Preparation technology of ethylene glycol terephthalate and preparation method of polyester

A technology for ethylene phthalate and a preparation process, which is applied in the field of polyester waste recycling and reuse, can solve the problems of high energy consumption and complicated processes, and achieves simplification of recycling devices, reduction of explosion-proof grades, number of equipment and technical requirements general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

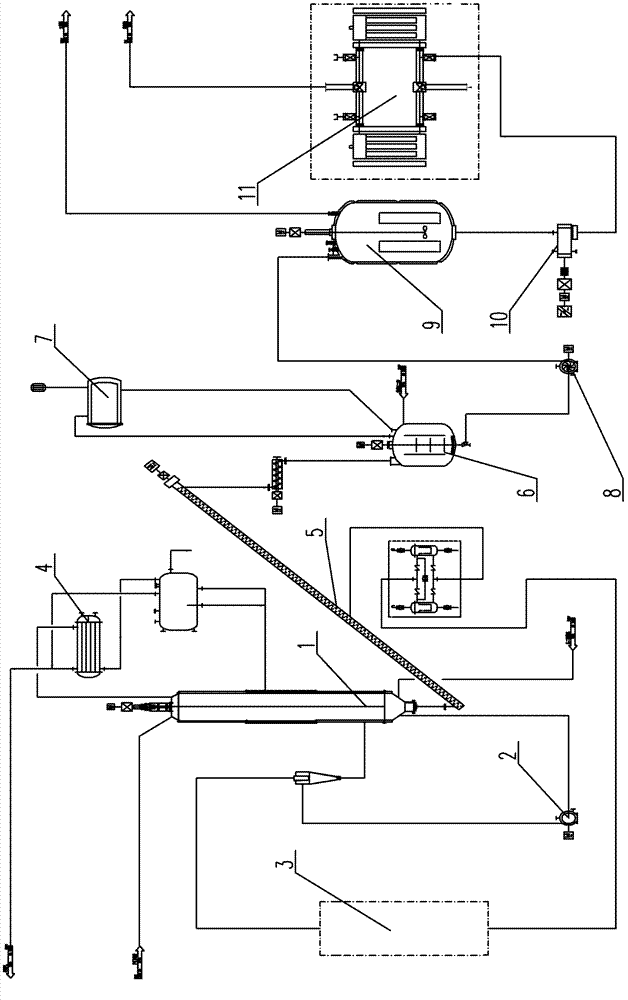

Image

Examples

Embodiment 1

[0045] The continuous feed rate of polyester waste is 3350kg / h, remove impurities, dry, and feed continuously from the top of the pre-alcoholysis reactor through the discharge screw conveyor of the drier, and the feed temperature is less than 105°C;

[0046] After the polyester waste material enters the pre-alcoholysis reactor, it contacts step by step with the superheated steam of ethylene glycol added from the bottom of the pre-alcoholysis reactor to form the effect of a packed tower; the gas phase outlet at the top of the tower is controlled between 102°C and Residual moisture is removed; gas-phase water vapor is condensed into liquid by the tower top condenser, and part of it is refluxed into the reactor. The non-condensable components are sent to the tail gas device for treatment, and a little water is sent to the sewage treatment device.

[0047] Adjust the flow rate of superheated steam, and control the liquid phase temperature at the bottom of the tower to 215°C;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com