Method and system for cleaning of and heat recovery from hot gases

a technology of hot gas and heat recovery, which is applied in the direction of electrical equipment, electrochemical generators, lighting and heating equipment, etc., can solve the problems of cyclones and scrubbers being less effective, thermal reactors having restrictions on the type of fuel to be used, and waste of heat energy of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]The present invention provides inter alia an improved method and an improved system or installation for thermal conversion of solid fuels into energy, hereof at least part of the energy as hot water.

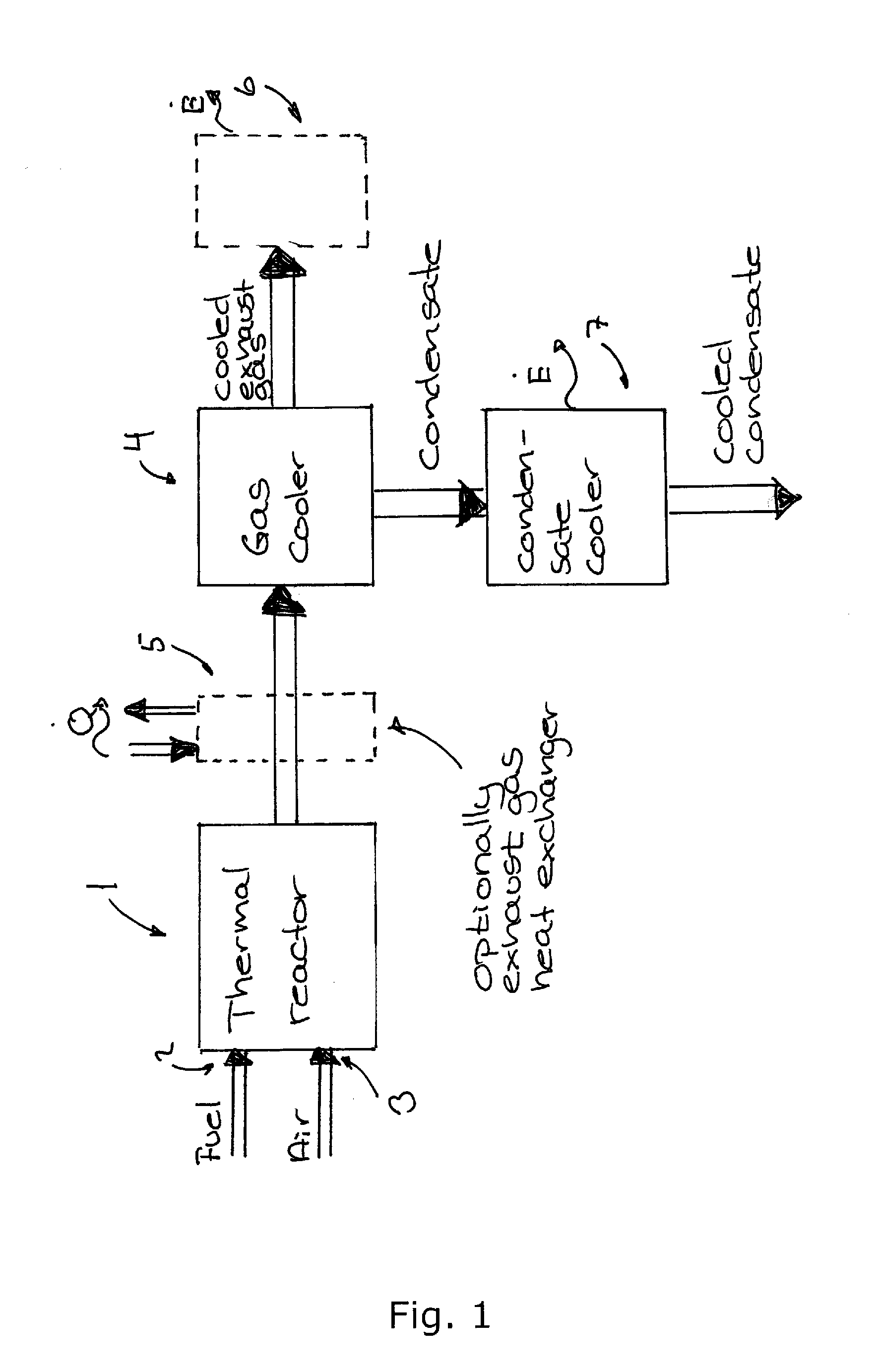

[0083]In a first aspect the present invention relates to a thermal plant comprising[0084]a thermal reactor in which a chemical process takes place during which process solid fuels reacts with oxygen to produce an exhaust gas comprising hot flue gas and / or a burnable gas[0085]a gas cooler cooling the exhaust gas to a temperature below the dew point of the water present in the exhaust gas thereby producing a condensate;[0086]a condensate cooler cooling the condensate to extract energy from the condensate.

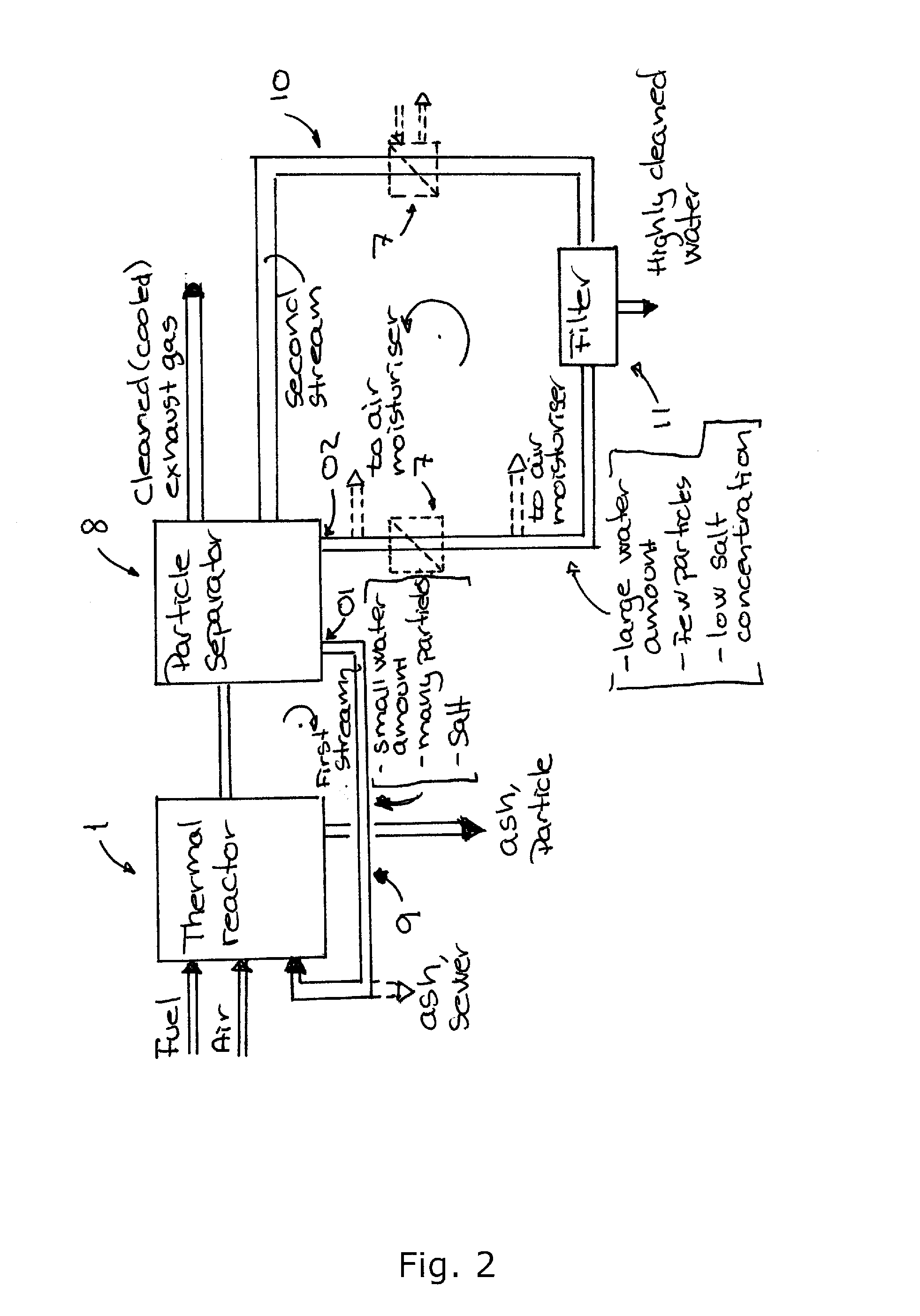

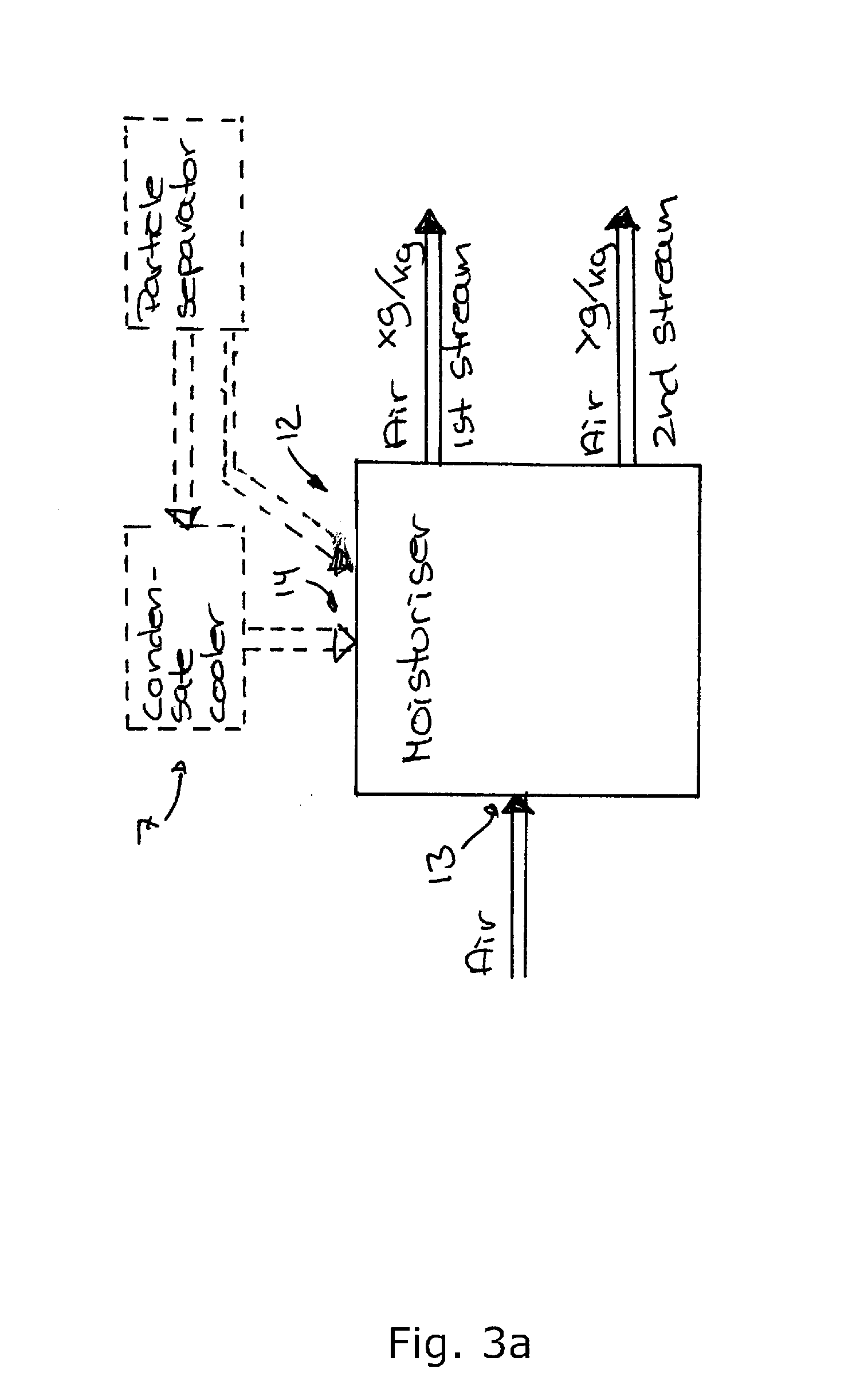

[0087]The present invention further relates inter alia to a particle separation system of a a thermal plant according to the invention into which particle separator a stream of fluid (gas and / or liquid) which contain particles enters and where at least two streams of water are produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com