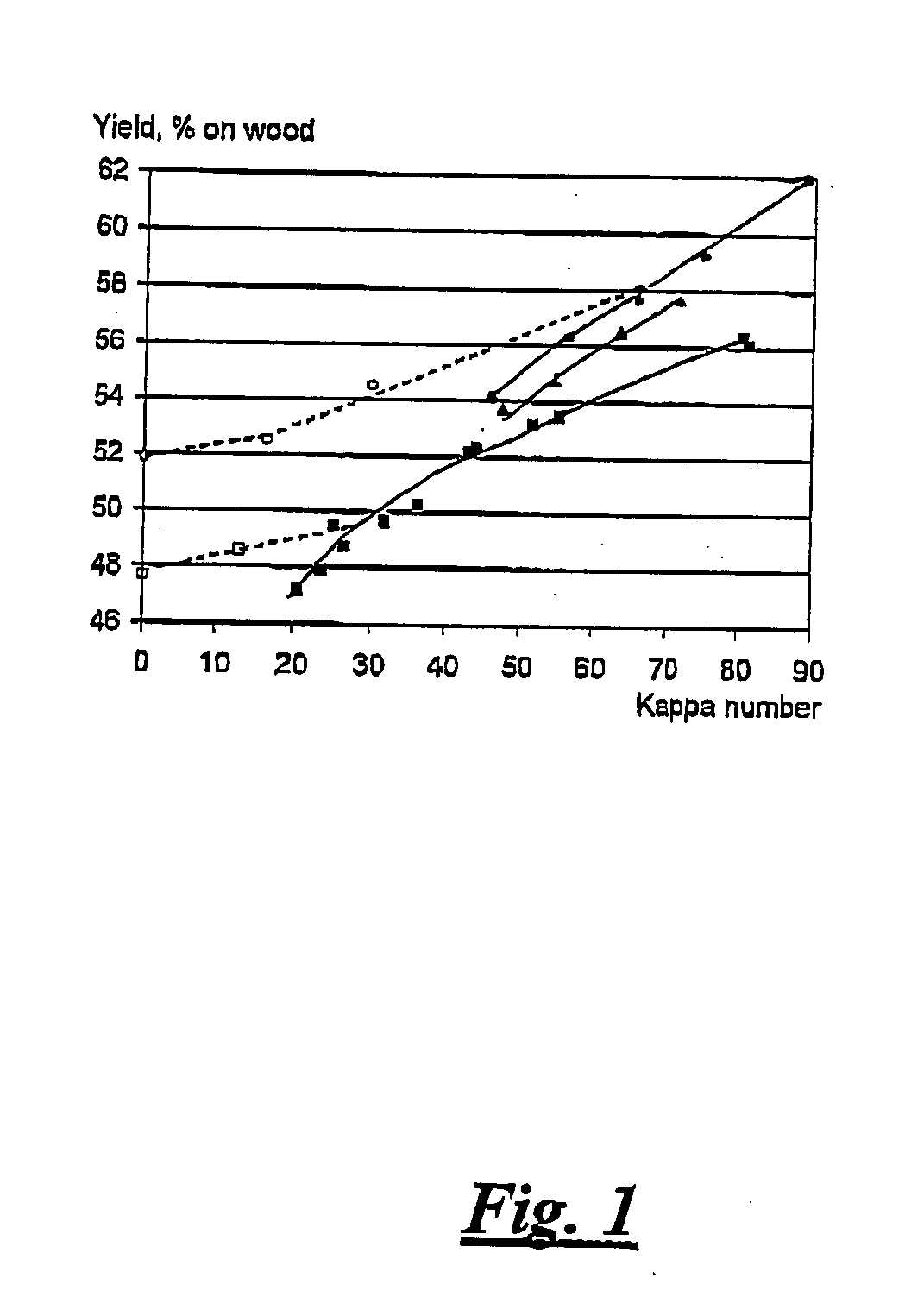

Method and a device for preparing cellulose pulp

InactiveUS20060070710A1Reduce the cooking temperatureImprove economyPulp liquors combustionPretreatment with alkaline reacting compoundsBlack liquorPulp mill

A method and an apparatus for preparing cellulose pulp, in which a lignin-containing raw material is impregnated with impregnation liquor and the impregnated raw material is cooked. The black liquor obtained by cooking is concentrated in an evaporation plant integrated in a chemical recovery plant. In the impregnation, the lignin-containing raw material is impregnated with a circulating alkaline impregnating liquor, which impregnating liquor is concentrated by evaporating water from it in at least one evaporator unit of the evaporation plant arranged in the chemical recovery plant of a pulp mill.

Owner:VALMET TECH INC

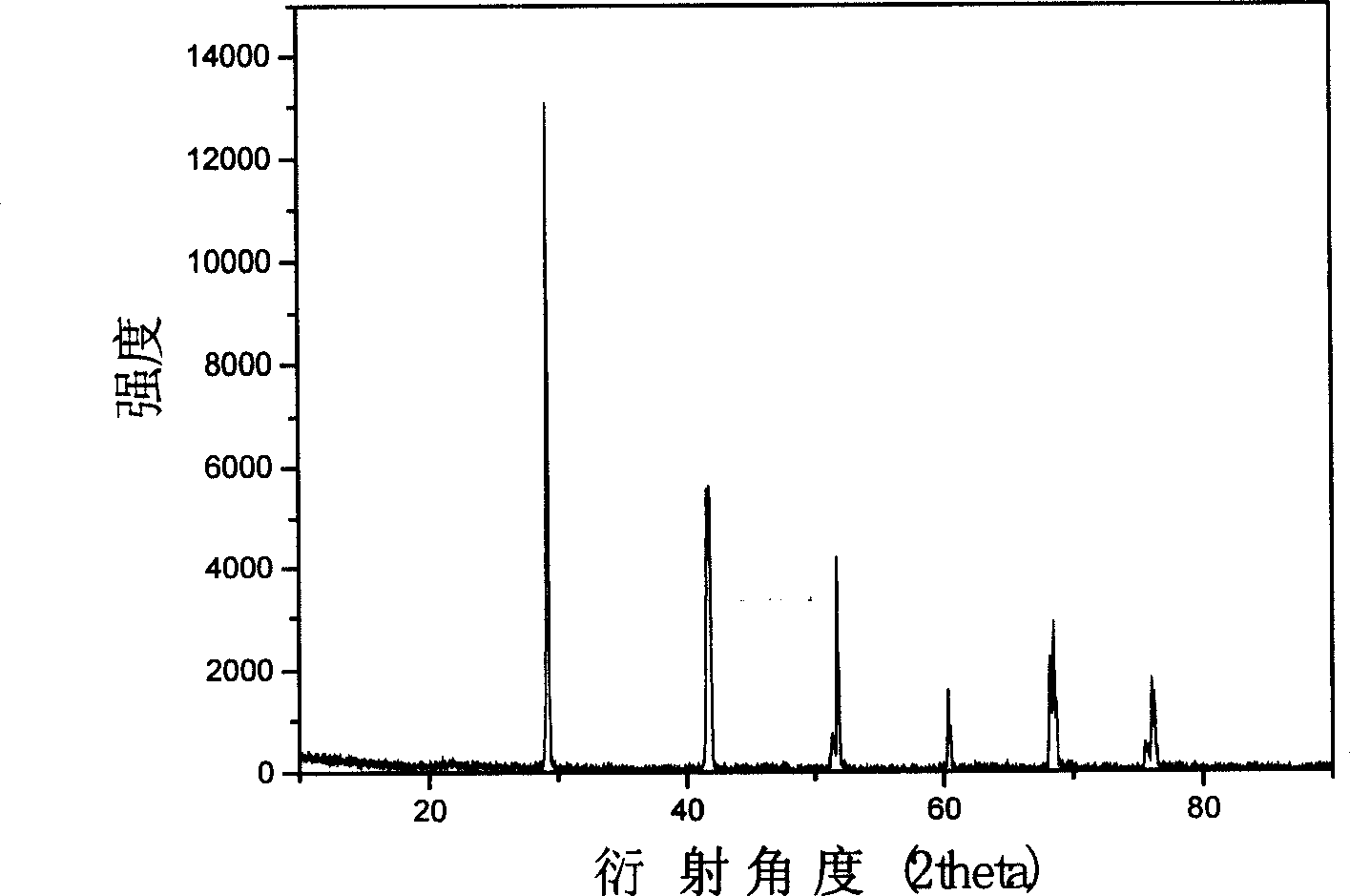

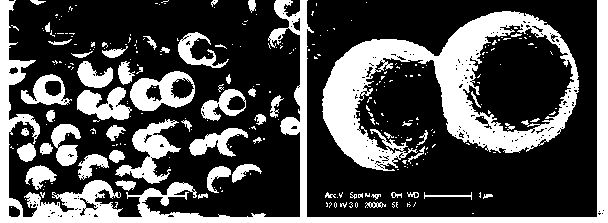

Method of preparing Sn-Sb alloy material for negative electrode of lithium ion cell

InactiveCN1688044AHigh specific capacityImprove cycle performanceElectrode manufacturing processesChemical recoveryAlloy

This invention provides a method for applying carbothermic method to prepare Sn Sb alloy negative material of Li ionic batteries characterizing in matching the oxide of Sn and Sb according to the Sn and Sb proportion in their generated alloy, then introducing a proper proportion of carbon powder as the reducer to get a mixture to be ground and put in N or Ar atmosphere to increase the temperature with the speed of 5-30deg.C / minute to arrive at different temperatures and keep them cut off to be cooled to the room temperature. Compared with the method of liquid phase chemical recovery and powder metallurgy, this invented method costs less, the particles of SnSb alloy powder are fine and uniform and good at crystallinity, the produced negative material has high specific capacity and stable circulation.

Owner:UNIV OF SCI & TECH BEIJING

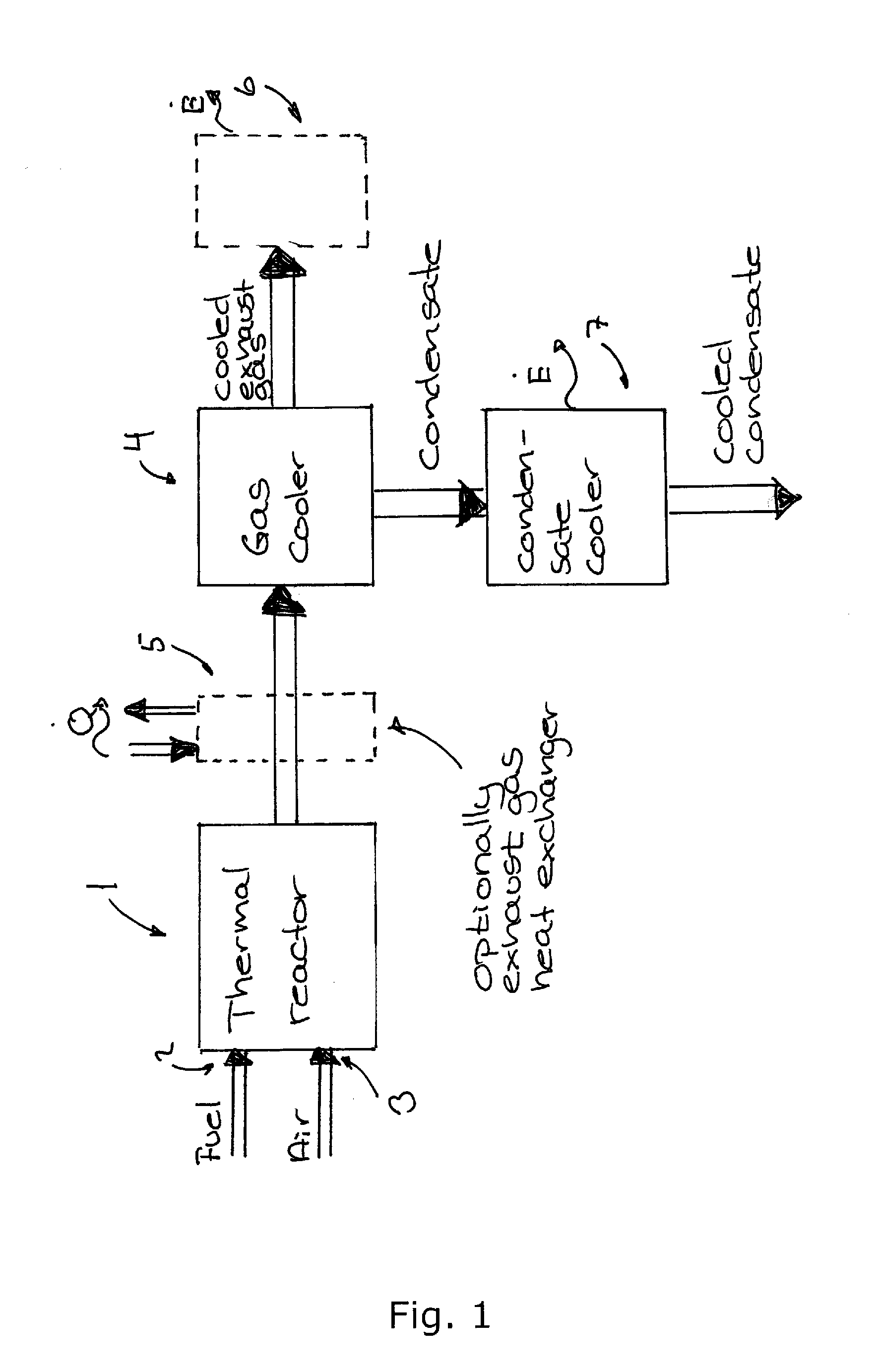

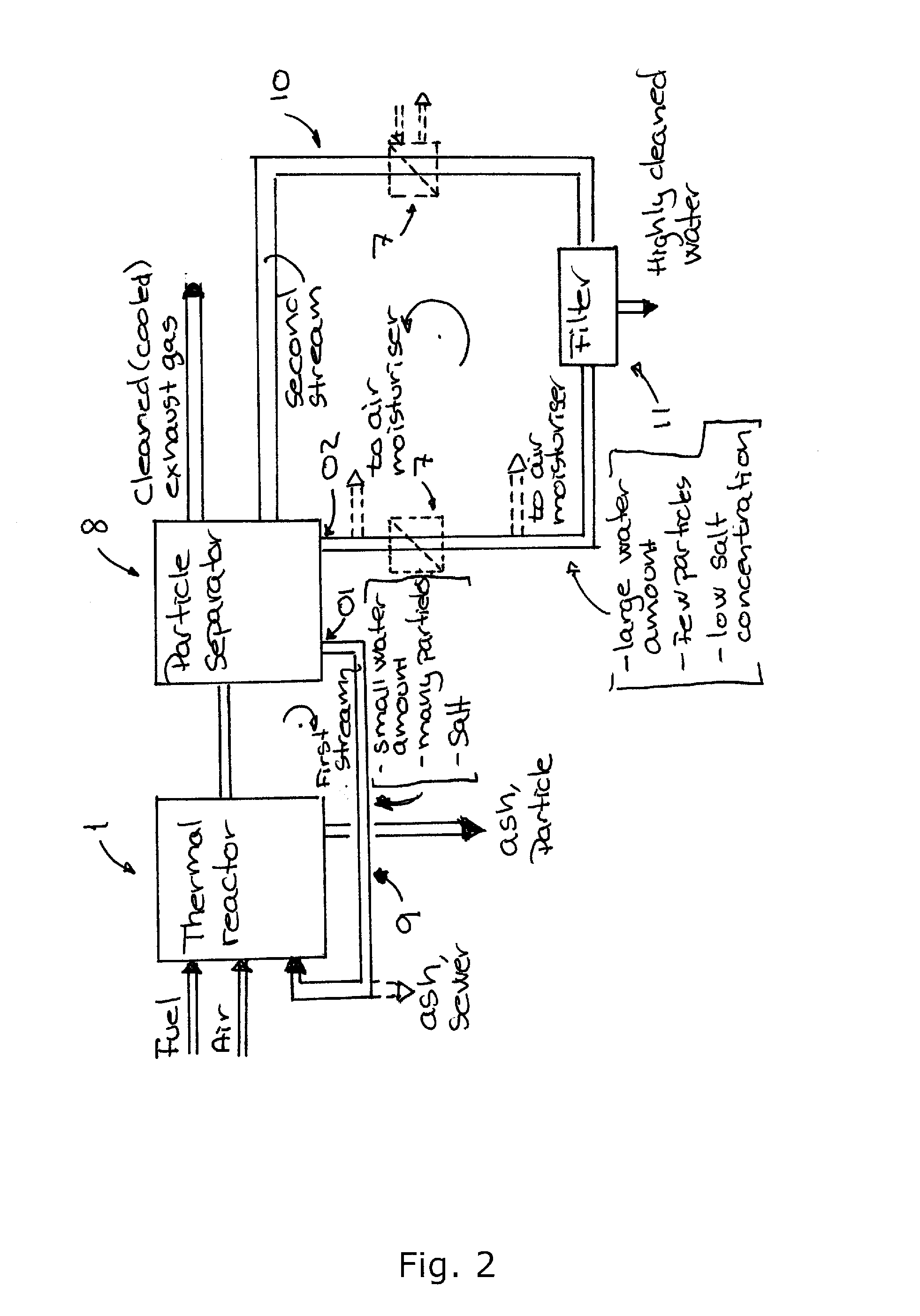

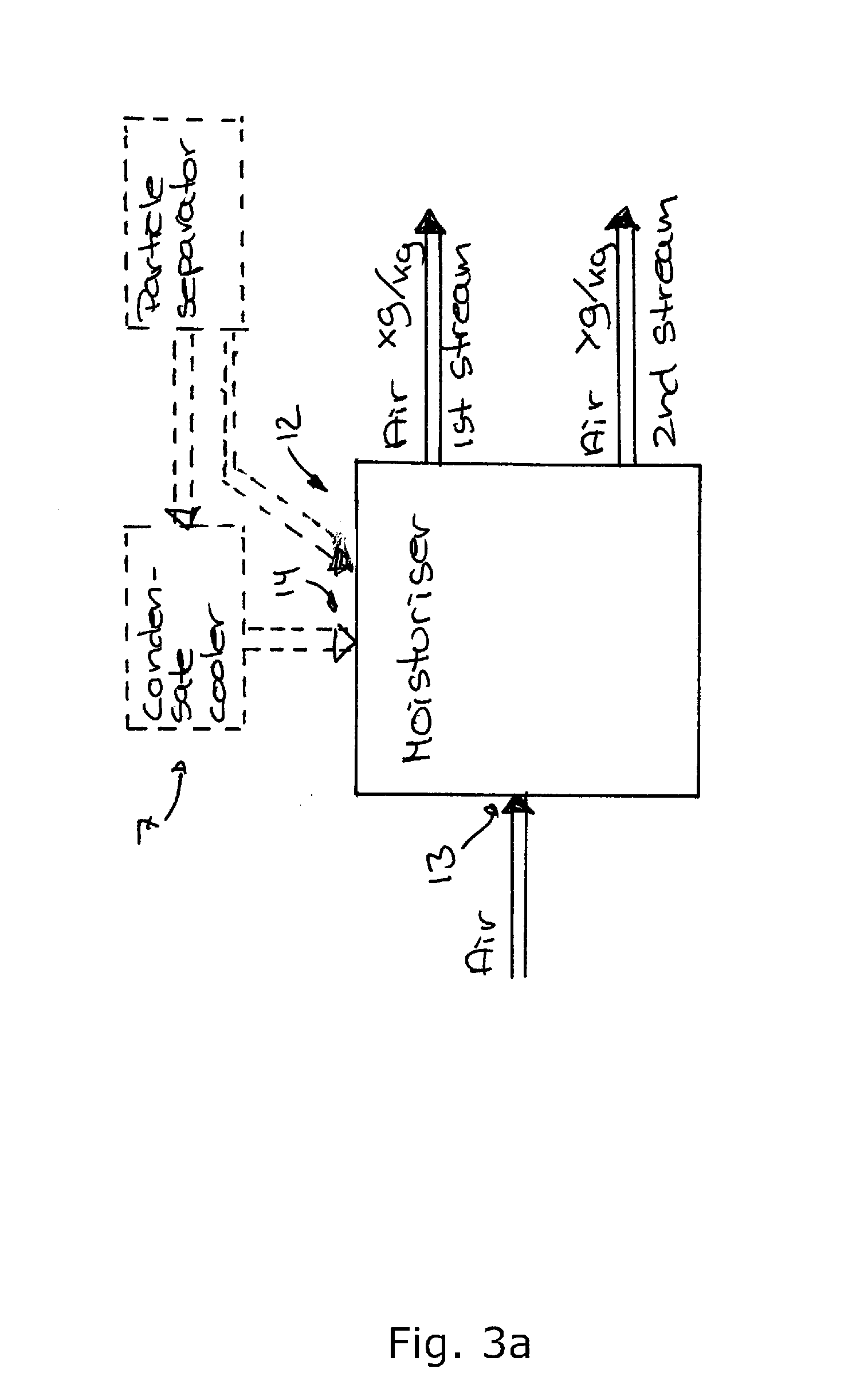

Method and system for cleaning of and heat recovery from hot gases

InactiveUS20120167461A1Extended service lifeEasy to cleanUsing liquid separation agentHeat recoveryChemical recoveryExhaust fumes

Exhaust gas, produced in a thermal reactor (1) that is fed with solid fuel can be cooled and in a gas cooler (4) which produce a condensate that is further cooled in a condensate cooler (7) which produce energy. By using air moisturizing and particle separation technology the exhaust gas and the excess condensate can be clean and the energy efficiency of the plant can be increased. The method can be used for a broad spectrum of fuels and conversion technologies.

Owner:DALL ENERGY HLDG

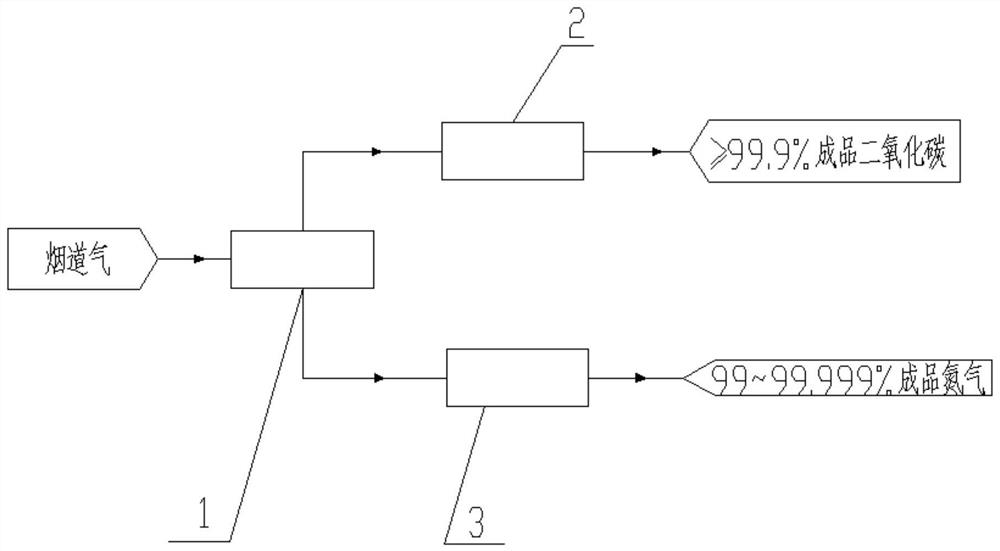

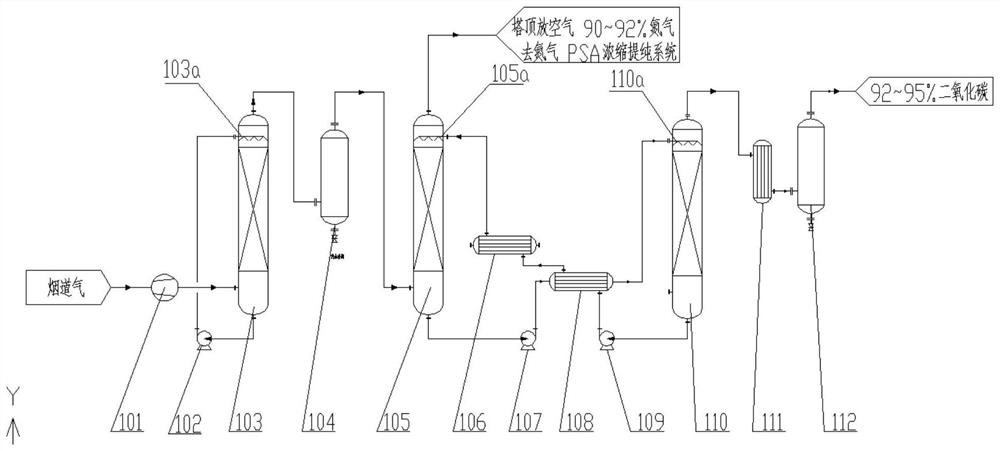

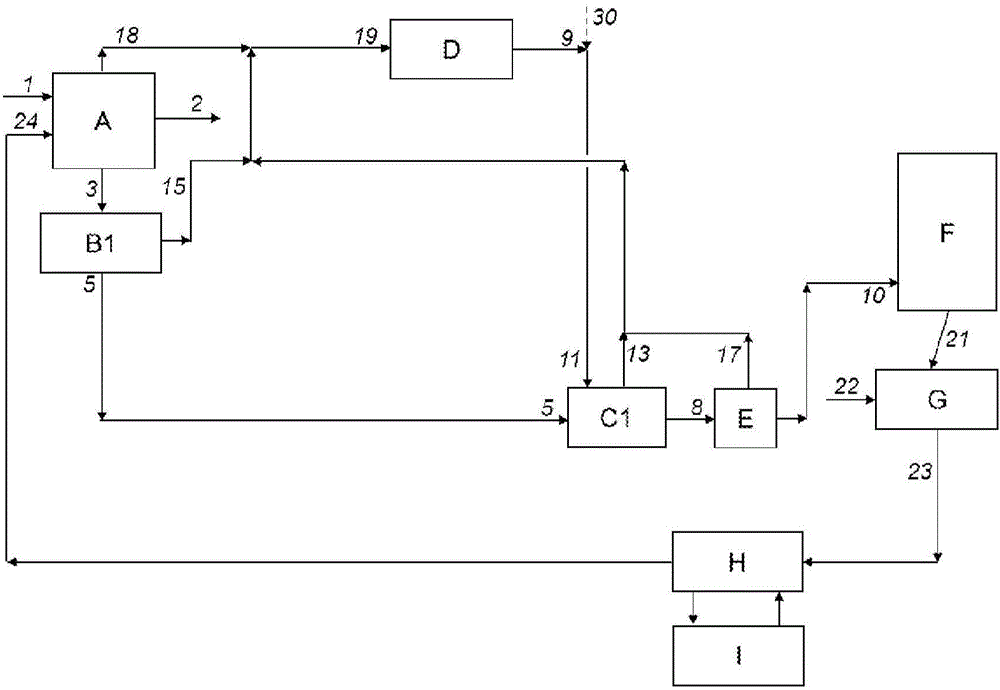

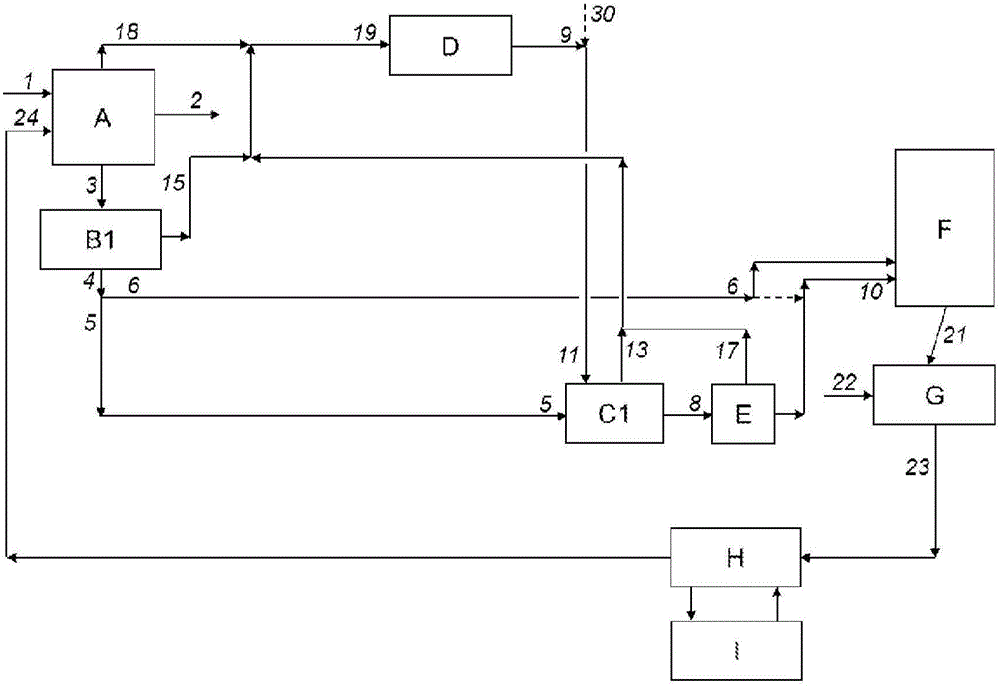

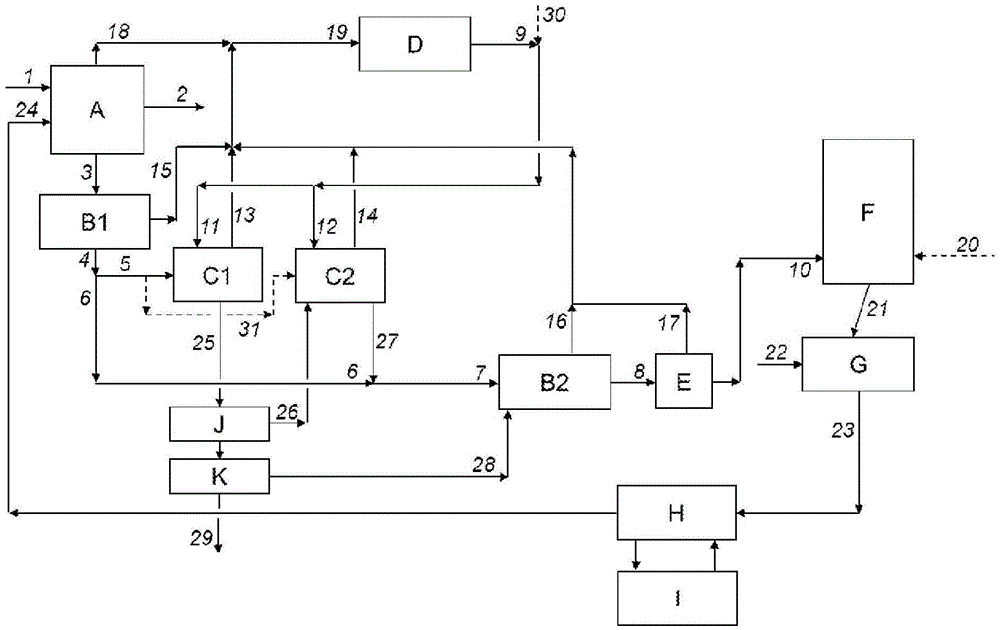

System and method for synchronously recovering carbon dioxide and nitrogen in flue gas by chemical method and PSA (Pressure Swing Adsorption) method

The invention belongs to the technical field of recycovering of boiler flue gas, and particularly relates to a system and method for synchronously recovering carbon dioxide and nitrogen in flue gas through a chemical method and a PSA method. The system for synchronously recovering the carbon dioxide and the nitrogen in the flue gas by the chemical method and the PSA method comprises a carbon dioxide chemical method recovery system, a carbon dioxide refining and liquefying system and a nitrogen PSA concentration and purification system; and the carbon dioxide chemical recovery system comprises a carbon dioxide absorption tower, a carbon dioxide regeneration tower, a heat exchanger and a first cooler. The system for synchronously recovering the carbon dioxide and the nitrogen in the flue gas by the chemical method and the PSA method has a good recovery effect on the carbon dioxide and the nitrogen, and can effectively save energy.

Owner:DALIAN UNIV OF TECH +1

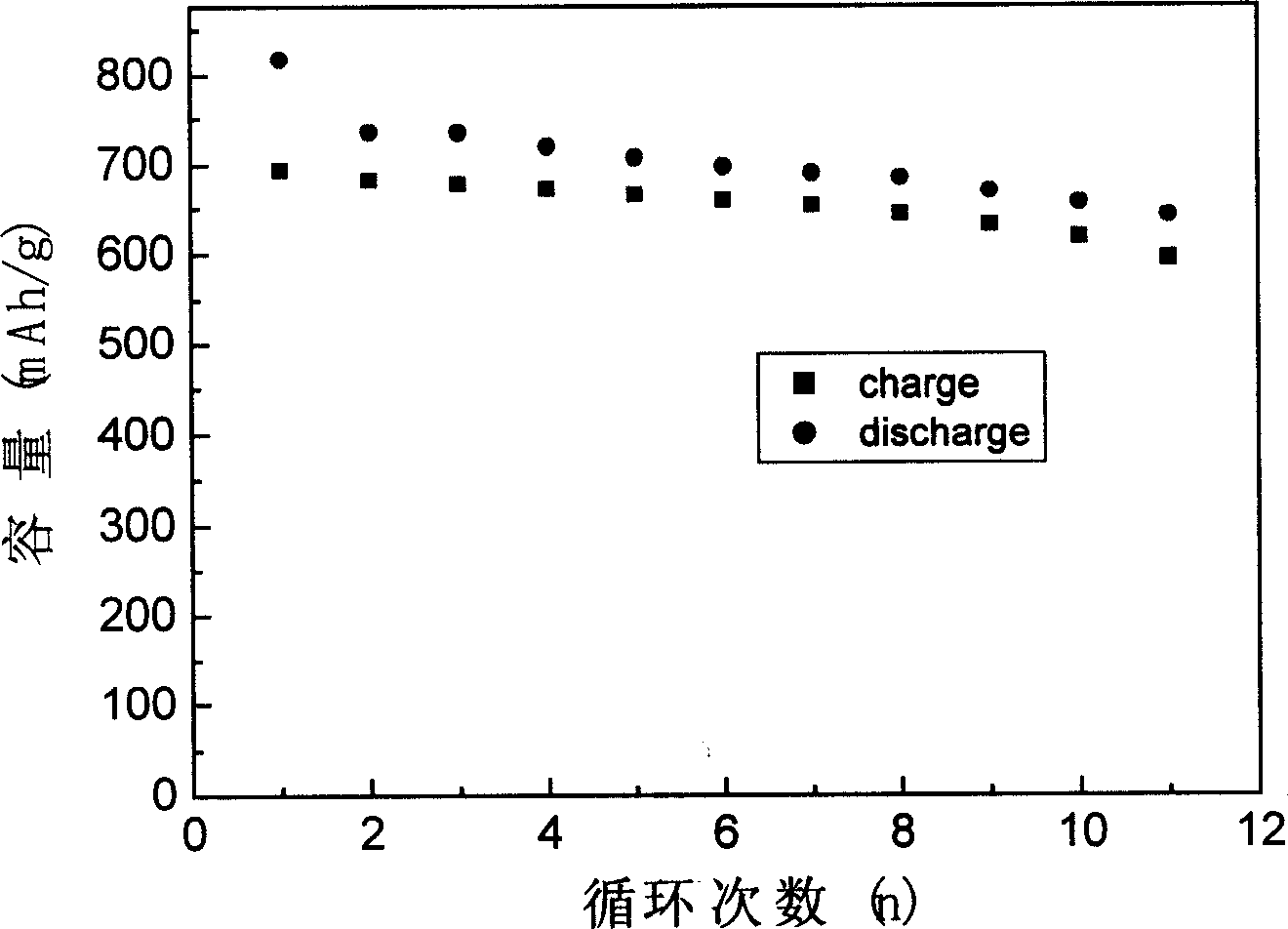

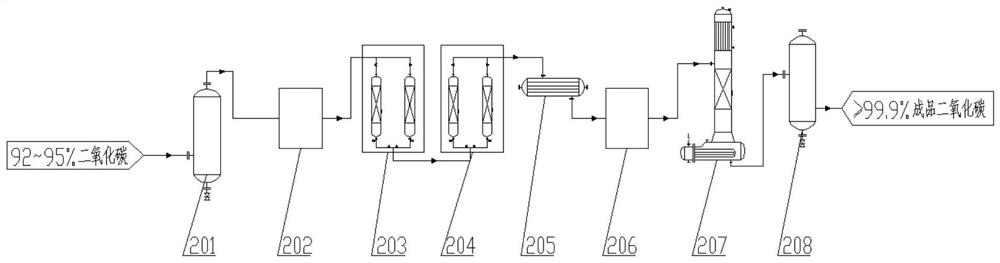

Electrochemical lithium recovery method

ActiveCN103276406AAchieve recyclingHigh selectivityPhotography auxillary processesWaste accumulators reclaimingLithium iron phosphatePhysical chemistry

The invention discloses an electrochemical lithium recovery method. Lithium in a solution is enriched through an electrochemical process by iron phosphate (FePO4), and the obtained lithiated iron phosphate material undergoes heat treatment to prepare a lithium iron phosphate positive electrode material. The electrochemical method which is used to extract lithium has a high lithium extraction selectivity, and is not influenced by other ions in the solution, and the electrochemical product lithiated iron phosphate can be directly converted to the lithium iron phosphate material after processing. So the method is very suitable for the direct extraction of lithium from the ionic solution having low values, and has the advantages of simple process, easy control and low cost, substantial practical values and good application prospect.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

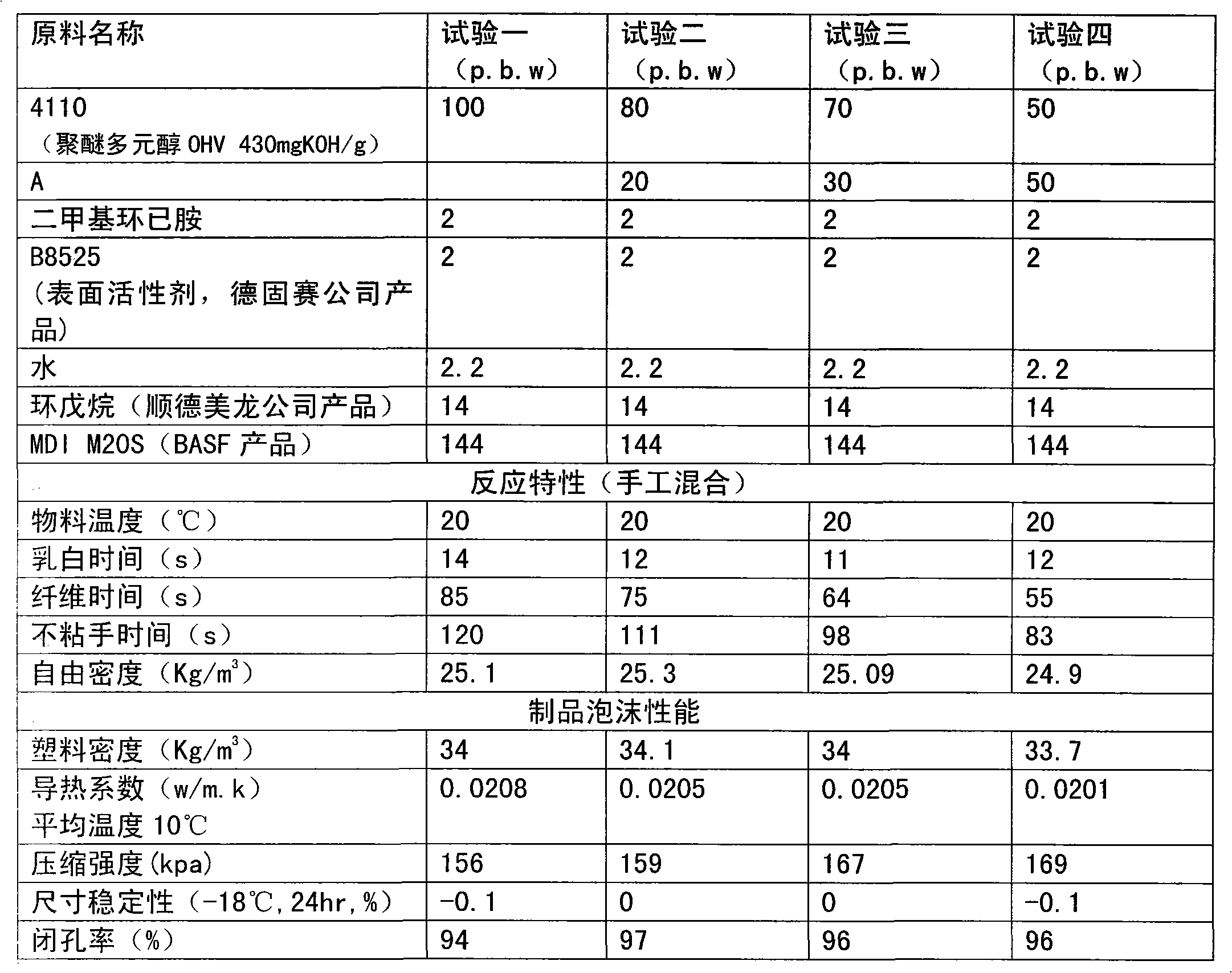

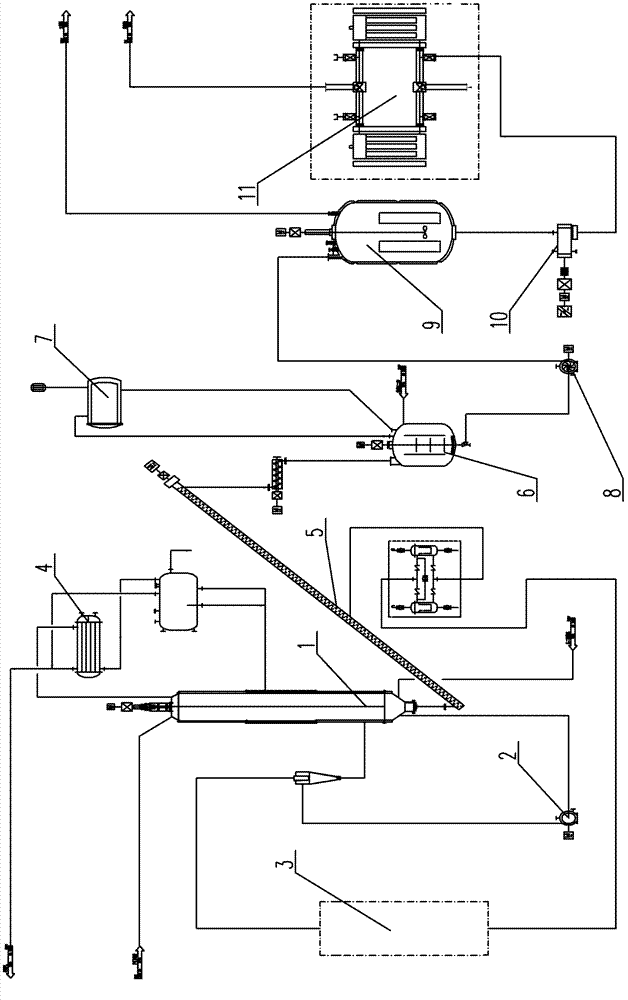

Waste polyurethane foam aminolysis recycling method

InactiveCN103012838ASolve pollutionTo achieve the goal of cost reduction and efficiency increasePlastic recyclingMechanical crushingPolyol

The invention relates to a waste polyurethane foam aminolysis recycling method, which comprises: a, removing surface attachments of waste polyurethane products; b, carrying out cutting or mechanical crushing on the surface attachment-removed waste polyurethane products into small blocks; c, preparing a mixture of regeneration polyol and aromatic amine; and d, preparing the mixture of the regeneration polyol and the aromatic amine into combination polyether for hard foam, and carrying out foaming. According to the present invention, a chemical recovery method is adopted to decompose waste polyurethane products, and processing utilization is performed, such that an environment pollution problem caused by the polyurethane foam is solved.

Owner:绍兴广佳庄鑫建材制造有限公司

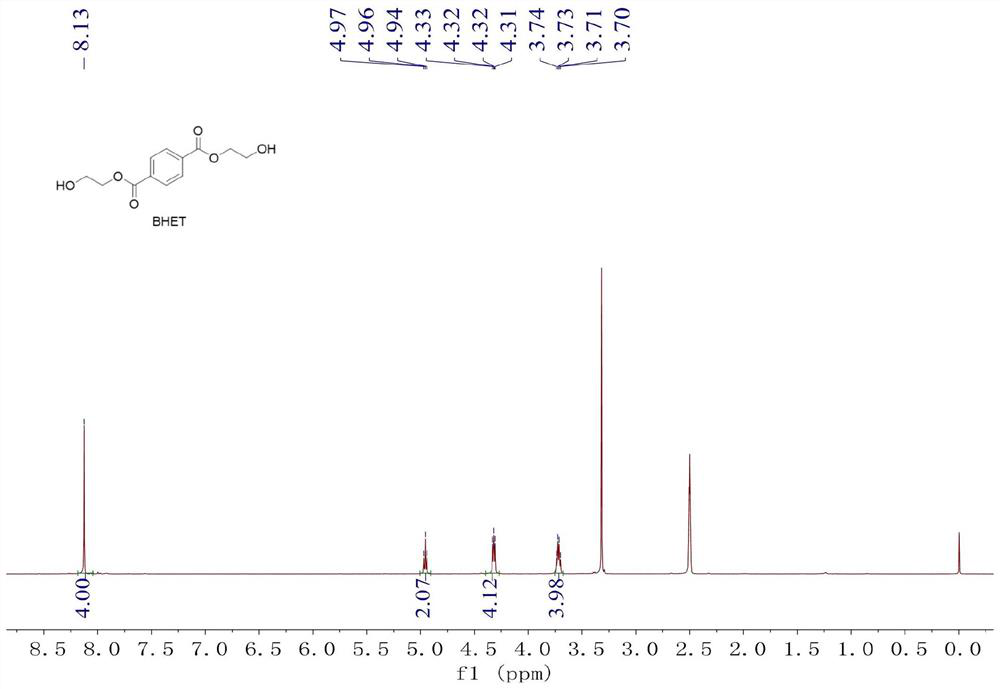

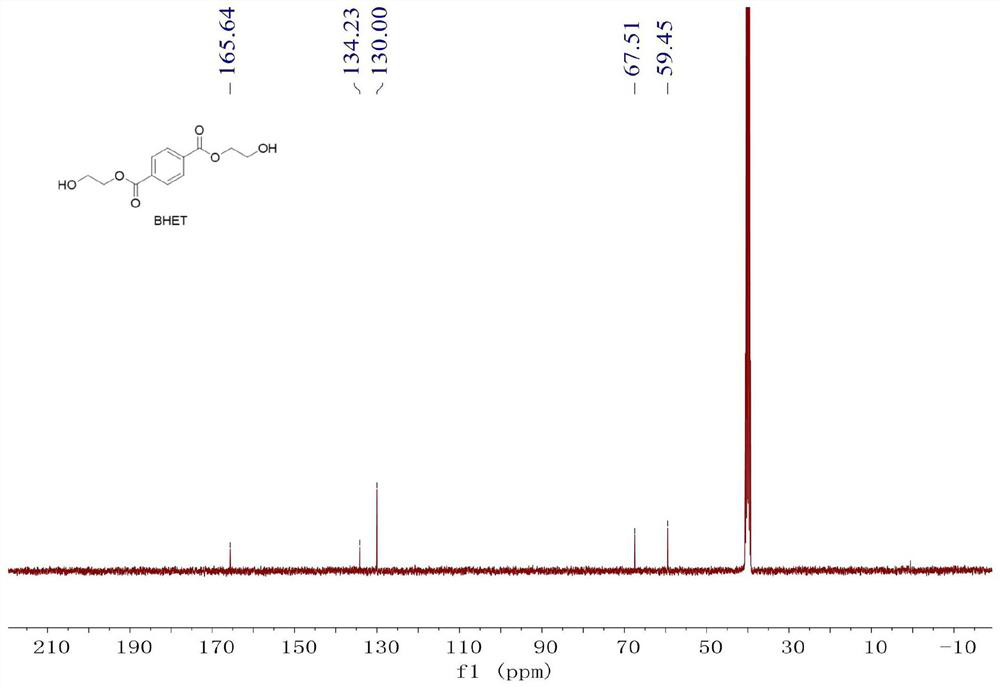

Preparation technology of ethylene glycol terephthalate and preparation method of polyester

ActiveCN103360260AGeneral Quantity RequirementsGeneral Technical RequirementsPreparation by ester-hydroxy reactionPolyesterChemical recovery

The invention provides a preparation technology of ethylene glycol terephthalate and a preparation method of a polyester. The preparation technology of the ethylene glycol terephthalate (BHET) comprises the steps of: pretreatment of polyester waste, pre-alcoholysis reaction, deep alcoholysis reaction, impurity removal of an alcoholysis product and the like. The polyester (PET) can be prepared again from the obtained BHET; by adopting the preparation technology of the BHET, a chemical recovery method is utilized; an industrial production technology with low energy consumption is provided; the index of the product can achieve the standards of food grade and environmental wire grade.

Owner:镇江宝利玛环保设备有限公司

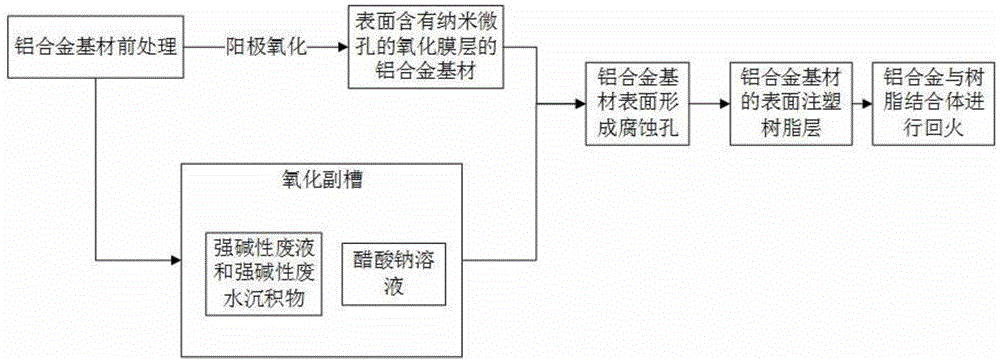

Preparation method of aluminum alloy resin composite body and aluminum alloy resin composite body

InactiveCN104626453AImprove bindingImprove structural strengthAnodisationMetal layered productsSodium acetateChemical recovery

The invention discloses a preparation method of an aluminum alloy resin composite body. The preparation method comprises the following steps: S1. carrying out anodic oxidation on a pre-treated aluminum alloy base material to obtain an aluminum alloy base material with a nano micro-pore in the surface; S2. mixing strong-alkaline waste liquid and strong-alkaline wastewater sediment, which are generated by an alkali corrosion groove in a pre-treatment process of the step S1 with a sodium acetate solution to form a mixed solution; and S3. putting the aluminum alloy base material into the mixed solution, and further corroding so as to form a corroded hole in the surface of the aluminum alloy base material. The invention further discloses the aluminum alloy resin composite body. Aiming at the problems that the application of a previous resin combining body is limited, the bonding force is poor, the structure strength requirements of a product cannot be met and the like, the corroded hole with a relatively large hole diameter is formed by corroding the nano micro-pore for multiple times, and the aluminum alloy resin composite body with the high bonding force and good structure strength is prepared; and a chemical recovery process is adopted so that the environment-friendly and pollution-free effects are achieved in the preparation process, and the industrialized production and environmental protection are facilitated.

Owner:广东东明新材科技有限公司 +1

Alkaline process for the manufacturing of pulp using alkali metaborate as buffering alkali

The present invention relates to a new and environmentally sound process for the manufacturing of a chemical pulp from lignocellulosic material with an integrated recovery system for recovery of pulping chemicals. The process is carried out in several stages involving a pre-treatment stage followed by one or more delignification stages using an alkaline buffer solution comprising alkali metaborate and sodium carbonate as major components. The alkaline components of the pulping liquor are recovered from a chemicals recovery furnace and at least a portion of the alkali is recycled and used for delignification without any prior reactions with lime or calcium compounds for generation of alkali hydroxide. A quinone based delignification catalyst may be added to be present during delignification.

Owner:KIRAM

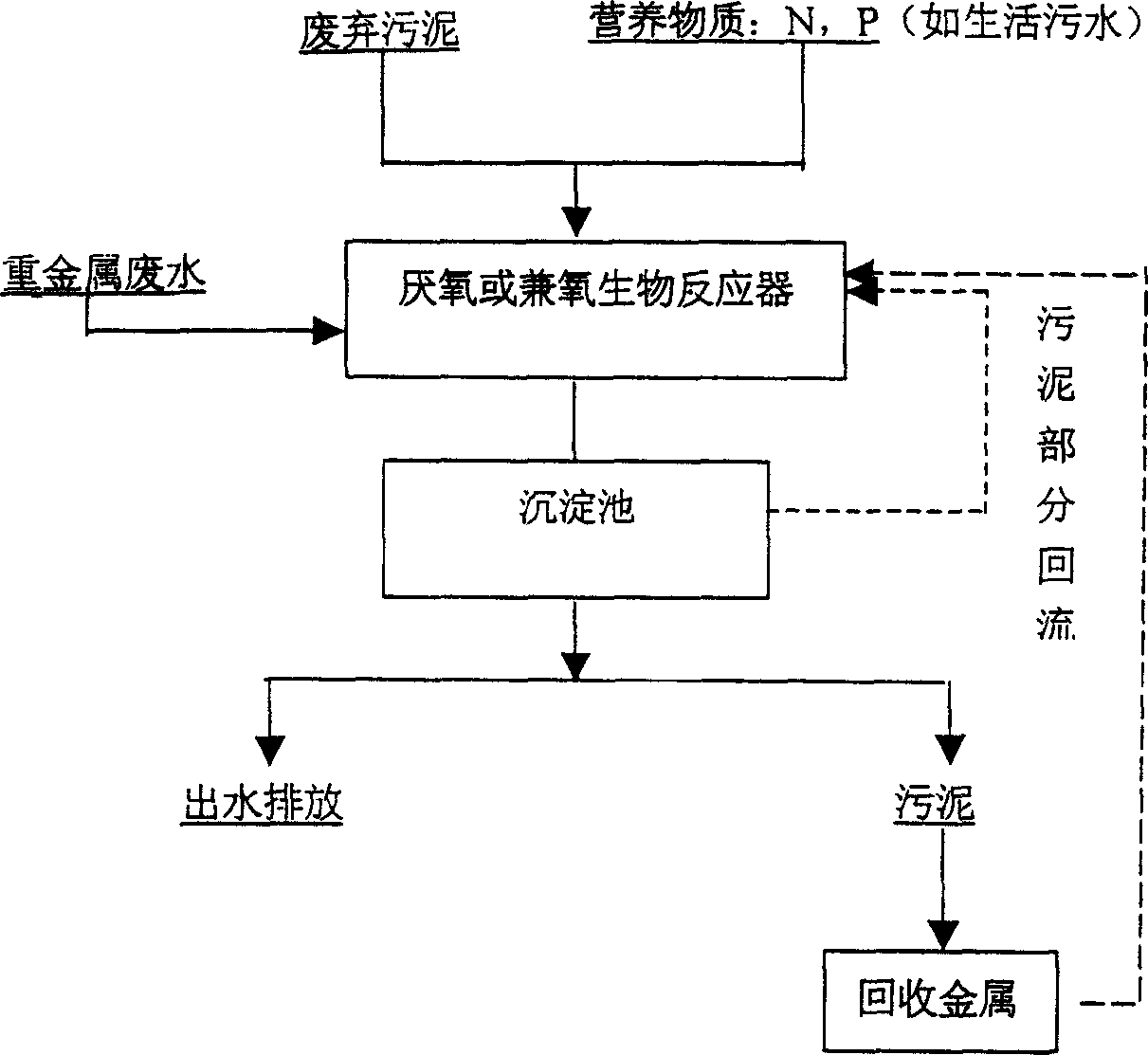

Method of treating waste water containing heavy metal with waste sludge as carrier

InactiveCN1548382AImprove purification efficiencyShort cycleTreatment with anaerobic digestion processesWater/sewage treatment by flocculation/precipitationRefluxMicroecosystem

Owner:CENT SOUTH UNIV

Process for Chemical Recycling of Post Consumption Poly(Ethylene Terephthalate) and Equipment for Chemical Recycling of Post Consumption Poly(Ethylene Terephthalate)

InactiveUS20080097120A1Easy to separateEliminate effectiveGaseous chemical processesOrganic compound preparationDepolymerizationChemical recovery

Process for chemical recycling of post consumption poly(ethylene terephthalate) and equipment to perform the chemical recycling of post consumption poly(ethylene terephthalate) comprising a chemical process performing the depolymerization of poly(ethylene terephthalate)—PET—with the purpose of promoting the post consumption chemical recycling of this polymer. It also describes the equipment required for its performance. Such process is based on hydrolysis reaction, which causes the rupture in of the ester bonds formed between the polymer precursors (terephthalic acid and ethylene glycol) at the time of polymerization. The purpose is to recover, from the PET wastes and post consumption PET, terephthalic acid and ethylene glycol. The advantage of this patent are the working conditions at low to moderate pressure, at temperatures of 215 to 450oC, allowing to reach the energy level required to the PET hydrolysis desired, and simultaneously promoting the separation and purification of the terephthalic acid and ethylene glycol and / or another glycol present in the formulation of the PET formed in this hydrolysis reaction. The product obtained in this recycling is the terephthalic acid and the ethylene glycol, that thereby closes the cycle of life of the PET returning it to its raw materials, avoiding its accumulation in the planet biosphere.

Owner:BRASKEM SA +2

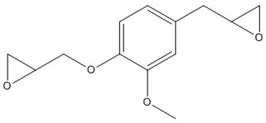

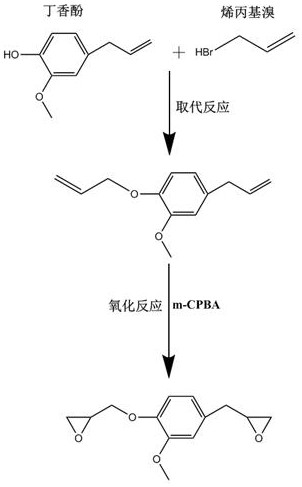

Recyclable eugenol-based epoxy resin Vitrimer material and preparation method thereof

The invention relates to a recyclable eugenol-based epoxy resin Vitrimer material and a preparation method of the recyclable eugenol-based epoxy resin Vitrimer material. Biomass-based eugenol is used as a raw material, an eugenol-based epoxy resin matrix similar to DGEBA is prepared through a two-step method including an allyl bromide substitution reaction and a m-chloroperoxybenzoic acid oxidation reaction, then the eugenol-based epoxy resin matrix is mixed with a dicarboxylic acid curing agent system containing and not containing dynamic bonds, curing is conducted in a gradient heating mode, and theeugenol-based epoxy resin Vitrimer material with a dynamic reversible exchange key anddisulfide bond is otained. The epoxy resin Vitrimer material has the advantages of high physical remodeling reprocessability, high chemical recovery efficiency and the like, and overcomes the defects that the traditional epoxy resin takes petrochemical resources as raw materials and is difficult to recycle after being used; and green development and sustainable utilization of the thermosetting polymer material are promoted.

Owner:SHAANXI UNIV OF SCI & TECH

Method for recovering chemicals and by-products from high-sulphidity pulping liquors

The subject of the invention is a new method to be used in connection with the recovery of pulping chemicals from the spent pulping liquor produced by kraft- type pulping at very high sulphidity. The sulphidity is most preferably in the range 70–100 %. In the new method, spent pulping liquor (5) is acidified to a relatively low pH, preferably below 7, most preferably below 6, in order to convert a large part, or all, of the sulphide and hydrosulphide in the liquor into H2S. Sulphur containing gases (19), mainly H2S, released from the spent pulping liquor, together with other sulphur gases collected at the pulp mill, are converted into an acid compound, preferably H2SO4 (9), which is then employed as an acidification agent in the previously mentioned acidification step. The amount of acid thus generated is sufficient to provide most, if not all, of that required for the acidification step. The acidification of the spent pulping liquor may be further exploited as a means to increase recovery of by-products and / or to purge non-process elements from the chemical-recovery cycle.

Owner:ANDRITZ AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com