Patents

Literature

120results about "Flue gas purification components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

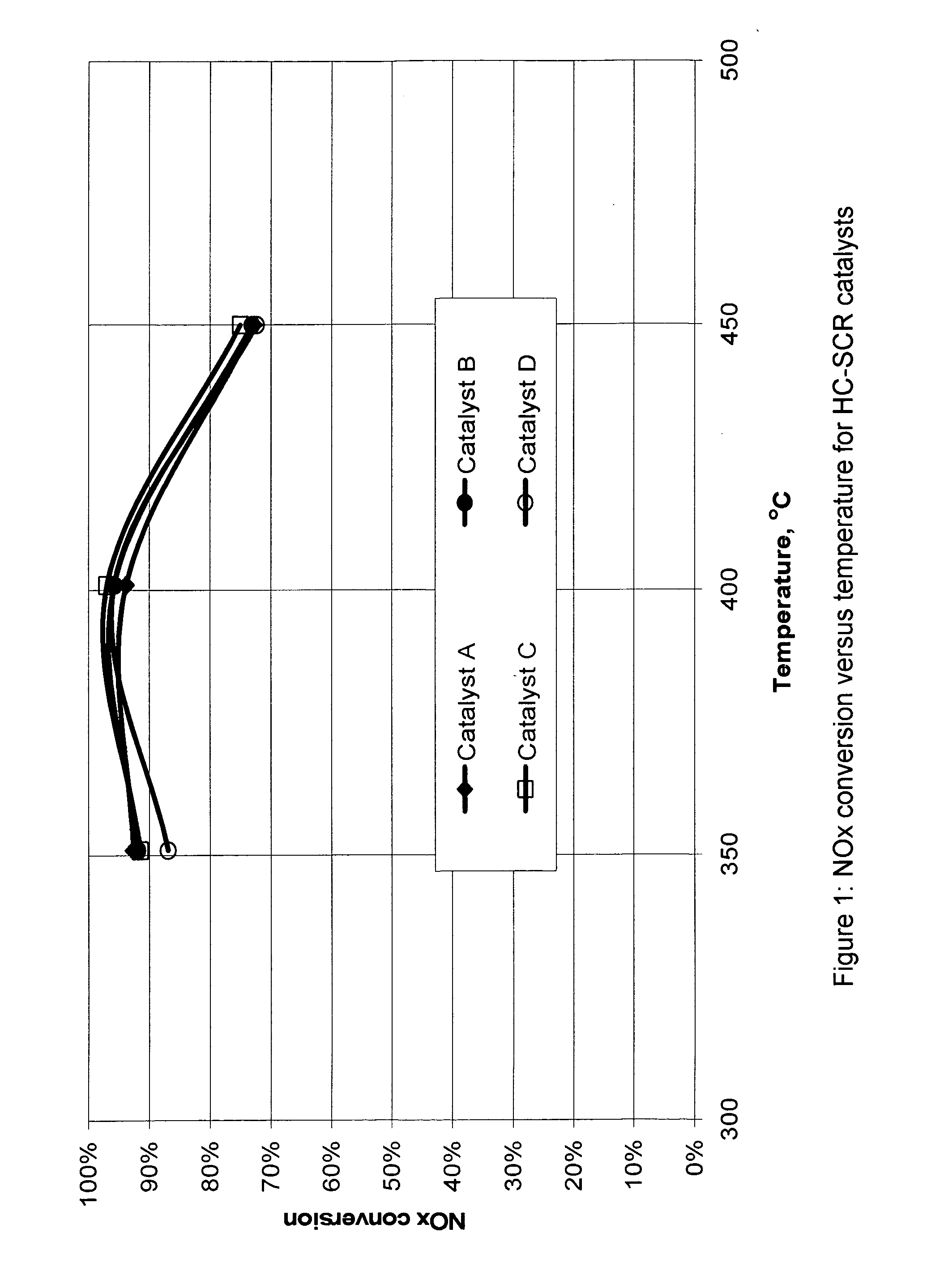

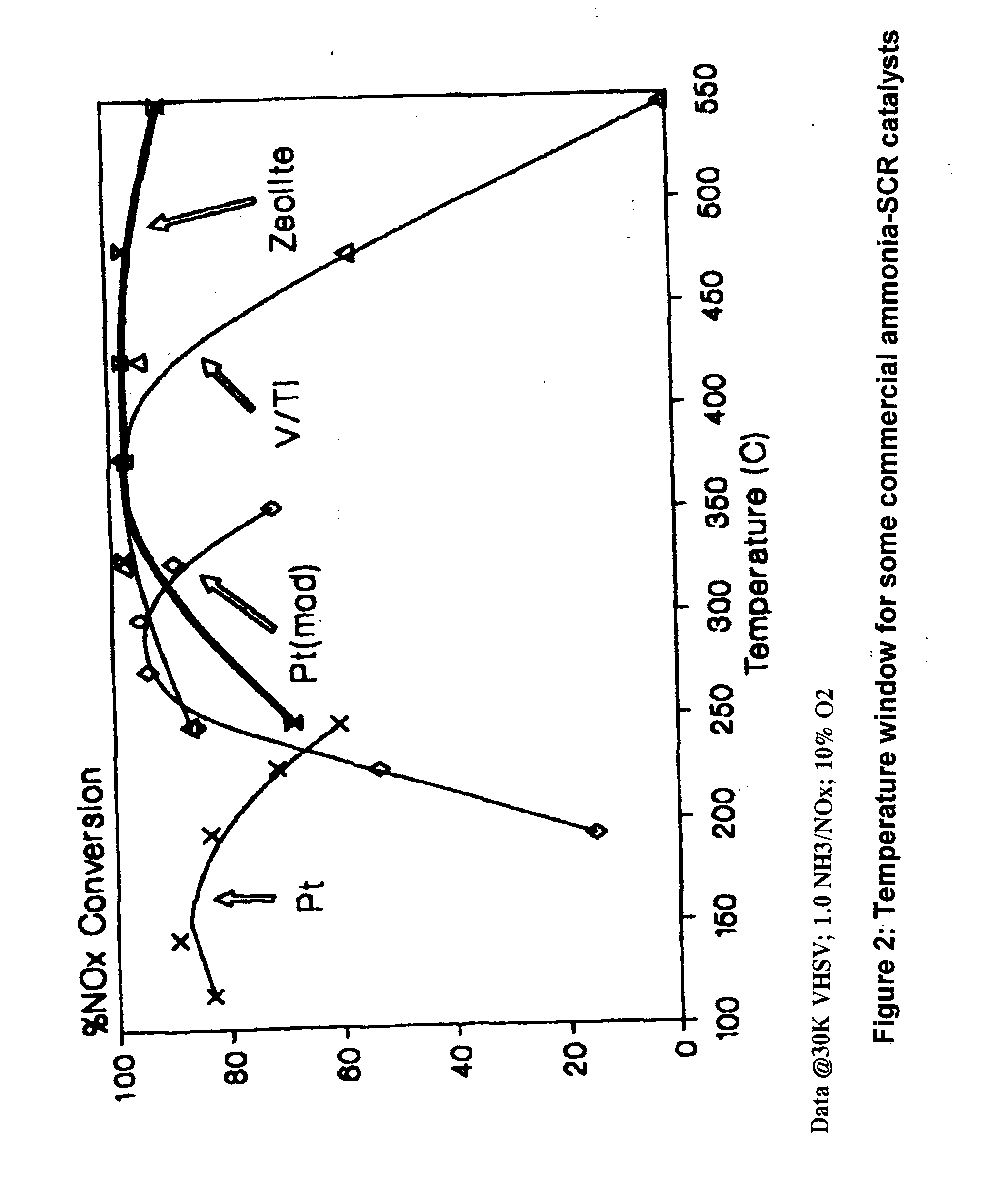

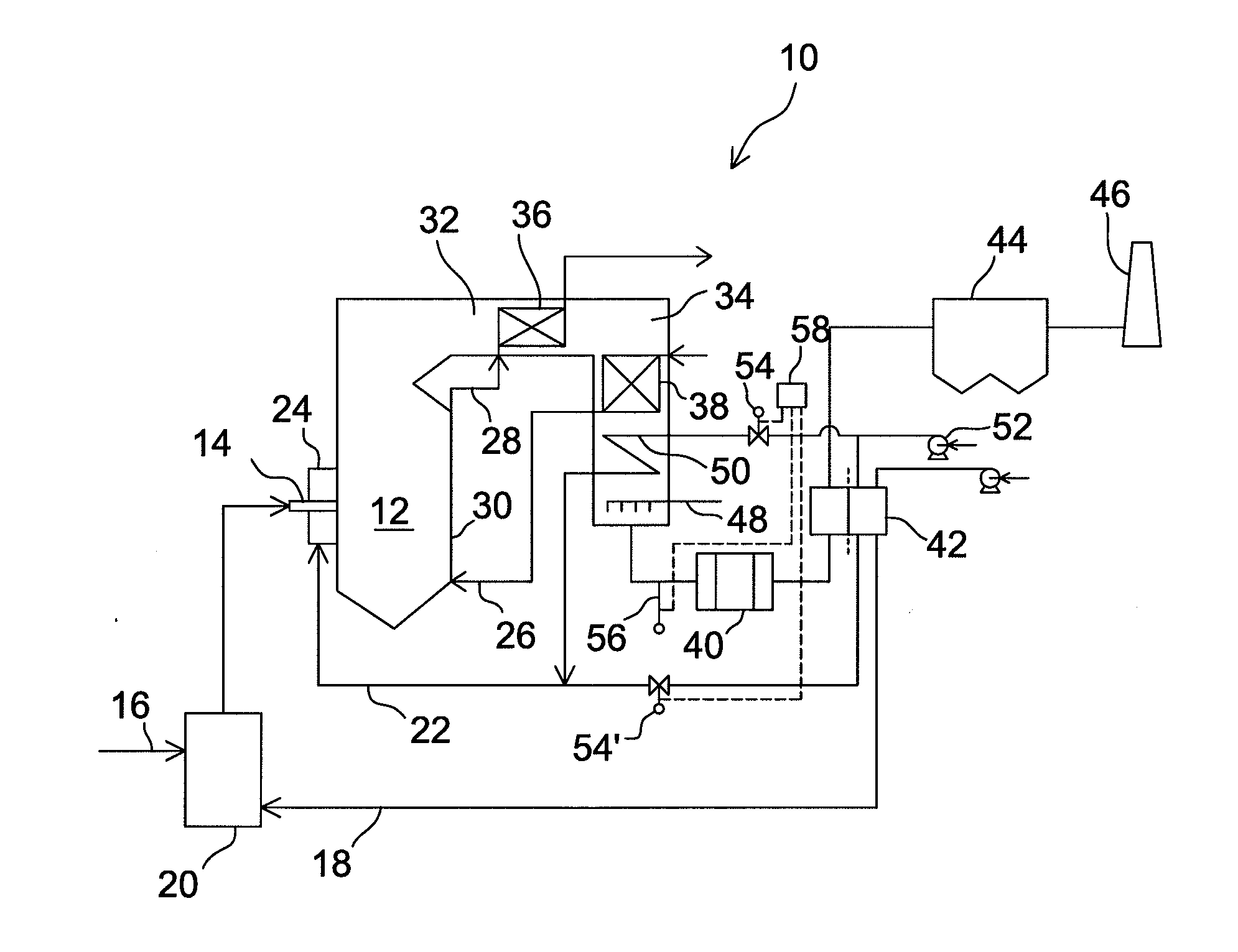

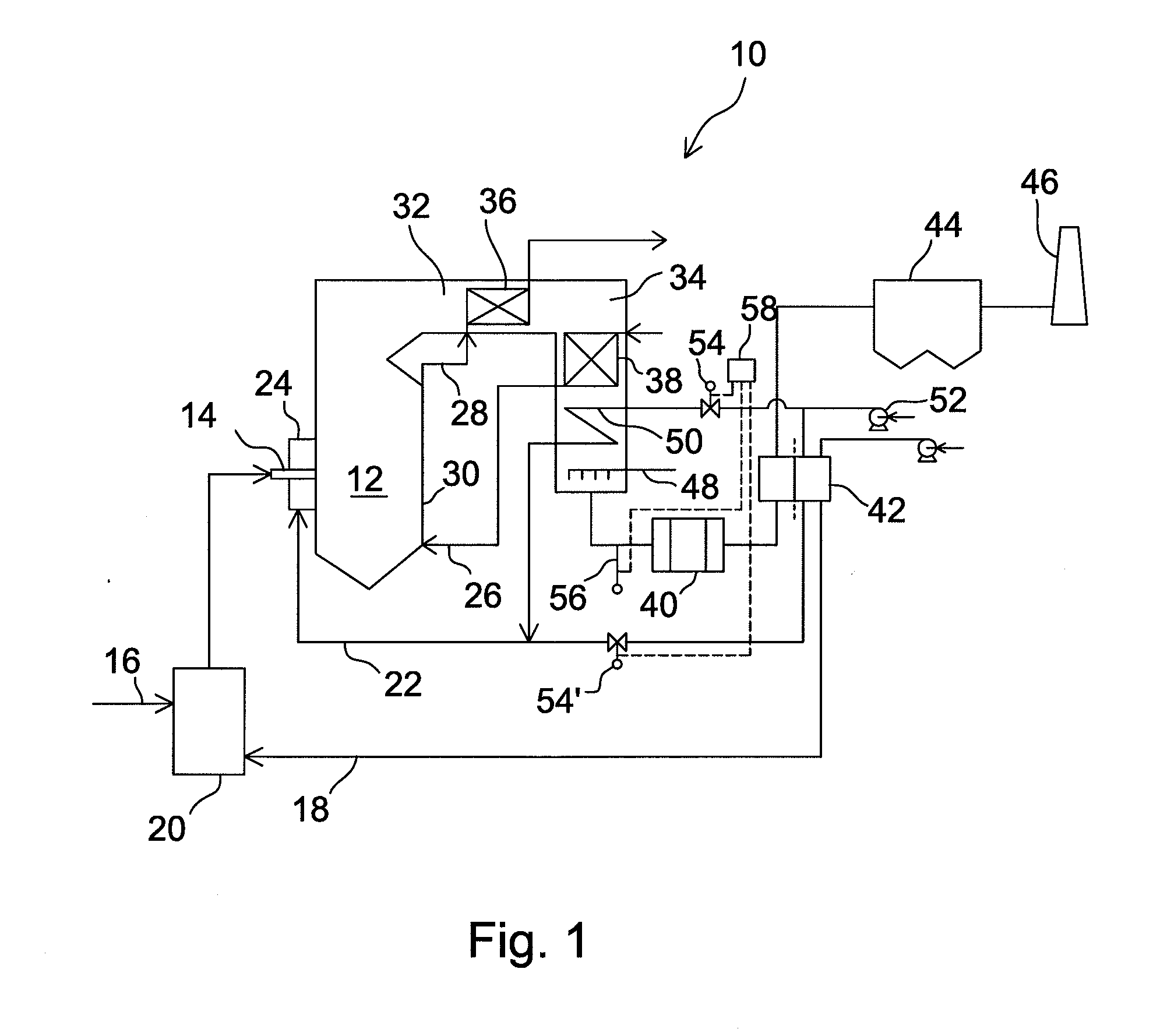

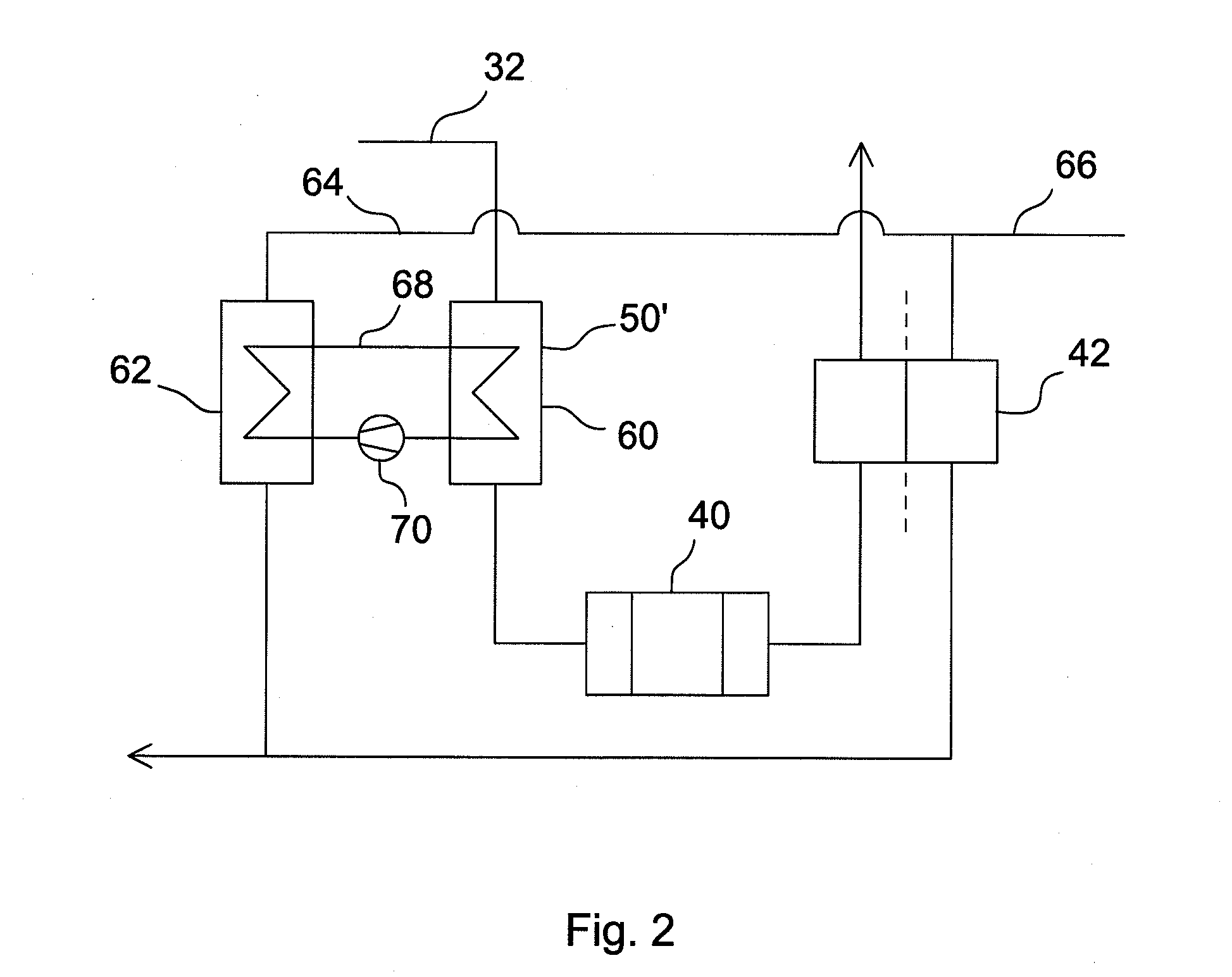

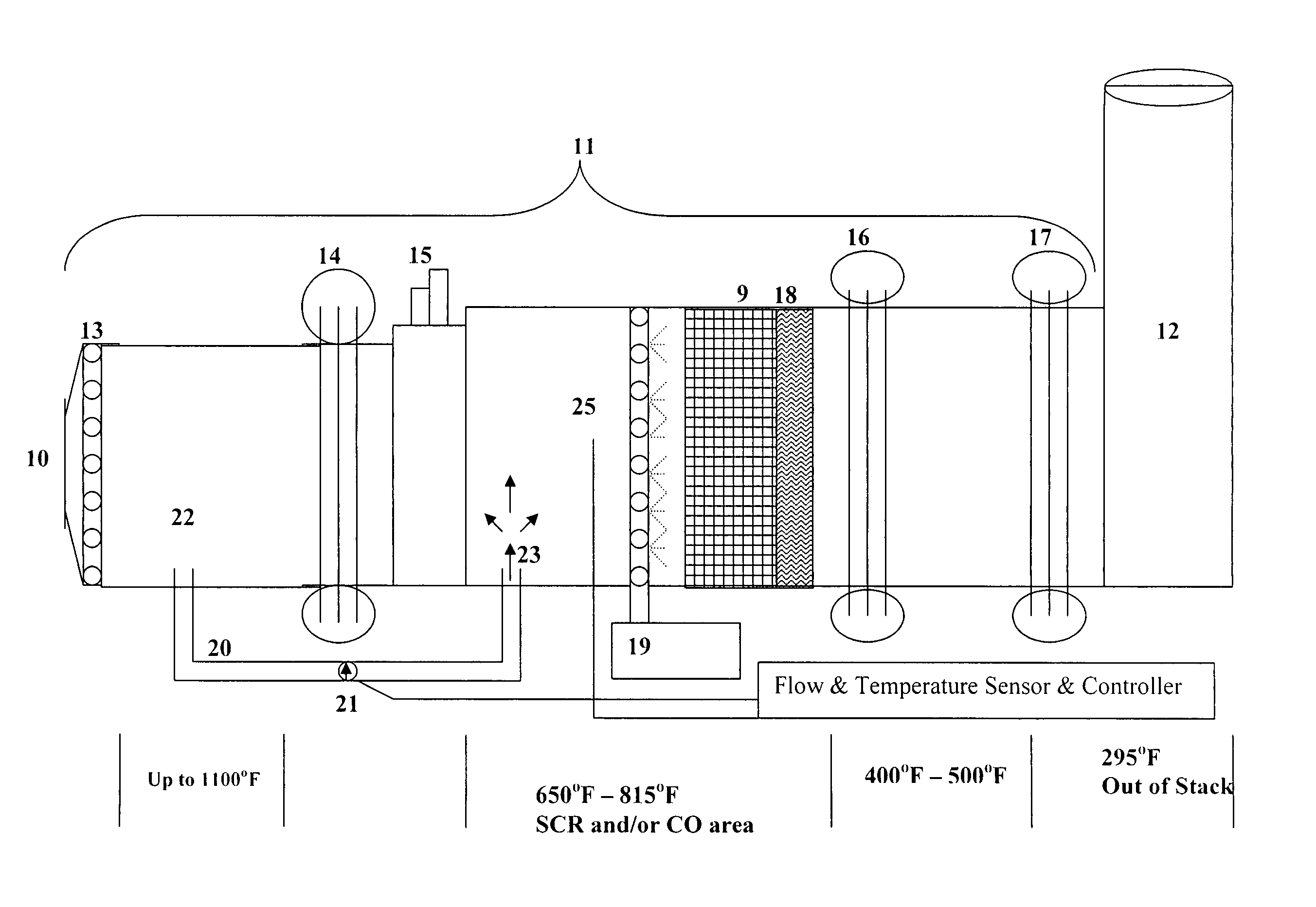

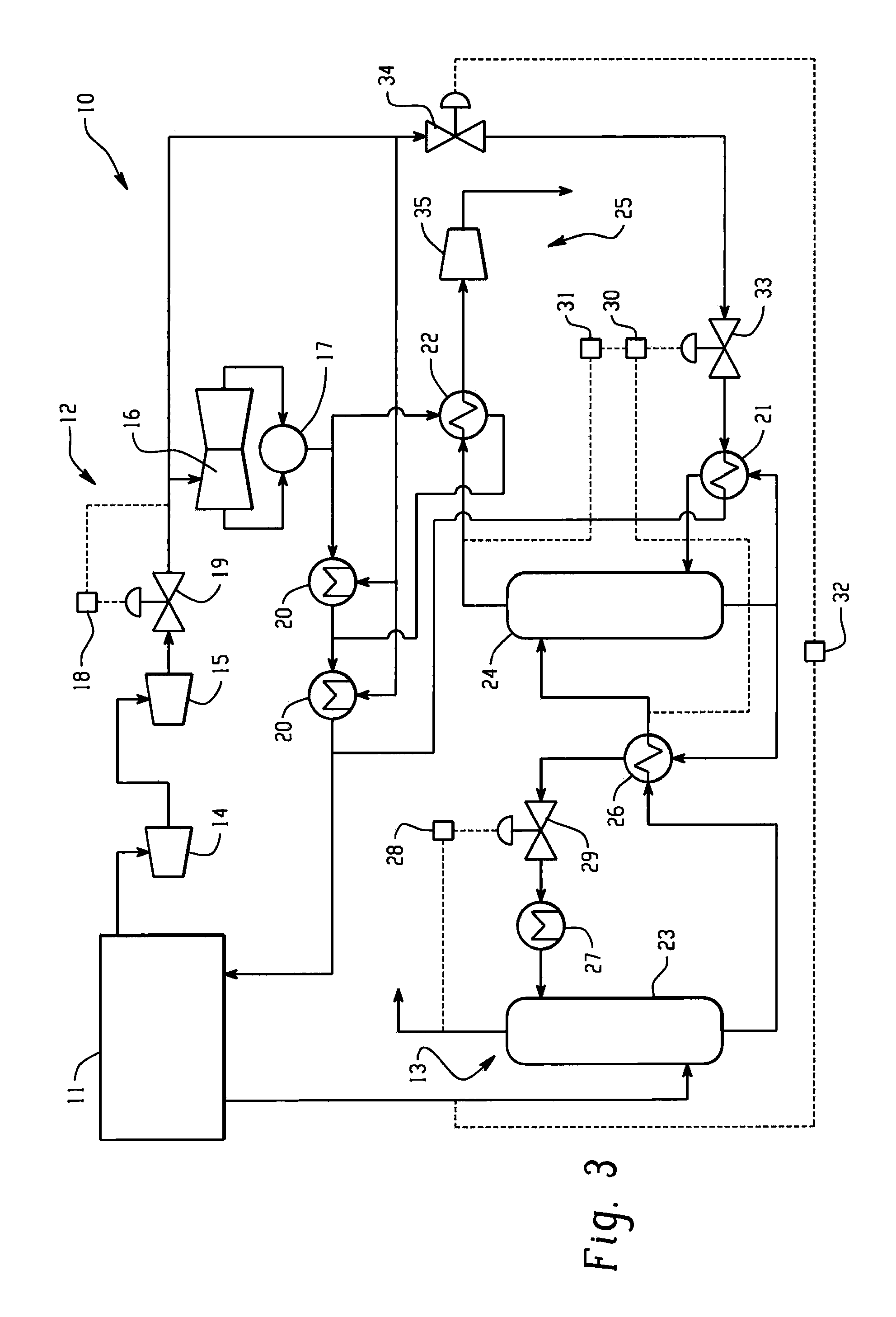

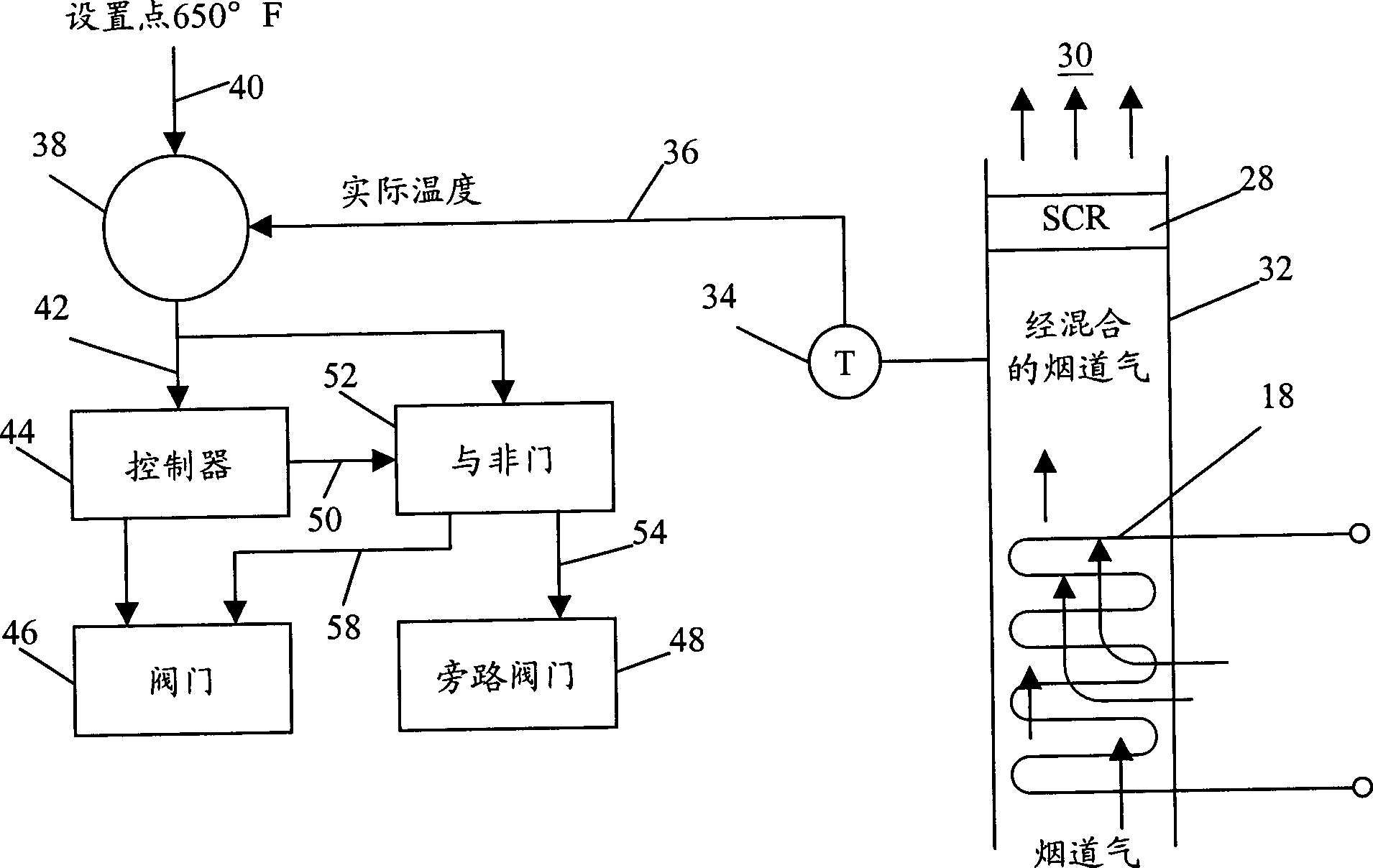

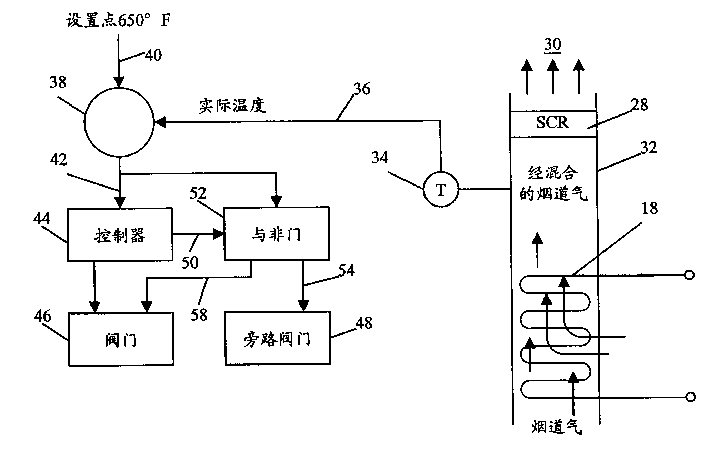

Emission reduction system for use with a heat recovery steam generation system

InactiveUS20090282803A1Quantity minimizationSmall sizeSteam generation heating methodsExhaust apparatusCombustorExhaust fumes

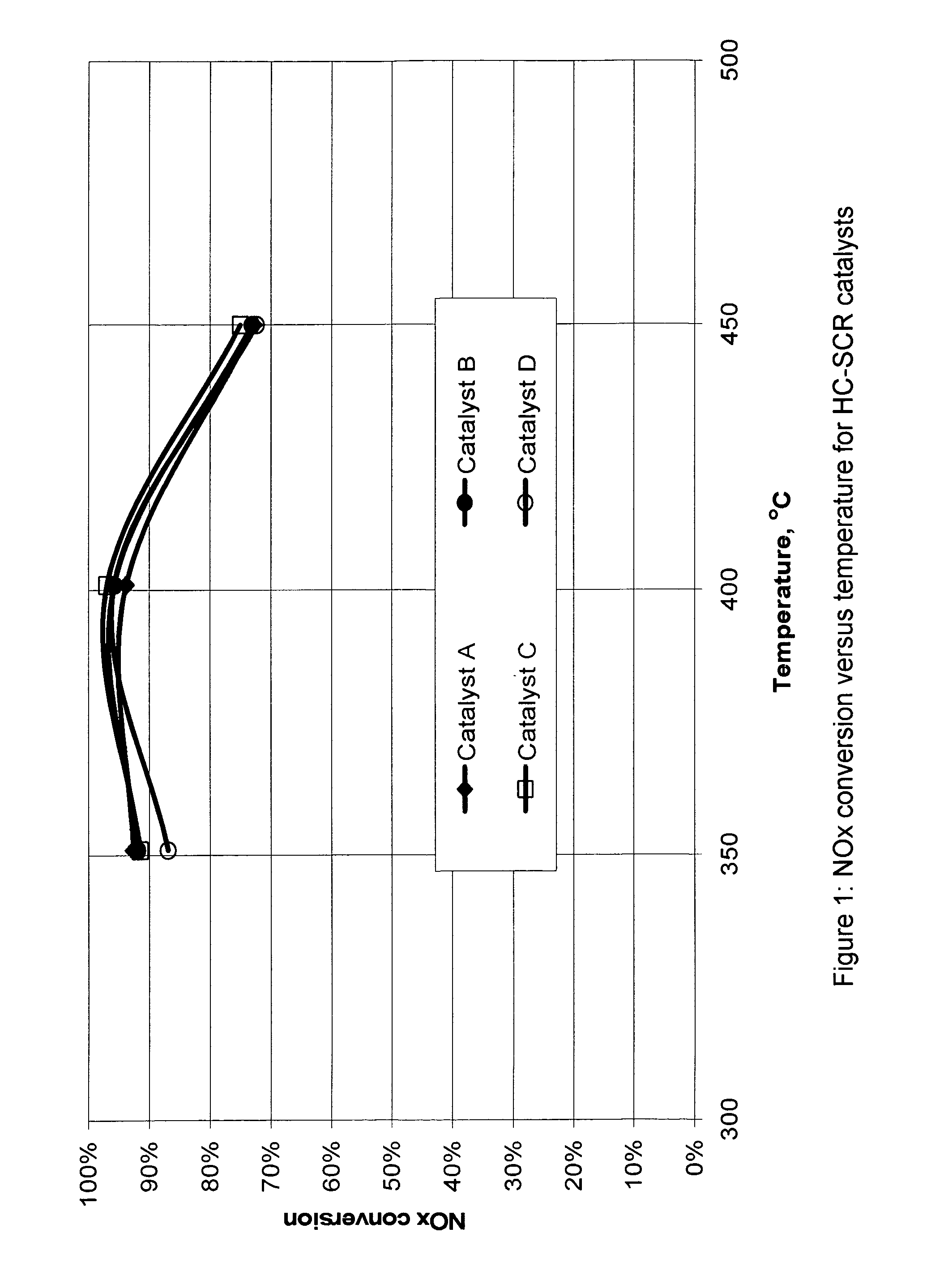

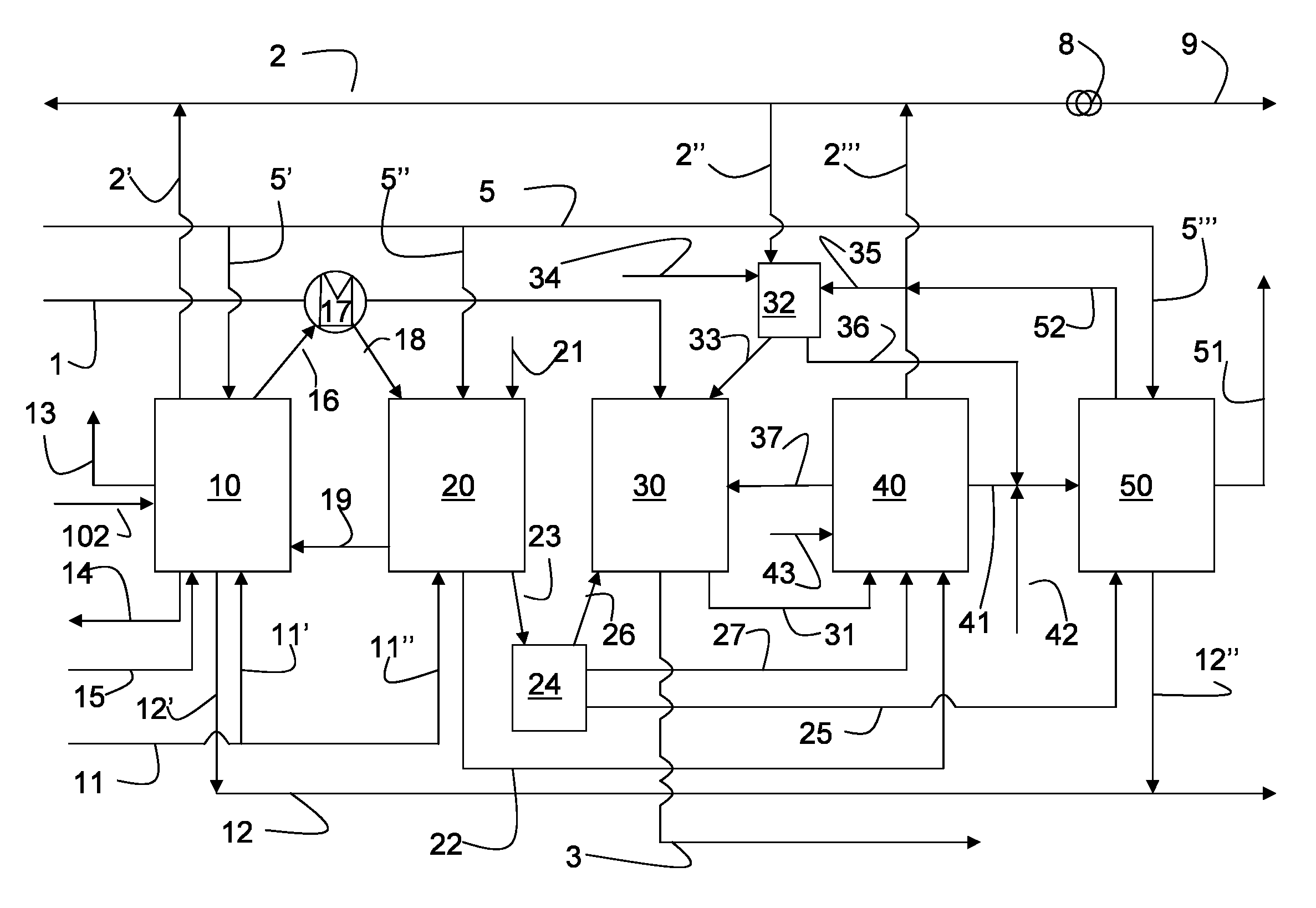

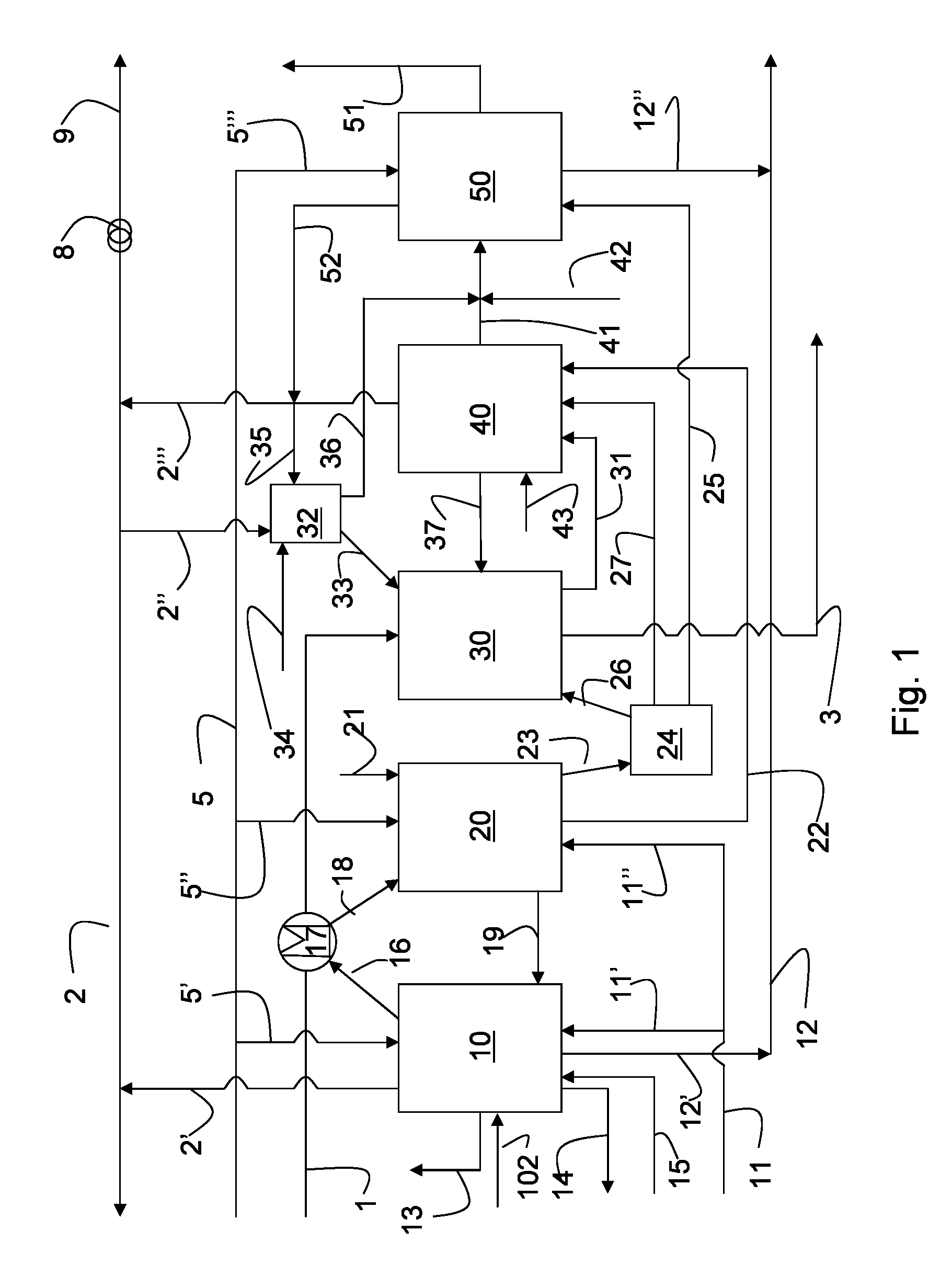

A system and method of maintaining an optimal temperature range for a catalyst section in a HRSG comprising placing a portion of the exhaust stream in a heat exchanger and superheater, diverting a second portion around the heat exchanger and superheater, combining the two portions and contacting the two portions with a catalyst section. Alternatively, a system of heat exchangers are employed to address the fluctuating exhaust temperature caused by the intermittent use of the duct burners.

Owner:JOHNSON MATTHEY INC

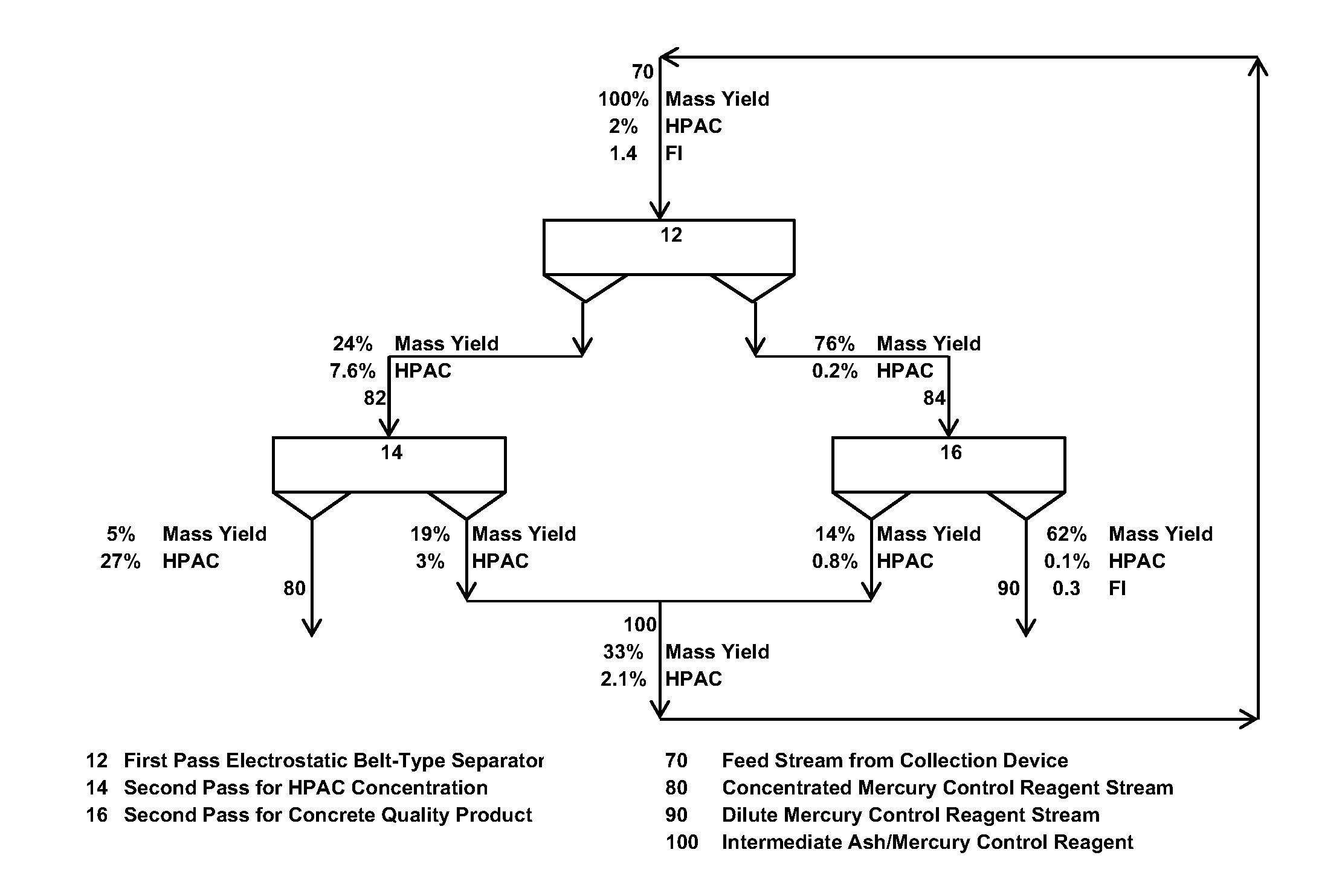

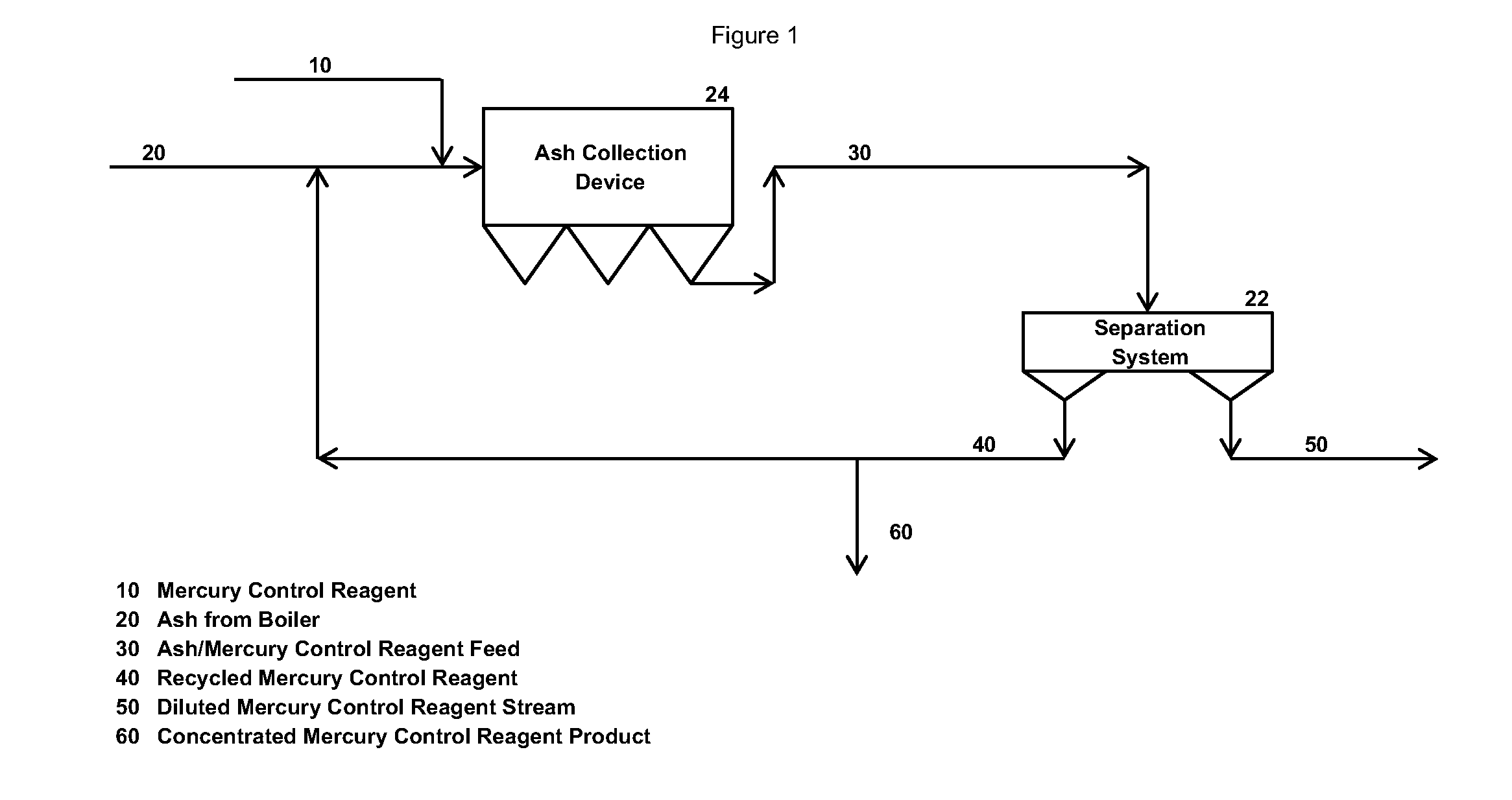

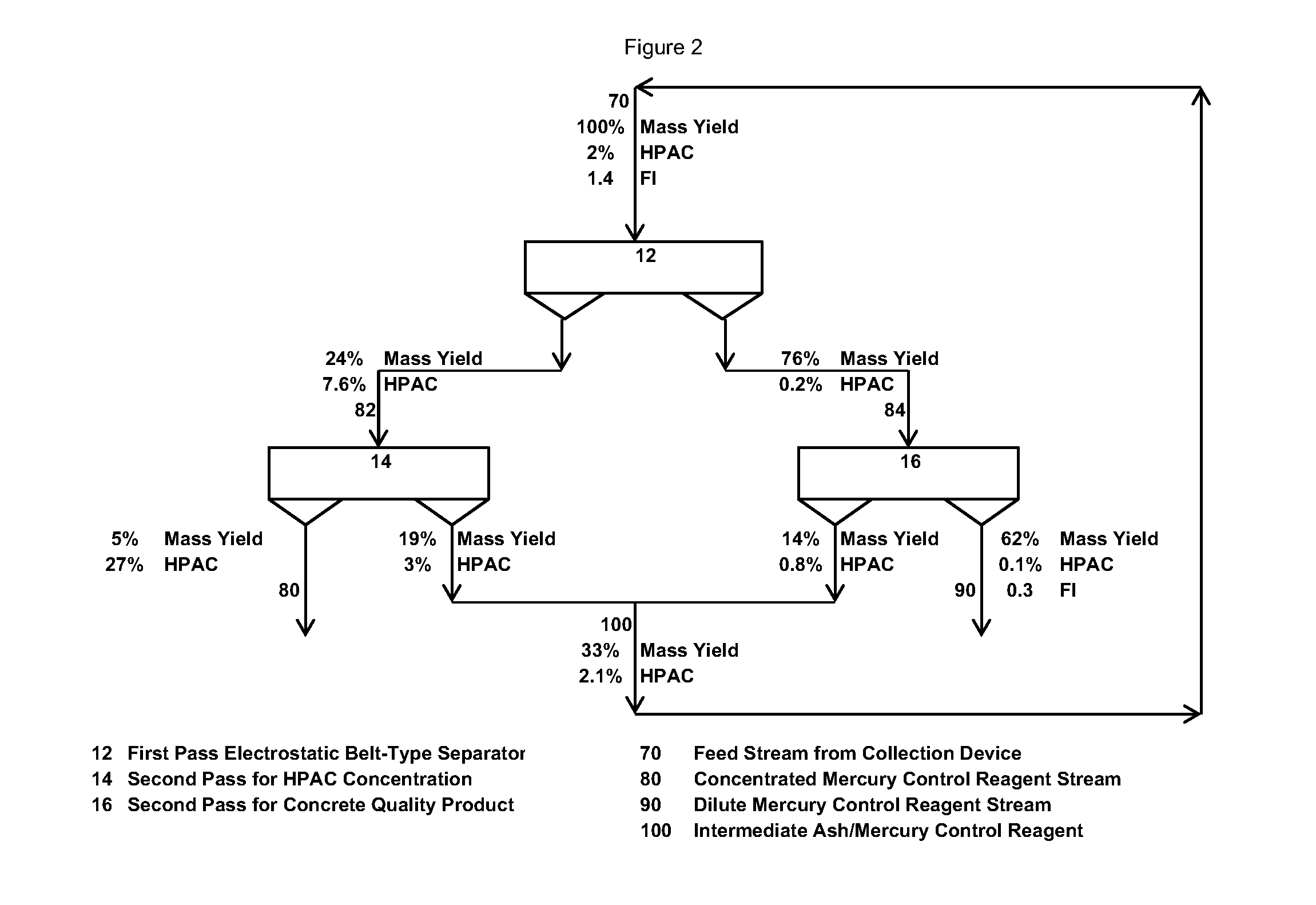

Recovery of mercury control reagents by tribo-electric separation

InactiveUS20110289923A1Reduce the amount requiredImprove recycling efficiencyGas treatmentElectrostatic separationParticulatesElectricity

A method and apparatus for recovering mercury control reagents from particulate materials is disclosed. The particulate materials include fly ash mixed with mercury control reagents collected from boiler flue gases. The particulate materials are provided to an electrostatic separation system, which is operated under predetermined conditions so as to produce a concentrated stream of the mercury control reagent and a diluted stream containing minimal mercury control reagent.

Owner:SEPARATIONS TECH

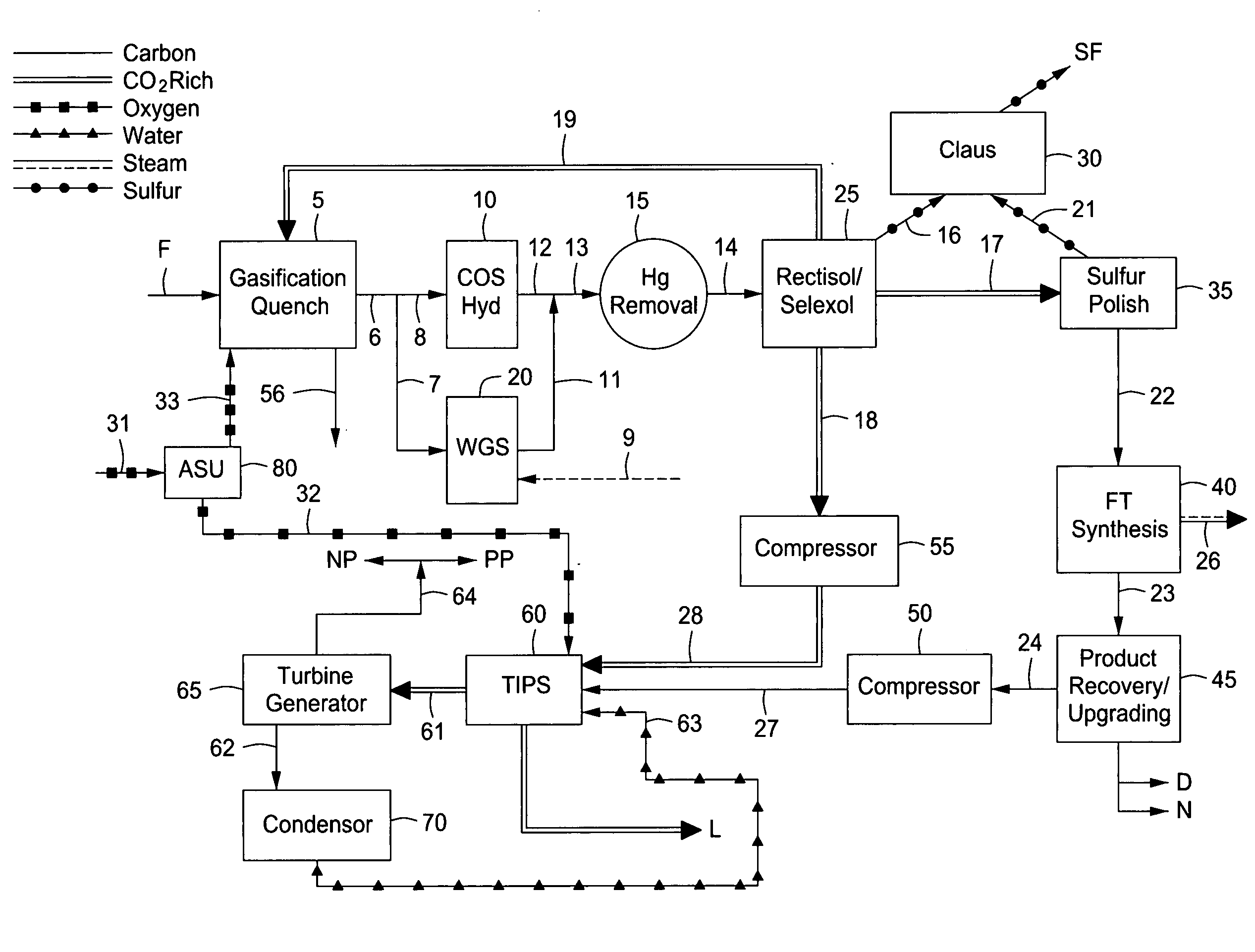

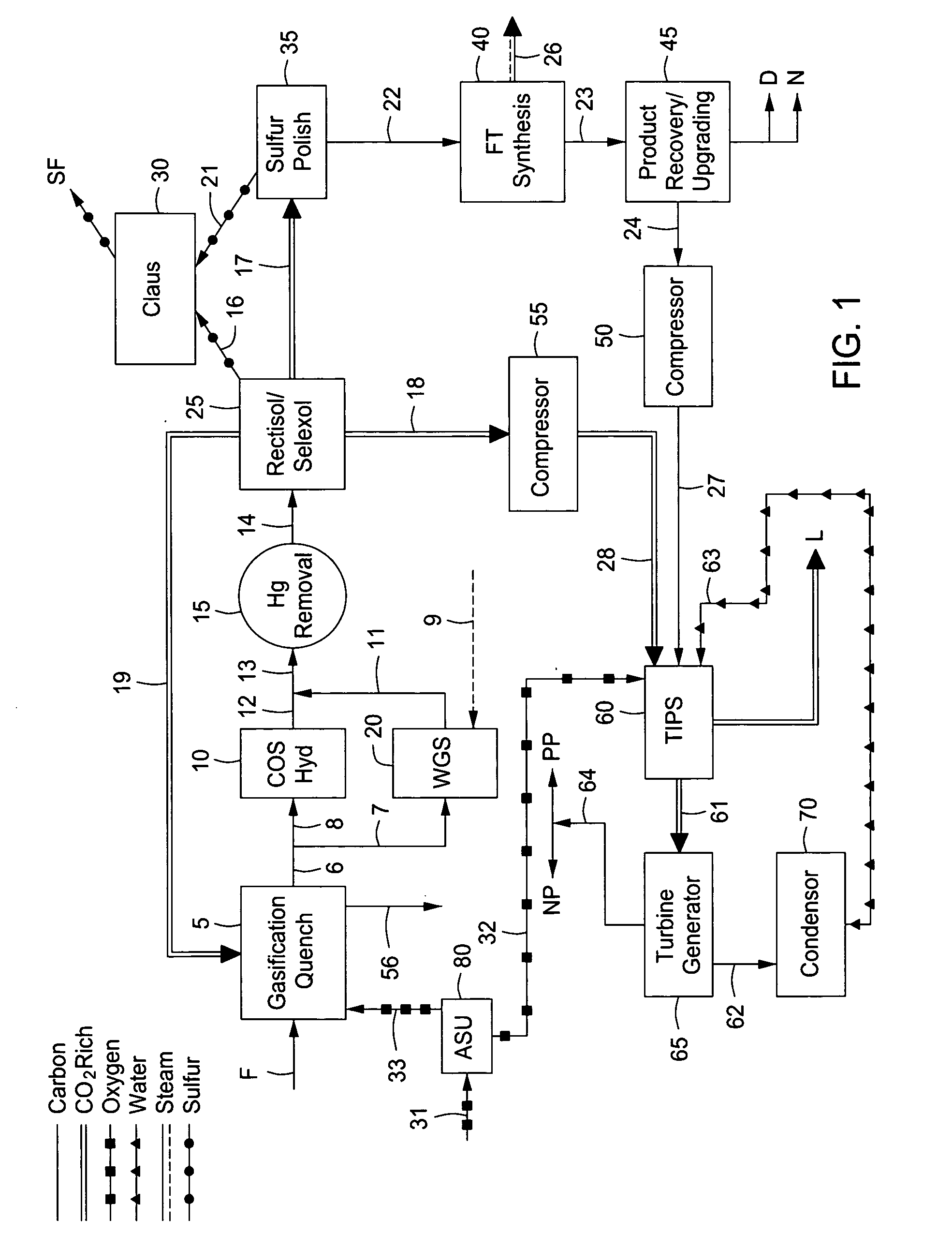

Carbon capture compliant polygeneration

InactiveUS20100018216A1Efficient and cost-effectiveReduce in quantityHydrogenGas turbine plantsLiquid fuelProcess engineering

Embodiments include a method and apparatus for producing liquid fuel from a carbon-containing feed fuel such as coal. With embodiments, coal or other carbon-containing feed fuel may be utilized to produce co-products, including one or more liquid fuels, power, and / or other useful co-products, while capturing carbon dioxide for further use, storage, and / or sequestration.

Owner:FASSBENDER ALEXANDER G

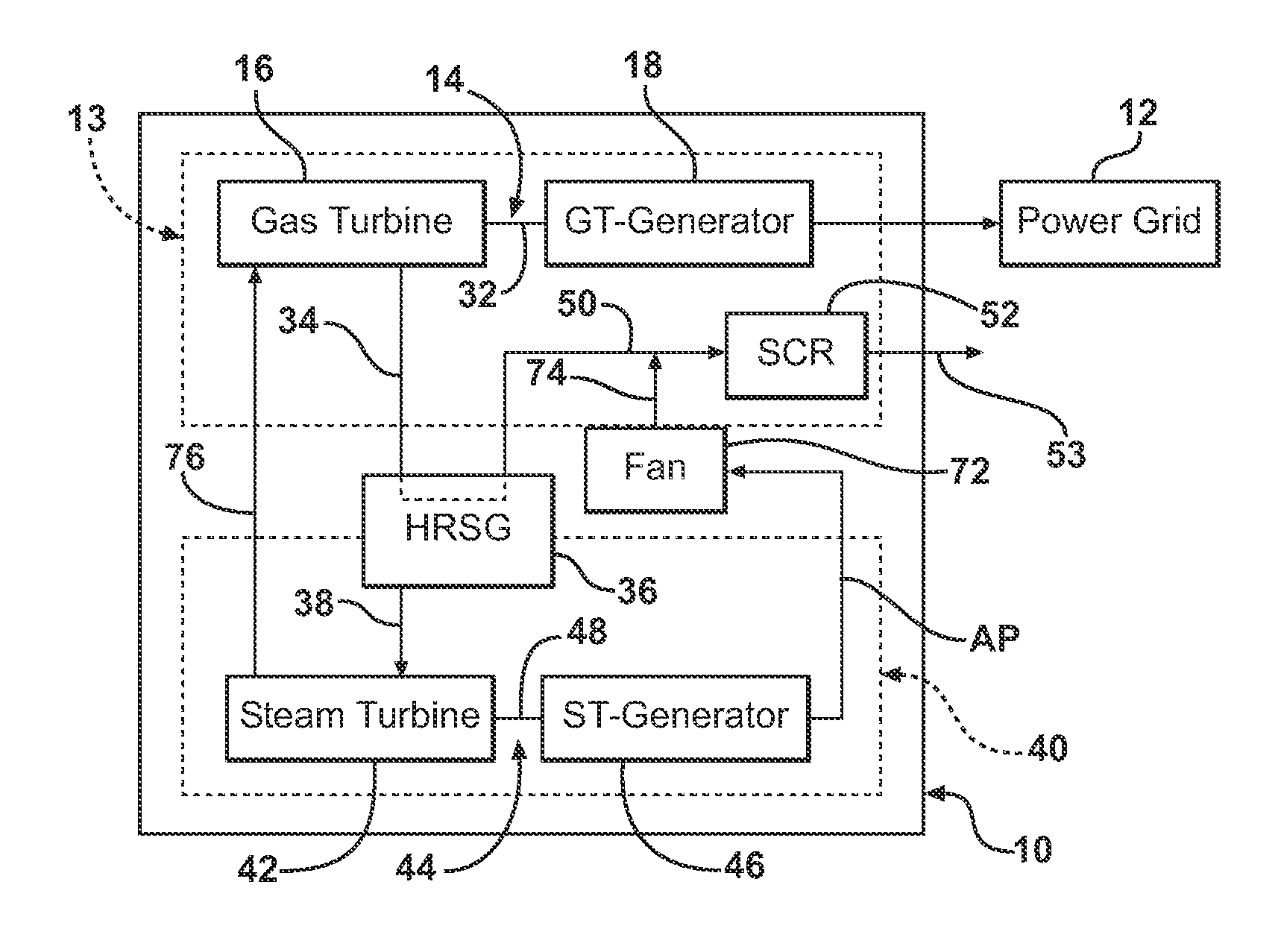

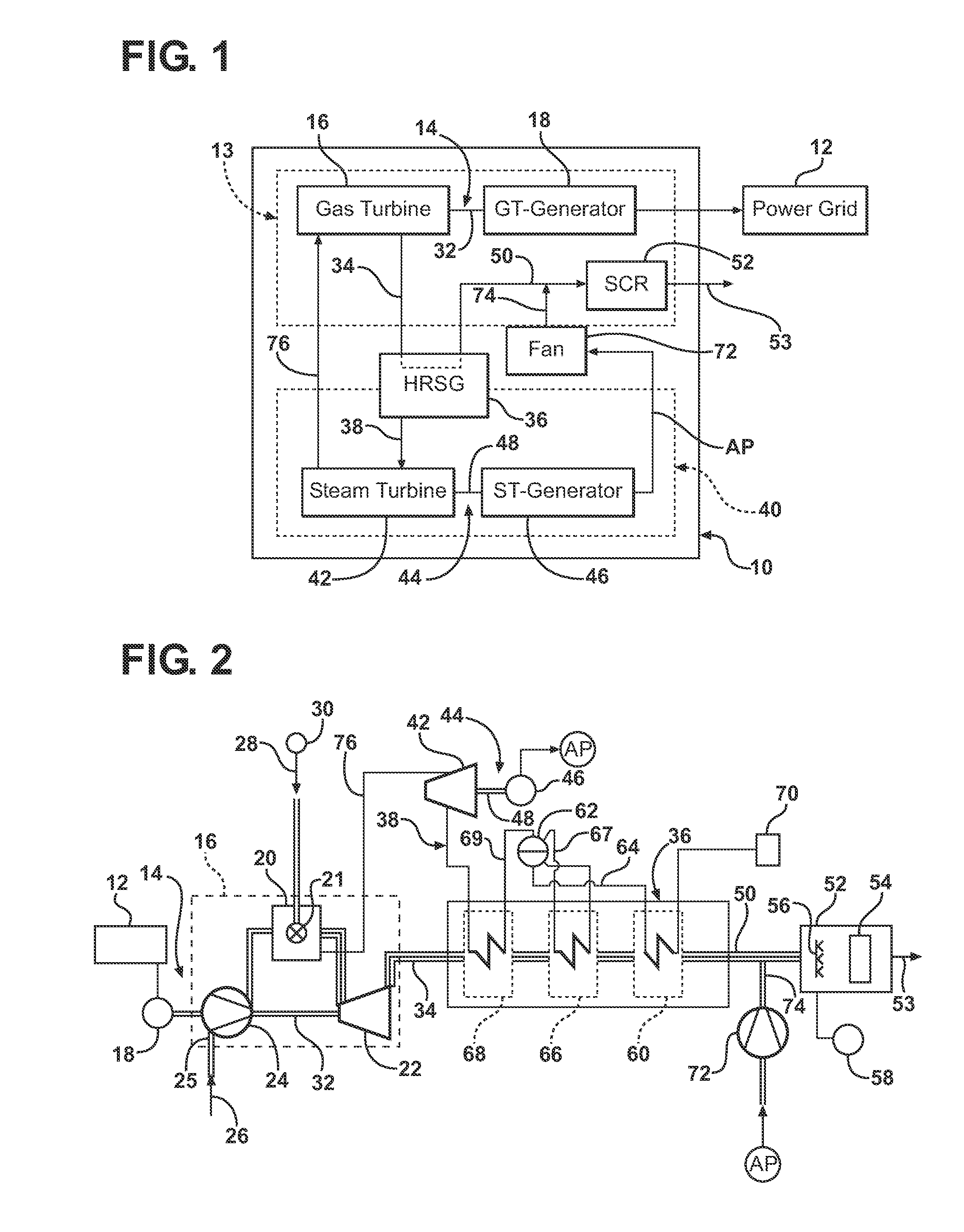

Method of Operating a Gas Turbine Power Plant with Auxiliary Power to Reduce Emissions

InactiveUS20110138771A1Emission reductionReduce the temperatureTurbine/propulsion fuel supply systemsExhaust apparatusPower stationEngineering

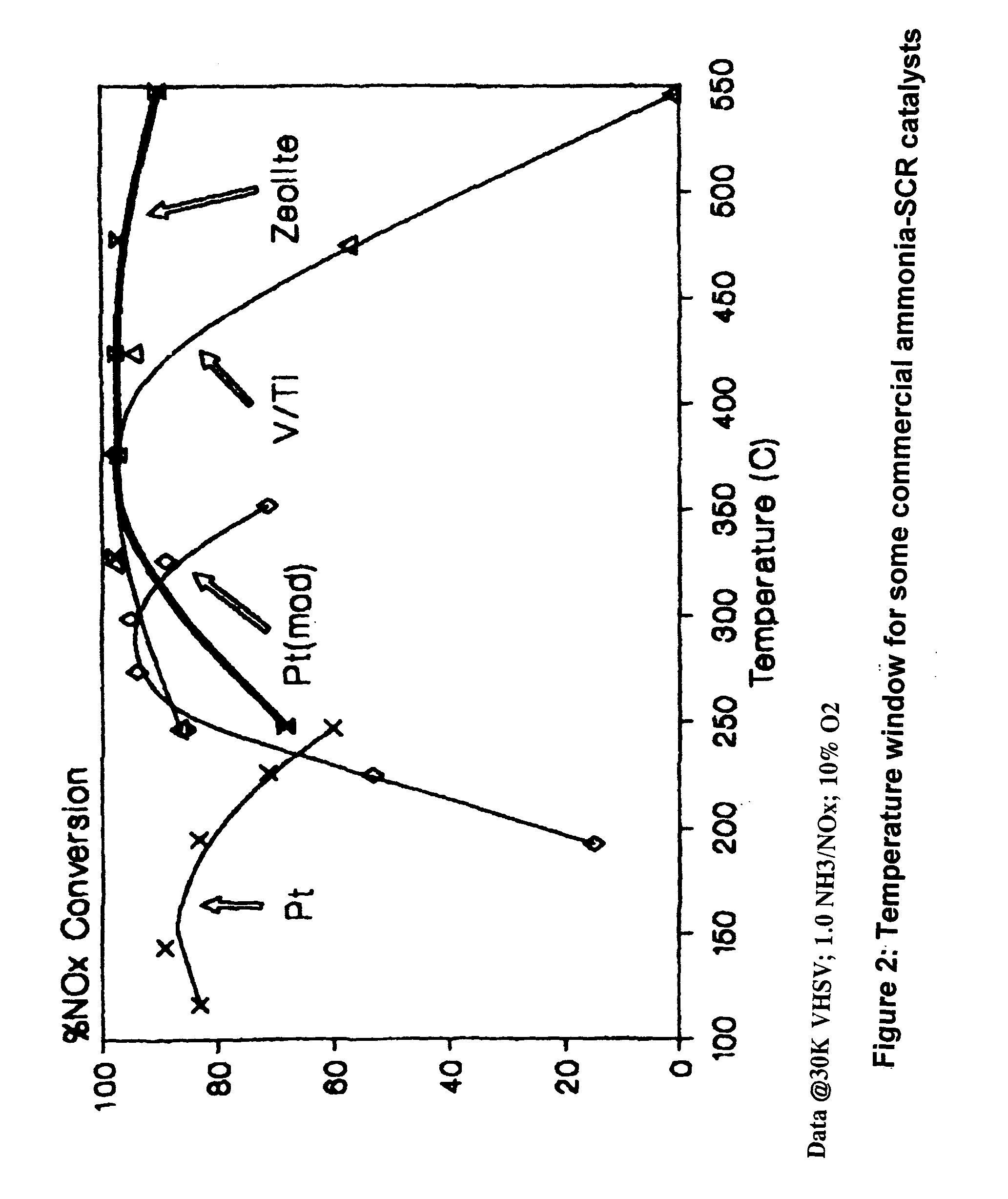

A method of operating a gas turbine power plant including an auxiliary power output for reducing power plant emissions. A heat recovery steam generator receives an expanded working medium from a gas turbine and removes heat from the expanded working medium to form a reduced temperature exhaust gas and to generate steam from the heat removed from the expanded working medium. A steam turbine and generator assembly operates on the steam to produce an auxiliary plant output. A selective catalytic reduction (SCR) system is provided for receiving the reduced temperature exhaust gas; and an auxiliary fan is powered by the auxiliary plant output to supply dilution air for further reducing the temperature of the exhaust gas to prior to passing the exhaust gas through the SCR system.

Owner:SIEMENS ENERGY INC

Passive system for optimal NOx reduction via selective catalytic reduction with variable boiler load

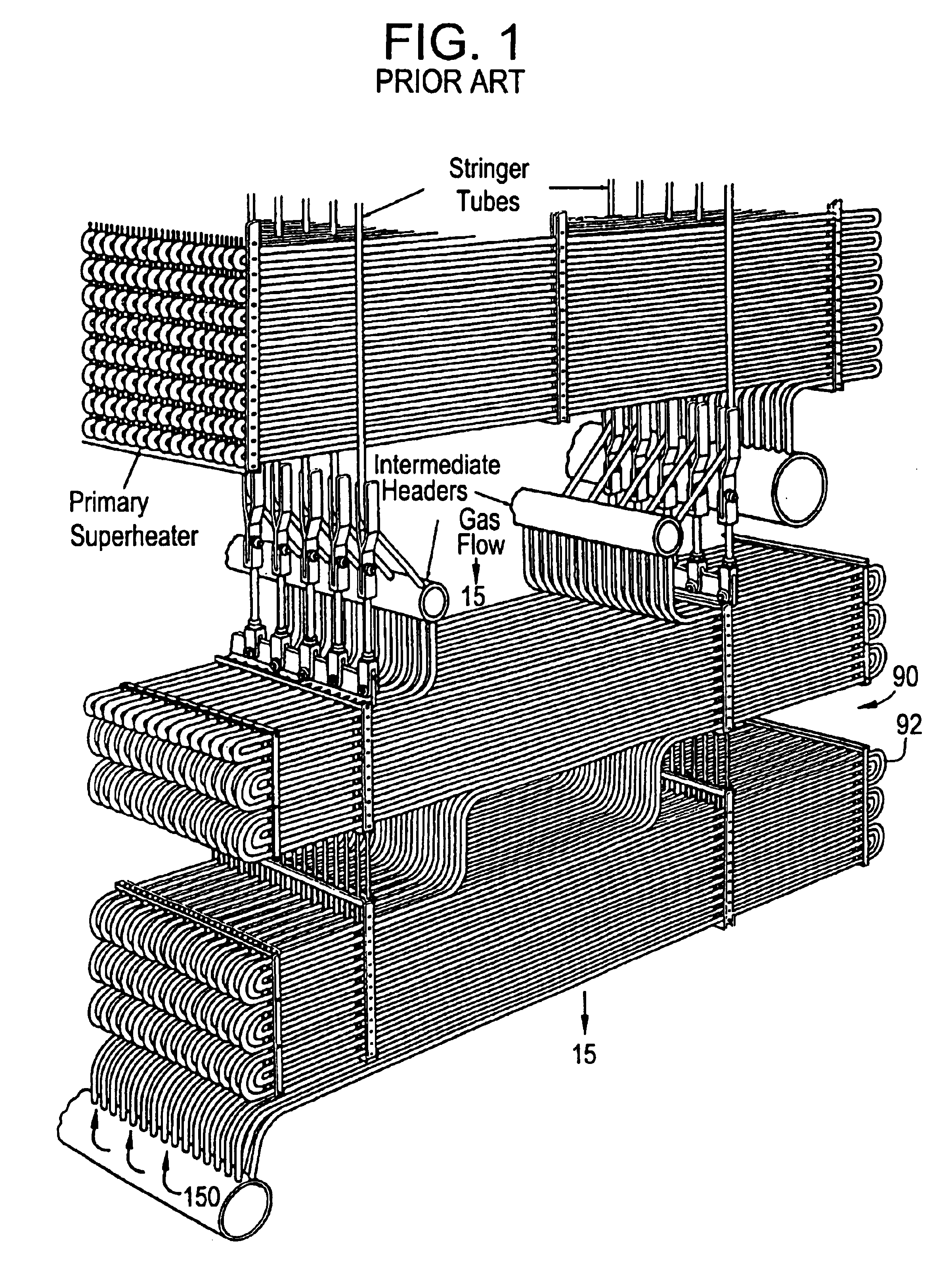

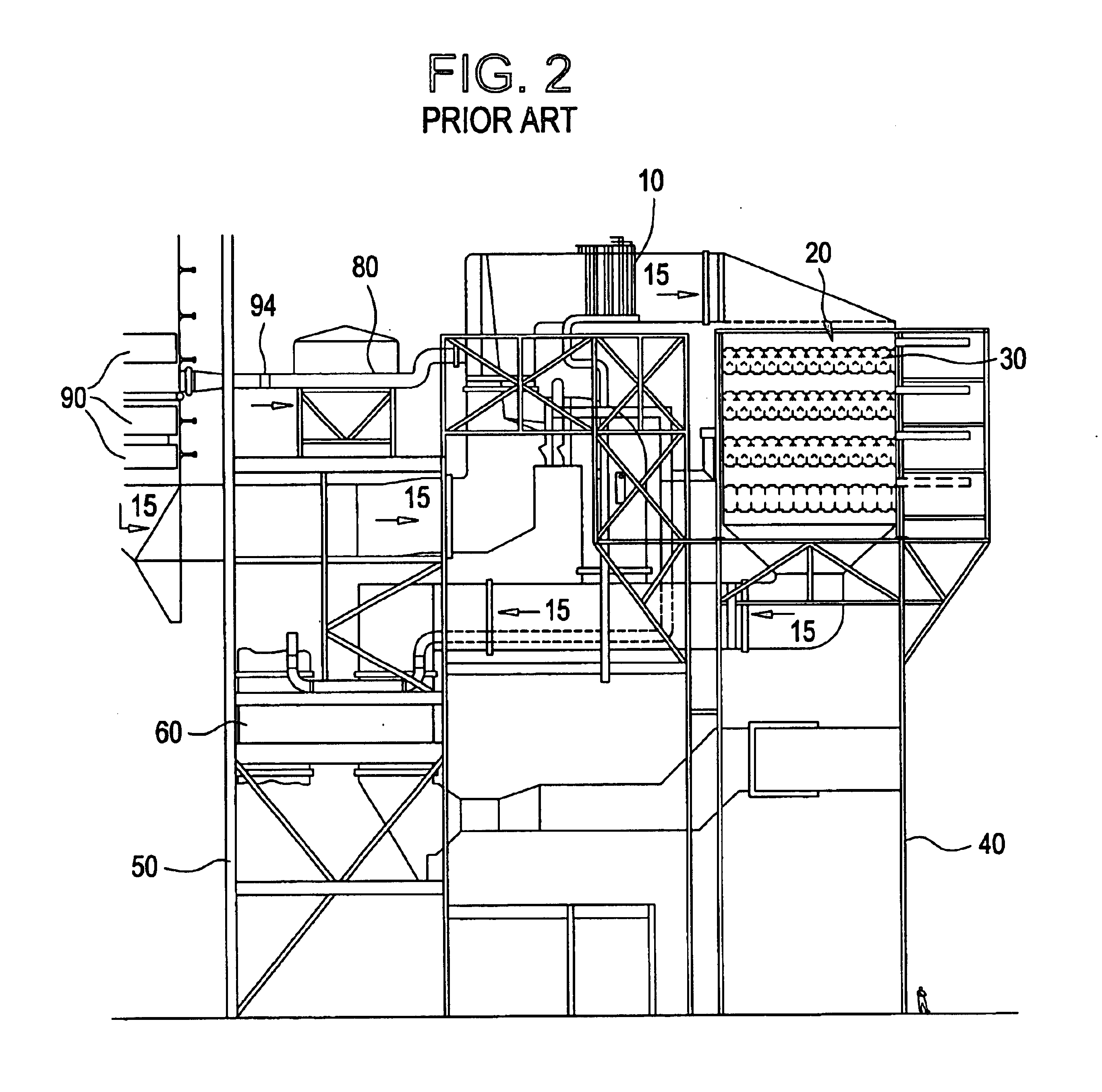

InactiveUS7021248B2Efficient removalImprove thermal efficiencyCombination devicesFluidized bed combustionFlue gasProcess engineering

A passive system for recovering energy and nitrogen oxides from flue gas produced by a boiler, and which employs a particular arrangement of economizer surface to ensure that the temperature of the flue gas entering a selective catalytic reduction (SCR) reactor is maintained within a required range over a wide range of boiler loads.

Owner:THE BABCOCK & WILCOX CO

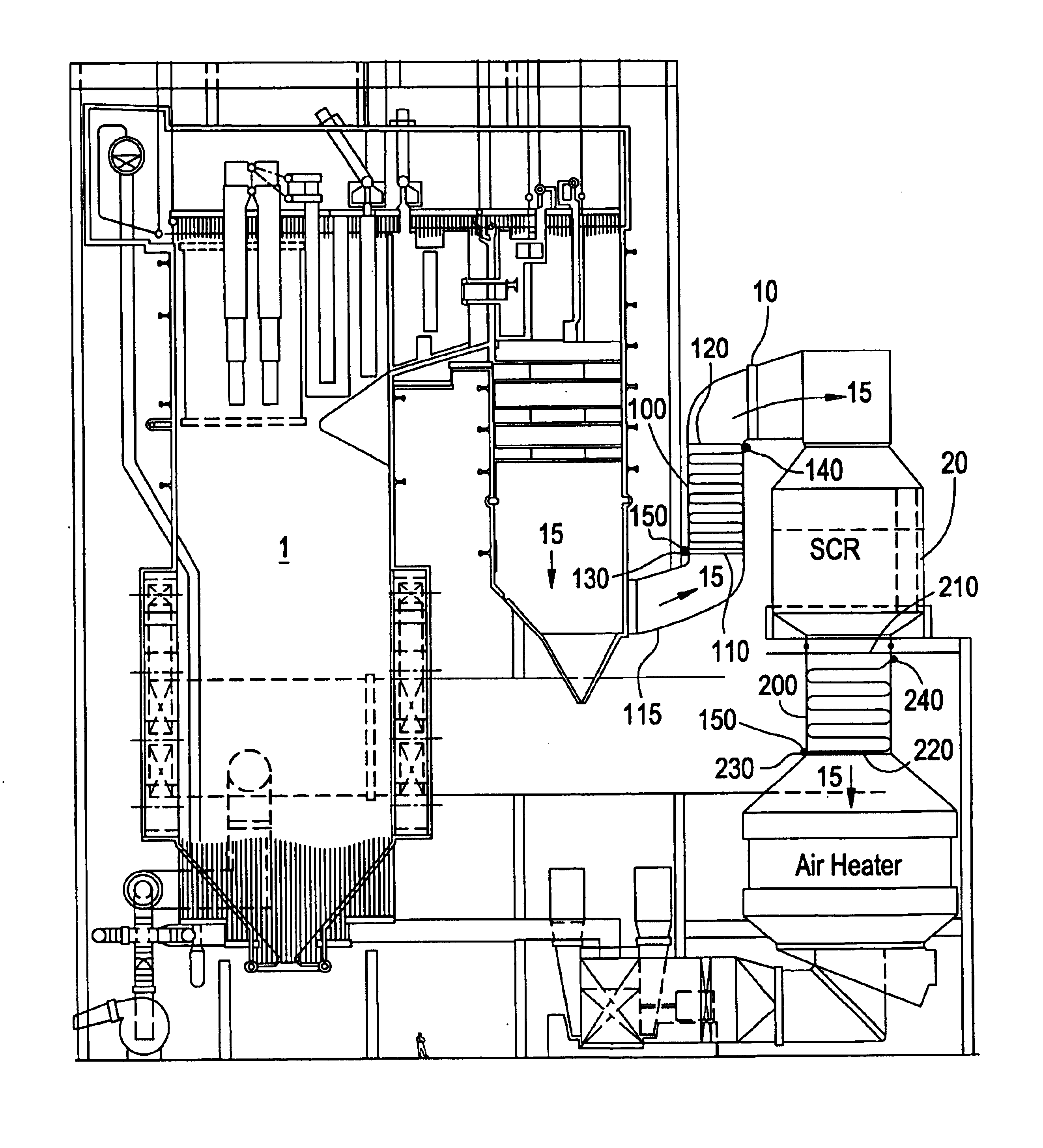

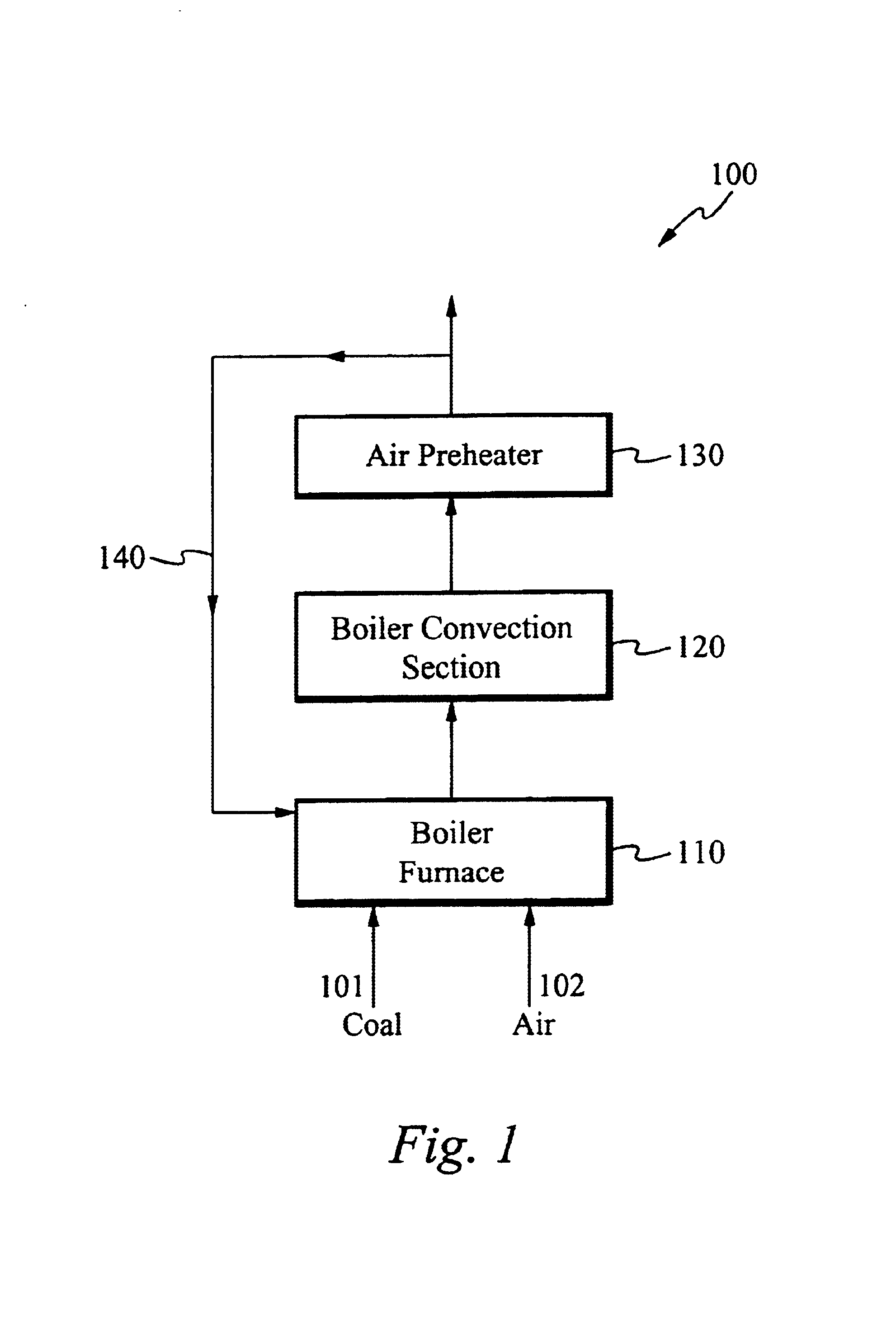

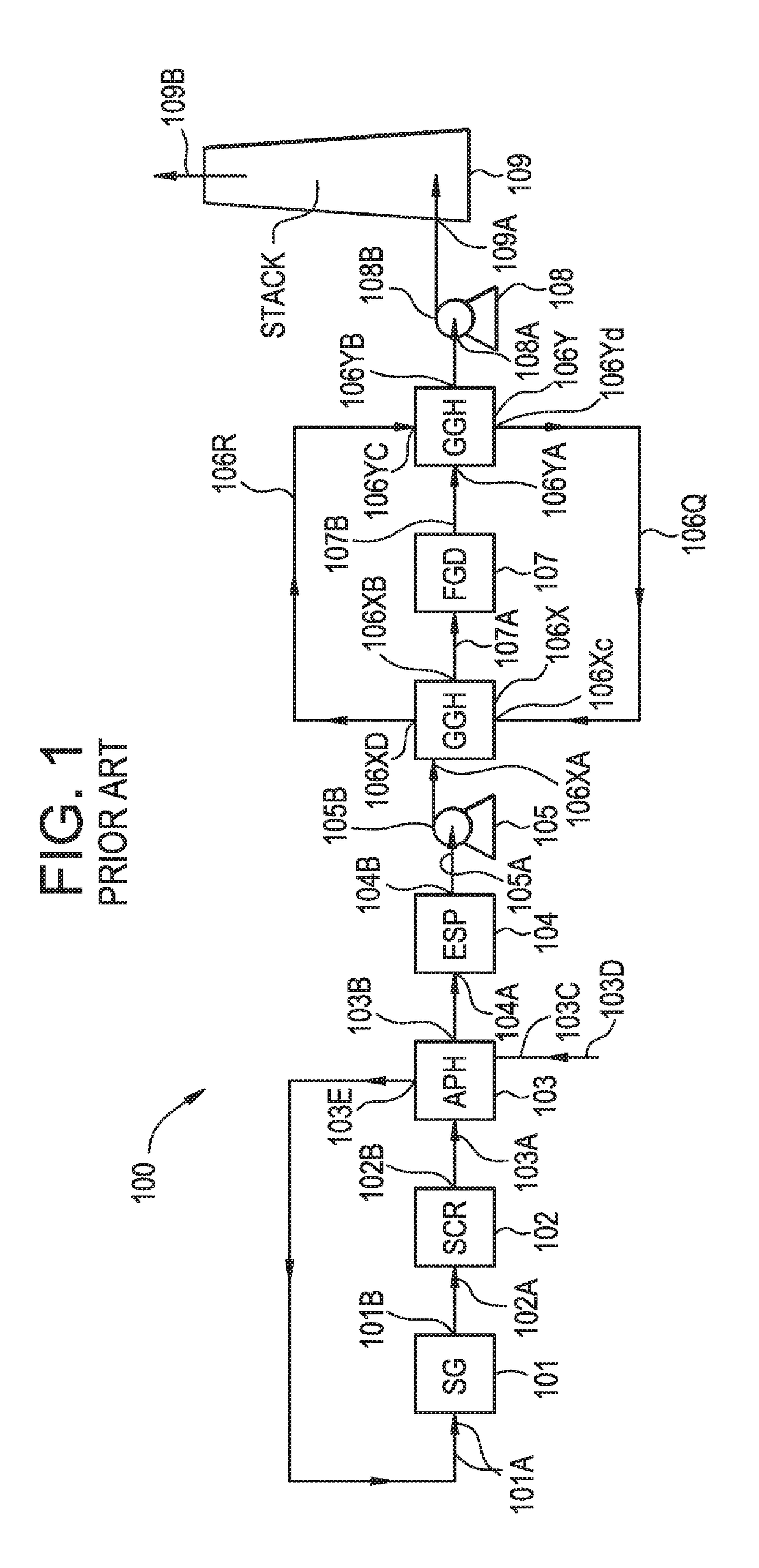

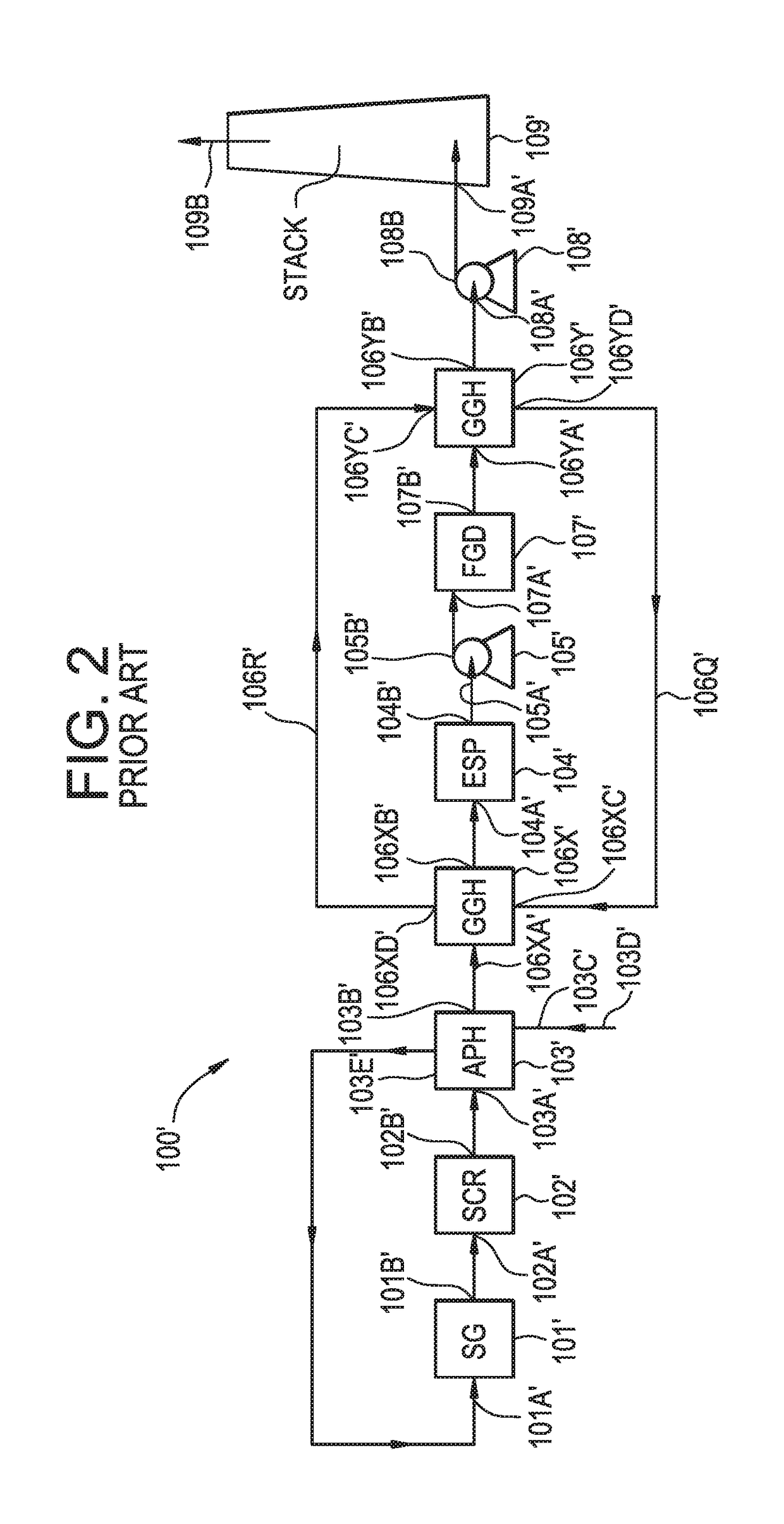

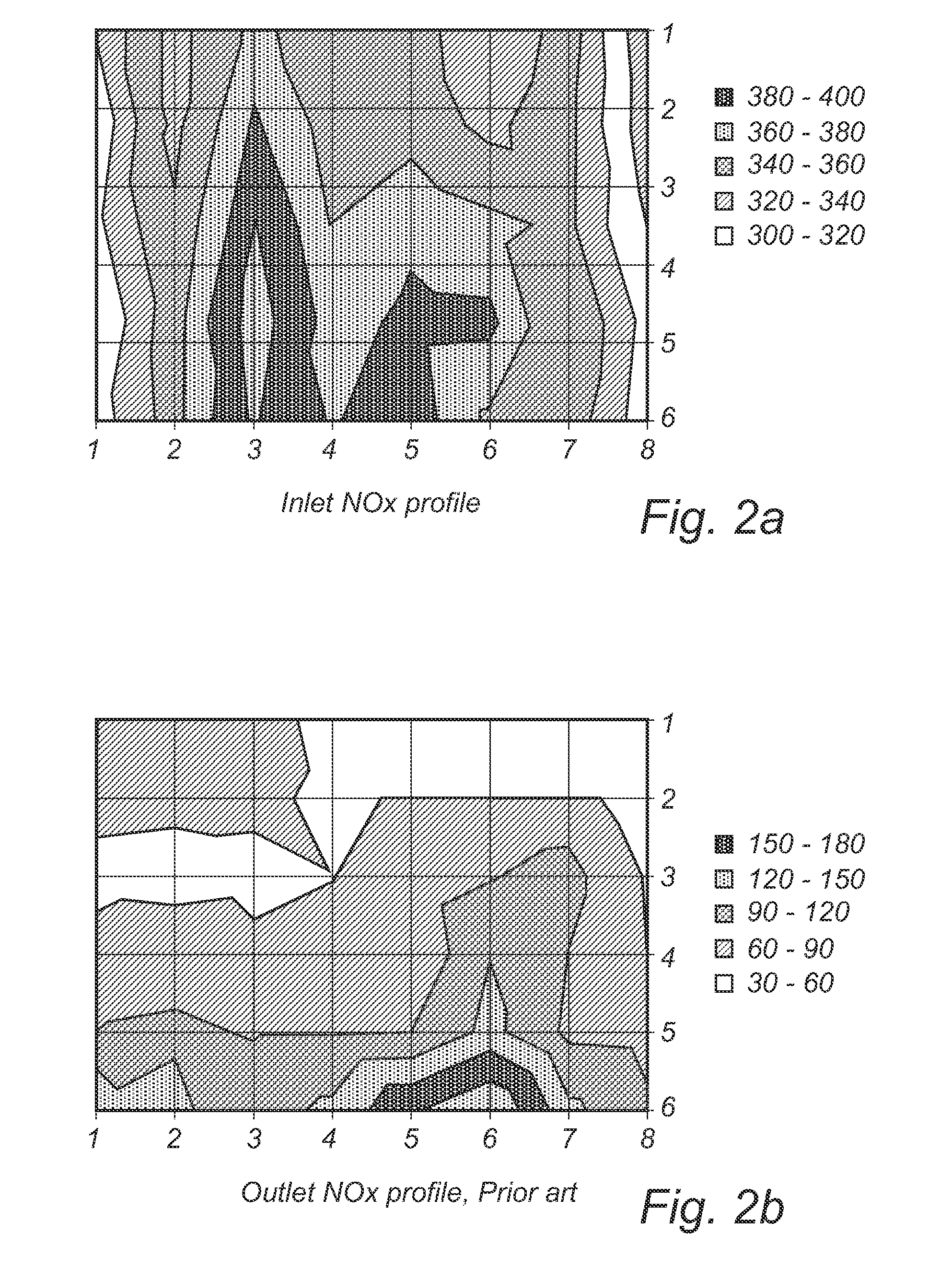

Method of and Apparatus for Selective Catalytic NOx Reduction in a Power Boiler

InactiveUS20120160142A1Minimizes problemEasy to operateBurnersIndirect carbon-dioxide mitigationFlue gasProcess engineering

A method of selective catalytic NOX reduction in a power boiler and a power boiler with selective catalytic NOX reduction. Fuel is combusted in a furnace of the boiler and a flue gas stream that includes NOX is generated. The flue gas stream is conducted from the furnace along a flue gas channel to a stack. The flue gas stream is cooled in a heat recovery area, including an economizer section, arranged in the flue gas channel. At least a portion of the NOX is reduced to N2 in an NOX catalyst arranged in the flue gas channel downstream of the economizer section. The flue gas is further cooled, and heated air is generated in a gas-to-air heater arranged in the flue gas channel downstream of the economizer section and upstream of the NOX catalyst. The gas-to-air heater may be a tubular air heater or a heat exchanger with a recirculating heat transfer fluid.

Owner:FOSTER WHEELER NORTH AMERICA CORP

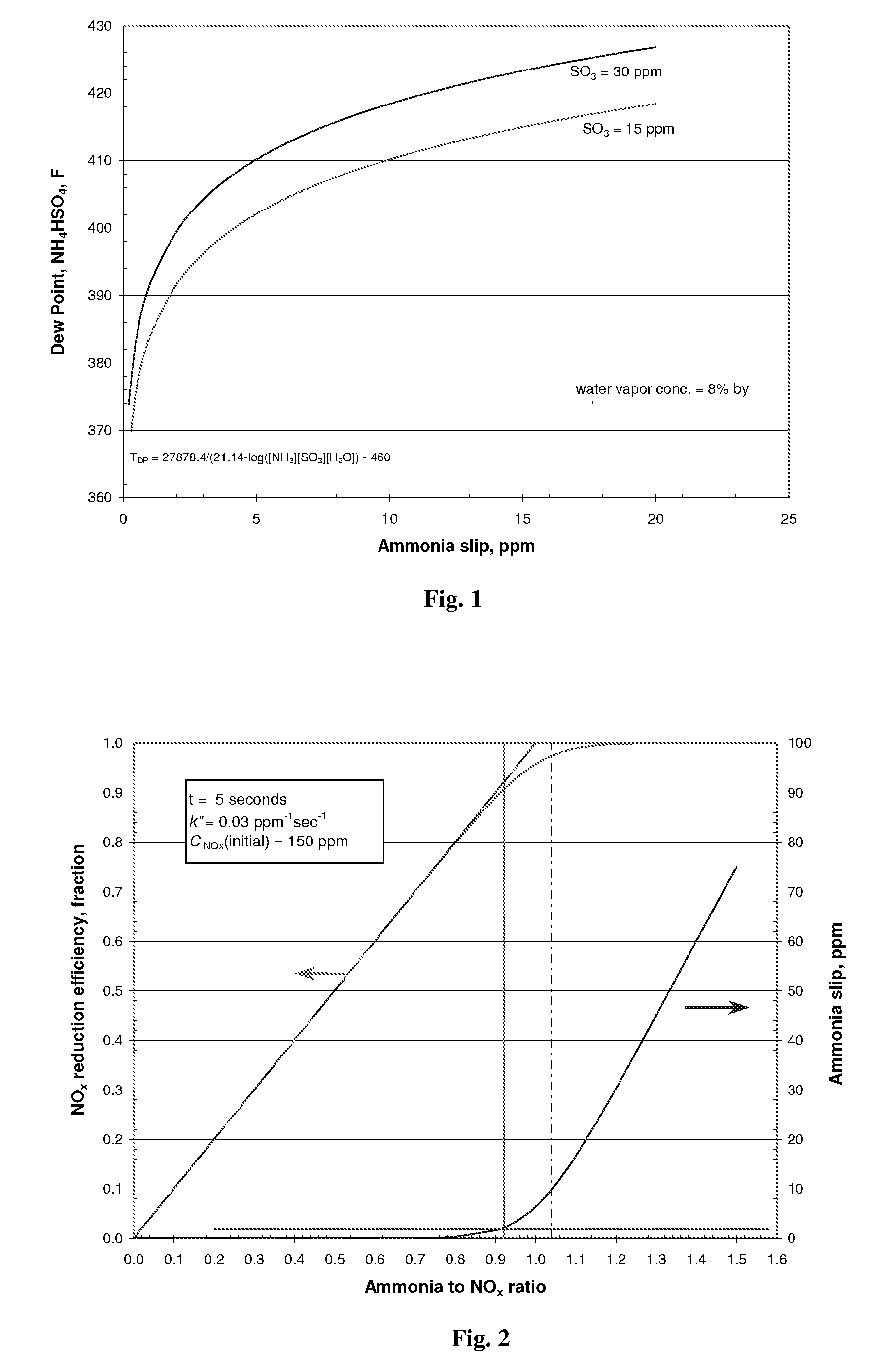

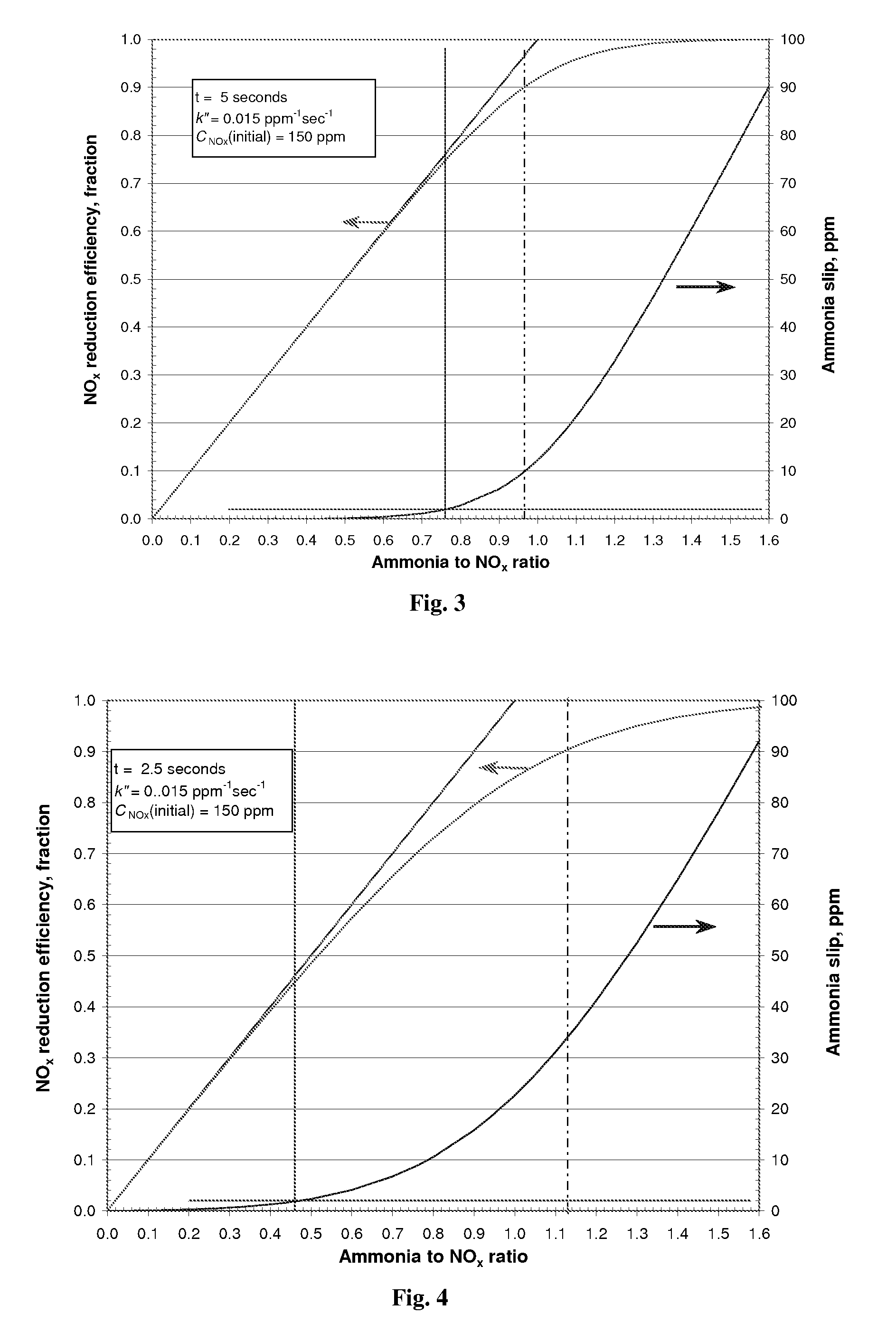

Enhancement of conventional scr and sncr processes with ammonia destruction catalyst

InactiveUS20090252665A1Increasing ammonia slipIncrease the supply rateNitrous oxide captureGas treatmentInjection pointEnvironmental engineering

An apparatus and method for achieving increased NOx removal efficiency from an emissions control portion of a fossil fuel fired boiler while controlling ammonia slip provides excess levels of ammonia above those levels conventionally employed in SCR and / or SNCR applications. The apparatus and methods comprise, in part, use of a NOx reduction system comprising at least one selective catalytic reduction system which receives ammonia in higher amounts than conventional practice from an upstream ammonia injection point, and an ammonia reduction system positioned downstream of one or more ammonia injection points and the NOx reduction system. The excess ammonia achieves increased NOx removal, while the ammonia reduction system contains at least one ammonia destruction catalyst which permits the NOx reduction system to be operated at an increased NOx removal efficiency without a corresponding increase in ammonia slip.

Owner:THE BABCOCK & WILCOX CO

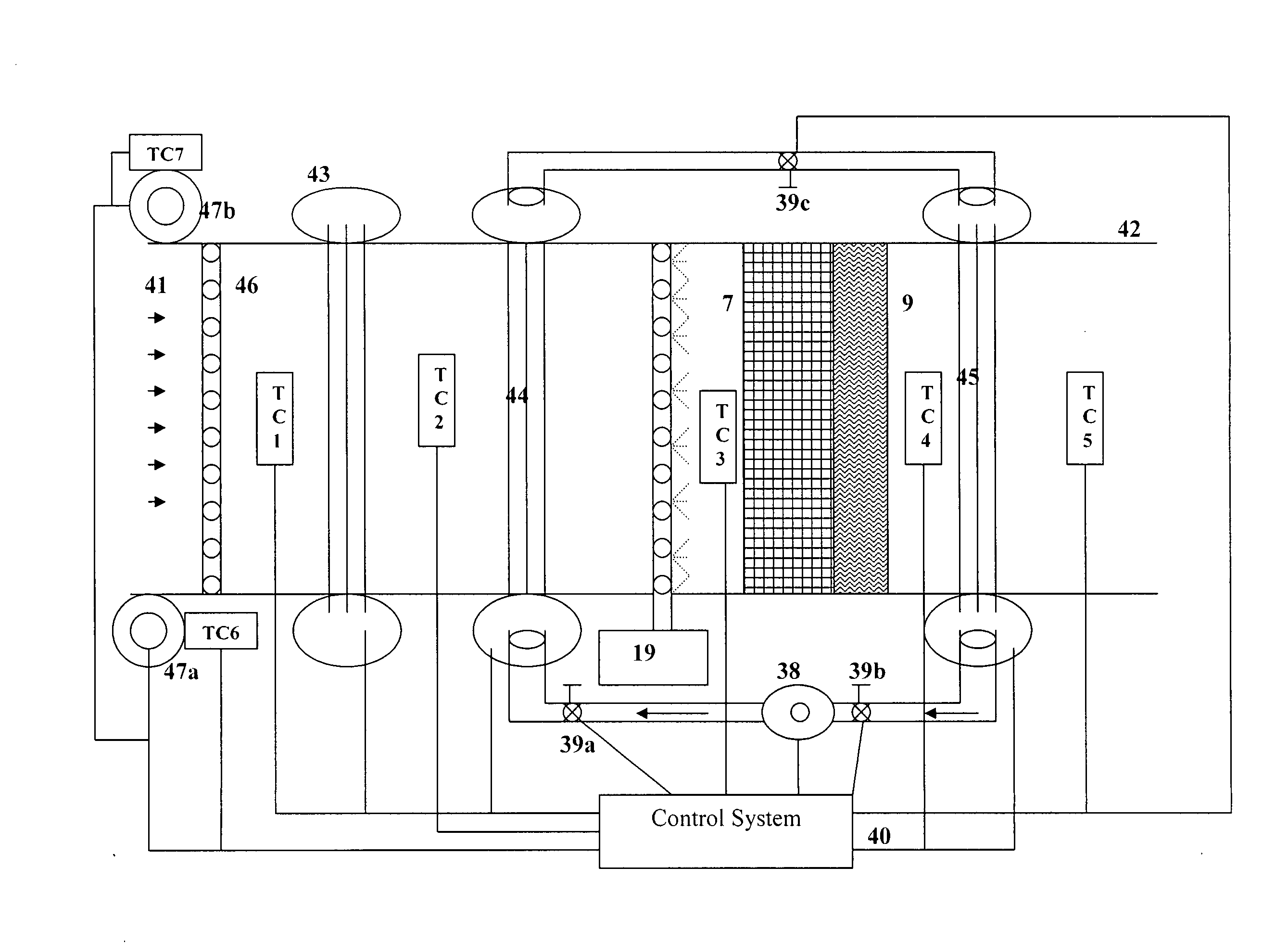

Emission control system internal to a boiler

InactiveUS20080317652A1Reduce back pressureReduce harmful emissionsNitrous oxide captureCombination devicesControl systemEngineering

Owner:CATALYTIC SOLUTIONS INC

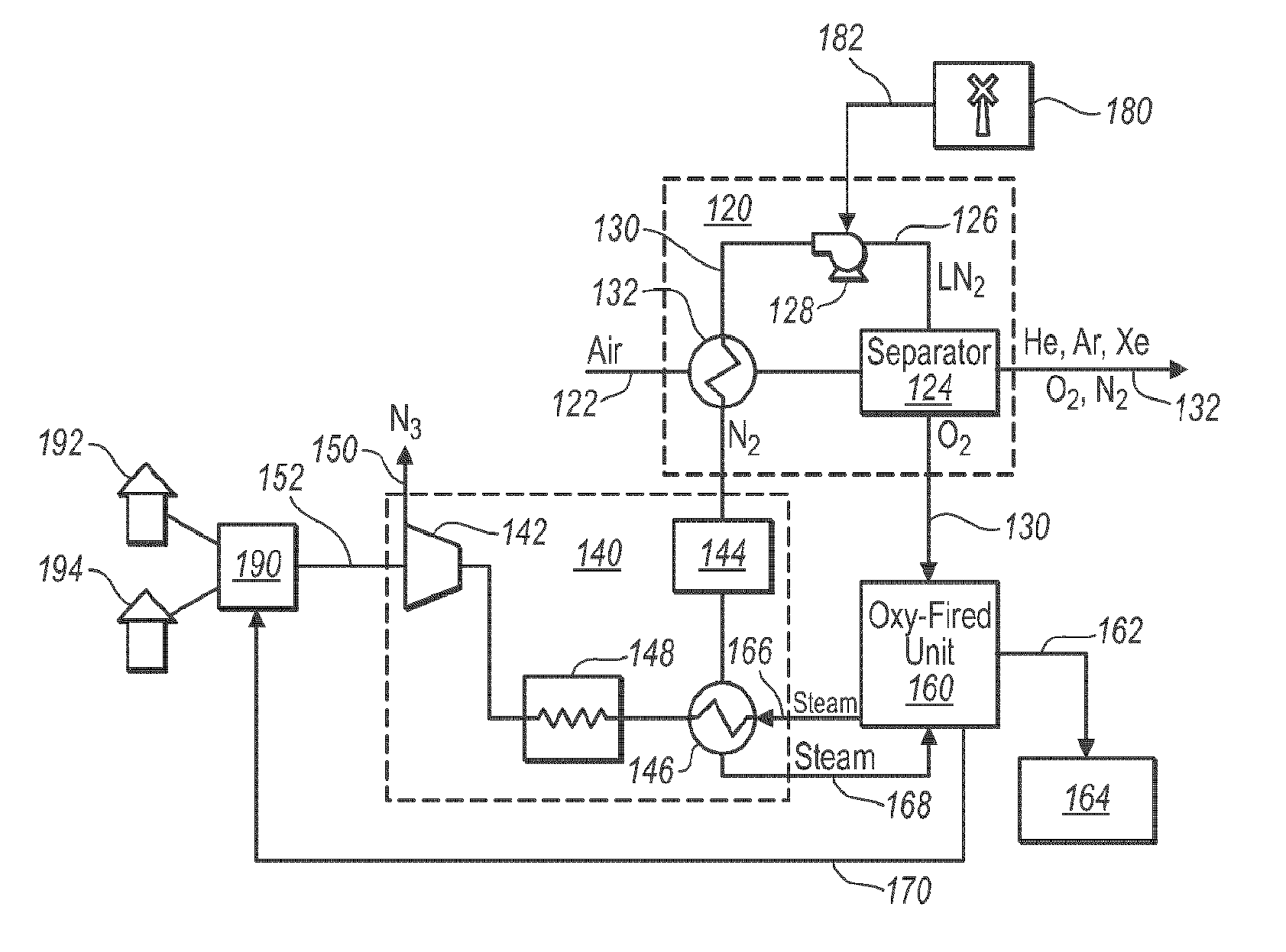

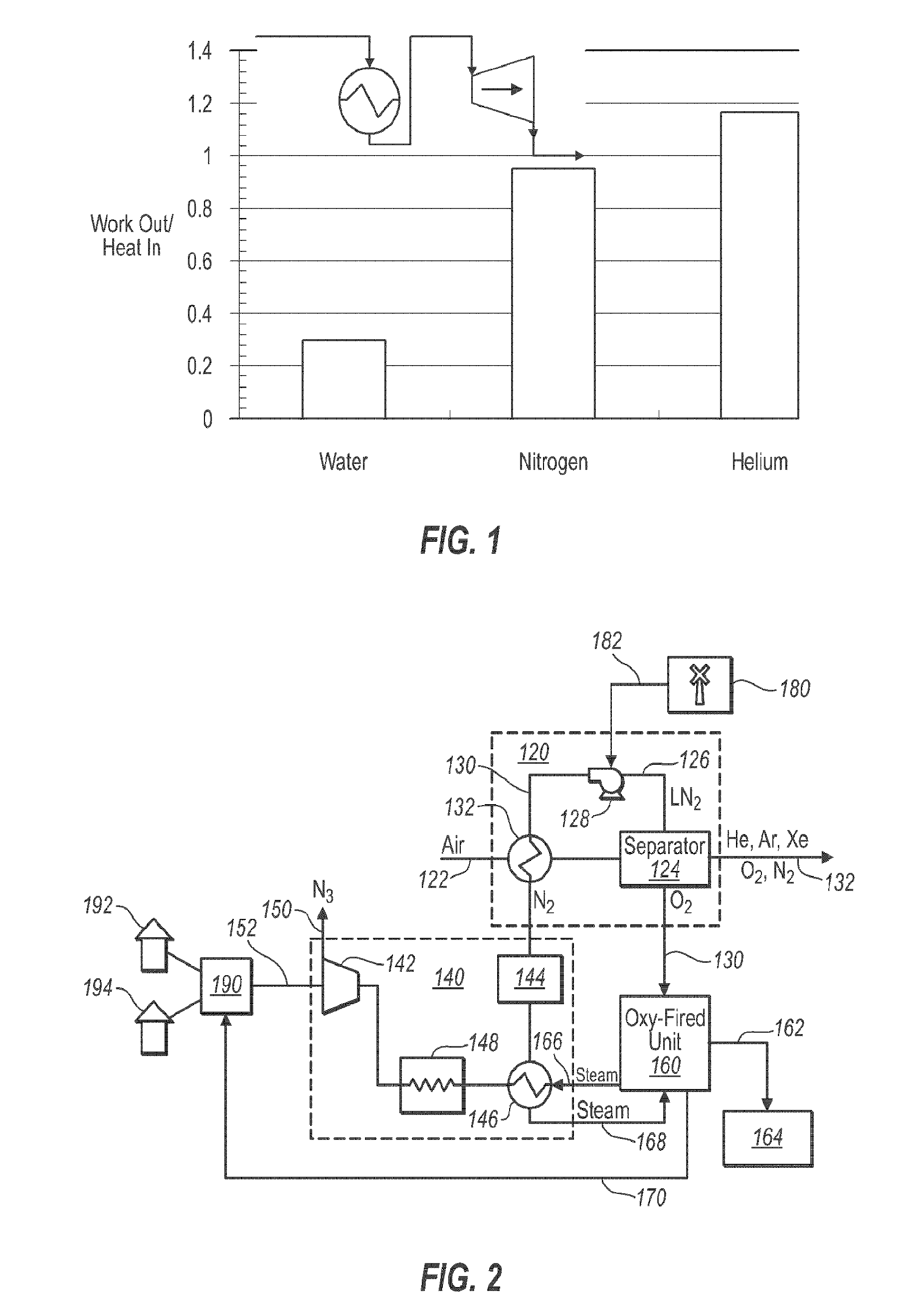

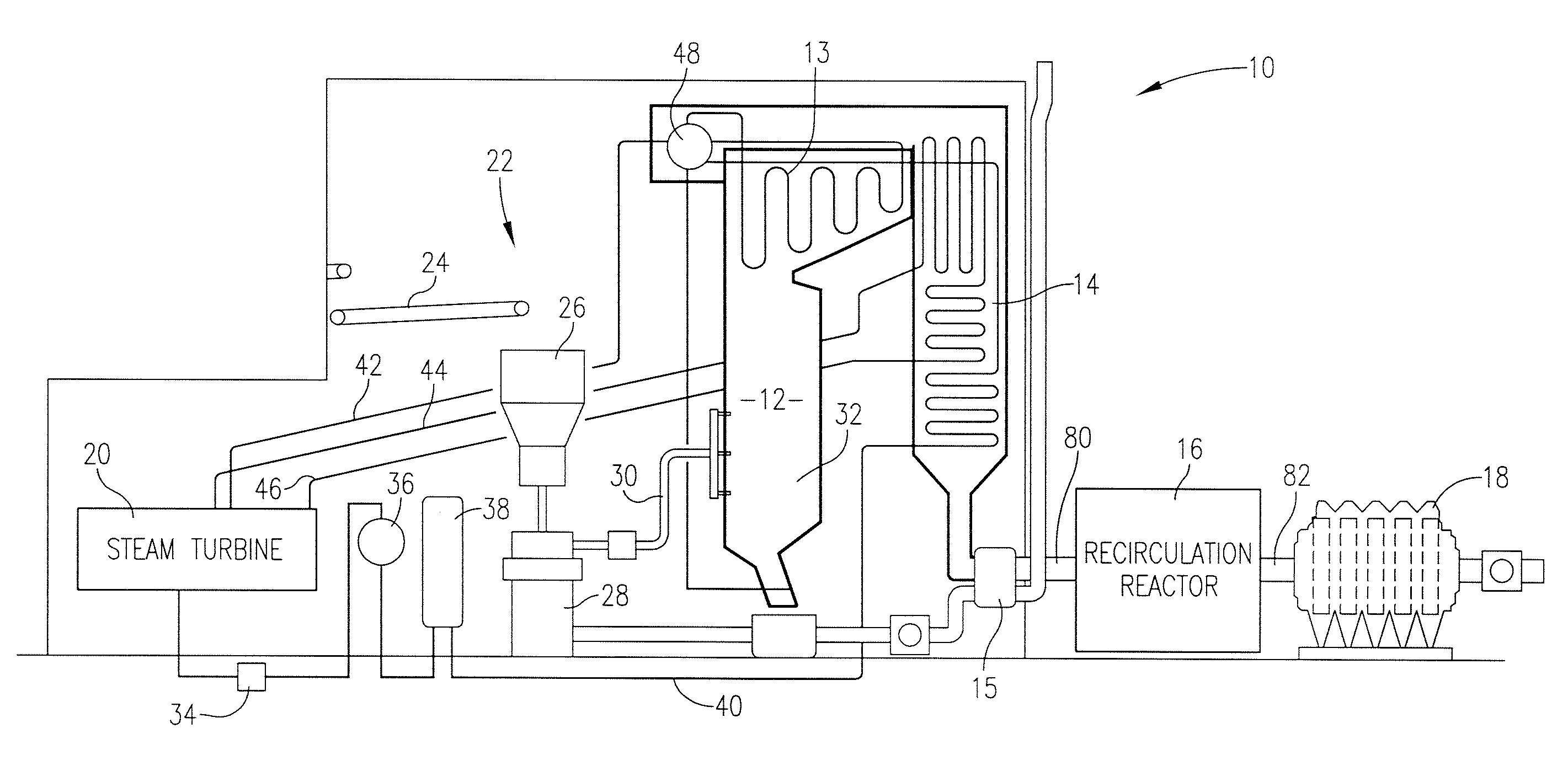

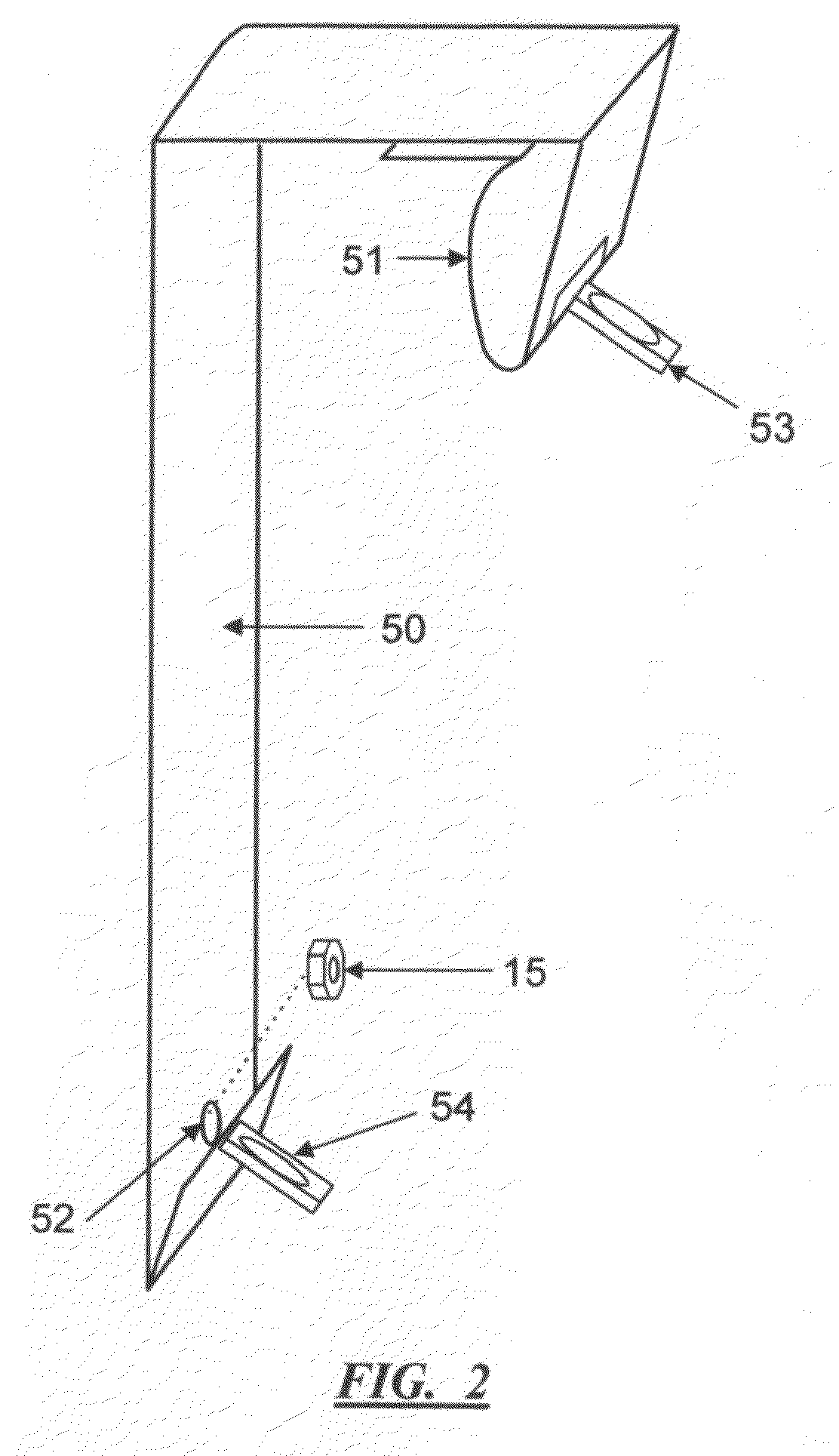

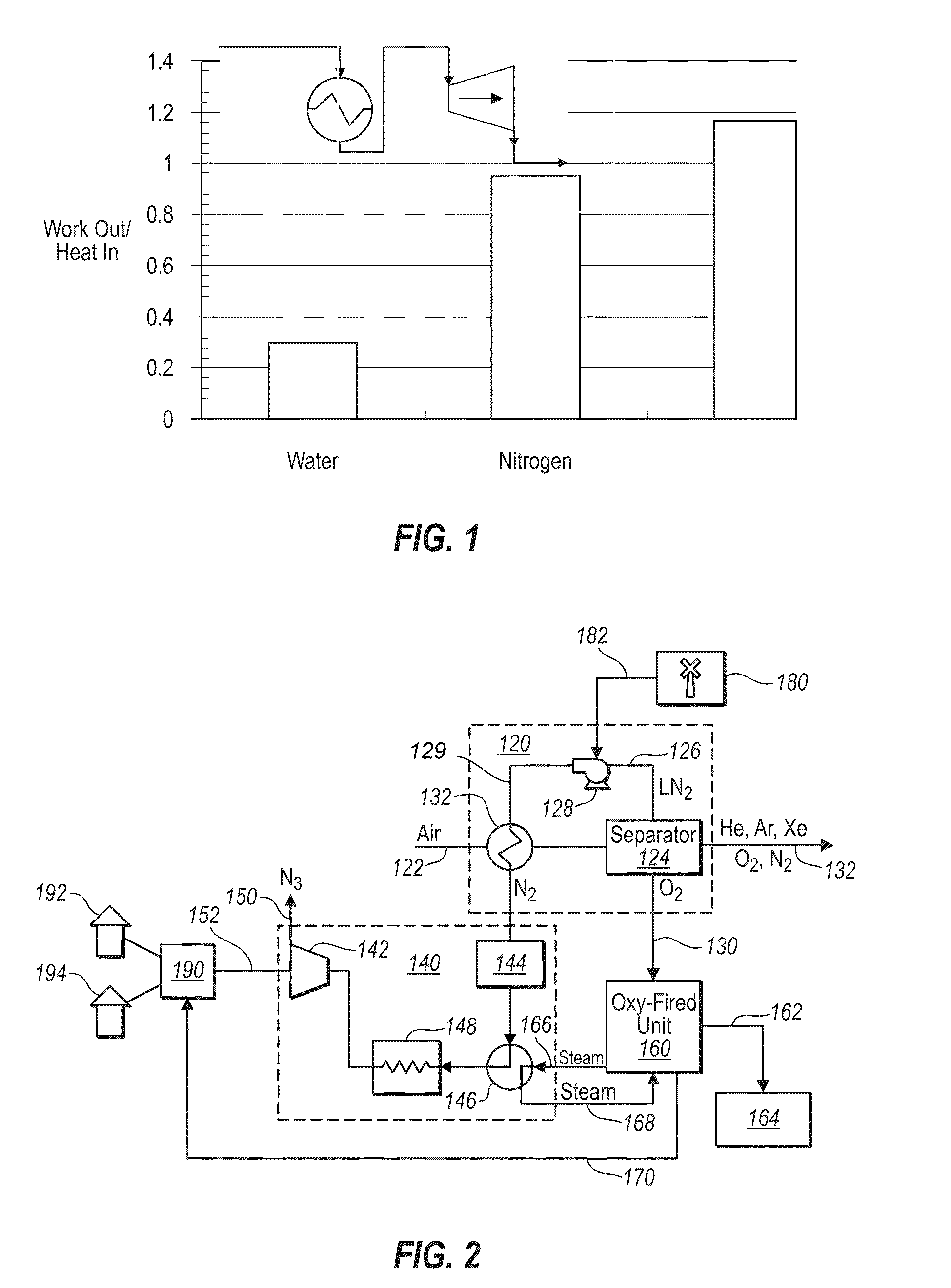

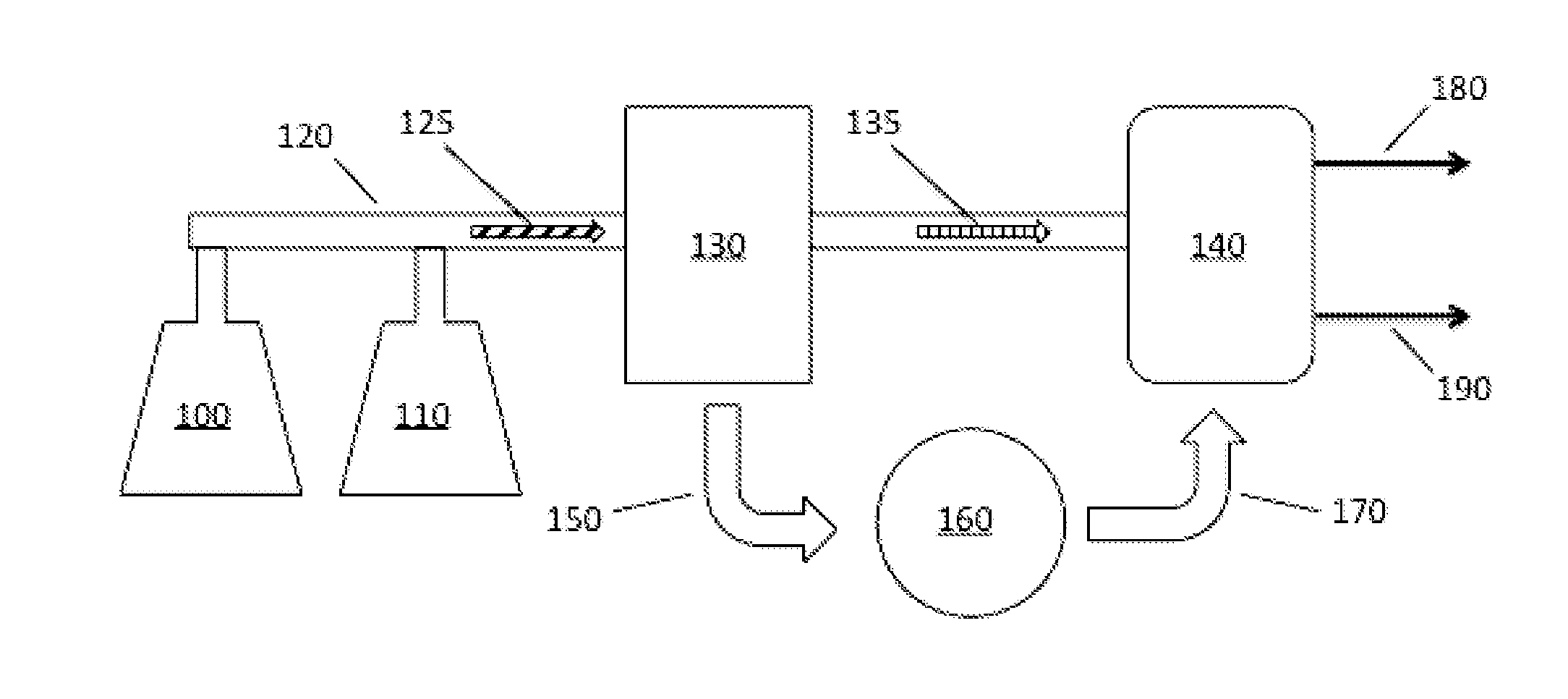

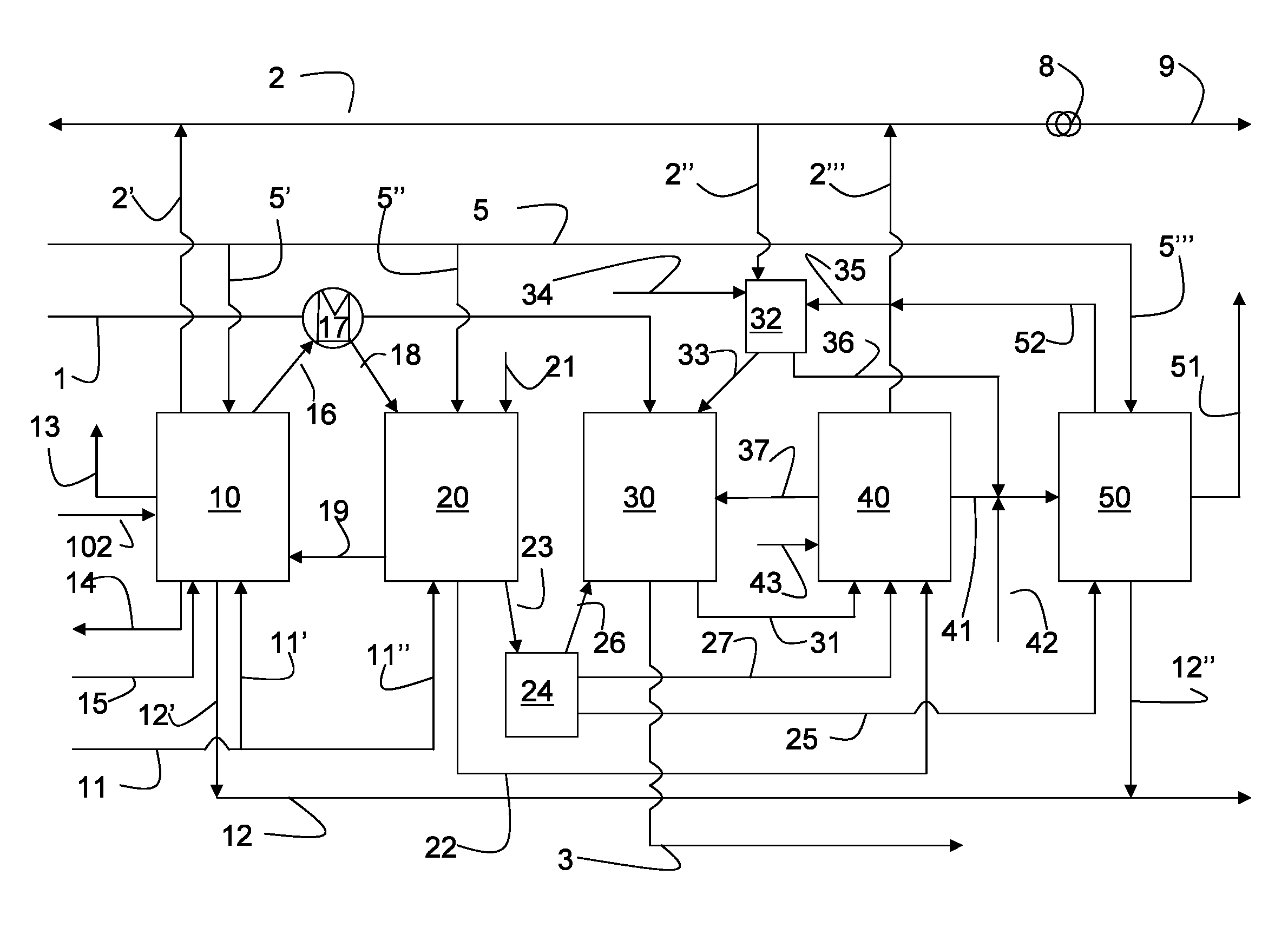

Methods and systems for generating power from a turbine using pressurized nitrogen

ActiveUS20110061385A1Efficient power generationImprove efficiencySolidificationLiquefactionWorking fluidEngineering

An air separation unit is integrated with a power generating plant to improve the efficiency of power generation. The methods and systems improve the efficiency of power generation by utilizing liquid nitrogen from the air separation unit as the working fluid in a turbine. The liquid nitrogen is pressurized while in the liquid state. After warming the pressurized nitrogen stream by cooling the air for the air separator unit, the compressed nitrogen is expanded in a turbine to perform work. After expansion, the nitrogen is vented to ambient air. The nitrogen in its pressurized state can be used for energy storage and / or for smoothing out power demand on a power grid.

Owner:U S BANK TRUST CO NAT ASSOC

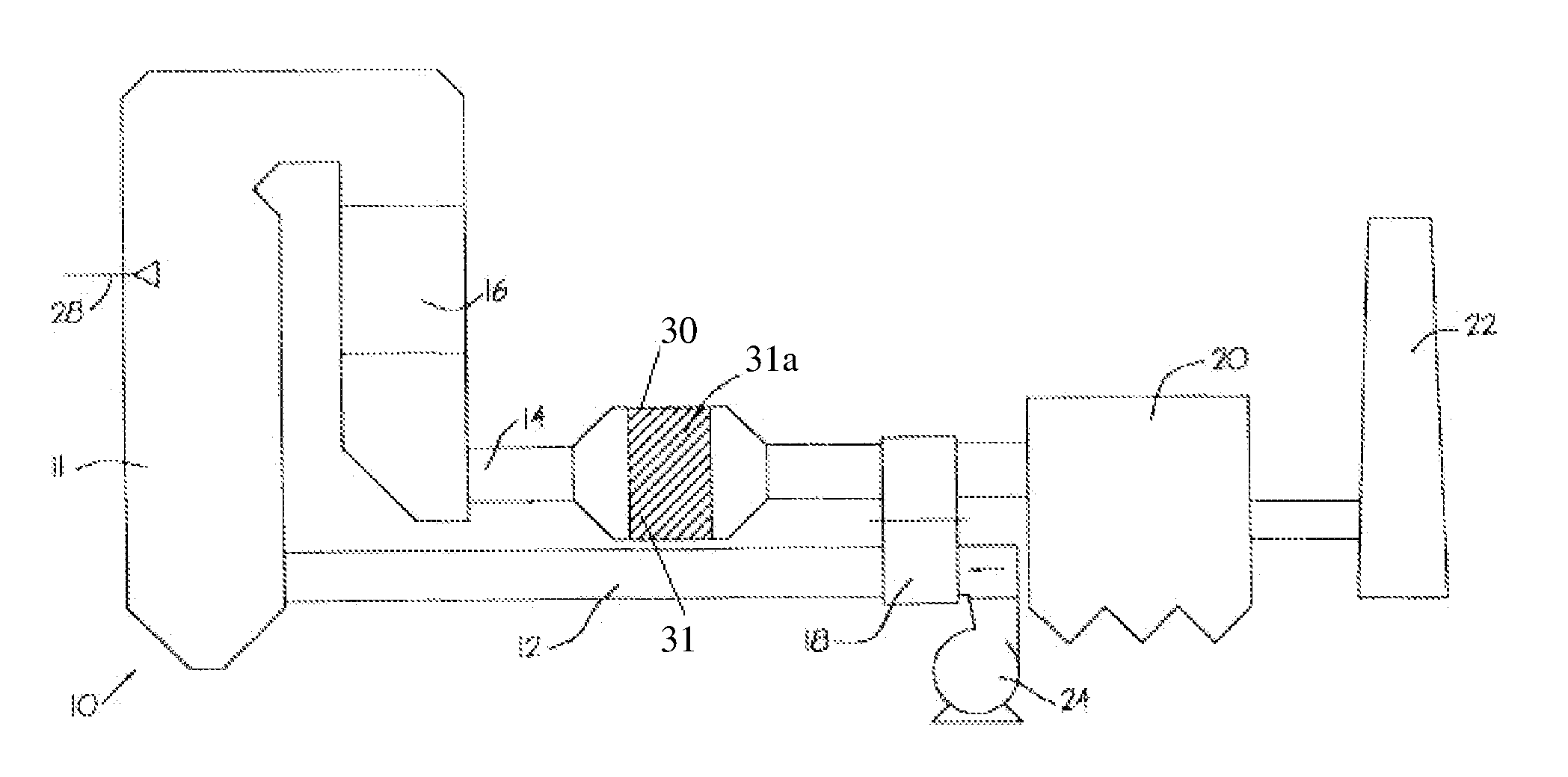

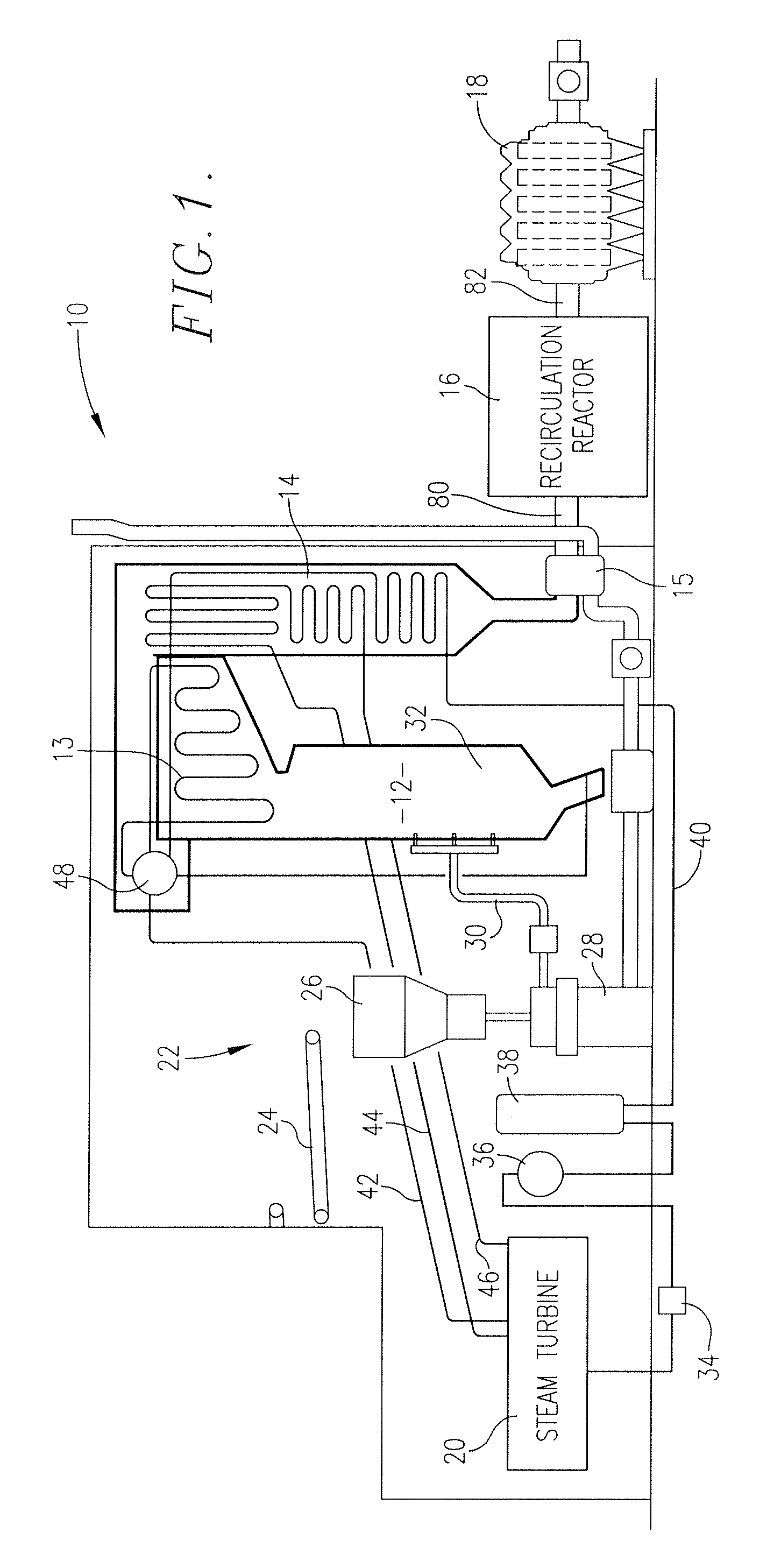

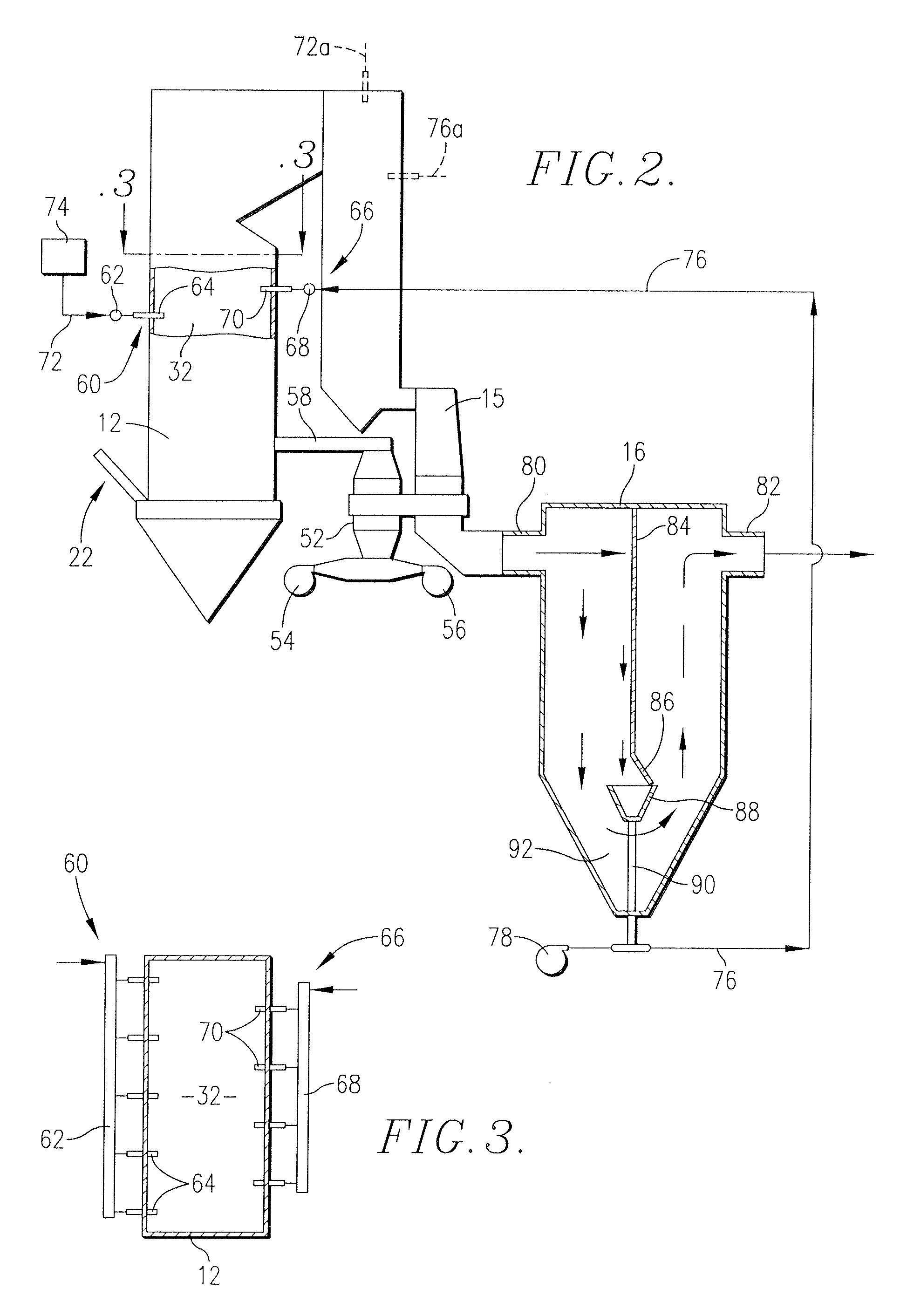

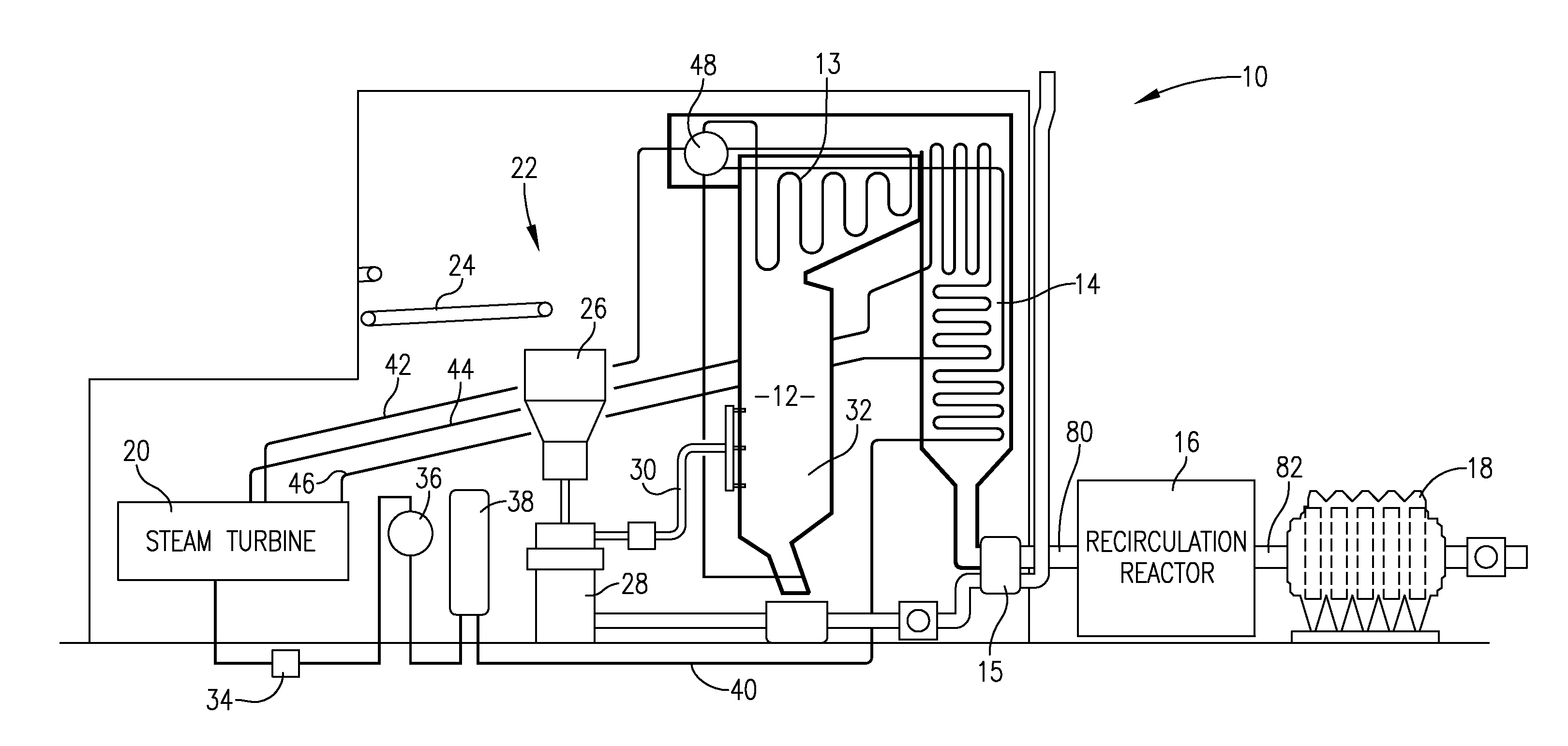

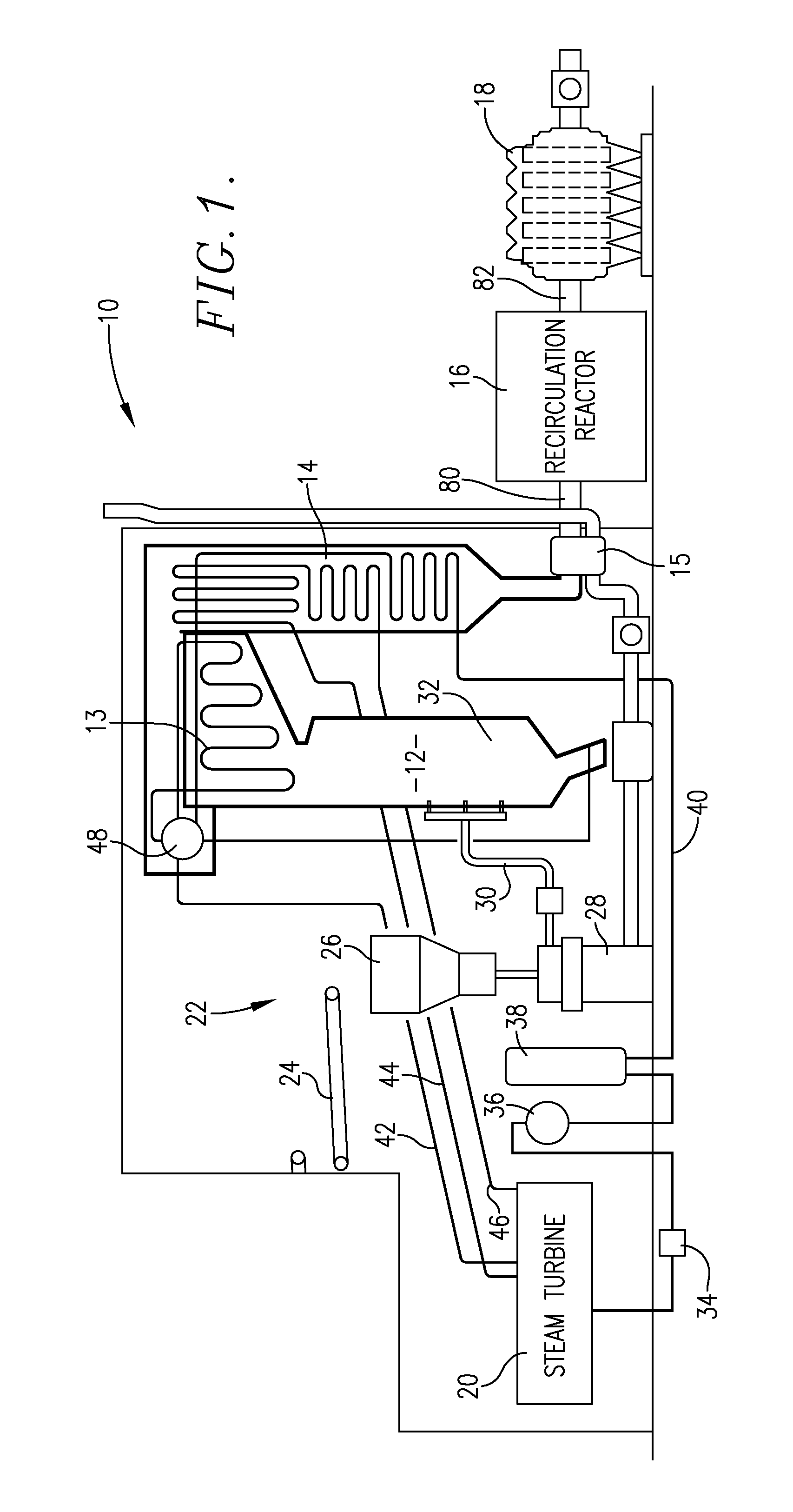

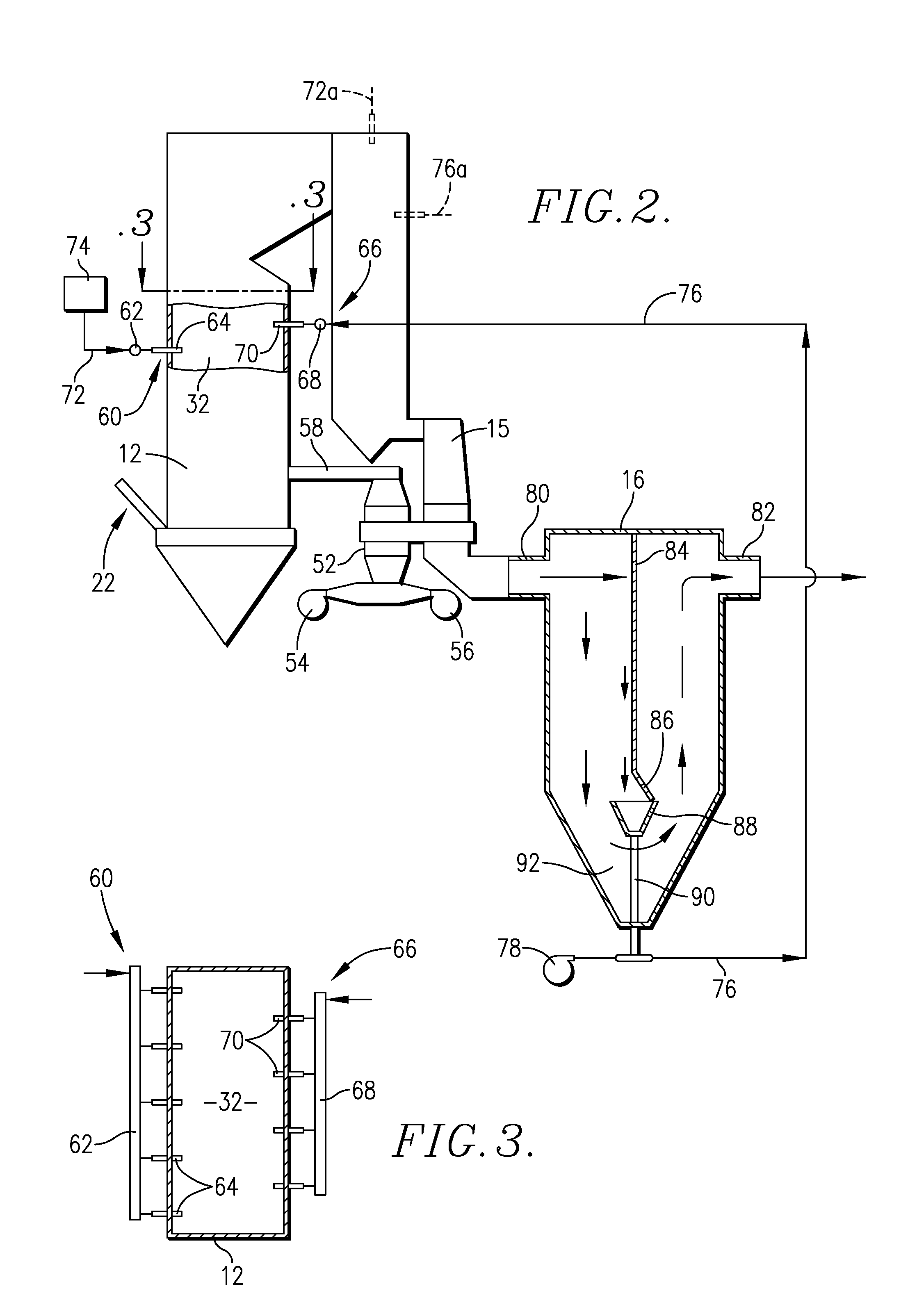

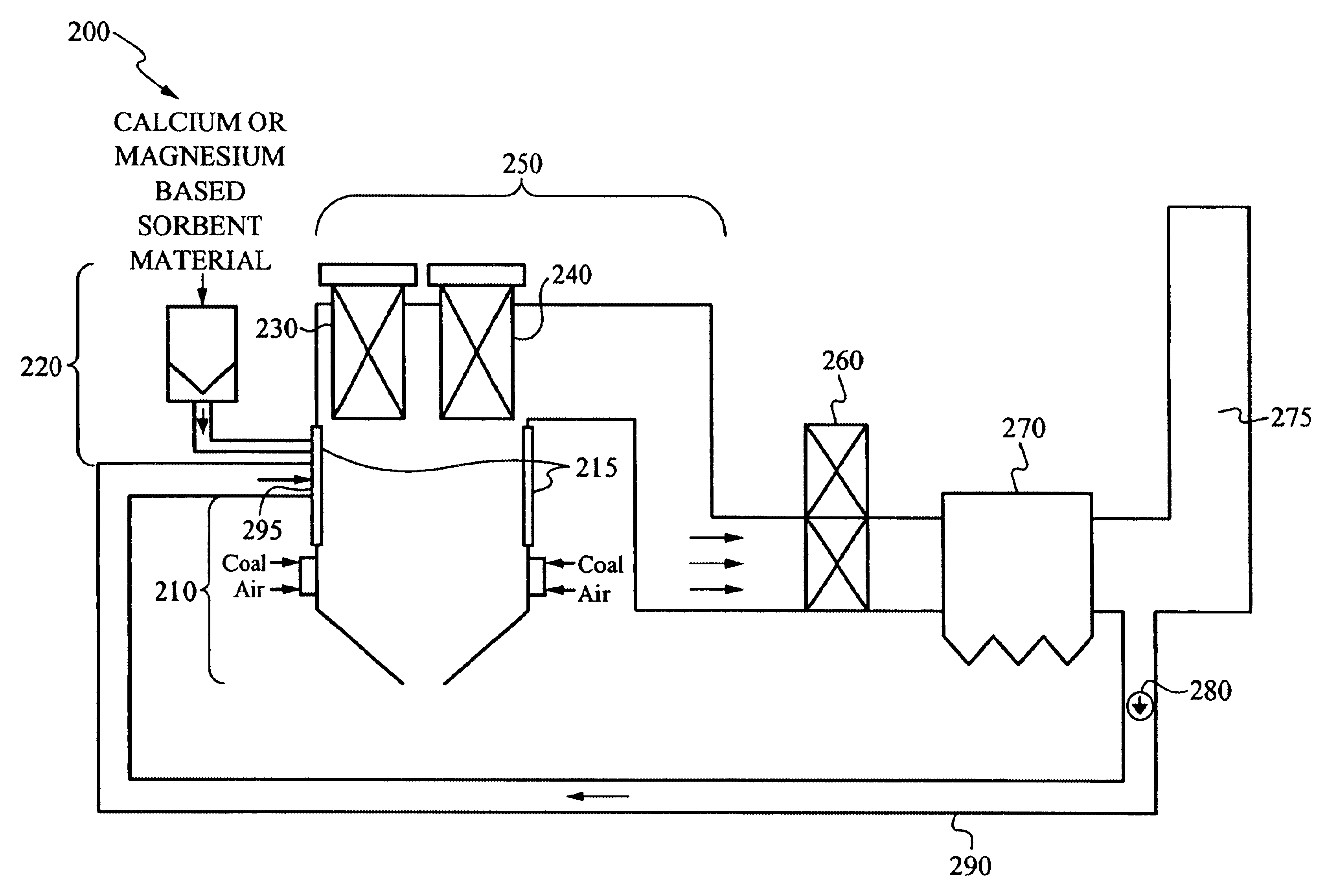

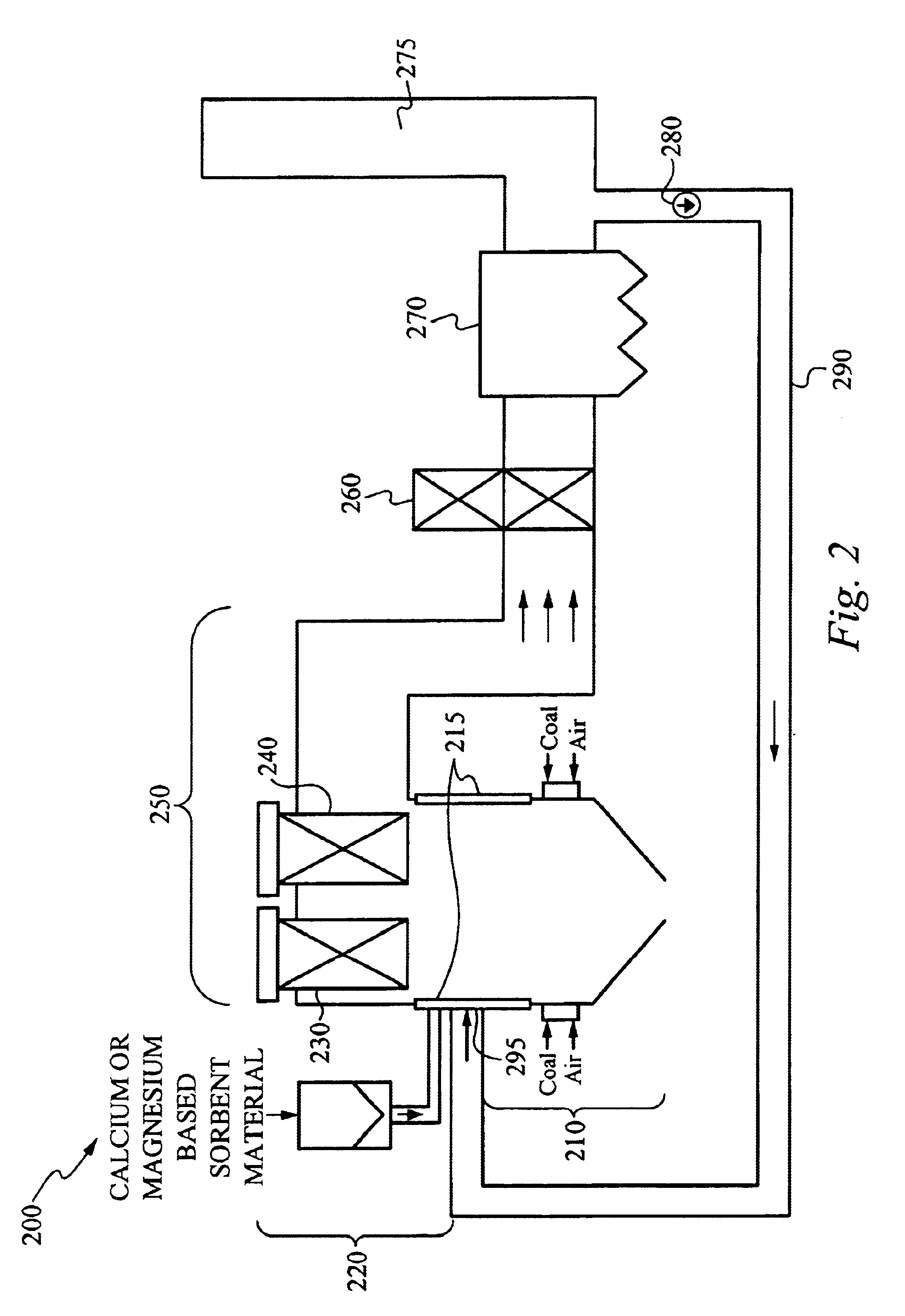

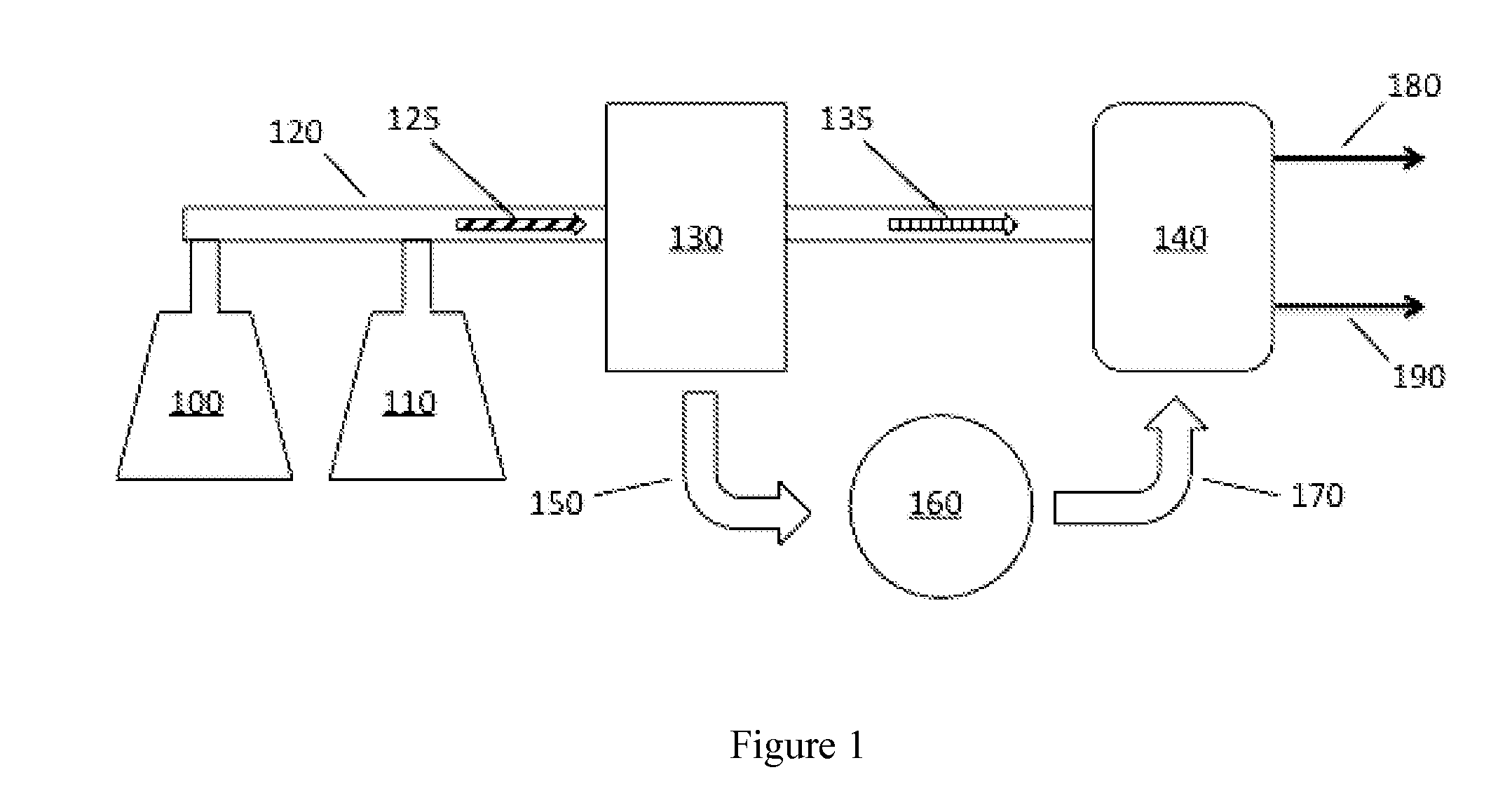

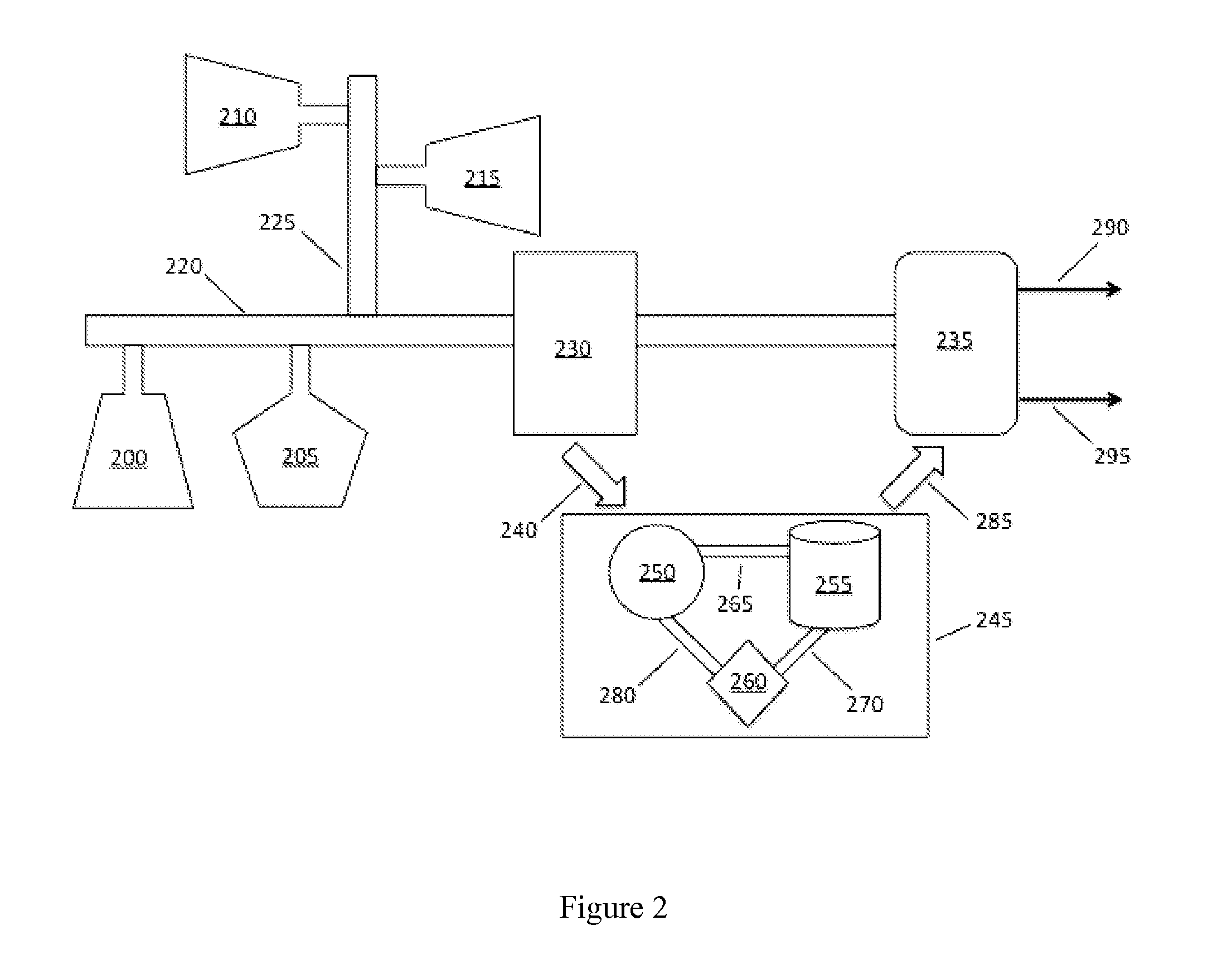

Pollution abatement process for fossil fuel-fired boilers

InactiveUS20100263577A1High degreeLow-cost operationGas treatmentSteam generation heating methodsParticulatesSodium bicarbonate

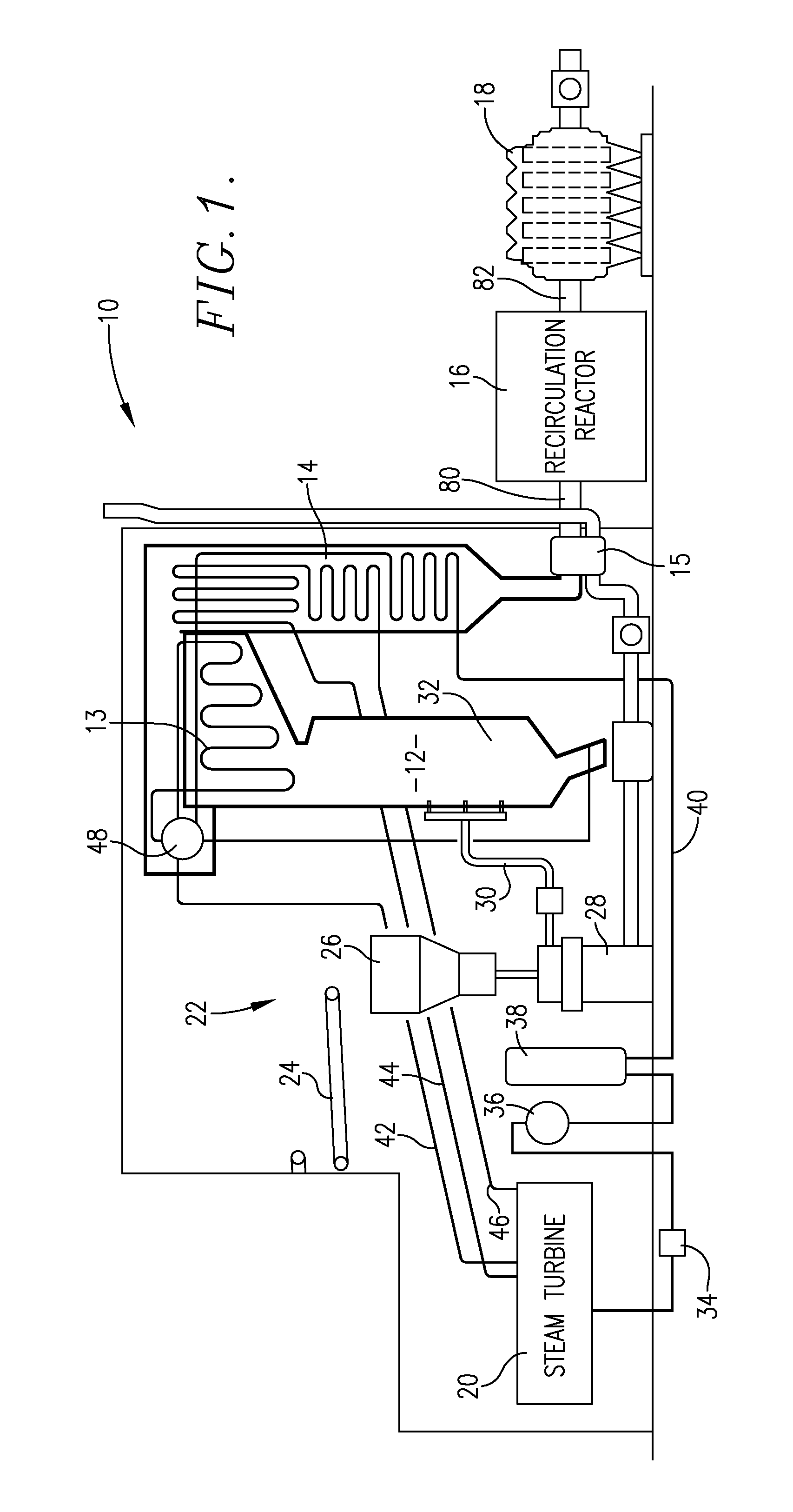

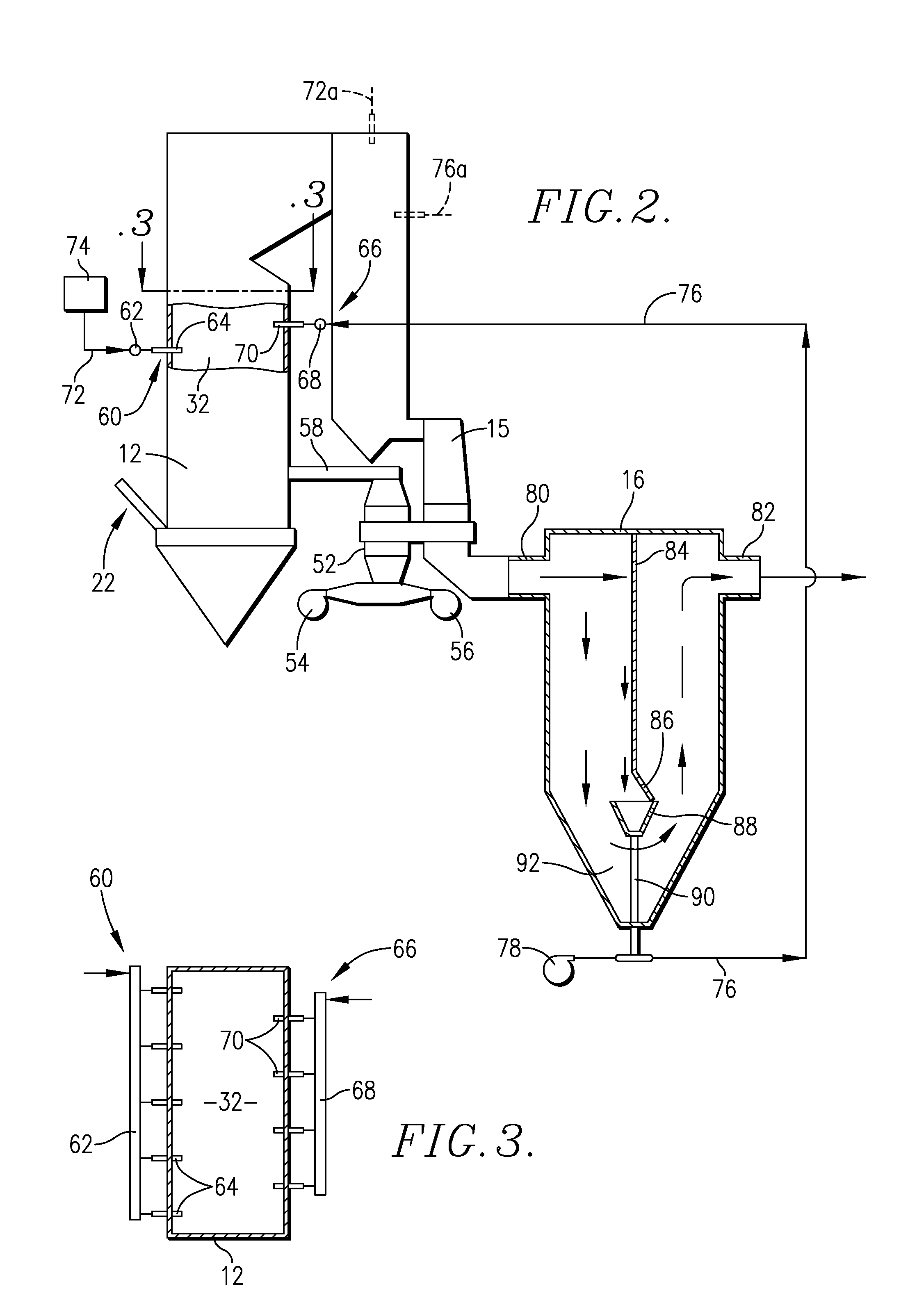

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16).The present invention can also be used in industrial applications where the same emissions are generated and are needed to be controlled. Examples of such applications are Cement and Lime Kilns.

Owner:INDAL ACCESSORIES

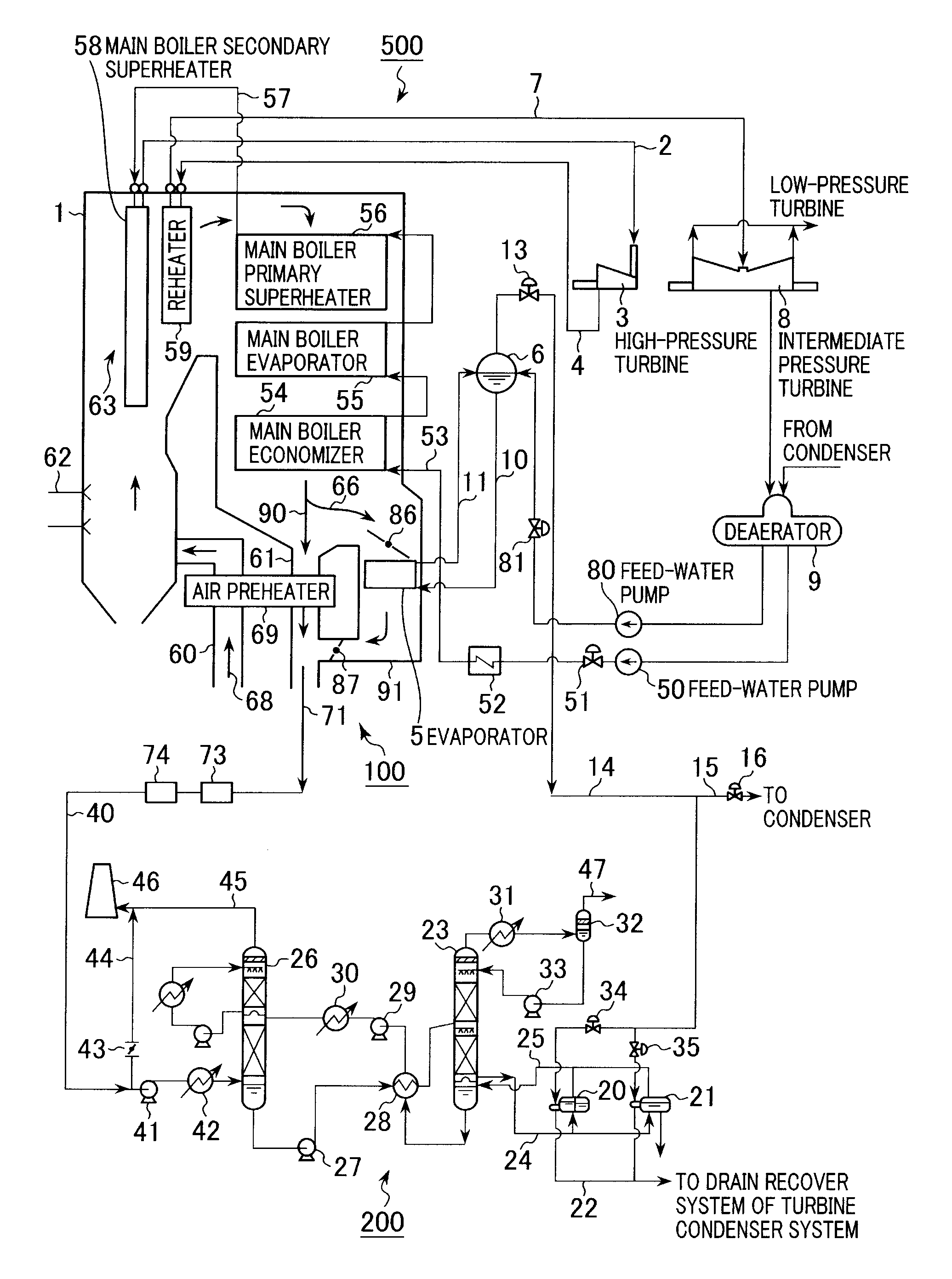

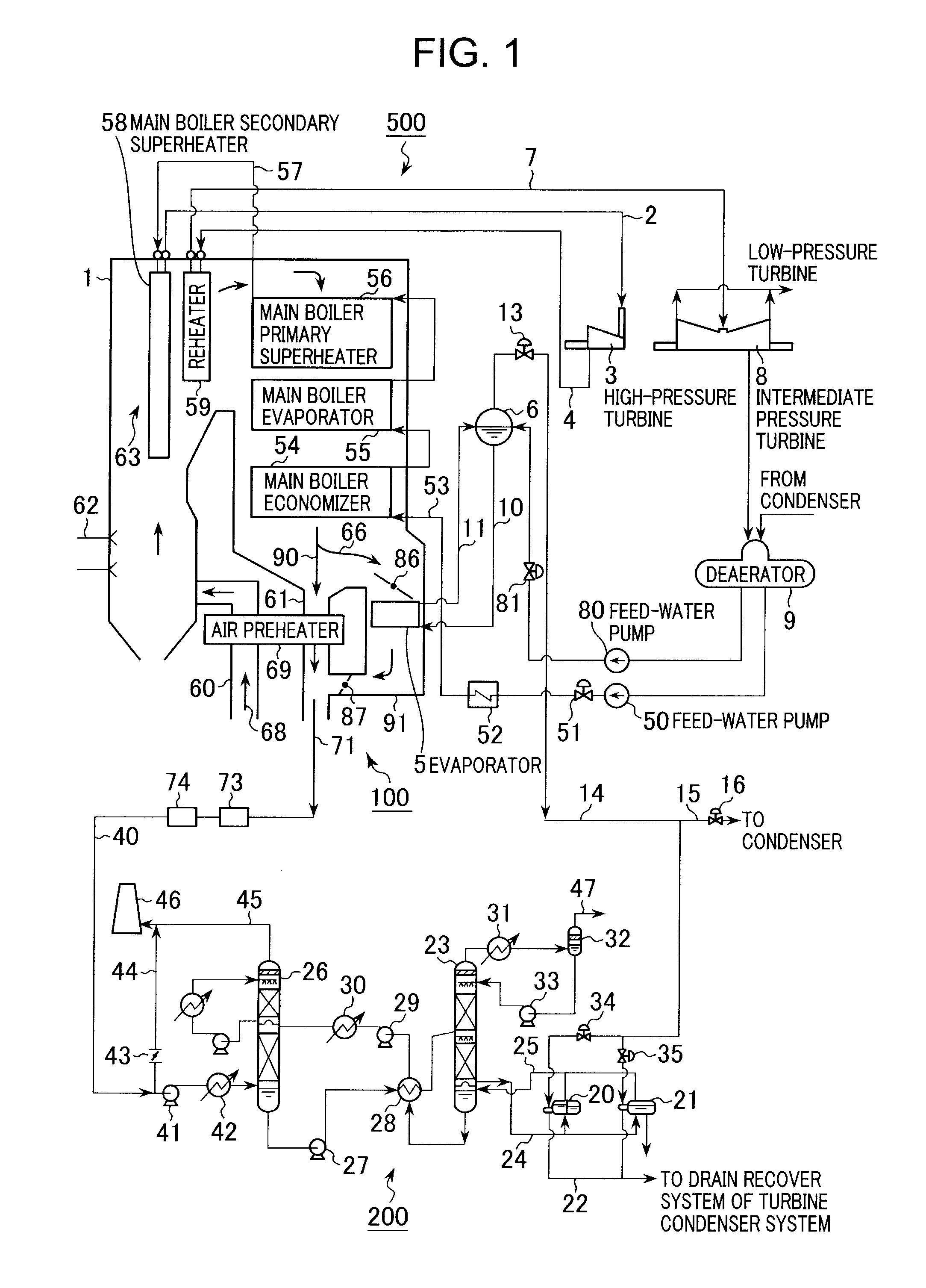

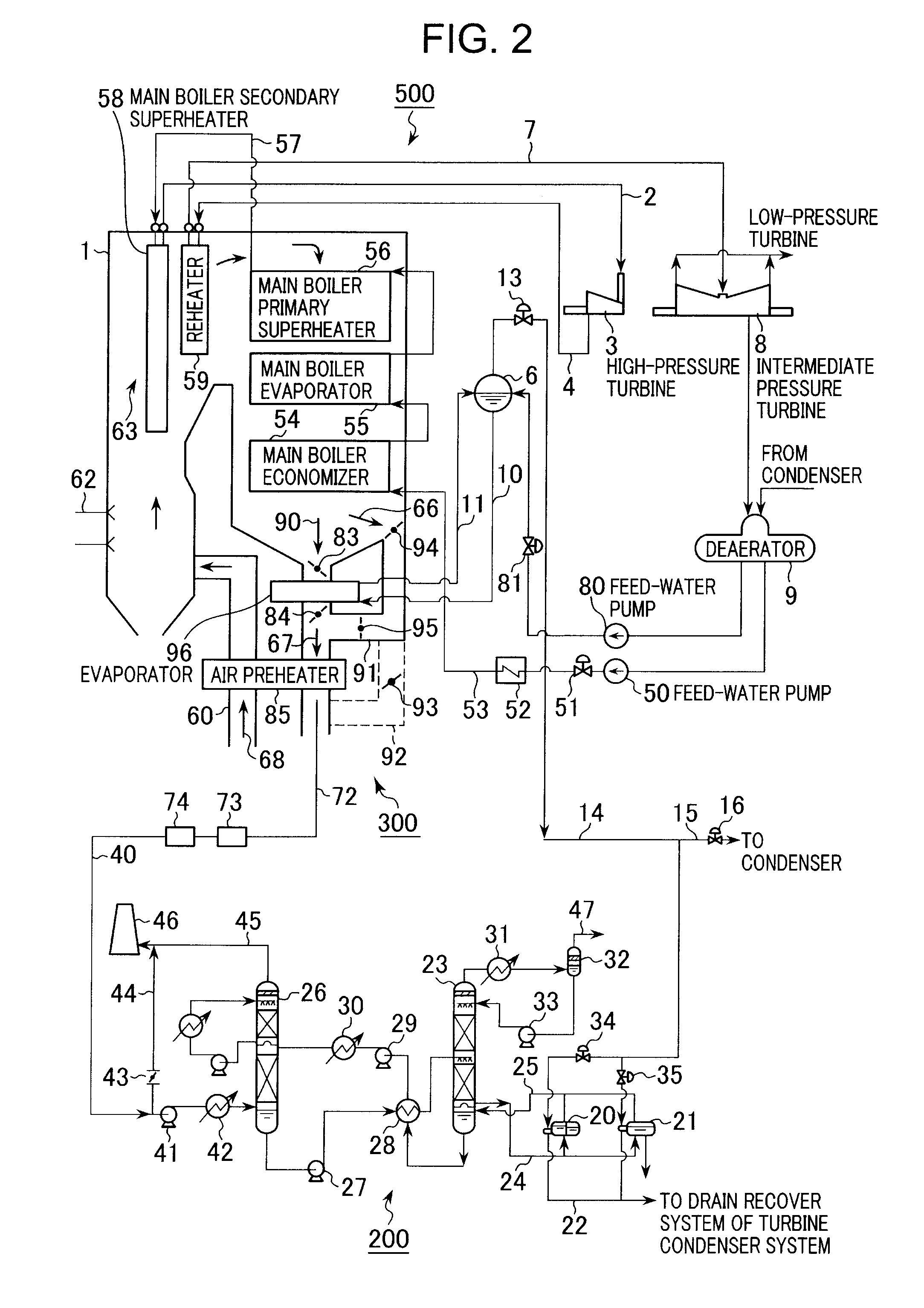

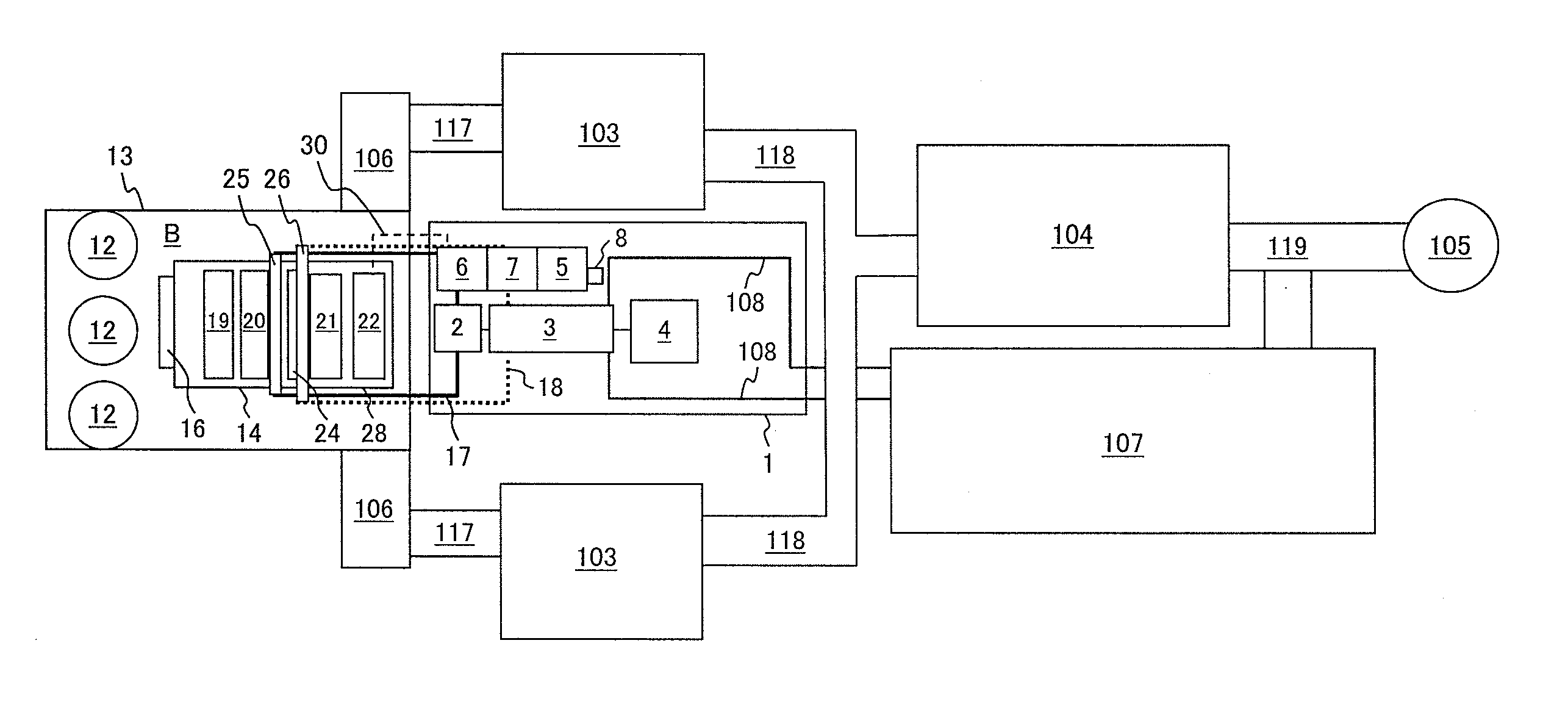

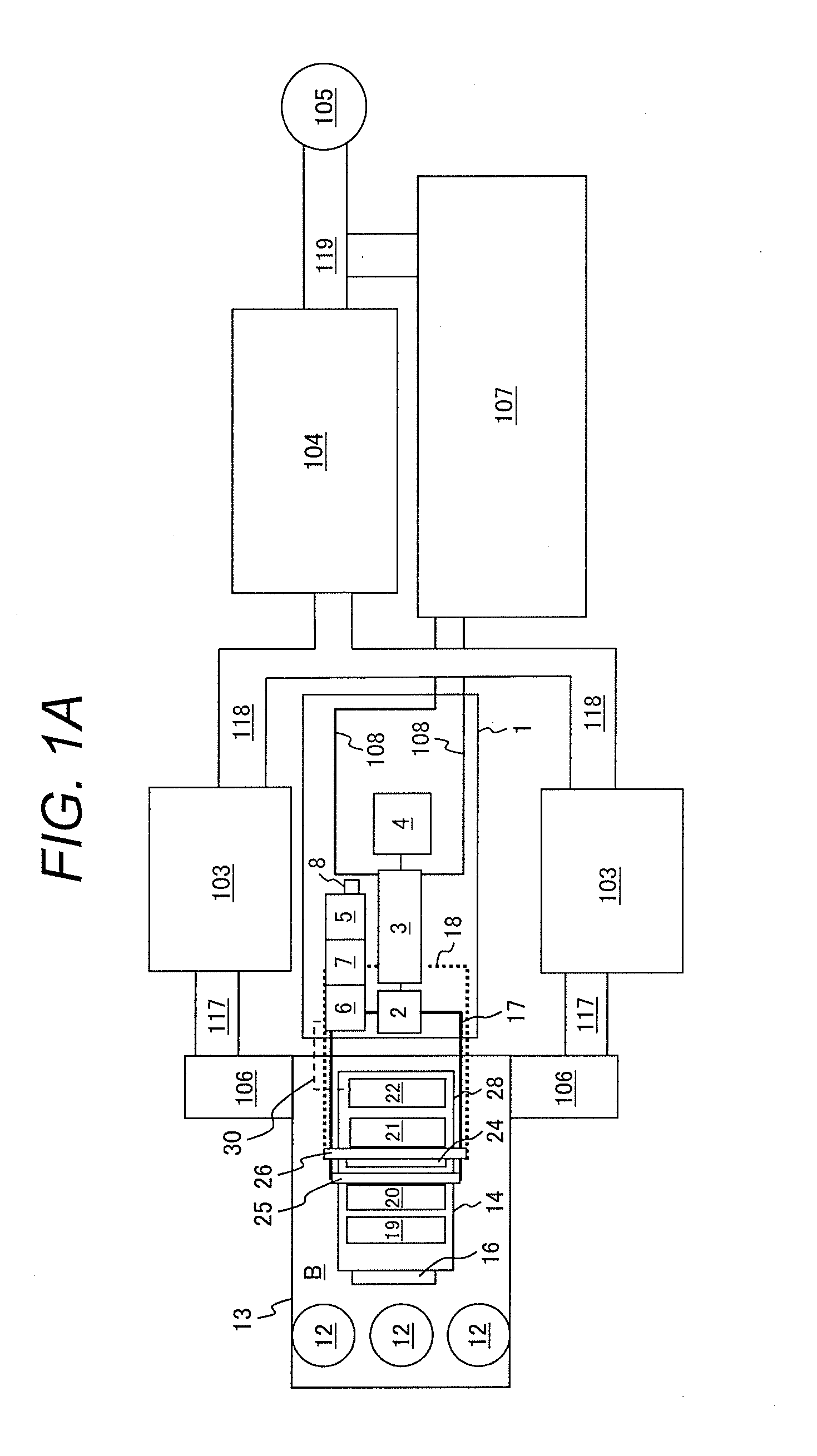

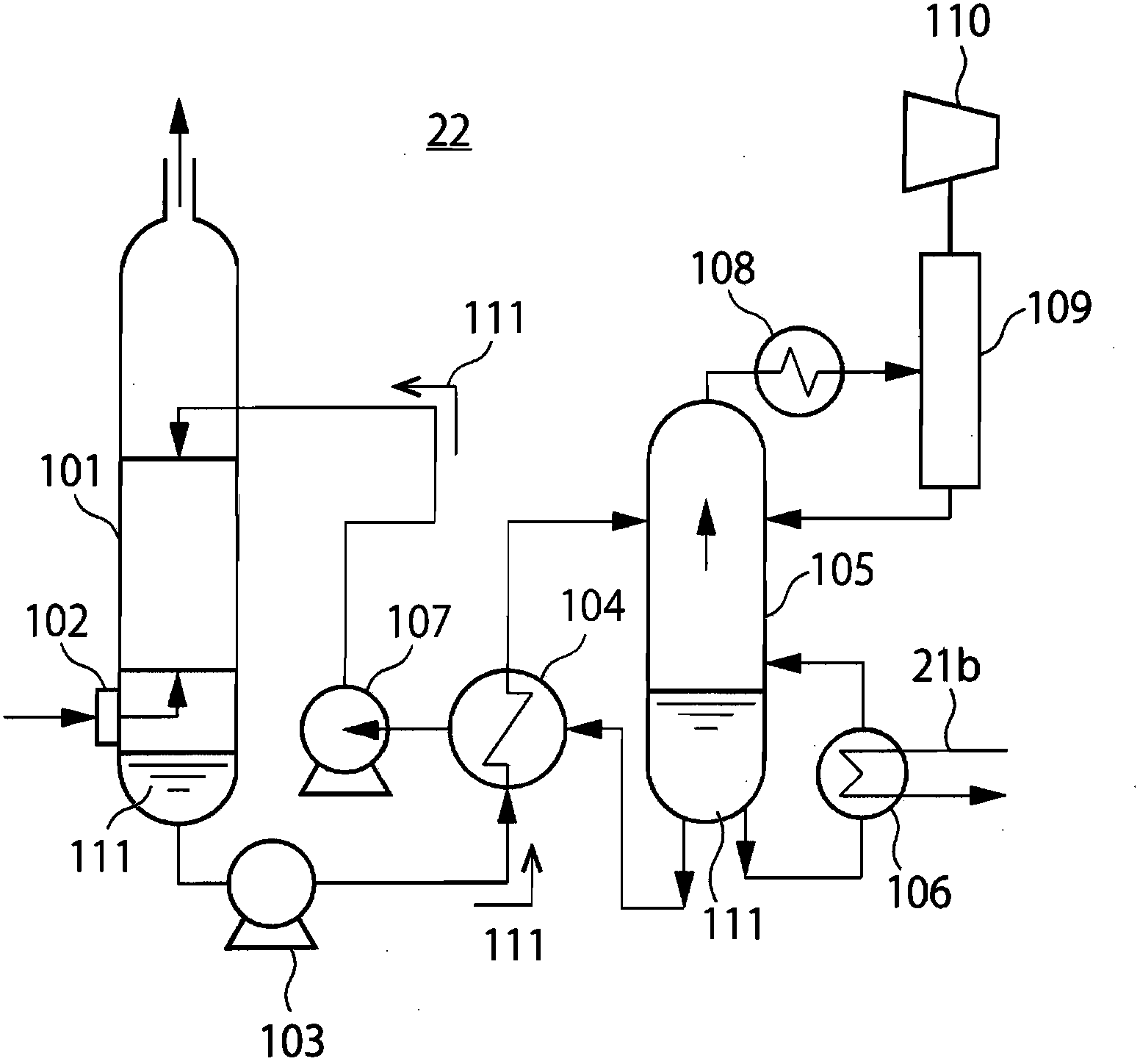

Boiler Apparatus

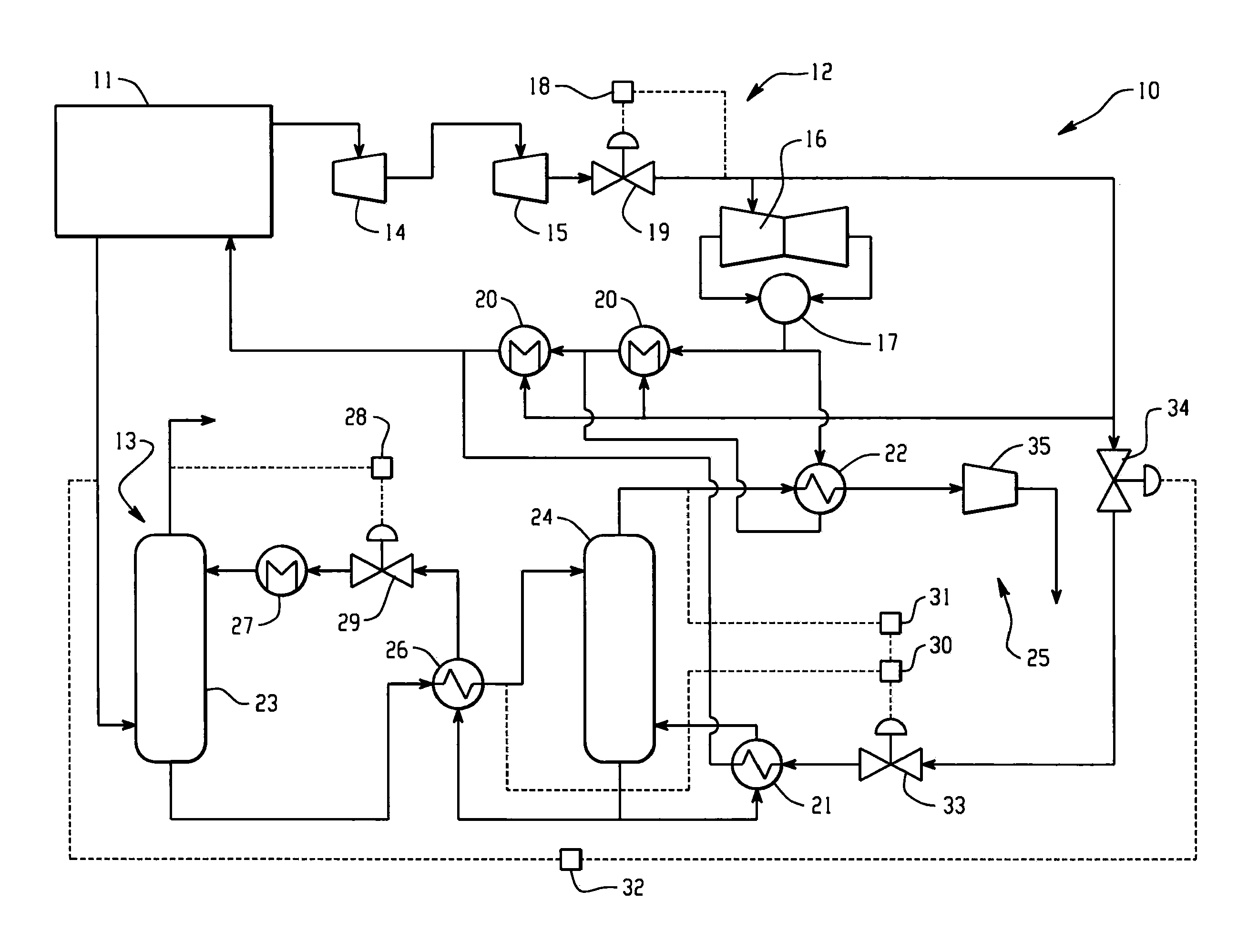

ActiveUS20110232286A1Efficient regenerationWithout lowering steam turbine efficiencyGas treatmentBoiler water tubesAir preheaterWorking fluid

A boiler apparatus is provided that generates a heat source capable of efficiently regenerating absorbing liquid while maintaining steam turbine efficiency to a maximum extent.The boiler apparatus includes: an economizer 54 preheating water serving as working fluid of a steam turbine system 500; an air preheater 69 installed downstream of the economizer 54; an evaporator 5 installed downstream of the economizer 54; an evaporator drum 6 using the water vapor from the evaporator 5 to generate saturated water vapor; a reboiler 20 using the saturated water vapor from the evaporator drum 6 to evaporate the absorbing liquid from a regeneration tower 23; a steam bypass pipe 15 connected to a steam pipe 14 through which the saturated water vapor from the evaporator drum 6 passes; a steam escape valve 16 installed in the steam bypass pipe 15; an exhaust gas bypass pipe 44 connected to an exhaust gas pipe 40 connecting the air preheater 69 with an absorption tower 26; and a butterfly valve 43 installed in the exhaust gas bypass pipe 44.

Owner:MITSUBISHI POWER LTD

Emission reduction method for use with a heat recovery steam generation system

InactiveUS8220274B2Quantity minimizationSmall sizeSteam generation heating methodsEmission preventionCombustorExhaust fumes

Owner:JOHNSON MATTHEY INC

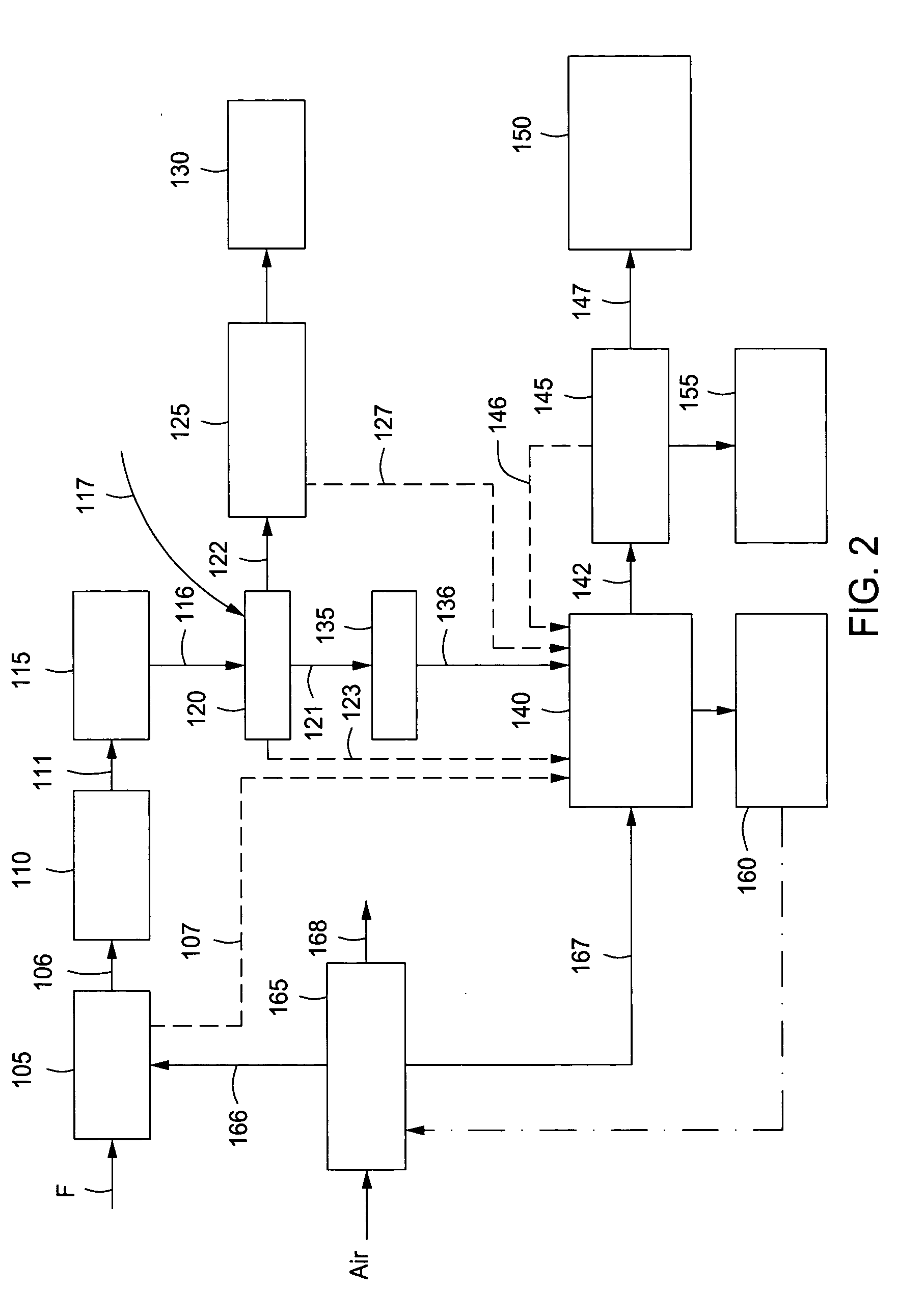

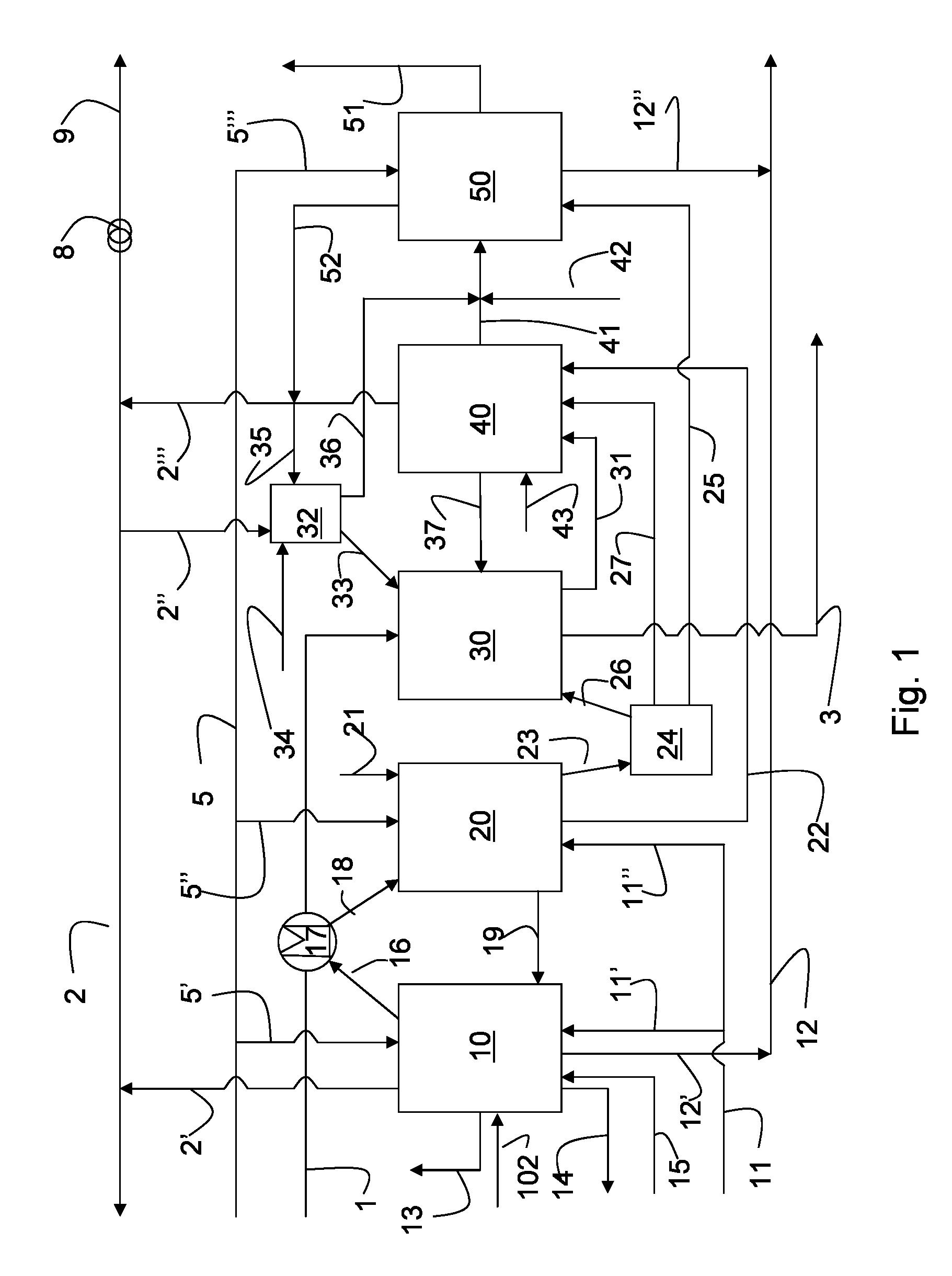

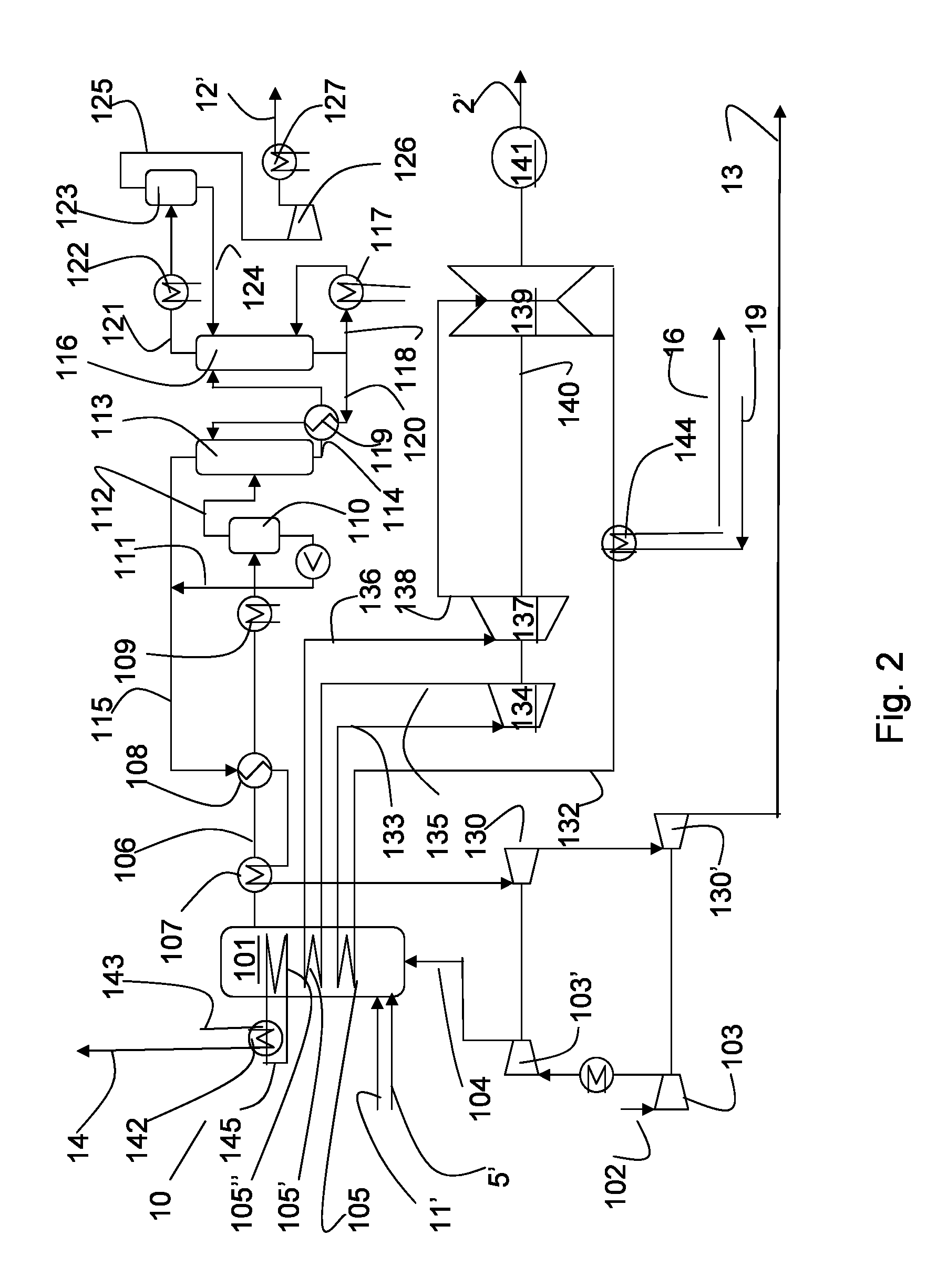

Oil sand production without co2 emmission

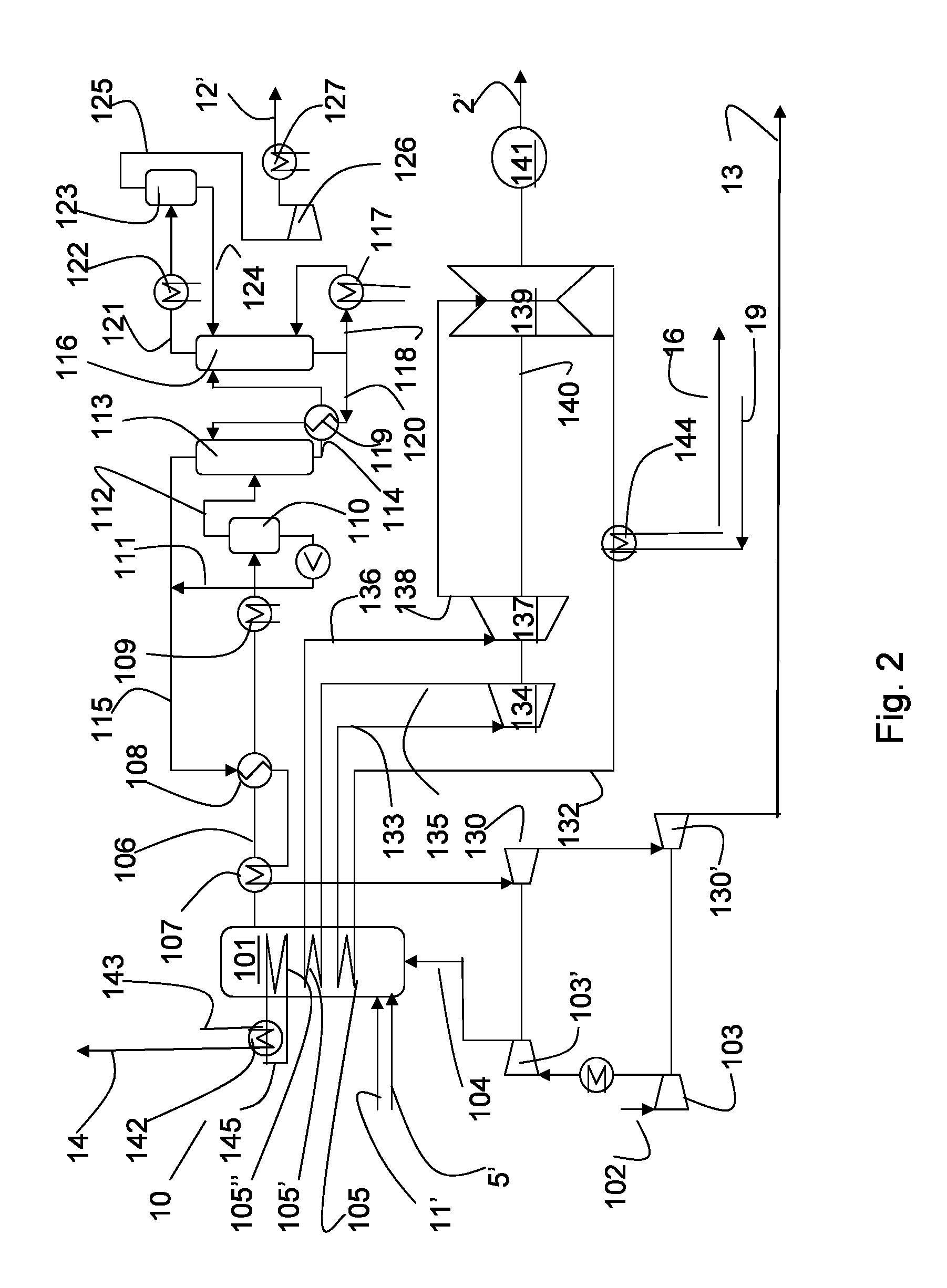

A plant for generation of steam for oil sand recovery from carbonaceous fuel with capture of CO2 from the exhaust gas, comprising heat coils (105, 105′, 105″) arranged in a combustion chamber (101) to cool the combustion gases in the combustion chamber to produce steam and superheated steam in the heat coils, steam withdrawal lines (133, 136, 145) for withdrawing steam from the heat coils, an exhaust gas line (106) for withdrawal of exhaust gas from the combustion chamber (101), where the combustion chamber operates at a pressure of 5 to 15 bara, and one or more heat exchanger(s) (107, 108) are provided for cooling of the combustion gas in line (106), a contact device (113) where the cooled combustion gas is brought in countercurrent flow with a lean CO2 absorbent to give a rich absorbent and a CO2 depleted flue gas, withdrawal lines (114, 115) for withdrawal of rich absorbent and CO2 depleted flue gas, respectively, from the contact device, the line (115) for withdrawal of CO2 depleted flue gas being connected to the heat exchangers (107, 108) for heating of the CO2 depleted flue gas, and where the rich absorbent is regenerated an absorbent regenerator (116), the regenerated lean absorbent is recycled to the absorber (113), and a gas withdrawal line (121) connected to the absorber for withdrawal of CO2 and steam from the regenerator (116), is described.

Owner:CO2 CAPSOL

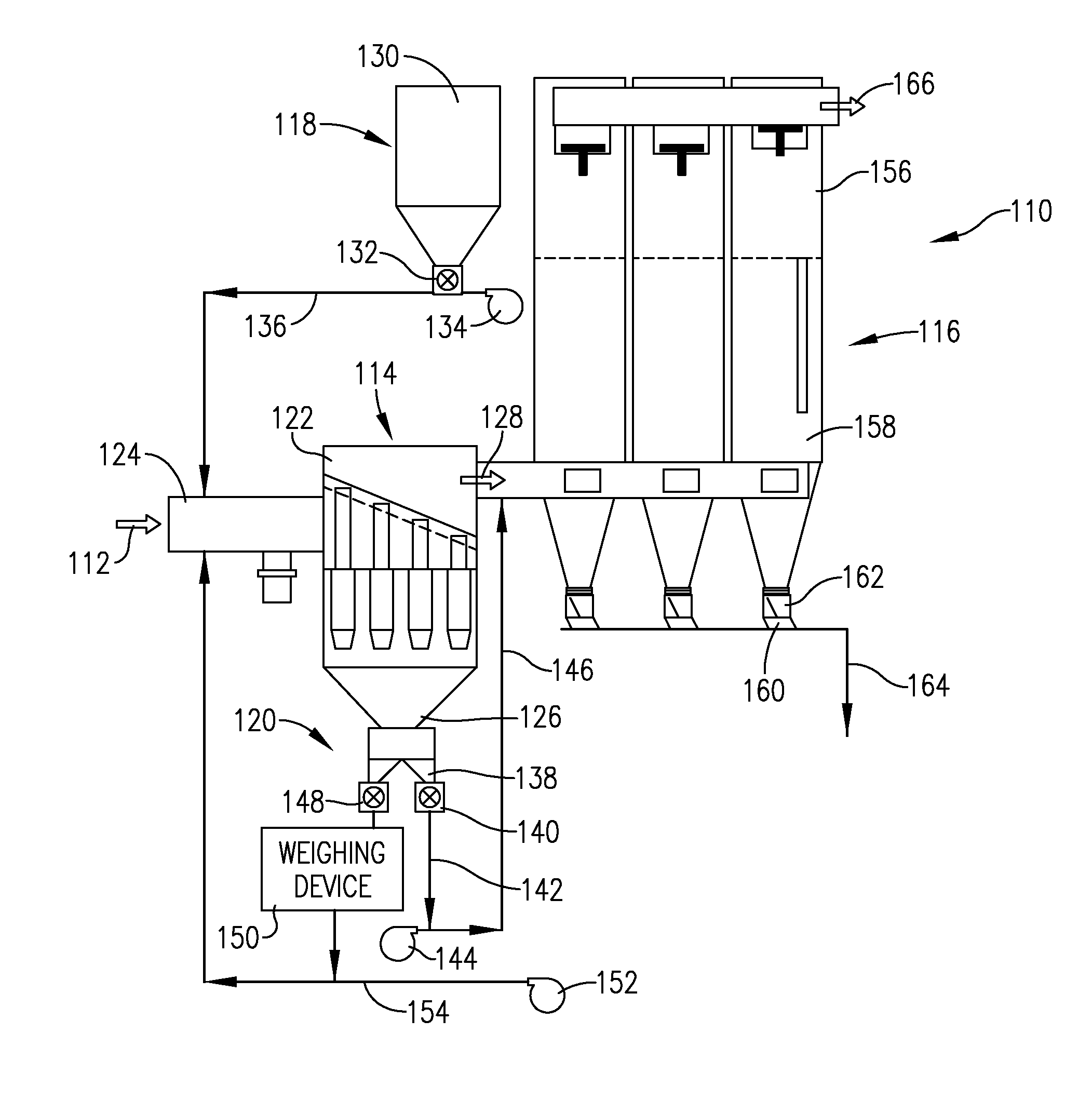

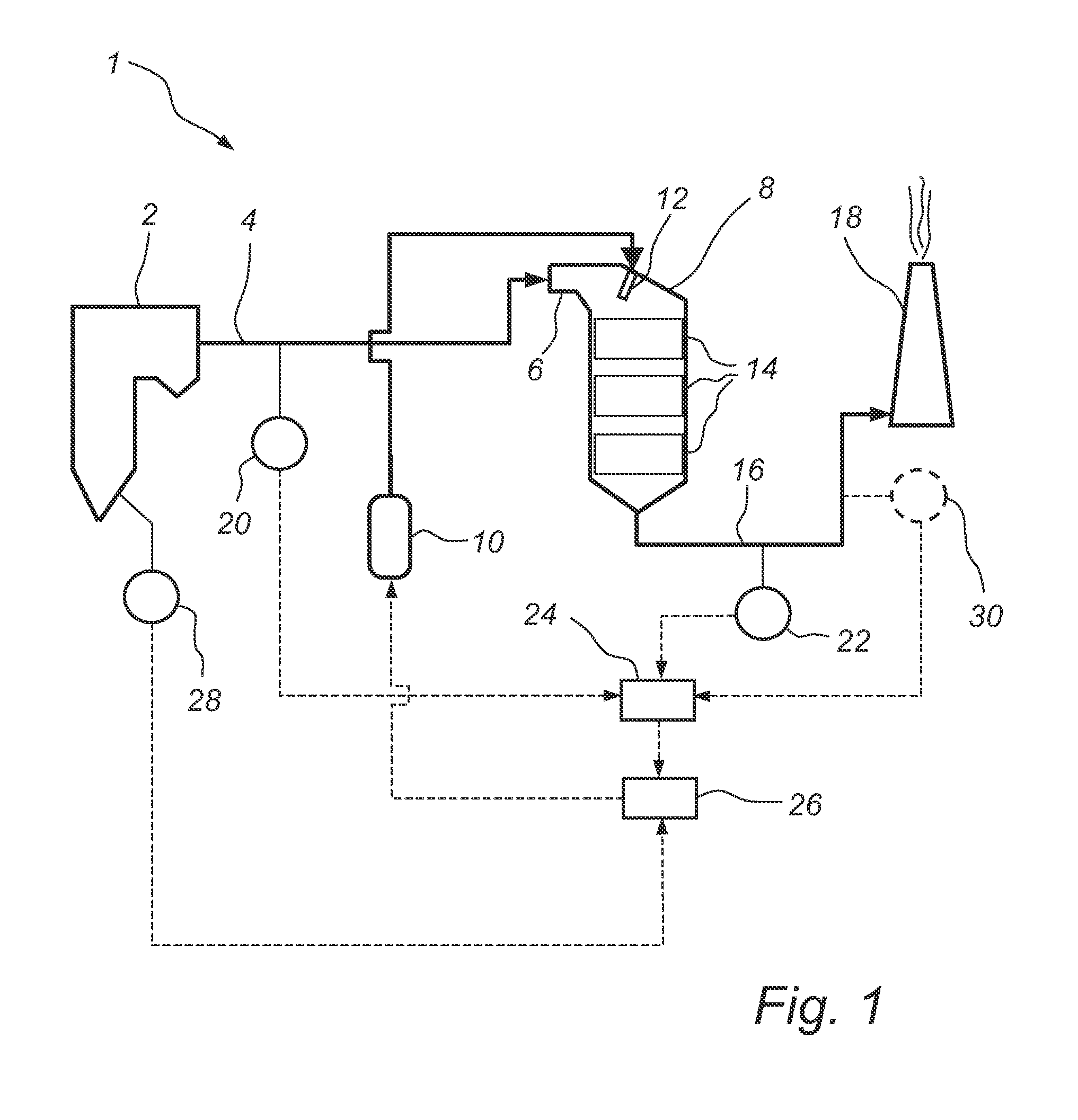

Pollution abatement process for fossil fuel-fired boilers

ActiveUS20110303133A1Requisite amount can be minimizedHigh degreeGas treatmentEmission preventionSodium bicarbonateParticulates

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16).Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOX, SOX, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16). In another aspect, the invention provides pollution abatement apparatus (110) and methods employing an upstream recirculation reactor (114), a supply of fresh sorbent (118), and a downstream collector (116). In the reactor (114), fresh sorbent reacts with incoming hot flue gas (112) to generate a reduced pollutant flue gas (128) and a solids fraction including reacted sorbent and pollutants, and unreacted sorbent. Recirculation apparatus (120) provided between the reactor outlet (126) and reactor (114) serves to generate a substantially constant mass or volume flow rate of the reactor solids fraction, which minimizes the use of fresh sorbent and maximizes the pollution abatement efficiency of the apparatus (110).

Owner:INDAL ACCESSORIES

Method for reduction of slagging and fouling of the waterwalls and of the firebox and superheater and reheater of steam boilers with coal combustion

InactiveUS6883443B2Prevent slaggingAvoid foulingBoiler cleaning apparatusSolid fuel combustionCombustion chamberSorbent

The present invention is a method for reducing the slagging and fouling of the surfaces of the waterwalls, firebox, superheater, and reheater of the furnace of a coal-fired steam boiler. The process reduces the firebox exit temperature to below the specific ash melting temperature by injecting the following, either alone or in combination, into ports located in the upper section of the firebox: recirculated flue gas from downstream of the electrostatic precipitator, atomized water, or a sorbent water slurry. All of these materials have a lower temperature than the main flue gas or require additional heat for evaporation. Mixing these materials with the main flue gas from the furnace will not affect the coal combustion process, yet will reduce the temperature of any fly ash particles in the main flue gas to below the specific ash fusion temperature, and thus, prevent slagging and fouling within the furnace.

Owner:APTECH ENG SERVICES

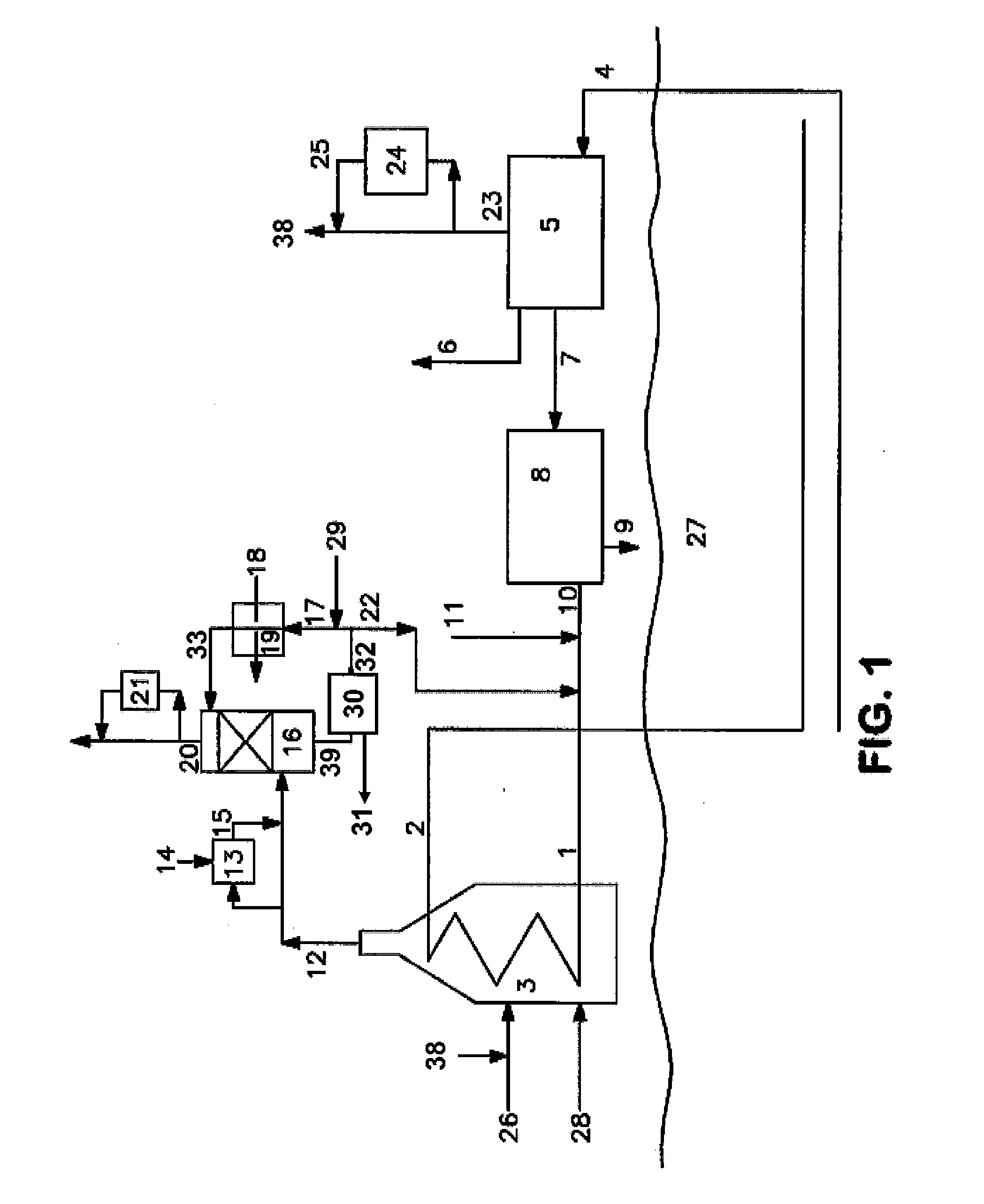

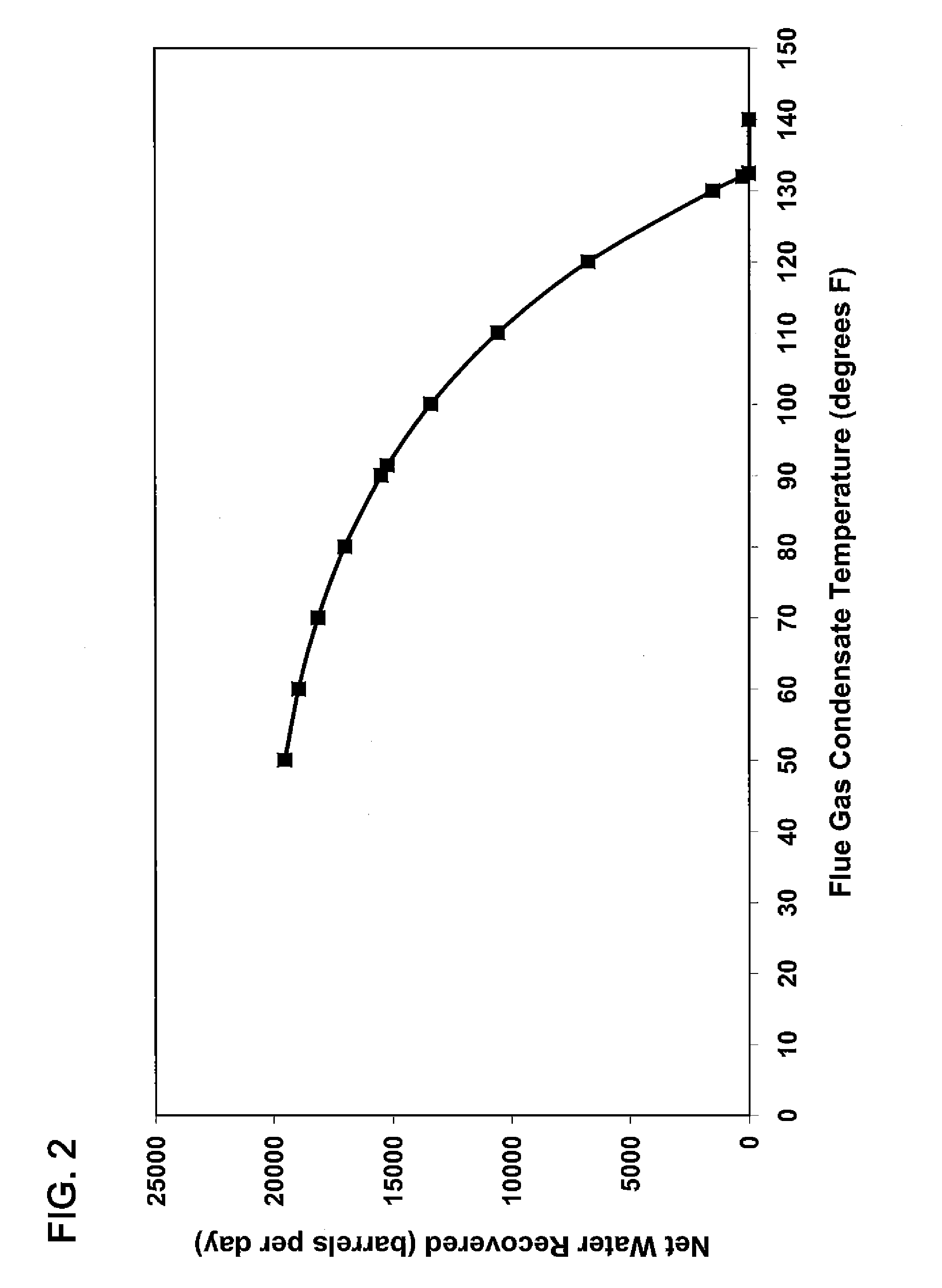

Water recovery and acid gas capture from flue gas

Methods for removing acid gases and recovering water from flue gas. A flue gas is introduced into a water spray tower and is cooled by direct contact with a sprayed aqueous stream to condense a portion of the water vapor in the flue gas. Acid gases present in the flue gas are absorbed into the aqueous mixture, and a chemical added to the stream facilitates conversion of absorbed acid gases. The aqueous stream leaving the spray tower is next treated to remove contaminants, such as carbonates and bicarbonates, thereby producing a cleaned aqueous stream that may be split into a stream that is cooled prior to reuse in the spray tower, as well as a stream that is fed back to the boiler.

Owner:PHILLIPS 66 CO

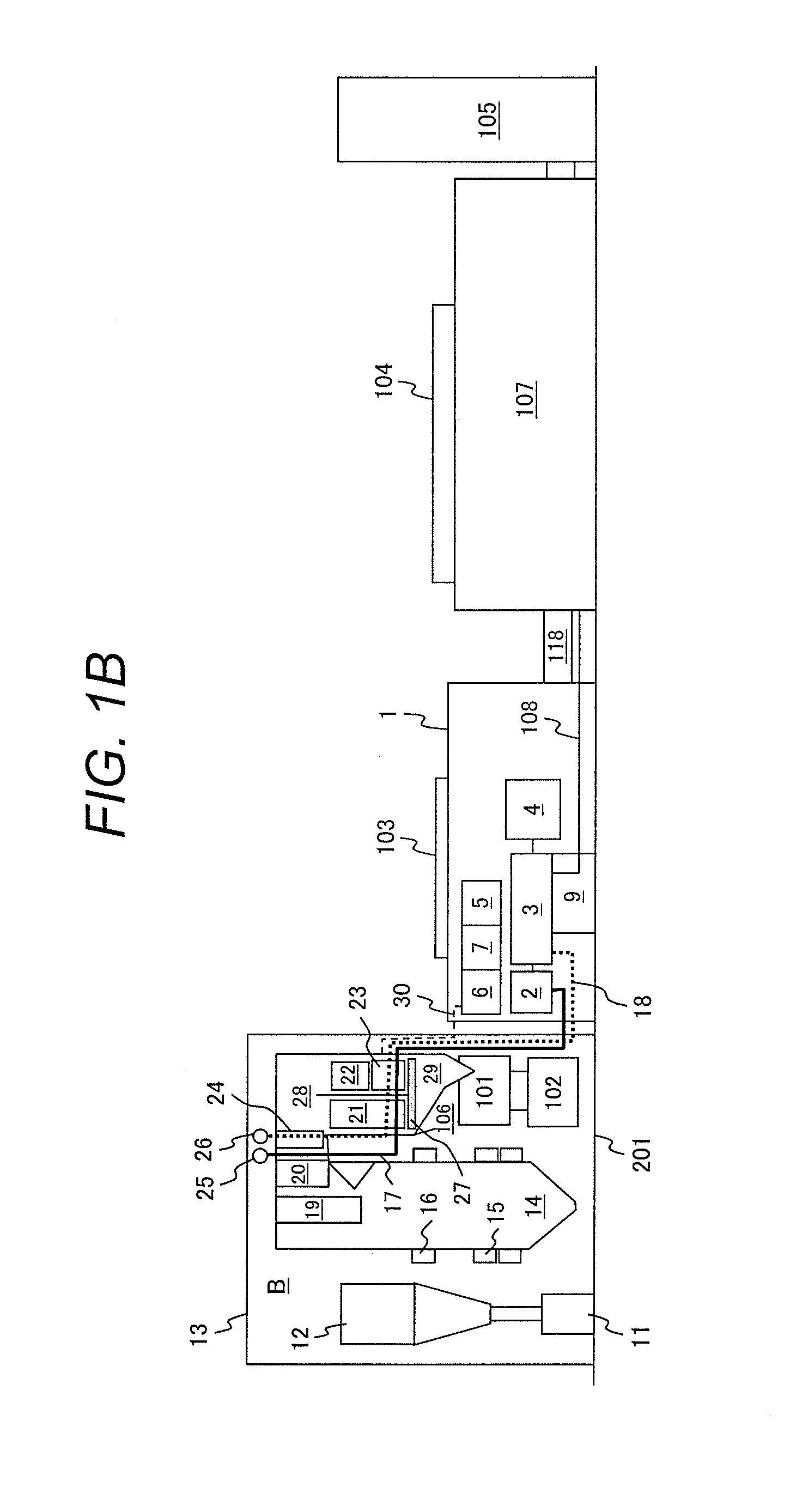

Thermal Power Plant

InactiveUS20120102955A1Reduce construction costsReduce material costsBoiler supporting/setting arrangementsDirect carbon-dioxide mitigationProcess engineeringSteam turbine

A thermal power plant is proposed for achieving high reliability, low material cost, and low construction cost by devising the arrangement and structures of a boiler, steam turbines, and a flue gas treatment apparatus to reduce a usage amount of high-temperature resistance material and further to reduce a thermal elongation of piping. In a thermal power plant including a 2 pass-type boiler having a furnace for burning fuel, a rear heat recovery area for recovering heat from combustion gas exhausted from the furnace, steam turbines are arranged near the rear heat recovery area.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

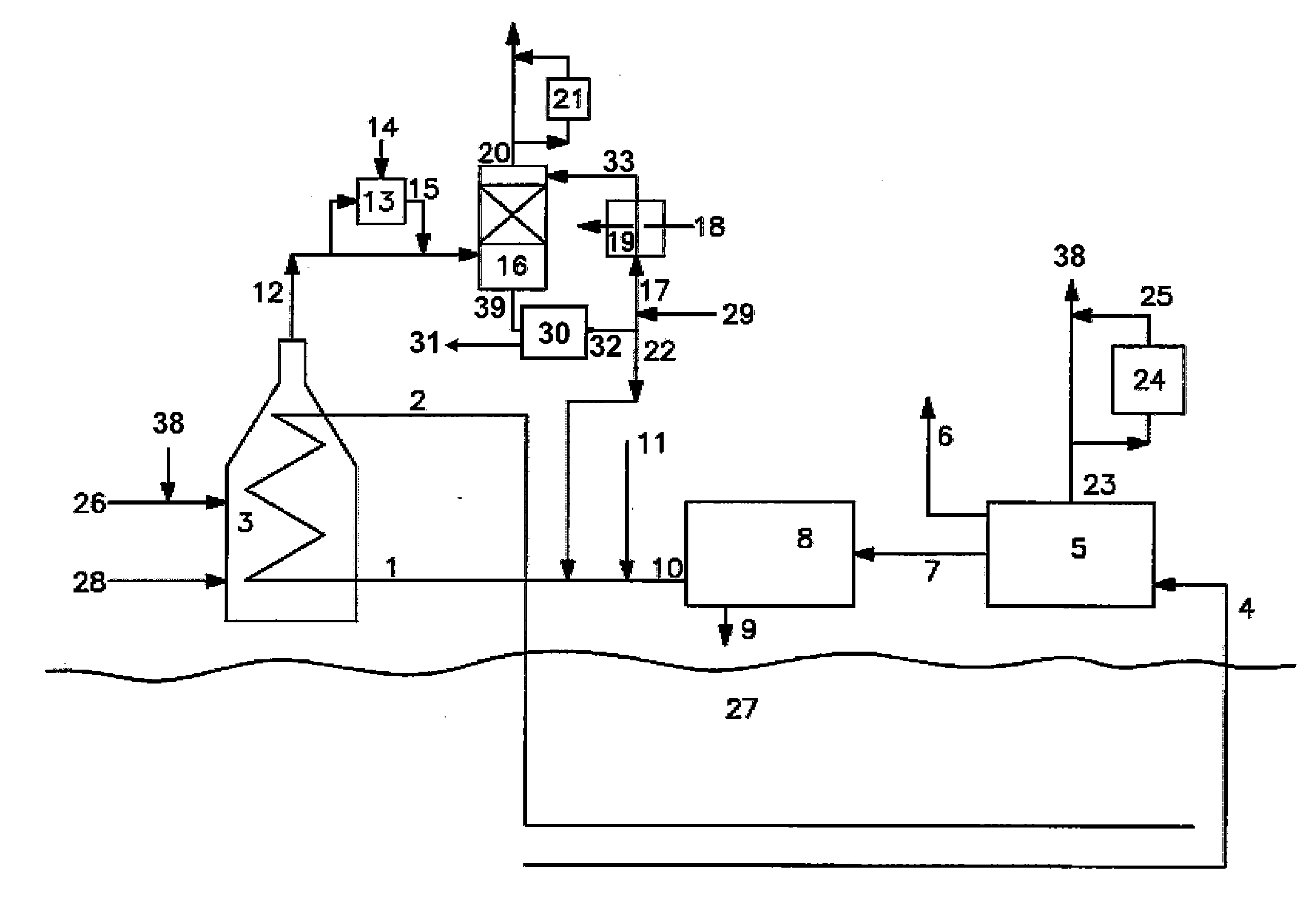

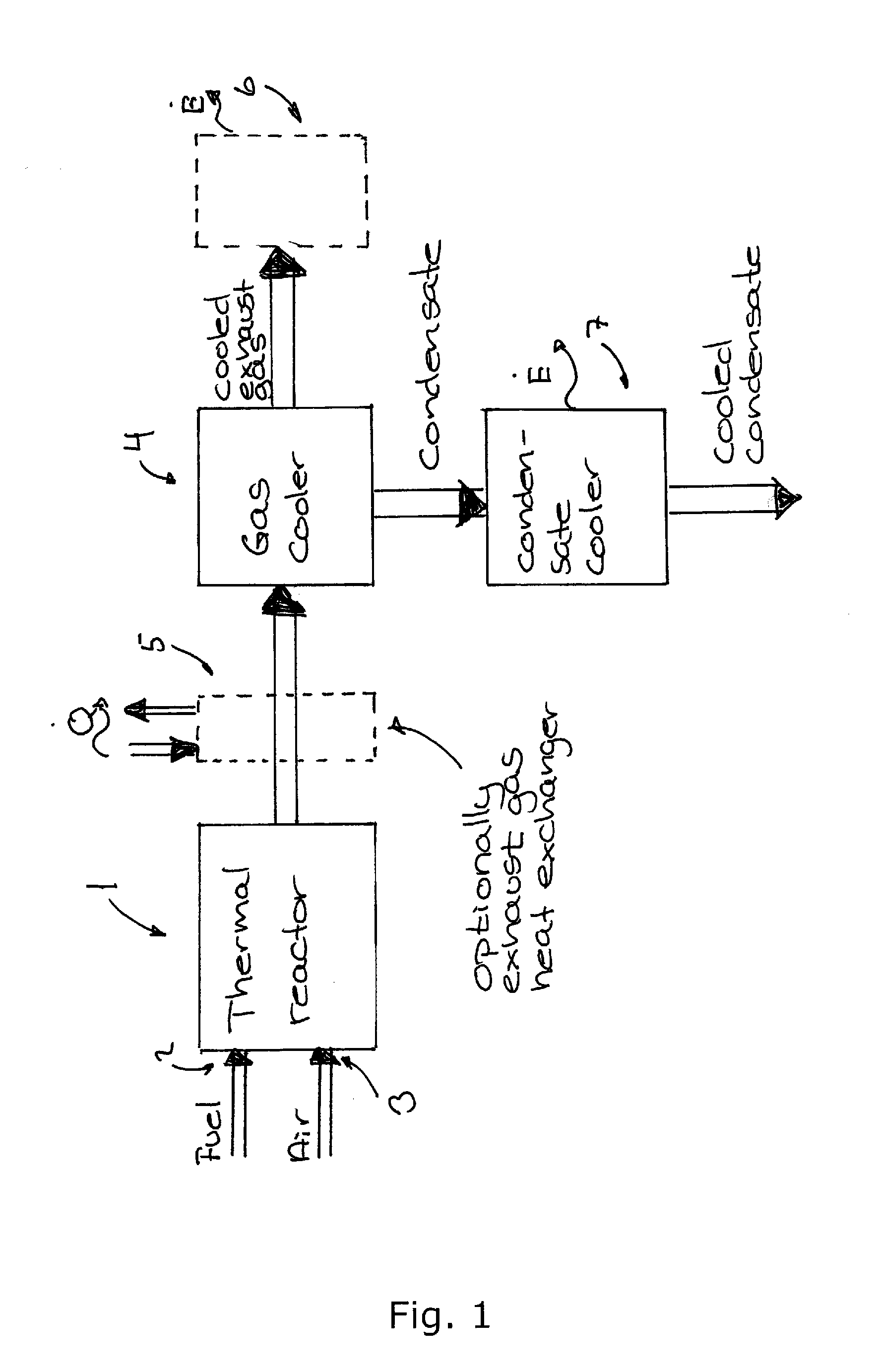

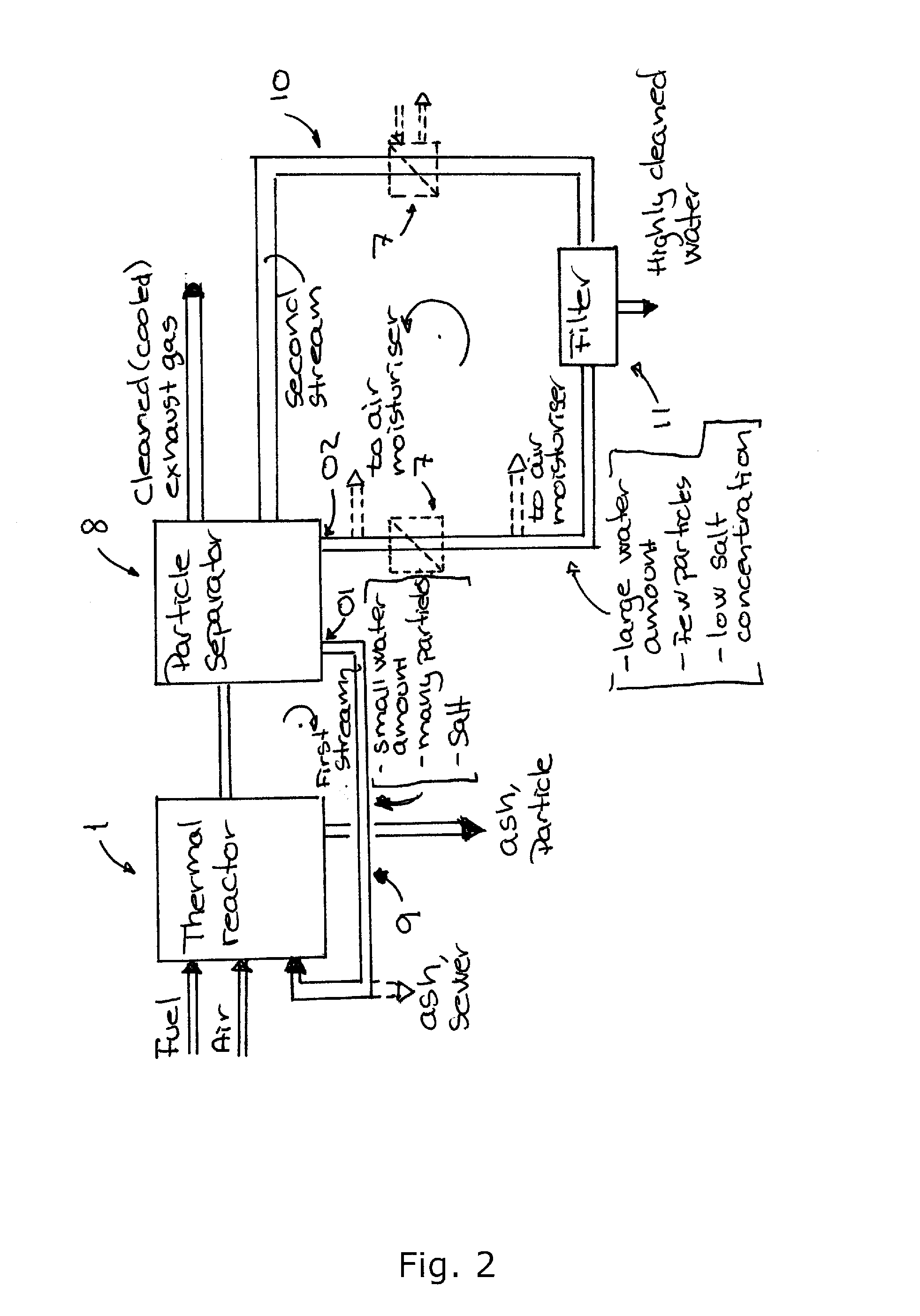

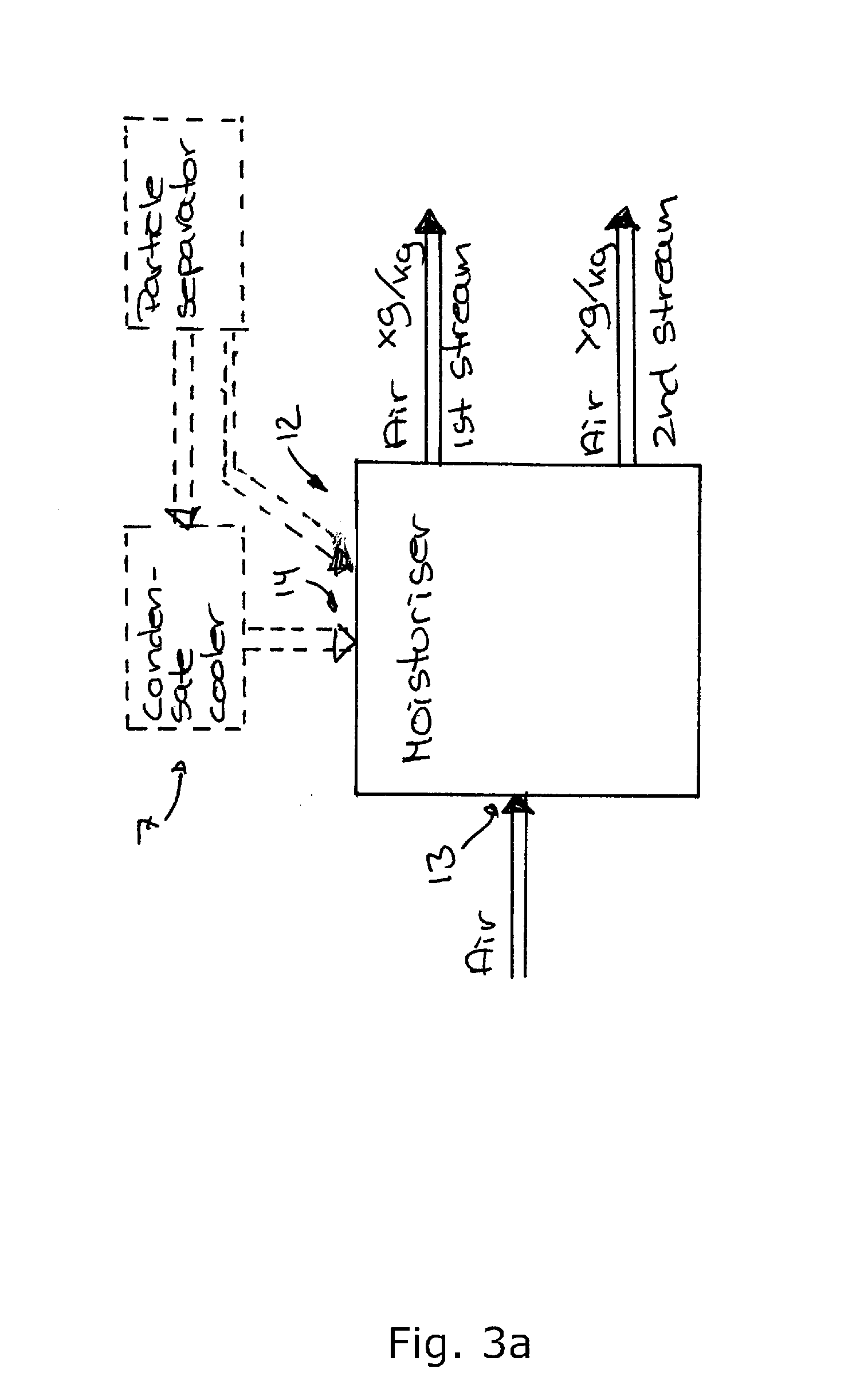

Method and system for cleaning of and heat recovery from hot gases

InactiveUS20120167461A1Extended service lifeEasy to cleanUsing liquid separation agentHeat recoveryChemical recoveryExhaust fumes

Exhaust gas, produced in a thermal reactor (1) that is fed with solid fuel can be cooled and in a gas cooler (4) which produce a condensate that is further cooled in a condensate cooler (7) which produce energy. By using air moisturizing and particle separation technology the exhaust gas and the excess condensate can be clean and the energy efficiency of the plant can be increased. The method can be used for a broad spectrum of fuels and conversion technologies.

Owner:DALL ENERGY HLDG

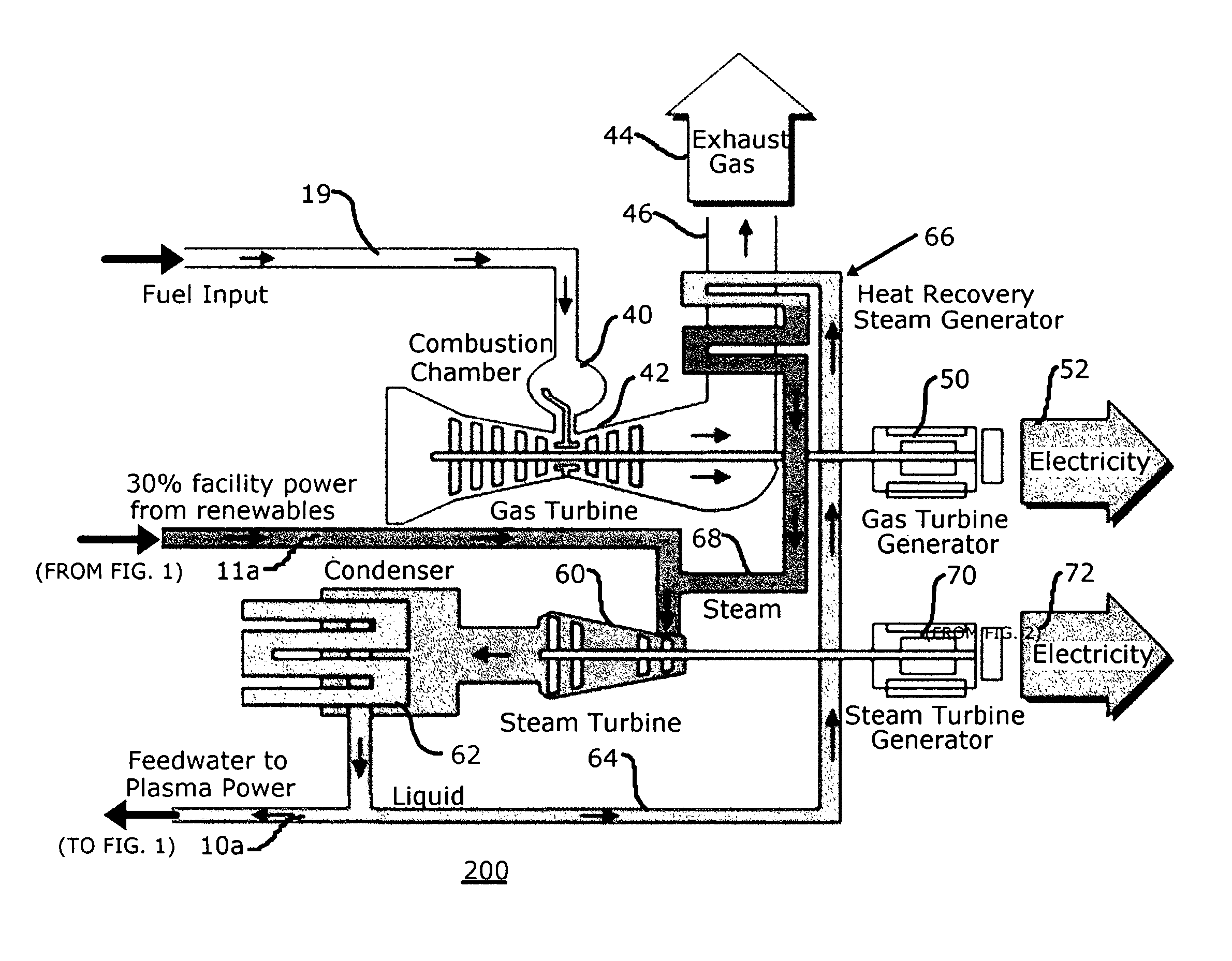

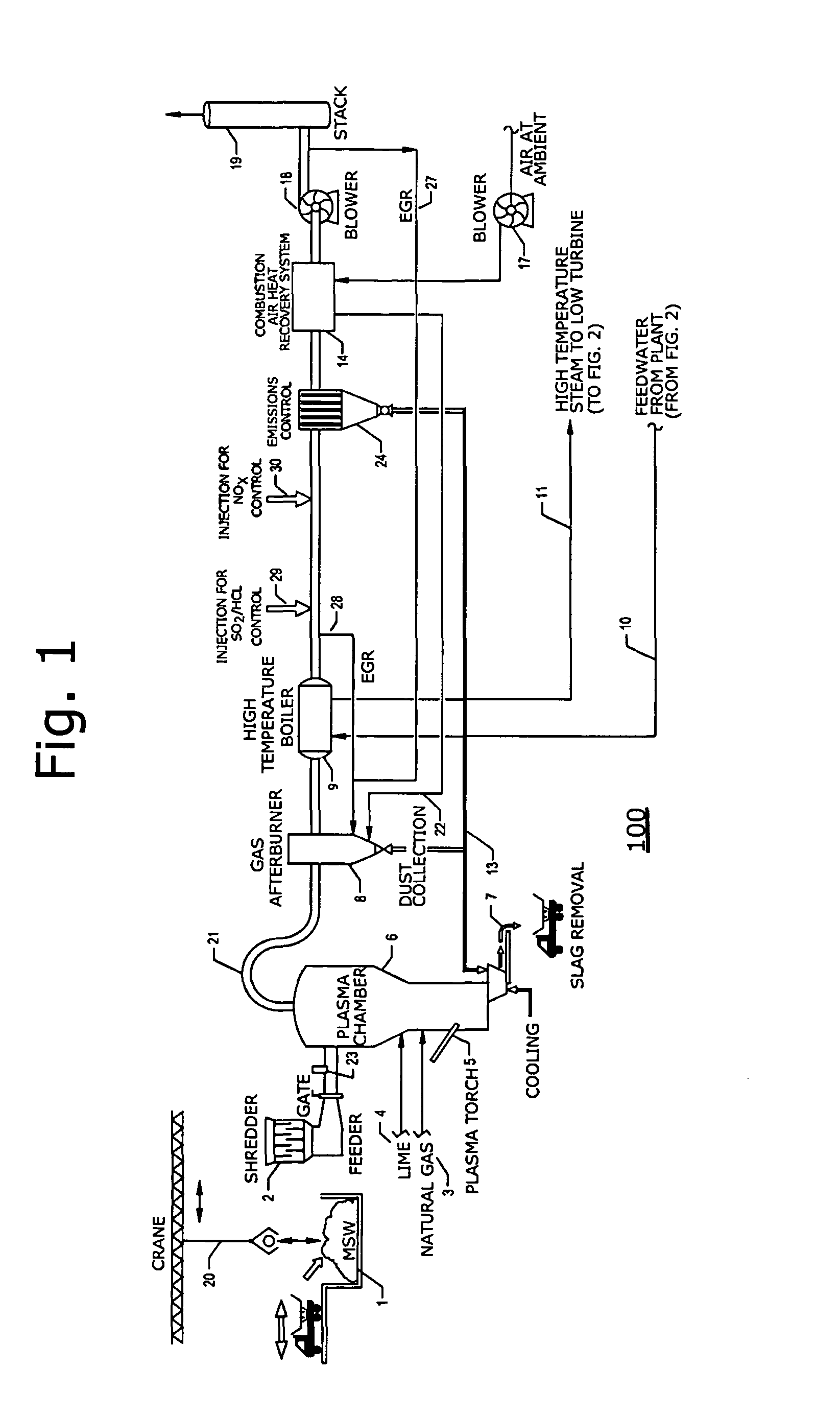

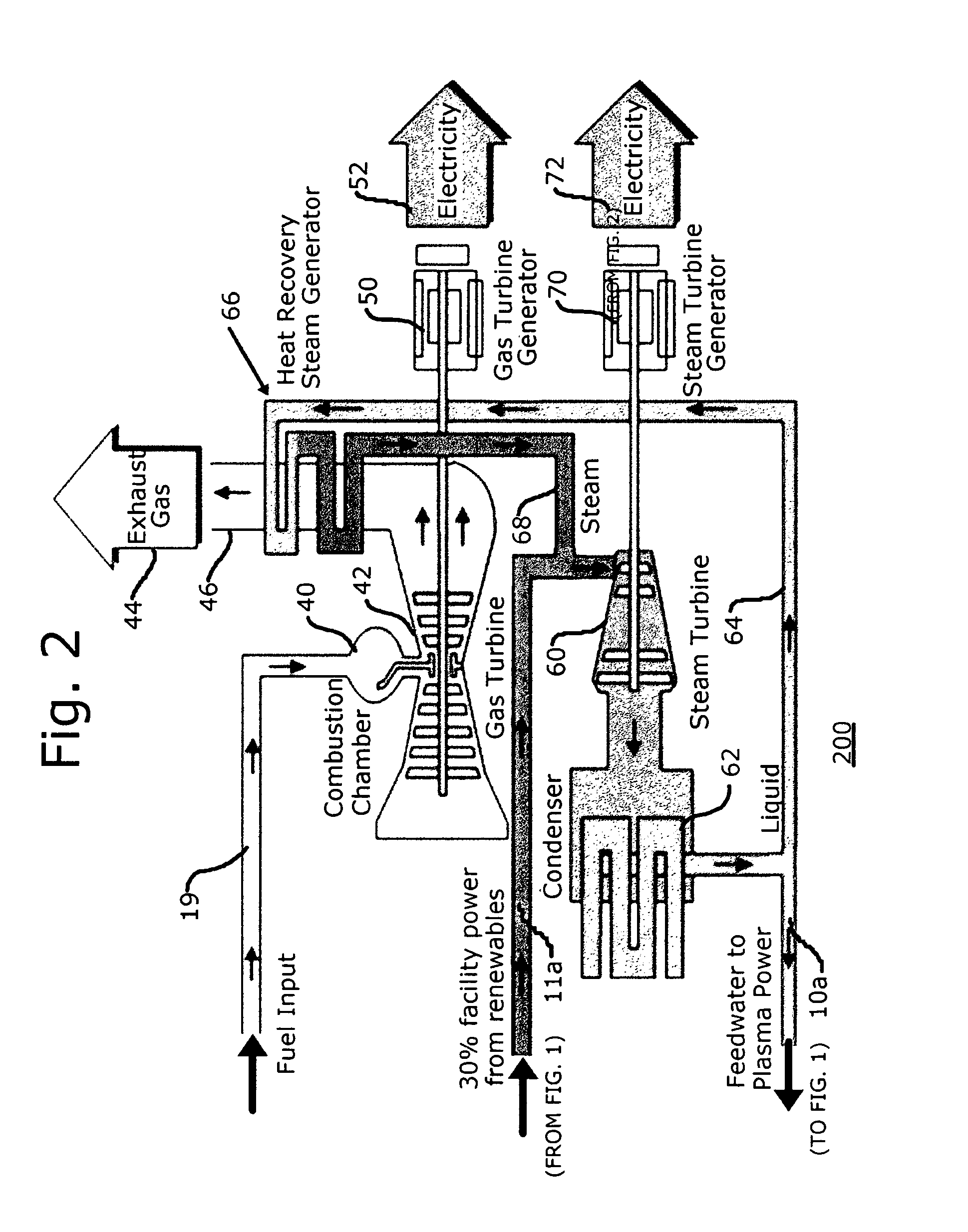

Renewable Combined Cycle Low Turbine Boost

ActiveUS20130312424A1Emission reductionSupplement extractedGasifier electrodesBiofuelsSyngasEnergy transfer

A method and system for cost effectively converting a feedstock using thermal plasma, or other styles of gassifiers, into to a feedwater energy transfer system. The feedstock can be any organic material, or fossil fuel. The energy transferred in the feedwater is converted into steam which is then injected into the low turbine of a combined cycle power plant. Heat is extracted from gas product issued by a gassifier and delivered to a power plant via its feedwater system. The gassifier is a plasma gassifier and the gas product is syngas. In a further embodiment, prior to performing the step of extracting heat energy, there is provided the further step of combusting the syngas in an afterburner. An air flow, and / or EGR flow is provided to the afterburner at a rate that is varied in response to an operating characteristic of the afterburner. The air flow to the afterburner is heated.

Owner:PLASMA TECH HLDG LLC

Pollution abatement process for fossil fuel-fired boilers

ActiveUS8695516B2High degreeLow-cost operationGas treatmentEmission preventionParticulatesSodium bicarbonate

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16). In another aspect, the invention provides pollution abatement apparatus (110) and methods employing an upstream recirculation reactor (114), a supply of fresh sorbent (118), and a downstream collector (116). In the reactor (114), fresh sorbent reacts with incoming hot flue gas (112) to generate a reduced pollutant flue gas (128) and a solids fraction including reacted sorbent and pollutants, and unreacted sorbent. Recirculation apparatus (120) provided between the reactor outlet (126) and reactor (114) serves to generate a substantially constant mass or volume flow rate of the reactor solids fraction, which minimizes the use of fresh sorbent and maximizes the pollution abatement efficiency of the apparatus (110).

Owner:INDAL ACCESSORIES

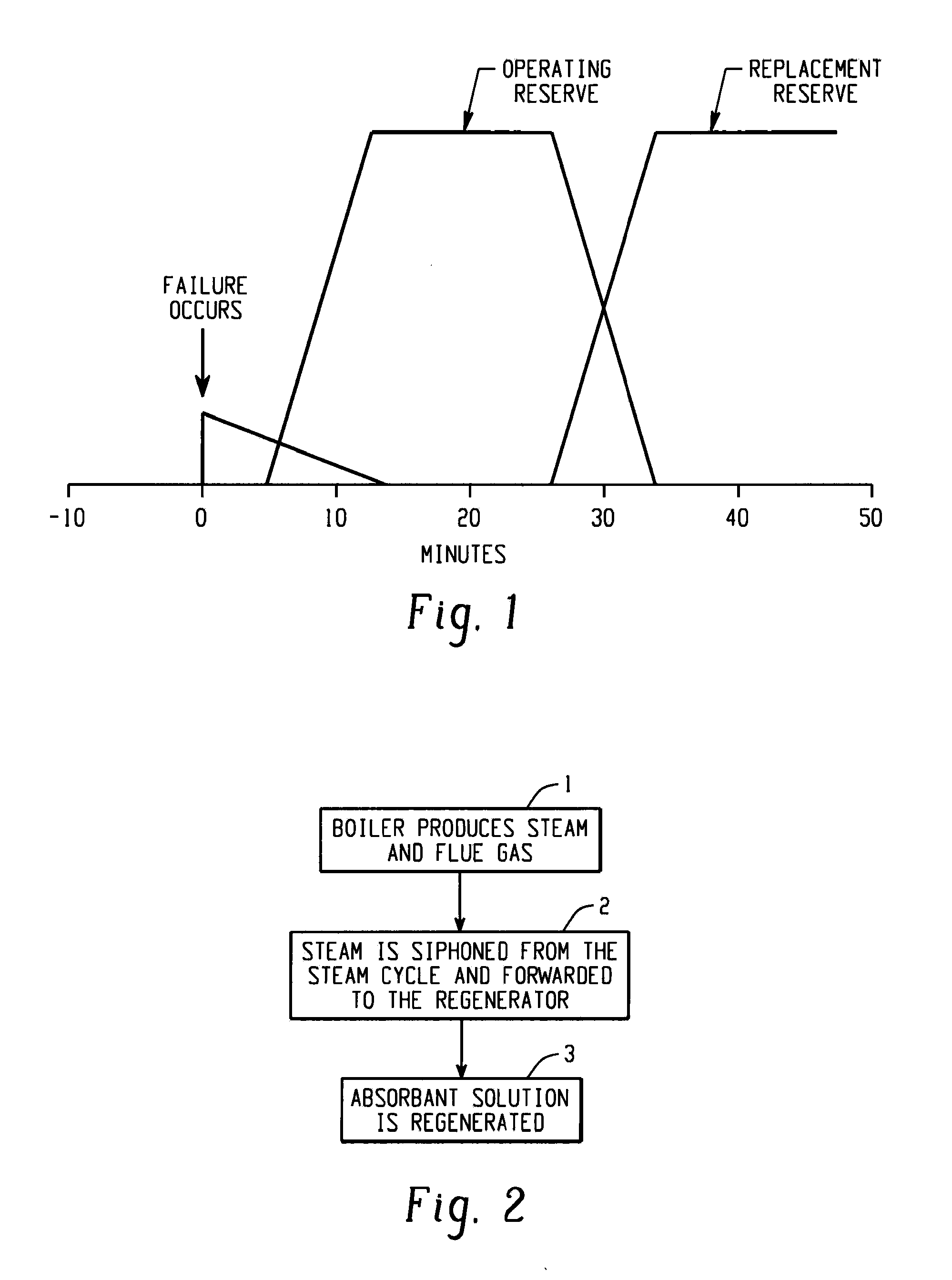

Methods for using a carbon dioxide capture system as an operating reserve

InactiveUS20130099508A1Weakening rangeDemand power outputPower network operation systems integrationSteam usePower stationPower grid

A method of controlling a power system includes monitoring a load on an electrical grid, monitoring a power generation from one or more power producers connected to the electrical grid, wherein at least one of the one or more power producers is a power plant including a carbon dioxide capture system, and utilizing the carbon dioxide capture system of the one or more power producers as a operating reserve in response to an increase in the load on the electrical grid or a reduction in the power generation from one or more power producers connected to the electrical grid.

Owner:ALSTOM TECH LTD

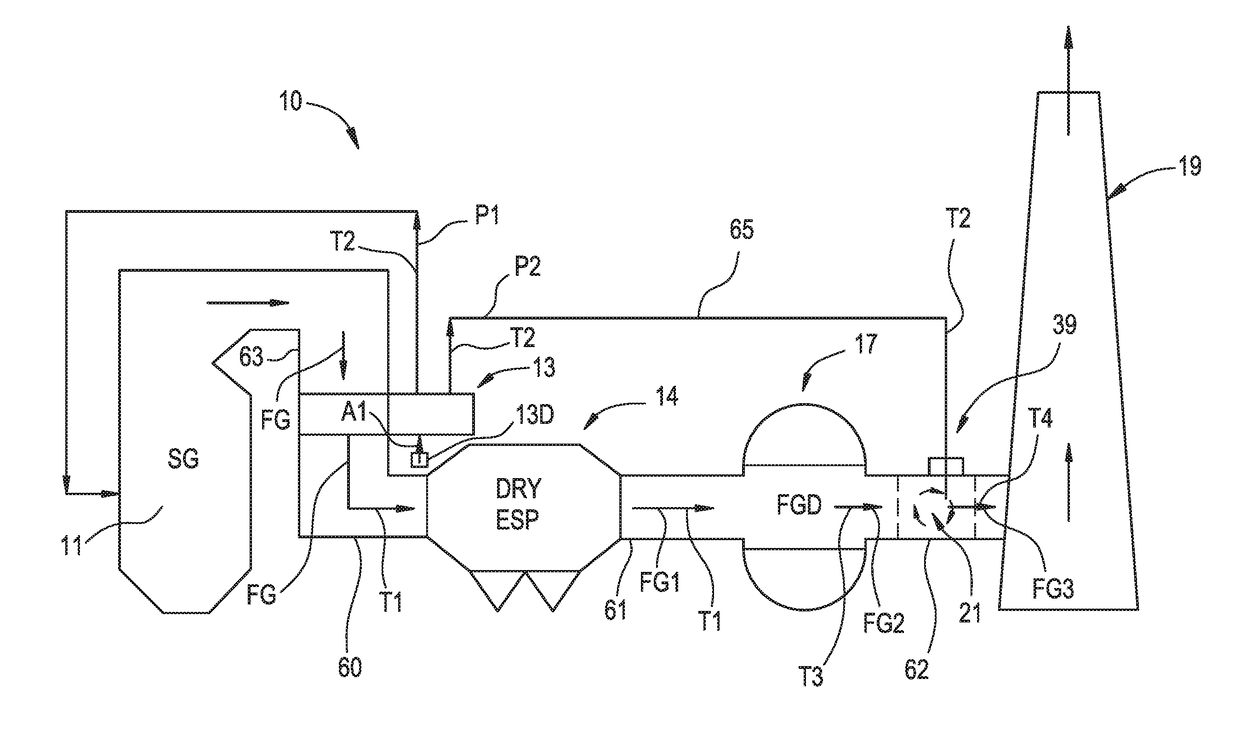

Method and system for improving boiler effectiveness

ActiveUS20180010792A1Mitigate visible plume exitingImprove efficiencyEmission preventionDispersed particle separationAir preheaterParticulates

A method for improving effectiveness of a steam generator system includes providing air to an air preheater in excess of that required for combustion of fuel and providing the air at a mass flow such that the air preheater has a cold end metal temperature that is no less than a water dew point temperature in the air preheater and such that the cold end metal temperature is less than a sulfuric acid dew point temperature. The method includes mitigating SO3 in the flue gas which is discharged directly from the air preheater to a particulate removal system and then directly into a flue gas desulfurization system. Flue gas reheat air is fed from the air preheater to heat the flue gas prior to entering a discharge stack to raise the temperature of the flue gas to mitigate visible plume exiting and to mitigate corrosion in the discharge stack.

Owner:ARVOS LJUNGSTROM LLC

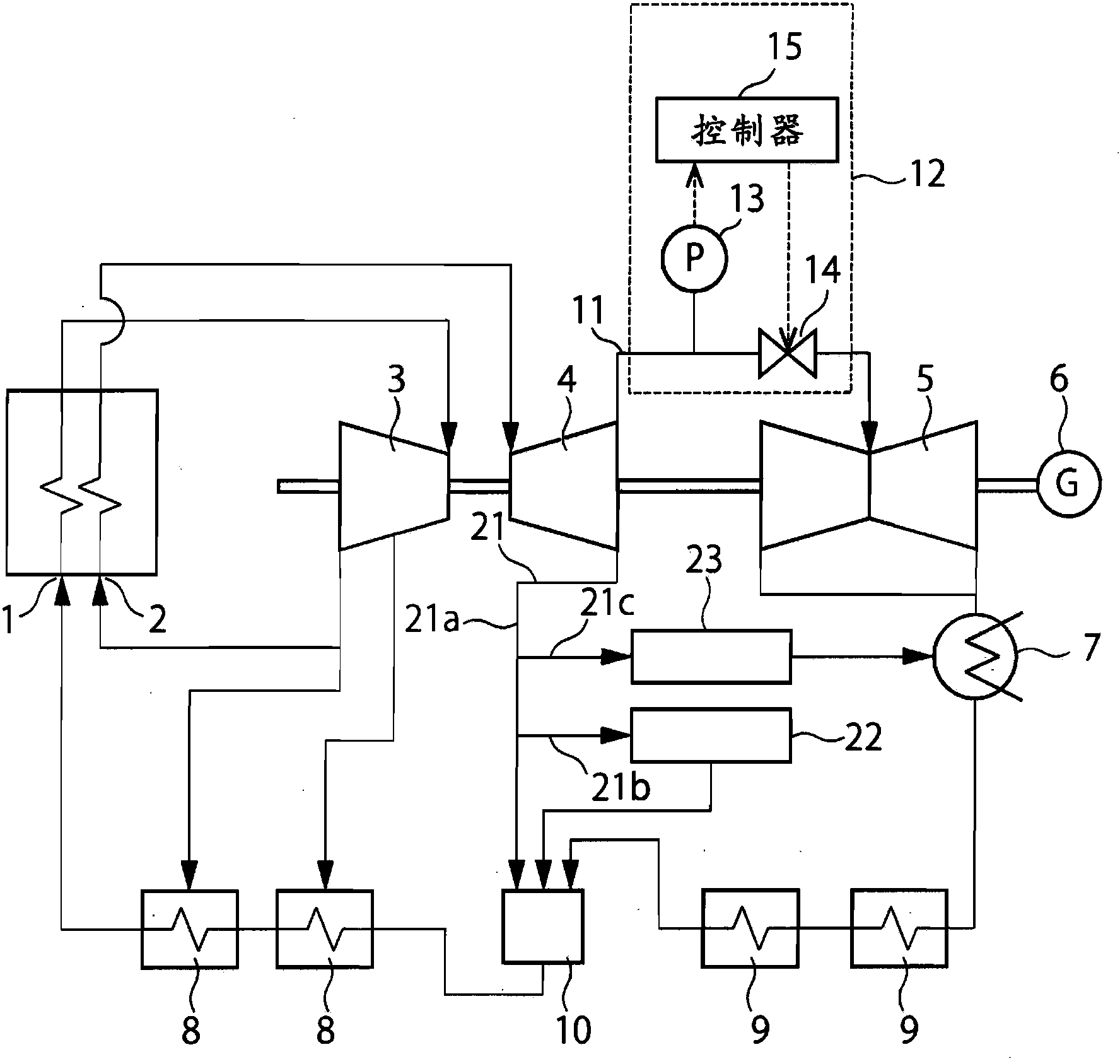

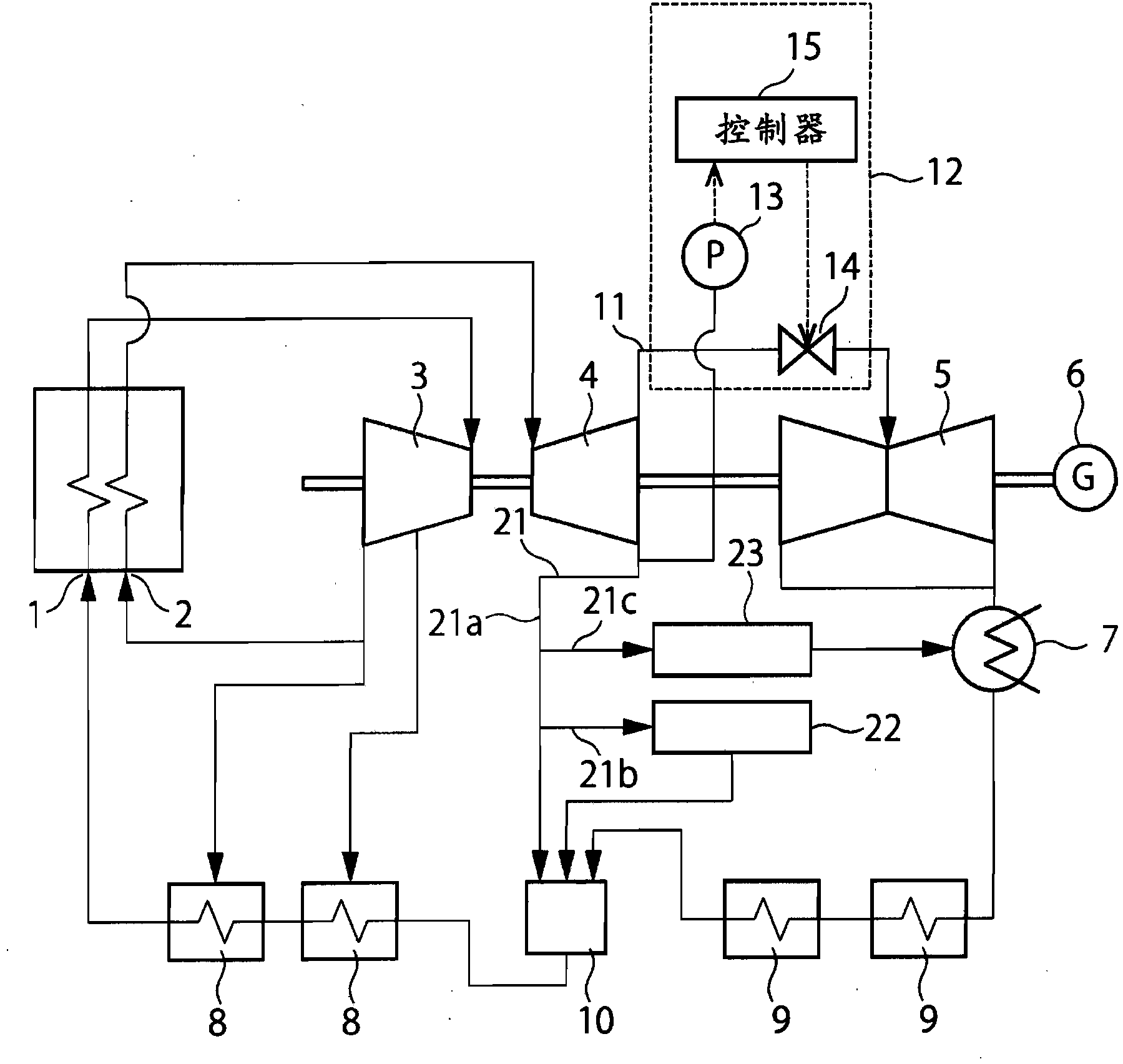

Steam turbine plant and control method and control system thereof

The invention relates to a steam turbine plant and a control method and a control system thereof. In one embodiment, the steam turbine plant includes a first turbine driven by steam from a boiler, a second turbine driven by steam from a reheater, a third turbine driven by the steam exhausted from the second turbine, and a carbon dioxide capturing system including a reboiler to heat an absorbing liquid with the steam exhausted or extracted from the second turbine. The plant further includes a steam pipe to feed the steam exhausted from the second turbine to the third turbine, and a first steam extraction pipe to send the steam exhausted or extracted from the second turbine to the reboiler. The plant further includes a pressure detector to detect a pressure of the steam flowing through the steam pipe or the first steam extraction pipe, a pressure adjustment valve provided on the steam pipe, and a controller to control the valve based on the detected pressure.

Owner:KK TOSHIBA

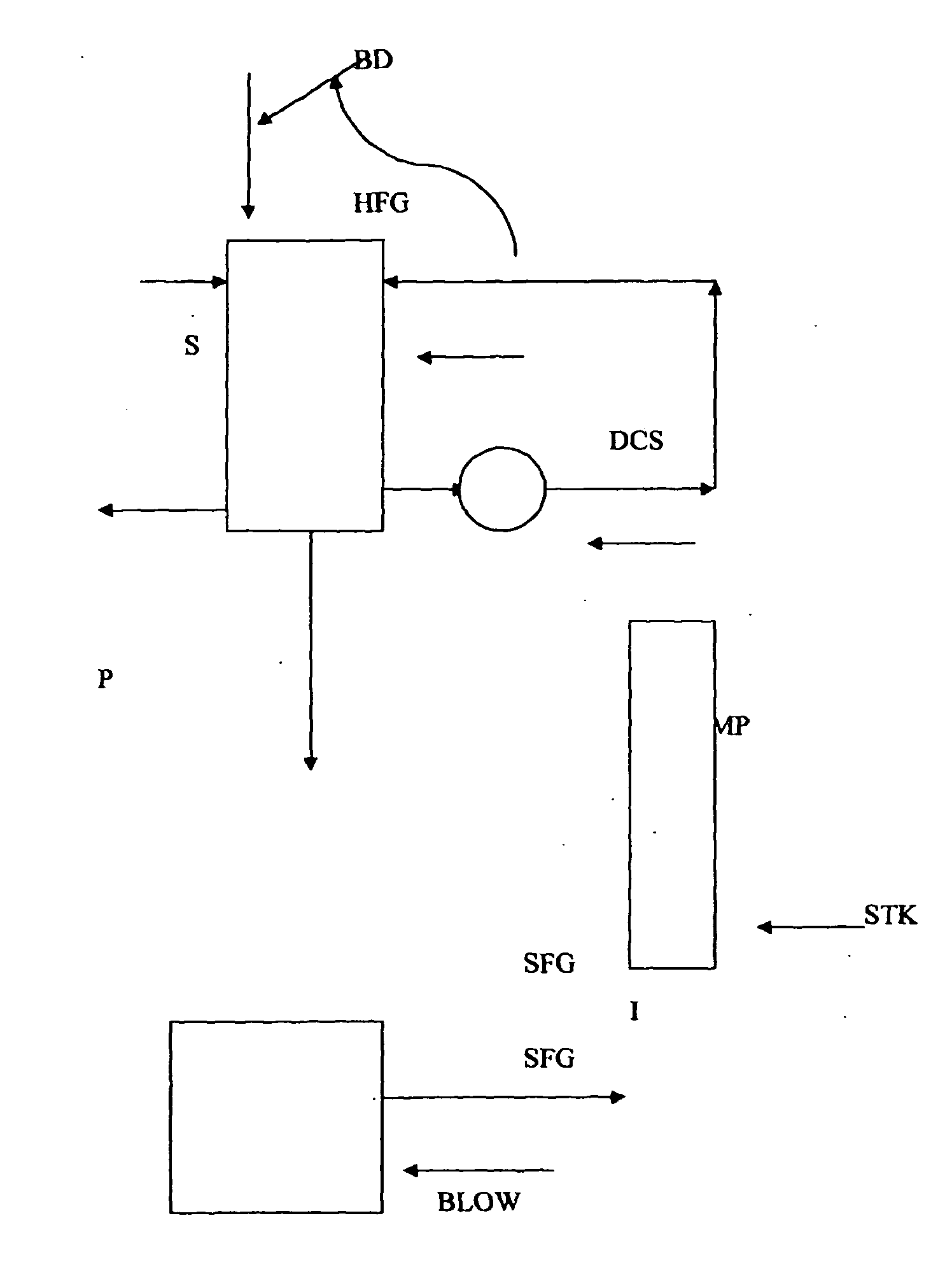

Process and system for quenching heat, scrubbing, cleaning and neutralizing acidic media present in the flue gas from the firing of fossil fuel

InactiveUS20120285353A1High base numberStrong alkalineUsing liquid separation agentSolid fuel combustionAlkalinityNuclear engineering

The present invention provides a novel process for quenching heat, scrubbing, cleaning and neutralizing the hot and dirty fossil fuel fired flue gas liberated by a fossil fuel fired boiler using the high temperature and high pressure present in fossil fuel fired boiler blow-down comprising the steps of quenching the fossil fuel fired flue gas by evaporating sufficient quantity of water from sea water / scrubbing liquid and mixing vapors thus generated with hot and dirty flue gas; using the high temperature and high pressure present in fossil fuel fired boiler blow-down (waste water) for atomizing / spraying high alkalinity sea water / scrubbing liquid on said flue gas to neutralize the acidic substances in said flue gas.

Owner:KUMAR SUBRAHMANYAM

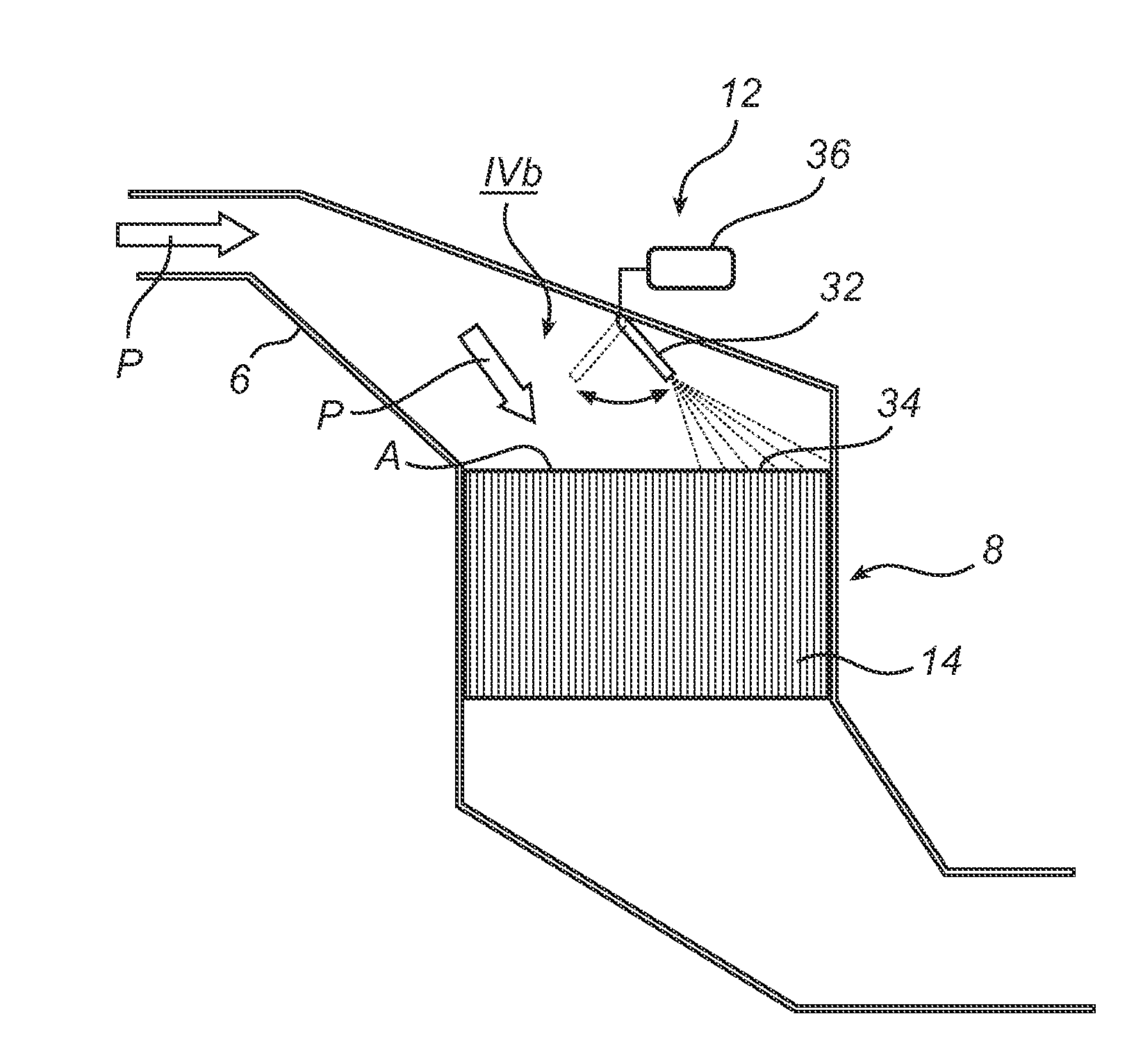

Method and device for controlling the supply of a reducing agent to an scr system

ActiveUS20110150732A1Easy to handleCombination devicesPhysical/chemical process catalystsProcess engineeringAmmonia

A selective catalytic reduction reactor (8), which comprises at least one catalyst layer (14), is operative for removing NOx from a flow of process gas of a process plant, such as a combustion plant or an incineration plant. A device for controlling the feeding of a reducing agent, such as urea or ammonia, to said at least one catalyst layer (14), which has an attack area (A) facing the flow (P) of process gas, comprises at least one supply nozzle (32) which is operative for supplying reducing agent in at least one supply area (34) which corresponds to a part of the attack area (A), and a moving device (36) which is operative for moving said supply area (34) over the attack area (A).

Owner:GENERAL ELECTRIC TECH GMBH

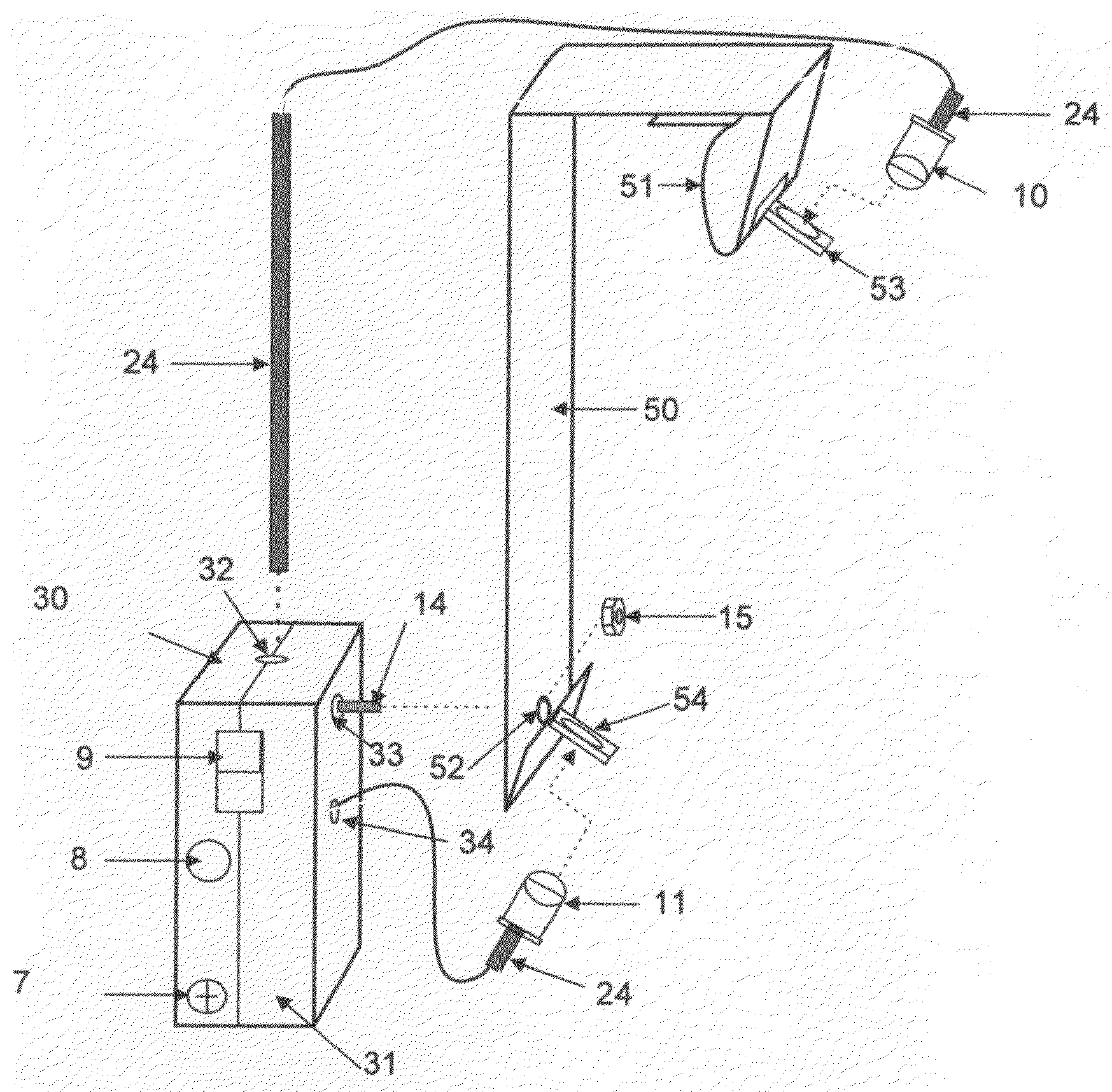

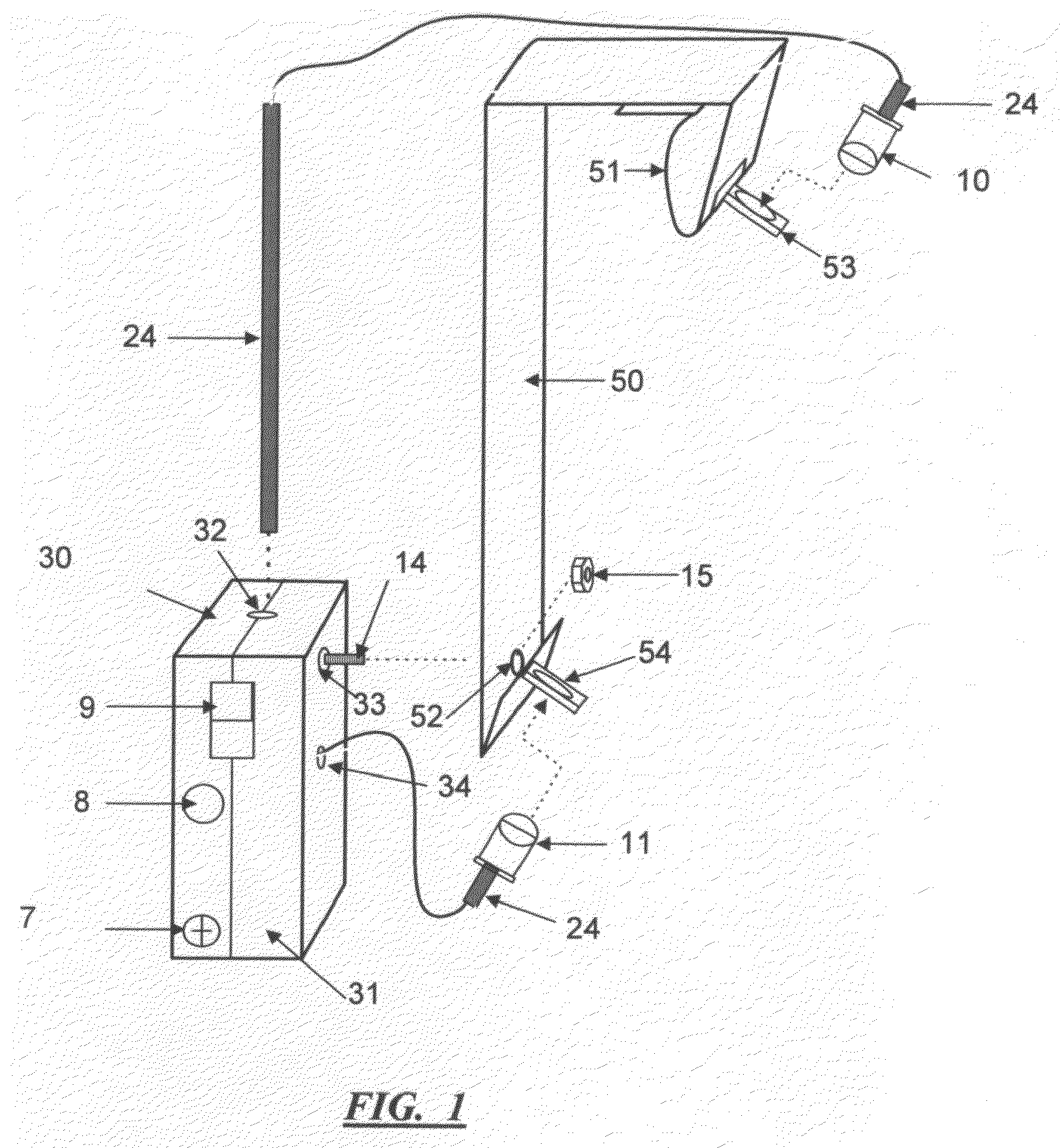

Furnace filter alert

A dust particle detector comprised of one or more light beam emitters (10) and detectors (11), mounted on a hanging arm (50) which is attached to rear case (31). Enclosed in front case (30) and said rear case, a buzzer (4), battery (1), control potentiometer (5), switch (9) and electronic chips (2 and 3). After hanging the Filter Alert on the furnace filter, the light beam path soon becomes block with dust and dirt, which triggers the buzzer (4).

Owner:SWORD TECH CORP

Methods and systems for generating power from a turbine using pressurized nitrogen

ActiveUS8963347B2Improve efficiencyOut power demand powerSolidificationLiquefactionWorking fluidEngineering

An air separation unit is integrated with a power generating plant to improve the efficiency of power generation. The methods and systems improve the efficiency of power generation by utilizing liquid nitrogen from the air separation unit as the working fluid in a turbine. The liquid nitrogen is pressurized while in the liquid state. After warming the pressurized nitrogen stream by cooling the air for the air separator unit, the compressed nitrogen is expanded in a turbine to perform work. After expansion, the nitrogen is vented to ambient air. The nitrogen in its pressurized state can be used for energy storage and / or for smoothing out power demand on a power grid.

Owner:U S BANK TRUST CO NAT ASSOC

Method for reducing flue gas carbon dioxide emissions

InactiveUS20140109575A1Reduce carbon dioxide emissionsEmission preventionDirect carbon-dioxide mitigationFlue gasFlue-gas stack

Plants, devices, and methods are presented which economically and effectively reduce carbon dioxide (CO2) emissions from flue gases by converting heat derived from one or more sources of flue gas to drive a heat engine, which generates power, energy, and / or work that is utilized by a CO2 capture unit coupled to the stream of flue gas. CO2 captured from the flue gas stream may be sequestered and / or utilized for commercial purposes.

Owner:FLUOR TECH CORP

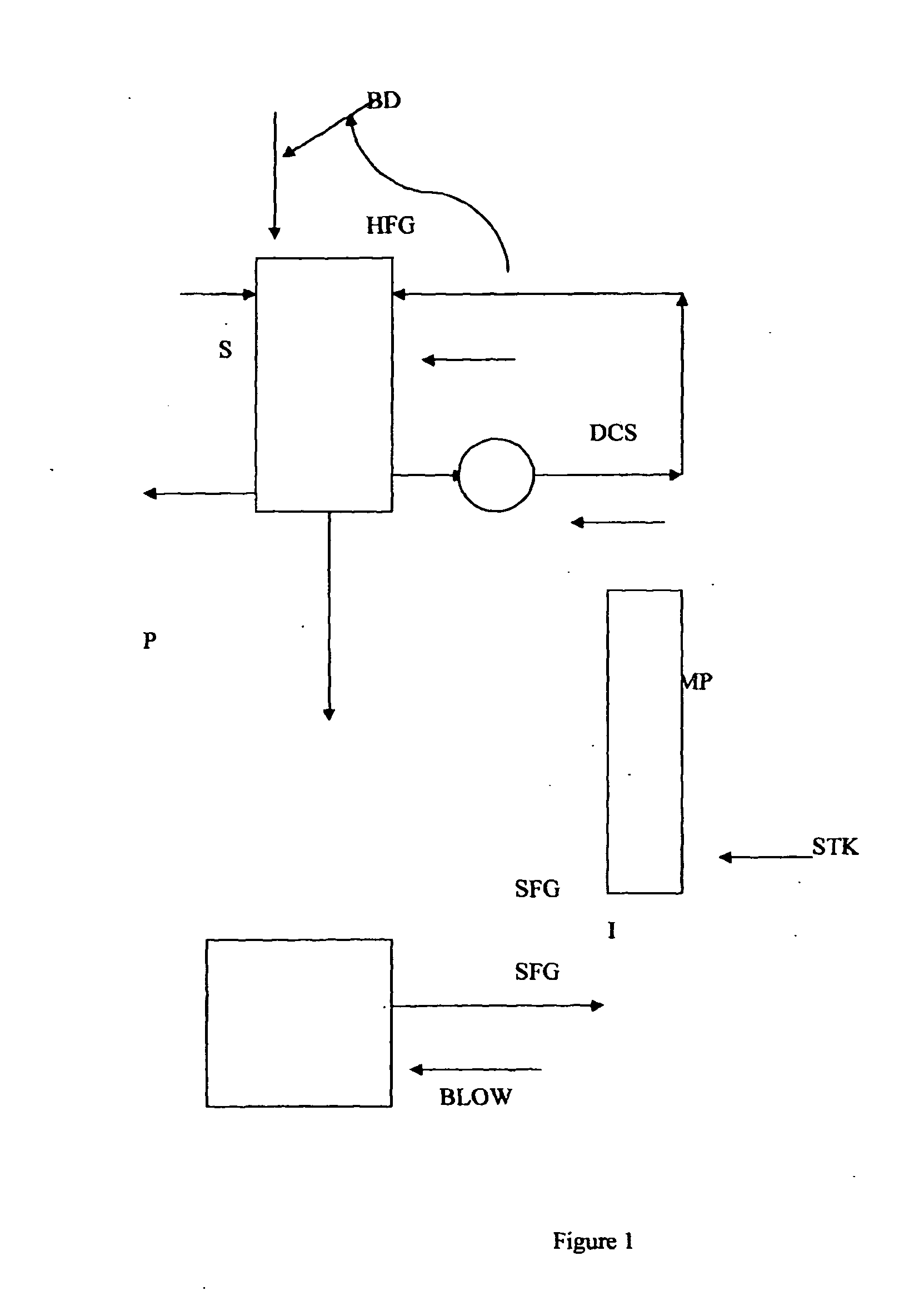

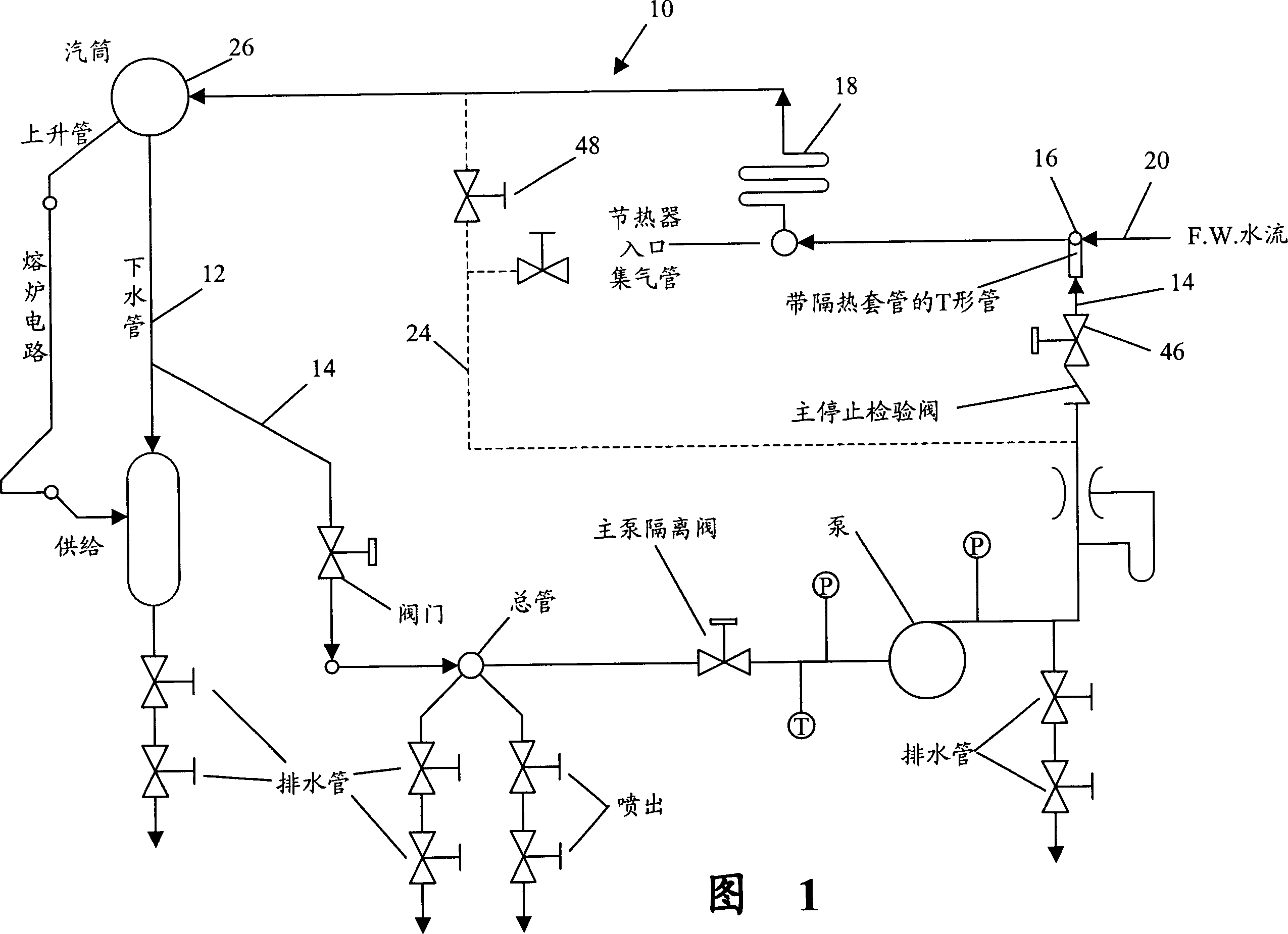

System for optimum SCR operation for controlling exhaust temp of flue

A system for maintaining an optimal flue gas inlet to a boiler mounted SCR assembly in the flue of the boiler is accomplished by mixing the normal inlet feedwater to an economizer of the boiler with near saturation water from downcomers of the boiler to thereby raise the temperature of the flue gas passing across the economizer and raising the SCR inlet to the desired optimal SCR operation temperature.

Owner:THE BABCOCK & WILCOX CO

Oil sand production without CO2 emission

A plant for generation of steam for oil sand recovery from carbonaceous fuel with capture of CO2 from the exhaust gas, comprising heat coils (105, 105′, 105″) arranged in a combustion chamber (101) to cool the combustion gases in the combustion chamber to produce steam and superheated steam in the heat coils, steam withdrawal lines (133, 136, 145) for withdrawing steam from the heat coils, an exhaust gas line (106) for withdrawal of exhaust gas from the combustion chamber (101), where the combustion chamber operates at a pressure of 5 to 15 bara, and one or more heat exchanger(s) (107, 108) are provided for cooling of the combustion gas in line (106), a contact device (113) where the cooled combustion gas is brought in countercurrent flow with a lean CO2 absorbent to give a rich absorbent and a CO2 depleted flue gas, withdrawal lines (114, 115) for withdrawal of rich absorbent and CO2 depleted flue gas, respectively, from the contact device, the line (115) for withdrawal of CO2 depleted flue gas being connected to the heat exchangers (107, 108) for heating of the CO2 depleted flue gas, and where the rich absorbent is regenerated an absorbent regenerator (116), the regenerated lean absorbent is recycled to the absorber (113), and a gas withdrawal line (121) connected to the absorber for withdrawal of CO2 and steam from the regenerator (116), is described.

Owner:CO2 CAPSOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com