Method for recovering chemicals and by-products from high-sulphidity pulping liquors

一种硫化度、化学品的技术,应用在从高硫化度制浆液回收化学品和副产物领域,能够解决成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

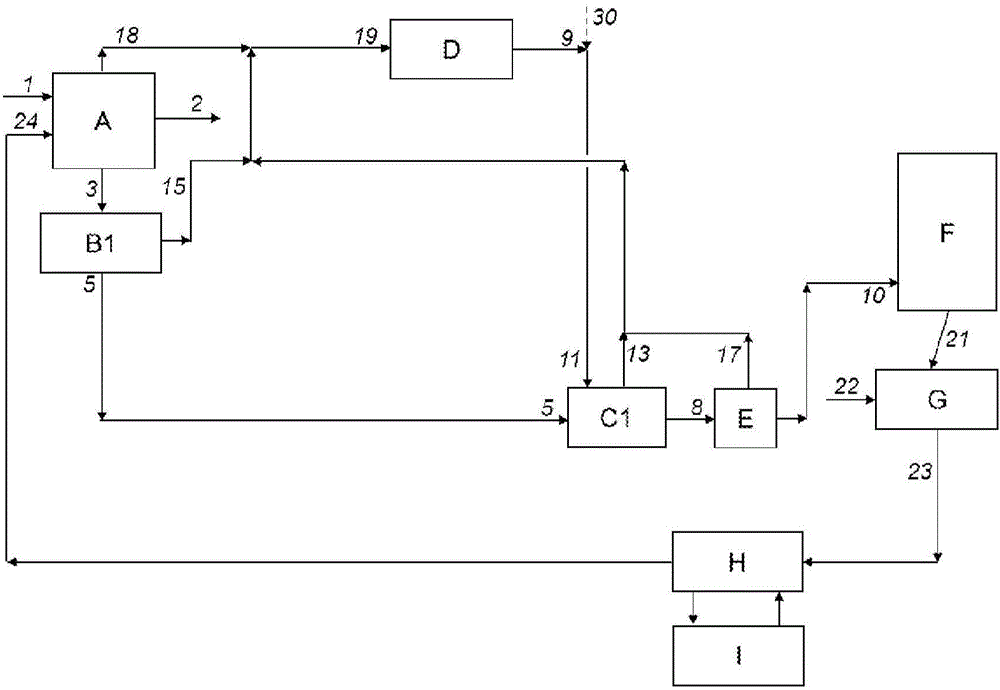

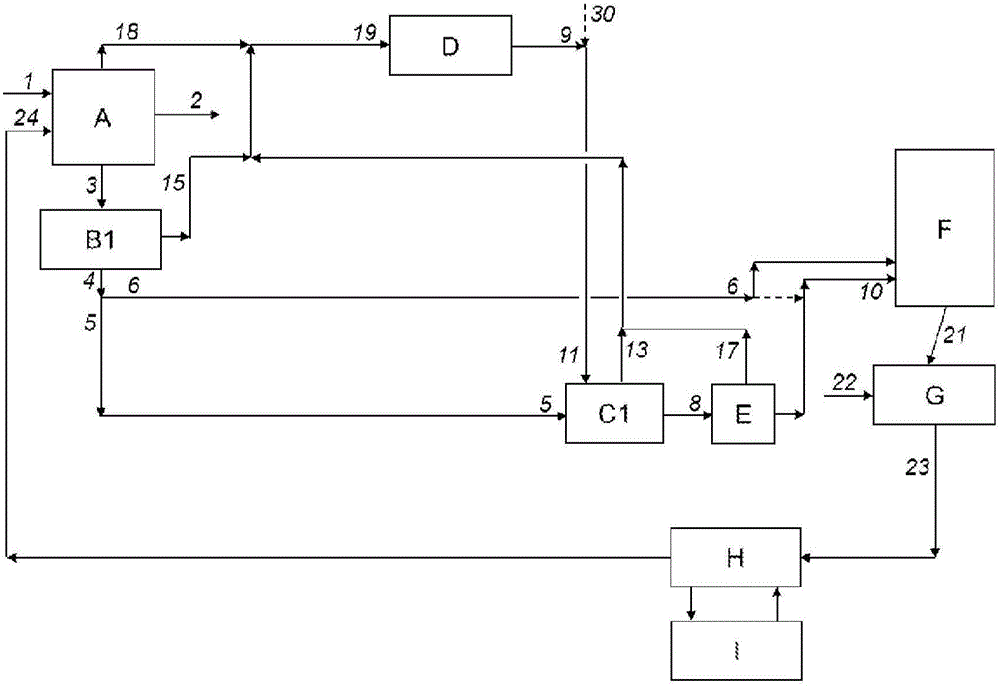

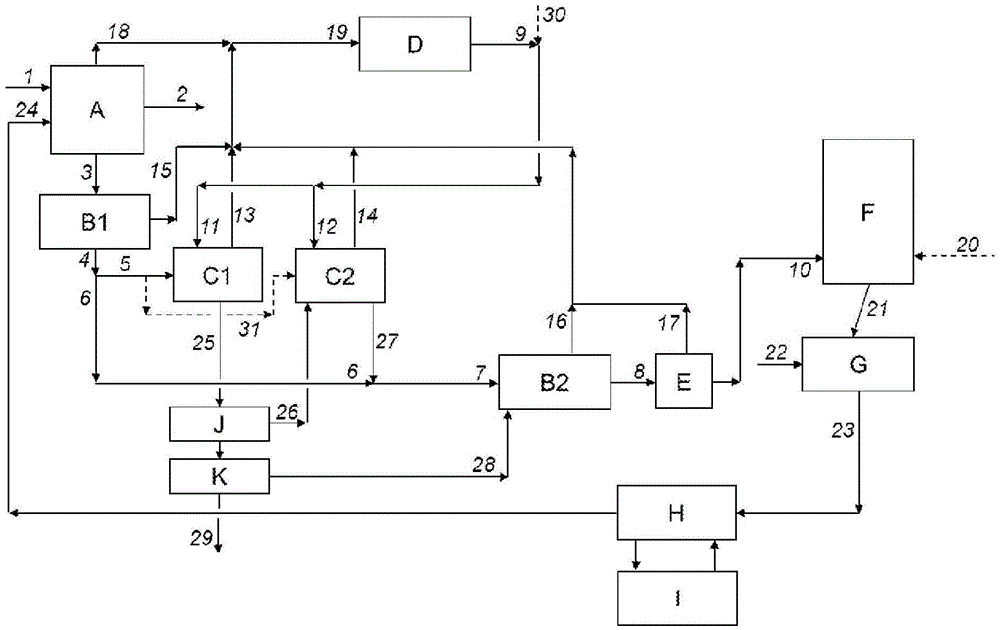

Image

Examples

Embodiment

[0109]EXAMPLE AND WITH NEW PROCESS The mass flow rates of the major components in the various liquid streams of the recovery procedure are provided in Tables 1-5 below. The example recovery procedure does not incorporate removal of by-products or non-process elements and acidification of spent pulping liquor. The acidification procedure is applied to the entire effluent stream. Where applicable, compare flow rates to those referenced to conventional kraft recovery procedures. In the case of the new method, the pulping of softwood was carried out at 80% degree of sulfidation and 17.5% EA (effective alkali as NaOH on wood), while in the reference procedure it was carried out at 35% degree of sulfide and 19.5% EA pulping. Other key assumptions are: (1) Na 2 S is fully hydrolyzed in the pulping liquor, ie sulfides are completely converted to hydrosulfides according to reaction 2, (2) reduction efficiency in the recovery furnace is 95%, and (3) causticity is 85%. Mass flow unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com