Chemical recovery method for mortar in wire cutting technology

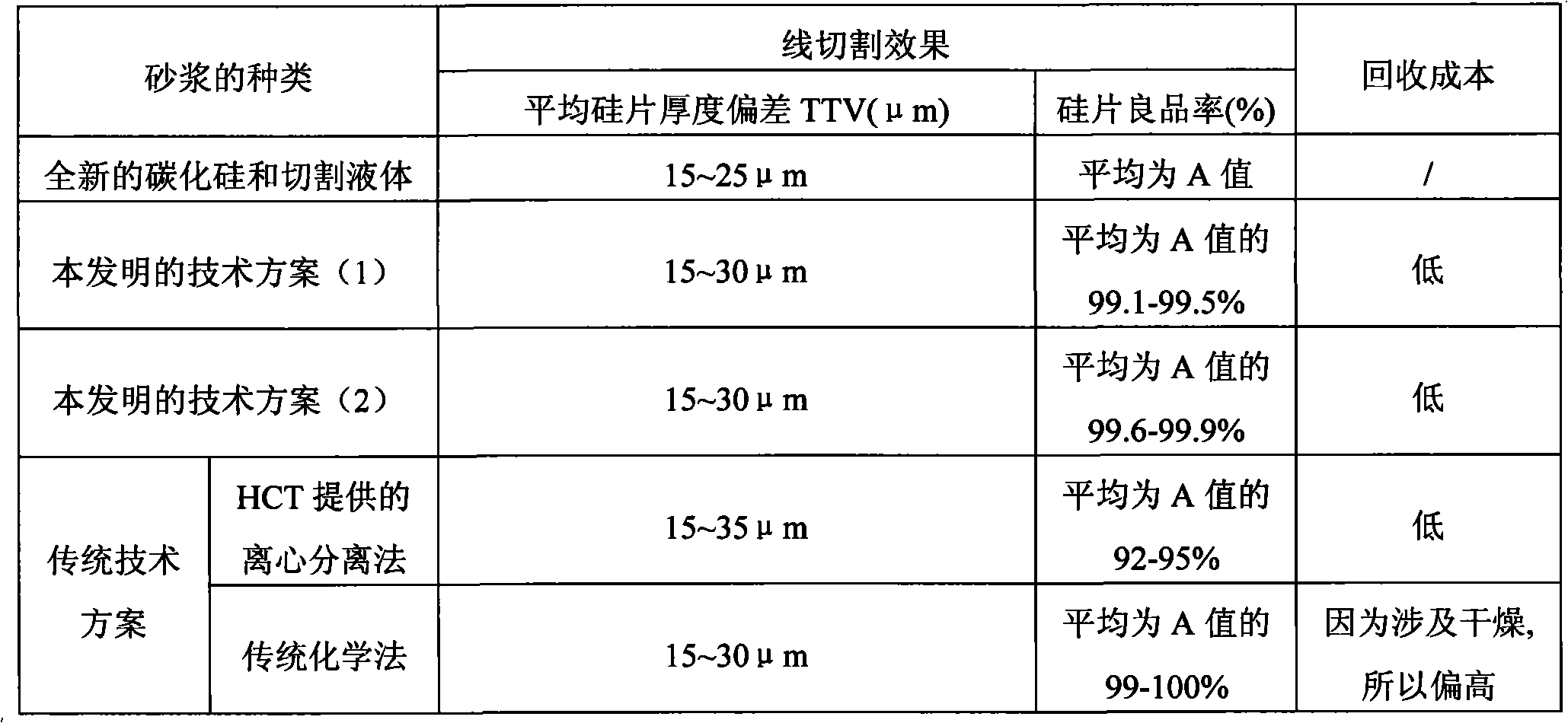

A technology of chemical recycling and wire cutting, applied in the direction of working accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of silicon wafer surface quality degradation, high scrap rate, poor uniform dispersion, etc., to reduce chemical recycling costs and save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, a chemical recovery method for mortar in a wire cutting process, its operation steps are: (1) the mixed mortar containing cutting fluid A, silicon powder, metal shavings, and silicon carbide abrasive after wire cutting is used is solidified Liquid separation to obtain liquid part B and solid part C; (2) using chemical treatment to remove silicon powder and metal filings in solid part C to obtain solid part D rich in silicon carbide abrasives; wherein: (3) will be rich in carbide The solid part D of the silicon abrasive is directly stirred with the cutting fluid E to obtain the mixture G and then used for wire cutting; the cutting fluid E is a mixture of the liquid part B and the new cutting fluid F.

Embodiment 2

[0051] Embodiment 2, a chemical recovery method for mortar in a wire cutting process, its operation steps are: (1) the mixed mortar containing cutting fluid A, silicon powder, metal shavings, and silicon carbide abrasive after wire cutting is used is solidified Liquid separation obtains liquid part B and solid part C; (2) adopts chemical treatment to remove silicon powder and metal shavings in solid part C to obtain solid part D rich in silicon carbide abrasives; The solid portion D is separated again to obtain the solid portion D1 of the coarse-grained silicon carbide abrasive and the solid portion D2 of the fine-grained silicon carbide abrasive; wherein: (3) the coarse-grained solid of the silicon carbide abrasive is enriched Part D1 is directly stirred with the cutting fluid E to obtain the mixture G and then used for wire cutting; the cutting fluid E is the liquid part B after removing appropriate moisture after heating.

Embodiment 3

[0052] Embodiment 3, a chemical recovery method of mortar in wire cutting process, the cutting fluid E used is the liquid part B after removing appropriate moisture after heating. The water content in the cutting fluid E can be controlled at 0.01% by weight, or any one of 0.1%, 0.2%, 1%, 2%, 3%, 4%, and 5%. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com